Patents

Literature

46results about How to "Low critical speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

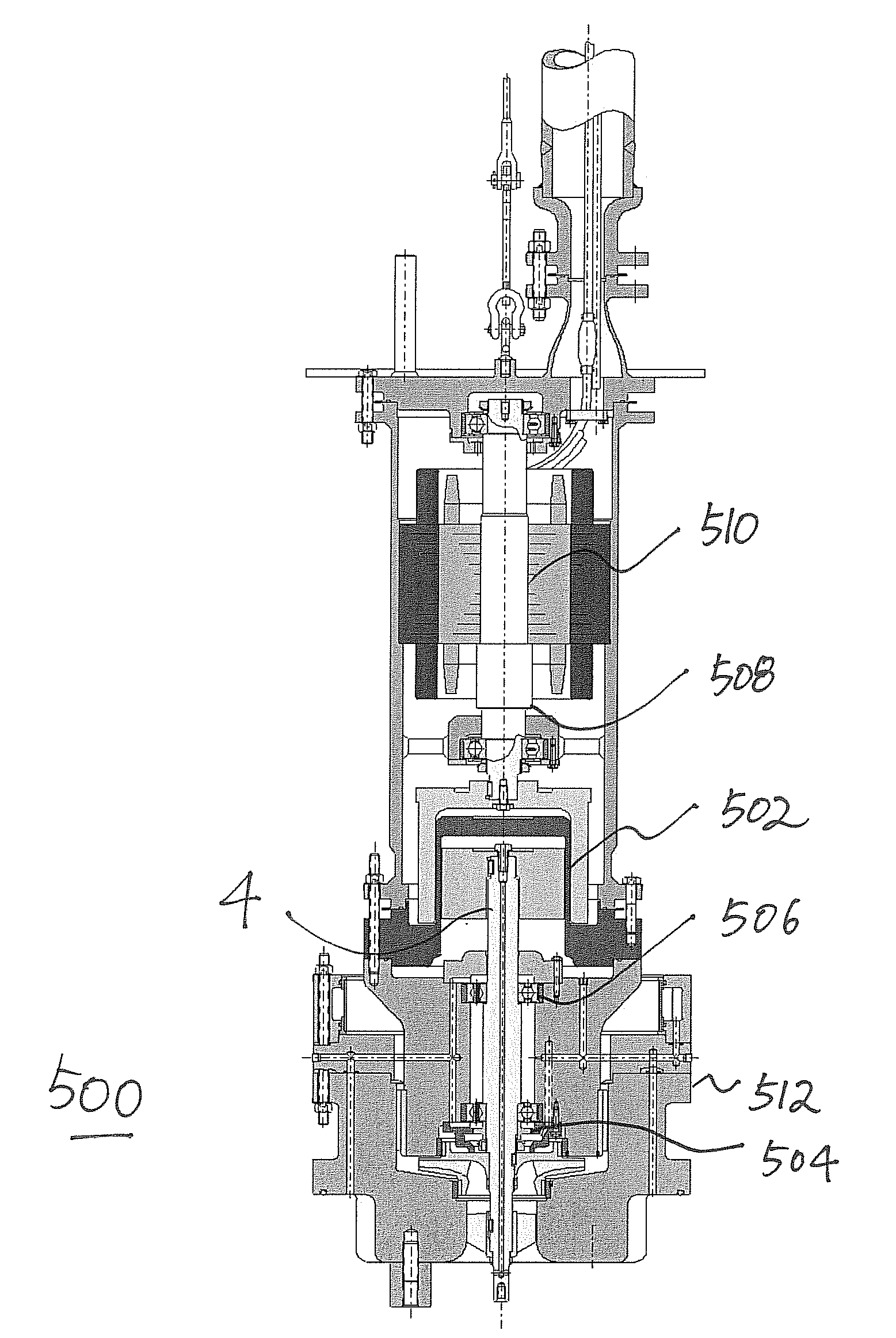

Magnetically-levitated blood pump with optimization method enabling miniaturization

ActiveUS20110237863A1Quality improvementReduce stiffnessControl devicesBlood pumpsBlood pumpMiniaturization

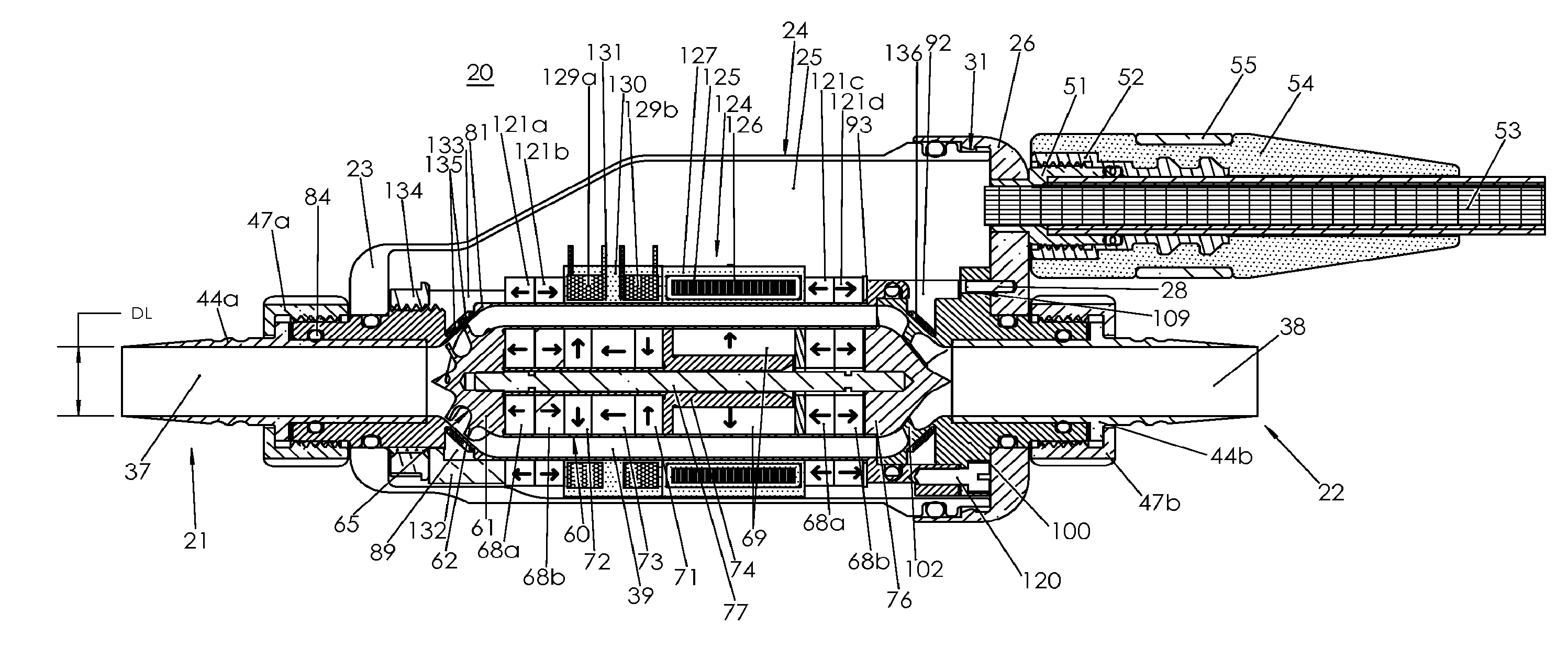

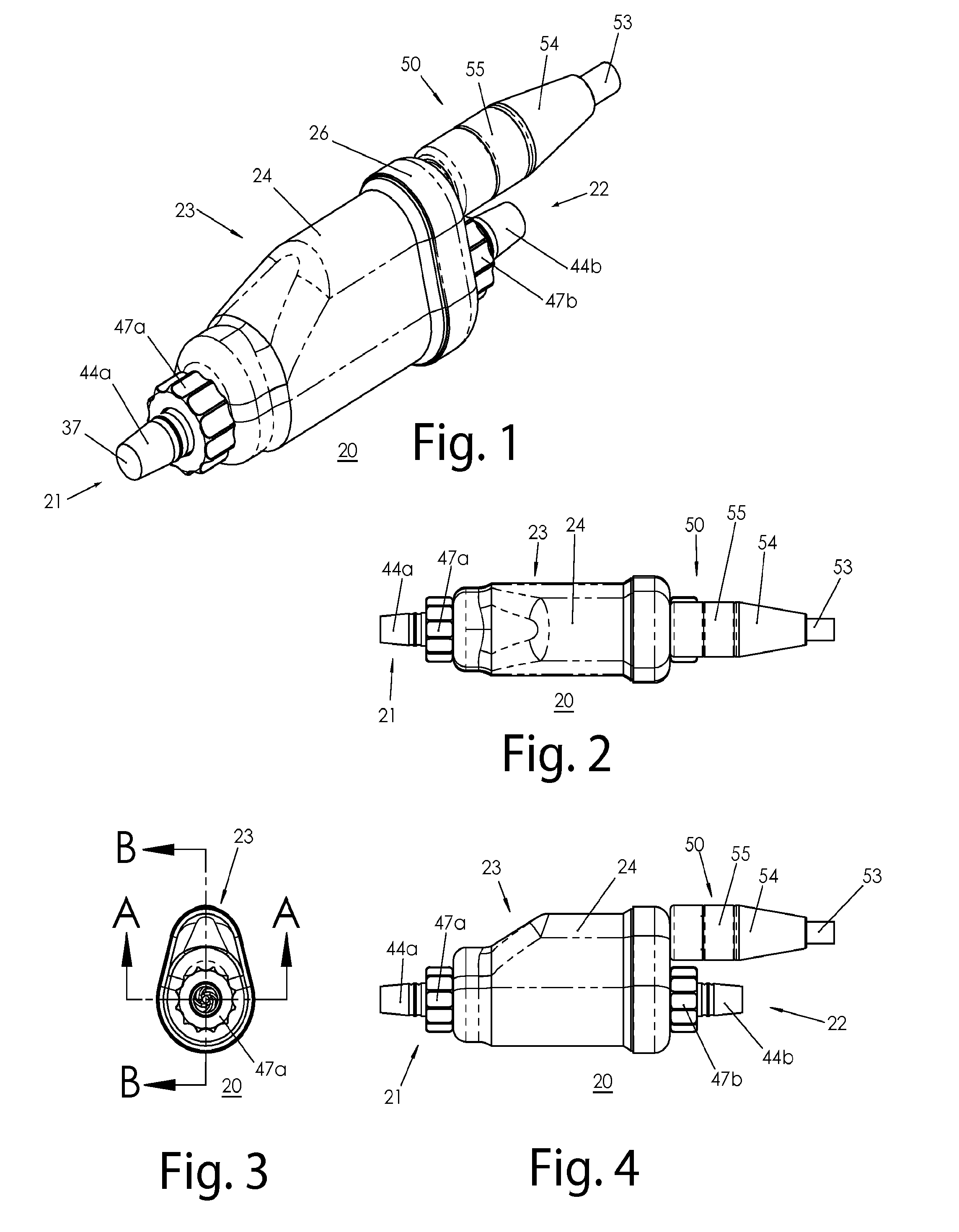

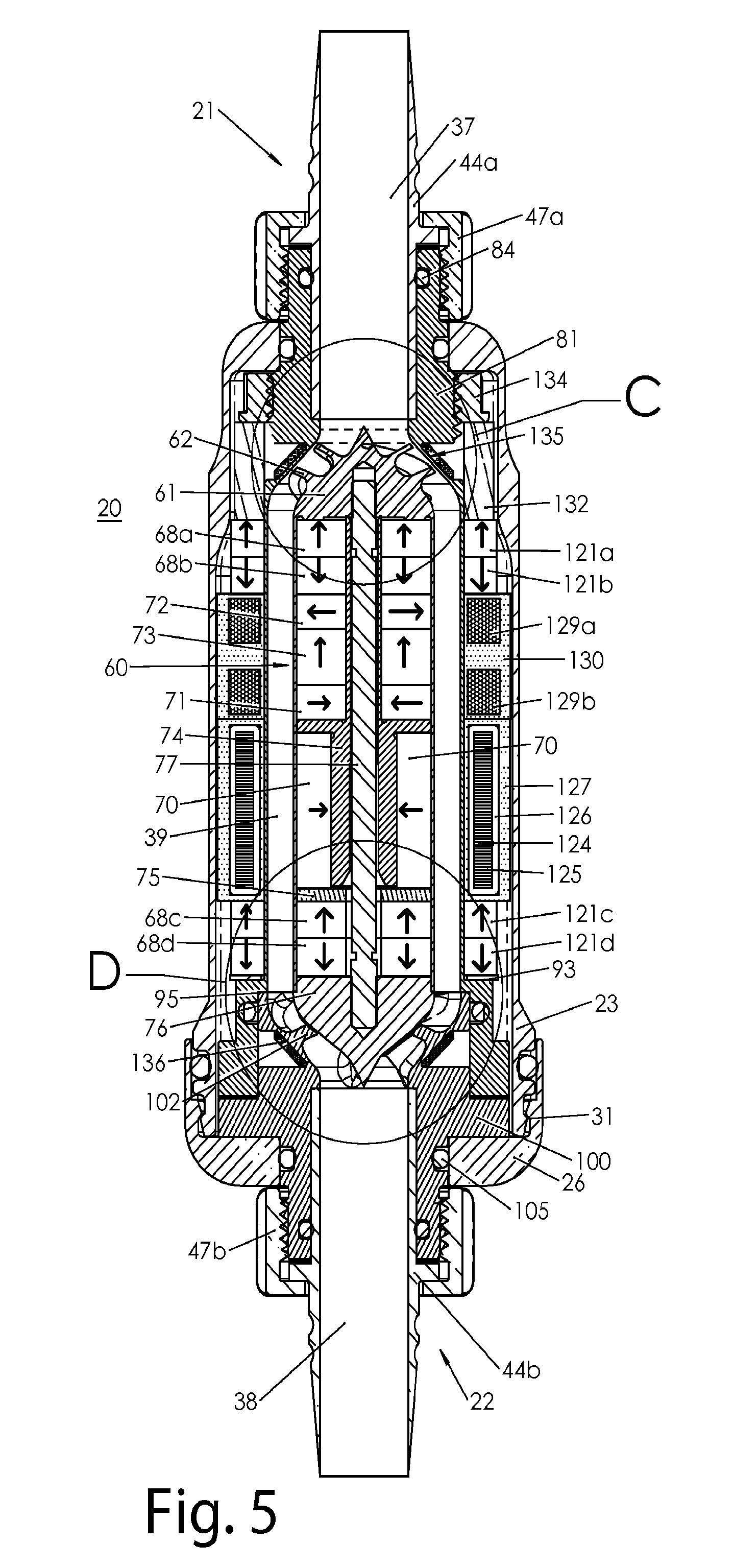

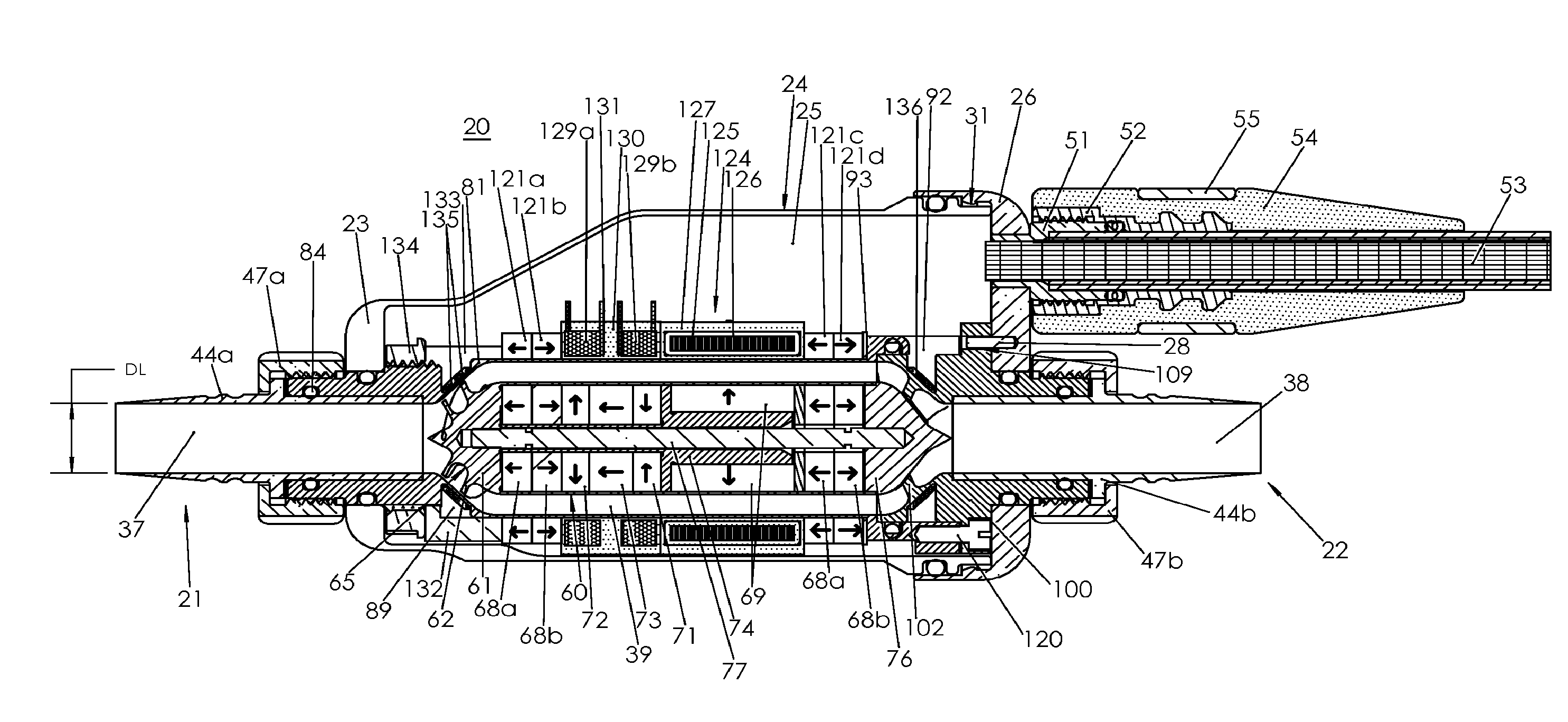

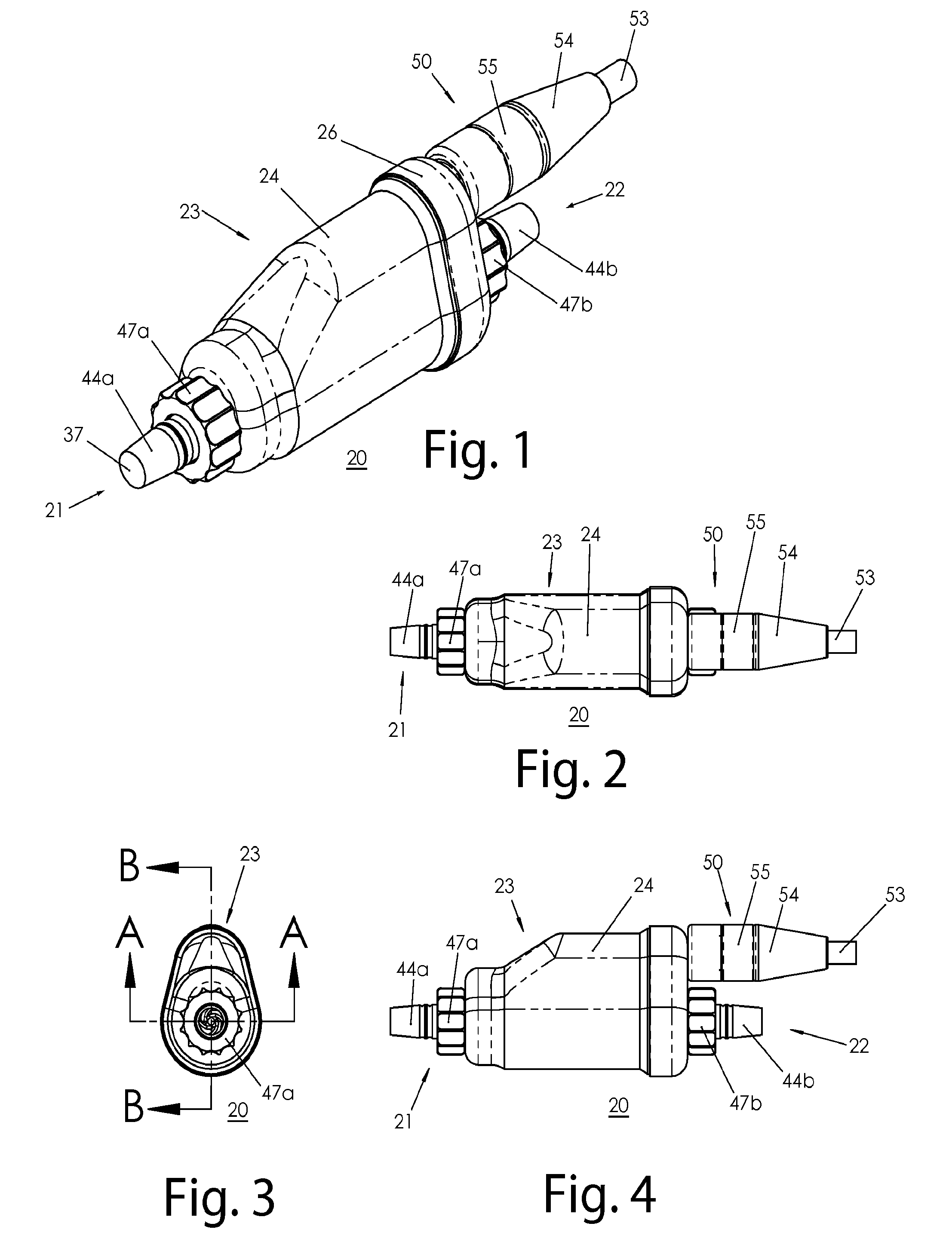

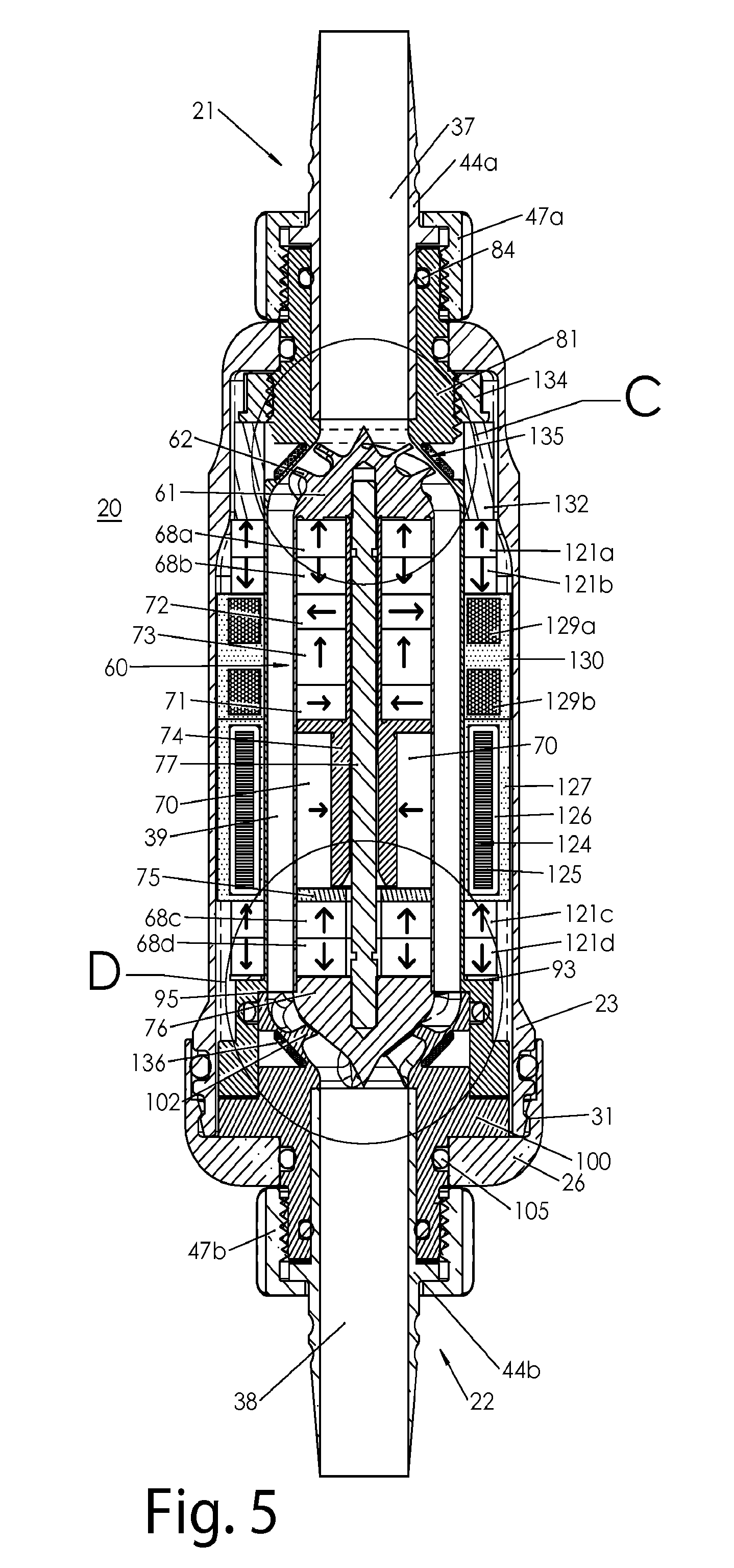

A magnetically-levitated blood pump with an optimization method that enables miniaturization and supercritical operation. The blood pump includes an optimized annular blood gap that increases blood flow and also provides a reduction in bearing stiffness among the permanent magnet bearings. Sensors are configured and placed optimally to provide space savings for the motor and magnet sections of the blood pump. Rotor mass is increased by providing permanent magnet placement deep within the rotor enabled by a draw rod configuration.

