Patents

Literature

421results about How to "Clean up comprehensively" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

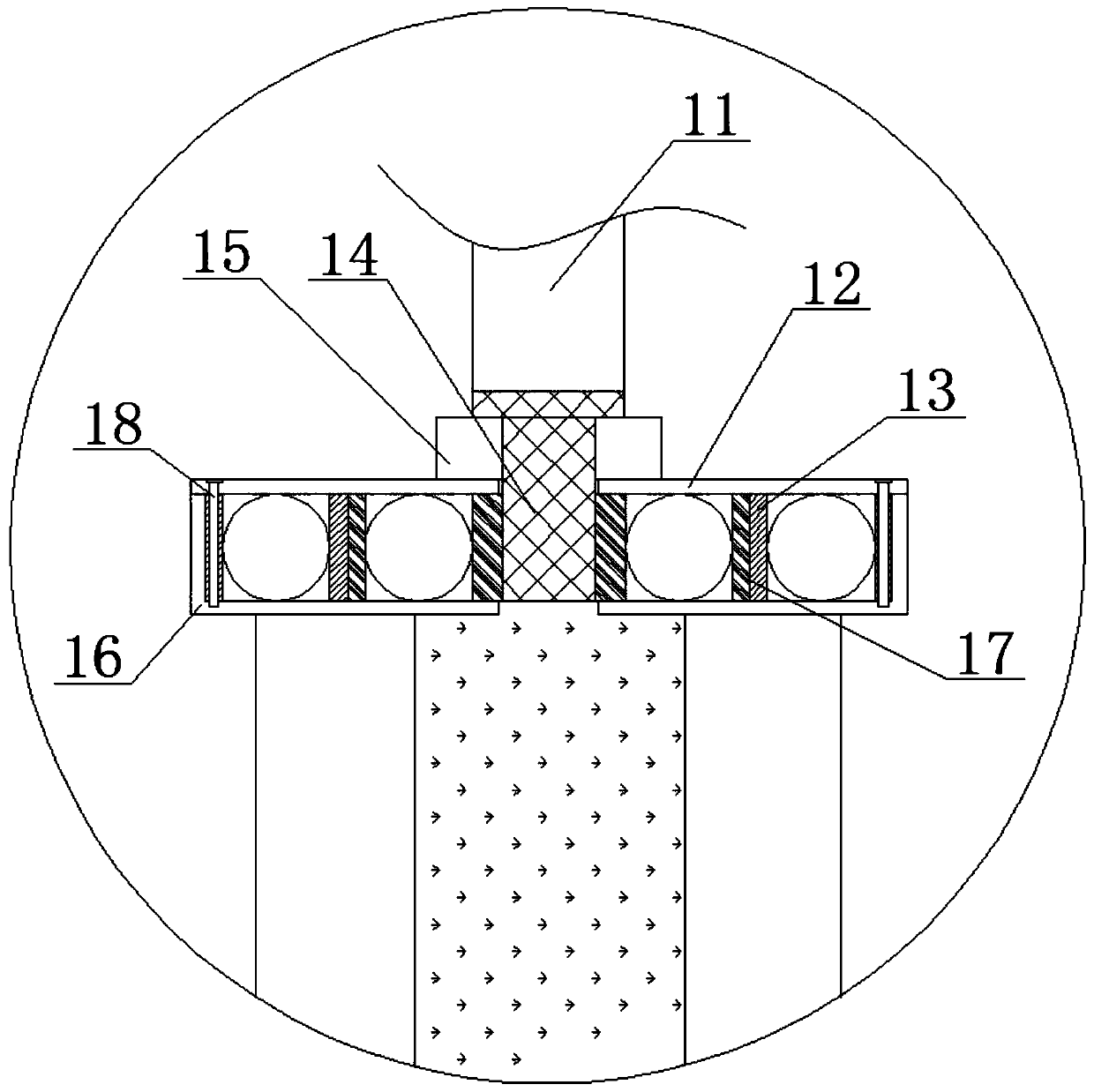

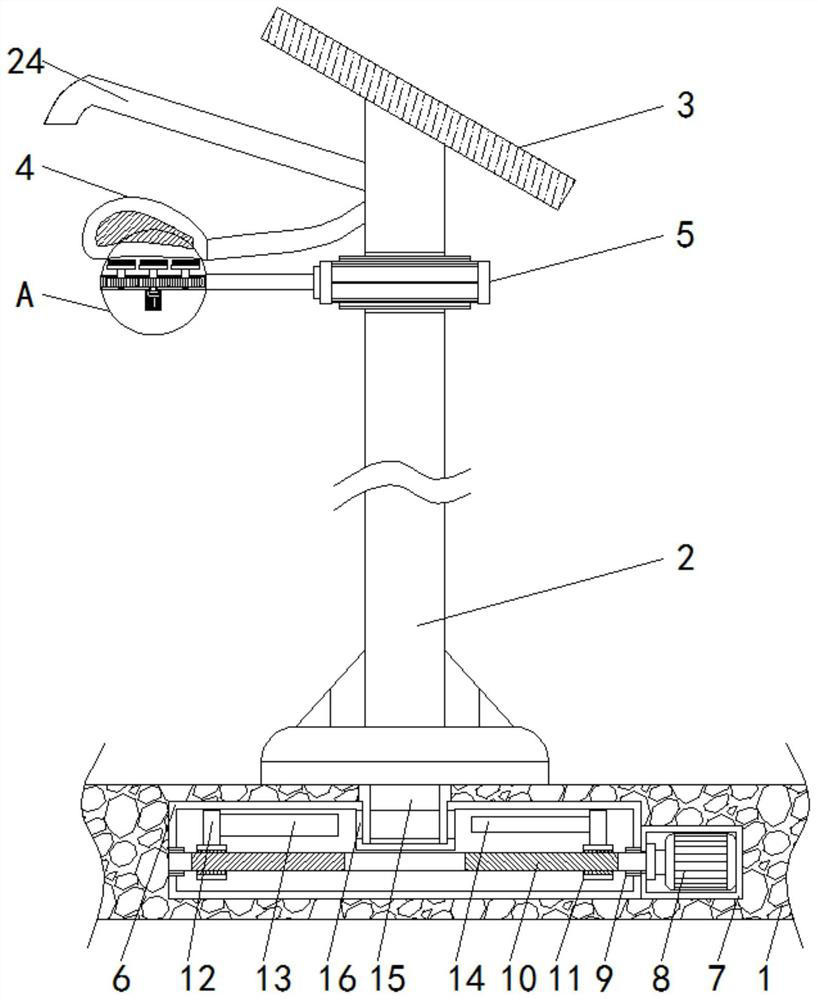

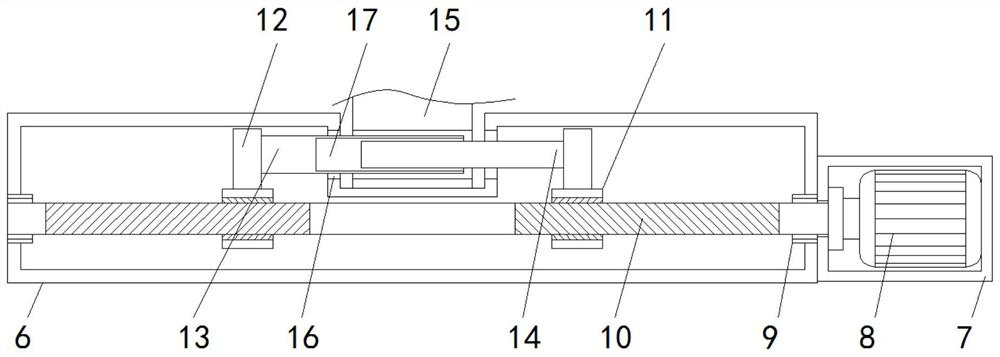

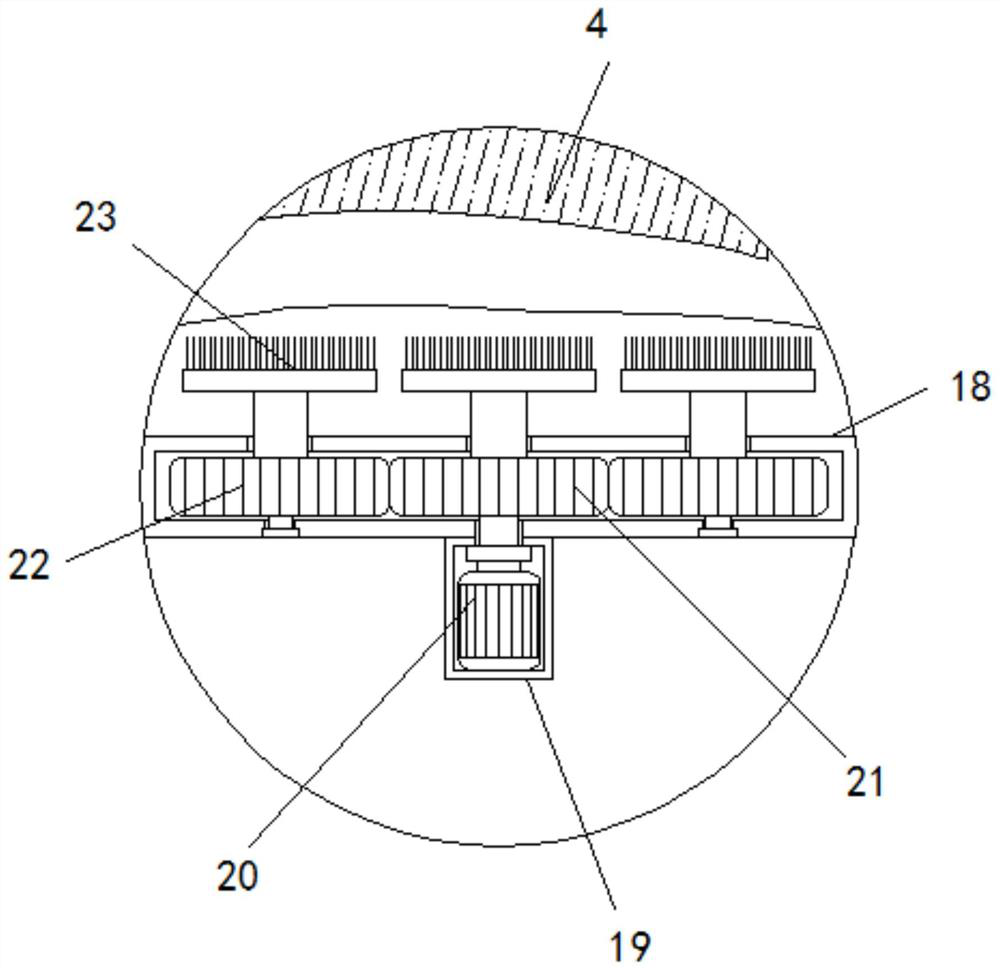

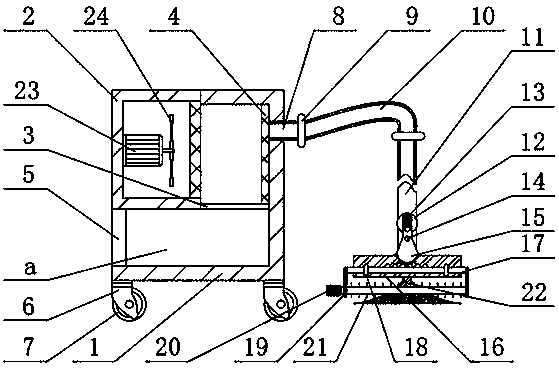

Photovoltaic panel frame with cleaning and protecting functions

InactiveCN106788207AEnable selective useEasy to usePhotovoltaic supportsPhotovoltaic energy generationImpuritySnow

The invention discloses a photovoltaic panel frame with cleaning and protecting functions. The photovoltaic panel frame comprises a base plate, a bracket, a mounting panel and a photovoltaic panel. The photovoltaic panel frame is characterized in that a cleaning assembly is rotatably mounted on the mounting panel and comprises a mounting block, a first pipeline is fixedly connected to the end surface of the mounting block, a water pump is mounted on the base plate, a water outlet of the water pump is connected with one end of the first pipeline, and a first valve is arranged at the joint of the water outlet and the first pipeline; a plurality mounting grooves are formed in the mounting block, worm wheels are mounted in the mounting groove, and nozzles are radially and fixedly connected to the side walls of the worm wheels; worm rods matched with the worm wheels are rotatably mounted on the mounting block and coaxially connected with a second electric motor mounted on the mounting block; and the photovoltaic panel frame further comprises a hose, one end of the hose is communicated with inner cavities of the nozzles, and the other end of the hose is communicated with an inner cavity of the first pipeline. According to the photovoltaic panel frame with the cleaning protecting function, the photovoltaic panel can be cleaned completely with no dead angle, accumulated dust, impurities, accumulated snow and ice on the photovoltaic panel can be effectively cleaned, and the photovoltaic panel can be protected under bad weather environments.

Owner:国网山东省电力公司潍坊市寒亭区供电公司 +1

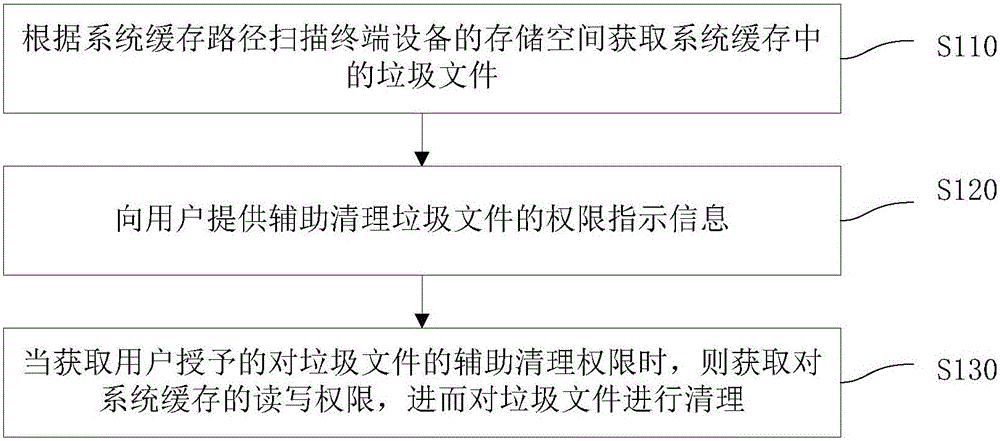

System cache garbage cleaning method and device and terminal equipment

InactiveCN105893278ARun fastClean up comprehensivelyMemory systemsTerminal equipmentOperating system

The invention discloses a system cache garbage cleaning method and device and terminal equipment. The method comprises the steps that a storage space of the terminal equipment is scanned according to a system cache path to obtain garbage files in a system cache; permission indication information assisting in cleaning the garbage files is provided for a user; when an assist cleaning permission, awarded by the user, to the garbage files is obtained, a read-write permission to the system cache is obtained, and therefore the garbage files are cleaned. According to the method, the read-write permission to the system cache is actively applied from the user, automatic cleaning of the garbage files in the system cache is achieved, the cleaning efficiency of the garbage files is improved, occupying of a memory by the garbage files is avoided, and the operating speed of the terminal equipment is increased.

