High pressure bundle array automatic cleaning device

An automatic cleaning and beam array technology, which is applied to cleaning heat transfer devices, washing, lighting and heating equipment, etc., can solve the problems of low cleaning efficiency and achieve high cleaning efficiency, convenient operation and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

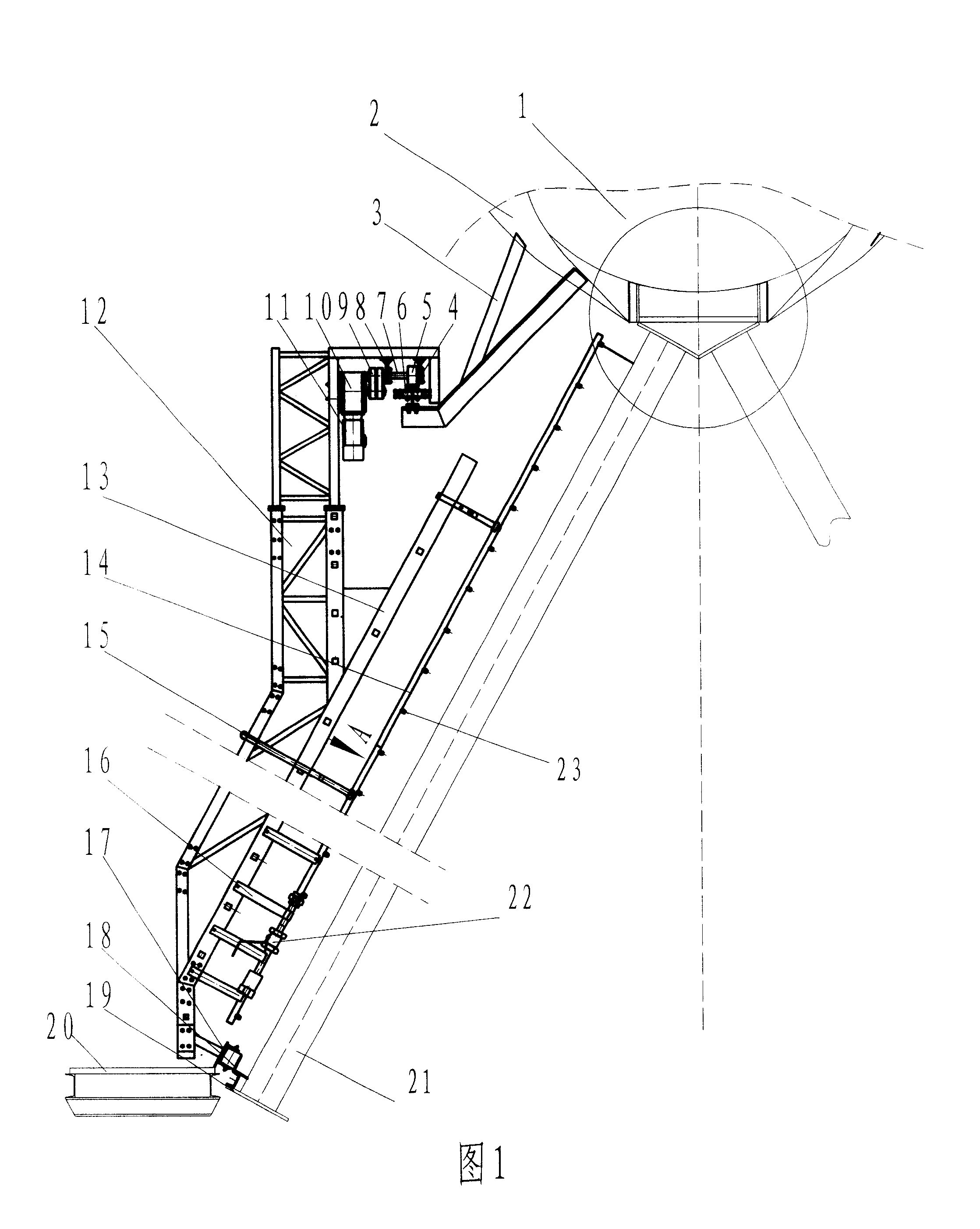

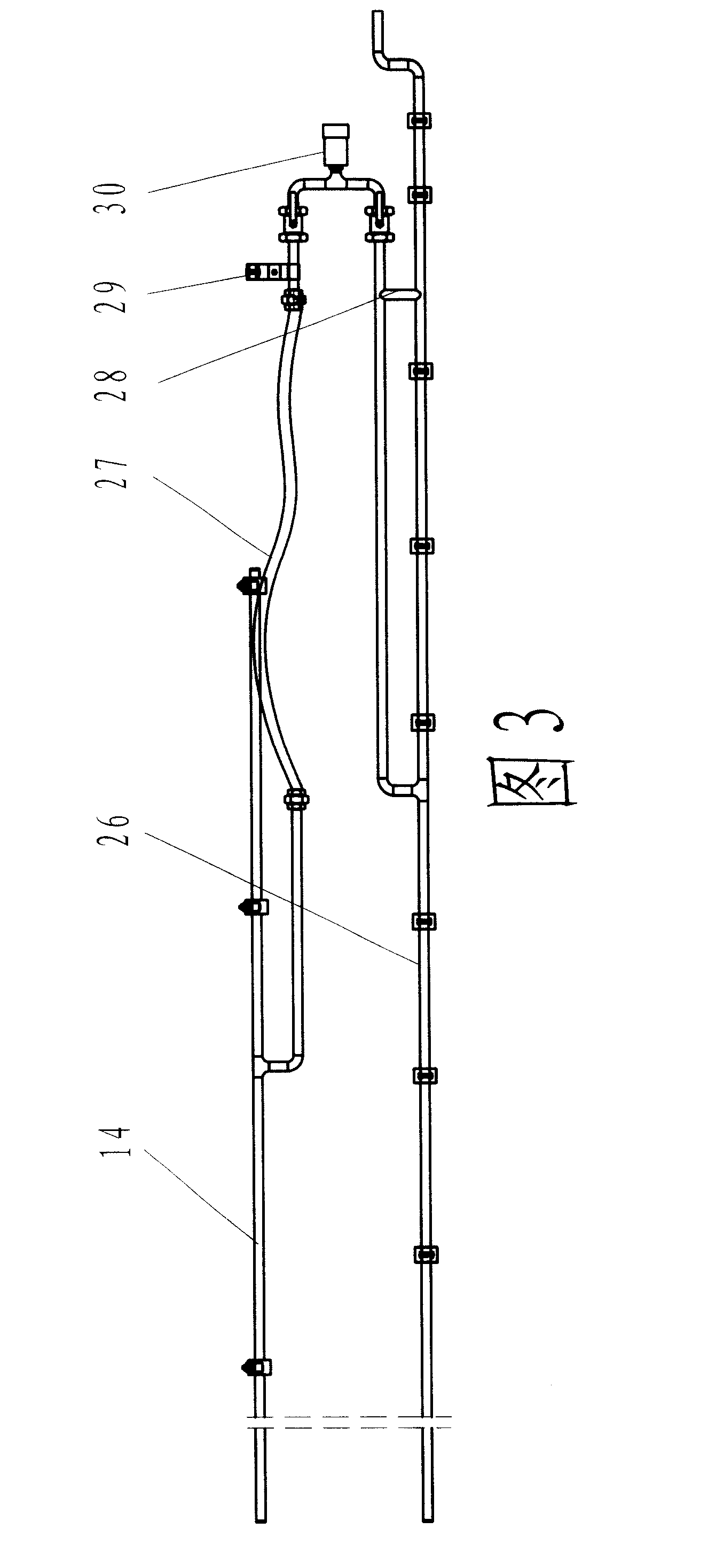

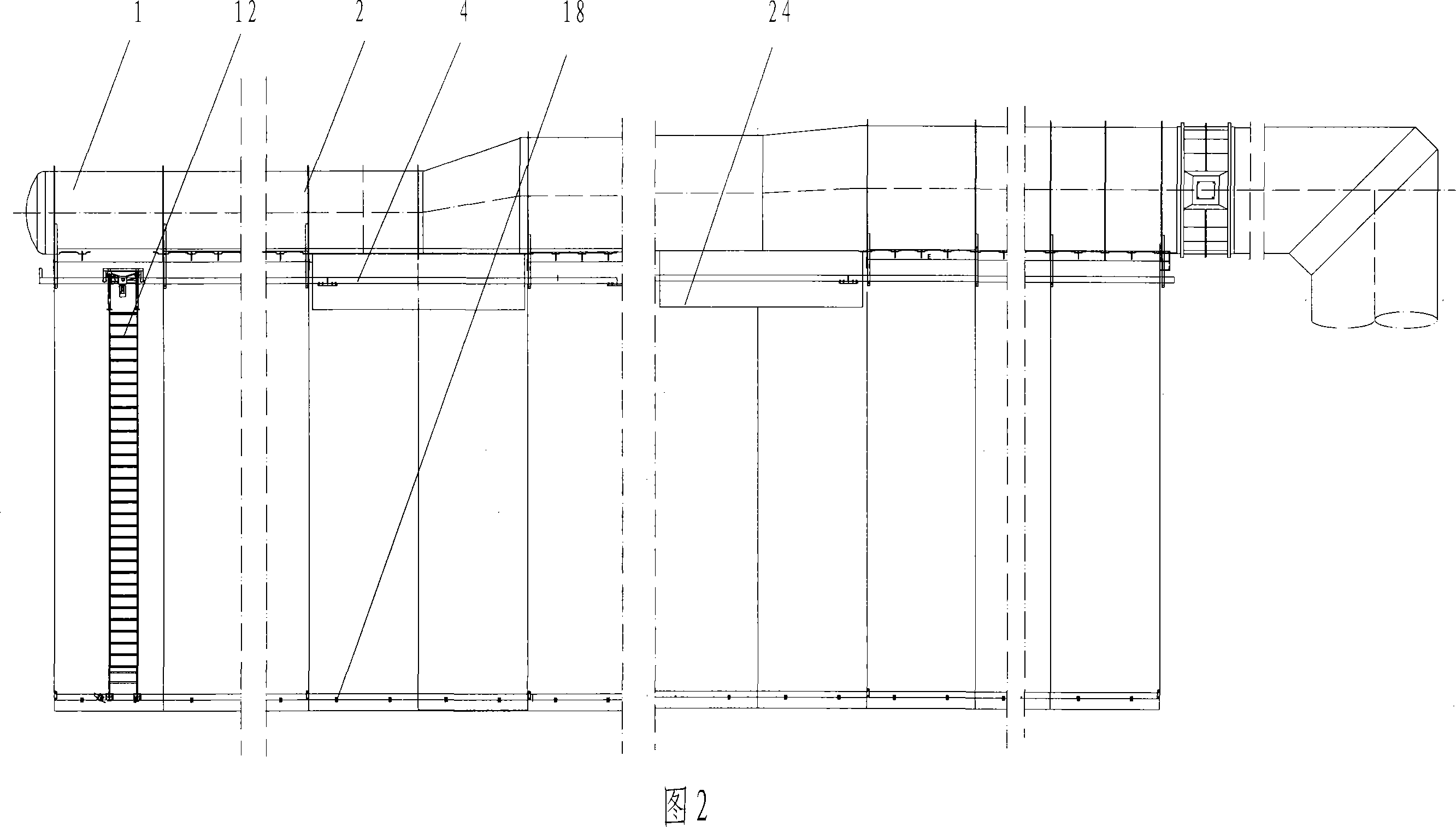

[0026] Shown in Fig. 1-3, the structure of the present invention is installed on the A-shaped air cooler in the direct air-cooling system (EGA) of the power plant, and respectively installs a set of structure of the present invention on both sides of the A-shaped air cooler respectively, will be detailed below Describe the structure installed on one side of the A-shaped air cooler.

[0027] First, the triangular support frame 3 is fixedly welded on the reinforcing ring 2 of the steam distribution pipe 1 at the upper end of the cooler, and an I-steel upper guide rail 4 is fixed on the triangular support frame 3; The lower guide rail 18 is fixed on the steel liner 19 at the lower end of the condenser through its corresponding bracket 17 .

[0028] On the upper guide rail 4 and the lower guide rail 18, a bracket type cleaning platform 12 with traveling wheels is provided, and a horizontal drive unit walking along the guide rail is arranged on the cleaning platform 12 near the pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com