Owner:WORLD HEART +1

Blood pump

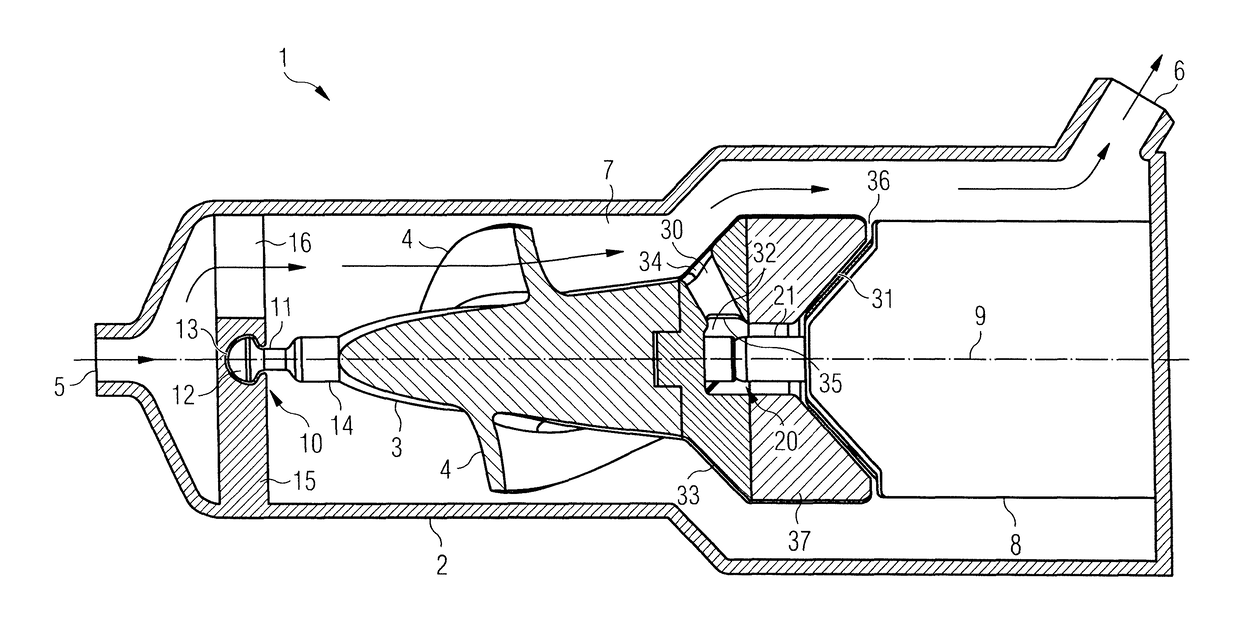

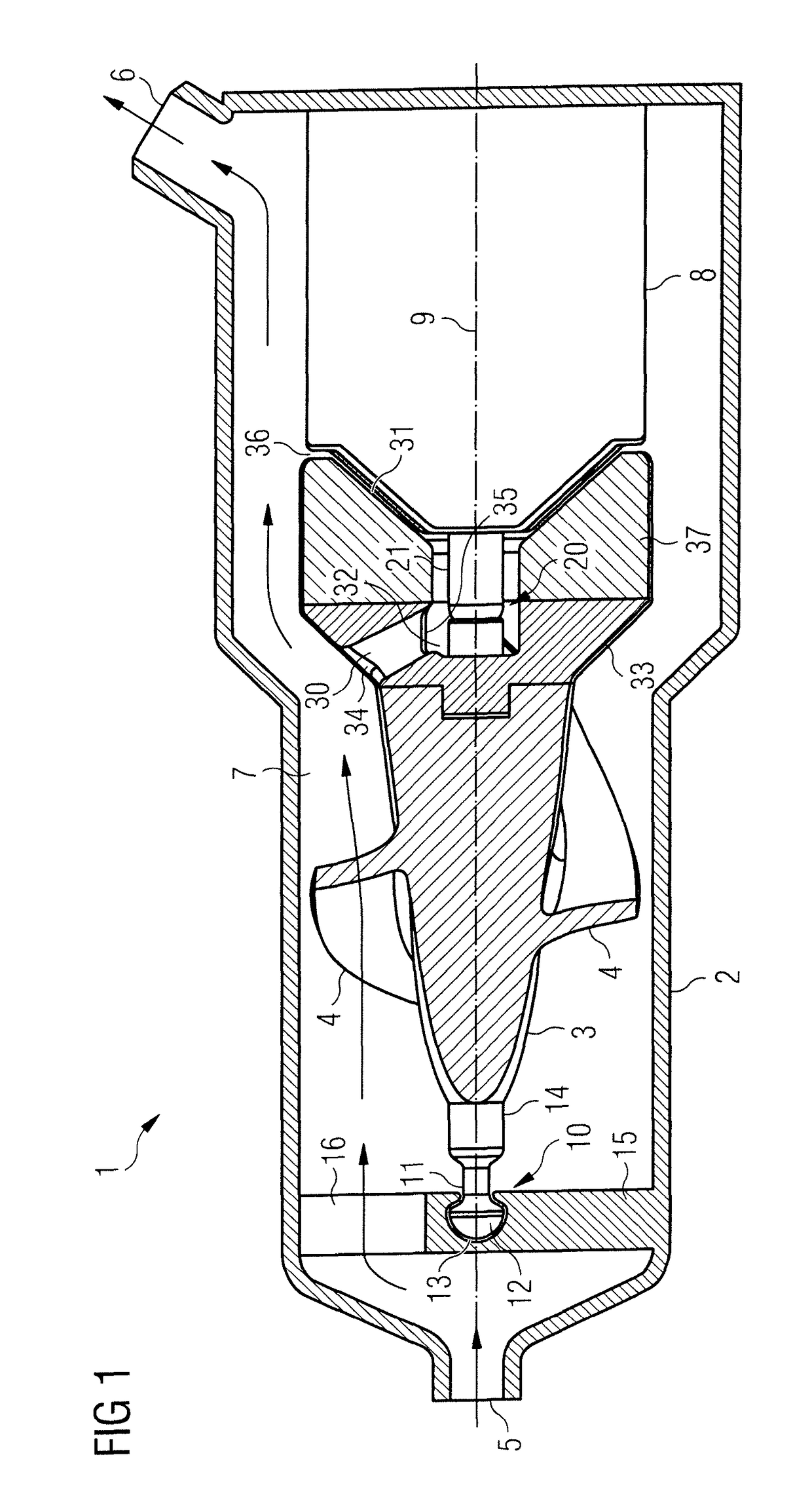

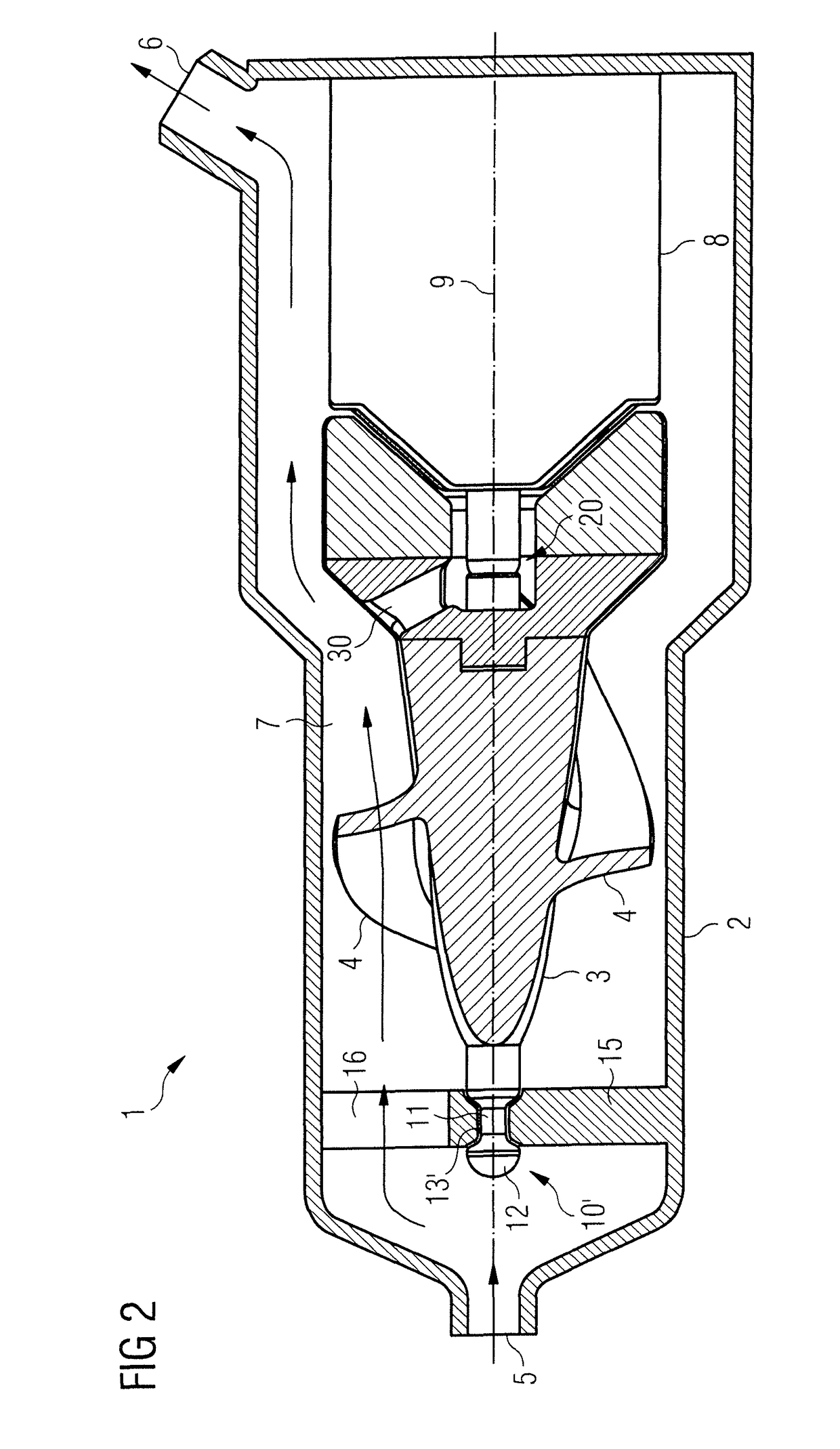

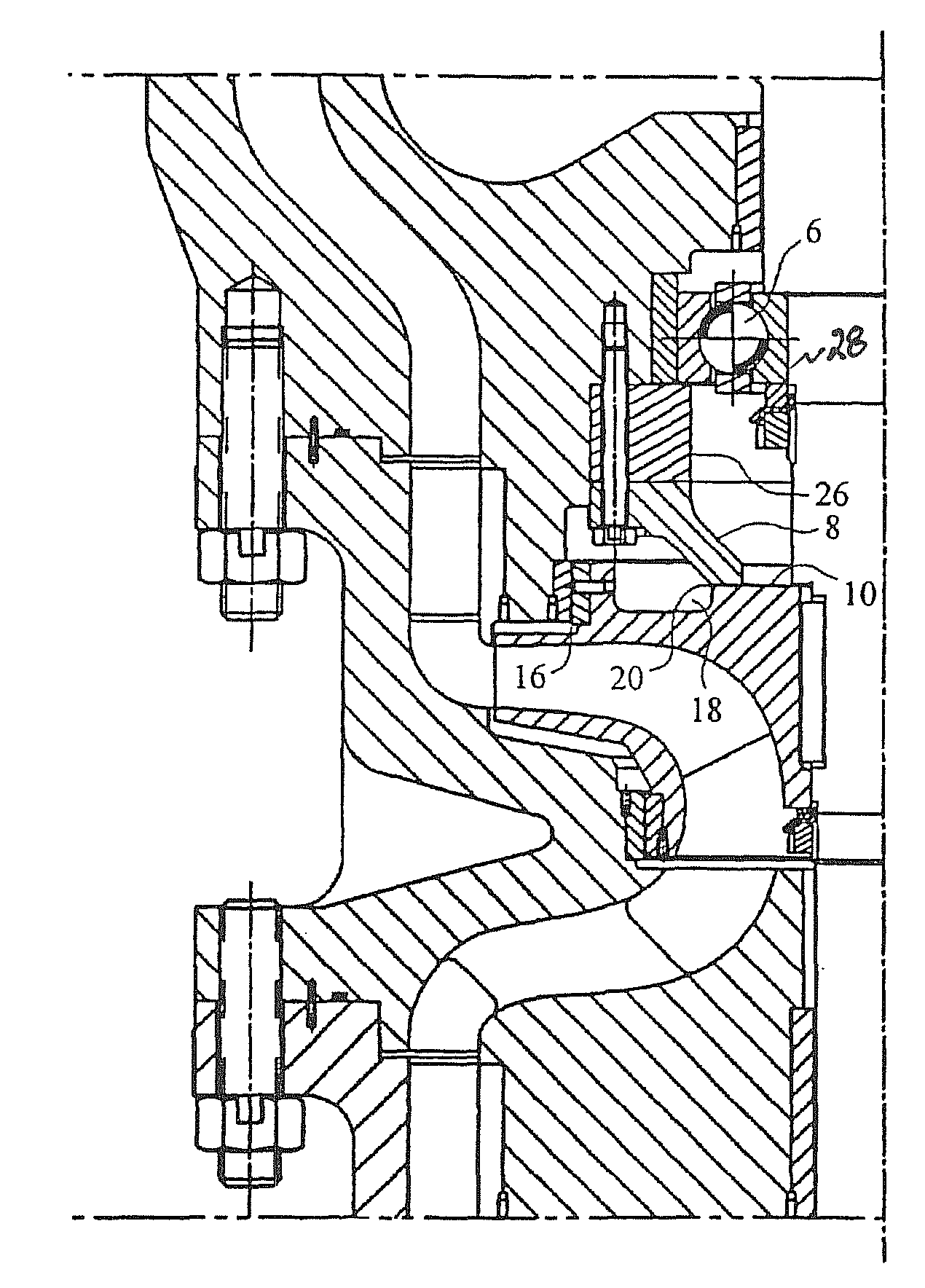

ActiveUS20180050142A1None have achieved superiorLow critical speedBlood pumpsMedical devicesImpellerBlood pump

A blood pump (1) comprises a pump casing (2) having a blood flow inlet (5) and a blood flow outlet (6) connected by a passage (7), and an impeller (3) arranged in said pump casing (2) so as to be rotatable about an axis of rotation (9). The impeller (3) is provided with blades (4) sized and shaped for conveying blood along the passage (7) from the blood flow inlet (5) to the blood flow outlet (6), and is rotatably supported in the pump casing (2) by a first bearing (10) at a first axial end of the impeller (3) and a second bearing (20) axially spaced apart from the first bearing (10). The first bearing (10) comprises a projection (11) extending along the axis of rotation (9) and connected to one of the impeller (3) and the pump casing (2) and a cavity (13) in the other one of the impeller (3) and the pump casing (2), the projection (11) comprising an enlarged portion (12) that engages the cavity (13) such that the first bearing (10) and the second bearing (20) are arranged to bear axial forces in the same axial direction.

Owner:ABIOMED EURO

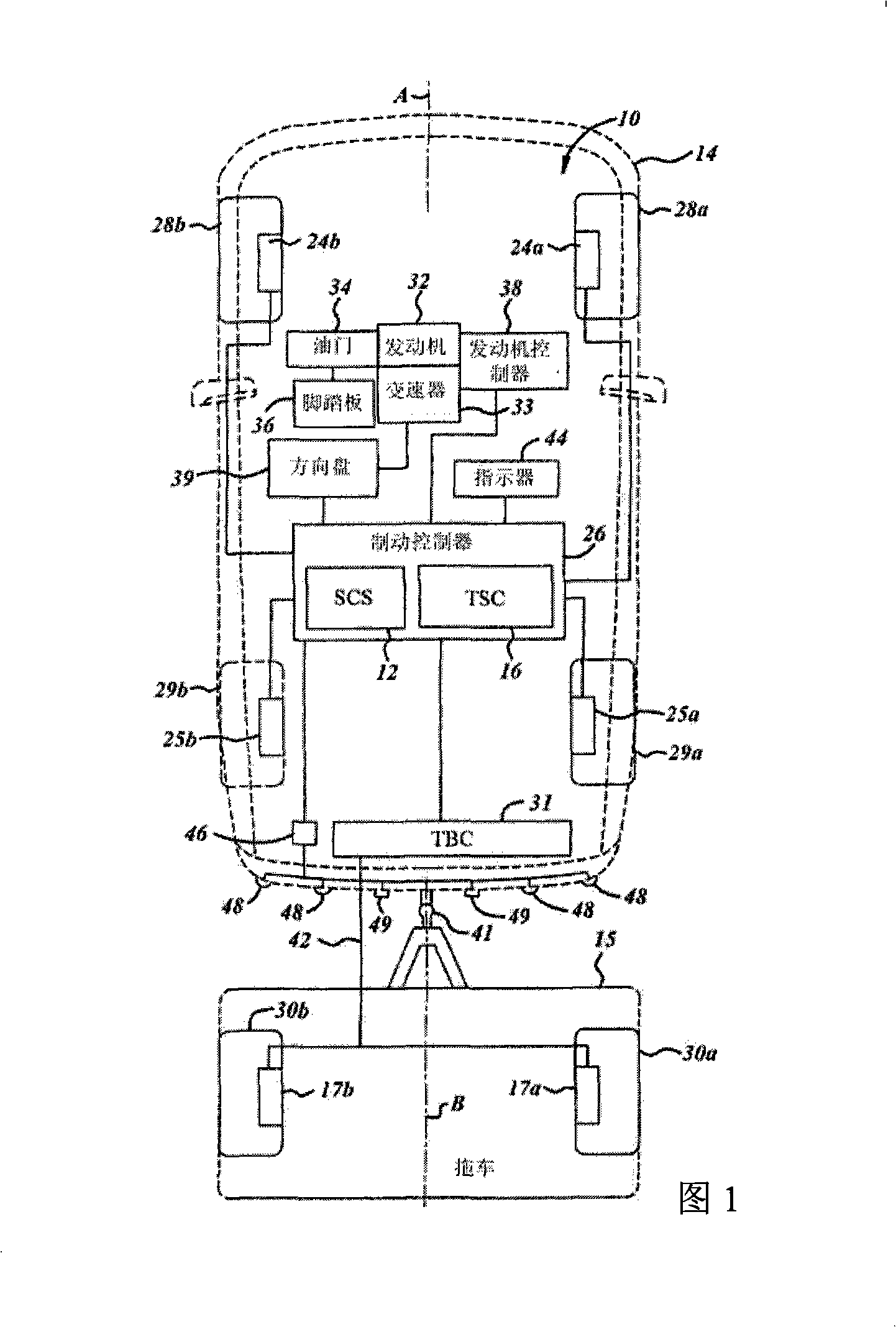

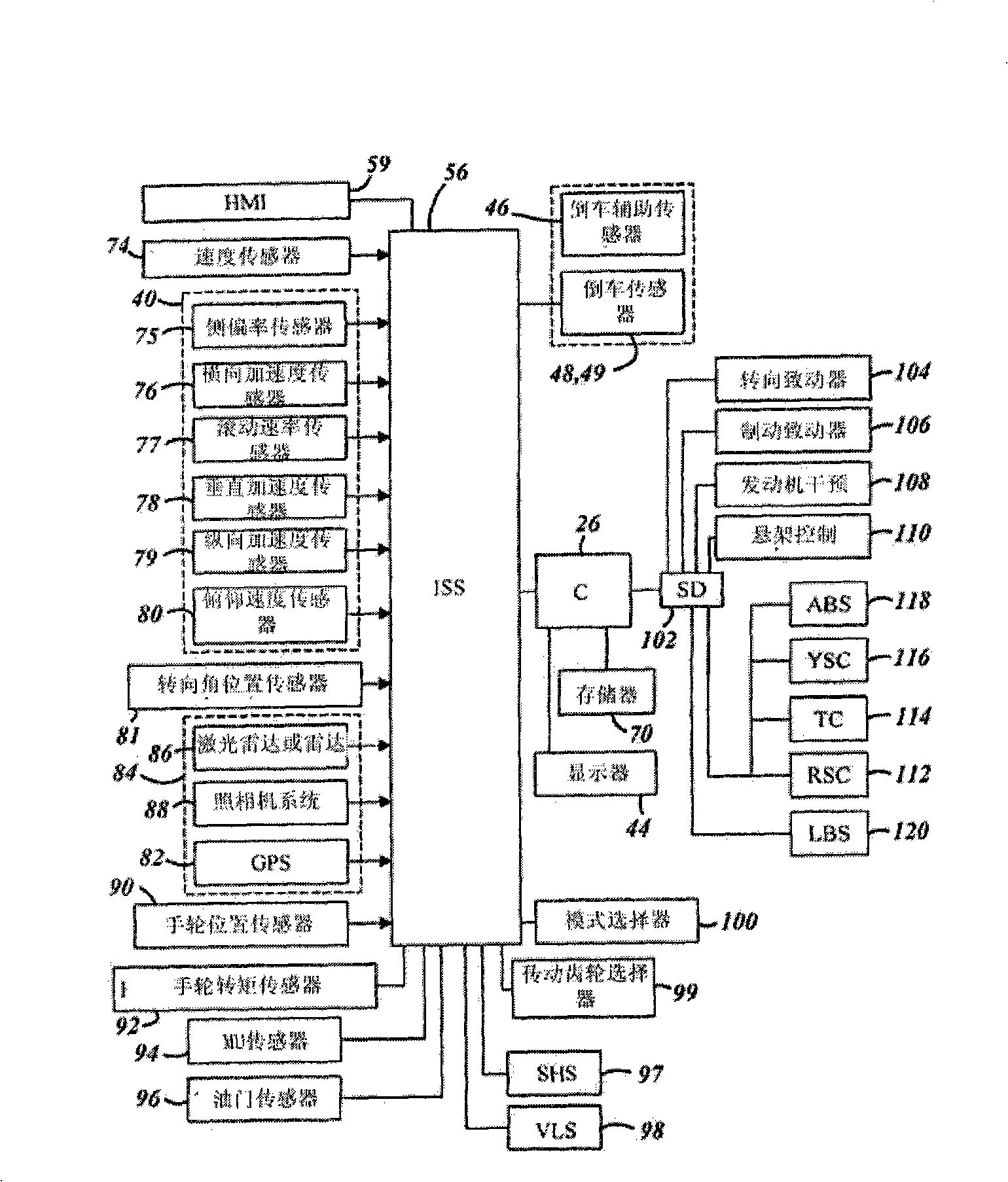

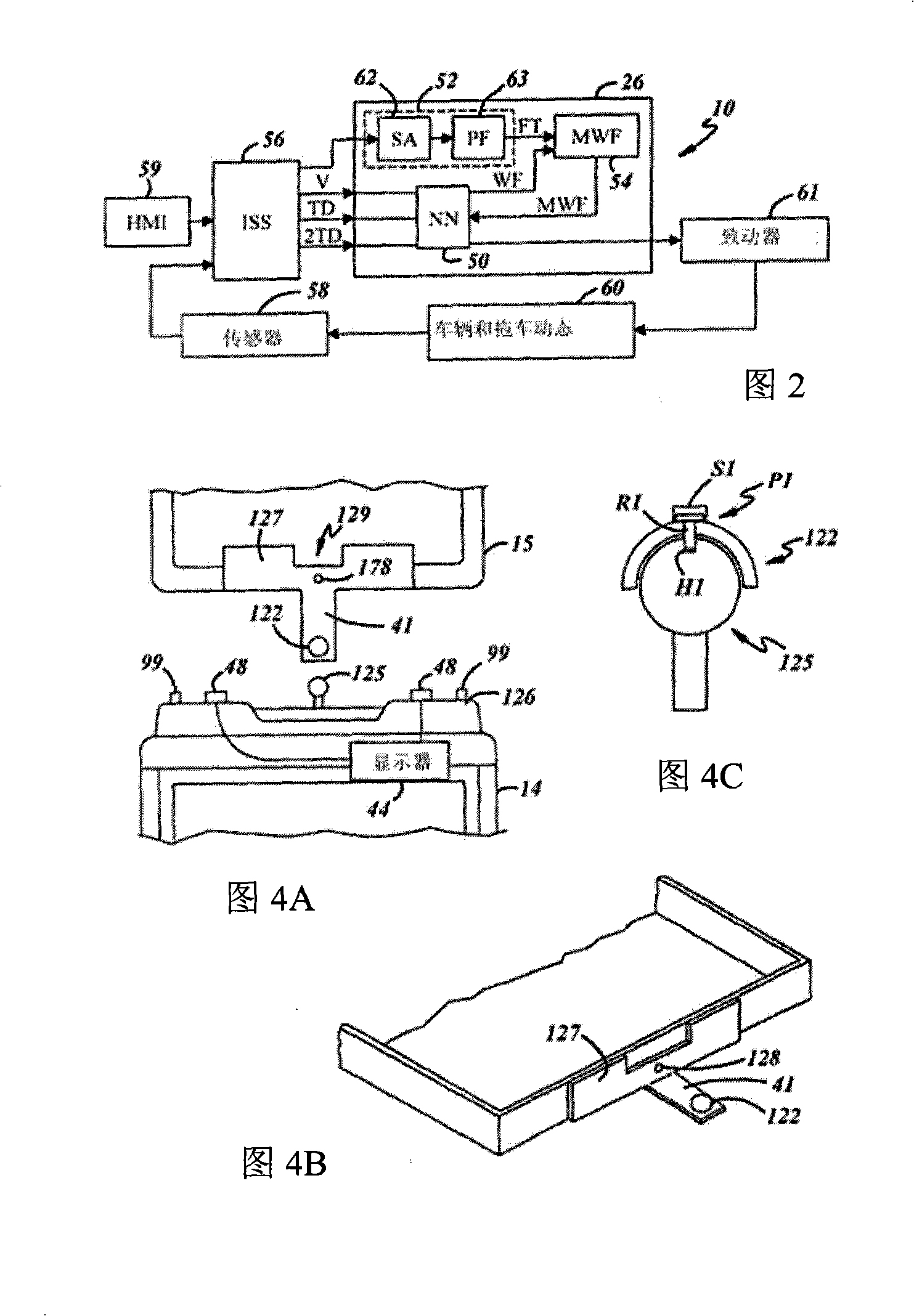

Trailer oscillation detection and compensation method for a vehicle and trailer combination

InactiveCN101402363ALow costLow critical speedVehicle testingAutomatic initiationsVehicle dynamicsSignal response

A system and method of controlling a vehicle with a trailer comprises determining the presence of a trailer, generating an oscillation signal indicative of trailer swaying relative to the vehicle, generating an initial weighted dynamic control signal for a vehicle dynamic control system in response to the oscillation signal, operating at least one vehicle dynamic system according to the dynamic control signal, and thereafter, iteratively generating a penalty function for the weighted dynamic control signal as a function of the oscillation signal response. A neural network with an associated trainer modifies the dynamic control signal as a function of trailer sway response.

Owner:FORD GLOBAL TECH LLC

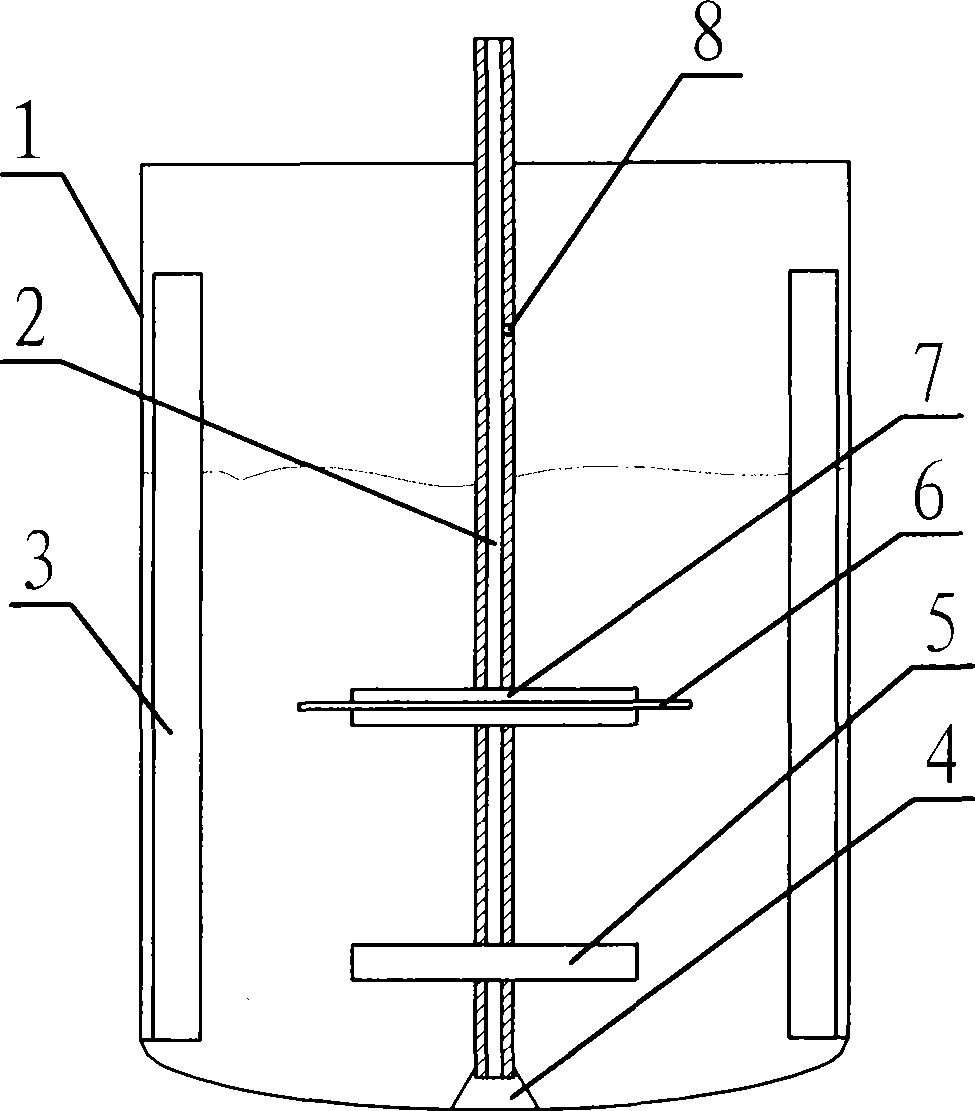

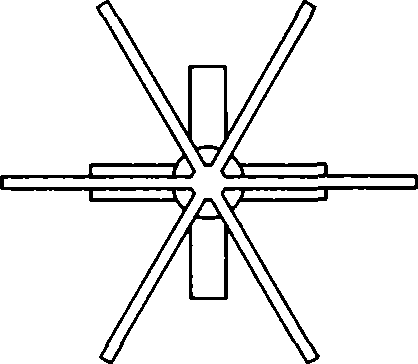

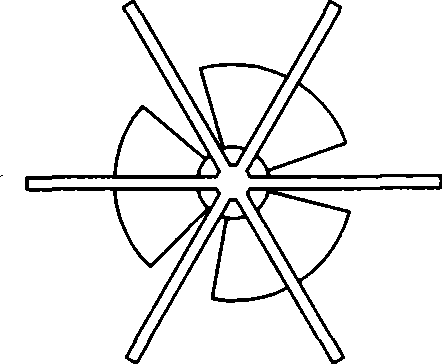

Self-suction mixing reactor

InactiveCN101444715ALow critical speedIncrease inhalationRotary stirring mixersChemical/physical/physico-chemical stationary reactorsProduct gasEngineering

The invention relates to a self-suction mixing reactor, comprising a cylinder body and a mixing device which is arranged in the cylinder body. The self-suction mixing reactor is characterized in that the mixing device comprises a hollow mixing shaft with an air inlet; the lower part of the hollow mixing shaft is sequentially connected with a self-suction mixing oar and a lower layer mixing oar; the self-suction mixing oar is connected with an air outlet branch pipe which is communicated with the hollow mixing shaft. The self-suction mixing oar is provided with the air outlet branch pipe for dispersing gas, an upper-push axial-flow oar is used as the lower layer mixing oar and a full-baffle structure is employed; all the three measures reduce the critical rotation speed to different extent when being sucked in, increase the suction quantity of the gas, lead the contact of gas and liquid to be good, improve the mass transfer efficiency, lead the cooperation of mixing rotation speed and mixing energy dissipation to be simple, thus obviously improving the yield of the product.