Owner:KINGSOFT

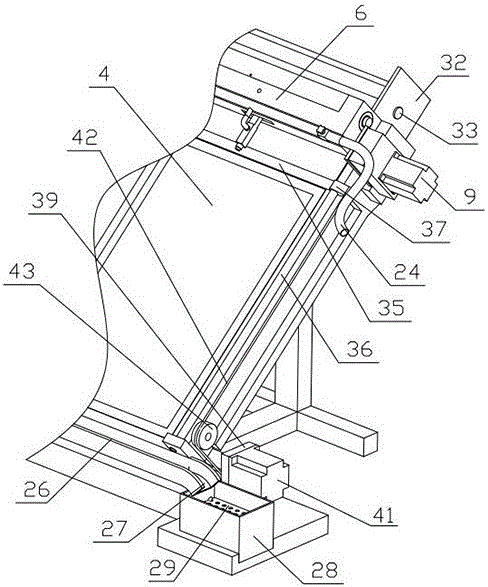

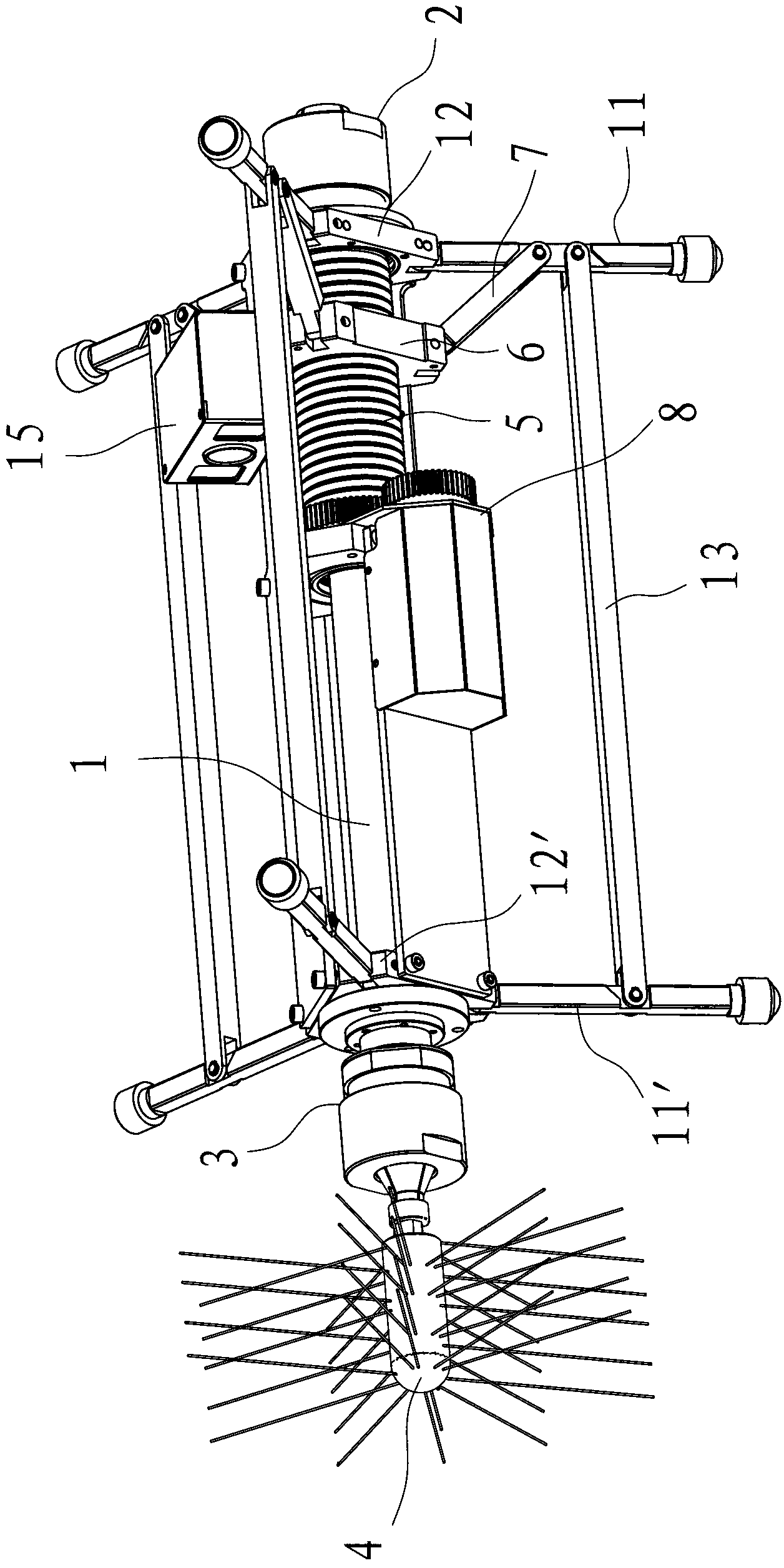

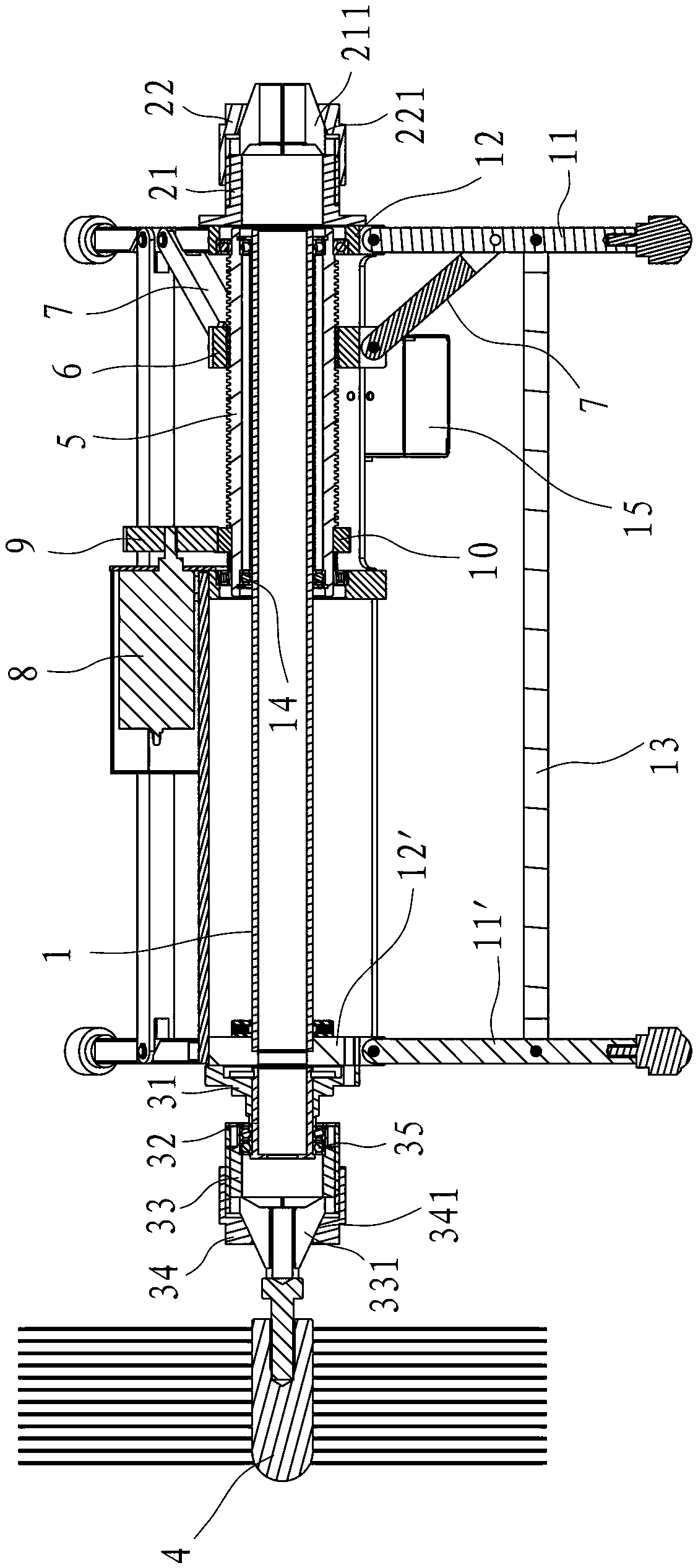

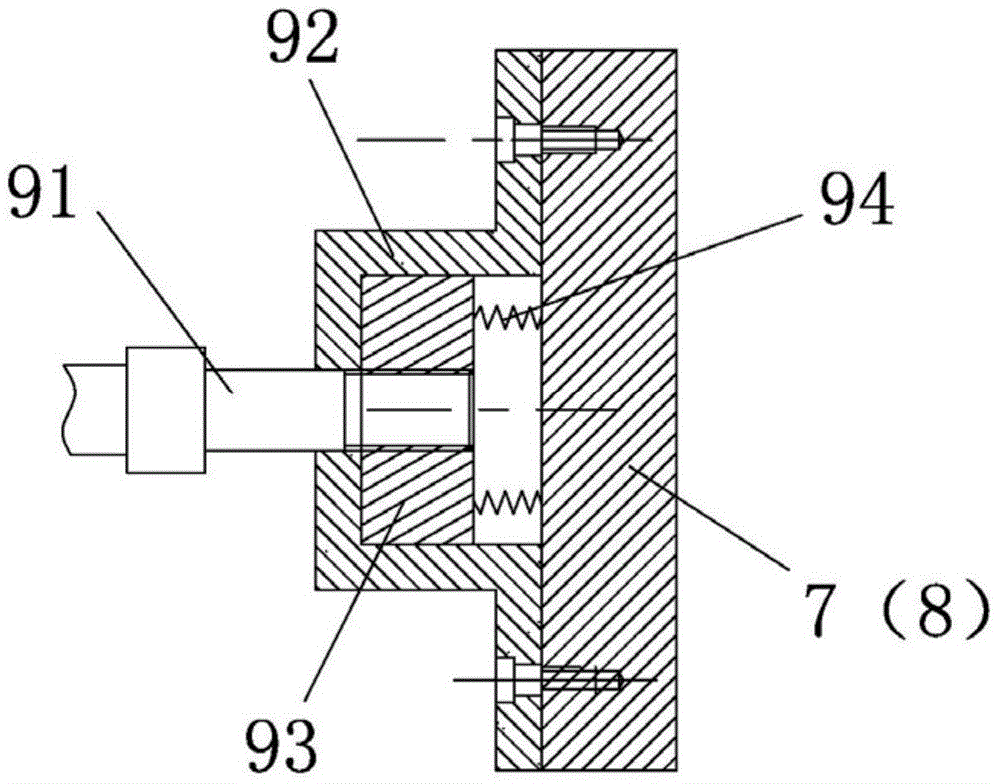

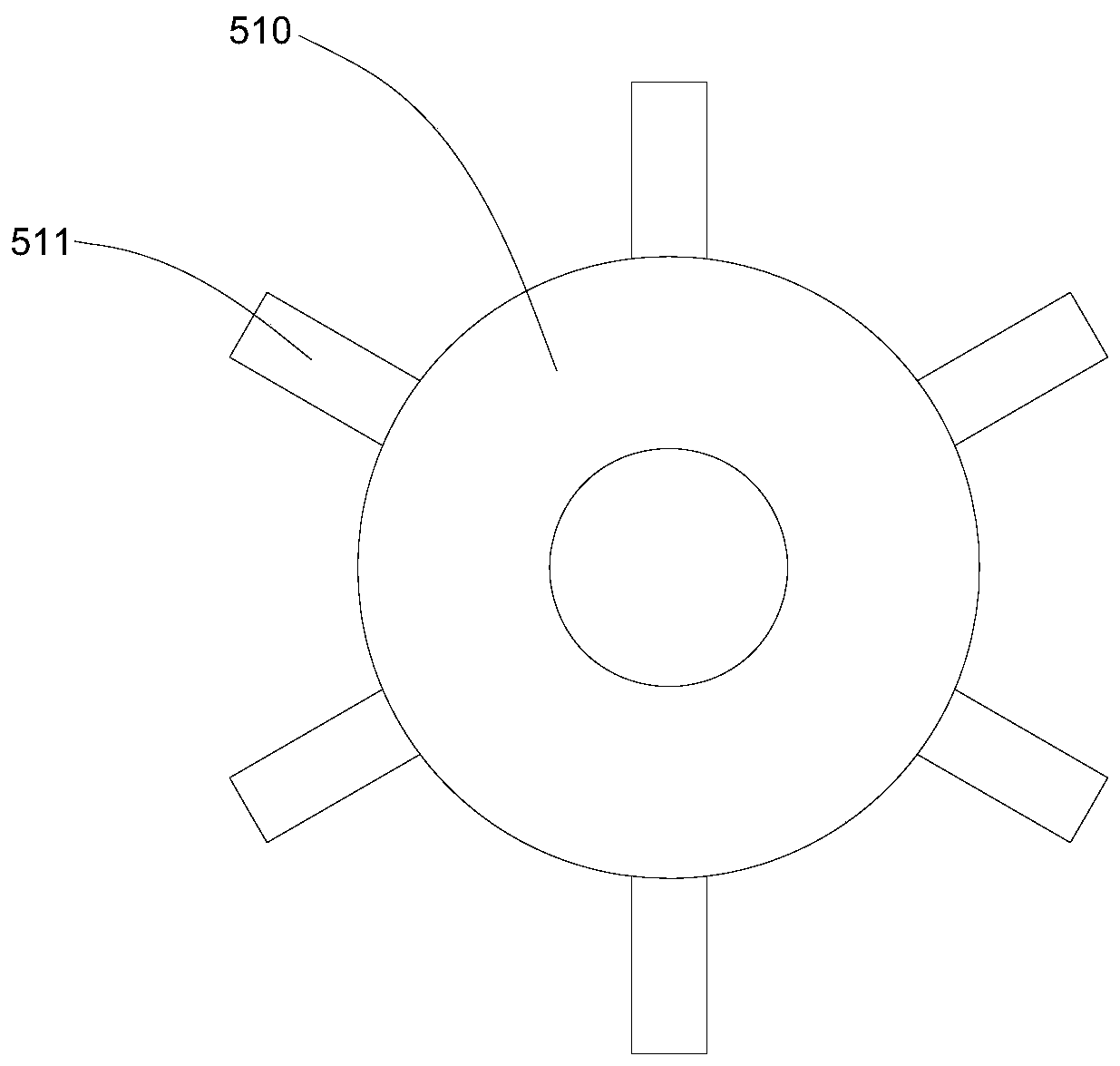

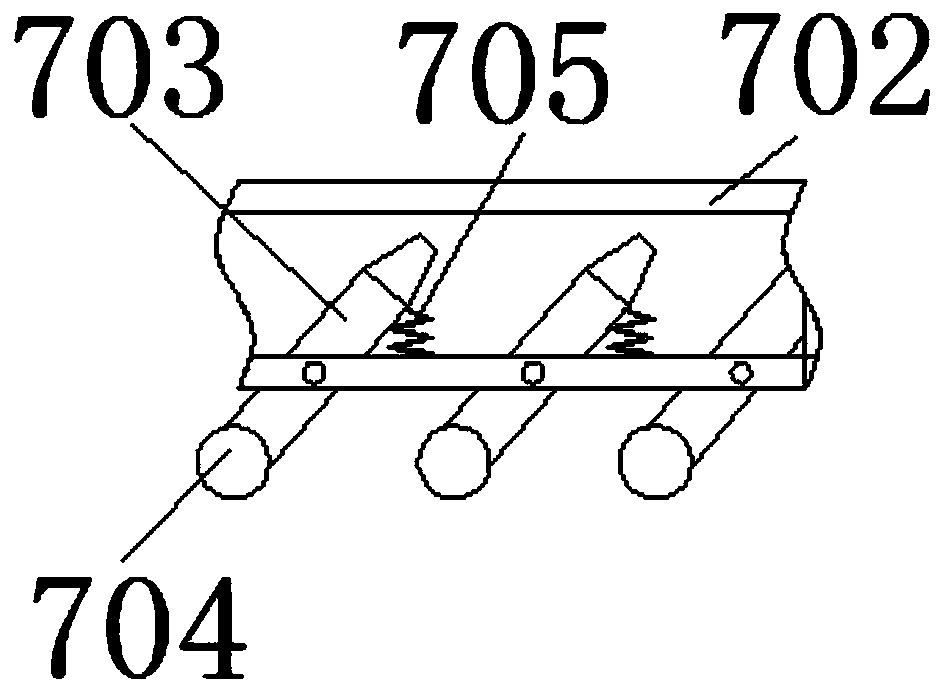

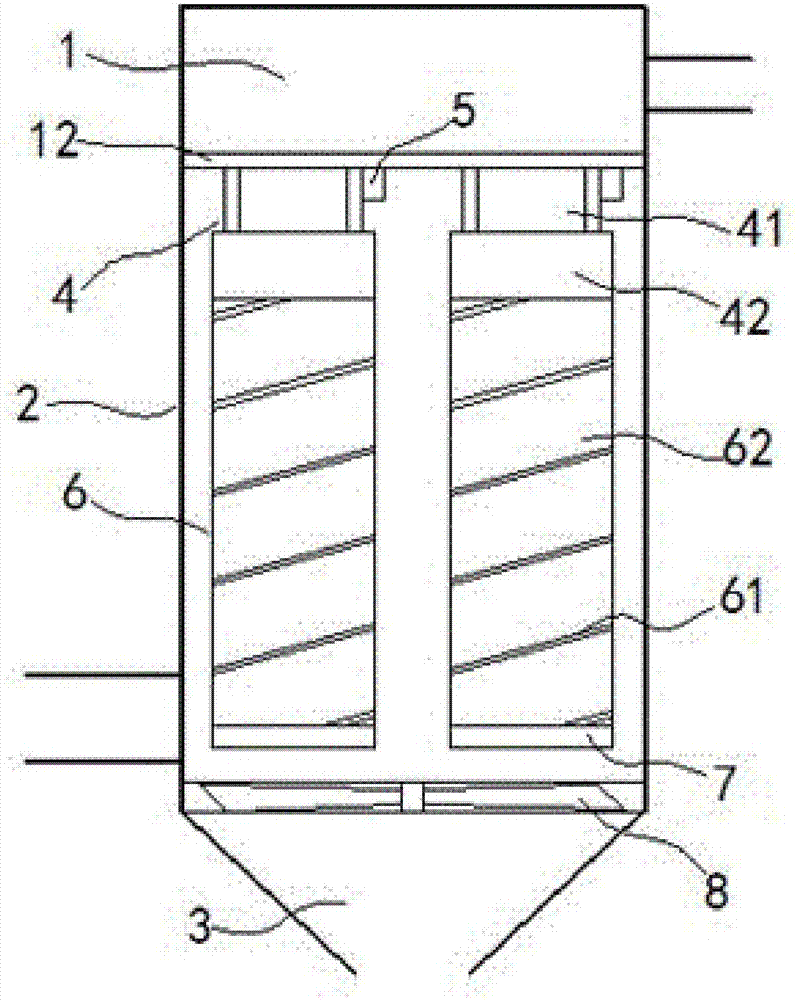

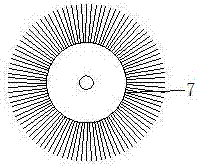

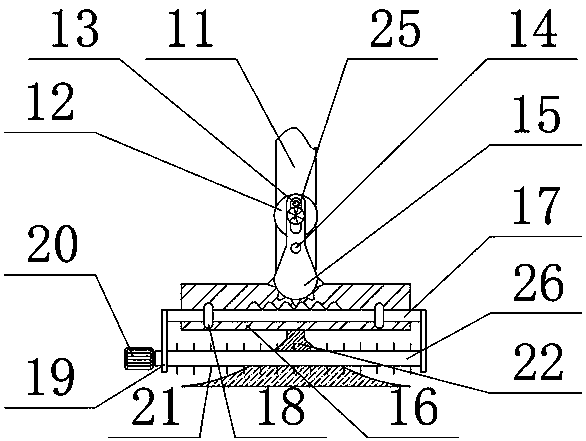

Robot for cleaning round pipelines

ActiveCN103316872ARealize automatic cleaningEasy to replaceHollow article cleaningEngineeringMechanical engineering

The invention relates to a robot for cleaning round pipelines. The robot for cleaning the round pipelines can be used in combination with a rotatable flexible shaft and comprises a cylindrical body, a first clamping head assembly, a second clamping head assembly, a cleaning head, a support frame and an adjusting mechanism, wherein the first clamping head is connected at one end of the cylindrical body, and the second clamping head is rotatably connected at the other end of the cylindrical body; the cleaning head can rotate along with the second clamping head assembly; the support frame is used for fixing the cylindrical body with the inner wall of a round pipeline and comprises a first support and a second support which are arranged on the cylindrical body, and the first support and the second support respectively comprises at least two support rods rotatably connected with the cylindrical body; the adjusting mechanism is used for adjusting the included angles between the support rods and the axis of the cylindrical body. The robot for cleaning the round pipelines has the advantages of being capable of achieving the automatic cleaning of the inside of a round pipeline, being high in working efficiency and avoiding the problems of great difficulty, large workload and low working efficiency and the like of manual cleaning.

Owner:马鞍山严格特种机器人有限公司

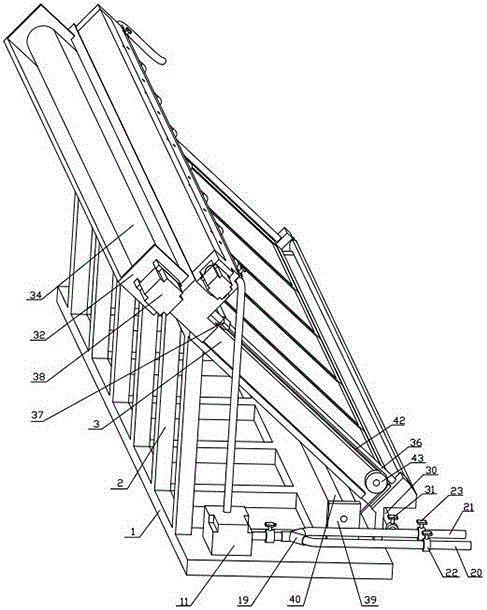

Overwater garbage disposal device

ActiveCN107354925AAvoid cloggingEasy to clogBatteries circuit arrangementsWater cleaningSiphonRefuse collection

The invention relates to an overwater garbage disposal device. The device comprises a solar panel, a solar panel support, a transverse main support, a control box, a vertical main channel, a siphon, a garbage collecting bag and a garbage compressing box. Through a negative pressure formed in the vertical main channel, power is generated to drive water flow to move into the device, solid garbage enters the disposal device along with the water flow, through all filtering boards arranged in the device, the solid garbage and the water flow are separated, and then through the collecting device and the compressing device, the garbage is collected and compressed for storage, so that the unmanned miniaturized low-energy cruise-type overwater garbage disposal device is achieved.

Owner:ANHUI ZHONGHAN ENERGY SAVING ENVIRONMENTAL PROTECTION TECH

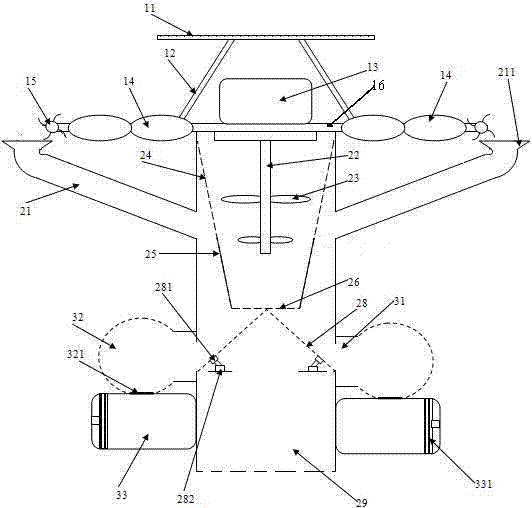

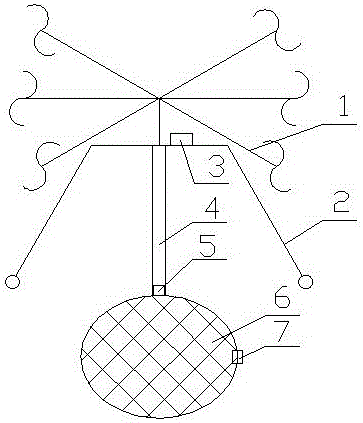

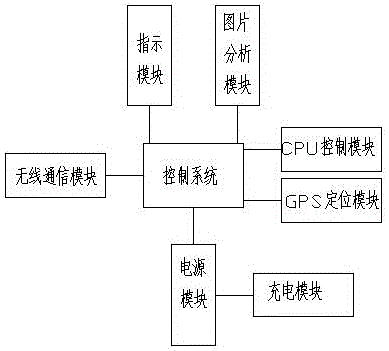

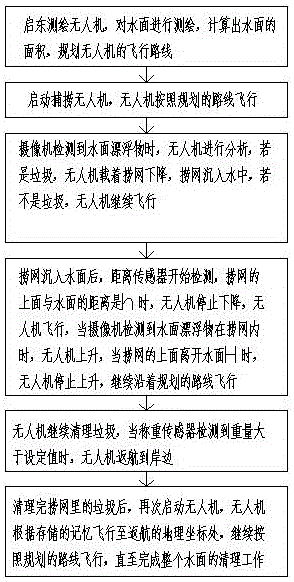

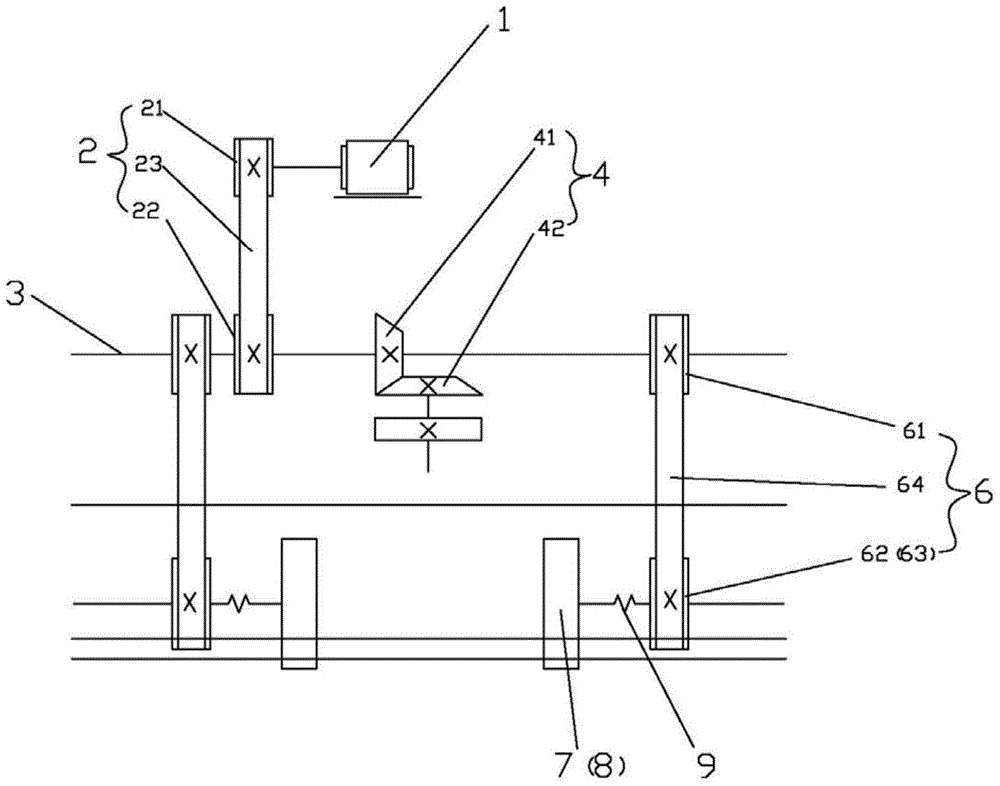

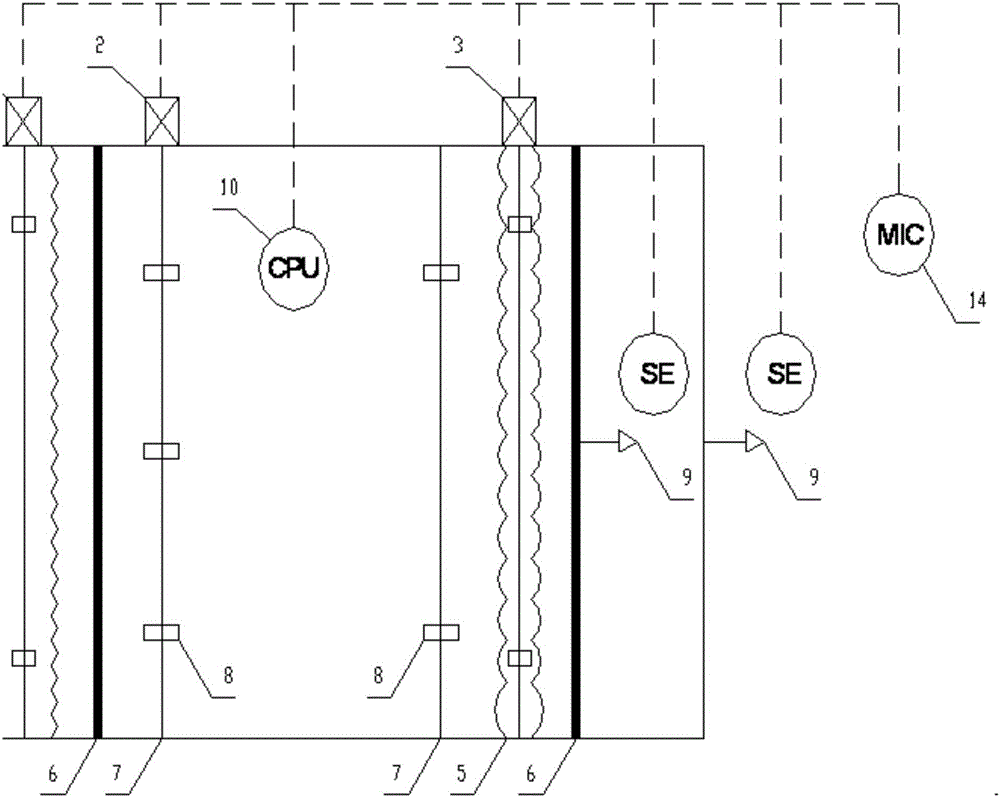

Unmanned aerial vehicle system used for removing water surface garbage

InactiveCN106741894AAchieve cleanupClean up comprehensivelyAircraft componentsWater cleaningUncrewed vehicleEngineering

The invention discloses an unmanned aerial vehicle system used for removing water surface garbage. The system comprises unmanned aerial vehicles, a support, a camera, a connecting rod, a weighing sensor, a catching net and a distance sensor. Each unmanned aerial vehicle comprises a charging module, a power module, a CPU control module, a wireless communication module, a GPS positioning module, a picture analysis module and an indication module. According to a working method, pictures of the water surface are acquired by the camera, the unmanned aerial vehicles make analysis and judgment, and the garbage is caught through the catching net. The unmanned aerial vehicle system is high in efficiency, easy to operate, high in practicality and capable of saving time and labor.

