Brushless submersible motor for anti-erosion self-cleaning through motor driving

A submersible motor and motor-driven technology, which is applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems that the brushless submersible motor is easily corroded, the brushless submersible motor is damaged, and the dirt cannot be obtained. Cleaning function, long service life, good self-cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

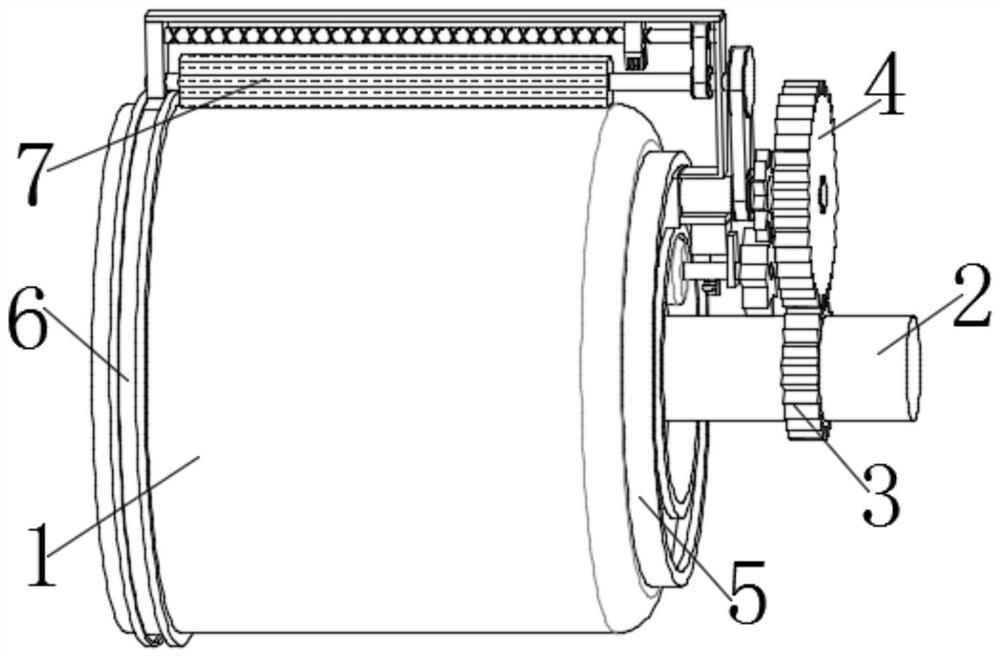

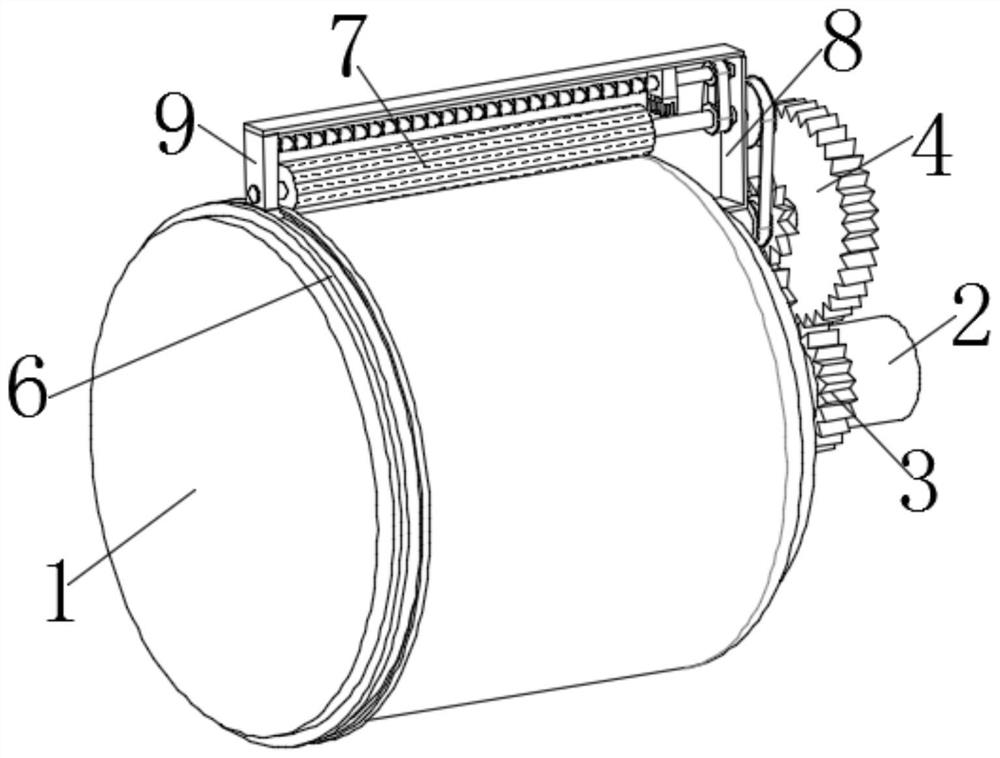

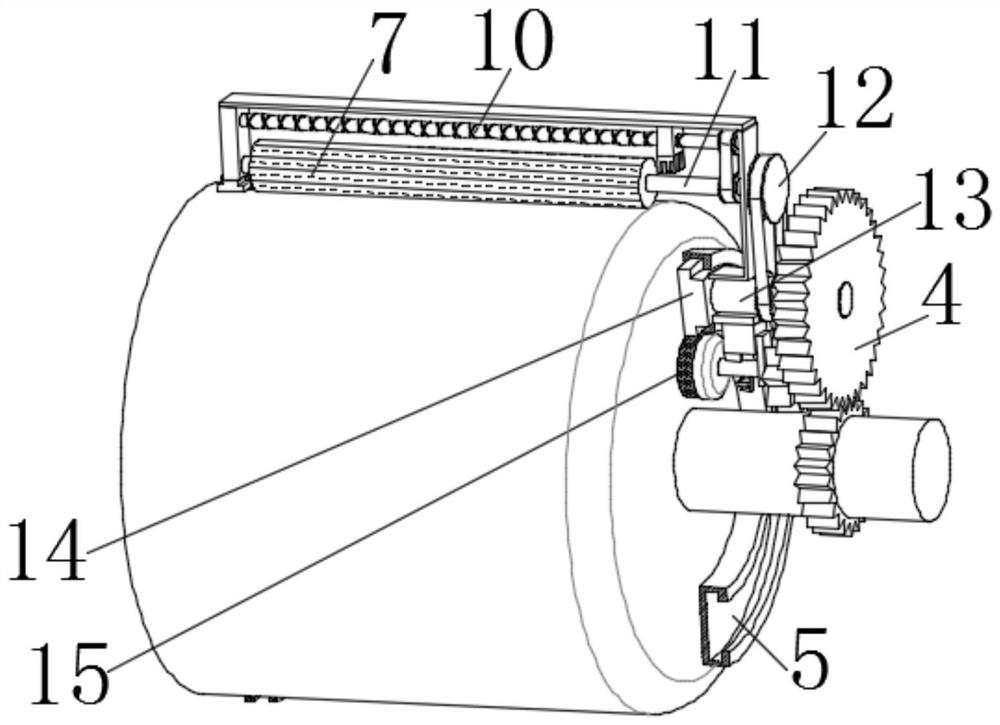

[0040] Example: Reference Figure 1-8 Shown is a brushless submersible motor driven by a motor for anti-erosion self-cleaning, including a submersible motor body 1, a motor output shaft 2 installed on the submersible motor body 1, and a built-in ring fixedly installed at the end of the submersible motor body 1 5. The built-in ring 5 can be any metal ring in the prior art, which is welded and fixed to the end of the submersible motor body 1 . The built-in ring 5 and the motor output shaft 2 are located on the same central axis, and the built-in ring 5 is equipped with a motor side cleaning part for self-cleaning the side of the submersible motor body 1 and a self-cleaning part for self-cleaning the end of the submersible motor body 1 The motor end cleaning part, the motor side cleaning part and the motor side cleaning part are connected through the connection conduction unit for power transmission, the connection conduction unit is fitted with the motor output shaft 2, the moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com