Owner:EAST CHINA UNIV OF SCI & TECH +1

Magnetically-levitated blood pump with optimization method enabling miniaturization

Owner:WORLD HEART +1

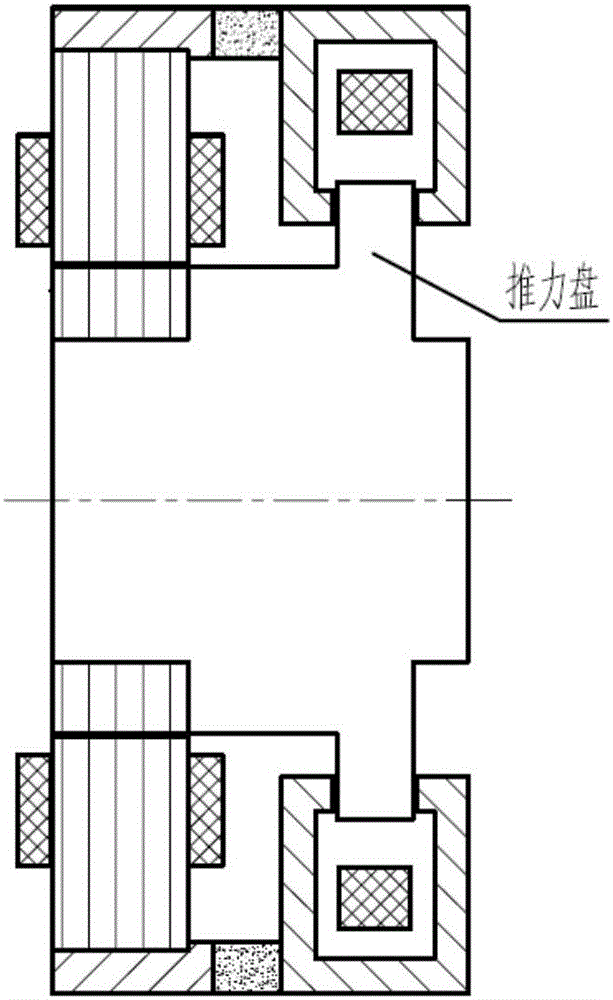

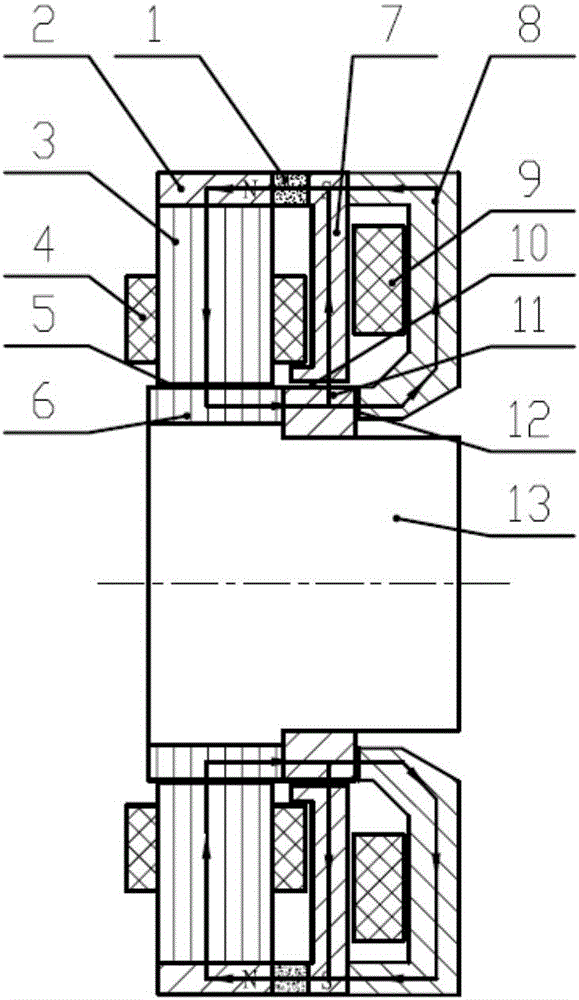

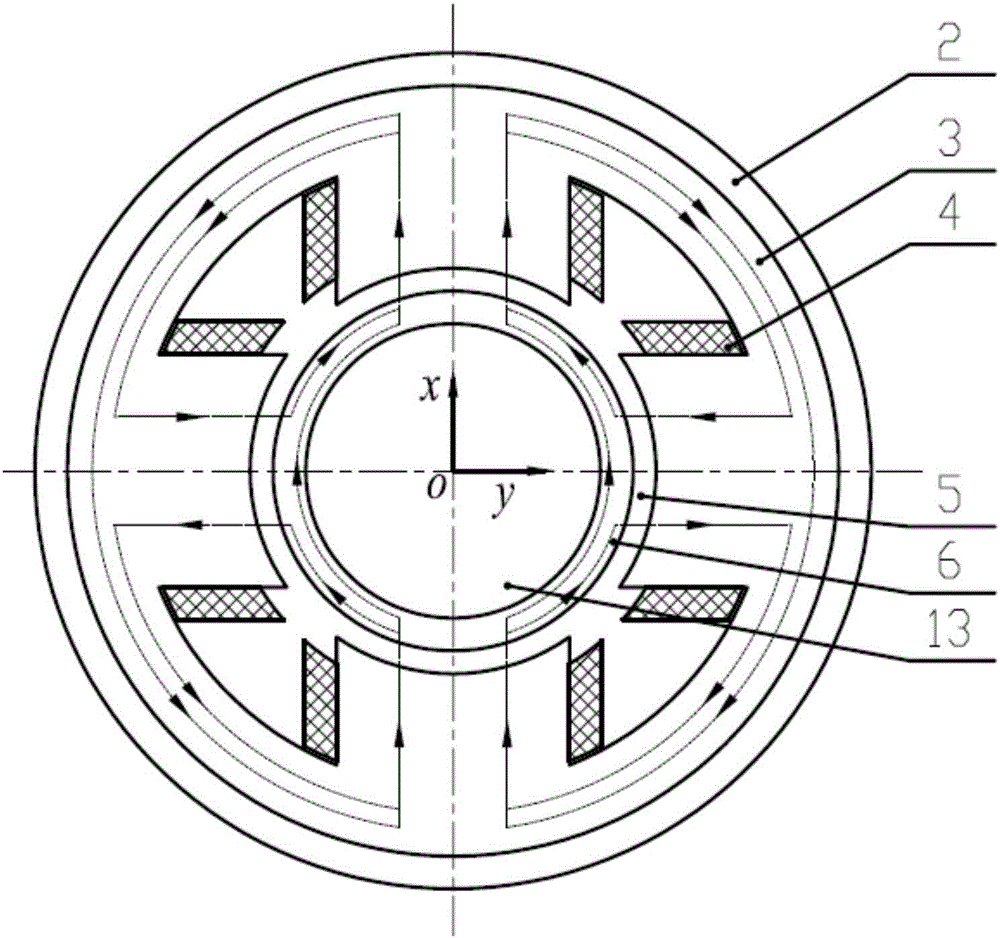

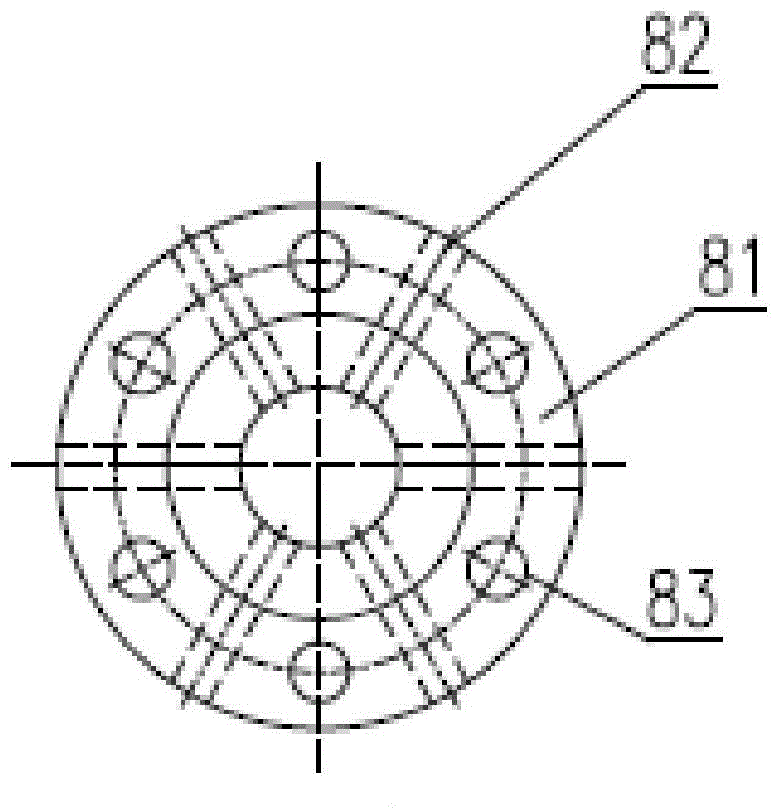

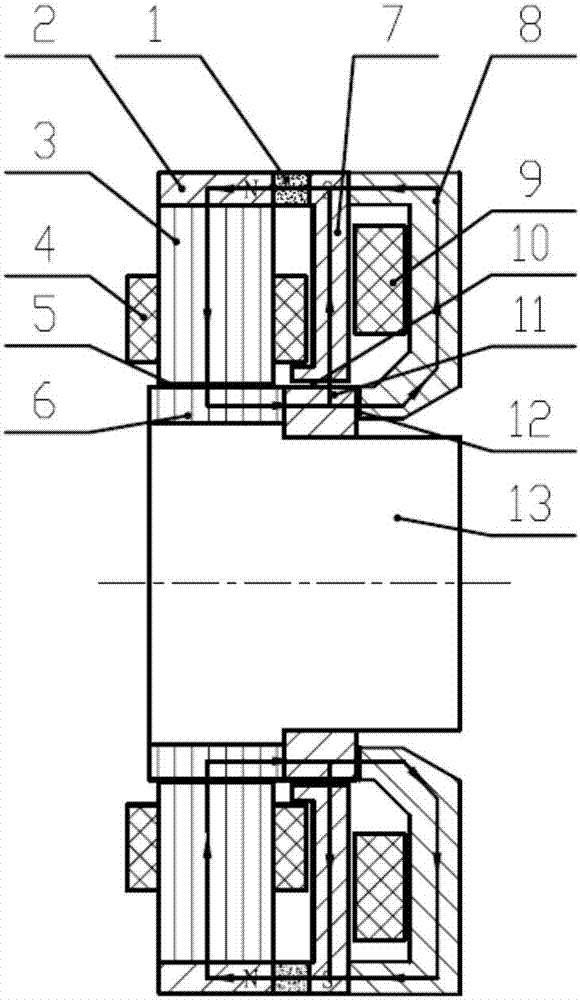

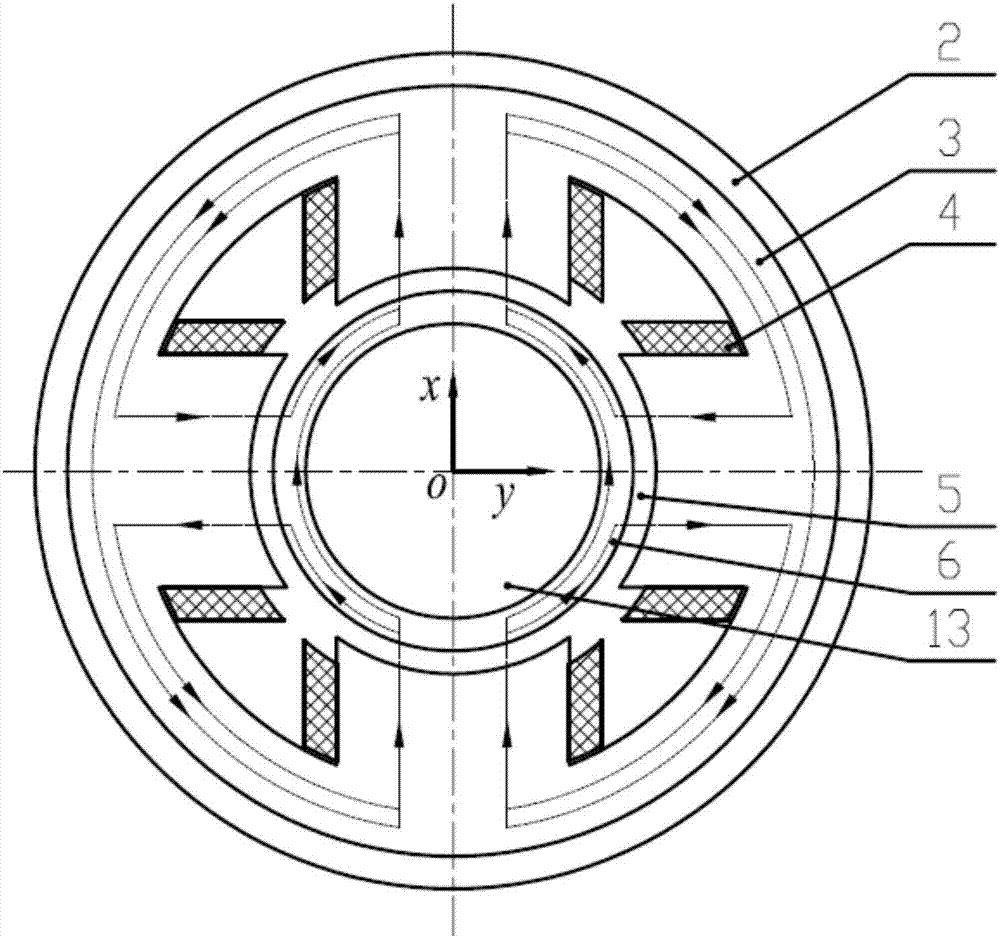

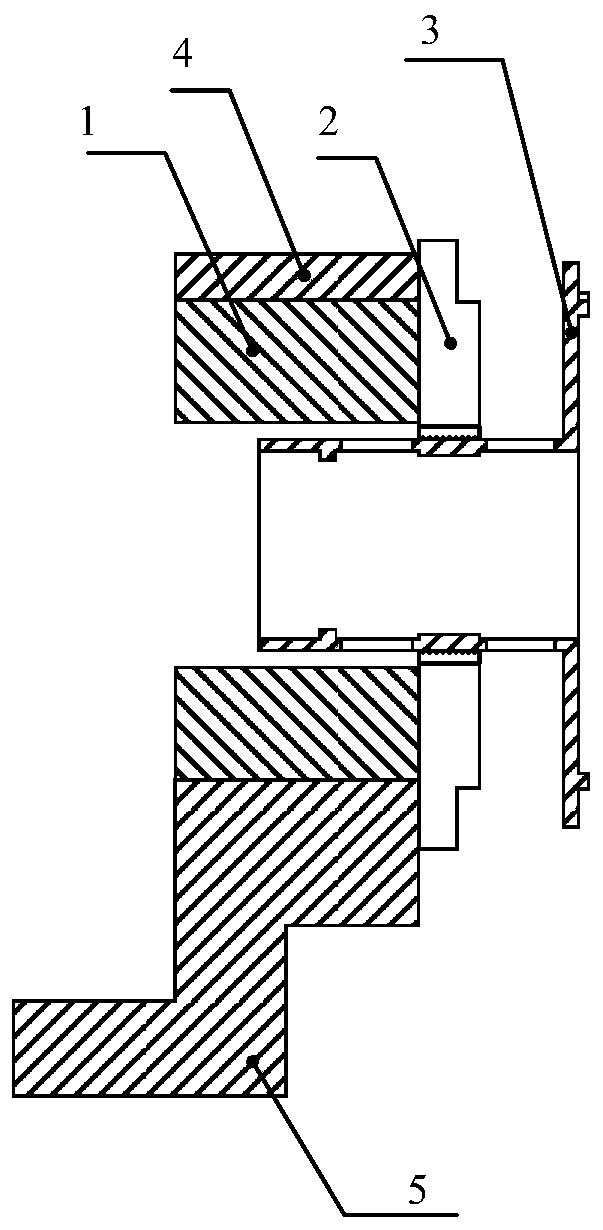

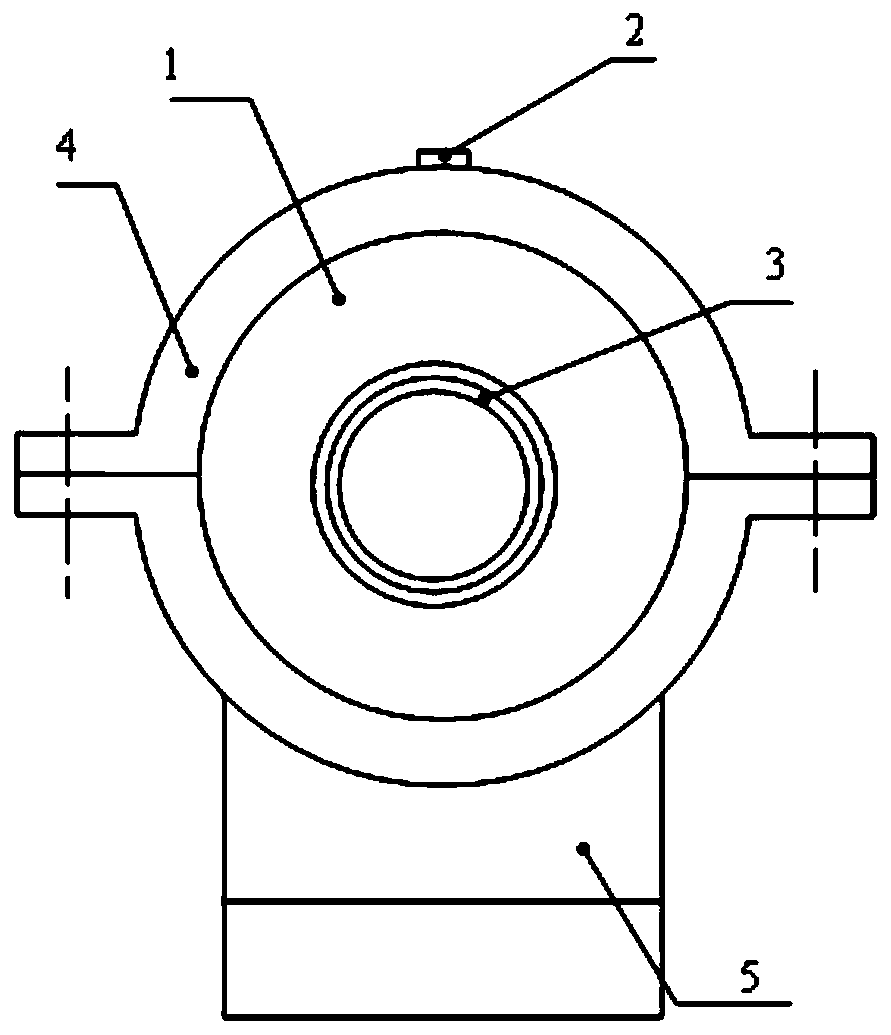

Non-thrust-disc radial and axial integrated permanent magnet biased magnetic bearing

ActiveCN106594072AIncrease the outer diameterIncrease surface speedBearingsMagnetic bearingMagnetic poles

A non-thrust-disc radial and axial integrated permanent magnet biased magnetic bearing comprises a permanent magnet body, a magnetic conducting ring, a radial stator core, radial coils, a rotor core, an annular magnetic pole, an axial stator core, axial coils, a thread ring and a rotating shaft, wherein the permanent magnet is used for providing a biased magnetic field; biased magnetic flux and axial control magnetic flux are transferred through the annular magnetic pole; an annular air gap which is longer than a radial air gap is formed between the annular magnetic pole and the thread ring; the magnetic bearing generates force in a differential manner through four magnetic poles of a radial stator; the magnetic bearing is free of a thrust disc and generates force through the end surface of the thread ring; the thread ring is used for compressing the rotor core. An existing radial and axial integrated magnetic bearing axially generates forces through the thrust disc, thus the outside diameter of a rotor, the linear velocity and the ventilation losses are increased, and the mechanical safety margin and critical speed of rotation of the rotor are reduced. The non-thrust-disc radial and axial integrated permanent magnet biased magnetic bearing can solve the shortage of the existing radial and axial integrated magnetic bearing which axially generates force through the thrust disc; the non-thrust-disc radial and axial integrated permanent magnet biased magnetic bearing has the advantages of reducing the losses, and improving the mechanical safety margin and critical speed of rotation of the rotor.