Owner:XUZHOU FLY DREAM ELECTRONICS & TECH

All-directional automatic shoe washer

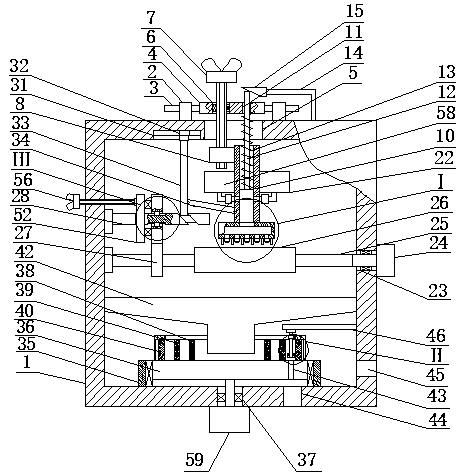

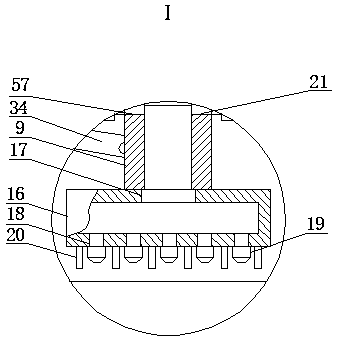

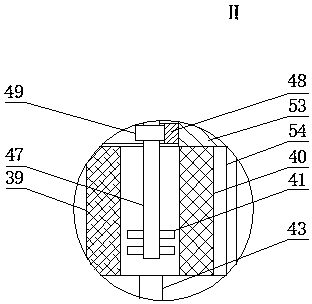

InactiveCN104027055AImprove cleaning area and efficiencyCompact structureFootwear cleanersEngineeringPower transmission

The invention provides an all-directional automatic shoe washer. The all-directional automatic shoe washer comprises a main motor, a power transmission mechanism, a side brush mechanism, a front brush mechanism, an internal brush mechanism and a bottom and rear brush mechanism. The all-directional automatic shoe washer is provided with washing brushes, including an inner brush for washing the interior of a shoe, in all directions, so that the shoe can be washed in all directions, and the washing efficiency is improved.

Owner:WUHAN UNIV OF SCI & TECH

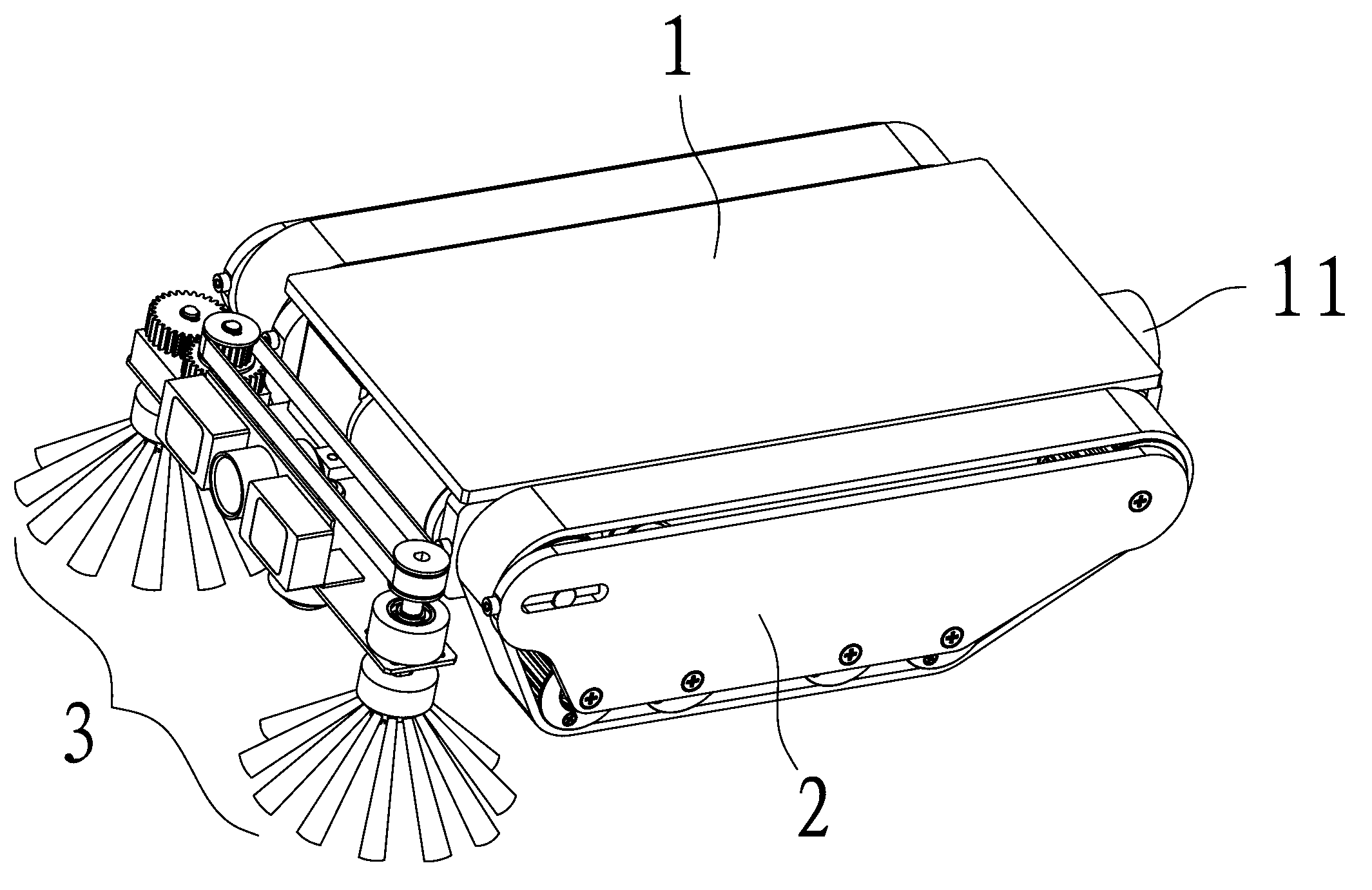

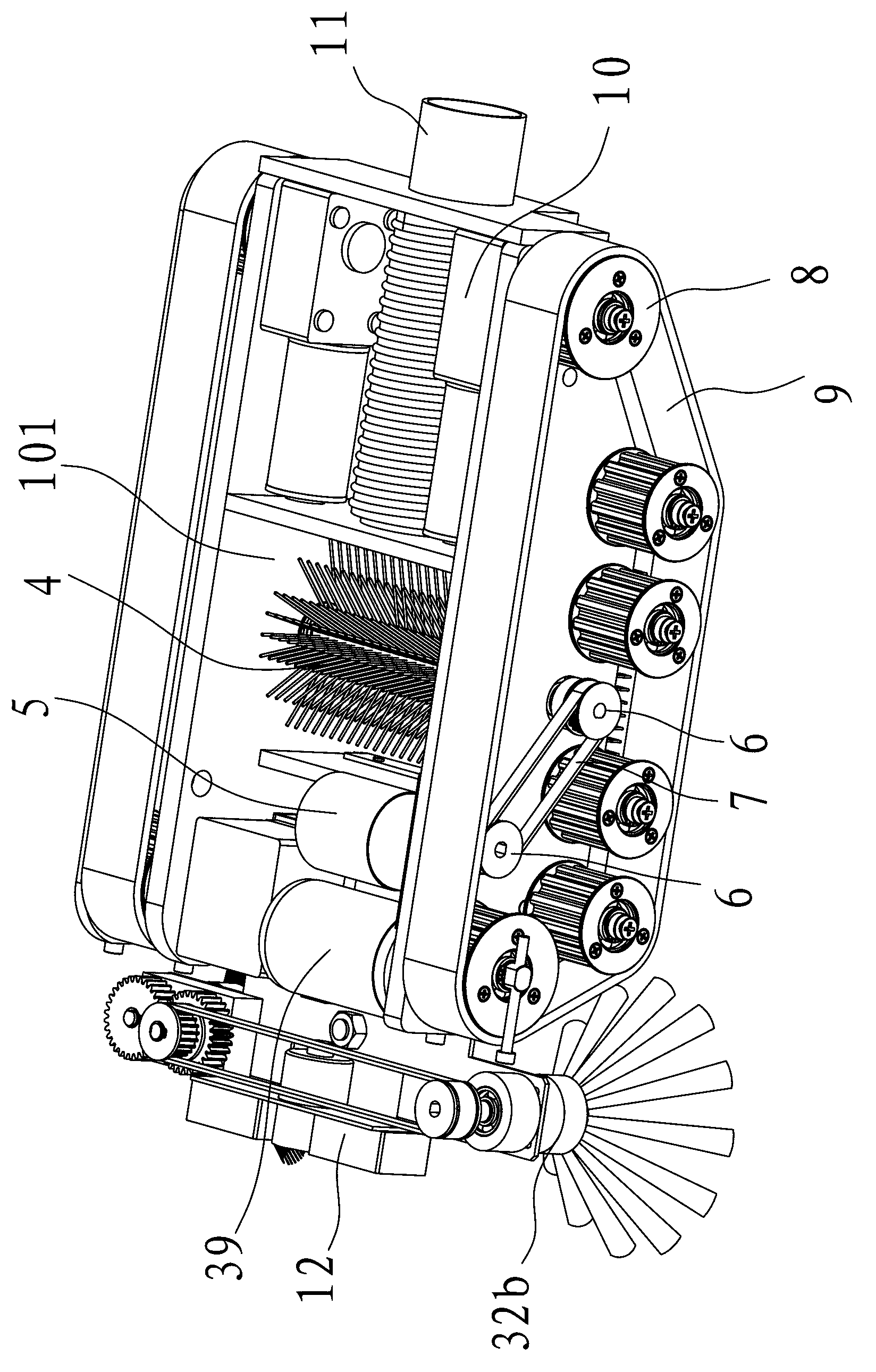

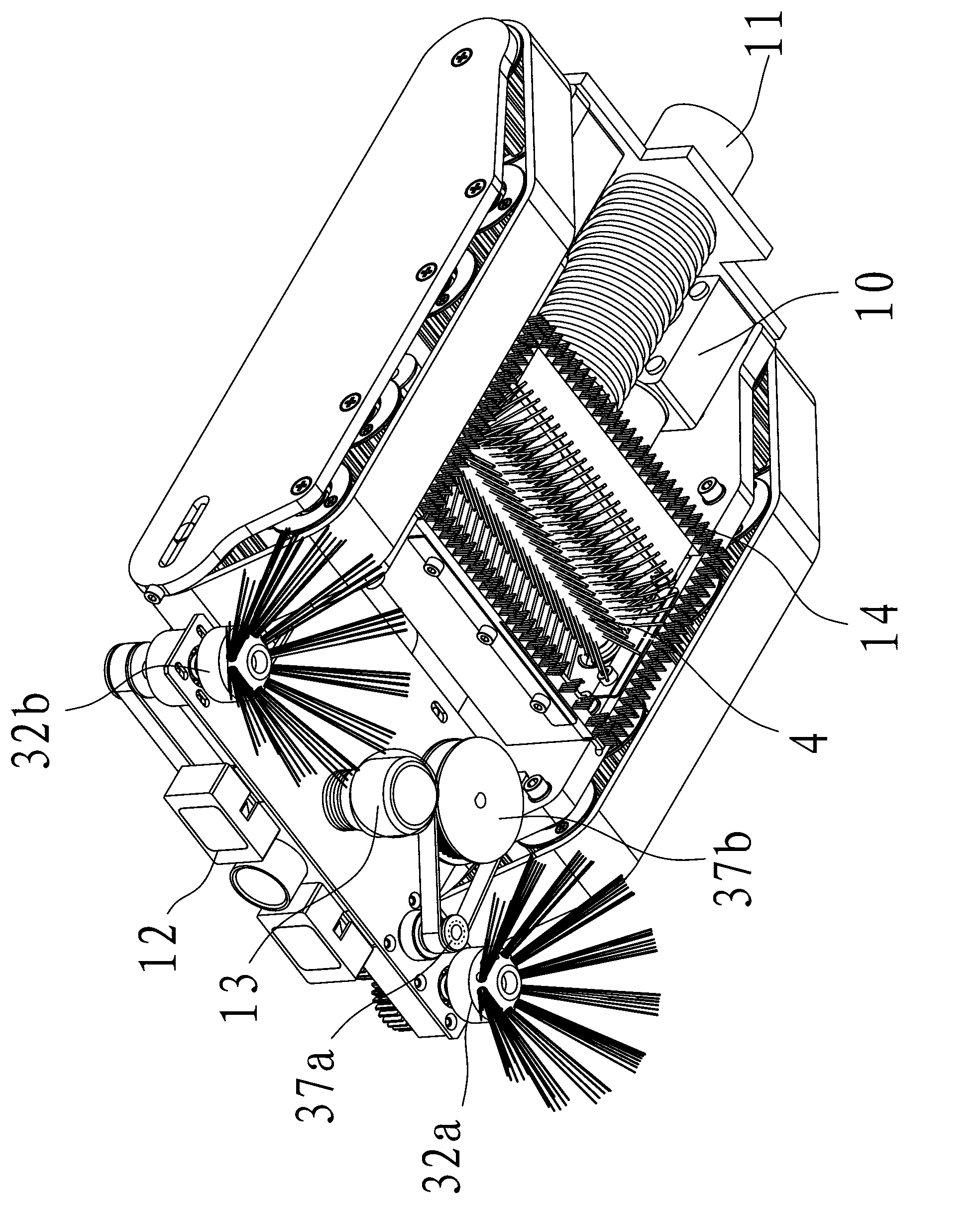

Three-in-one dust collection robot

InactiveCN103316874AClean thoroughlyAchieving processing powerHollow article cleaningDirt cleaningControl systemEngineering

The invention relates to a three-in-one dust collection robot. The three-in-one dust collection robot comprises a rack, a first cleaning mechanism, a second cleaning mechanism and a control system, wherein a cavity is formed in the middle of the rack, and a traveling mechanism which drives the rack to go forward or backward is arranged on the rack; the first cleaning mechanism comprises a cleaning head and a first drive mechanism which drives the cleaning head to rotate in the axial direction perpendicular to the ground, the cleaning head is disposed at the front end of the rack, the second cleaning mechanism comprises a cleaning rolling brush and a second drive mechanism which drives the cleaning rolling brush to rotate in the axial direction parallel to the ground, the cleaning rolling brush is arranged in the cavity in the middle of the rack, the cavity is connected with a dust collection pipeline which is connected with external dust collection equipment, and the control system is used for controlling actions of the mechanisms. The three-in-one dust collection robot has the advantages that automatic cleaning of pipelines can be achieved, and the problems that manual cleaning is high in cleaning difficulty, large in workload, low in working efficiency and the like are solved.

Owner:胡雄华

Scrap iron cleaning device

InactiveCN103567063AClean up comprehensivelyGood effectCleaning using toolsMagnetic separationMetalSmall hole

The invention provides a scrap iron cleaning device, belongs to the technical field of surface coating production of automobiles or other metal, and solves the problem that scrap iron relatively tightly adhered to the surface of an automobile body is difficult to clean by a conventional scrap iron cleaning device. The scrap iron cleaning device provided by the invention comprises a casing provided with an inner chamber; the casing is provided with a working face opposite to the surface of a to-be-cleaned object; a brush capable of cleaning scrap iron is fixedly connected to the working face; a plurality of small holes allowing the inner chamber to be communicated with the outside are formed in the working face; a magnetic component capable of sucking scrap iron into the inner chamber from the small holes is arranged in the casing; the brush works with the magnetic component. The scrap iron cleaning device can clean scrap iron on the surface of metal with any profile and scrap iron on the surface of metal with a relatively large inner chamber, can suck certain scrap iron that the brush can not reach easily, and has the advantages of double effects, completeness in cleaning, and good effect.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

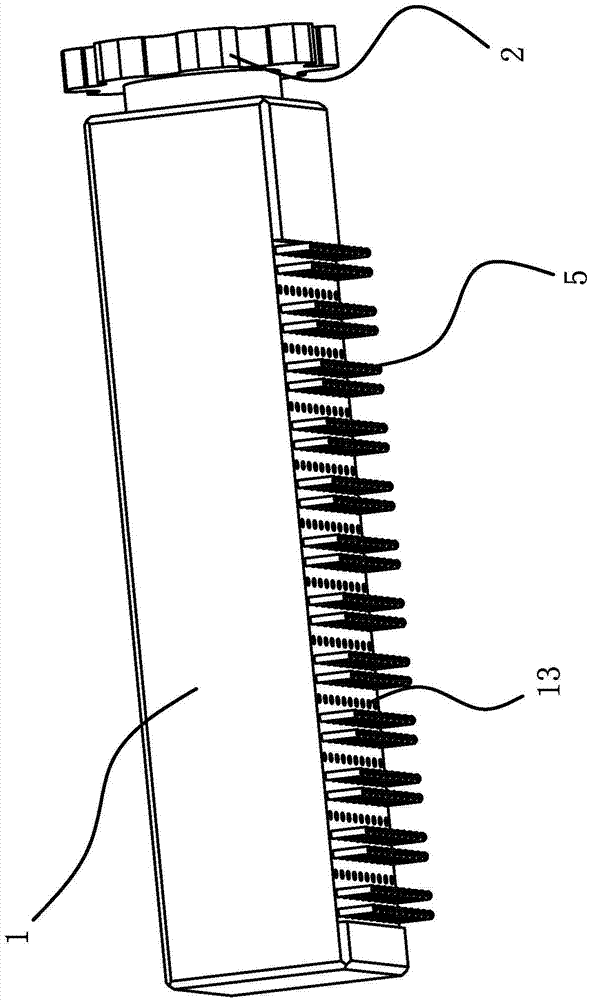

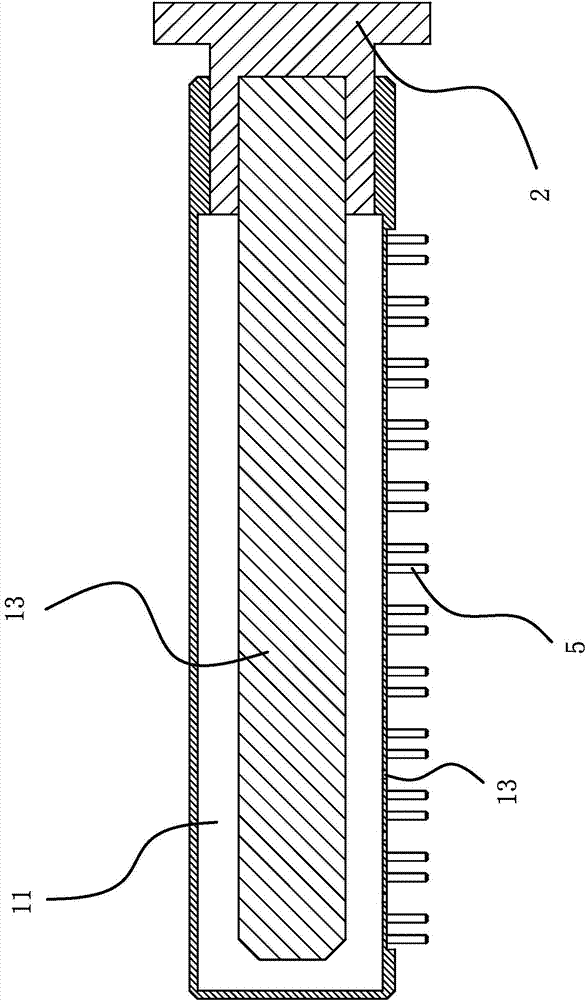

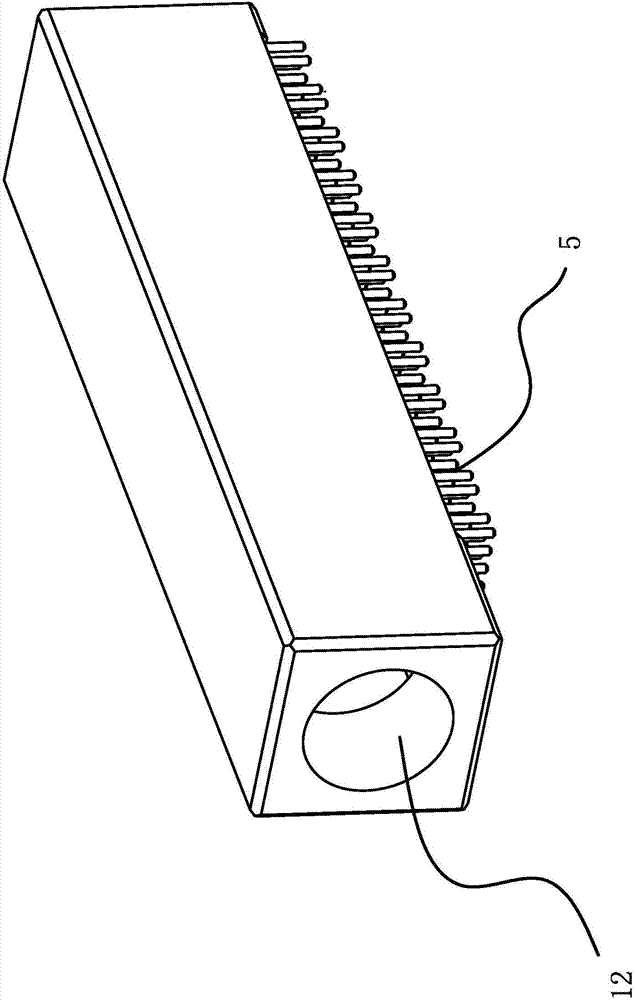

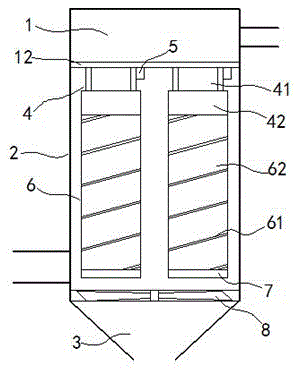

Spring cartridge dust remover

ActiveCN105664612AClean up comprehensivelyAvoid flyingCombination devicesDispersed particle filtrationElectromagnetic shieldingEngineering

