Patents

Literature

31results about How to "Fully deposited" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing high-temperature wear-resistant coating on continuous casting crystallizer copper alloy plate surface

InactiveCN102851632AHigh bonding strengthImprove deposition efficiencyMolten spray coatingWear resistantThermal shock

The invention discloses a method for preparing a high-temperature wear-resistant coating on a continuous casting crystallizer copper alloy plate surface, which comprises the following step: spraying metal ceramic powder on a pretreated copper alloy plate surface by a plasma spraying process to form a metal ceramic coating of which the thickness is 0.5mm, wherein the metal ceramic powder is Cr3C2-NiCr powder of which the particle size is 325-500 meshes; the Cr3C2-NiCr powder comprises 70-80 wt% of Cr3C2 and the balance of NiCr alloy powder; and the Ni / Cr mass ratio in the NiCr alloy powder is 80:20. The coating prepared by the method disclosed by the invention has the advantages of high bonding strength, favorable thermal shock resistance and long thermal-fatigue life, can satisfy the working requirements for crystallizer copper alloy plates, and obviously prolongs the service life of the crystallizer copper alloy plate.

Owner:JIANGSU UNIV OF SCI & TECH

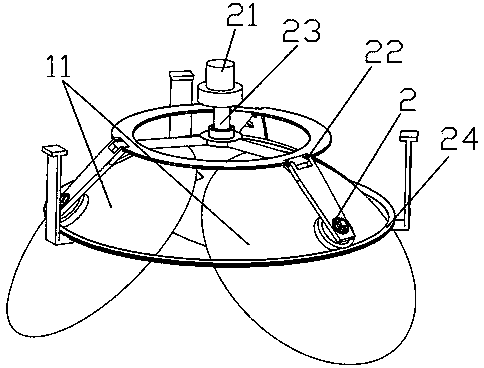

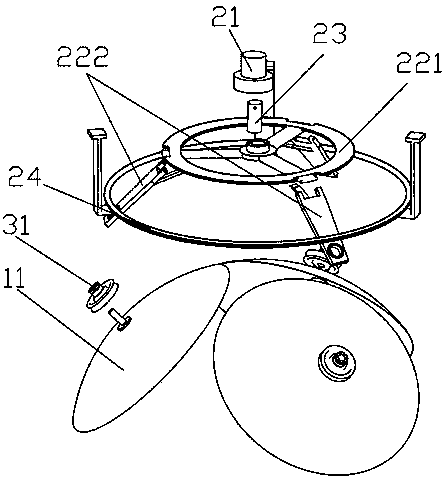

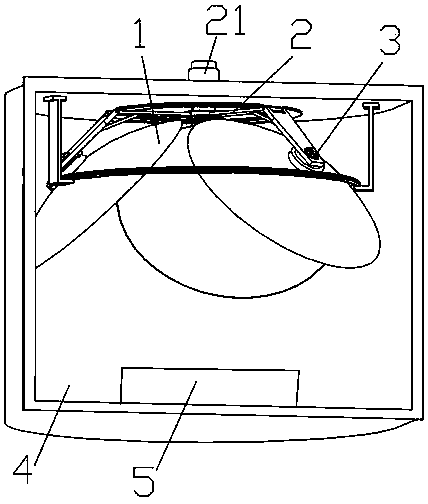

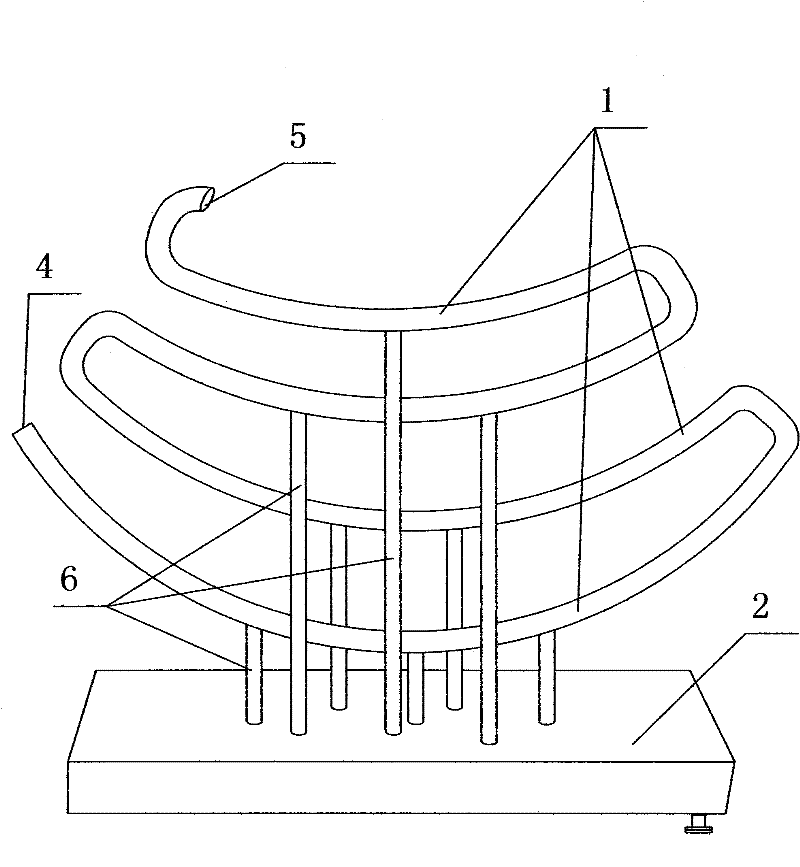

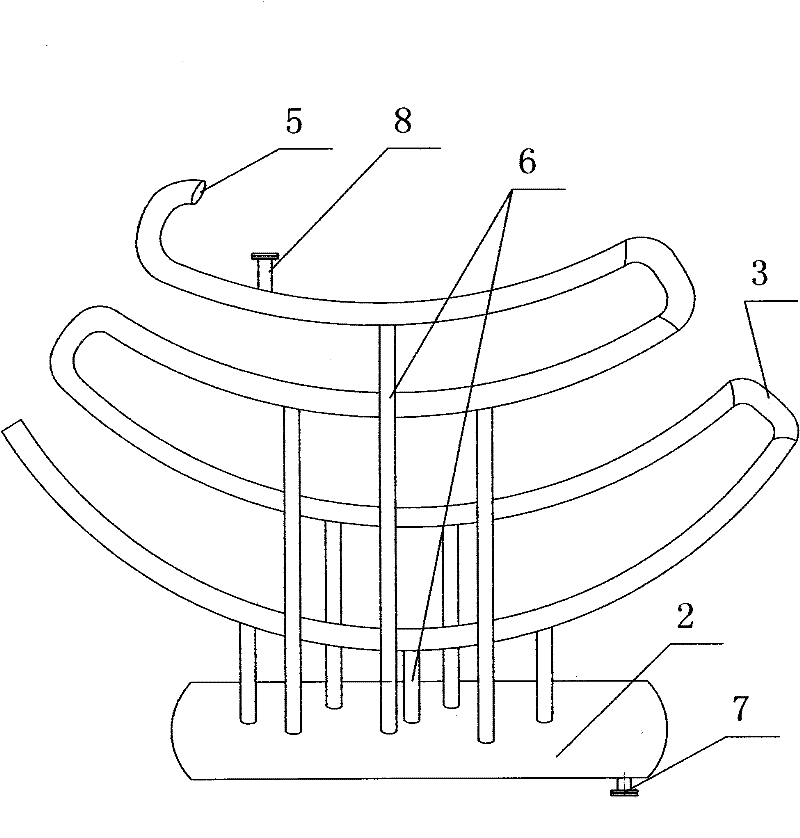

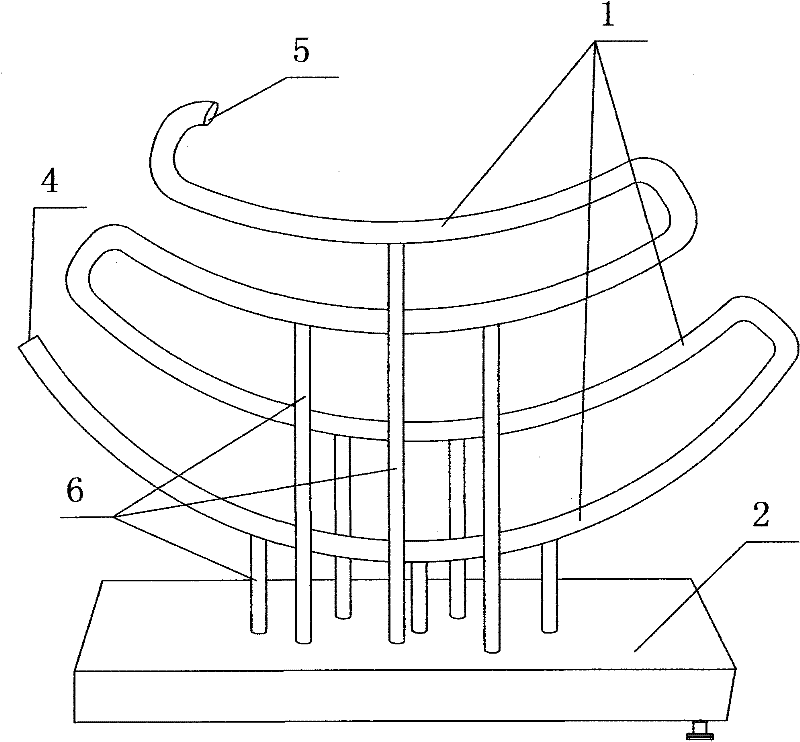

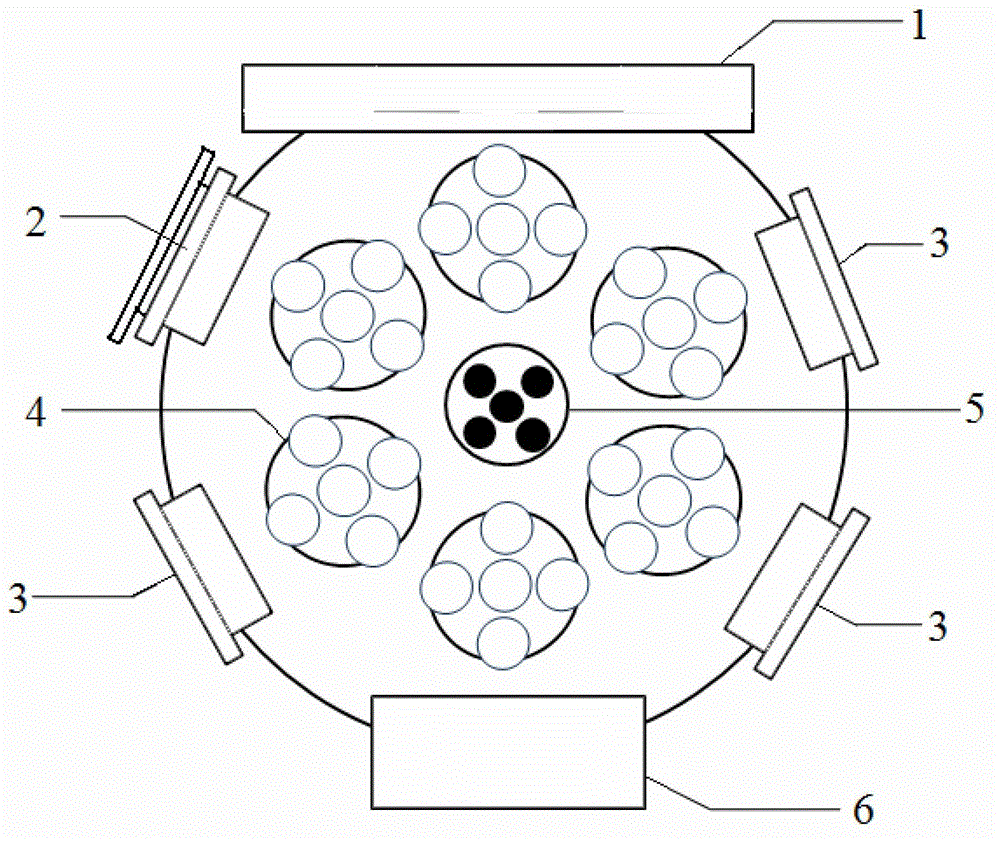