Owner:BEIHANG UNIV

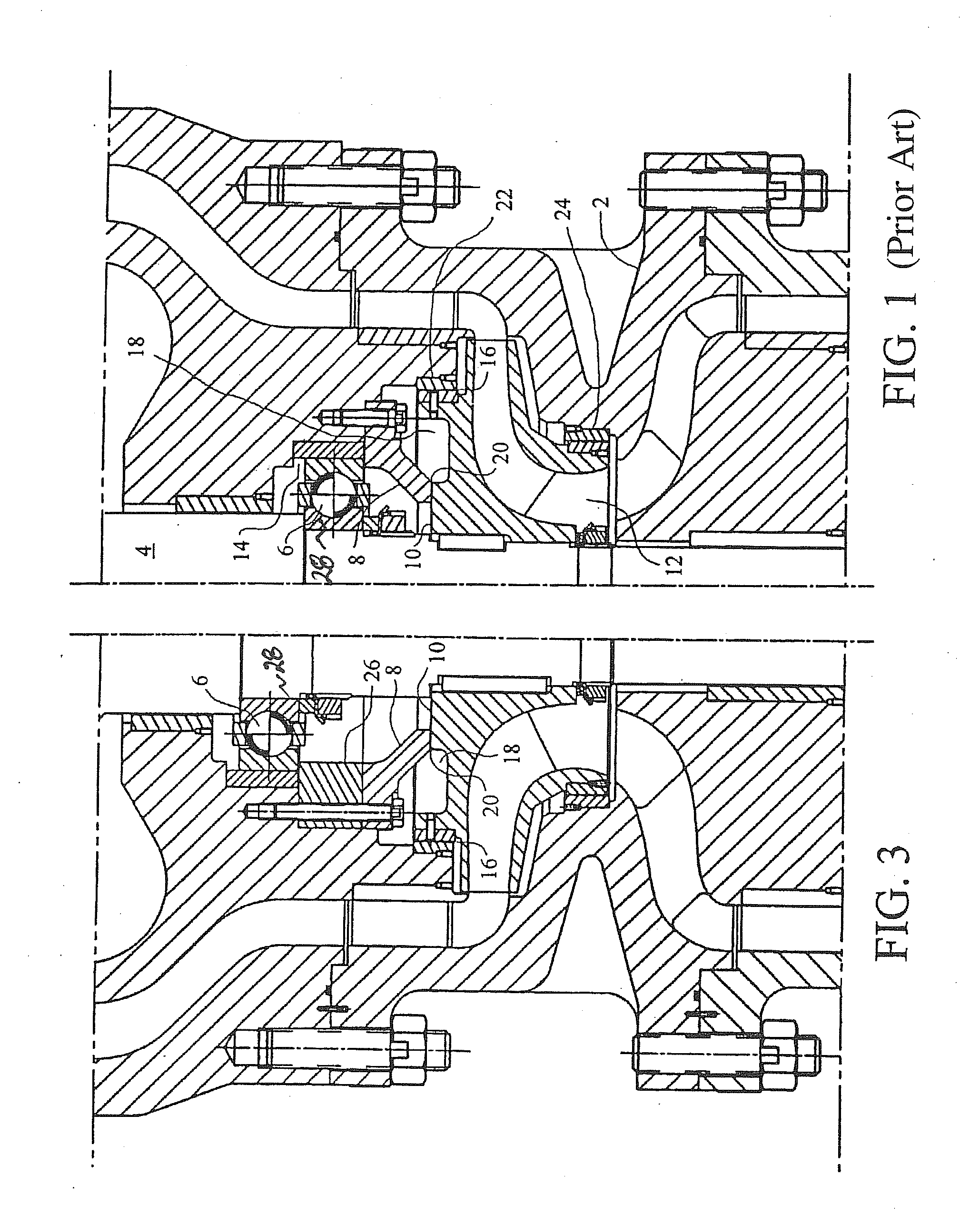

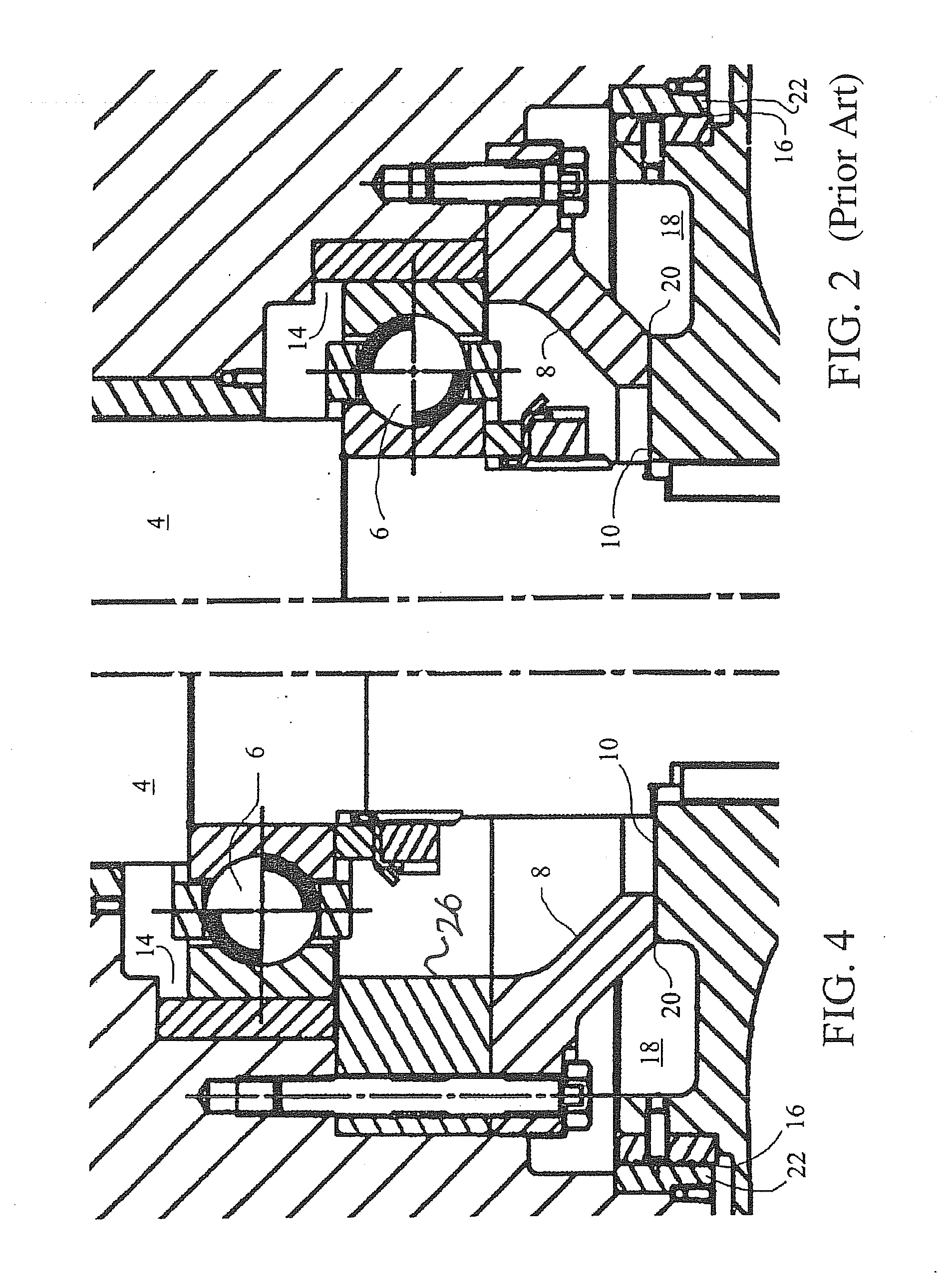

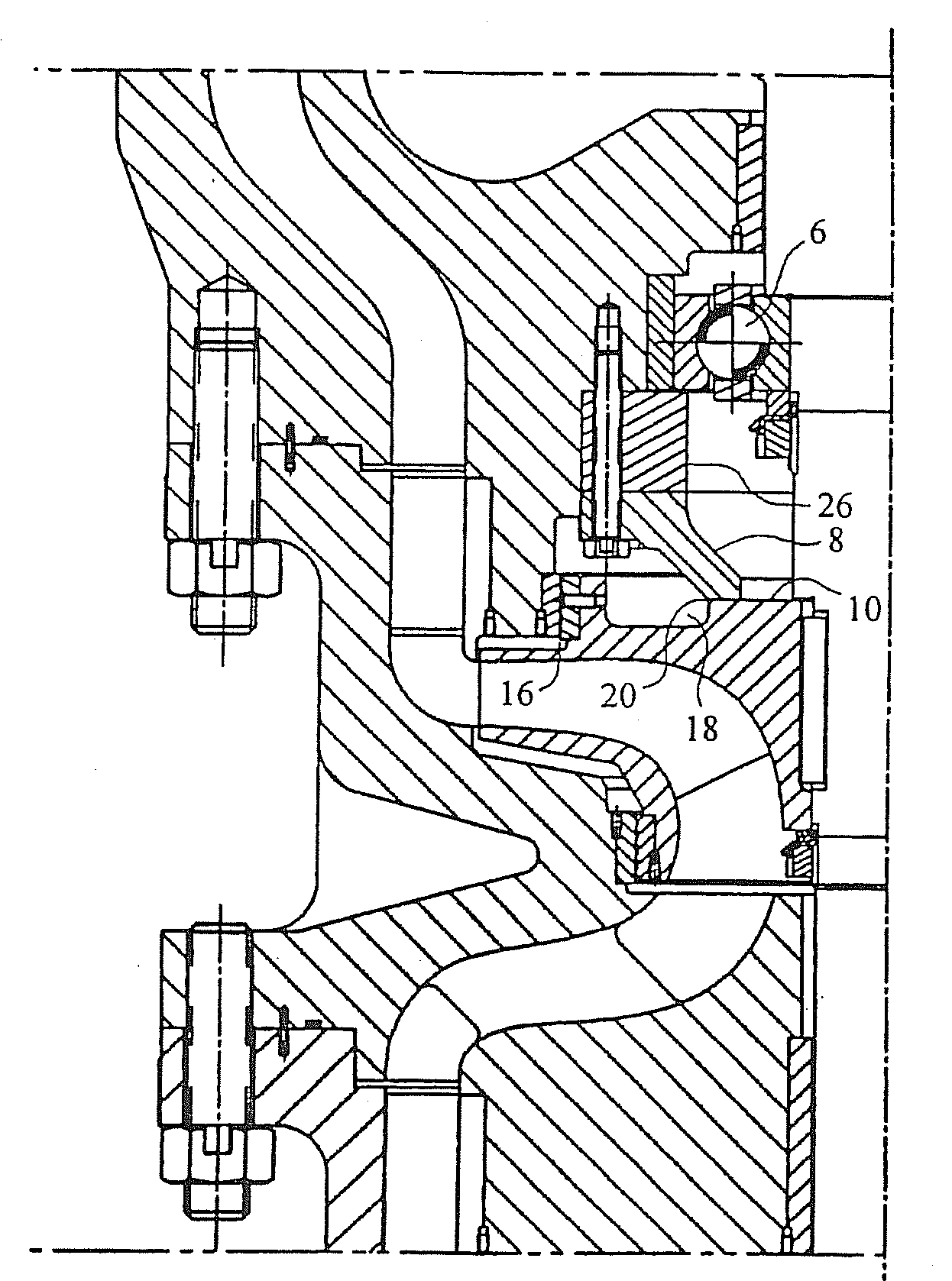

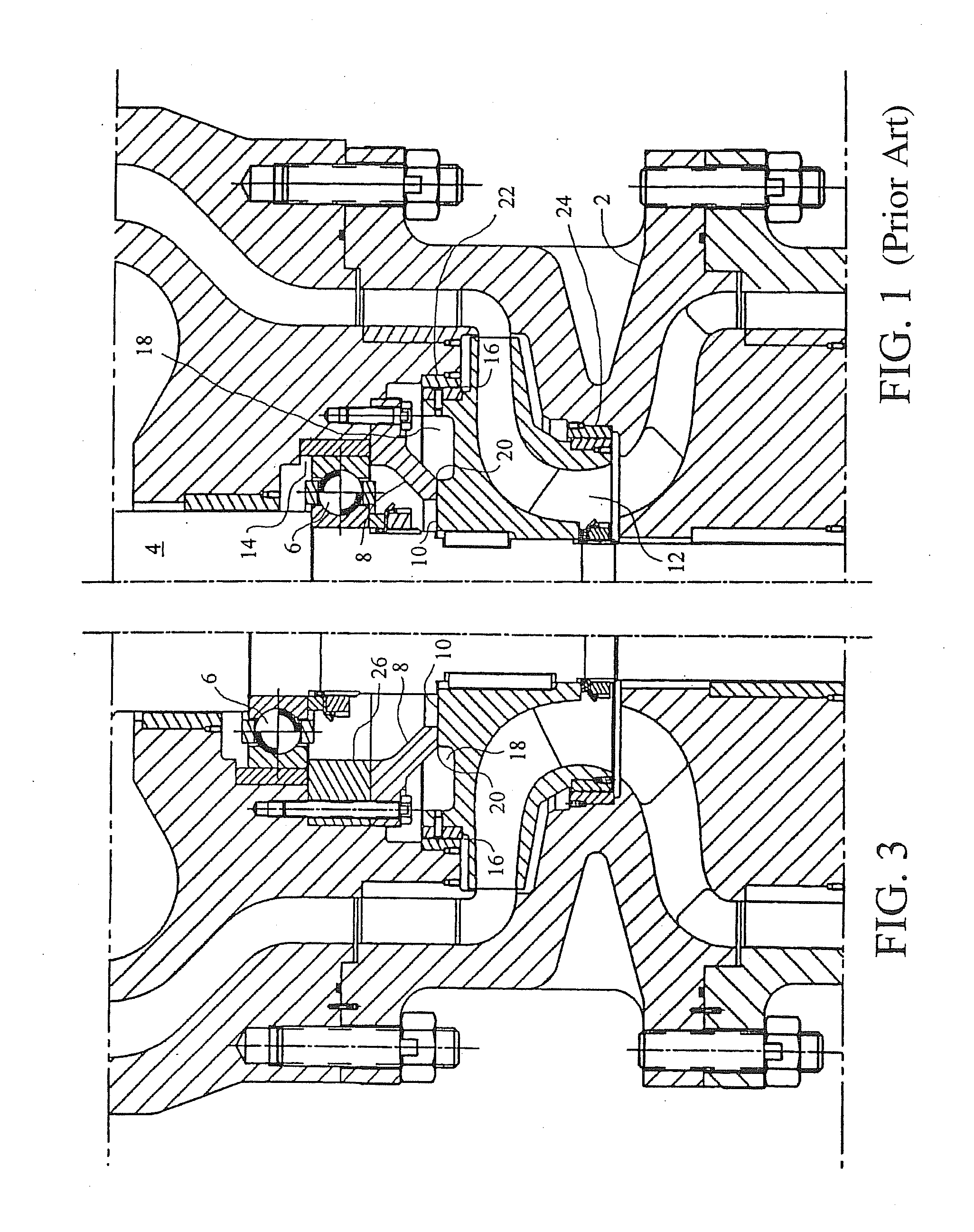

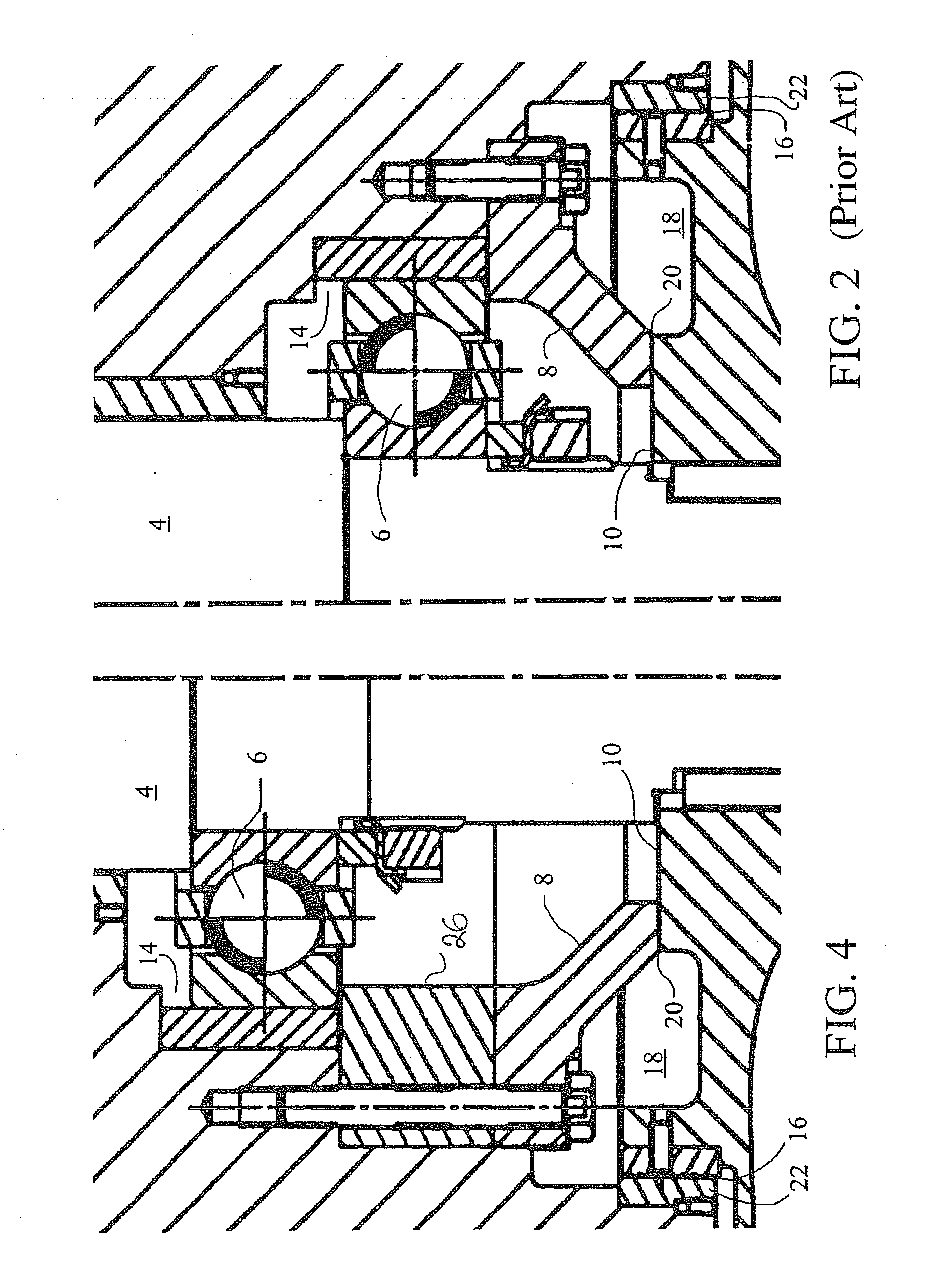

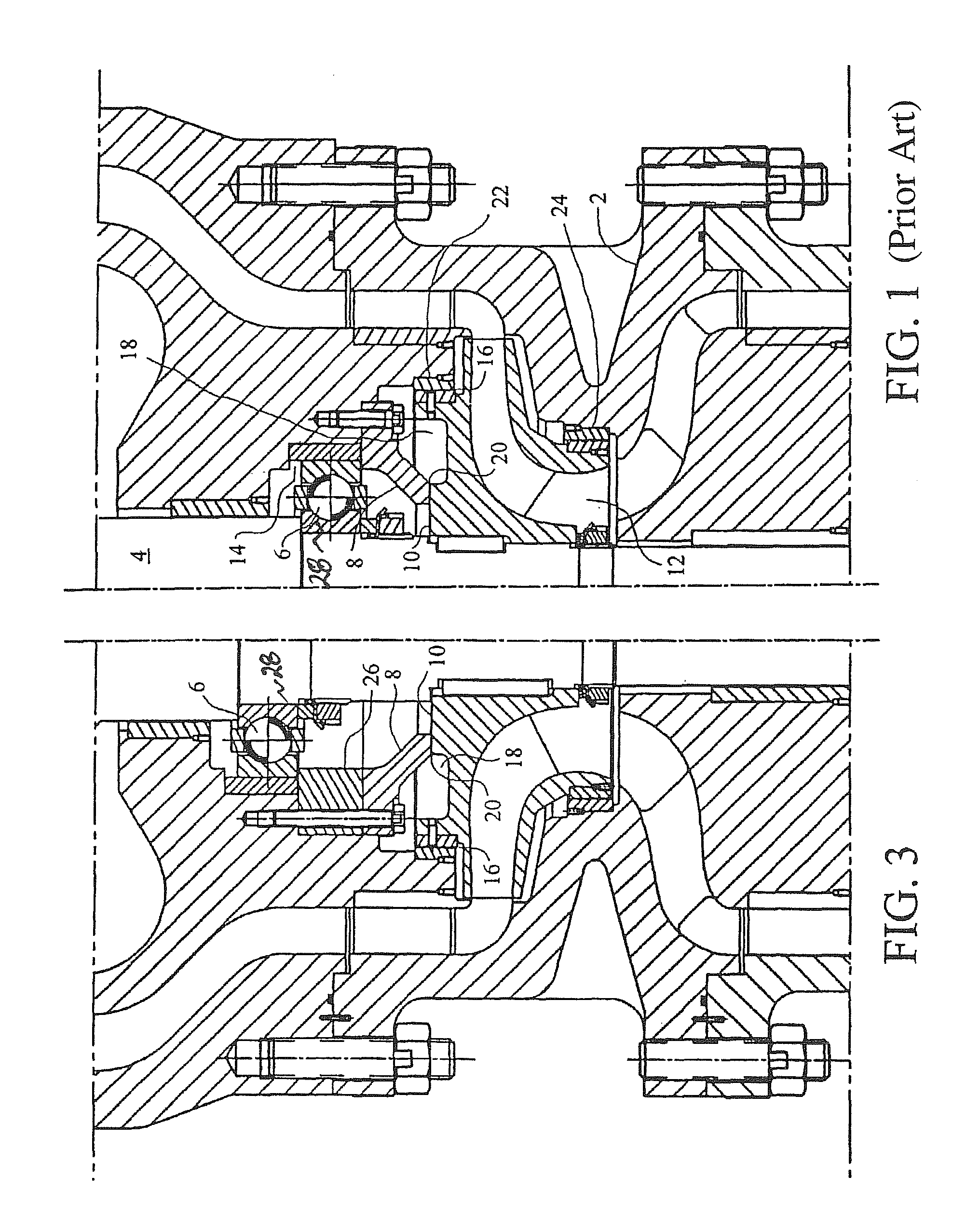

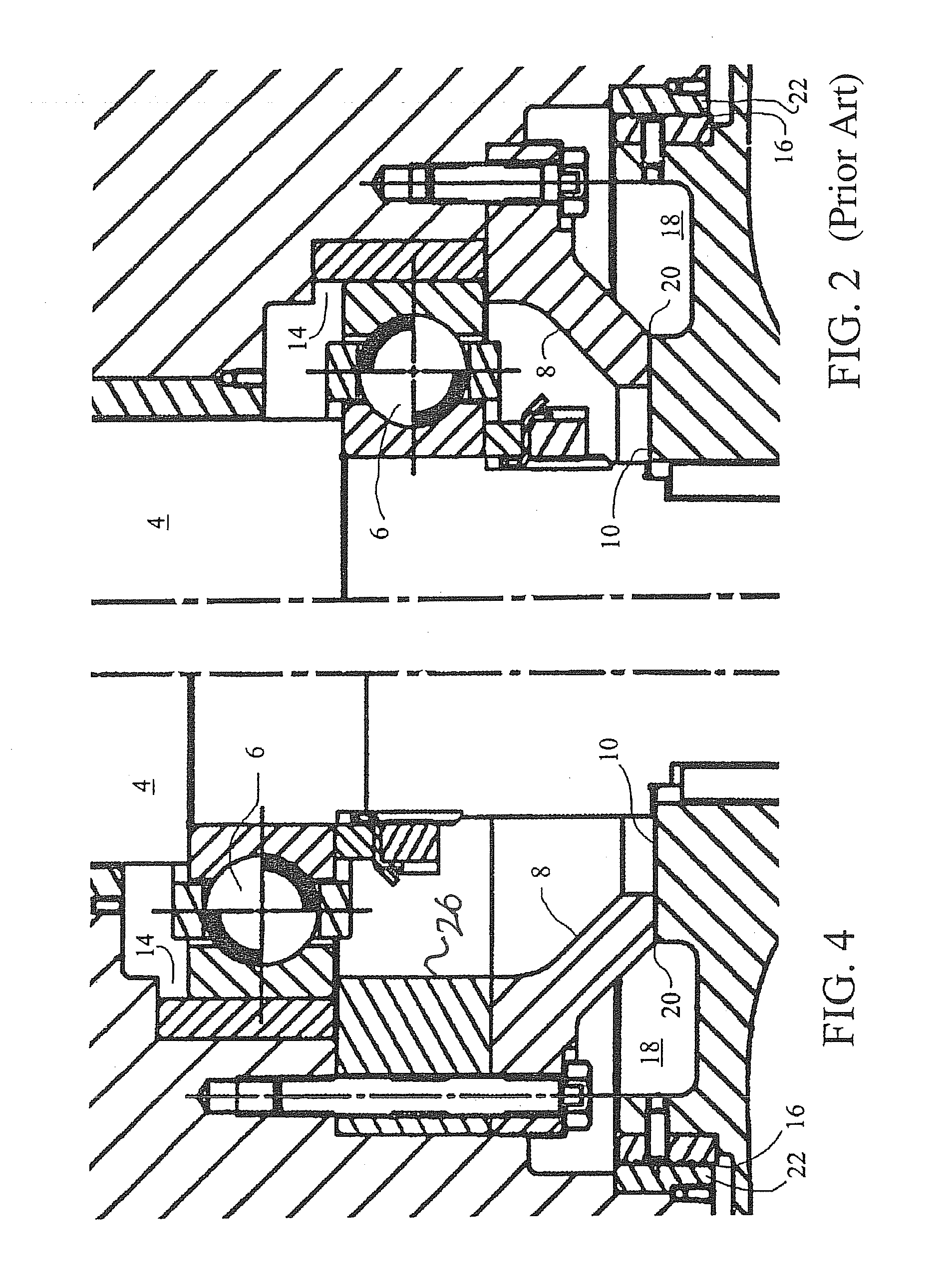

Thrust Balancing Device For Cryogenic Fluid Machinery

ActiveUS20110210556A1Reducing gap therebetweenReduce gapEngine manufacturePump componentsEngineeringTurbine

An improvement for a turbine generator or pump having main bearings separated by a span of shaft and a thrust equalizing mechanism adjacent one of said main bearings, the improvement comprising a stationary length compensator interposed between the thrust equalizing mechanism and its adjacent main bearing to reduce the span between said main bearings. Preferably the length compensator is composed of material that shrinks less than the shaft of the generator, and the height of the length compensator, i.e., the compensating dimension, is selected according to desired thrust equalizing mechanism operating parameters over a temperature range.

Owner:ELLIOTT CO

Thrust balancing device for cryogenic fluid machinery

InactiveUS20090074560A1Reducing gap therebetweenReduce gapEngine sealsRolling contact bearingsTurbineFixed length

An improvement for a turbine generator or pump having main bearings separated by a span of shaft and a thrust equalizing mechanism adjacent one of said main bearings, the improvement comprising a stationary length compensator interposed between the thrust equalizing mechanism and its adjacent main bearing to reduce the span between said main bearings. Preferably the length compensator is composed of material that shrinks less than the shaft of the generator, and the height of the length compensator, i.e., the compensating dimension, is selected according to desired thrust equalizing mechanism operating parameters over a temperature range.

Owner:ELLIOTT CO

Deep-sea submarine mineral collecting device and mineral collecting method thereof

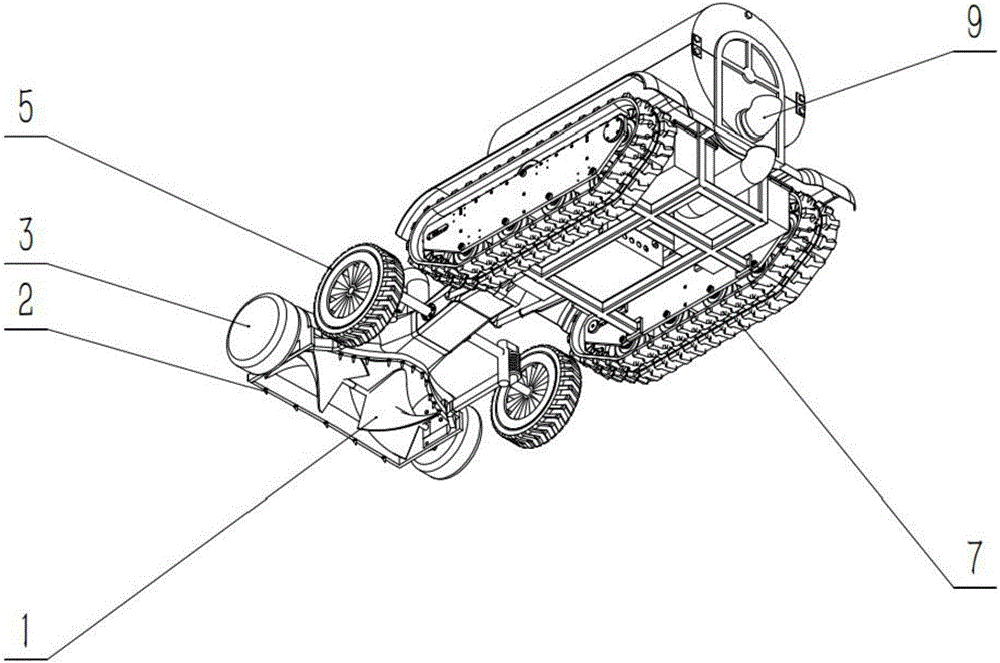

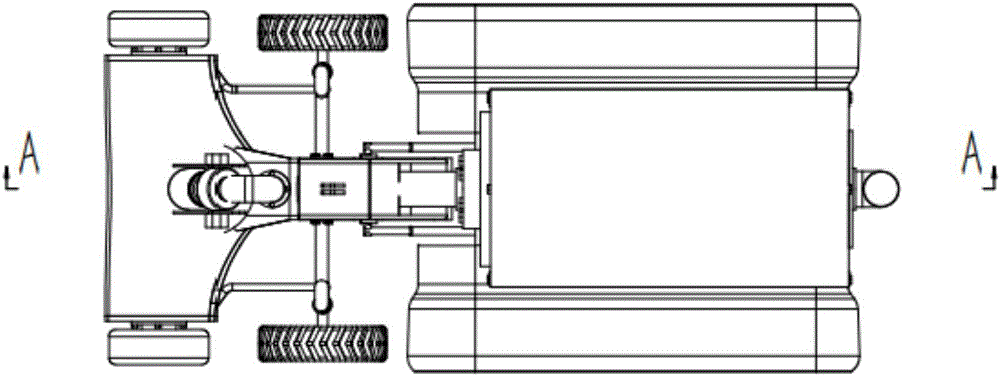

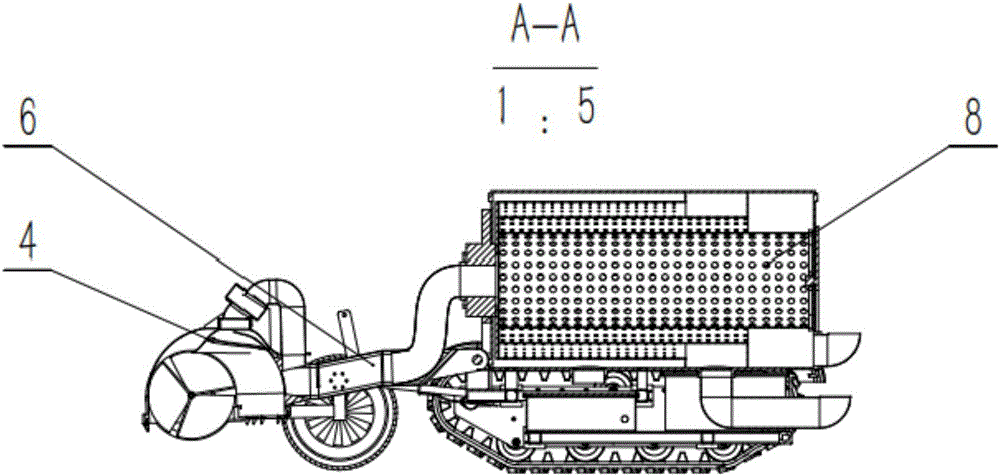

ActiveCN106121656ALow critical speedAvoid cloggingMineral miningUnderwater equipmentDrive wheelEcological environment

The invention provides a deep-sea submarine mineral collecting device and a mineral collecting method thereof. The device comprises a hydraulic mineral collecting system, a sieving system and a crawler belt walking system, wherein the hydraulic mineral collecting system comprises a hydraulic mineral collecting head, a rotating spiral plate, a water jetting device, a motor, spiral mineral sucking covers, a driven wheel and a mineral collecting head and vehicle body connecting component, the sieving system comprises a rotating screen drum and a mineral outlet, and the crawler belt walking system comprises a crawler belt device. The deep-sea submarine mineral collecting device and the mineral collecting method, provided by the invention, can increase mineral collecting efficiency, efficiently save energy and reduce the damage of a submarine mining process to the surface ecological environment of a sea bed.

