Automatic sweeper for blasting holes

An automatic cleaning and blast hole technology, which is applied in the field of cleaners, can solve the problems of increasing construction time, construction cost, broken medicine, polluting the construction environment, etc., and achieve the effect of reducing cleaning operation time, improving accuracy and good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

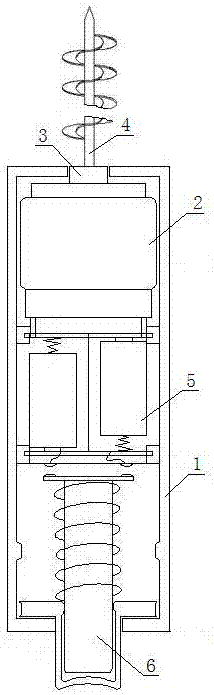

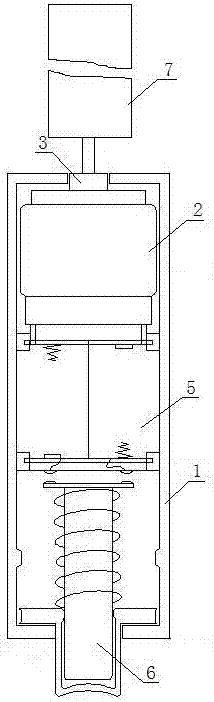

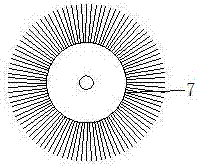

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0021] Such as figure 1 , figure 2 , image 3 As shown, an automatic cleaning device for demolition blasting blast holes includes a casing 1, which is a circular shell for assembling other parts. A DC motor 2 is arranged at one end of the casing 1, and the DC The end of the output shaft of the motor 2 is provided with a connecting sleeve 3, and an assembly hole is arranged on the connecting sleeve 3 along the axial direction of the output shaft of the DC motor. Of course, the assembly hole is coaxial with the output shaft of the DC motor.

[0022] A keyway is provided in the assembly hole, and the detachable cleaning head is assembled on the connecting sleeve 3 through a key connection, so that it is fast and convenient to replace the cleaning head.

[0023] The detachable cleaning head specifically has two structures, one is the helical blade shaft type ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com