Preparation method of cobalt-based anti-cavitation coating of plastic deposition based on work hardening

A work-hardening and anti-cavitation technology, applied in the direction of pressure inorganic powder coating, etc., can solve the problem of poor cavitation resistance of the coating, poor bonding between the alloy sheet and the substrate, and poor fit between the welding layer and the blade shape, etc. problems, to achieve excellent anti-cavitation performance, improve effective deposition efficiency, and improve the degree of plastic deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

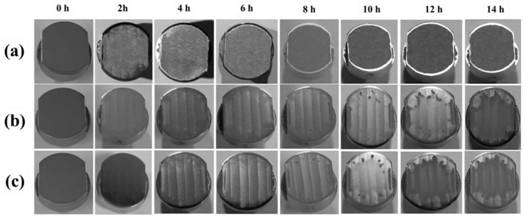

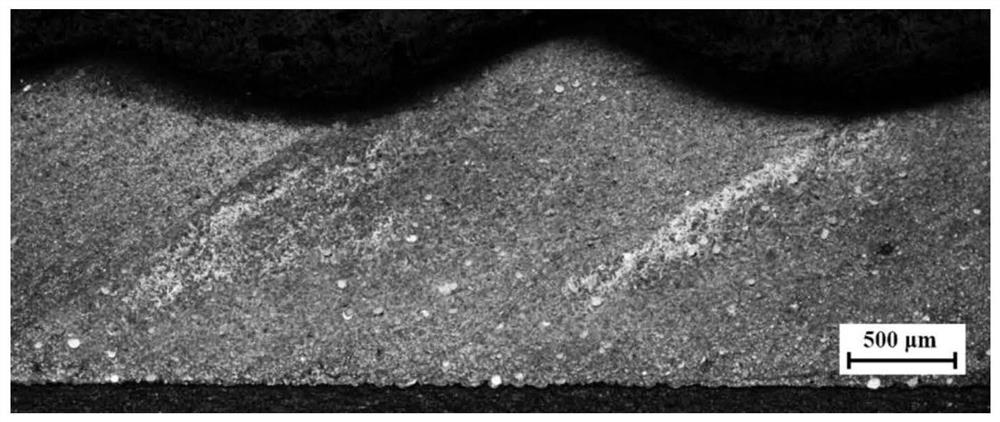

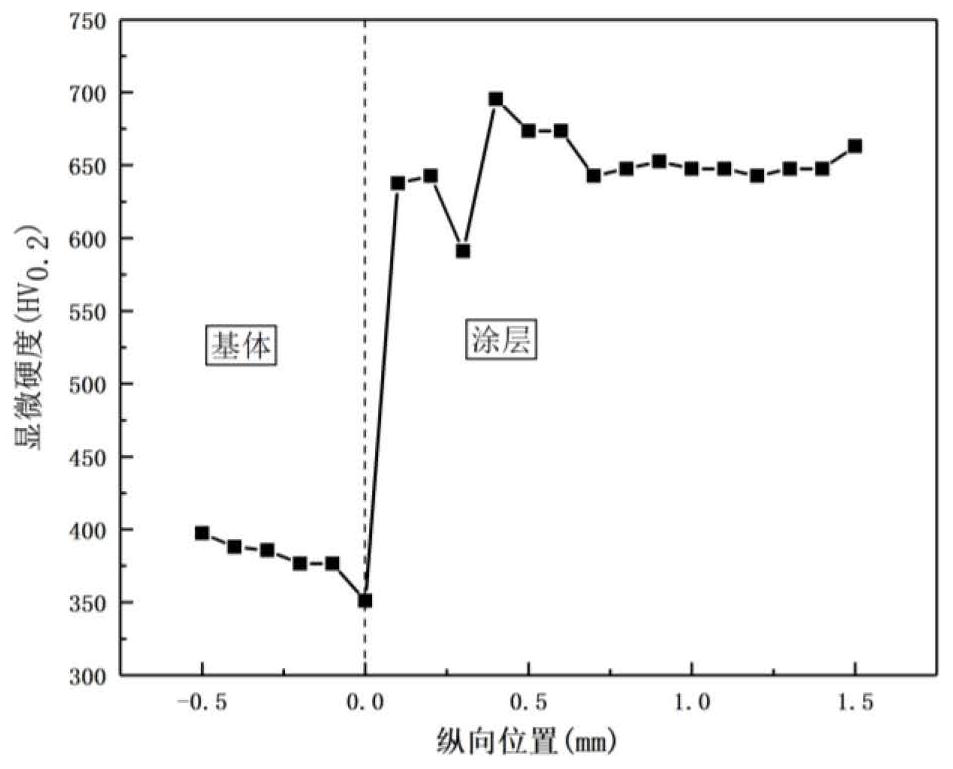

[0032] 17-4PH precipitation hardening stainless steel, which is commonly used in steam turbines, is used as the substrate. Firstly, sandblasting is carried out on the surface of the substrate to improve the surface roughness and remove surface oxides, then ultrasonically clean with absolute ethanol to remove surface oil and impurities, and dry in the air. Fix the processed substrate on the workbench; put the cobalt-based powder Stellite 6 alloy powder with a particle size of 15-30 μm in an oven at 120°C for 2 hours, cool to room temperature and put it into a powder feeder. Set the spraying carrier gas to nitrogen, the carrier gas pressure to 4MPa, the powder feeding rate to 1.5rpm, the powder preheating temperature to 700°C, the spraying distance to 30mm, and the scanning speed to 5mm / s. The laser power is 1000W, the overlap rate is 50%, and the supersonic laser deposition experiment is carried out. The obtained Stellite 6 coating has the following appearance: figure 1 shown....

Embodiment 2

[0034] Supersonic laser deposition experiments and laser cladding experiments of Stellite 6 powder were carried out on 17-4PH precipitation hardening stainless steel. Supersonic laser deposition experiment: first, sandblasting the surface of the substrate to improve surface roughness and remove surface oxides, then ultrasonically clean with absolute ethanol to remove surface oil and impurities, and dry in the air. Fix the treated substrate on the workbench; put the Stellite 6 alloy powder with a particle size of 15-30 μm in an oven at 120°C for 2 hours, and put it into the powder feeder after cooling to room temperature. Set the spraying carrier gas to nitrogen, the carrier gas pressure to 4MPa, the powder feeding rate to 1.5rpm, the powder preheating temperature to 700°C, the spraying distance to 30mm, and the scanning speed to 5mm / s. The laser power is 1000W, the overlap rate is 50%, and the supersonic laser deposition experiment is carried out. Laser cladding experiment: B...

Embodiment 3

[0036]The supersonic laser deposition experiment and laser cladding experiment of Stellite 6 powder were carried out on 17-4PH precipitation hardening stainless steel. Supersonic laser deposition experiment: first, sandblasting the surface of the substrate to improve surface roughness and remove surface oxides, then ultrasonically clean with absolute ethanol to remove surface oil and impurities, and dry in the air. Fix the treated substrate on the workbench; put the Stellite 6 alloy powder with a particle size of 15-30 μm in an oven at 120°C for 2 hours, and put it into the powder feeder after cooling to room temperature. Set the spraying carrier gas to nitrogen, the carrier gas pressure to 4MPa, the powder feeding rate to 1.5rpm, the powder preheating temperature to 700°C, the spraying distance to 30mm, and the scanning speed to 5mm / s. The laser power is 1000W and 1100W respectively, and the overlapping rate is 50%, and the supersonic laser deposition experiment is carried ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com