Owner:SHANGHAI JIAO TONG UNIV

Thrust balancing device for cryogenic fluid machinery

An improvement for a turbine generator or pump having main bearings separated by a span of shaft and a thrust equalizing mechanism adjacent one of said main bearings, the improvement comprising a stationary length compensator interposed between the thrust equalizing mechanism and its adjacent main bearing to reduce the span between said main bearings. Preferably the length compensator is composed of material that shrinks less than the shaft of the generator, and the height of the length compensator, i.e., the compensating dimension, is selected according to desired thrust equalizing mechanism operating parameters over a temperature range.

Owner:ELLIOTT CO

Cryogenic Liquid Rotary Machinery

ActiveUS20140030061A1Reduce gapLow critical speedRolling contact bearingsEngine manufactureTurbineMain bearing

An improvement for a turbine generator or pump having main bearings separated by a span of shaft and a thrust equalizing mechanism adjacent one of said main bearings, the improvement comprising a stationary length compensator interposed between the thrust equalizing mechanism and its adjacent main bearing to reduce the span between said main bearings. Preferably the length compensator is composed of material that shrinks less than the shaft of the generator, and the height of the length compensator, i.e., the compensating dimension, is selected according to desired thrust equalizing mechanism operating parameters over a temperature range.

Owner:ELLIOTT CO

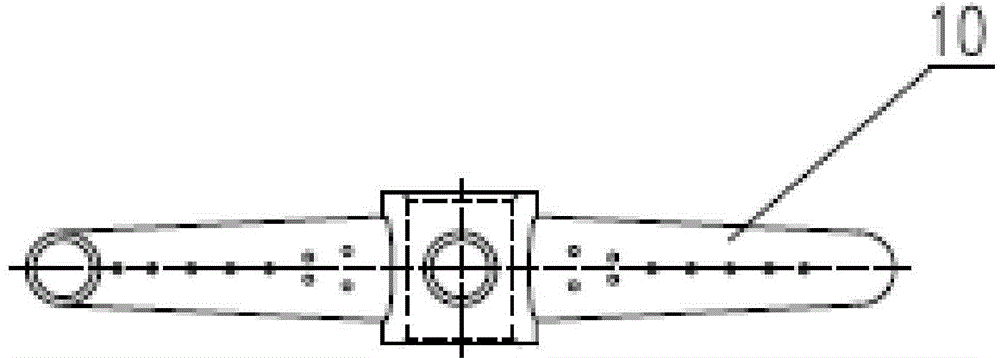

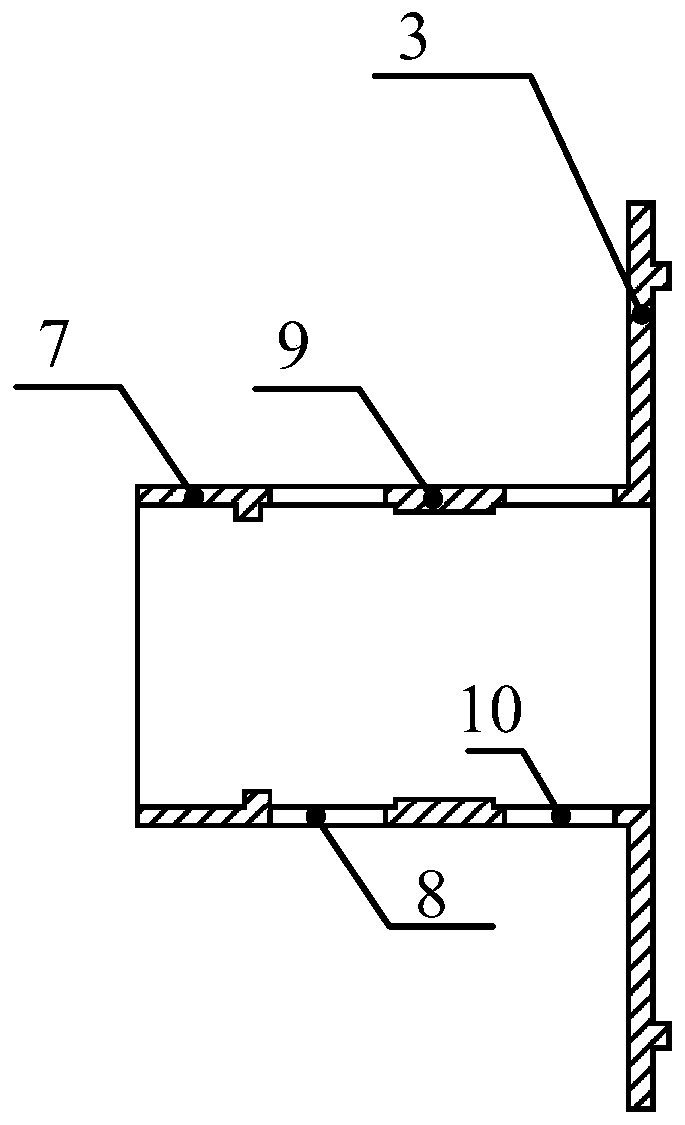

Elastic damping support for motor rotor of ultracentrifuge

InactiveCN101615822AAvoid defectsAvoid passingManufacturing dynamo-electric machinesSupports/enclosures/casingsRubber ringUltracentrifuge

The invention discloses an elastic damping support for a motor rotor of an ultracentrifuge, which comprises the structures of O-shaped rubber rings, a high-speed bearing, a supporting seat, the motor rotor, a motor stator and a motor shell, wherein the outer sides of the high-speed bearing at two ends of the rotor are provided with O-shaped rubber ring bases, and the O-shaped rubber rings are arranged between the supporting seat and the O-shaped rubber ring bases. The elastic damping support overcomes the defects that a domestic product has low precision, easy heat generation and short service life, and simultaneously solves the manufacturing difficulty of using metal rings in foreign countries; besides, the operation of the elastic damping support is better than the motor with the foreign metal rings, and the elastic damping support replaces the import and widens the international market.

Owner:SHANGHAI ZHIZHENG CENTRIFUGE +1

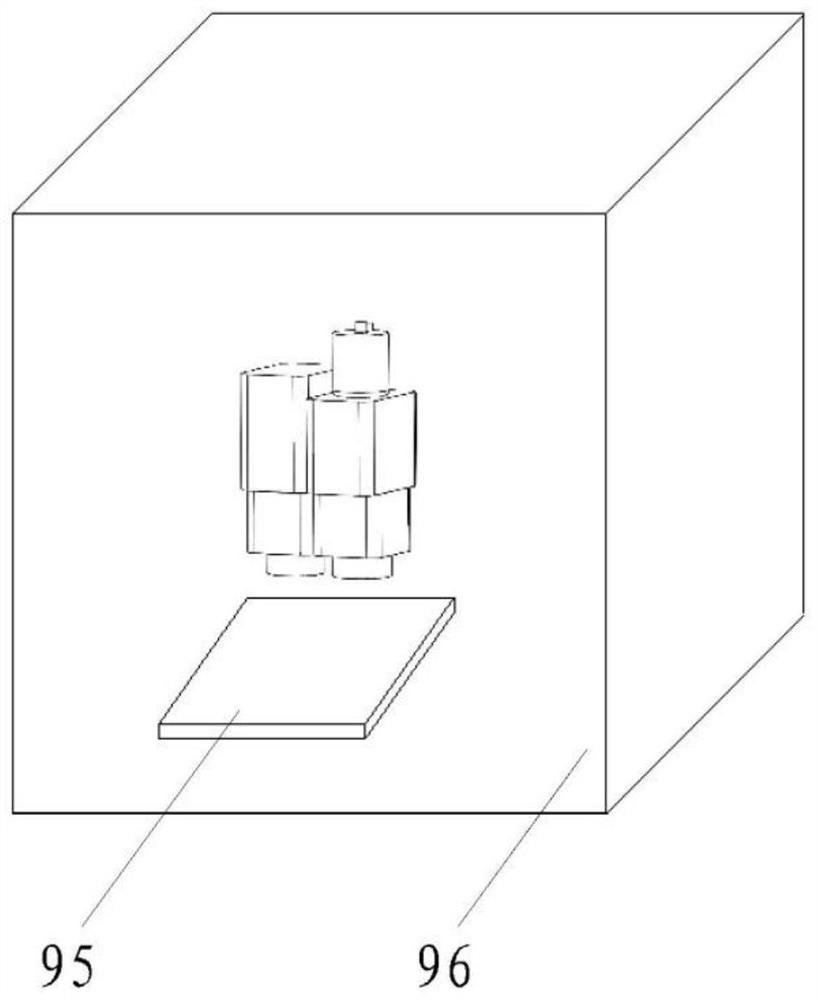

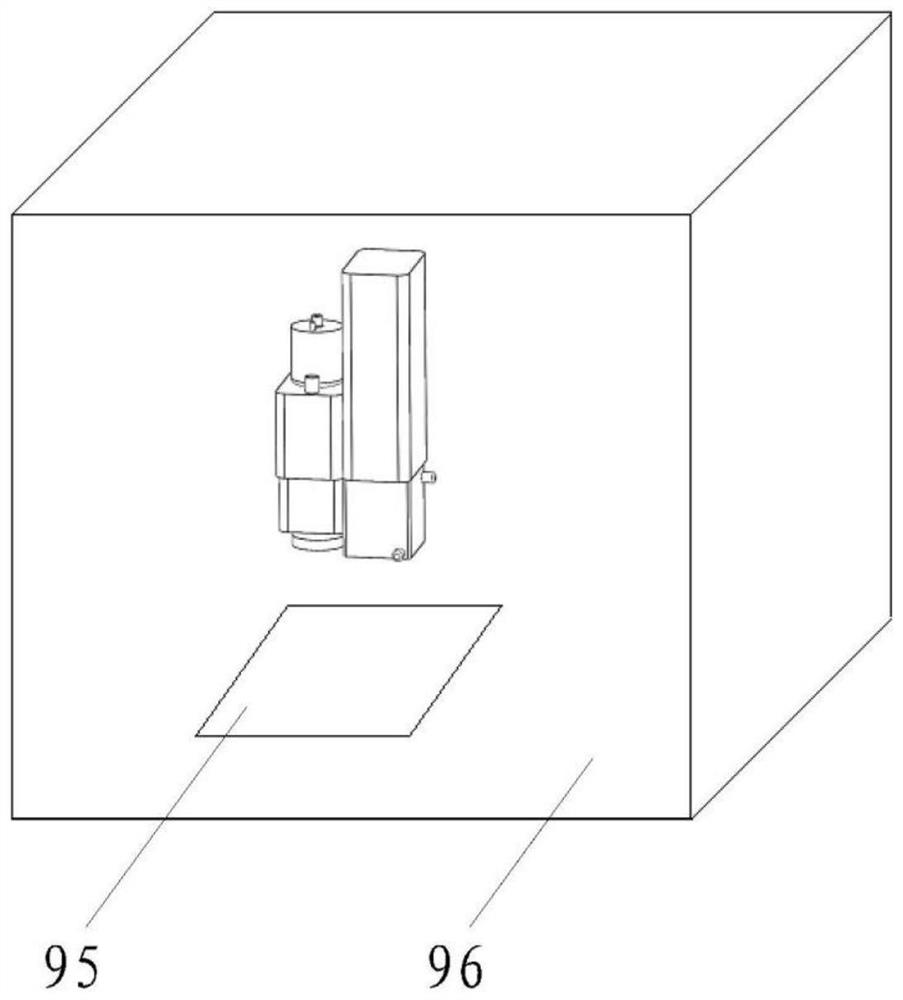

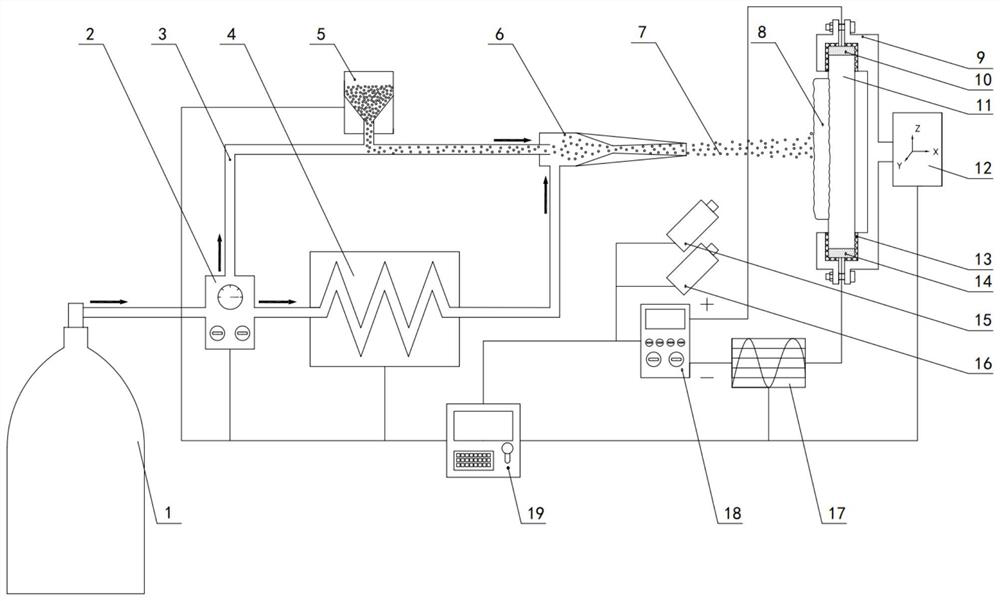

Vacuum electric scanning supersonic spray deposition electron beam additive manufacturing device

PendingCN112776322ASimplify the sintering processPrevent splashAdditive manufacturing apparatusAdditive manufacturing with solidsMolten stateMetallurgy

The invention discloses a vacuum electric scanning supersonic spray deposition electron beam additive manufacturing device. The vacuum electric scanning supersonic spray deposition electron beam additive manufacturing device comprises a forming workbench and an electron beam spray additive device mounted above the workbench, wherein the electron beam spray additive device comprises a cold spraying head, a high-energy electron beam emitter and an electron beam control device. The spraying direction of the cold spraying head can be adjusted, so that sprayed powder particle beams can be scanned on the workbench based on shapes of parts; the electron beam control device is mounted at an emitting opening of the high-energy electron beam emitter and is used for controlling emitting directions of electron beams, so that the electron beams and the powder particle beams sprayed by the cold spraying head are collected at one point, and the surface of a substrate and the powder particles are heated to form a molten state. According to the device, the parts are formed by directionally spraying the powder and heating and sintering in real time; the powder is not needed to be laid layer by layer and sintered; the forming efficiency is greatly improved; the waste of the powder is avoided; the forming cost is reduced; the forming quality consistency is good; the forming quality is improved; the part sintering process is simplified; and the sintering efficiency is improved.

Owner:重庆交通大学绿色航空技术研究院 +1

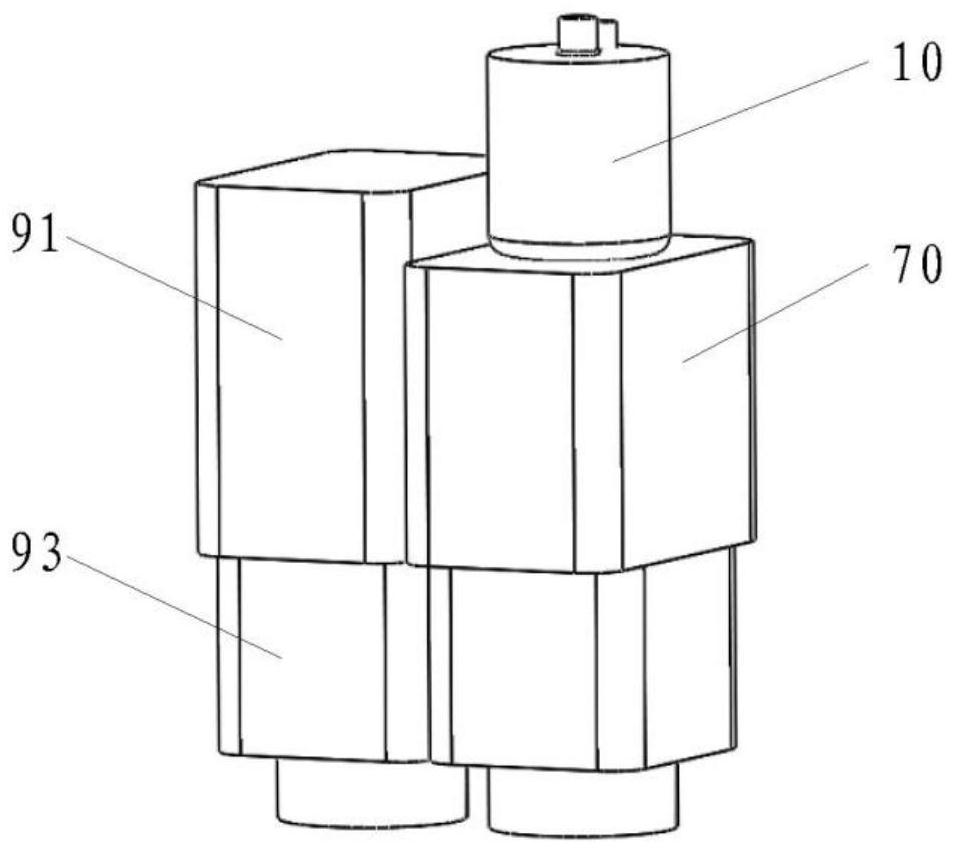

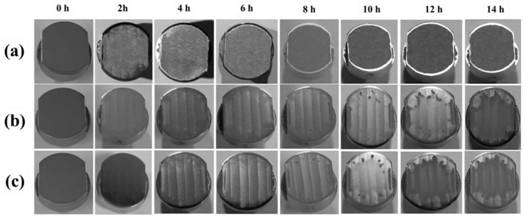

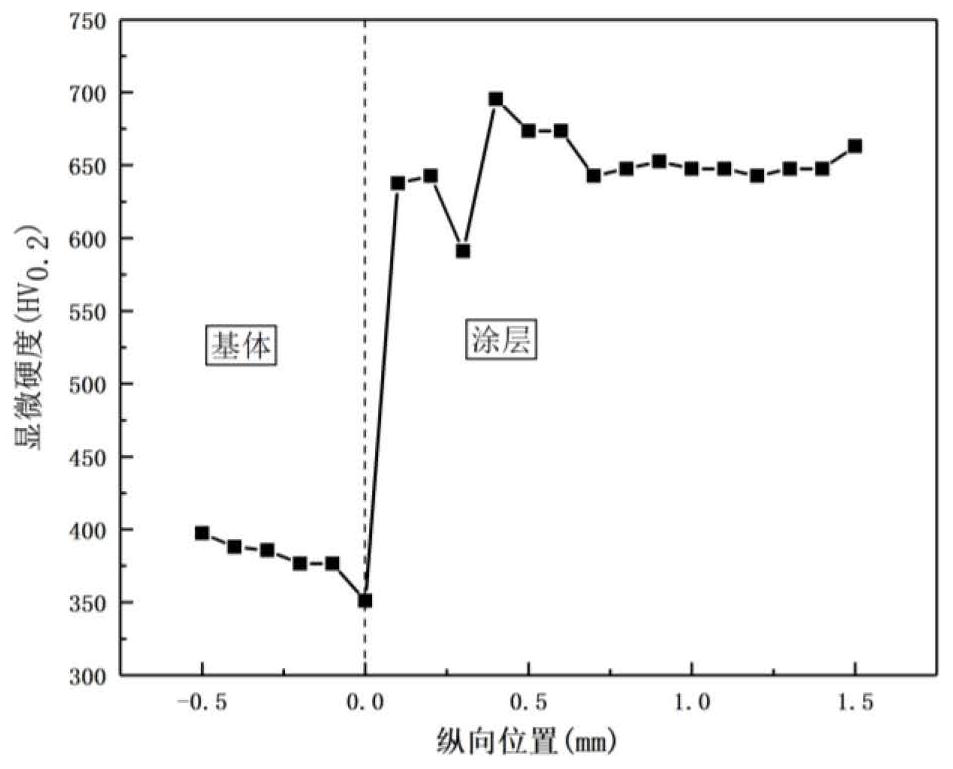

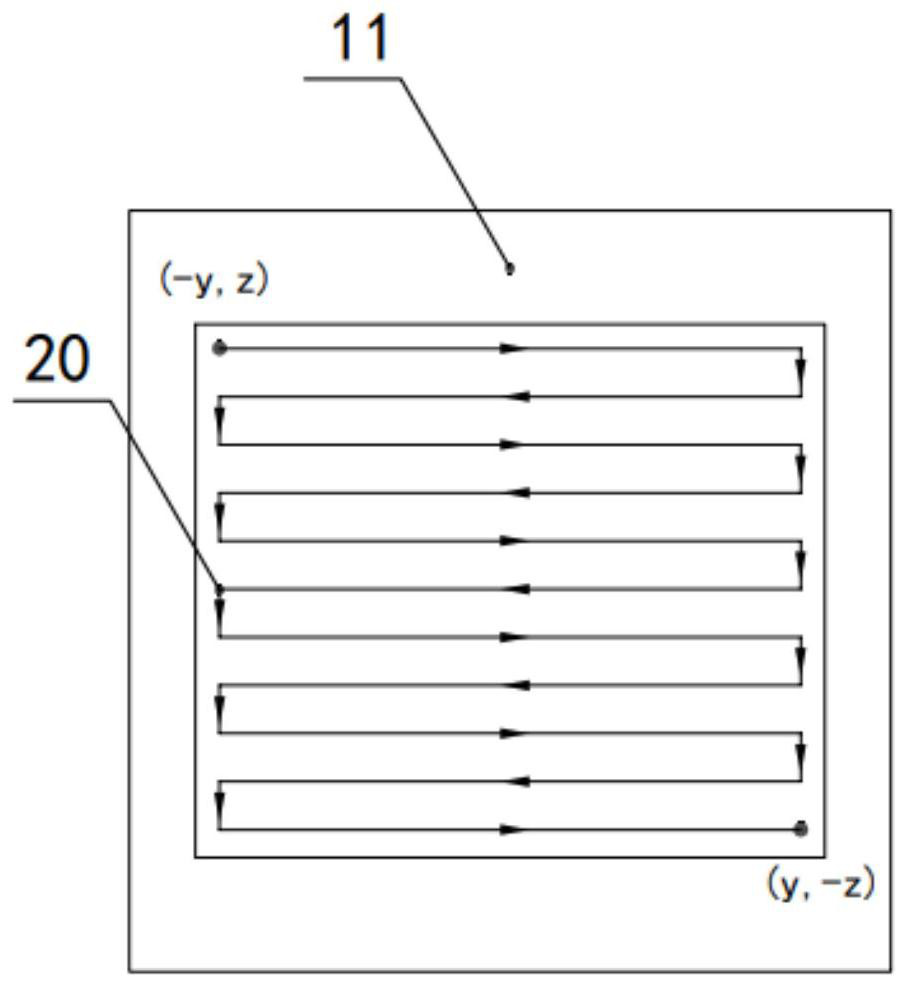

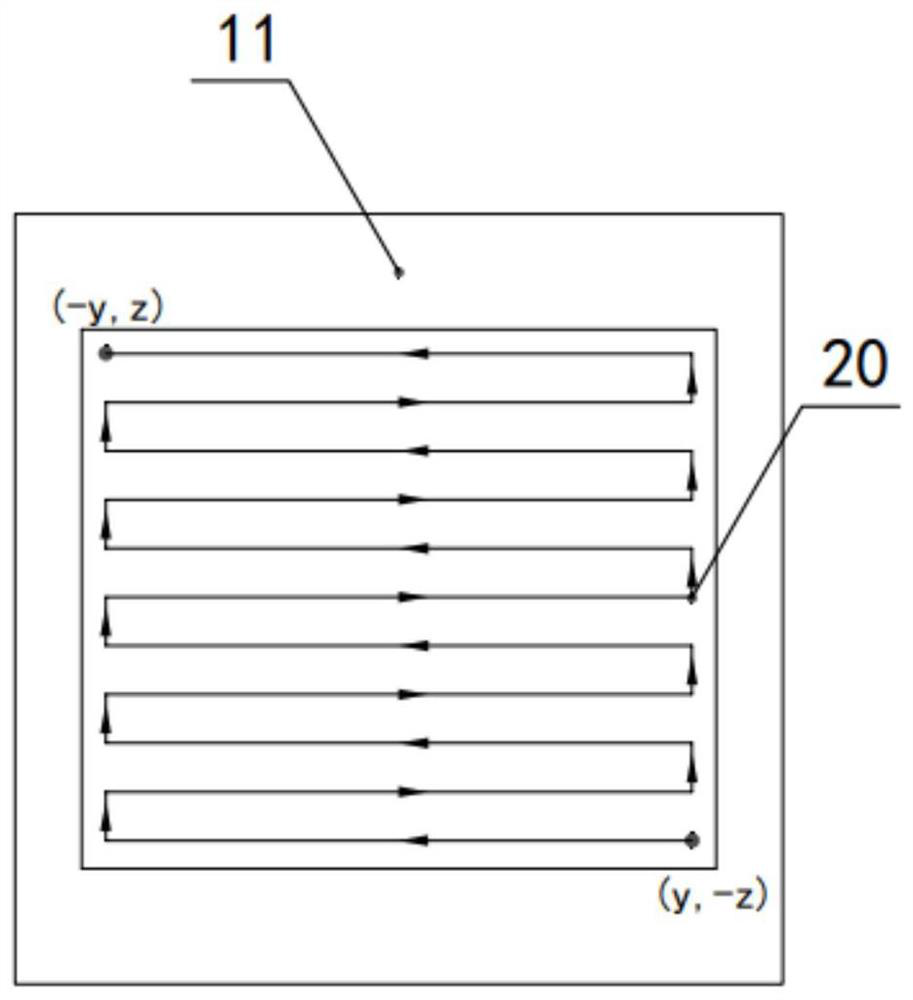

Preparation method of cobalt-based anti-cavitation coating of plastic deposition based on work hardening

InactiveCN111793795ALow critical speedImprove anti-cavitation performancePressure inorganic powder coatingCoated surfaceRobotic arm

A preparation method of a cobalt-based anti-cavitation coating of plastic deposition based on work hardening comprises the steps that an oxidization film on the surface of a metal matrix is removed, oil dirt and residual impurities on the surface are removed through cleaning, and after the metal matrix is dried in air, the matrix is fixed to a workbench; (2) powder is placed in a vacuum drying boxto be dried, and after being dried, the powder is cooled to room temperature to be placed in a powder feeder; (3) the carrier gas kind, the carrier gas pressure, the preheating temperature and the powder feeding rotating speed are set in a cold spraying panel; (4) laser power is set in a laser control panel; (5) a mechanical arm is started, the spraying coating lap-joint rate and the scanning speed are input, the mechanical arm is adjusted, so that a cold spraying nozzle is perpendicular to the surface of the matrix, and the angle of a laser head is adjusted, so that laser spots coincide withspraying powder spots; (6) equipment is started, and supersonic-speed laser deposition experimenting is carried out in the matrix; and (7) after processing is completed, the coating on the surface ofthe metal matrix is subjected to aftertreatment, and the surface of the coating is leveled.

