Wafer slicer, roller module thereof, and method for slicing wafer

A slicing machine and wafer technology, applied to metal sawing equipment, fine working devices, working accessories, etc., can solve the problems of affecting the wafer slicing accuracy, uneven distribution, and reducing the service life of the roller 11, so as to reduce cutting The effects of wire shaking, shortened process time, and high slicing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0072] Before the present invention is described in detail, it should be noted that in the following description, similar elements are denoted by the same numerals.

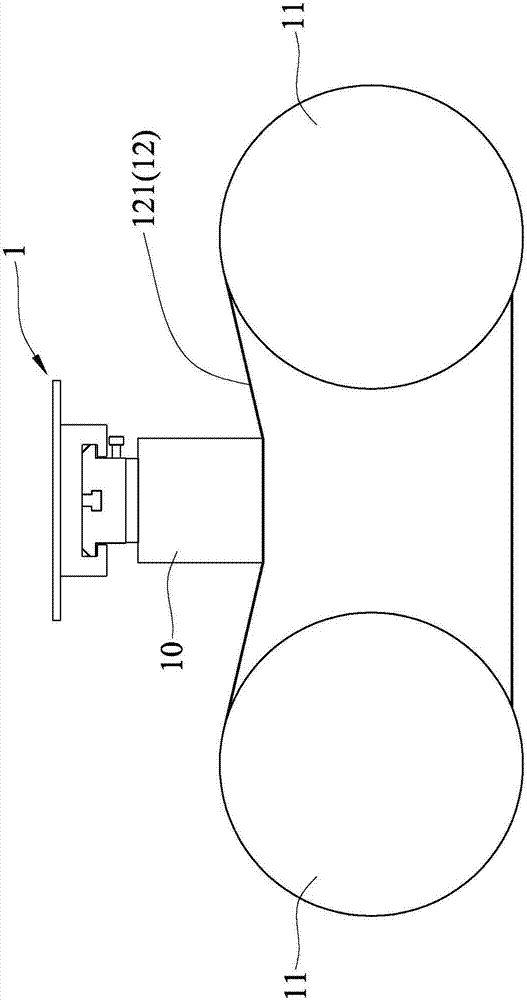

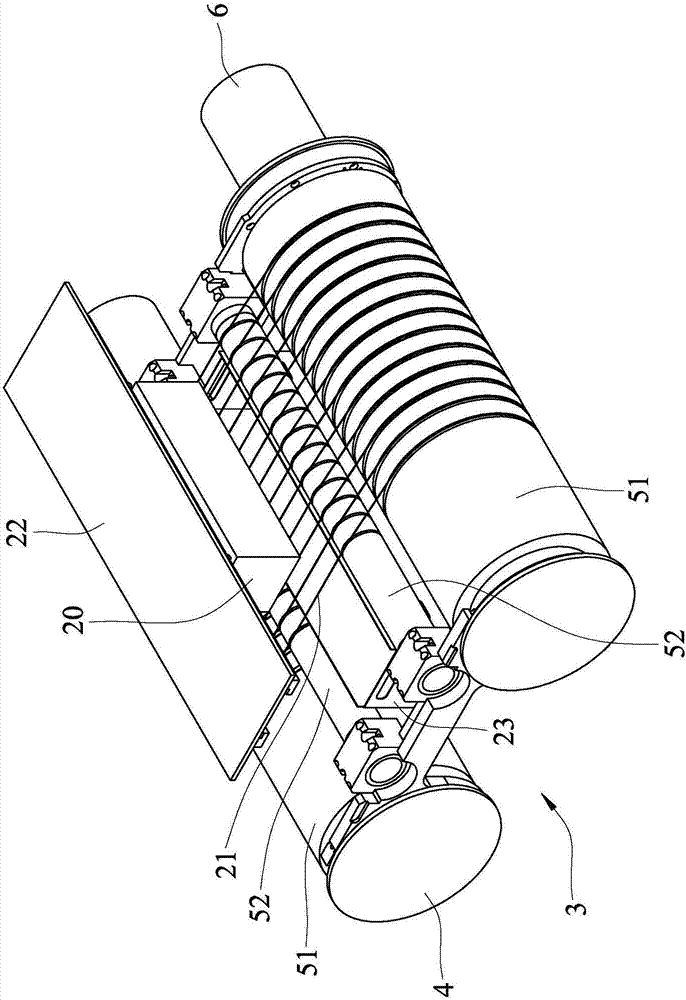

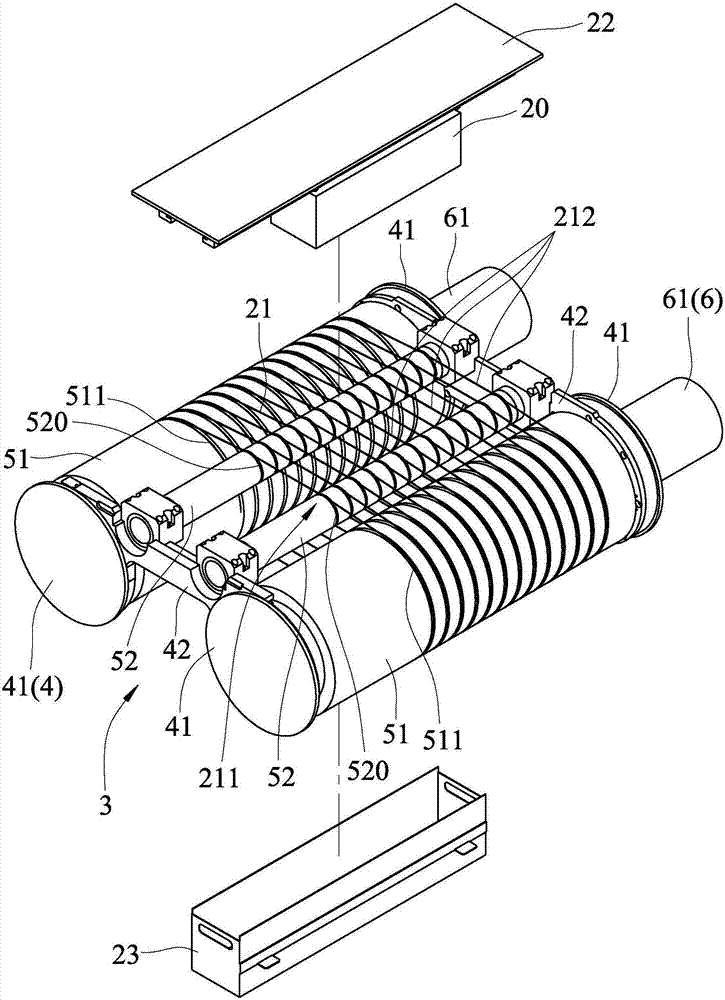

[0073] refer to figure 2 and image 3 , the first embodiment of the wafer slicer of the present invention includes a feeding unit 22 for installing a crystal rod 20 and driving the crystal rod 20 to move down, a cutting line 21 for installing and driving the cutting unit The wire 21 cuts the wheel structure 3 of the ingot 20 , and a fragment groove 23 located under the feeding unit 22 and the ingot 20 . The fragment groove 23 is used to accept the fragments of the ingot 20 that accidentally falls during the cutting operation.

[0074] The wheel set structure 3 includes a supporting unit 4 , two main rollers 51 , two auxiliary rollers 52 , and a driving unit 6 . In this embodiment, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com