The invention relates to a spring cartridge dust remover comprising a dust removal chamber, a purifying chamber and an ash bucket; the purifying chamber and the dust removal chamber are separated by a separation plate; dust removal units are rotationally and symmetrically distributed on the lower surface of separation plate; the dust removal units each comprise a fixed shaft and an electromagnetic ring, and each electromagnetic ring can slide along the axis of the fixed shaft in a reciprocating manner; the electromagnetic rings are electrically connected with a dust remover power supply; a dust removal cartridge is fixed below each electromagnetic ring and is coaxial with each fixed shaft; the lower end of each dust removal cartridge is sealedly fixed on a conductive sheet at the lower part of the dust removal chamber, and the conductive sheets are electrically connected with the dust removal power supply; each dust removal cartridge comprises an electromagnetic spring and a dust removal net, the upper end of each electromagnetic spring is electrically connected with the electromagnetic ring, and the lower end of each electromagnetic spring is electrically connected with the conductive sheet; the outer part of each electromagnetic spring is fixedly wrapped with the dust removal net; the dust remover is novel and unique in structure, can efficiently clear dust, and effectively improves the cleaning efficiency.

Owner:JIANGSU GUOQUAN AUTOMATION TECH CO LTD

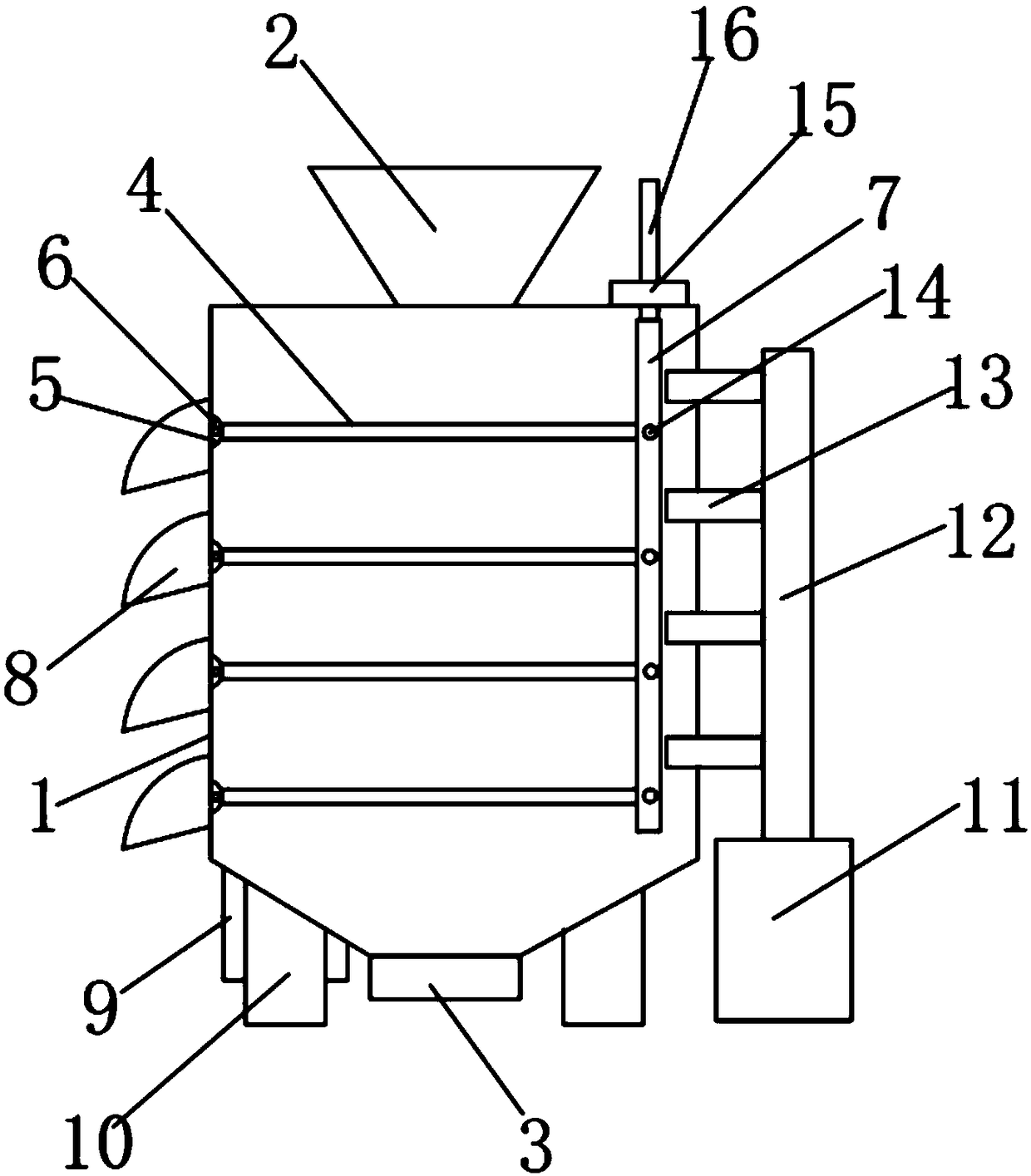

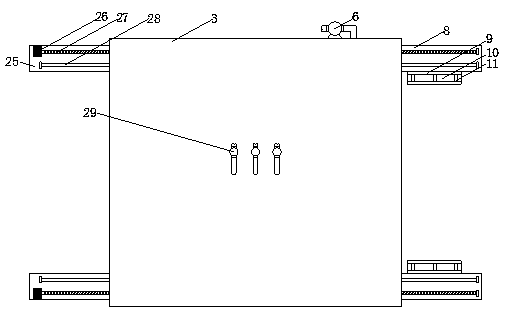

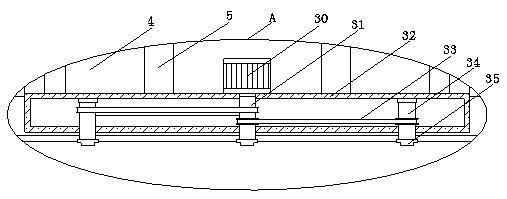

Novel grain cleaning equipment

The invention discloses novel grain cleaning equipment which comprises a machine box. A feeding opening is formed in the top end of the machine box, and a hopper is welded to the feeding opening. Thelower end of the machine box is of a conic structure, a discharging opening is formed in the position of the bottom end of the machine box, and an ash pipe is welded to the discharging opening. Multiple vibration screens spaced up and down are arranged in the machine box. According to the novel grain cleaning equipment, when the condition that screen holes are blocked by materials happens, a leadscrew is lifted, so that the right sides of the vibration screens ascend, the whole vibration screens are in an inclined state, at this moment, compressed air is generated by an air compressor and issprayed out from spray pipes, the materials clamped in the screen holes are blown away from the screen holes under the action of wind power, therefore, the screen holes are dredged, and the materialsblown away from the screen holes roll out from a screening outlet; and cleaning of the vibration screens can be fast achieved as a whole, efficiency is high, and personnel are more relaxed.

Owner:王荣

Silicon chip degumming technology

ActiveCN108711547ASo as not to damageClean up comprehensivelySemiconductor/solid-state device manufacturingMegasonic cleaningSilicon chip

The invention discloses a silicon chip degumming technology. The technology comprises following steps of placing a silicon sheet in a processing pool; adding de-ionized water in the processing pool; adding degumming liquid in the processing pool; allowing the silicon sheet stand for 35-50 min; carrying out spray-washing processing; controlling the temperature of the spray-washing water to be 30-35DEG C; placing the processed silicon sheet into the processing pool again and adding degumming liquid; vibrating the silicon sheet under the condition of 50-60 DEG C; after the silicon sheet reacts with the degumming liquid for 3-6min, carrying out ultrasonic cleaning on the silicon sheet; placing the vibrated silicon sheet in an ultrasonic cleaner for immersion; placing the silicon sheet in a surface processing pool again; adding surface processing liquid in the surface processing pool; immersing the silicon sheet for 30-50 min in the environment of 35-45 DEG C; and carrying out spray-washing processing again. According to the invention, residue glue on the silicon sheet is completely cleaned, degumming quality is ensured and the surface of the silicon sheet can be protected against damage.

Owner:浙江海顺新能源有限公司

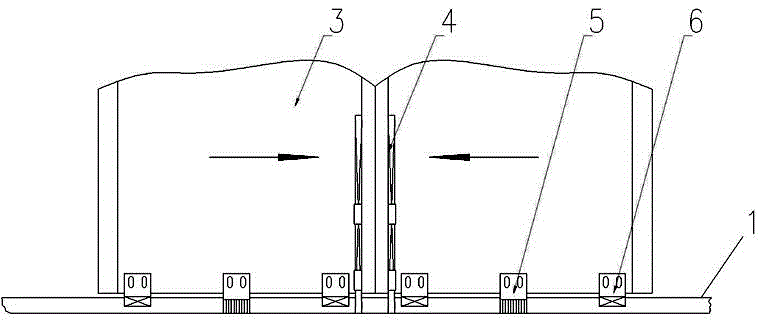

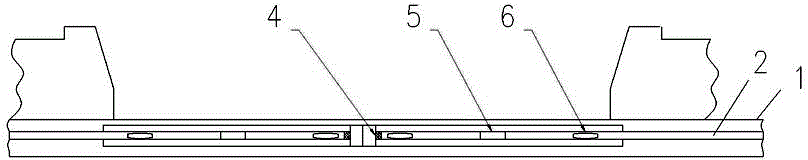

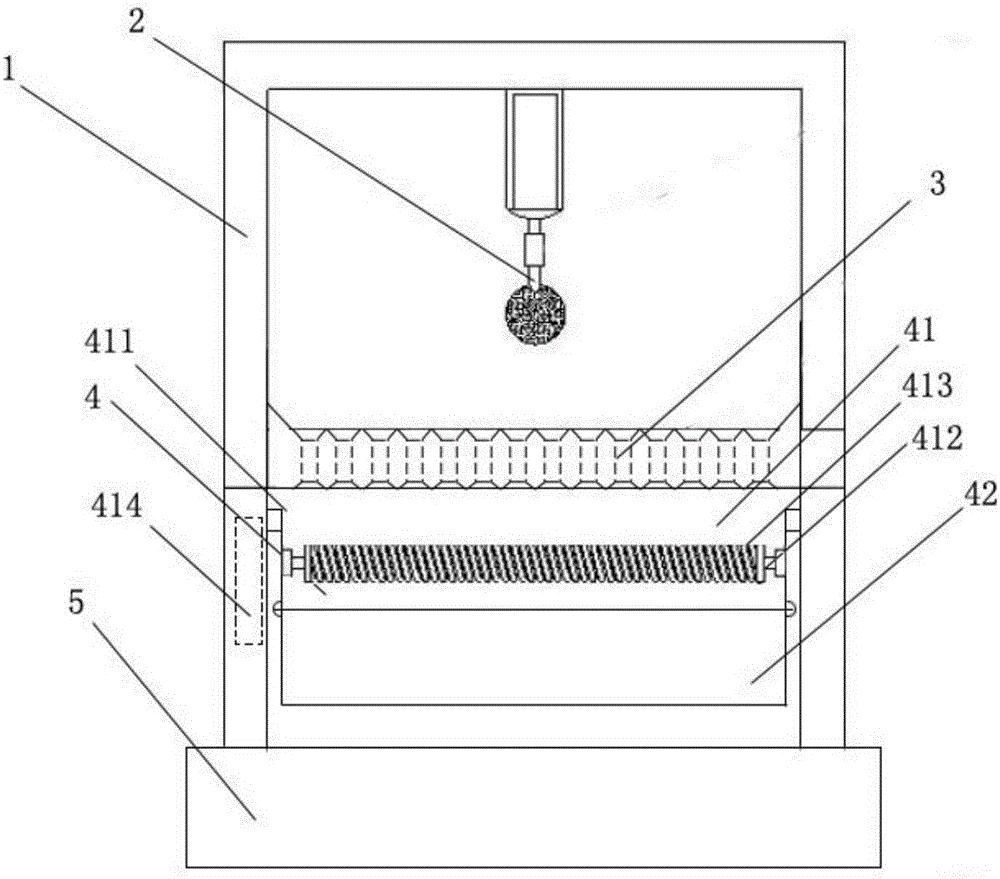

Accessory paint spraying anti-corrosion device and paint spraying method

InactiveCN110813594ALower the altitudeRealize semi-automatic loadingPretreated surfacesCleaning using toolsElectric machineEngineering

The invention discloses an accessory paint spraying anti-corrosion device and a paint spraying method. The device comprises a base plate, wherein the top of the base plate is fixedly provided with a cover shield, and the two sides of the cover shield are provided with access openings in a penetrating mode; two first connecting plates are fixedly arranged on one side of the base plate, and two second connecting plates are fixedly arranged on the other side of the base plate; and second rotating motors are fixedly arranged at the tops of the second connecting plates, second threaded rods are fixedly connected to the output ends of the second rotating motors, and sliding supporting bases are arranged on the second threaded rods. According to the accessory paint spraying and anti-corrosion device and the paint spraying method, lifting mechanisms, bearing plates and storage grooves are matched and used, and the height at which the bearing plates are located is reduced during feeding, so that the feeding difficulty and intensity are reduced, and the feeding operation is facilitated; and meanwhile, the storage grooves can limit the position of accessories, and paint spraying operation canbe carried out on the plurality of accessories at the same time, so that the working efficiency is improved.

Owner:天津万达鼎睿供应链有限公司

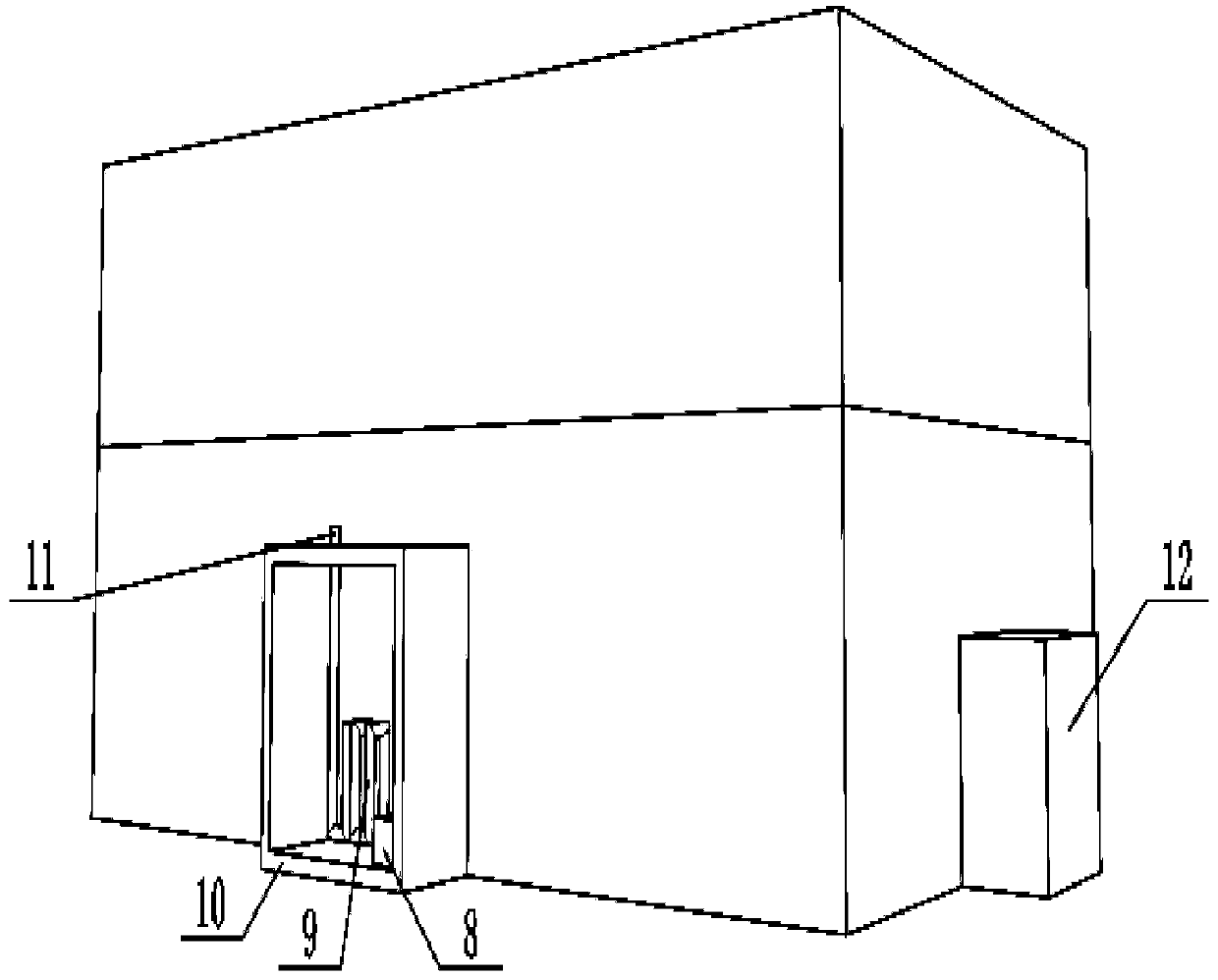

Film sticking device and method for electronic product

InactiveCN111086200AImprove cleaning effectImprove drying efficiencyCleaning using toolsDomestic articlesElectric machineryEngineering

The invention discloses a film sticking device and method for an electronic product, and relates to the technical field of film sticking devices and methods for electronic products. The film stickingdevice comprises a worktable, a dust-proof box is welded to the outer wall on the top of the worktable, a placement mechanism is arranged on the outer wall of the top of the worktable, and a dust-proof mechanism and a film pressing mechanism are arranged at the two ends of the inner wall of the top of the dust-proof box respectively. An air-drying mechanism is arranged in the middle of the inner wall of the top of the dust-proof box, a blower box and a negative-pressure case are fixedly arranged at the bottom ends of the outer wall on the two sides of the worktable through screws respectively,a negative-pressure machine is fixedly arranged on the inner wall of one side of the negative-pressure case through a screw, and the outer wall of the top of the dust-proof box is provided with an air conveying pipe joint. A second motor drives a first rotating shaft to rotate, a second dust-proof cloth barrel is wound with used dust-proof cloth, the used dust-proof cloth is conveniently replaced, the cleaning effect is improved, and the face, stuck with a film, of a second electronic product is convenient to clean.

Owner:南京雷石电子科技有限公司

Dirt cleaning device and method for pond intensive culture net cage

ActiveCN112170402AImprove cleaning efficiency and cleaning degreeComprehensive dirt cleaningClimate change adaptationHollow article cleaningElectric machineryIntensive culture

A dirt cleaning device of a pond intensive culture net cage is characterized in that a water body exchange module is arranged at the front end of the culture net cage, a dirt collection module is arranged at the rear end of the culture net cage, and the culture net cage comprises a culture tank formed below a buoyancy frame and provided with at least one group of sweeping modules and a steel wirerope transmission mechanism capable of driving the sweeping modules to reciprocate; the steel wire rope transmission mechanism comprises a motor and a rotating shaft connected with the motor, and further comprises at least two groups of steel wire rope assemblies capable of transmission, each steel wire rope assembly comprises a hanger rail, a steel wire rope, a pay-off reel and a take-up reel, each sweeping module comprises a plurality of groups of brushes capable of swinging and hinged to a cross beam, and balancing weights are assembled on the brushes; and hanging ropes capable of being connected to the steel wire ropes in the overhead rails respectively are connected to the cross beam, and the driving steel wire ropes drive the sweeping modules to move back and forth in the culture tank to sweep the bottom of the culture tank. The dirt cleaning device solves the problem that dirt sediment at the bottom of the net cage cannot be thoroughly cleaned and effectively improves the dirt cleaning efficiency and the dirt cleaning degree.