Owner:ZHEJIANG UNIV OF TECH

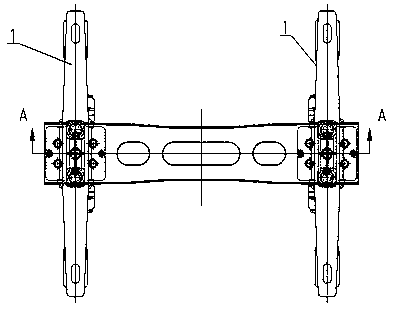

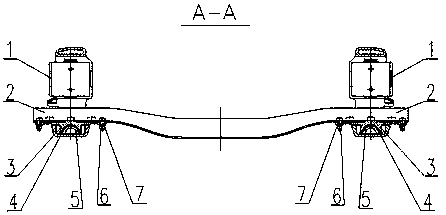

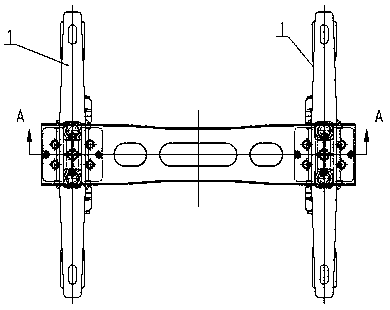

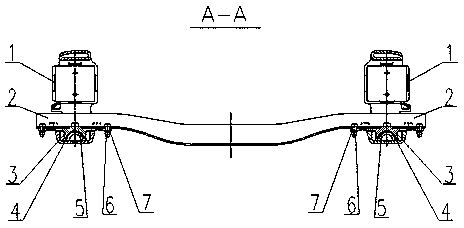

Transverse swing control method for wheel-rail low-power bogie

InactiveCN111301466AImprove reliabilityReduce operating costsBogiesBogie-underframe connectionsControl theoryTruck

A transverse swing control method for a wheel-rail low-power bogie is characterized in that spherical positioning seats are respectively mounted on mounting surfaces of inner cavities of lower chordsof central square frames of two side frames which are arranged in parallel on the wheel-rail low-power bogie, the spherical positioning seats are transversely and symmetrically arranged along the sideframes, spherical centers of the spherical positioning seats are positioned in the longitudinal direction of the side frames, namely a central plane along the running direction of a vehicle, and transverse swing of the side frames is controlled by the two spherical positioning seats. Transverse swing of the rail wagon side frames is effectively controlled through the two spherical positioning seats, the positioning reliability is high, and the problem of positioning reliability of a swing device in the prior art can be solved.

Owner:株洲市求拙机械制造有限公司

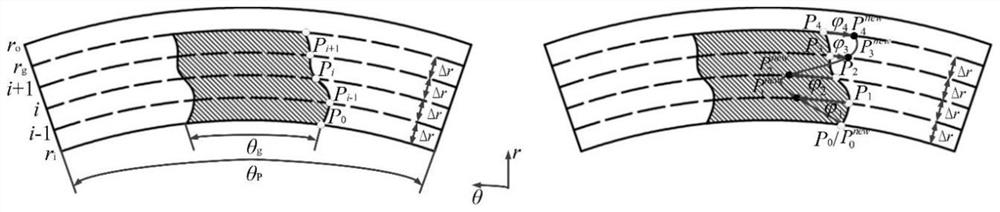

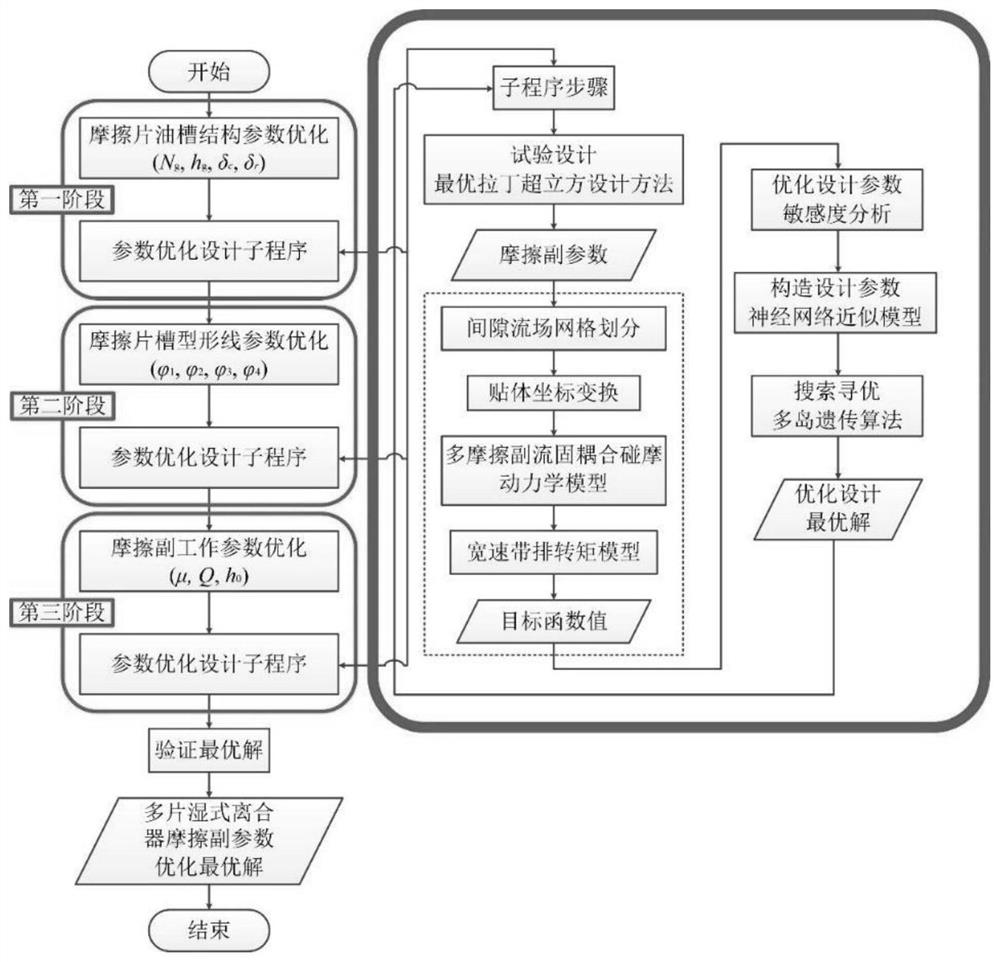

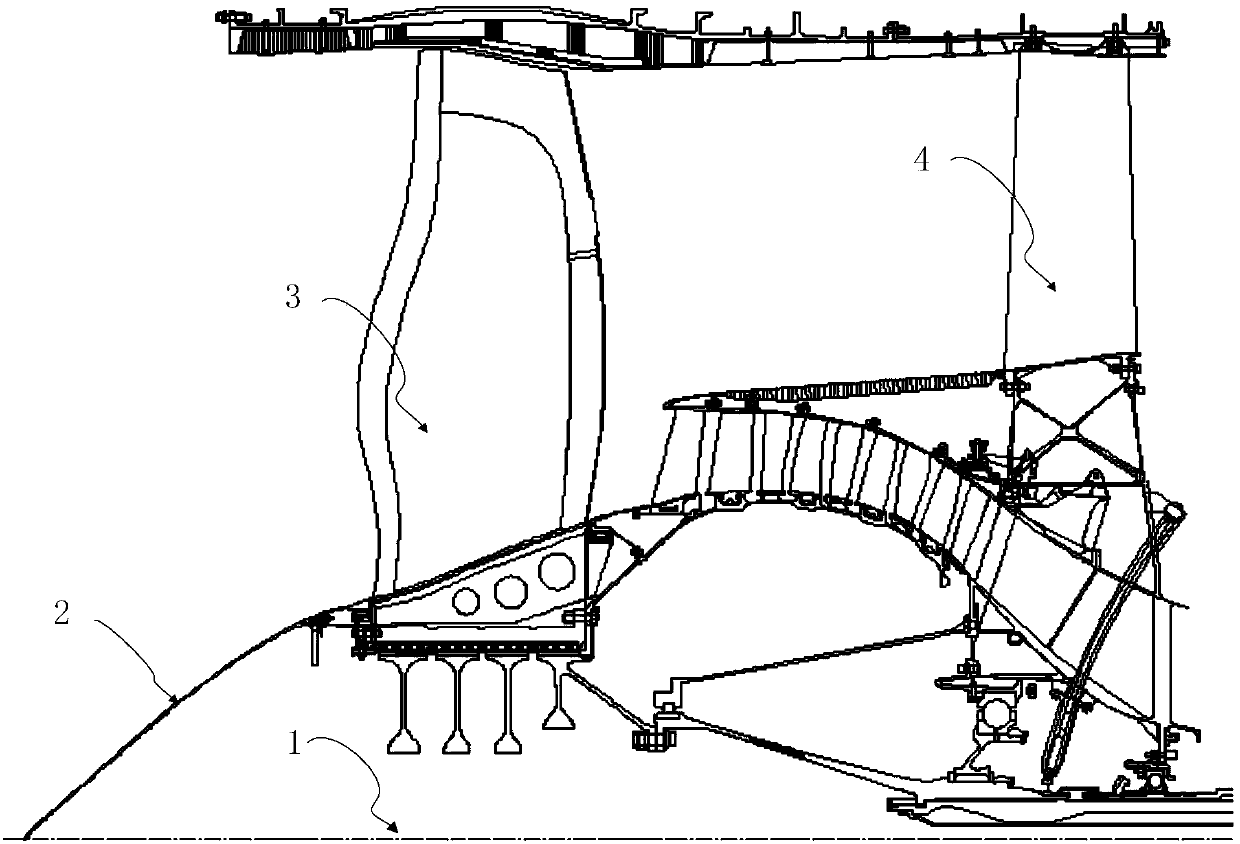

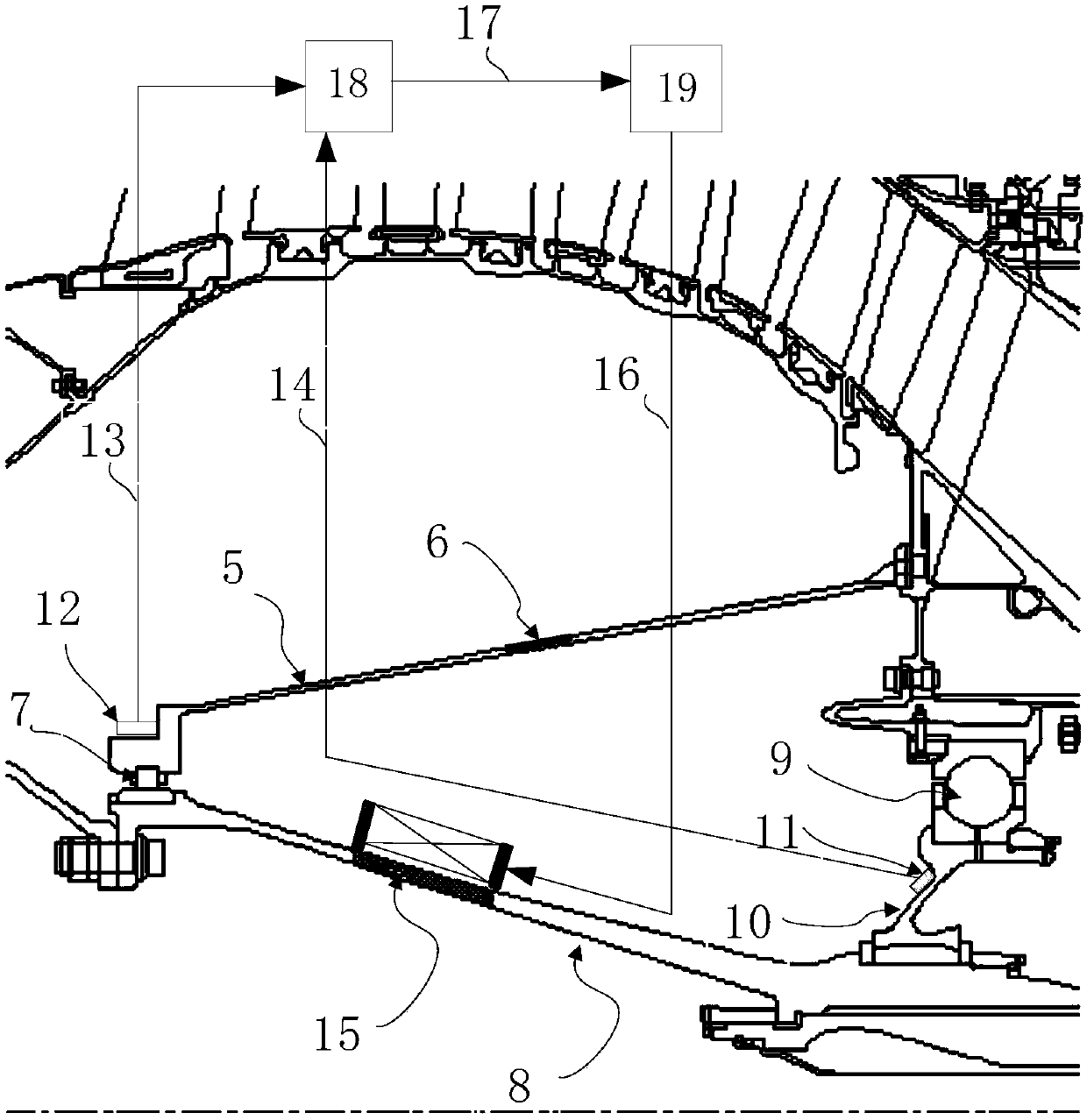

Wet clutch friction plate surface groove profile line optimization method

PendingCN114254440AReduce row torqueLow critical speedGeometric CADInternal combustion piston enginesProcess engineeringControl theory

The invention provides a wet clutch friction plate surface groove profile line optimization method. The method comprises the following steps that 1, parametric modeling is conducted on a friction plate surface oil groove profile line; 2, selecting a design variable, determining a constraint condition, and constructing a wet clutch wide-speed low-belt-exhaust optimization design model based on an optimization target; and step 3, searching and optimizing through an optimization algorithm to obtain an optimal solution of design variable optimization. And the optimized wet clutch friction plate surface structure is obtained. According to the wet clutch obtained through the method, under the no-load working condition, the critical rotating speed of the friction pair gap rotating flow field for maintaining full oil film lubrication at the low-speed stage is obviously reduced, the rub-impact frequency of the friction pair at the high-speed stage is obviously reduced, and the wide-speed-range driven discharge torque of the no-load wet clutch is obviously reduced through the method.

Owner:WUHAN UNIV OF SCI & TECH

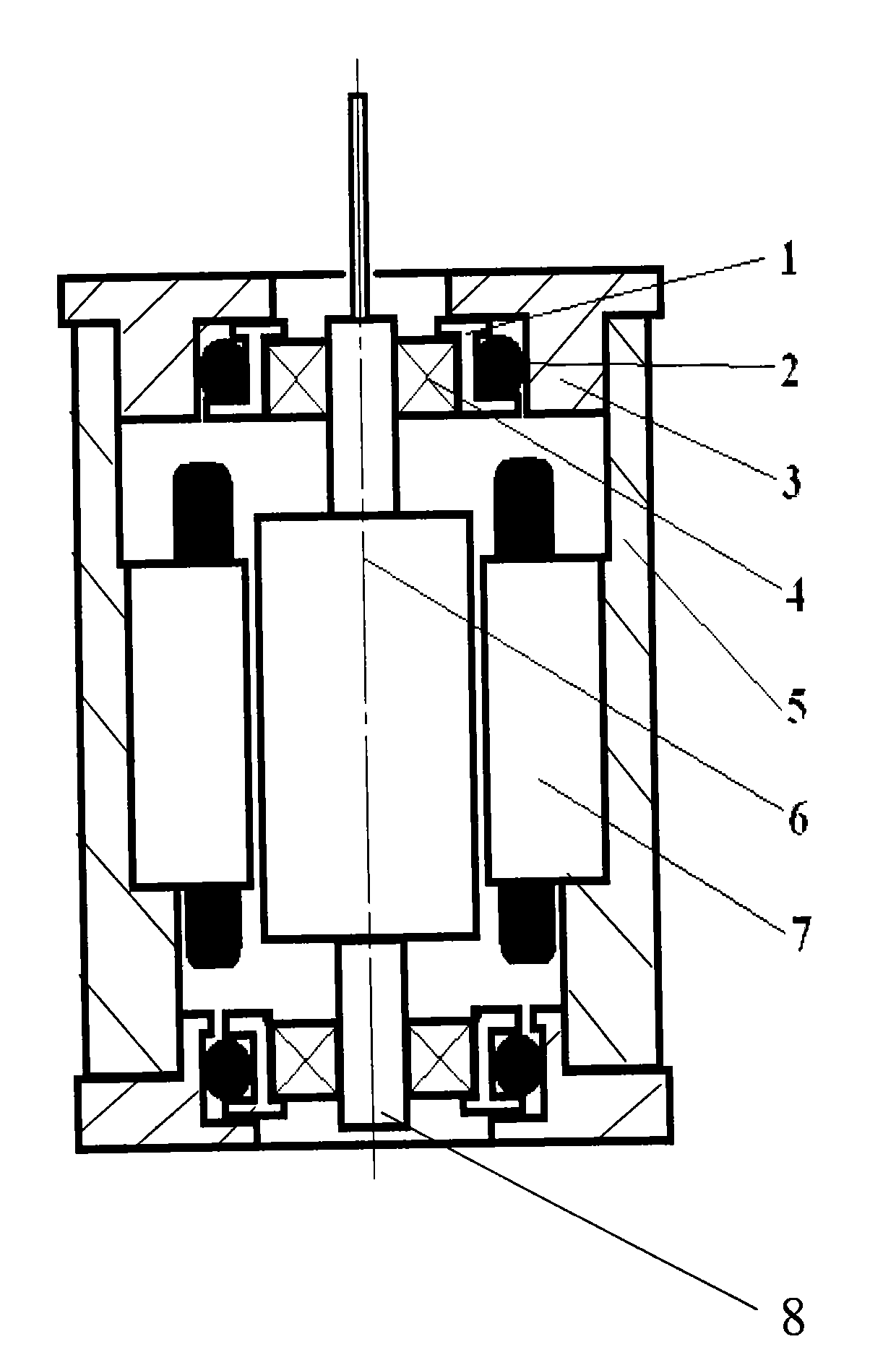

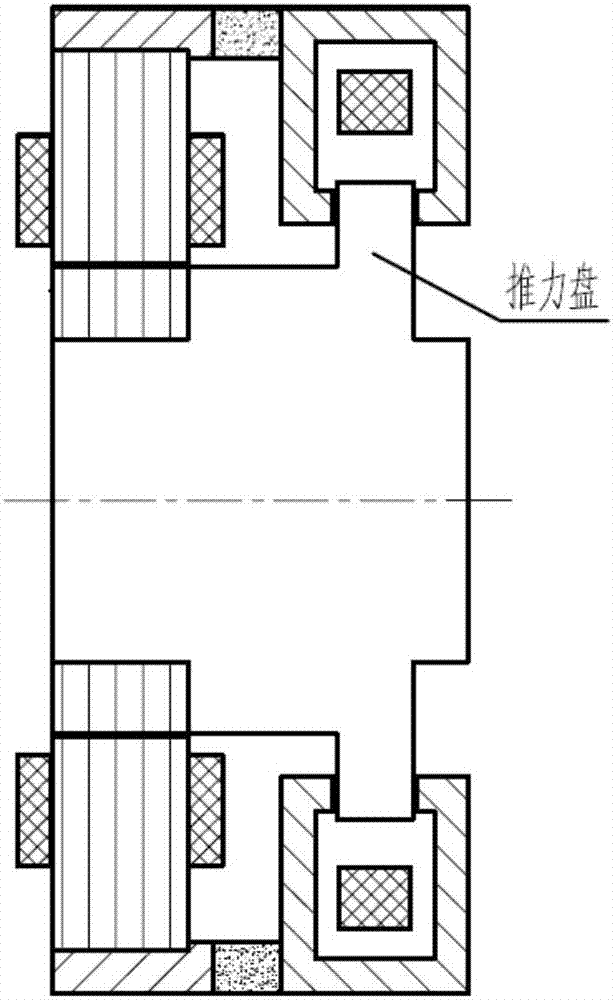

Load shedding device for fan blade out (FBO) event of aero-engine

ActiveCN110805496AReduce design difficultyIncreased cantilever lengthGas turbine plantsEngine controlAviationControl engineering

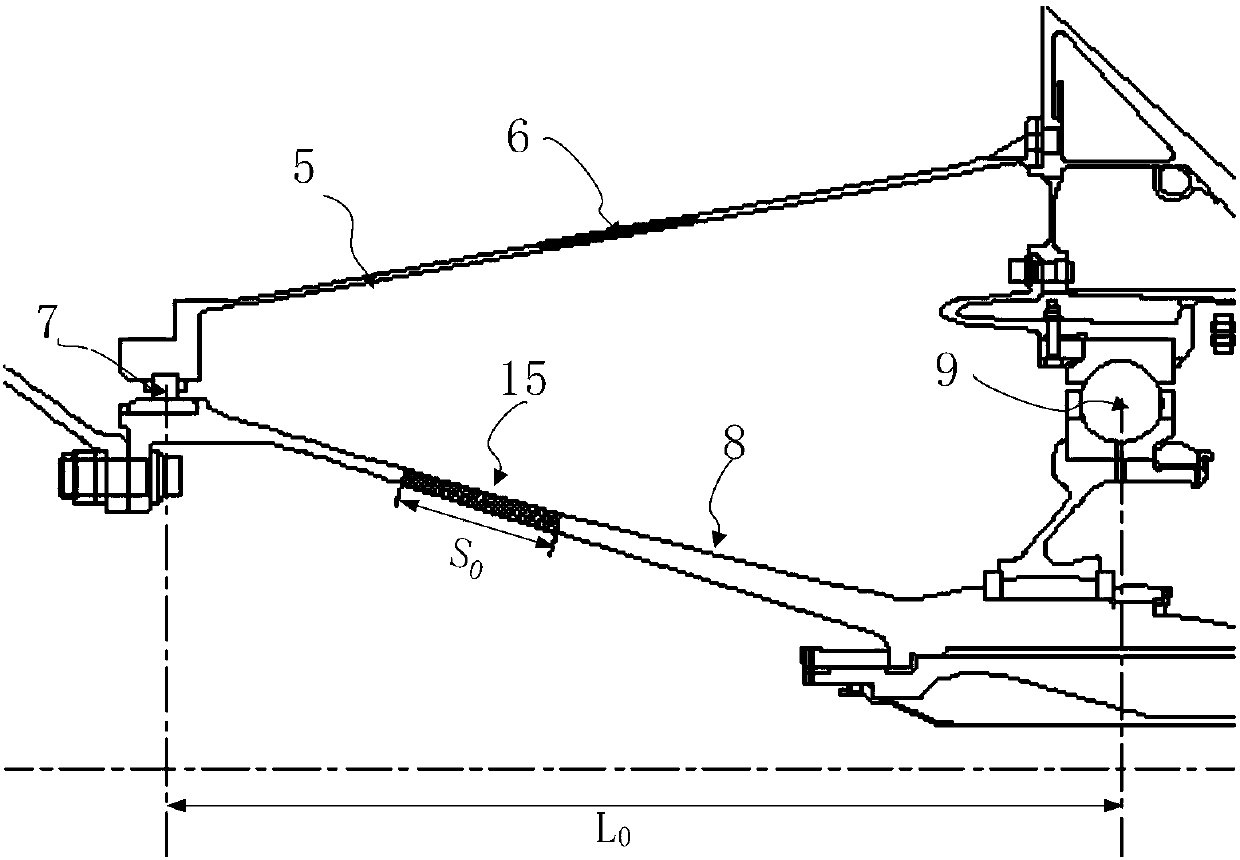

The invention provides a load shedding device and method for a fan blade out (FBO) event of an aero-engine. According to the load shedding device and method, when a fusing part of a low-pressure rotoris out of operation under the FBO load effect, the critical rotating speed of the low-pressure rotor can still be adjusted bidirectionally. The load shedding device comprises the fusing part, a fan shaft, two or more sensors and a controller, and the fusing part is arranged on a bearing seat or bearing conical wall of a first bearing; the fan shaft comprises an intelligent telescopic structure; the two or more sensors are used for monitoring dynamic response of the first bearing and a second bearing; and the controller is correlated with the sensors and the intelligent telescopic structure, wherein the sensors detect abnormal dynamic responses of the first bearing and the second bearing and transmit the detected dynamic responses to the controller, the controller sends signals to the intelligent telescopic structure, thus the intelligent telescopic structure can extend and retract in a predetermined range, and the length of the fan shaft is changed.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