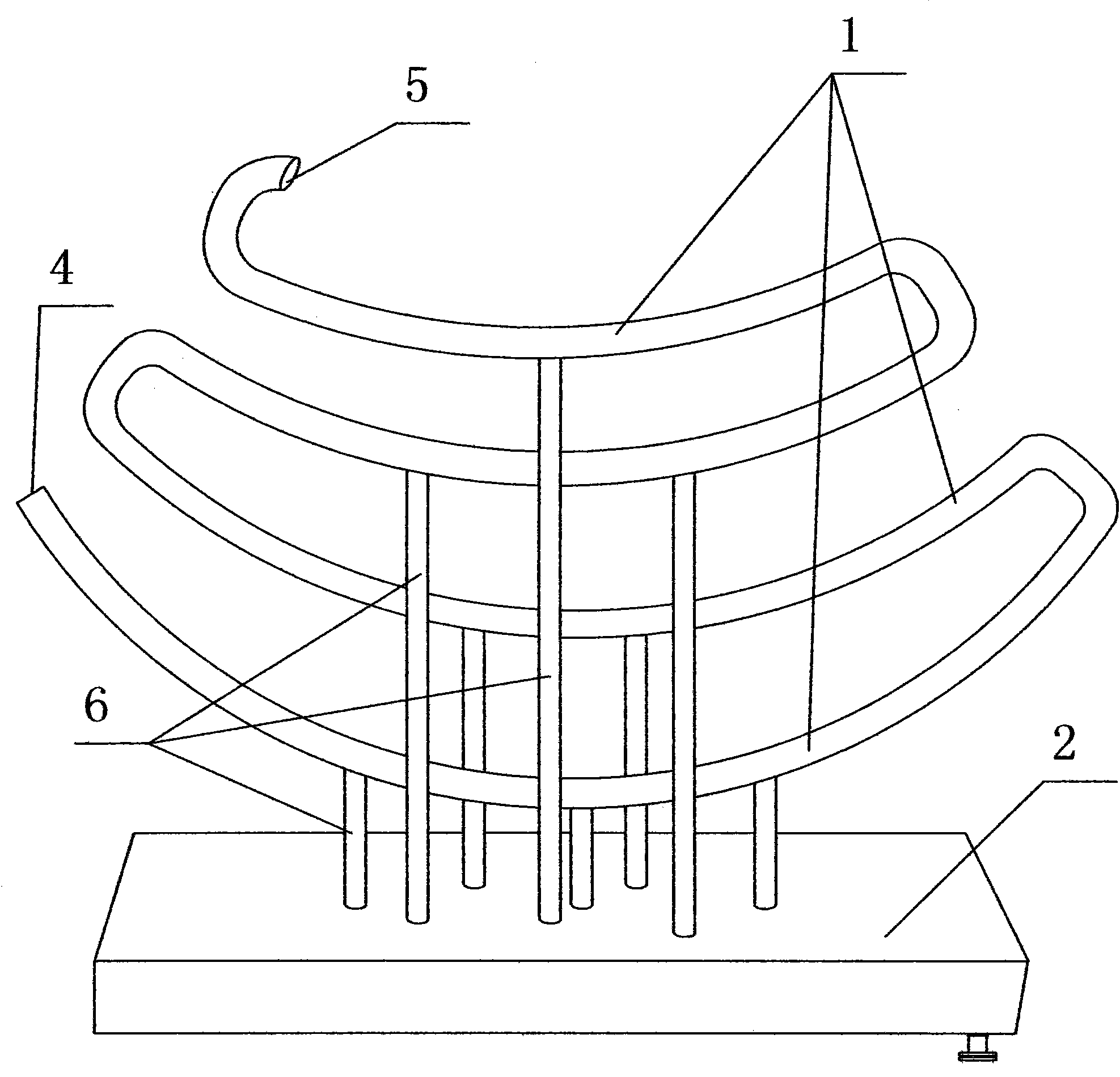

Planet-like coating jig capable of rotating and revoluting and use method of planet-like coating jig

InactiveCN104294234AAchieve uniformityUniform depositionVacuum evaporation coatingSputtering coatingEvaporationEngineering

The invention relates to a planet-like coating jig for evaporation coating inside a large-size coating machine cavity, and in particular relates to a planet-like coating jig capable of rotating and revoluting and achieving a uniform product coating effect in the large-size coating machine cavity, and a use method of the planet-like coating jig. The planet-like coating jig capable of rotating and revoluting and is mounted at the upper part inside the coating machine cavity and mainly comprises a jig body, a revolution system and a rotation system, wherein the jig body comprises three jig discs; the jig discs are umbrella-shaped, connecting columns are arranged at the sharp ends of the middle of the umbrella-shaped jig discs. The principle of planet movement is adopted, according to the regulation of rotation and revolution of a planet, the jig discs are enabled to rotate independently and revolute as a whole inside the coating machine cavity, the purpose that a protecting membrane layer is uniformly deposited on the surface of a product when a film is coated is achieved, and moreover not only is a main body part of a coated product uniformly coated, but also an optimal coating effect can be achieved for edges and corners of the coated product, and the uniformity of overall coating is achieved.