Owner:JIMEI UNIV +1

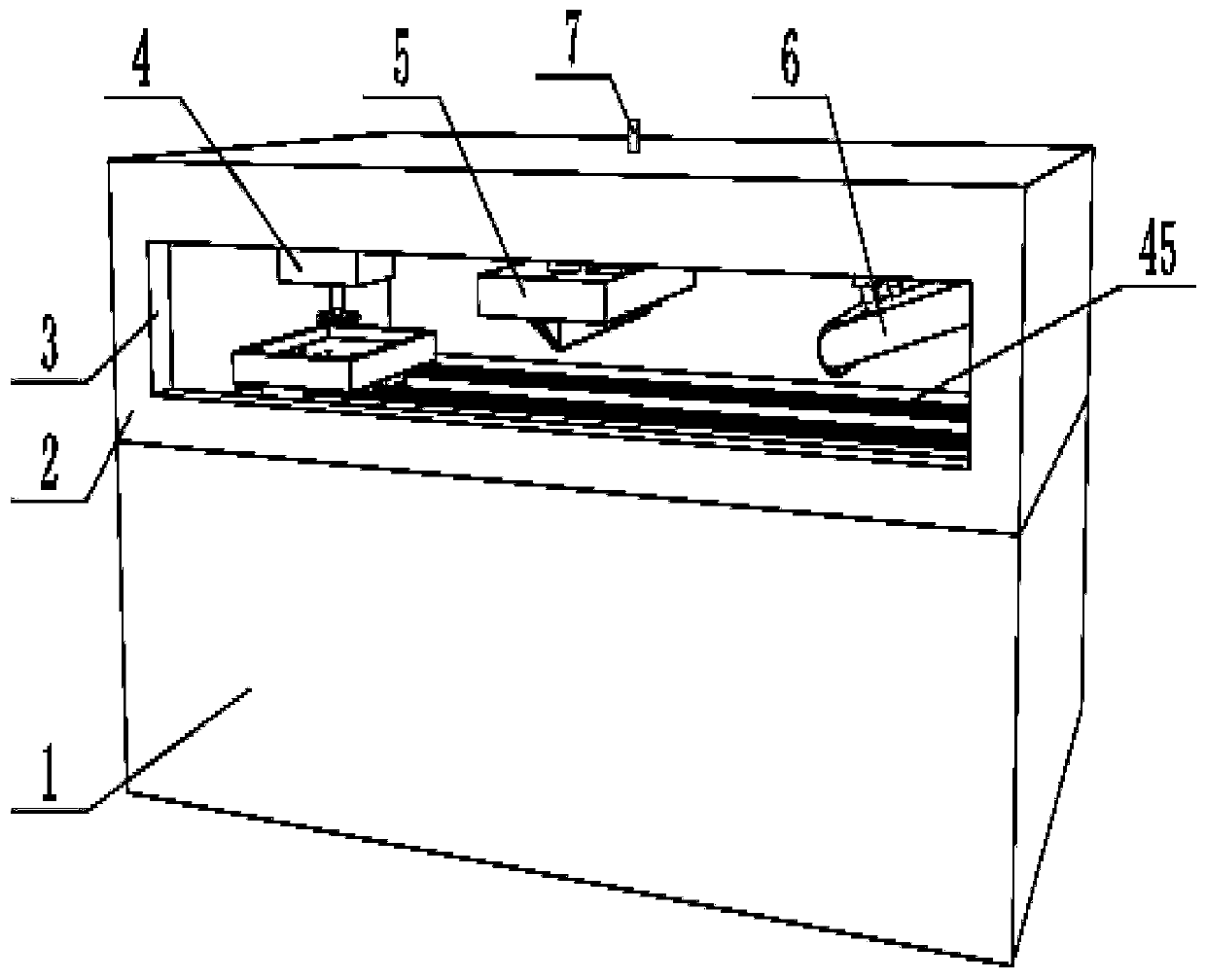

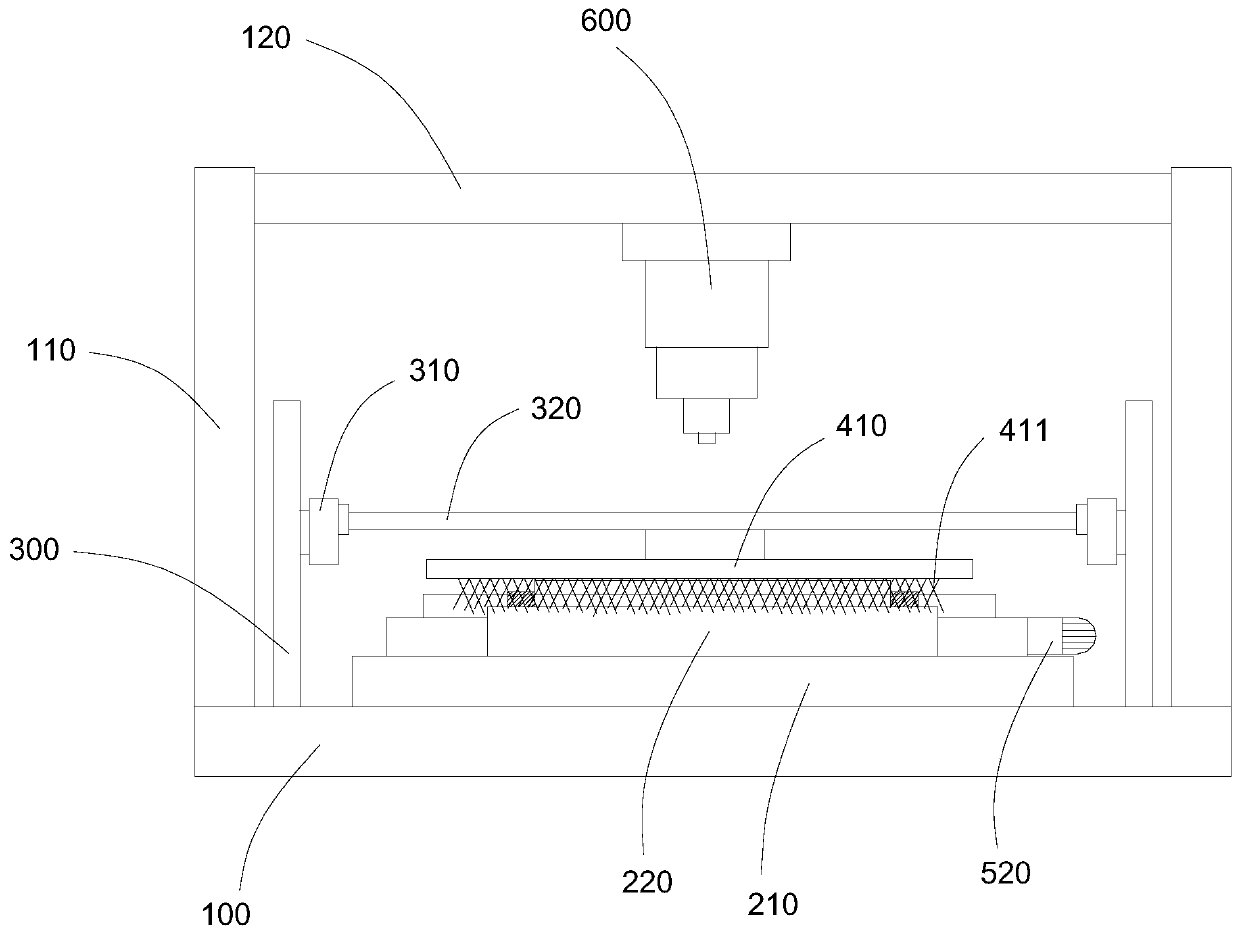

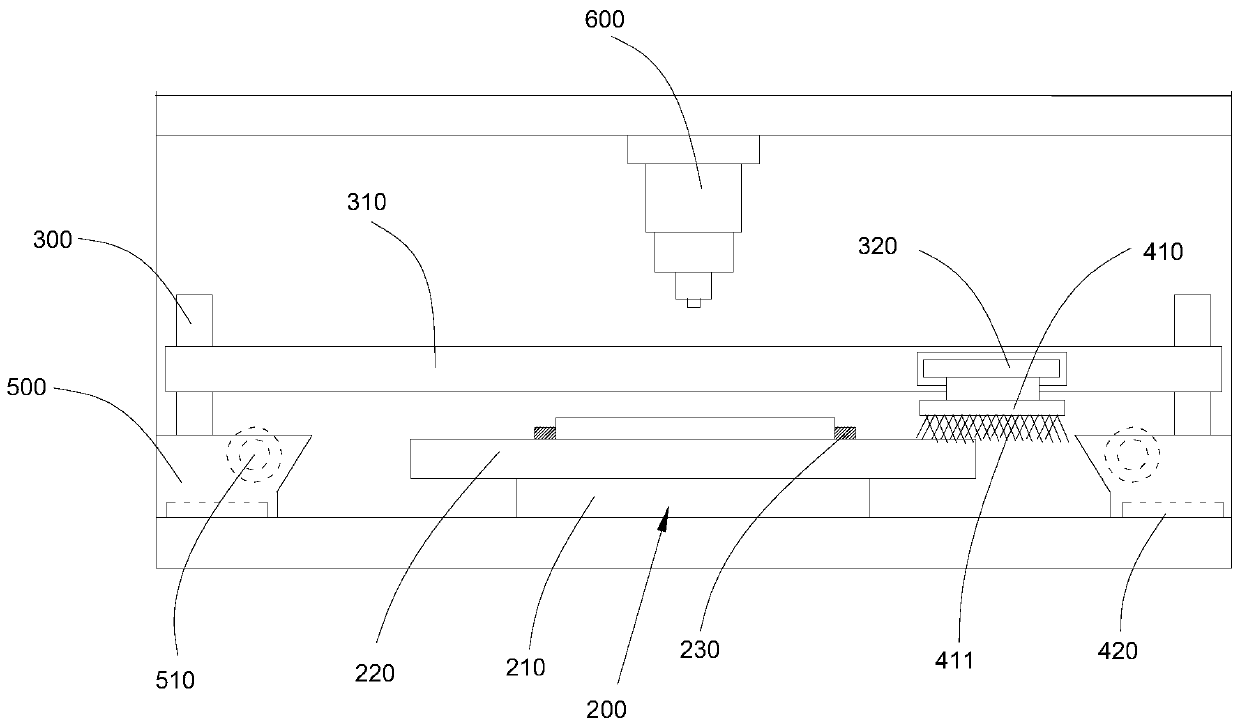

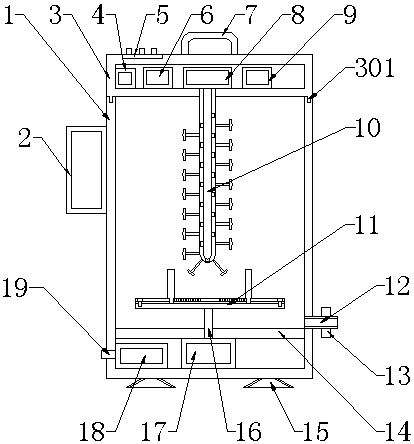

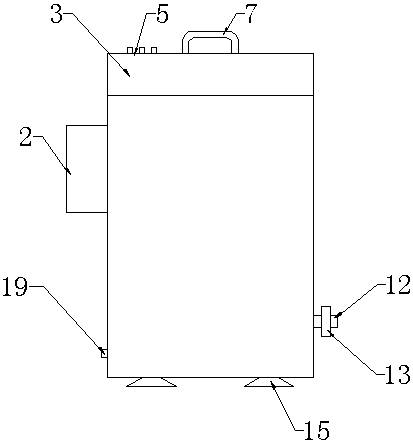

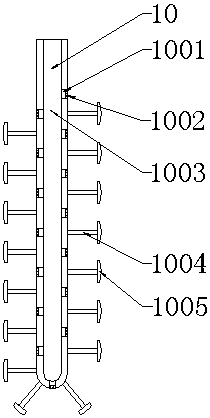

Ultra-precision horizontal micro-EDM machine tool

InactiveCN110935965ASimple structureEasy to cleanElectrical-based auxillary apparatusBristleElectric machinery

The invention provides an ultra-precision horizontal micro-EDM machine tool, which comprises a base and a workbench arranged on the base, and is characterized in that both sides of the workbench are provided with two supports, the two supports on the same side are provided with a first rodless cylinder therebetween, the two first rodless cylinders are located at the same height, a second rodless cylinder is erected between sliding blocks of the two opposite first rodless cylinders, a sliding block of the second rodless cylinder faces the workbench, the sliding block of the second rodless cylinder is provided with a first electromagnet plate, and the bottom surface of the first electromagnet plate is provided with bristles; and two ends of the workbench are further provided with scrap collecting boxes, each scrap collecting box is located between the two supports at the same end, the scrap collecting box is internally provided with a rotating roller, and the rotating roller is driven bya motor. The micro-EDM machine tool is simple in structure and capable of effectively cleaning a machined machine tool, common scraps or magnetized scraps are cleaned up, the accuracy of the placingposition of a workpiece is guaranteed, and thus the machining precision is improved.

Owner:邱爱鑫

Loudspeaker box dust screen cleaning device capable of combining inertial dust collection with airflow lotion dust collection

ActiveCN108970281AImprove cleaning qualityEasy to wipeDispersed particle filtrationTransportation and packagingDrive motorEngineering

The invention provides a loudspeaker box dust screen cleaning device capable of combining inertial dust collection with airflow lotion dust collection, and relates to the field of loudspeaker box cleaning equipment. The loudspeaker box dust screen cleaning device capable of combining inertial dust collection with airflow lotion dust collection comprises a supporting fixed housing, wherein the sidewall of the supporting fixed housing is spliced with a holding internal hollow fixing barrel; the side wall of the holding internal hollow fixing barrel is spliced with a lateral grip; the top of theinner wall of the supporting fixed housing is spliced with a dust-proof moisture-proof protecting case; the top of the supporting fixed housing is provided with a floating dust cleaning and removal mechanism. According to the loudspeaker box dust screen cleaning device capable of combining inertial dust collection with airflow lotion dust collection, one end of a rotary sliding rod is controlledby a driving motor to slide in a concave sliding ring to enable the rotary sliding rod to incline to one side of a jacking spring; after sliding, an overturning linkage rod is jacked under the elasticfunction of the jacking spring to drive a round knocking ball on the end part of the overturning linkage rod to knock the loudspeaker box dust screen, dust is separated from the dust screen due to the influence of inertia, and the dust removal efficiency of the loudspeaker box dust screen is effectively improved.

Owner:临沭县济才人力资源服务有限公司

Cleaning device for electronic product instrument

InactiveCN111346857AEasy to fixPrevent slidingDirt cleaningCleaning using toolsDust controlEngineering

The invention relates to the technical field of electronic products, in particular to a cleaning device for an electronic product instrument. The cleaning device comprises a bottom plate. A first clamping plate is fixedly connected with the left side of the upper end of the bottom plate. A first slide groove is formed in the right side of the upper end of the bottom plate. A second clamping plateis fixedly connected with the upper end of a connecting block. The middle of the upper end of a top plate is provided with a second slide groove. A movable block is slidingly connected into the secondslide groove. A dustproof device is fixedly connected with the lower end of an electric telescopic rod. Connecting plates are symmetrically connected with the upper portion of the right side of a first supporting plate. A connecting shaft is rotationally connected with the connecting plates through bearings. The left side of the dustproof device is fixedly connected with a push rod. The push rodis fixedly connected with a push head used in cooperation with a cylindrical cam. The cleaning device is reasonable in structural design and convenient to use, can comprehensively clean an instrumentpanel of electronic equipment, greatly reduces labor intensity of workers and is more convenient to use.

