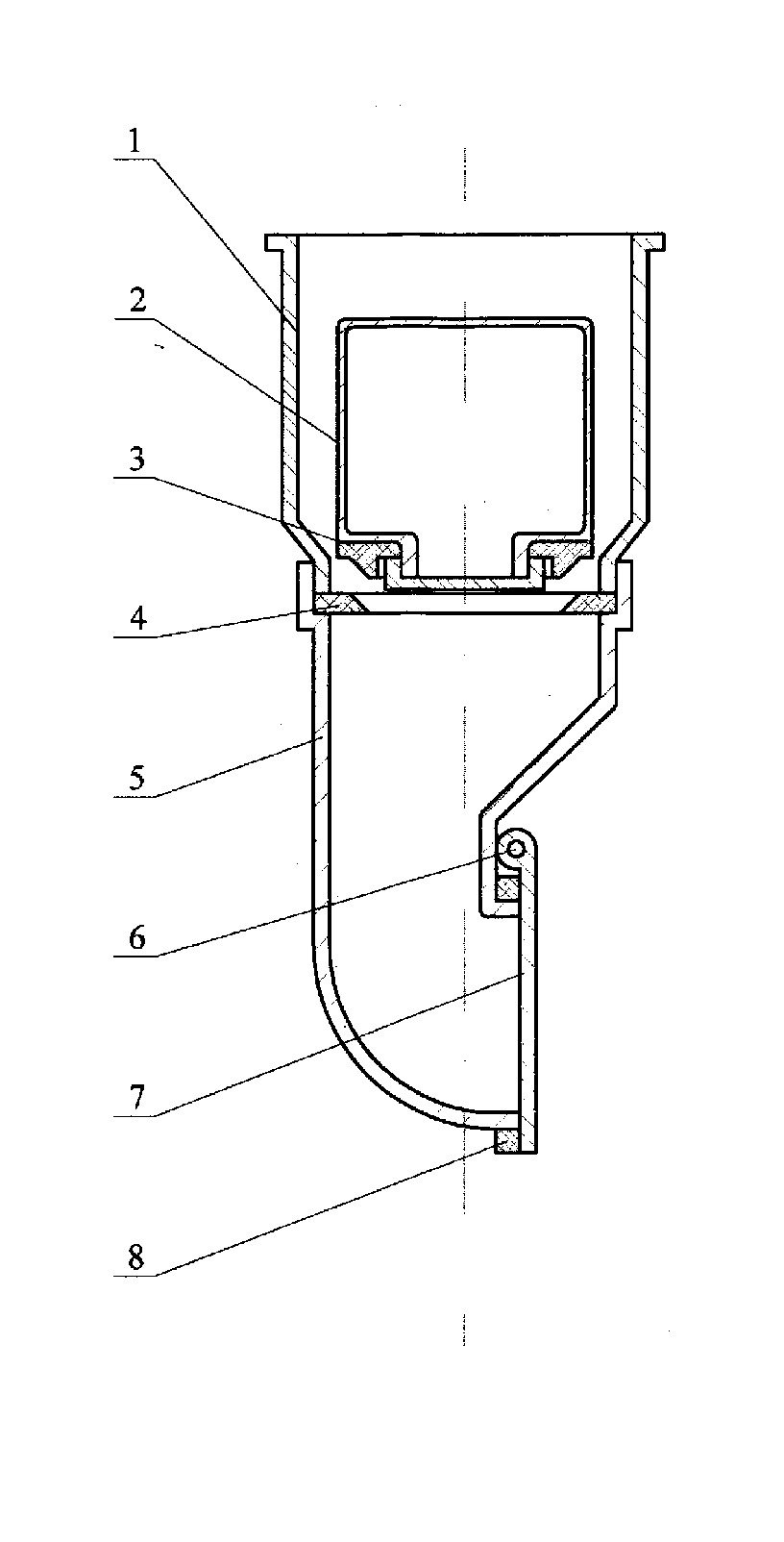

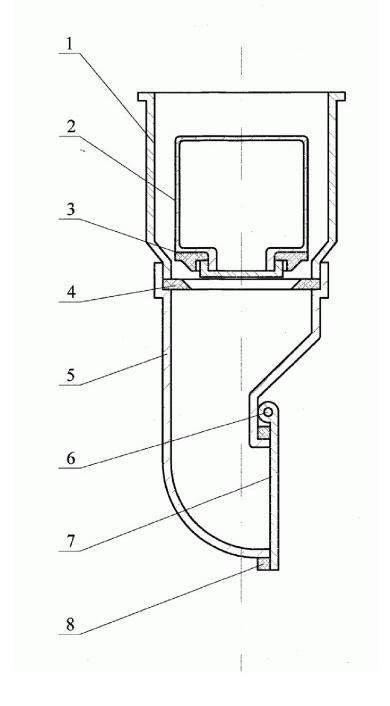

Dual mechanical seal floor drain core

A mechanical seal and floor drain technology, which is applied in indoor sanitary pipeline installations, water supply installations, buildings, etc., can solve problems such as poor drainage, poor water seal retention ability, unreasonable floor drain core structure, etc., and achieves convenient use and maintenance. Strong self-cleaning ability and good anti-backflow performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Referring to the accompanying drawings, the double mechanical seal floor drain core consists of the upper body 1 of the floor drain core, the float 2, the magnetic seal assembly 3, the magnetic seal assembly 4, the lower body 5 of the floor drain core, the rotating shaft 6, the movable door 7, and the sealing ring 8. Float 2 is installed in the upper body 1 of the floor drain core, and the lower end of the float 2 cooperates with the water outlet on the upper body 1 of the floor drain core. When the float 2 sinks, it can block the water outlet of the upper body 1 of the floor drain core. The magnetic seal assembly 3 is fixed on the lower end of the float 2, the magnetic seal assembly 4 is fixed around the water outlet of the main body 1 on the floor drain core, and corresponds to the magnetic seal assembly 3, relying on the magnetic seal assembly 3 and the magnetic seal combination The magnetic force generated between the parts 4 seals the water outlet of the main body 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com