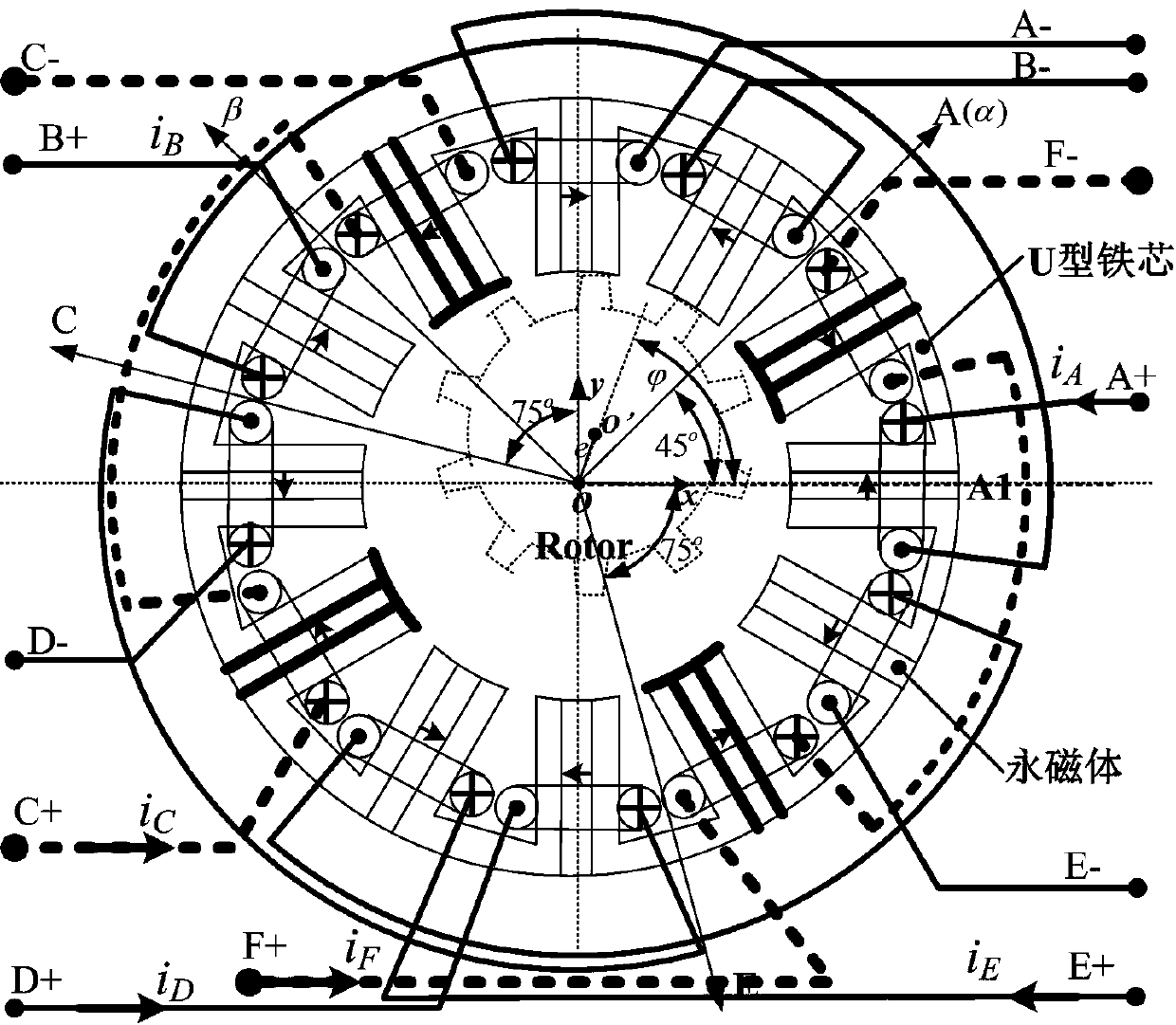

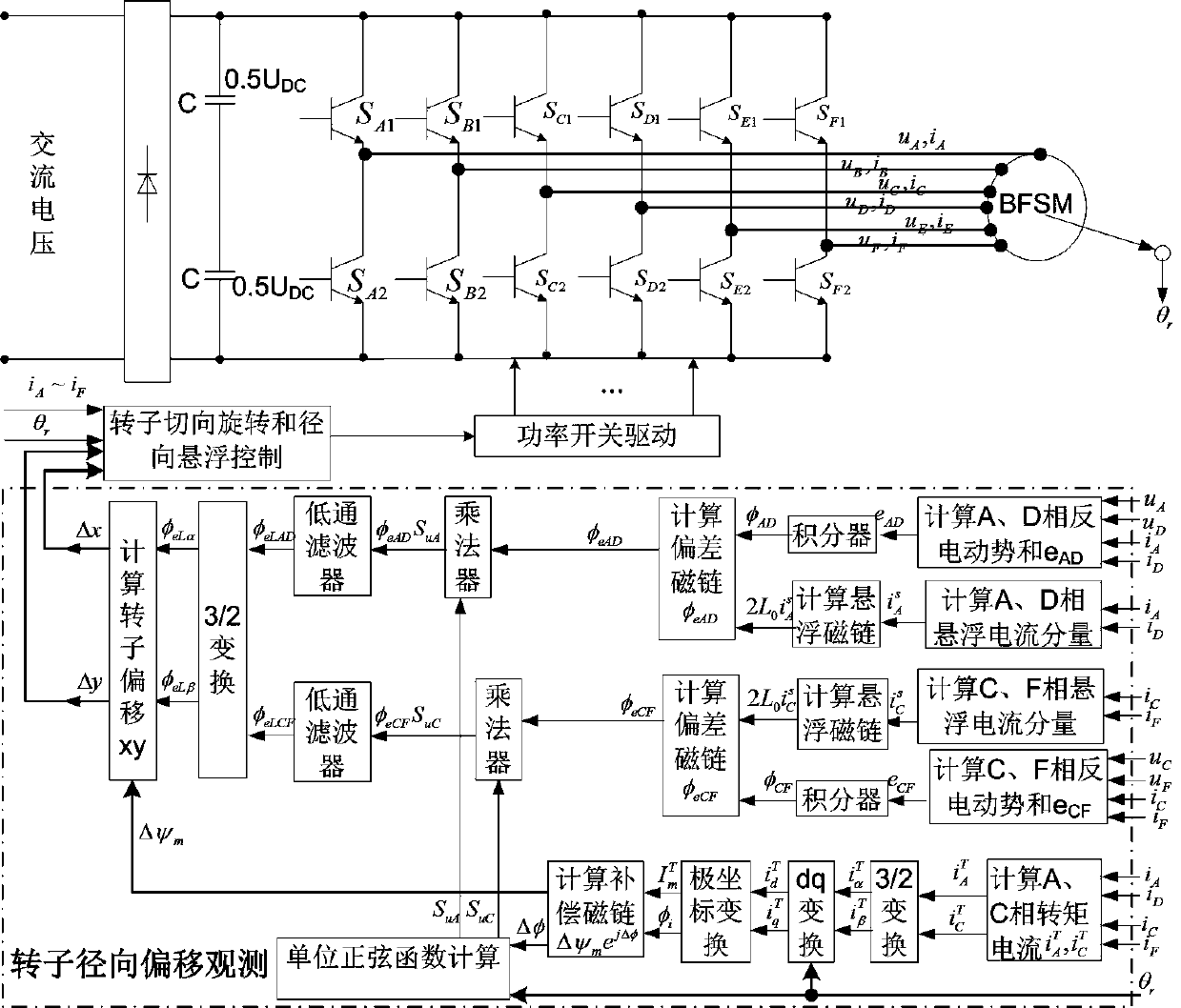

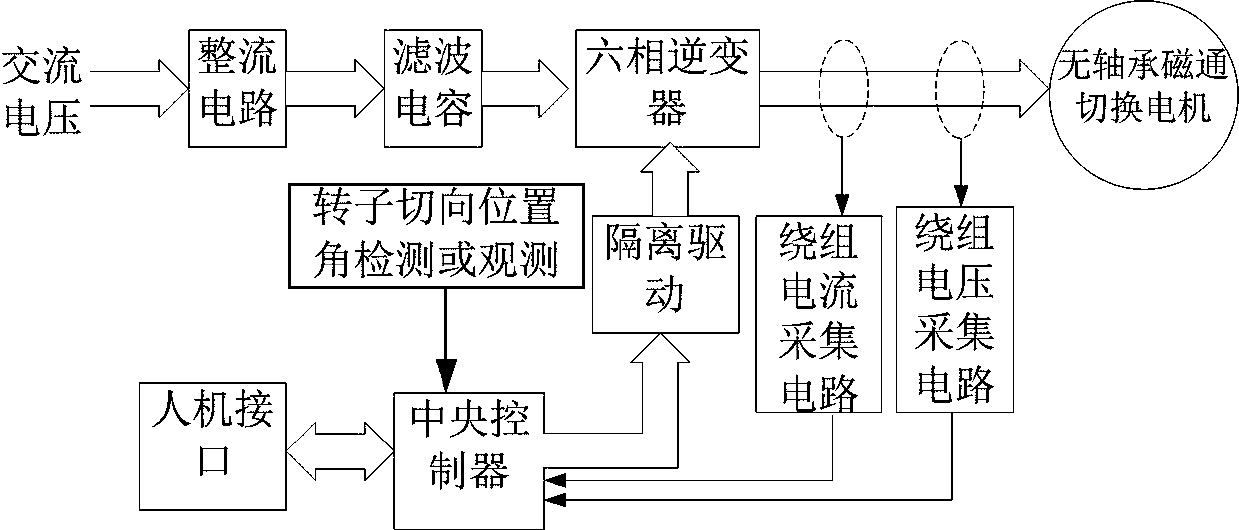

A rotor radial displacement observation method of bearingless flux switched motor based on space symmetrical flux sum of winding

ActiveCN109067280ALow costWide range of practical applicationsElectronic commutation motor controlVector control systemsNatural coordinate systemThermodynamics

The invention relates to a method for observing the radial displacement of a rotor of a bearingless flux switching motor based on the sum of space symmetrical winding flux linkage. The method comprises calculating the flux linkage of the phase winding of the bearingless flux switching motor by using the detected voltage and current of the phase winding of the bearingless flux switching motor; calculating the sum of two winding flux linkages with 180 degrees spatial symmetry; Transforming the sum of each pair of winding flux linkages with spatial symmetry in a natural coordinate system to a rectangular [alpha][beta] coordinate; according to the relationship between [alpha][beta] coordinate system flux linkage and rotor radial displacement [detal]x, [detal]y, observing the rotor radial displacement [detal]x, [detal]y is observed. The invention does not increase the manufacturing cost of the motor and the control, the radial displacement of the rotor can be observed by utilizing the winding voltage and the current of the motor and the tangential position angle of the rotor.

Owner:FUZHOU UNIV

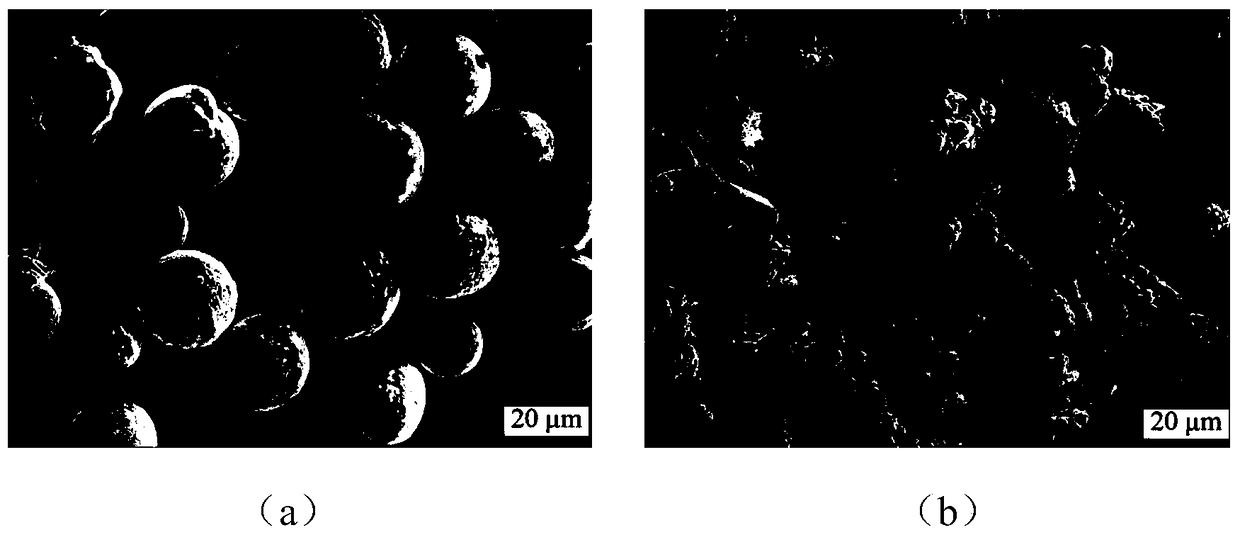

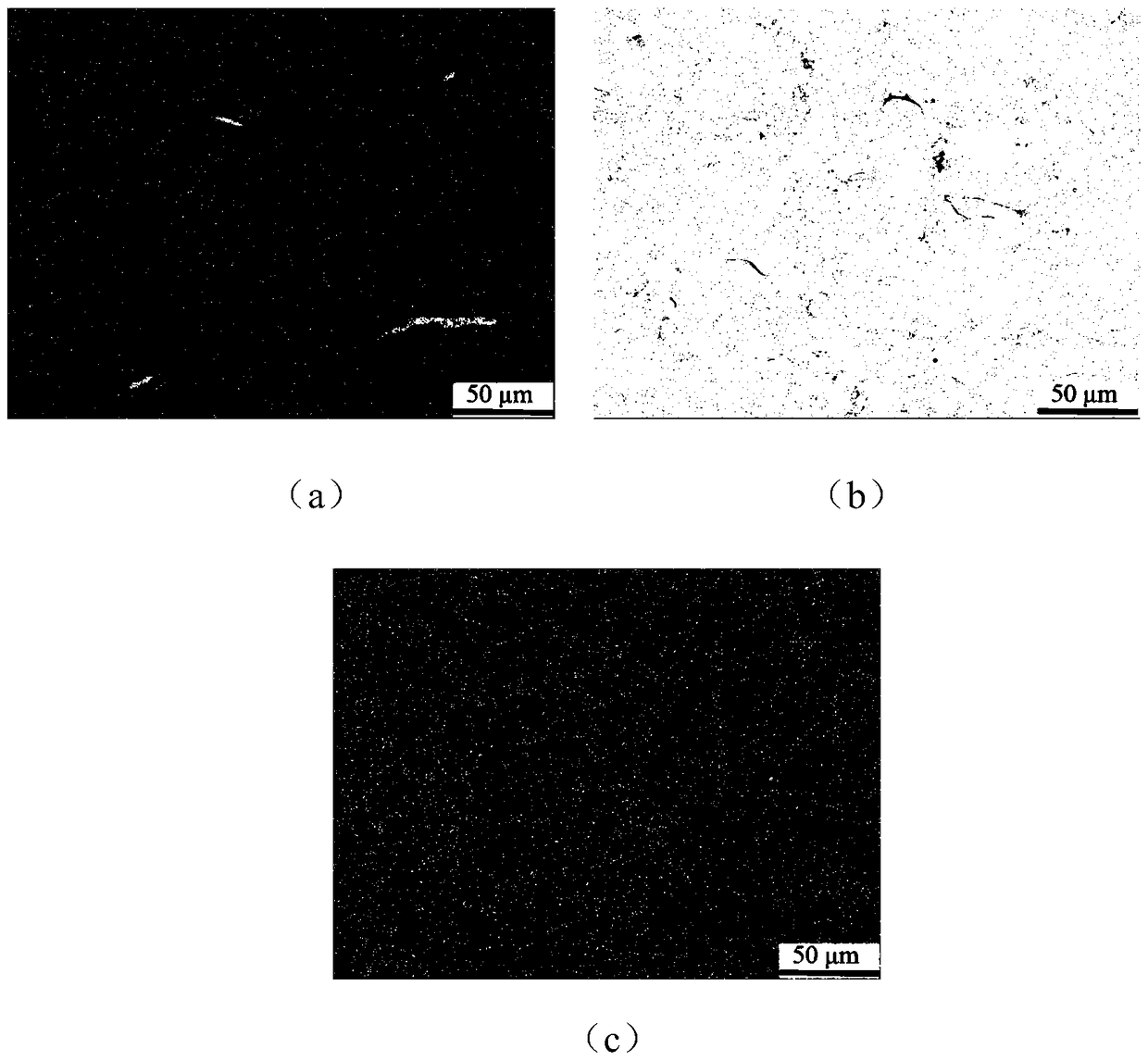

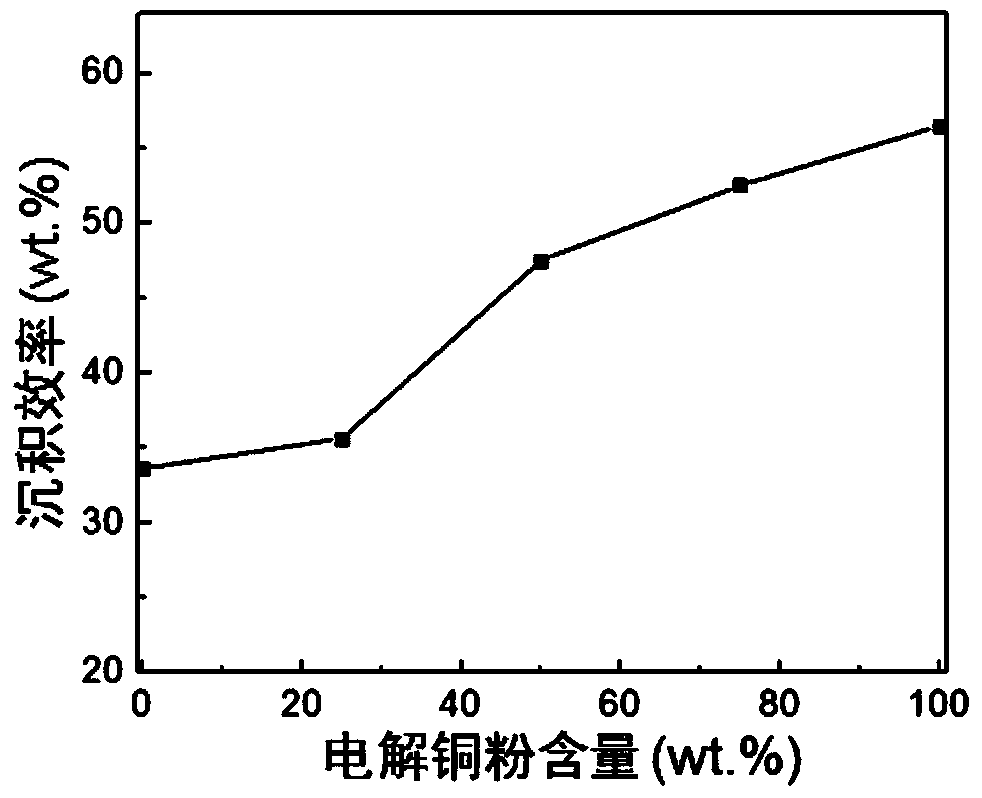

Preparation method of high-density cold sprayed metal deposition body based on mixed powder

ActiveCN105256306BFlying fastImprove deposition efficiencyPressure inorganic powder coatingHigh densityMetal powder

The invention discloses a manufacturing method for a high-density cold spraying metal sedimentary body based on mixed powder and belongs to the technical field of material engineering. The method includes the following steps that firstly, conventional atomized metal powder and ionized metal powder or hydroxyl metal powder are mechanically mixed to manufacture the mixed powder, wherein the conventional atomized metal powder and the ionized metal powder or the hydroxyl metal powder adopt the same metal components; and secondly, the surface of a base body or the surface of a workpiece to be sprayed is pretreated, the mixed powder serves as spraying powder, a coating or a blocky material is deposited through a cold spraying method. By the adoption of the method, the characteristic that the deposition efficiency of the electrolyzed / hydroxyl metal powder is high is maintained, the defects that the electrolyzed / hydroxyl metal powder is pool in fluidity and prone to blocking a spray gun are overcome, pores in the deposited electrolyzed / hydroxyl metal powder are closed through the strong tamping effect generated by impact of conventional atomized powder, and the completely-dense metal sedimentary body is obtained.

Owner:XUZHEN NEW ENERGY TECH (SHANGHAI) CO LTD

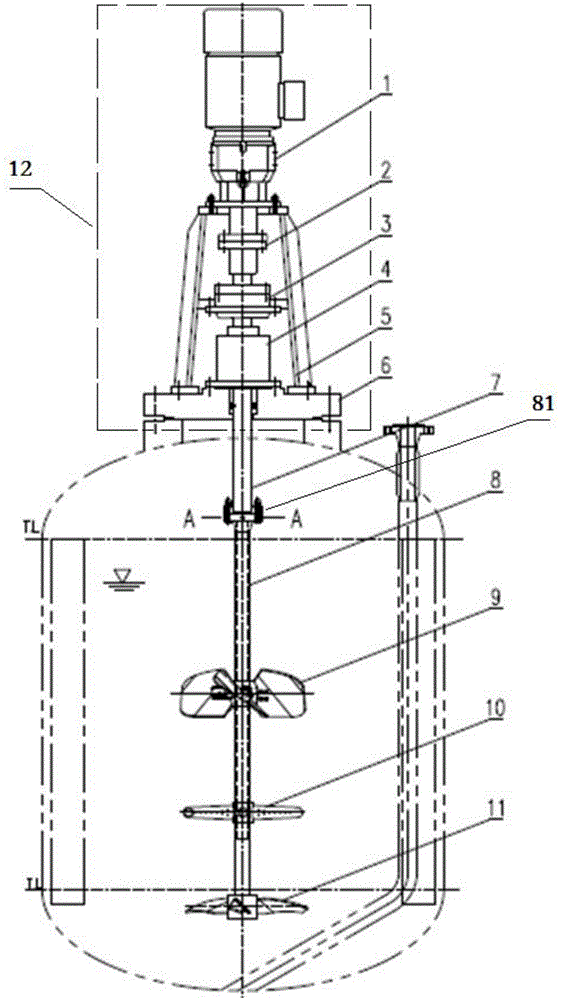

A high-efficiency self-priming stirring device

ActiveCN103406050BImprove gas utilizationDisperse evenly onceRotary stirring mixersTransportation and packagingEngineeringReaction speed

The invention provides a self-suction type efficient stirring device. The self-suction type efficient stirring device consists of necessary stirring driving parts such as a speed reducing motor, a hollow stirring shaft, an upper auxiliary stirring paddle, a self-suction type stirring paddle and a lower auxiliary stirring paddle, wherein the self-suction type stirring paddle is a reducing pipe type stirrer; the transverse radius of a stirring pipe is gradually decreased outwards along the circumferential direction; the stirring pipe is of an all-directional porous structure; gas outlets are formed in an outlet and the back liquid level side of the stirring pipe; the upper auxiliary stirring paddle and the lower auxiliary stirring paddle are different types of axial flow type stirring paddles. The self-suction type efficient stirring device has the advantages that the gas suction critical rotation speed is low, the gas suction speed rate is high, the bubble size is small; gas is uniformly mixed with liquid and solid phases; the contact area between heterogeneous phases is large; mass transfer coefficients are high; a solid-phase medium can be effectively prevented from being settled; the reaction speed rate and the yield are increased.

Owner:上海森永工程设备股份有限公司

A non-thrust disc radial and axial integrated permanent magnet bias magnetic bearing

ActiveCN106594072BIncrease the outer diameterIncrease surface speedBearingsMagnetic bearingMagnetic poles

Owner:BEIHANG UNIV

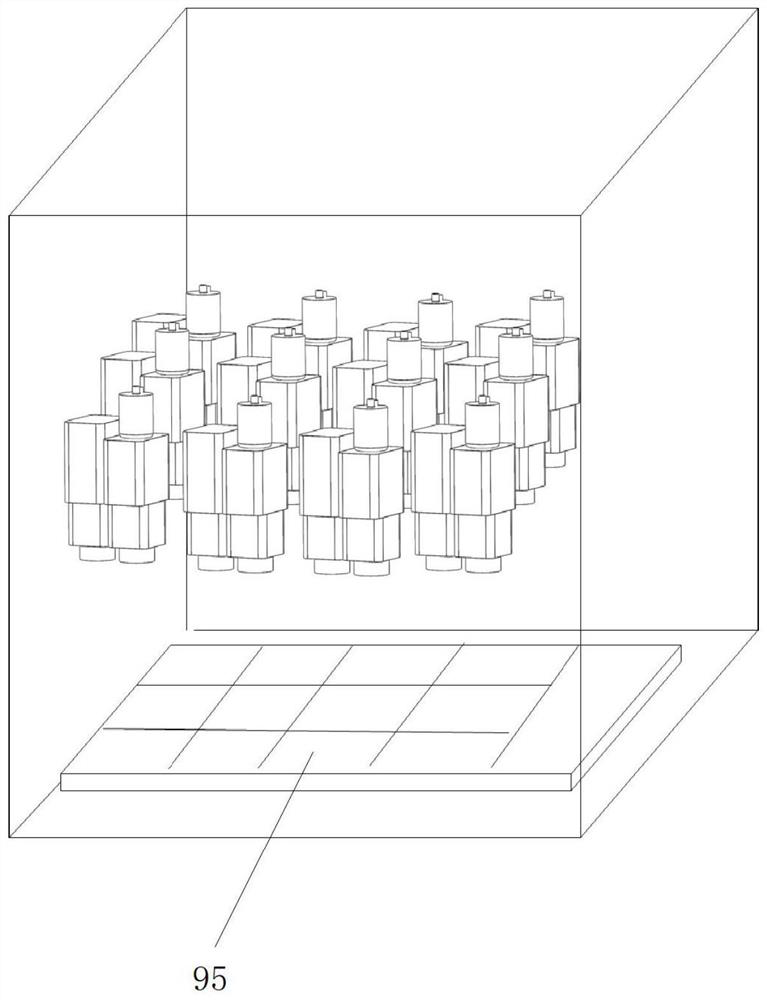

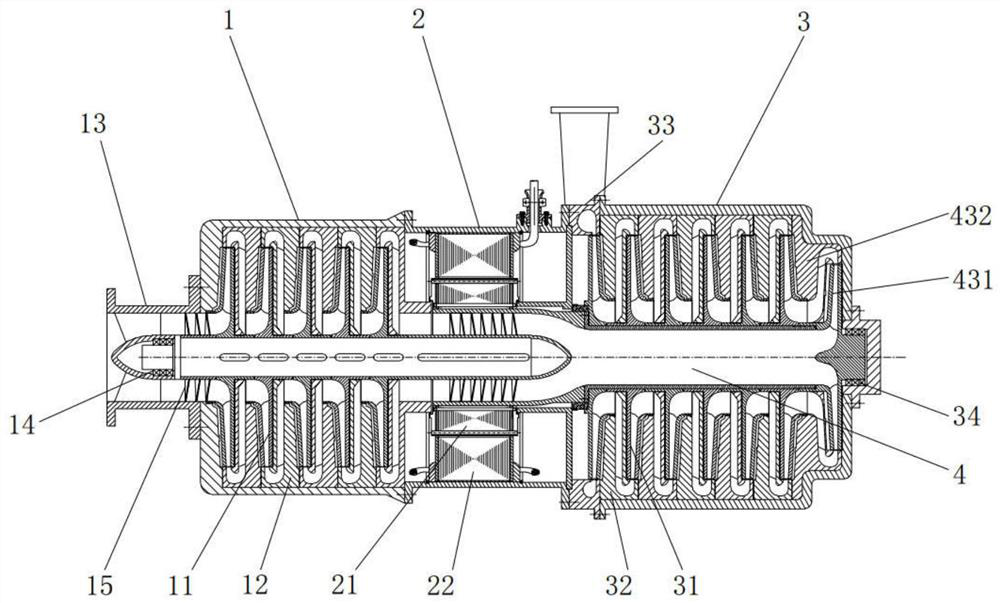

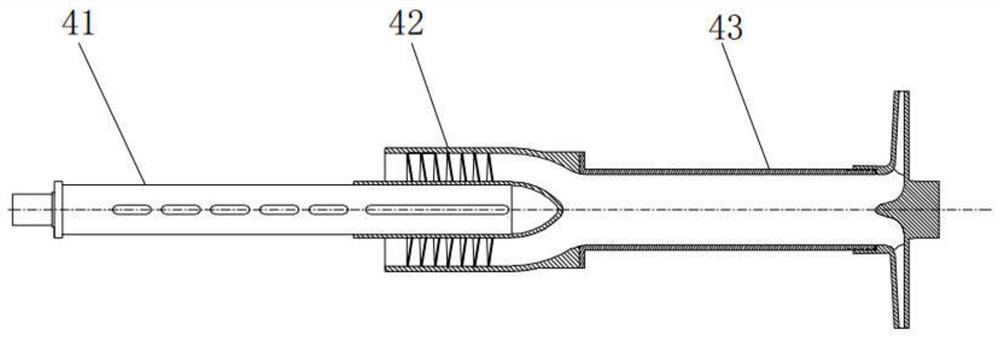

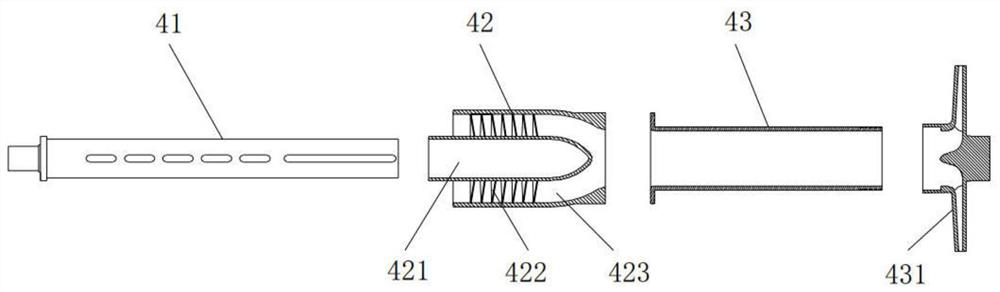

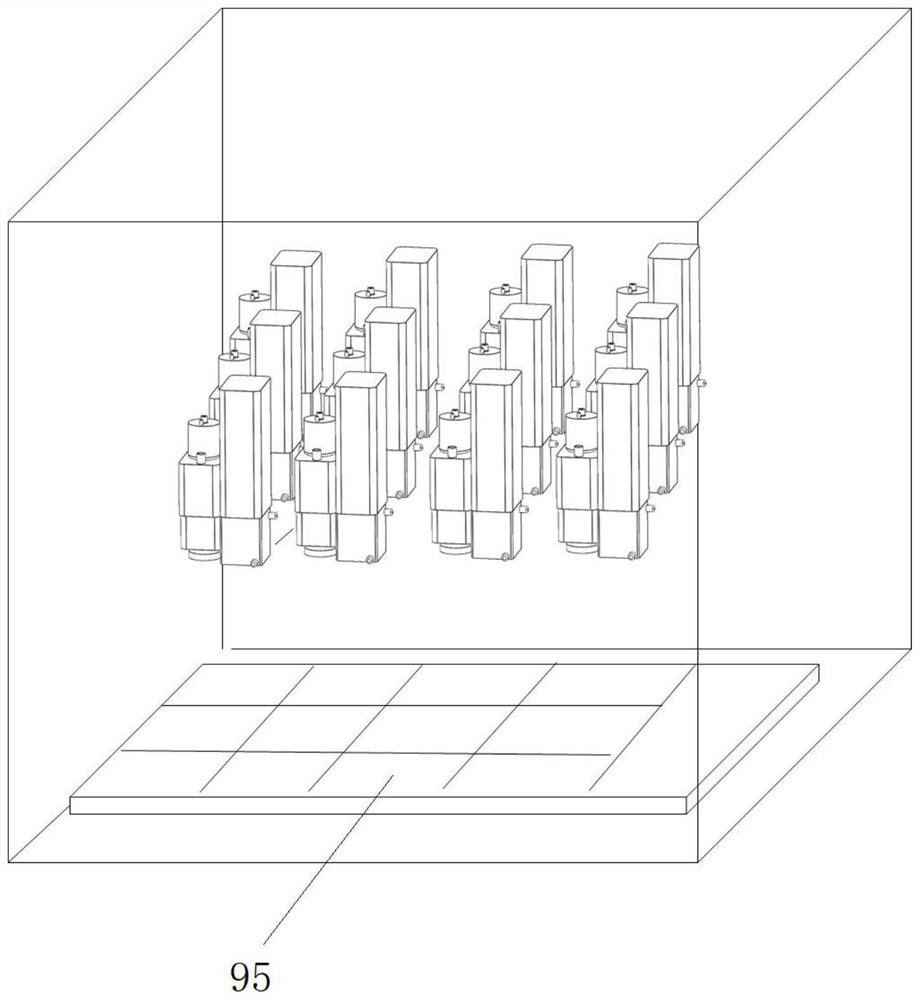

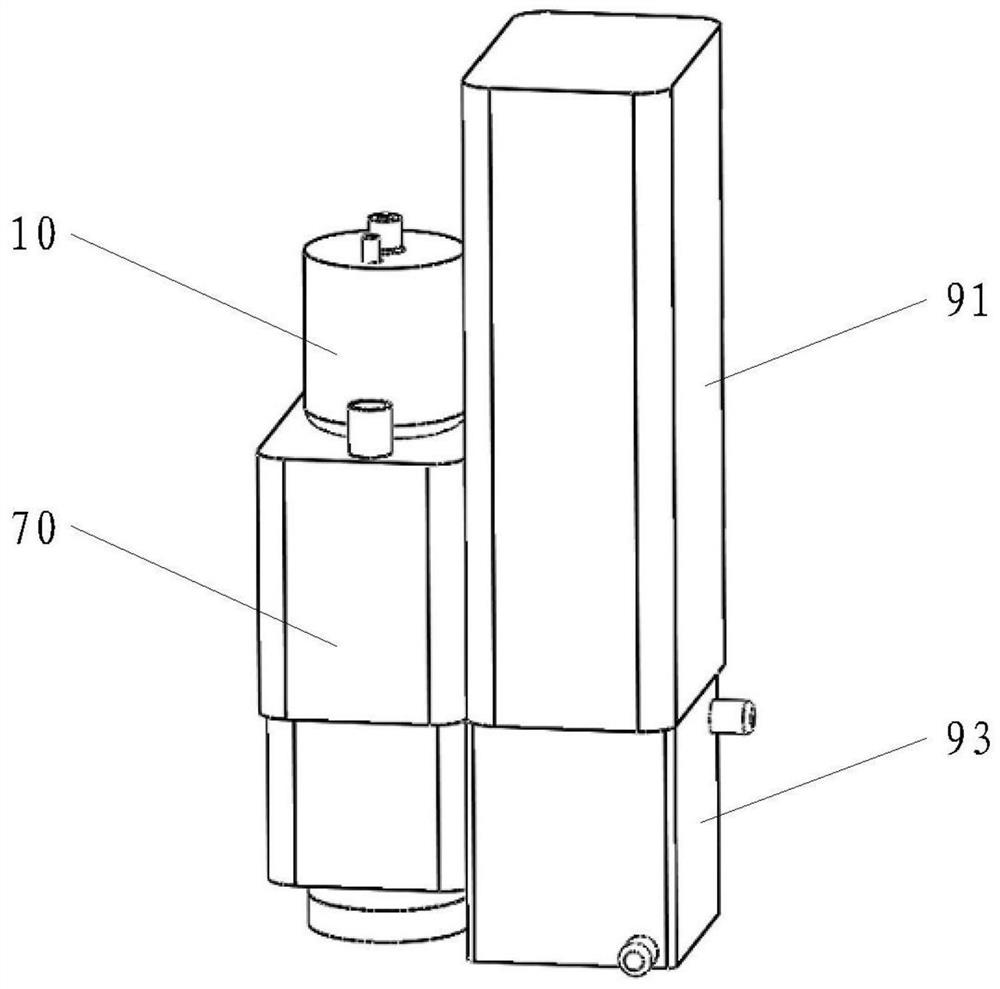

Multi-stage low-temperature centrifugal pump provided with built-in motor

ActiveCN112253492AImprove cooling effectImprove sealingPump componentsCooling/ventillation arrangementElectric machineryEngineering