Owner:吉林省初为科技有限公司

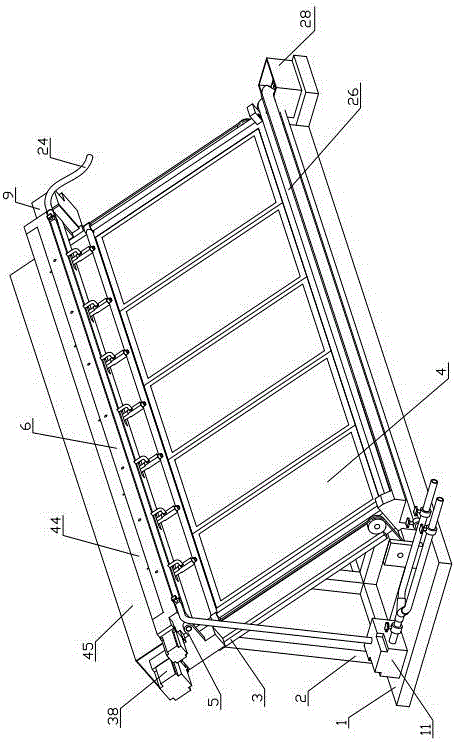

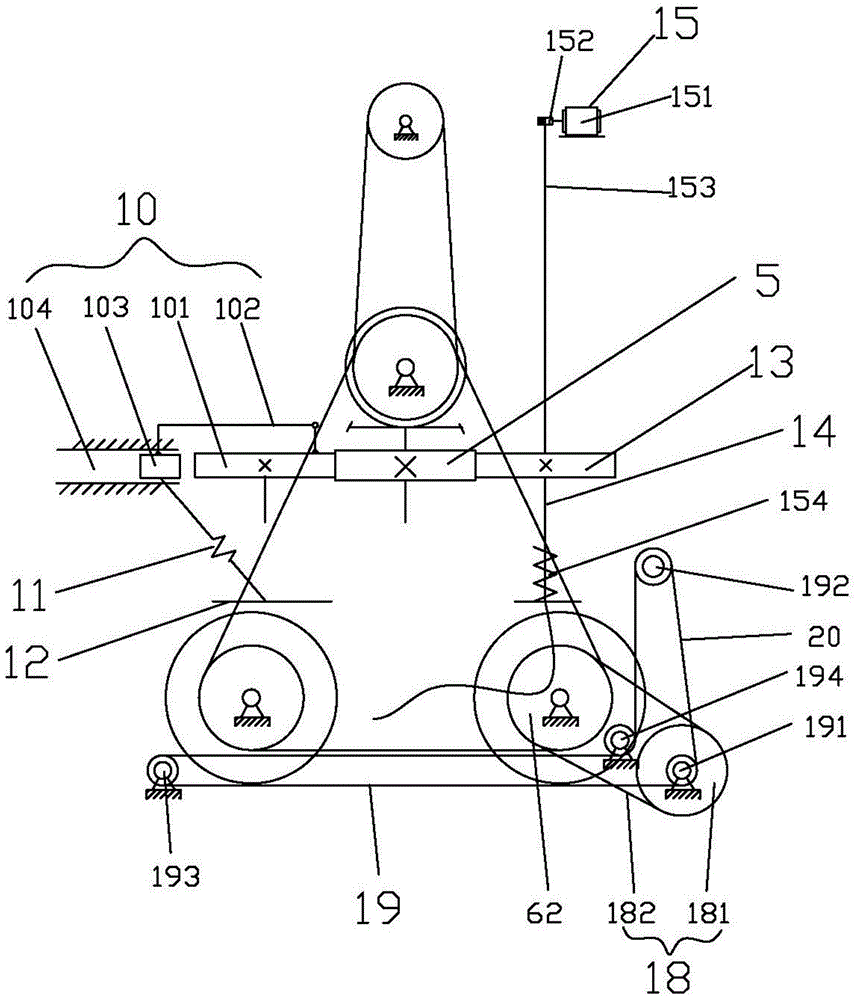

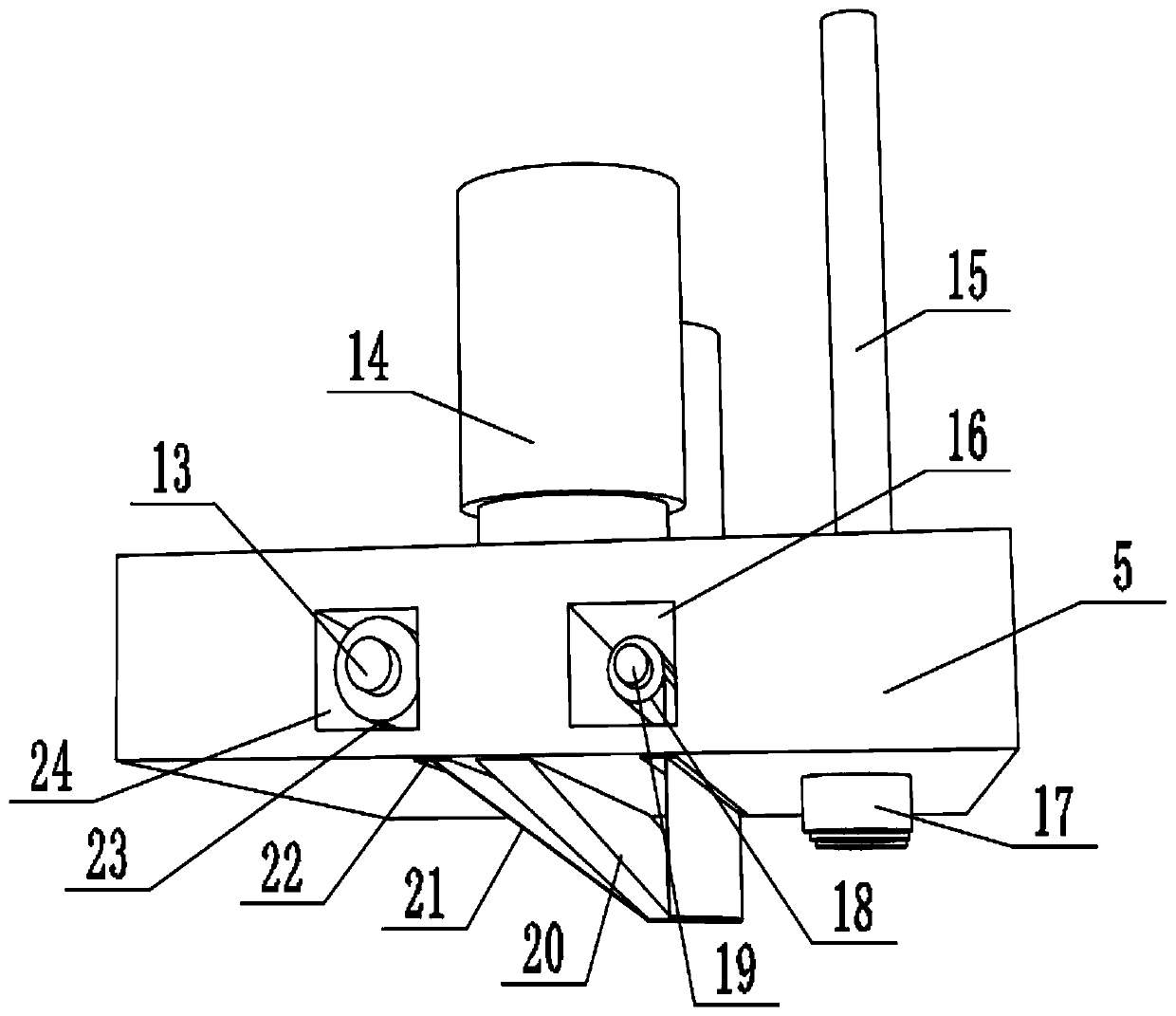

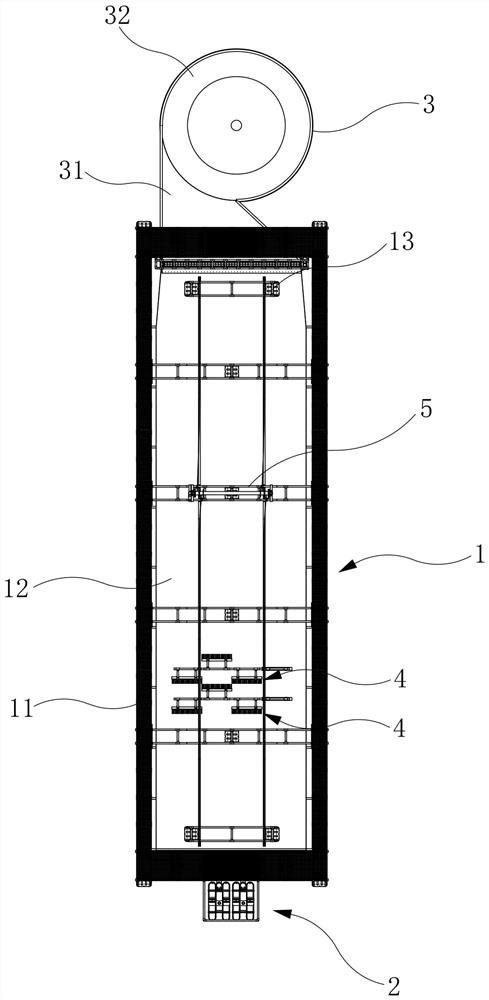

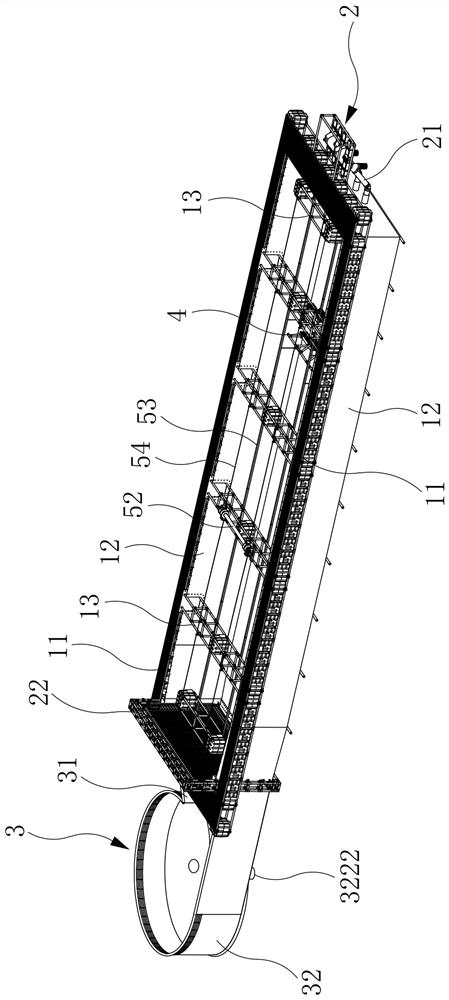

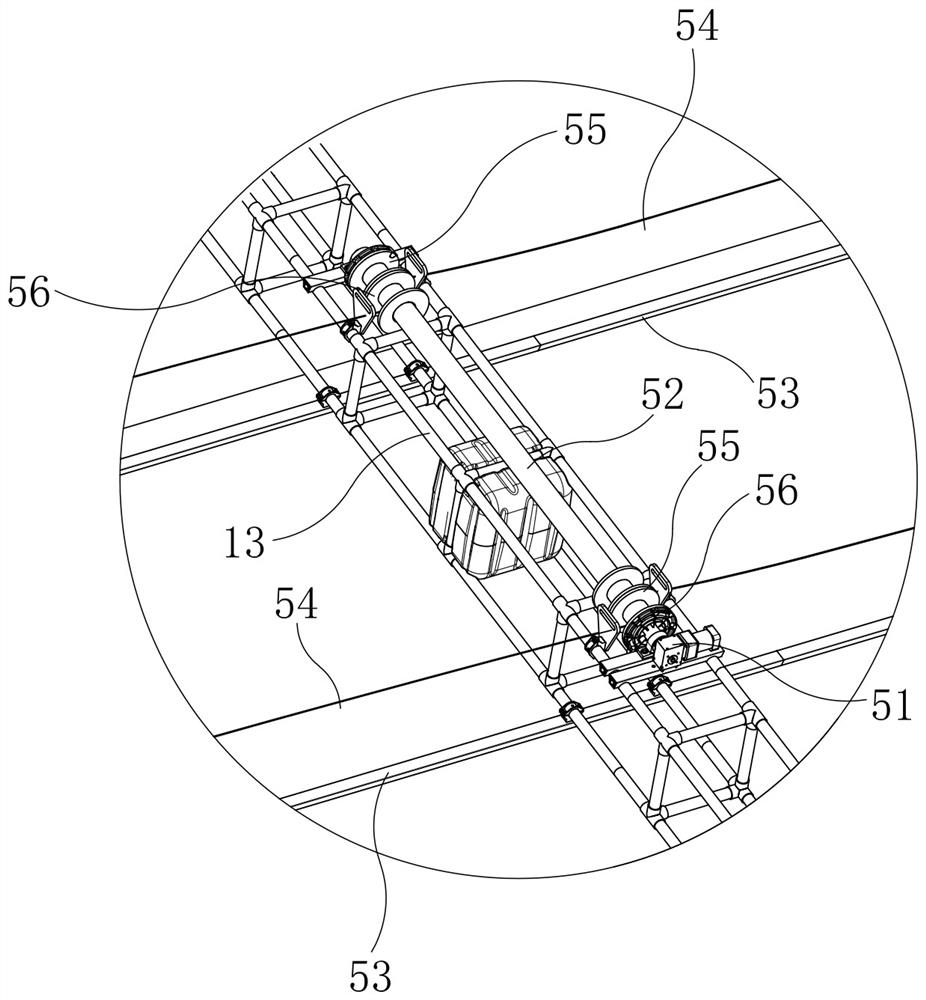

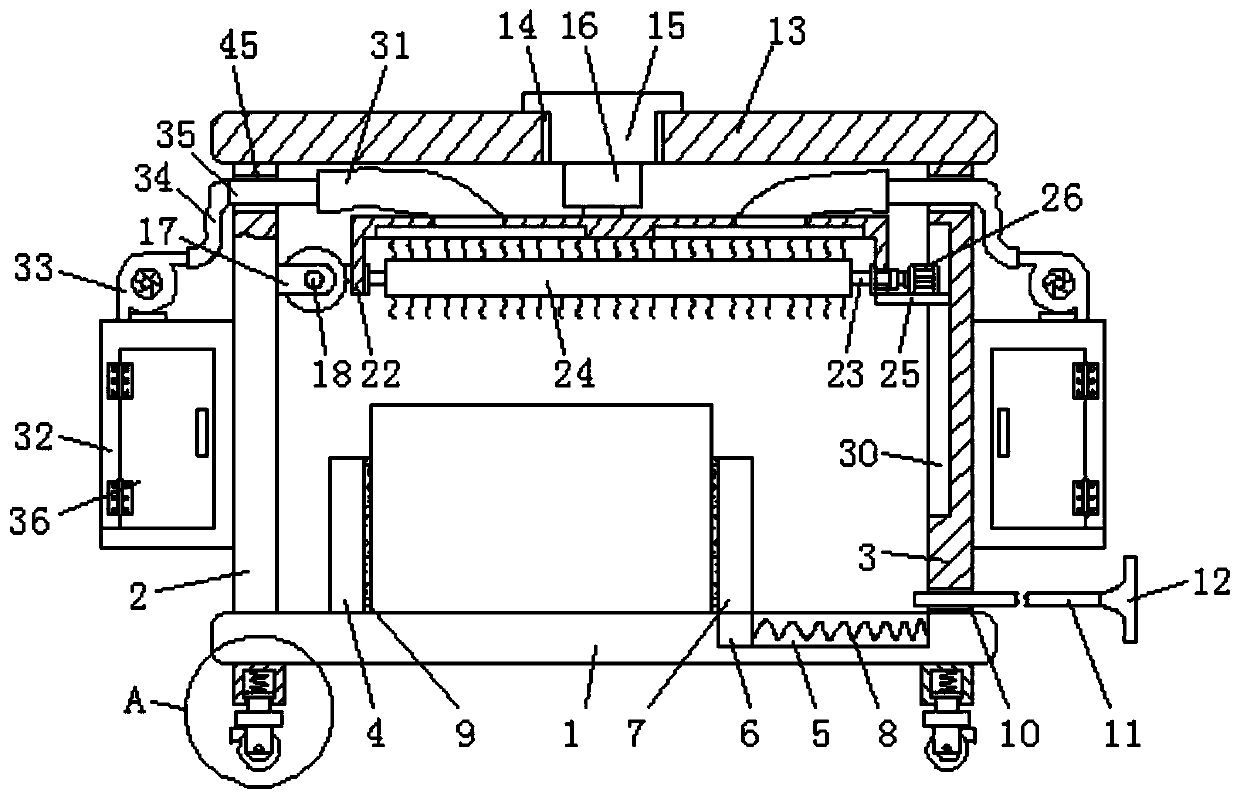

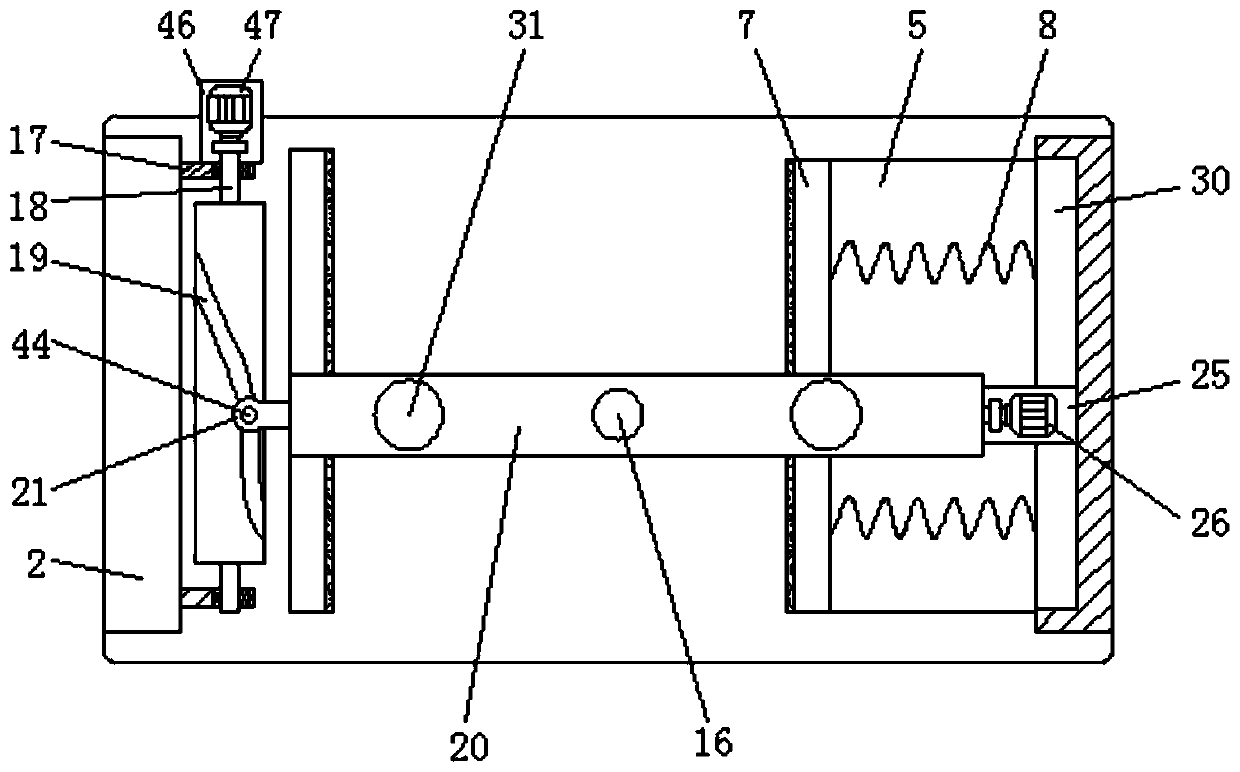

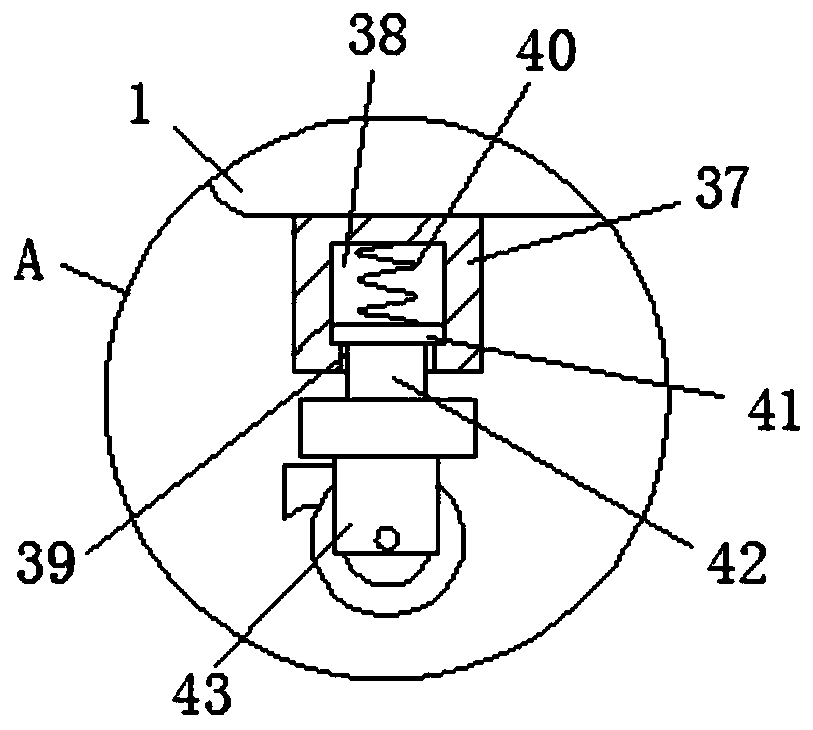

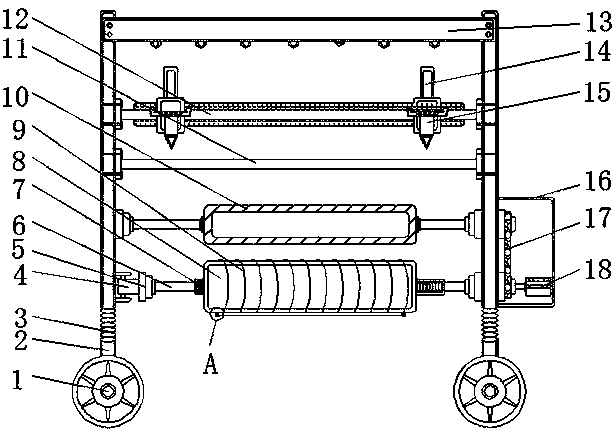

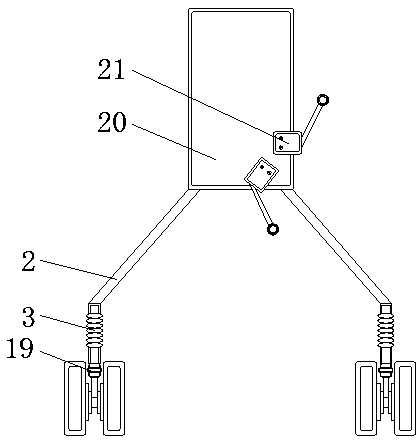

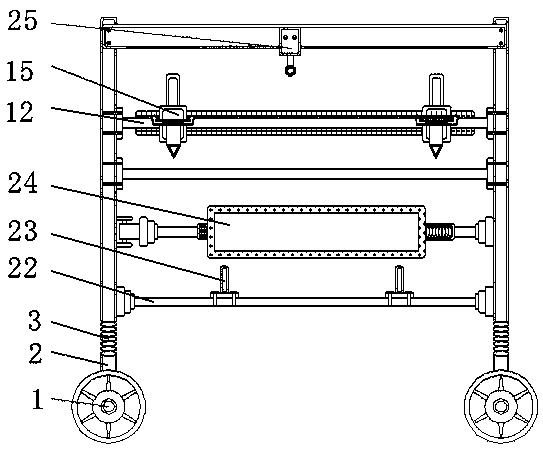

Automatic cleaning device for photovoltaic plates

ActiveCN106000950AExtend your lifeClean up comprehensivelyCleaning using toolsCleaning using liquidsElectricityBristle

The invention discloses an automatic cleaning device for photovoltaic plates. The automatic cleaning device for the photovoltaic plates is put forward mainly for the problem that a large amount of manpower is consumed in the photovoltaic plate cleaning process. The automatic cleaning device comprises a frame, walking devices, a cleaning device and a control device. The walking devices include the active walking device and the passive walking device. The active walking device comprises a walking drive device, a walking transmission shaft and driving walking wheels. The passive walking device comprises a passive walking shaft and passive walking wheels. The passive walking shaft and the walking transmission shaft are arranged in parallel in a spaced manner. The cleaning device at least comprises a cleaning mechanism. Each cleaning mechanism comprises a cleaning drive mechanism, a cleaning brush and an atomization flushing device. Each cleaning brush comprises a cleaning transmission shaft arranged parallel to the walking transmission shaft. Bristles are arranged on the outer surfaces of the cleaning transmission shafts. One end of each cleaning transmission shaft is connected with the corresponding cleaning drive mechanism. The walking drive device and the cleaning drive mechanisms are all electrically connected with the control device. The automatic cleaning device can automatically clean the photovoltaic plates and saves manpower.

Owner:MCC HUATIAN NANJING AUTOMATION ENG

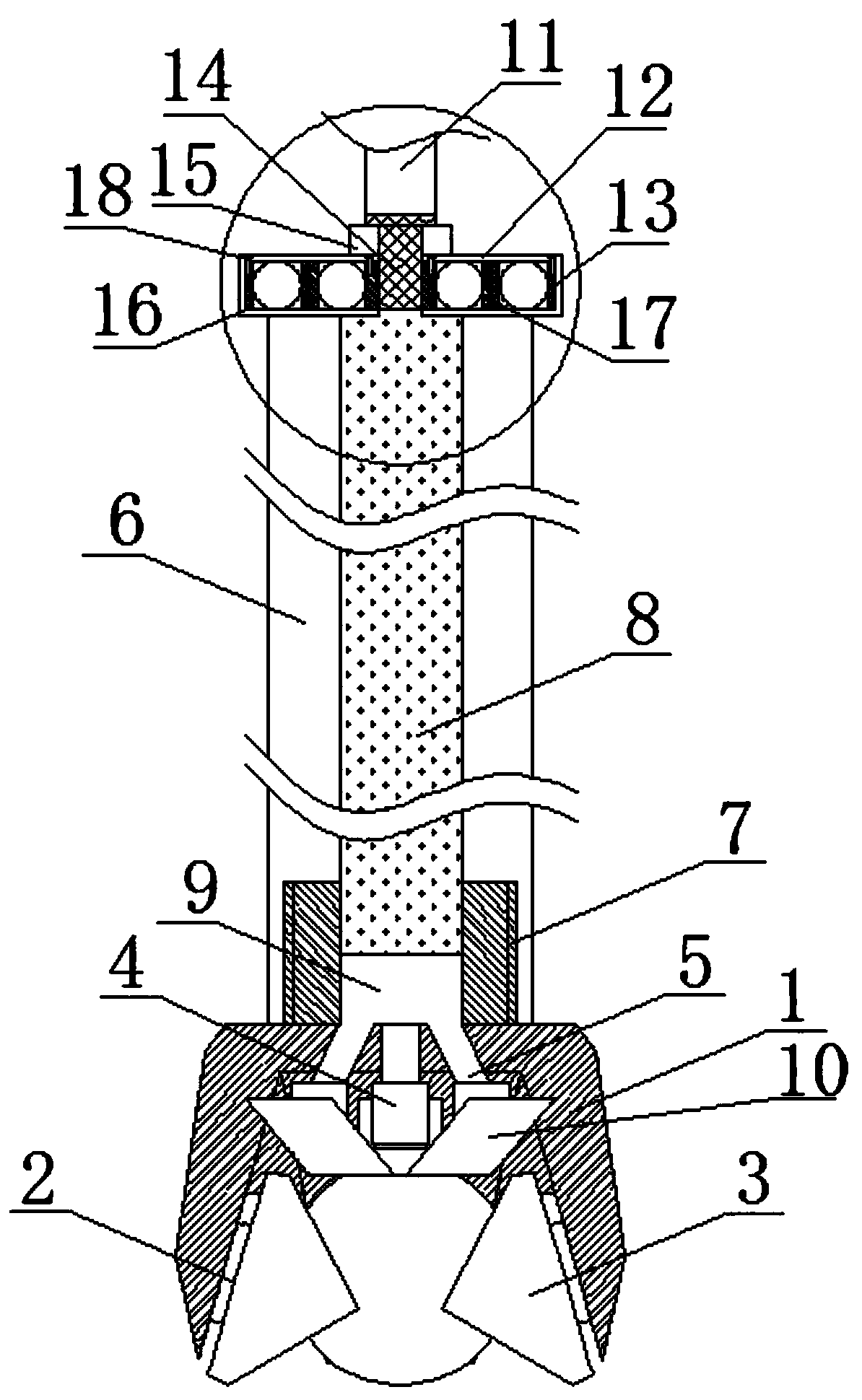

Oilfield drill bit with self-washing heat-dissipation function

InactiveCN110656889AQuick smashWith self-cleaning cooling functionDrill bitsDrilling rodsSteel tubeEngineering

The invention relates to the technical field of machinery, and discloses an oilfield drill bit with a self-washing heat-dissipation function. The drill bit comprises a drill bit shell, wherein the interior of the drill bit shell is provided with a roll shaft, drill bit shell and the roll shaft are connected with a drill bit body, the top of the drill bit body is provided with a spray head, the spray head is provided with a spray pipeline, the top of the drill bit shell is provided with a rotating steel pipe, the top of the drill bit shell is provided with a threaded connecting port connected with the rotating steel pipe, a cooling water storage pipe is arranged in the rotating steel pipe, a collecting water tank is connected between the bottom of the cooling water storage pipe and the spray pipeline, and a water inlet is formed in the top of the cooling water storage pipe. According to the oilfield drill bit with the self-washing heat-dissipation function, the cooling water storage pipe is arranged in the rotating steel pipe to be connected with the spray head at the top of the drill bit body, frictional heating occurs when the drill bit works, the effect of heat dissipation is achieved, when the drill bit makes contact with the hard ground, the effect of earth softening is achieved, and the employee operation is easier.

Owner:李茂林

Dust removing method of spring tube dust remover

ActiveCN107213721AClean up comprehensivelyAvoid flyingCombination devicesDispersed particle filtrationEngineering

Owner:无锡锡麦粮油装备工程有限公司

Dust removal fan for indoor air purification

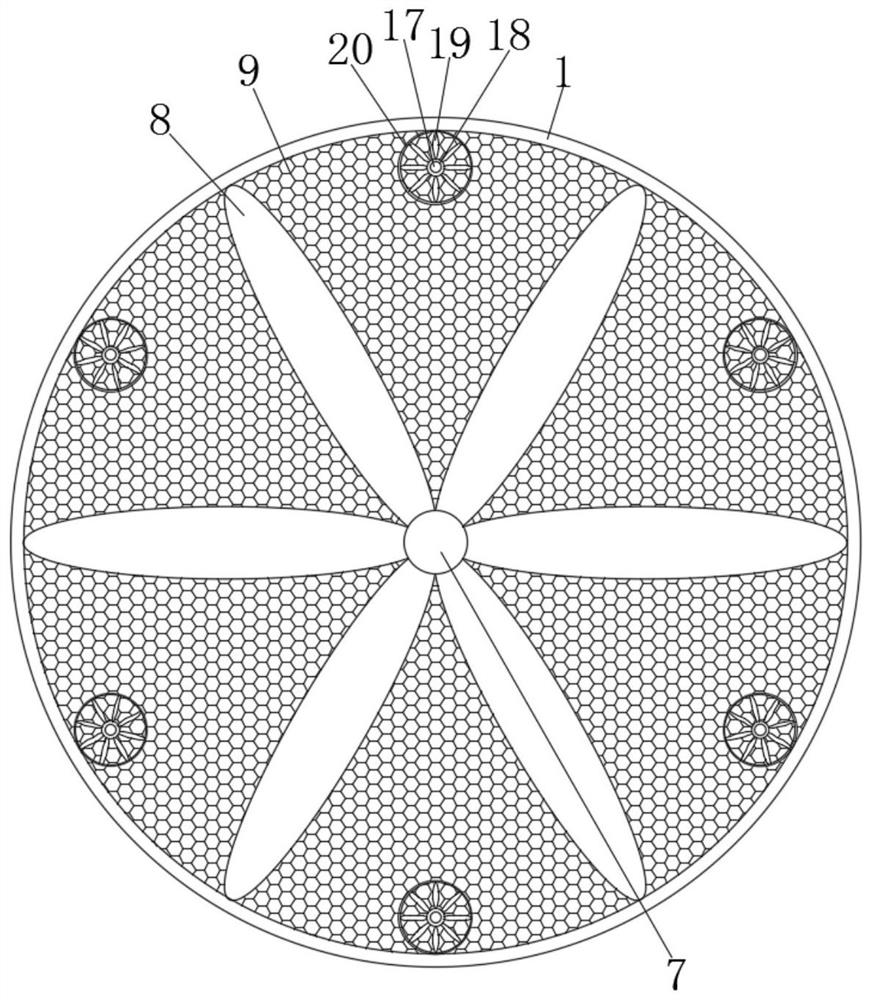

ActiveCN111911433AEvenly distributedEasy to clean up laterPump componentsPump installationsAir cleaningIndoor air

The invention discloses a dust removal fan for indoor air purification. The fan comprises a fan frame, a front cover and a rear cover are arranged at the two ends of the fan frame, four supporting rods are symmetrically and fixedly connected to the inner side wall of the fan frame, and shaft sleeves are fixedly connected to the ends, away from the fan frame, of the four supporting rods correspondingly. According to the fan, by arranging a dust uniform distribution device, a dust filter screen can be automatically driven to rotate under the action of wind power generated by first fan blades, itis ensured that dust, catkin and other impurities intercepted and filtered by the dust filter screen are uniformly distributed, subsequent clearing is facilitated, and the influence on the fan is reduced; a transmission device drives a transmission rod, a transmission shaft and third fan blades to rotate at a high speed, so that negative pressure is formed in an empty groove; and the dust, catkinand other impurities attached to the dust filter screen are sucked into the empty groove by means of a dust suction groove and fed into an impurity storage box under the action of wind force formed by the third fan blades, so that the impurities attached to the dust filter screen are cleared and collected.

Owner:珠海沛程电子有限公司

Printing ink recovery device of printing machine

ActiveCN110395048AEasy to cleanSimple structureFiltration circuitsPrinting press partsPrinting inkPrinting press

The invention discloses a printing ink recovery device of a printing machine. The printing ink recovery device of the printing machine comprises a box body, wherein four guide sleeves are fixedly arranged on the top surface of the box body; the four guide sleeves are in rectangular distribution; a horizontal polished rod is arranged in each guide sleeve; the four polished rods are fixedly connected through a transverse plate; a strip-shaped through groove is formed in the middle of the top surface of the box body; a first through hole is formed in the left side of the top surface of the transverse plate; a vertical first bolt is connected in the first through hole through a bearing; the bottom end of the first bolt penetrates through the strip-shaped through groove to enter the box body; the periphery of the bottom end of the first bolt is in threaded fit with a nut; the right side of the nut is fixedly provided with a vertical first sleeve; a piston is arranged in the first sleeve; the periphery of the piston is in contact fit with the inner wall of the first sleeve; and the right side of the top surface of the transverse plate is provided with a second through hole. Due to the arrangement of an annular filter plate, an annular filter screen and an annular semi-permeable film, ink can be separated and recovered from other impurities, the ink can be recycled conveniently, resources are saved, and convenience is brought to use.