The invention provides a multi-stage low-temperature centrifugal pump provided with a built-in motor. The multi-stage low-temperature centrifugal pump comprises a front shell, a motor shell and a backshell; a forward impeller and a forward guide vane are arranged in the front shell; the motor is arranged in the motor shell; a reverse impeller and a reverse guide vane are arranged in the back shell; the motor shell is located between the front shell and the back shell; an inlet horn pipe is arranged at the end of the front shell; an outlet volute is arranged between the back shell and the motor shell; the forward impeller, a motor rotor and the reverse impeller are connected in series through a rotating shaft assembly; the motor rotor is directly connected with the rotating shaft assemblyfrom the middle to drive the rotating shaft assembly to rotate so as to drive the forward impeller, the reverse impeller and an inducer to rotate. A low-temperature liquid enters a pump body from theinlet horn pipe, is pressurized by the forward impeller and the reverse impeller and is sprayed out of the outlet volute. According to the pump, the motor is arranged internally and is cooled throughthe low-temperature liquid, the overall sealing performance is good, the size is small, the weight is light, the structure is compact, and the pump is particularly applicable to conveying of low-temperature volatile liquids.

Owner:JIANGSU UNIV

Active load reducing device for sudden load of aero-engine tester

ActiveCN110320044ALow costGood repeatabilityGas-turbine engine testingJet-propulsion engine testingSelf adaptiveSafety design

The invention discloses an active load reducing device for a sudden load of an aero-engine tester. According to the device, a pneumatic chuck is fixed on the upper surface of a chuck support; a working sleeve at one end of a variable stiffness elastic support is arranged in the inner surface of the pneumatic chuck; a flange at the other end of the variable stiffness elastic support is connected with a simulation tester; a three-jaw chuck at one end face of the pneumatic chuck is in a clamping state when the three-jaw chuck is powered on and is in a release state when the three-jaw chuck is powered off; and the variable rigidity elastic support is clamped by adjusting the distance between chuck jaws. The device disclosed by the invention has the beneficial effects that by utilizing the variable stiffness elastic support, the support stiffness is adaptively changed and the critical rotation speed of a rotor system is significantly changed, thereby reducing an impact load of a blade flying off the rotor system and providing experimental support for the safety design of the rotor system when a sudden imbalance occurs; and the device has the characteristics of low cost, good repeatability and implementation convenience.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

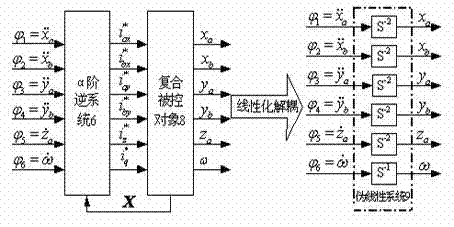

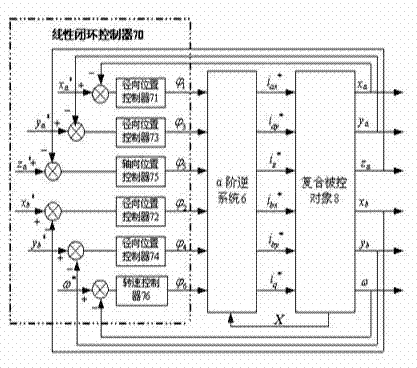

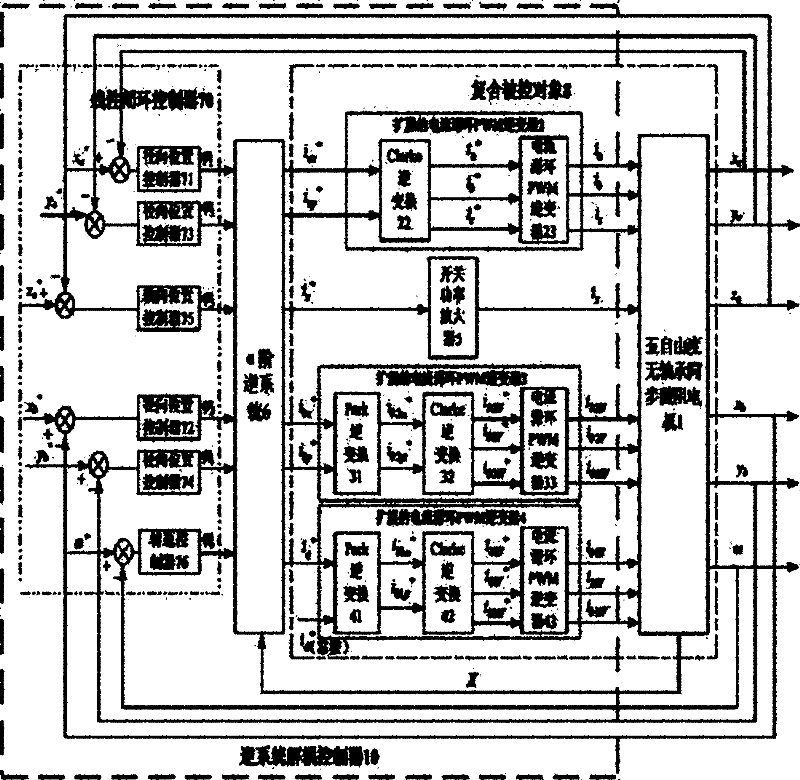

Five-DOF (freedom of degree) bearingless synchronous reluctance motor decoupling controller and construction method thereof

ActiveCN102136822BSimple designOvercoming the Difficulty of Obtaining the Analytic InverseElectronic commutation motor controlAC motor controlSynchronous reluctance motorIntegrator

The invention discloses a five-DOF (freedom of degree) bearingless synchronous reluctance motor decoupling controller and a construction method thereof. Three expanded current hysteresis loop PWM (pulse width modulation) inverters, a switch power amplifier and a five-DOF bearingless synchronous reluctance motor form a compound controlled object; five support vector machine second-order systems, one support vector machine first-order system and eleven integrators are utilized to construct a support vector machine alpha-order inverse system and offline training is carried out, the support vector machine alpha-order inverse system is placed in front of the compound controlled object to form a pseudo linear system, and the pseudo linear system is equivalent to five position second-order integration subsystems and one position first-order integration subsystem; and five position controllers and one rotating speed controller are respectively designed for the six integration subsystems, thus a linear closed-loop controller is formed. In the invention, a least square support vector machine is adopted to approach an alpha-order inverse model of a nonlinear system, the dynamic decoupling control among all the controlled variables is realized, and the control performance of the overall system is effectively improved.

Owner:江阴智产汇知识产权运营有限公司

Vacuum electric scanning supersonic spray deposition laser additive manufacturing device

ActiveCN112776324ASimplify the sintering processPrevent splashIncreasing energy efficiencyManufacturing environment conditioningParticle beamLaser additive manufacturing

The invention discloses a vacuum electric scanning supersonic spray deposition laser additive manufacturing device. The vacuum electric scanning supersonic spray deposition laser additive manufacturing device comprises a forming workbench and a laser spray additive device installed above the workbench, the laser spray additive device comprises a cold spray head, a laser generator and a laser beam control device, the spraying direction of the cold spray head can be adjusted so that sprayed powder particle beams can be scanned on the workbench based on the shape of a part, the laser beam control device is installed at an emitting opening of the laser generator and used for controlling the emitting direction of laser beams, the laser beams and the powder particle beams sprayed by the cold spray head are converged at one point, and the surface of the base body and the powder particles are heated to be in a molten state. According to the device, the part is formed by directionally spraying powder and heating and sintering in real time, layer-by-layer powder laying and sintering are not needed, the forming efficiency is greatly improved, the powder cannot be wasted, the forming cost is reduced, the forming quality consistency is good, the forming quality is improved, the part sintering procedure is simplified, and the sintering efficiency is improved.

Owner:AIR FORCE UNIV PLA +2

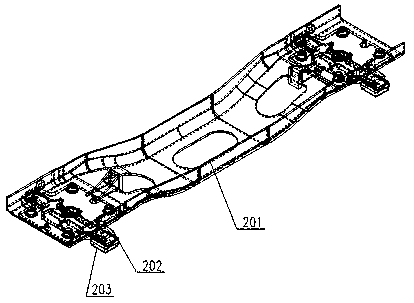

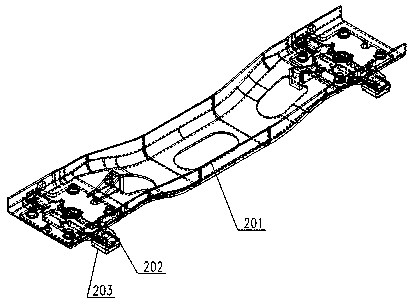

Wheel-rail low-power bogie with transverse swing control device

InactiveCN111301465AImprove reliabilityReduce operating costsBogiesBogie-underframe connectionsRolling-element bearingEngineering

A wheel-rail low-power-effect bogie with a transverse swing control device comprises a side frame transverse swing control device, a wheel set, a rolling bearing device, a bearing saddle, a splayed rubber elastic pad, a side frame assembly, a swing bolster assembly, a central suspension damping device, a normally-contacted elastic side bearing and a foundation braking device. The side frame transverse swing control device comprises side frames, a spring supporting plate, a spring bearing seat, a spherical wear-resistant gasket and spherical positioning seats; and the two spherical positioningseats are respectively arranged on the mounting surfaces of lower chord inner cavities of the central square frames of the two parallel side frames and are transversely and symmetrically arranged along the side frames, and the centers of spheres of the spherical positioning seats are positioned in the longitudinal directions of the side frames, namely the central plane along the running directionof the vehicle. Transverse swing of the rail wagon side frames is effectively controlled through the two spherical positioning seats, the positioning reliability is high, and the problem of positioning reliability of a swing device in the prior art can be solved.

Owner:株洲市求拙机械制造有限公司

Electroplastic auxiliary cold spraying device and coating preparation method

PendingCN113737169AProne to plastic deformationImprove plastic deformation abilityPressure inorganic powder coatingPorosityGas heater

The invention discloses an electroplastic auxiliary cold spraying device and a coating preparation method. The electroplastic auxiliary cold spraying device and the coating preparation method are suitable for a hard base body where powder is difficult to deposit and conductive powder which is prone to crack after deposition, a pulse power supply introduces pulse current into the base body through a positive electrode and a negative electrode, and air flow in an air storage tank is output in two ways after passing through an air valve, one air flow flows into a gas heater to be heated, the other air flow carries spraying particles after passing through an output port of a powder feeder, the two air flows impact the base body after being accelerated by a Laval nozzle, and a sample table drives the base body to circularly move according to a set spraying track, and a coating is formed on the base body. According to the electroplastic auxiliary cold spraying device and the coating preparation method, the electrodes are placed at the two ends of the base body, the pulse current is introduced, and softening of a base body material is stimulated, so that mechanical combination between the coating and the base body is facilitated, and therefore the combination strength of the coating and the base body is improved; and after the bottom layer coating is combined with the base body, pulse current is introduced into the bottom layer coating, so that during subsequent particle impact, combination of the bottom layer coating and the base body is tamped, and the compact coating low in porosity is formed.

Owner:JIANGSU UNIV

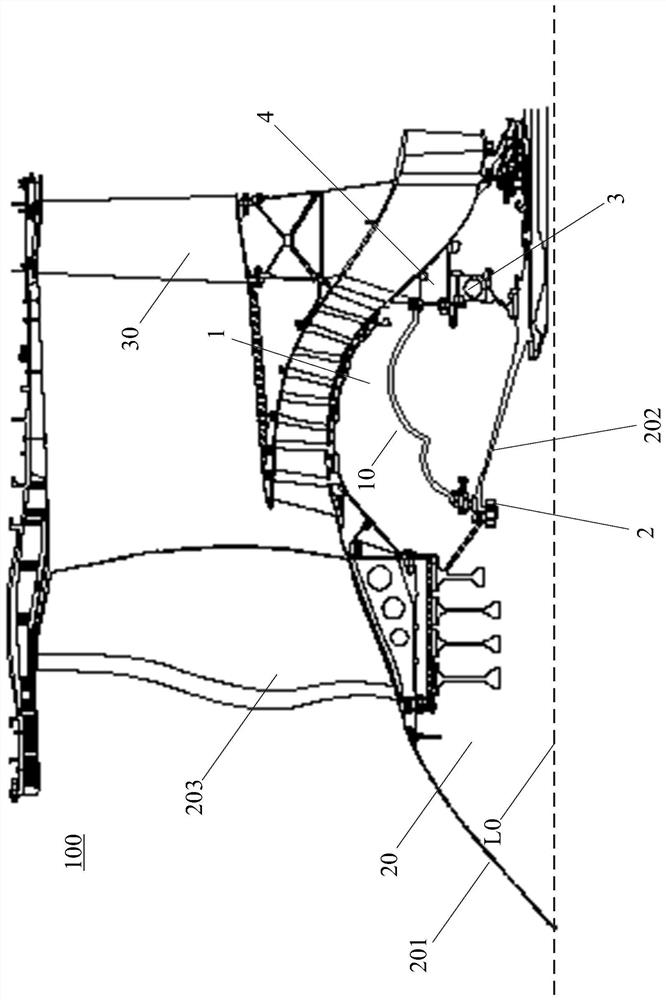

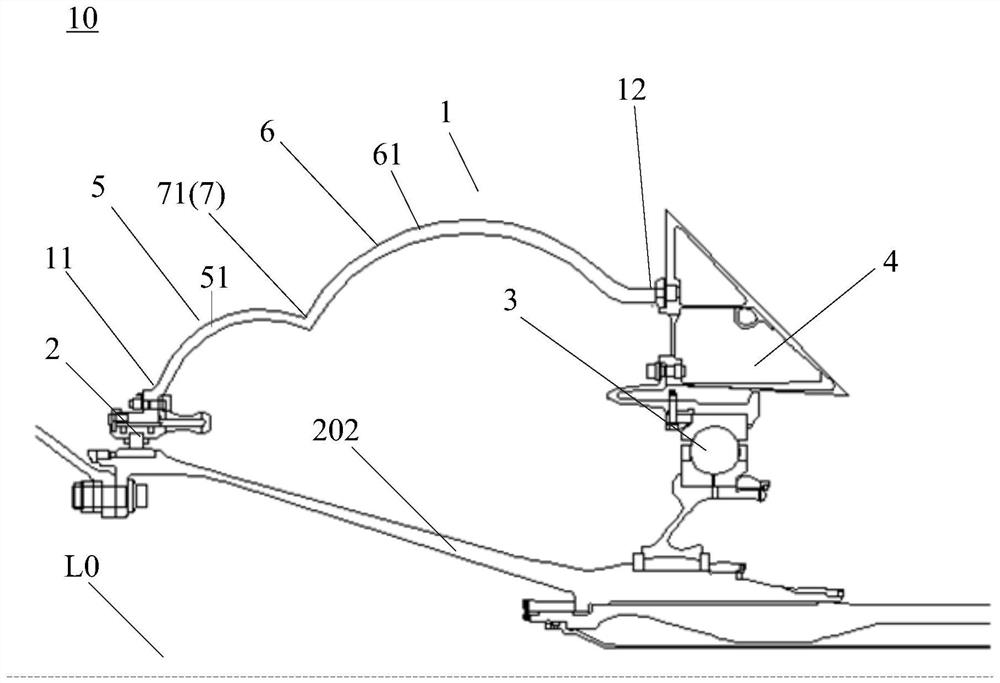

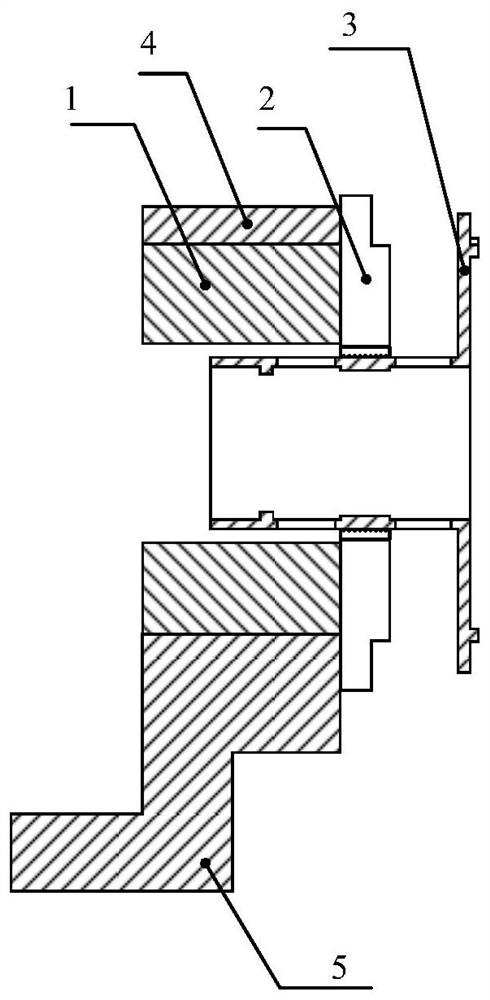

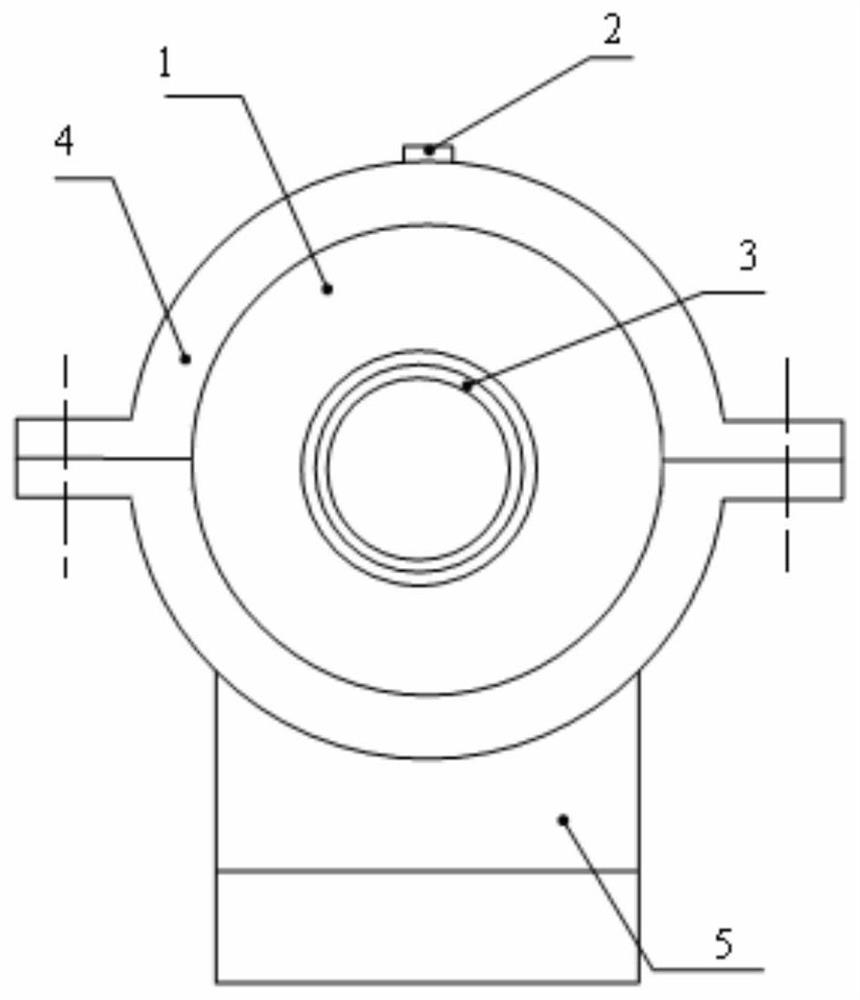

Fan rotor support system and its fan bearing support cone wall

ActiveCN111980959BLow critical speedReduce loadPump componentsPumpsSupporting systemClassical mechanics

The invention provides a fan bearing supporting cone wall, which is a hollow rotary thin-walled part with a large end and a small end. The stress concentration part is formed at the position where the shrinkage turns to gradual expansion, and the stress concentration part is set as a fuse part to deal with the FBO event. The present invention also provides a fan rotor support system comprising the fan bearing support cone wall. The fan bearing support cone wall described above can provide an alternative to this fusing design using thinned sections.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

Active load reduction device for aero-engine experimental device after sudden load

ActiveCN110320044BTo achieve the purpose of load reductionSimple structureGas-turbine engine testingJet-propulsion engine testingControl engineeringControl theory

The invention discloses an active load reducing device for a sudden load of an aero-engine tester. According to the device, a pneumatic chuck is fixed on the upper surface of a chuck support; a working sleeve at one end of a variable stiffness elastic support is arranged in the inner surface of the pneumatic chuck; a flange at the other end of the variable stiffness elastic support is connected with a simulation tester; a three-jaw chuck at one end face of the pneumatic chuck is in a clamping state when the three-jaw chuck is powered on and is in a release state when the three-jaw chuck is powered off; and the variable rigidity elastic support is clamped by adjusting the distance between chuck jaws. The device disclosed by the invention has the beneficial effects that by utilizing the variable stiffness elastic support, the support stiffness is adaptively changed and the critical rotation speed of a rotor system is significantly changed, thereby reducing an impact load of a blade flying off the rotor system and providing experimental support for the safety design of the rotor system when a sudden imbalance occurs; and the device has the characteristics of low cost, good repeatability and implementation convenience.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

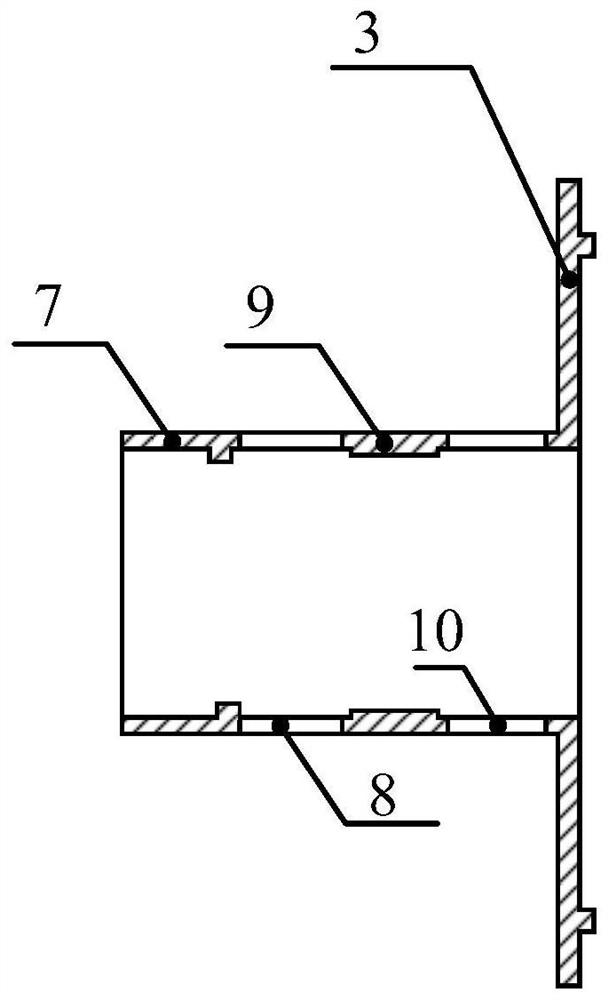

Inverse system decoupling controller of five-degree-of-freedom bearingless synchronous reluctance motor

InactiveCN102013870BShorten the axial lengthSimple structureElectronic commutation motor controlVector control systemsHysteresisMagnetic bearing

The invention discloses an inverse system decoupling controller of a five-degree-of-freedom bearingless synchronous reluctance motor. In the inverse system decoupling controller, a linear closed-loop controller, an alpha-th-order inverse system and a composite controlled object are connected in series successively; the composite controlled object consists of three extended hysteresis current controlled PWM inverters, a switching power amplifier and the five-degree-of-freedom bearingless synchronous reluctance motor; the alpha-th-order inverse system and the composite controlled object constitute a pseudo linear system; the five-degree-of-freedom bearingless synchronous reluctance motor consists of a three-degree-of-freedom active magnetic bearing and a two-degree-of-freedom bearingless synchronous reluctance motor which share one rotor; the rotor is provided with a plurality of eddy-current sensors; and the linear closed-loop controller consists of a rotary speed controller, four radial position controllers and an axial position controller. The controller disclosed by the invention has compact structure; and by adopting the invention, the radial suspension force, axial suspension force, motor radial suspension force and electromagnetic torque of the magnetic bearing can be controlled independently and the control performance of the entire system can be effectively increased.

Owner:江阴智产汇知识产权运营有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com