Owner:CHONGQING IND POLYTECHNIC COLLEGE

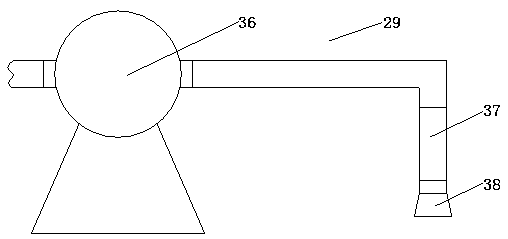

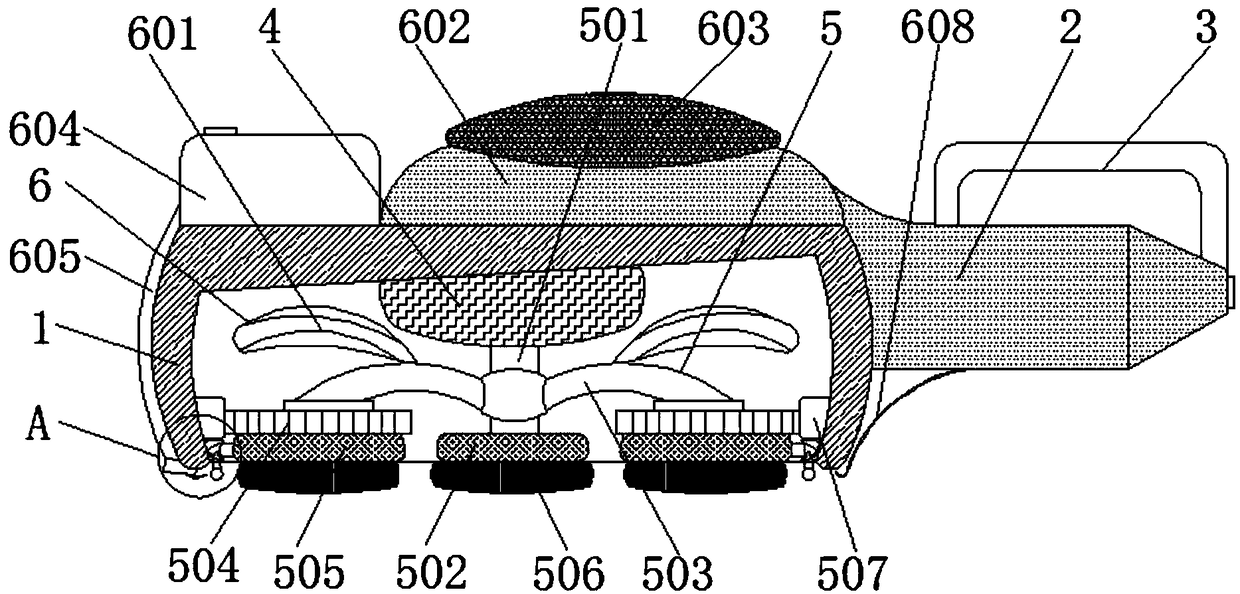

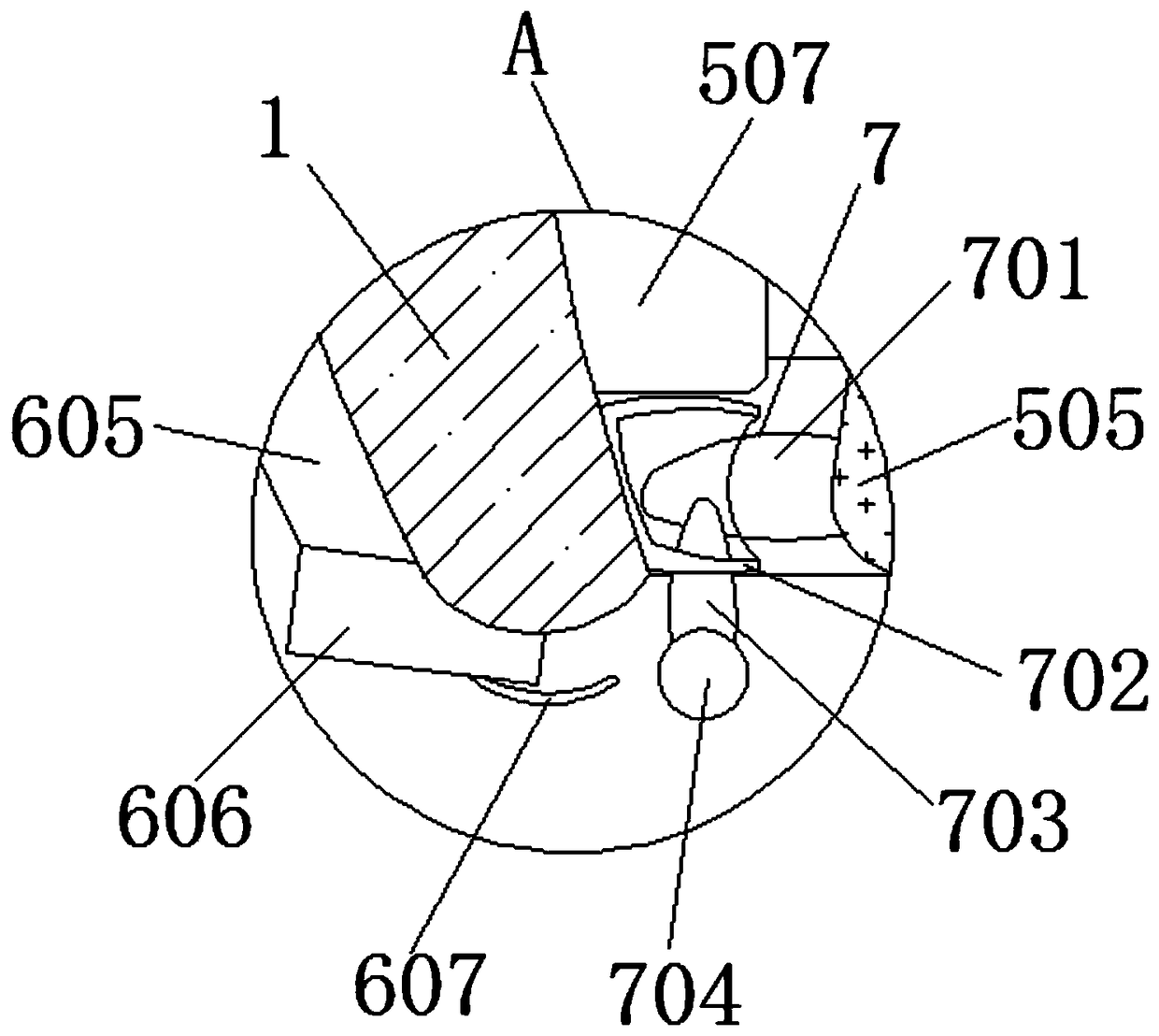

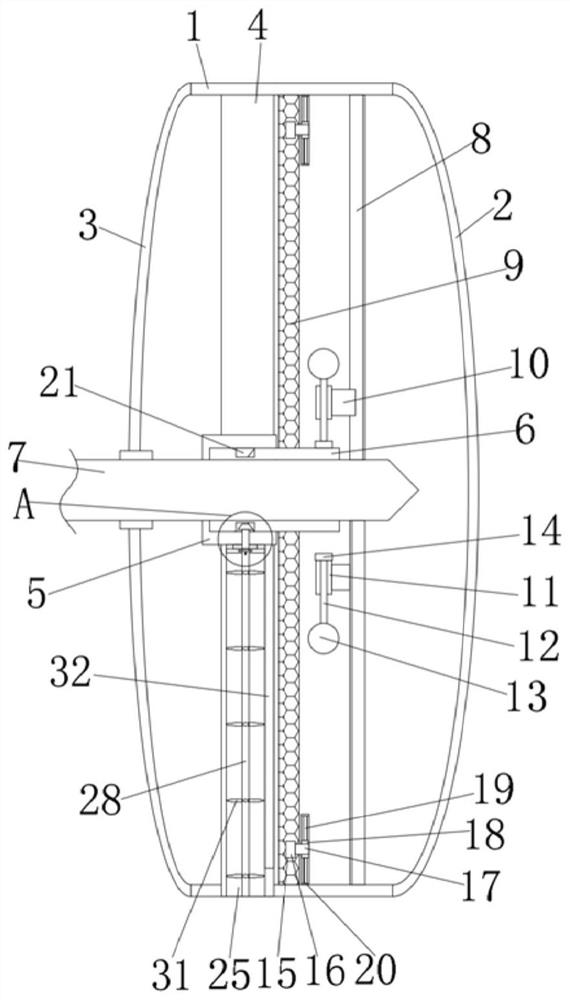

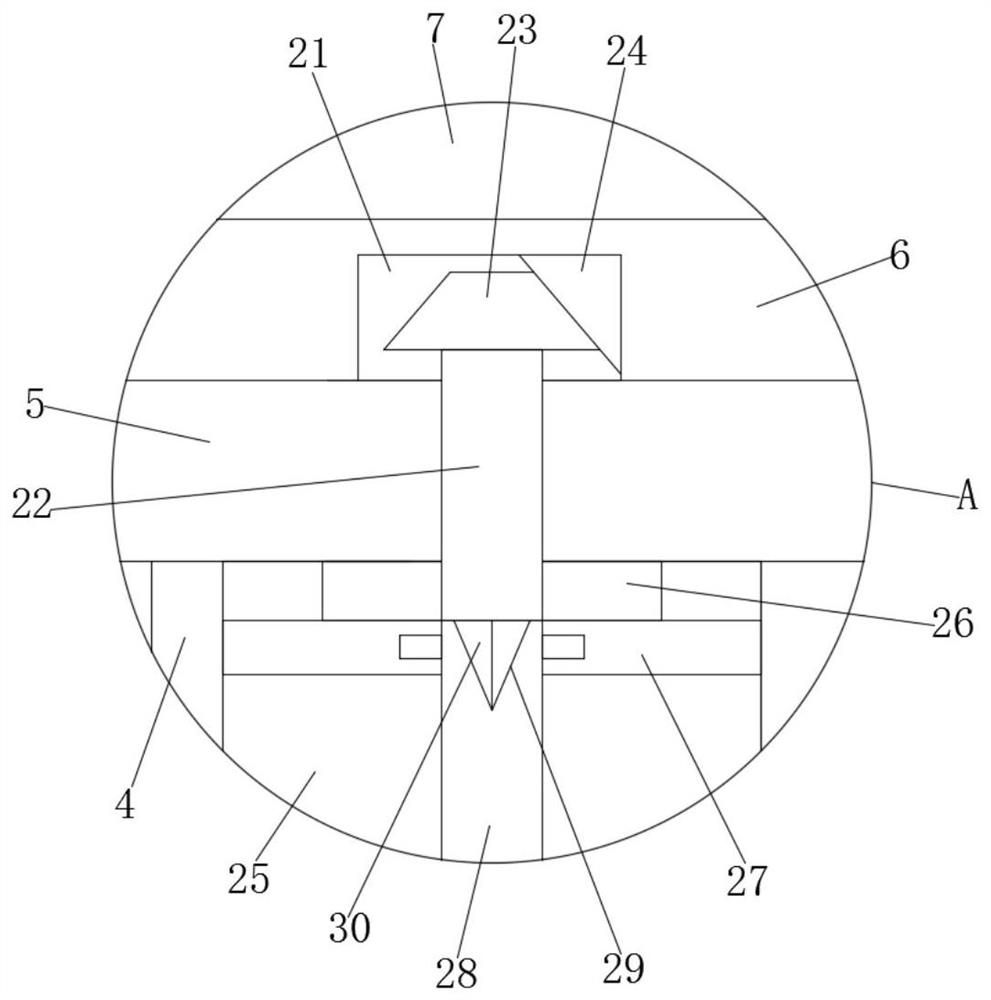

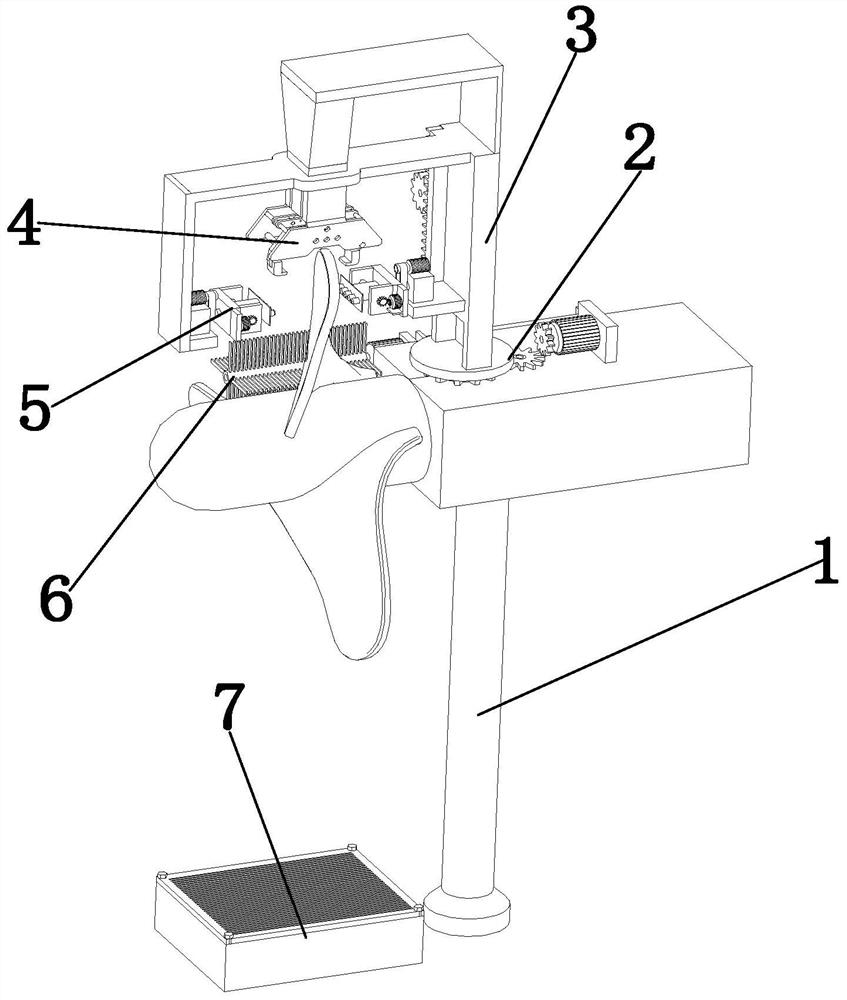

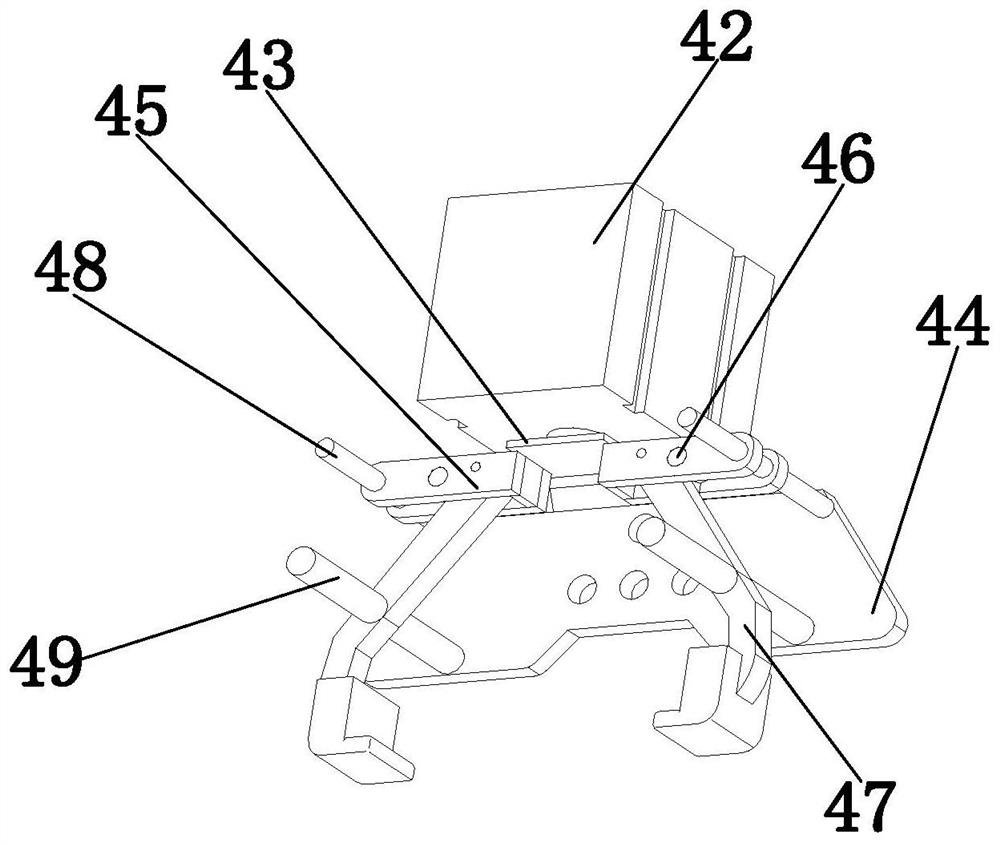

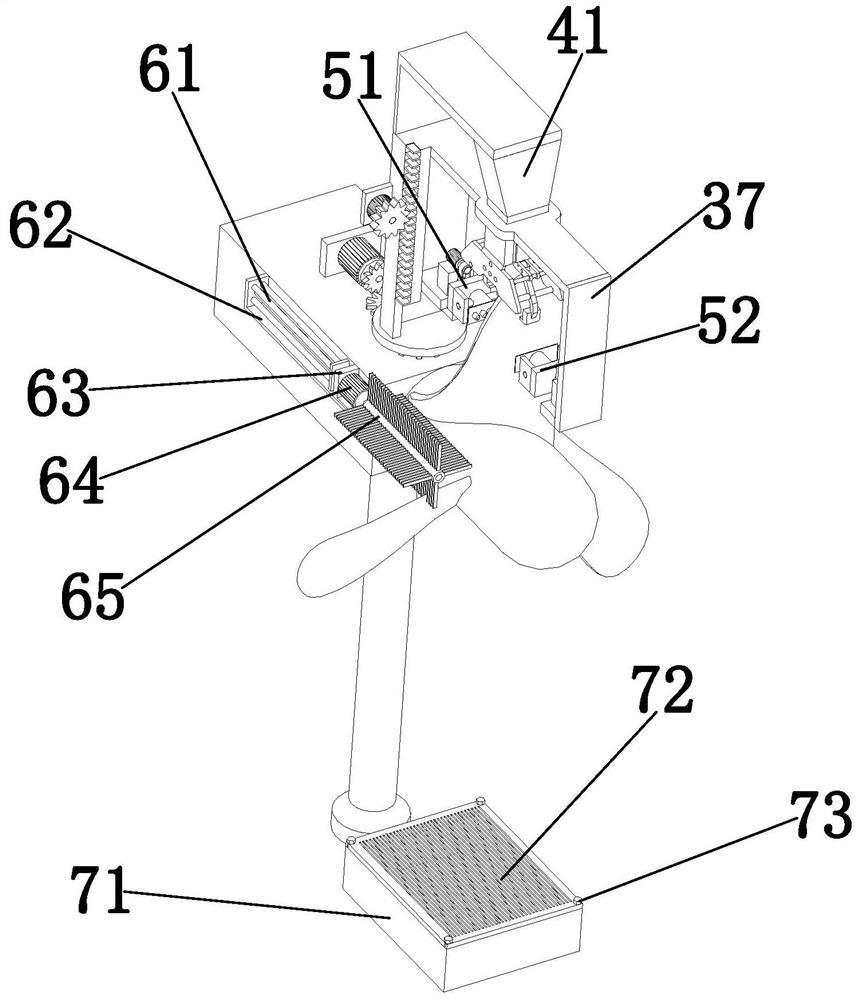

Wind driven generator blade cleaning device

InactiveCN112012892ADoes not affect normal workAccurate orientation can be adjustedMachines/enginesWind energy generationWind drivenWastewater

The invention relates to the technical field of generator blade cleaning, in particular to a wind driven generator blade cleaning device. The wind driven generator blade cleaning device comprises a wind driven generator body, a rotating device, a stretching device, a clamping device, a spray washing device, a washing device and a waste collecting device. The wind driven generator body is vertically placed on the ground; the rotating device is mounted at the top of the wind driven generator body; the stretching device is mounted at the top of the rotating device; the clamping device is mountedat the top of the stretching device; the spray washing device is mounted on the stretching device; the washing device is mounted on the side wall of the wind driven generator main body; and the wastecollecting device is placed on the ground. The rotating device adjusts the accurate position to clean the wind driven generator, the stretching device can adjust the accurate direction of blades of the wind driven generator to enable the work to be more accurate, the clamping device clamps and fixes the blades, the spray-washing device performs rotary spraying on the fixed blades, the washing device wipes the blades, and the waste collecting device collects waste water in the cleaning process.

Owner:张春生

Combined type device capable of automatically waxing, yarn guiding and batching for spinning

InactiveCN108263911AEasy to disassembleClean up comprehensivelyFilament handlingWebs handlingYarnEngineering

The invention relates to a combined type device capable of automatically waxing, yarn guiding and batching for spinning. The combined type device comprises rolling wheels, yarn guide heads, a belt, anut rod and a second rotating shaft; supporting frames are installed at the top ends of the rolling wheels, springs are arranged at the bottom ends of the interiors of the supporting frames, a transverse rotating shaft is installed at the lower ends of the right sides of the supporting frames, a rotating shaft is connected to the right side of the transverse rotating shaft, and a connecting rod isfixed on the right side of the rotating shaft; a pressing block is arranged on the left side of the front surface of the connecting rod, a rotating cylinder is inlaid in the middle part of the frontsurface of the connecting rod, and external threads are installed on the front surface of the rotating cylinder; and a wool remover is arranged above the rotating cylinder, and a textile machine placement area is arranged above the wool remover. The combined type device has the beneficial effects that the supporting frames of the combined type device capable of automatically waxing, yarn guiding and batching for spinning is of relatively inclined structure, the structure is in a trapezoid shape with the ground, so that the stability of the device is improved, and when the motor and the rotating cylinder on the device are rotated, the device is prevented from turning over.

Owner:李月仙

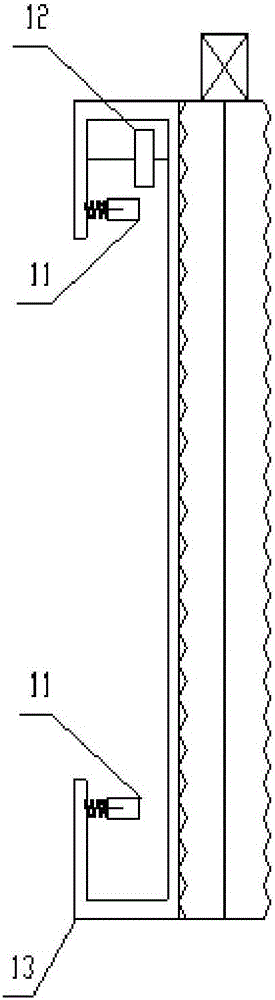

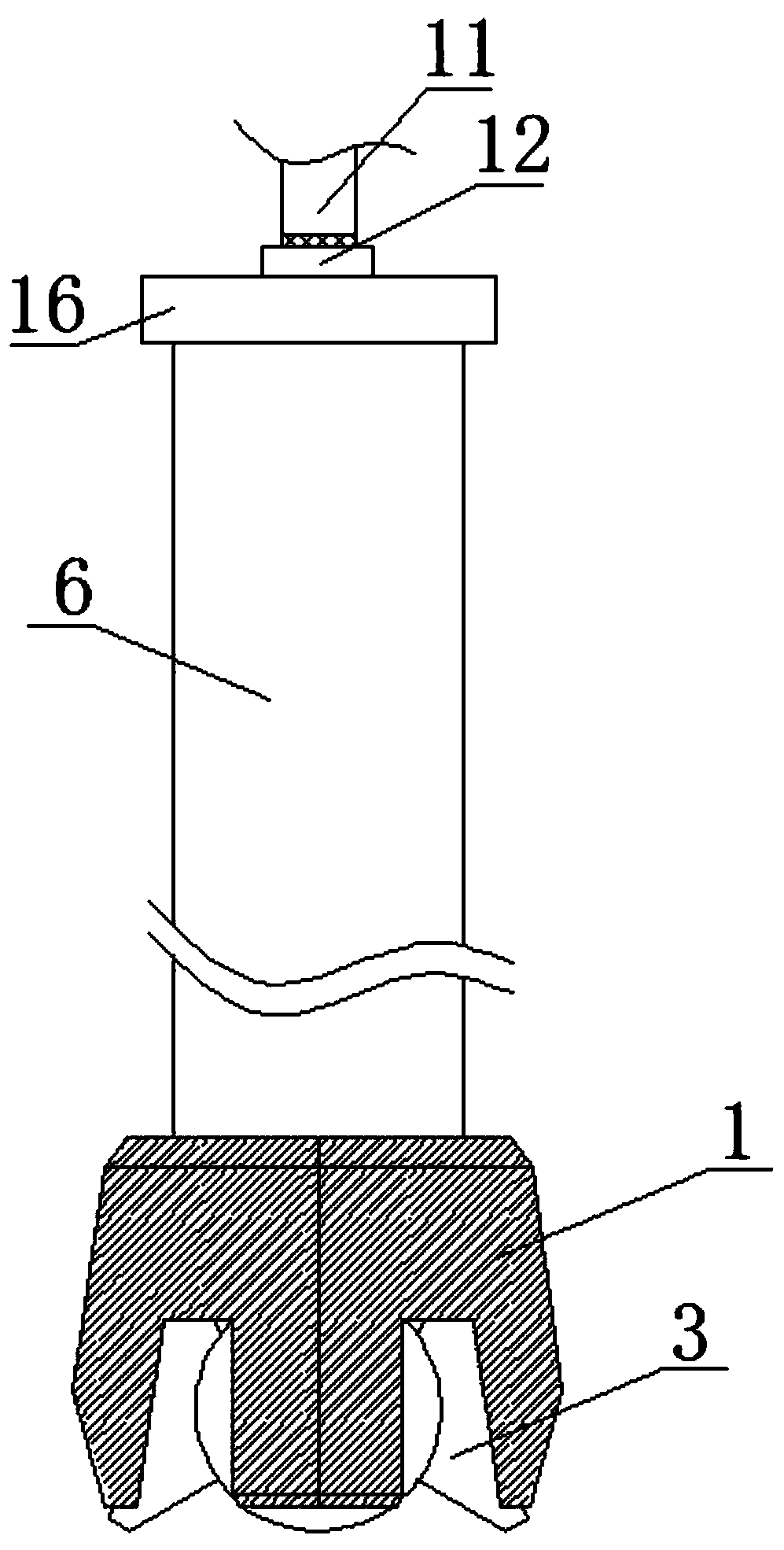

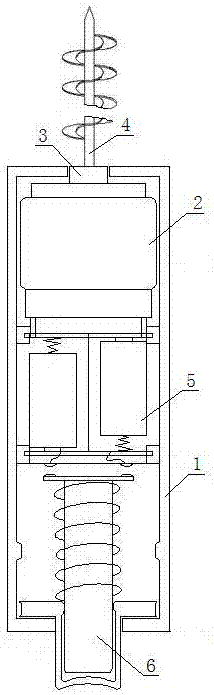

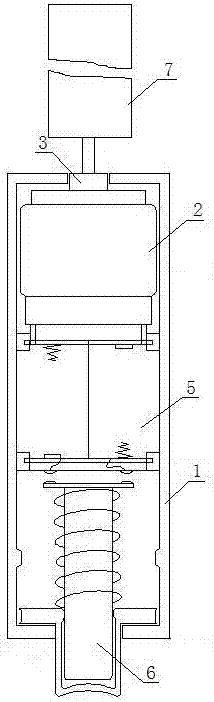

Automatic sweeper for blasting holes

PendingCN107413781AShorten cleaning timeHigh precisionHollow article cleaningElectrical batteryStructural engineering

The invention discloses an automatic sweeper for blasting holes. The automatic sweeper for the blasting holes comprises a sleeving pipe, a direct current motor is arranged at one end of the sleeving pipe, and a connecting sleeve is arranged at the end of an output shaft of the direct current motor. An assembly hole is formed in the connecting sleeve in the axial direction of the output shaft of the direct current motor, a key groove is formed in the assembly hole, and a detachable sweeping head is assembled on the connecting sleeve. Batteries are arranged on the position, adjacent to the direct current motor, in the sleeving pipe, one ends of the batteries are connected with the direct current motor through wires, and the other ends of the batteries are provided with a control switch. A press button of the control switch extends out of the sleeving pipe. According to the automatic sweeper for the blasting holes, in the whole sweeping process, large equipment and lots of professional workers are not needed, sweeping can be rapidly completed through operation of one person, the sweeping operation time of the blast holes in blasting construction is greatly shortened, the good-quality blast-hole environment is provided for explosive loading construction, and the accuracy of explosive loading is improved.

Owner:GUIZHOU XINLIAN BLAST ENG GRP

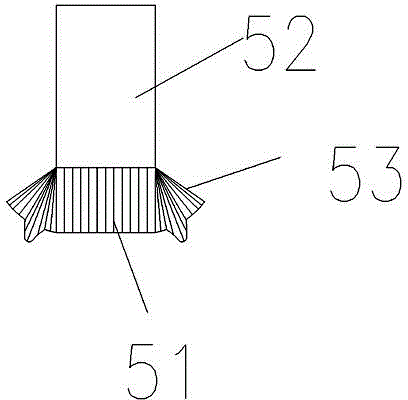

Cleaning device between elevator door and elevator sill

InactiveCN104803264AEasy to installEasy to disassembleBuilding liftsEngineeringMechanical engineering

The invention discloses a cleaning device between an elevator door and an elevator sill. A guide rail groove is formed in the elevator sill; the lower end of the elevator door moves in the guide rail groove; a basswood is arranged on the side surface of the elevator door, is vertically arranged and extends into the guide rail groove; a hair brush used for sweeping dust is also arranged at the lower end of the elevator door. Due to the fact that the basswood and the hair brush are combined to clean the sill, impurities, such as stones with relatively high mass can be cleaned, and dust can also be cleaned; the basswood and the hair brush are convenient to assemble and disassemble; cleaning is relatively complete and the effect is good.

Owner:WEIBO ELEVATOR

Chemical tool cleaning and drying device

InactiveCN108380609ASave waterEasy to cleanHollow article cleaningDrying gas arrangementsCompound (substance)Waste management

The invention provides a chemical tool cleaning and drying device which comprises a shell, a water tank, an upper cover, an operation panel, a handle, a cleaning brush, a rotary disc and a partition plate; the water tank is arranged on the upper side of the left end of the shell and is fixedly connected with the shell; the upper cover is arranged on the top of the shell and is connected with the shell in a clamping manner; the operation panel is arranged on the left side of the top of the upper cover and is fixedly connected with the upper cover; the handle is arranged at the middle part of the top of the upper cover and is fixedly connected with the upper cover; and the cleaning brush is arranged at the middle part of the bottom of the upper cover and is movably connected with the upper cover. As the chemical tool cleaning and drying device is provided with a hot air blower, hot air enters a cavity through a pipeline through the hot air blower, and then hot gas is jetted out through athrough hole to dry a chemical tool and can dry different positions of the chemical tool, so that the chemical tool cleaning and drying device is uniform in drying and strong in practicability, is suitable for production and use of the chemical tool cleaning and drying device and has a good development prospect.

Owner:叶玉妹

Scrap sucking device of polishing machine

InactiveCN106425872AAvoid inhalationClean up comprehensivelyGrinding/polishing safety devicesEngineeringScrap

The invention discloses a scrap sucking device of a polishing machine. The scrap sucking device comprises an operation box body, the polishing machine, a leakage plate and a scrap sucking device body; the polishing machine is installed on the upper top face of the operation box body, and a hollow leakage plate is arranged on the bottom face of the operation box body; the scrap sucking device body is fixedly connected to the bottom of the operation box body in a sealed manner; the scrap sucking device body is divided into a scrap sucking part and a scrap storage part from top to bottom, and the scrap storage part is installed at the bottom of the scrap sucking part in a separable manner; and the scrap sucking device further comprises a vibration device, and the operation box body is fixedly installed on the vibration device. The scrap sucking device is simple in structural design, good in scrap sucking effect and free of dead corners during scrap cleaning and facilitating maintaining and repairing of the device; the design of an annular coil is adopted in the scrap sucking device, an isolating layer is adopted for rapping, generated magnetic force is stronger, and the condition that scraps are too many and are left on the surface of the coil can be avoided.

Owner:GUANGXI UNIV

Solar street lamp

InactiveCN112050148ALarge bearing capacityGuaranteed stabilityMechanical apparatusLighting support devicesElectric machineEngineering

The invention relates to the technical field of solar street lamps, and discloses a solar street lamp. The solar street lamp comprises a foundation. According to the solar street lamp, by arranging anelectric telescopic rod and a receiving box, when dust of an illuminating lamp needs to be removed, the electric telescopic rod is controlled to push the receiving box to move to the bottom of the illuminating lamp, and at the moment, a cleaning brush is attached to a lampshade of the illuminating lamp, so that comprehensive cleaning can be ensured; by arranging a rotating motor, a rotating gearand driven gears, the rotating motor is controlled to drive the rotating gear to rotate during dust cleaning, the two driven gears are driven to rotate, and the cleaning brush begins to rotate for removing dust on the lampshade of the illuminating lamp, so that manual climbing operation is not needed, the purpose of automatically cleaning the dust is achieved, and the automation degree is high; and by arranging a rain shelter, a rain wash-proof effect can be achieved on the illuminating lamp in rainy days, and meanwhile a rain sheltering effect can be achieved on people in rainy days, so thatthe practicability is high.

Owner:扬州市博瑞光电照明有限公司

Brush capable of clearing snow conveniently for power equipment

The invention relates to the technical field of cleaning equipment, in particular to a brush capable of clearing snow conveniently for power equipment. The brush comprises a box body and a machine shell, wherein the machine shell is fixedly connected with the left end of the box body, a rotating fixed column is fixedly connected with the bottom end of the box body, wheels are rotatably connected with the inner side of the rotating fixed column, a sliding door is fixedly connected with the bottom end of the machine shell, and a second motor is fixedly connected with the left end of the inner wall of the machine shell. A filter layer is fixedly connected with the right end of the machine shell, a filter screen is fixedly connected with the top end of the filter layer, a splicing pipe is fixedly connected with the right end of the filter screen, and a plastic pipe is fixedly connected with the right end of a ring buckle. A steel pipe is fixedly connected with the bottom end of the plasticpipe, a disc is fixedly connected with the outer side of the steel pipe, and a third motor is fixedly connected with the outer side of the disc. The use and control of the motors are very convenient,the various operation requirements can be met, the operation is reliable, the price is low, the structure is firm, the economic benefits are great, the market prospect is wide, and the brush is worthy of popularization and use.

Owner:杨秀波

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com