Owner:东莞市华星镀膜科技有限公司 +1

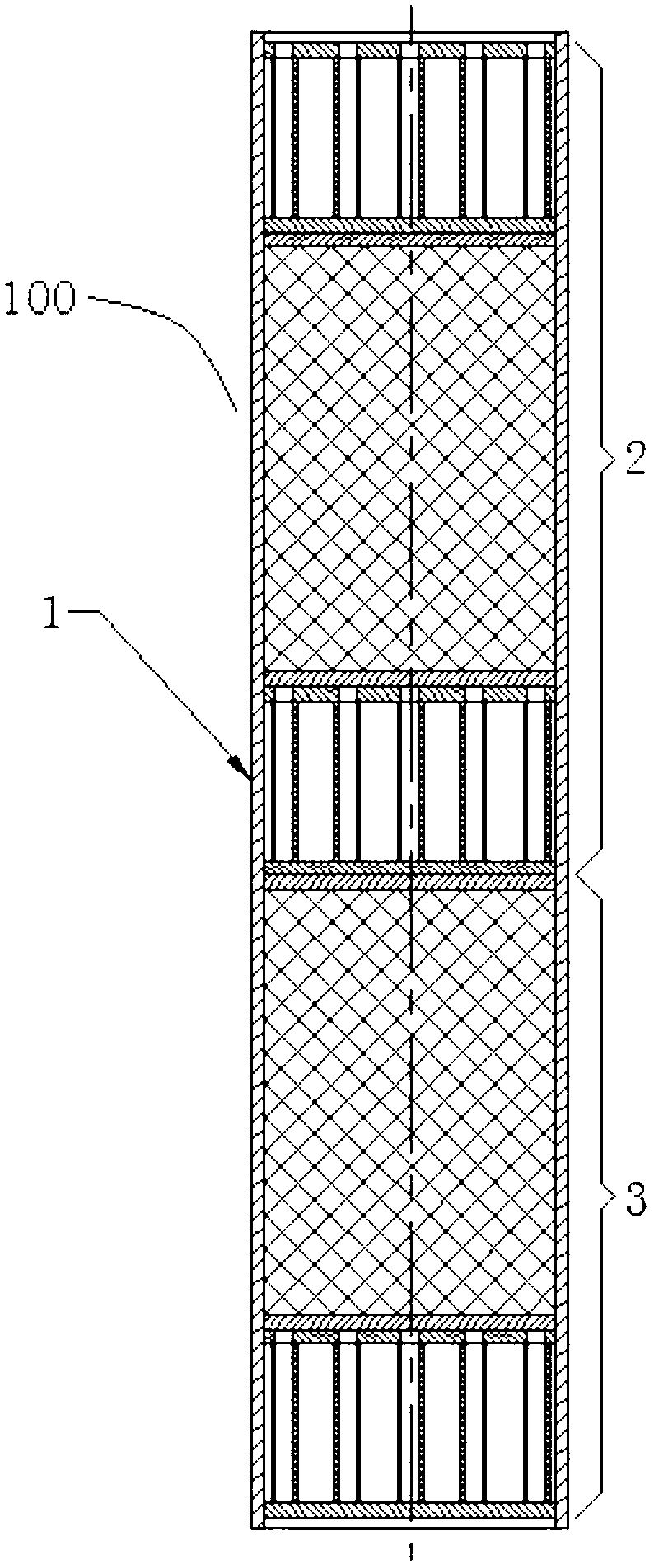

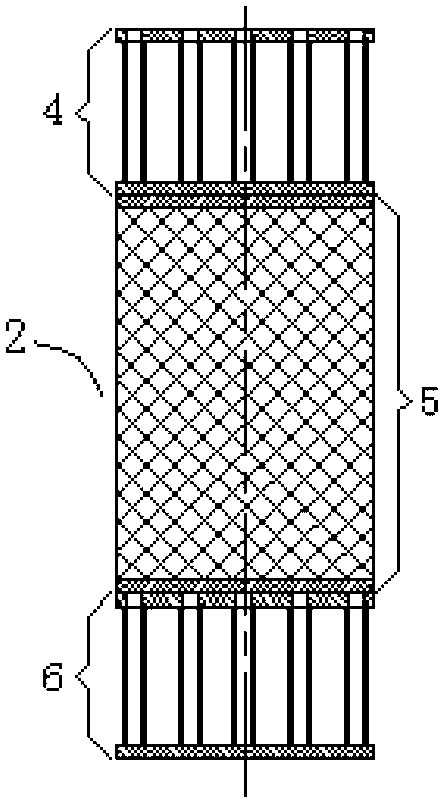

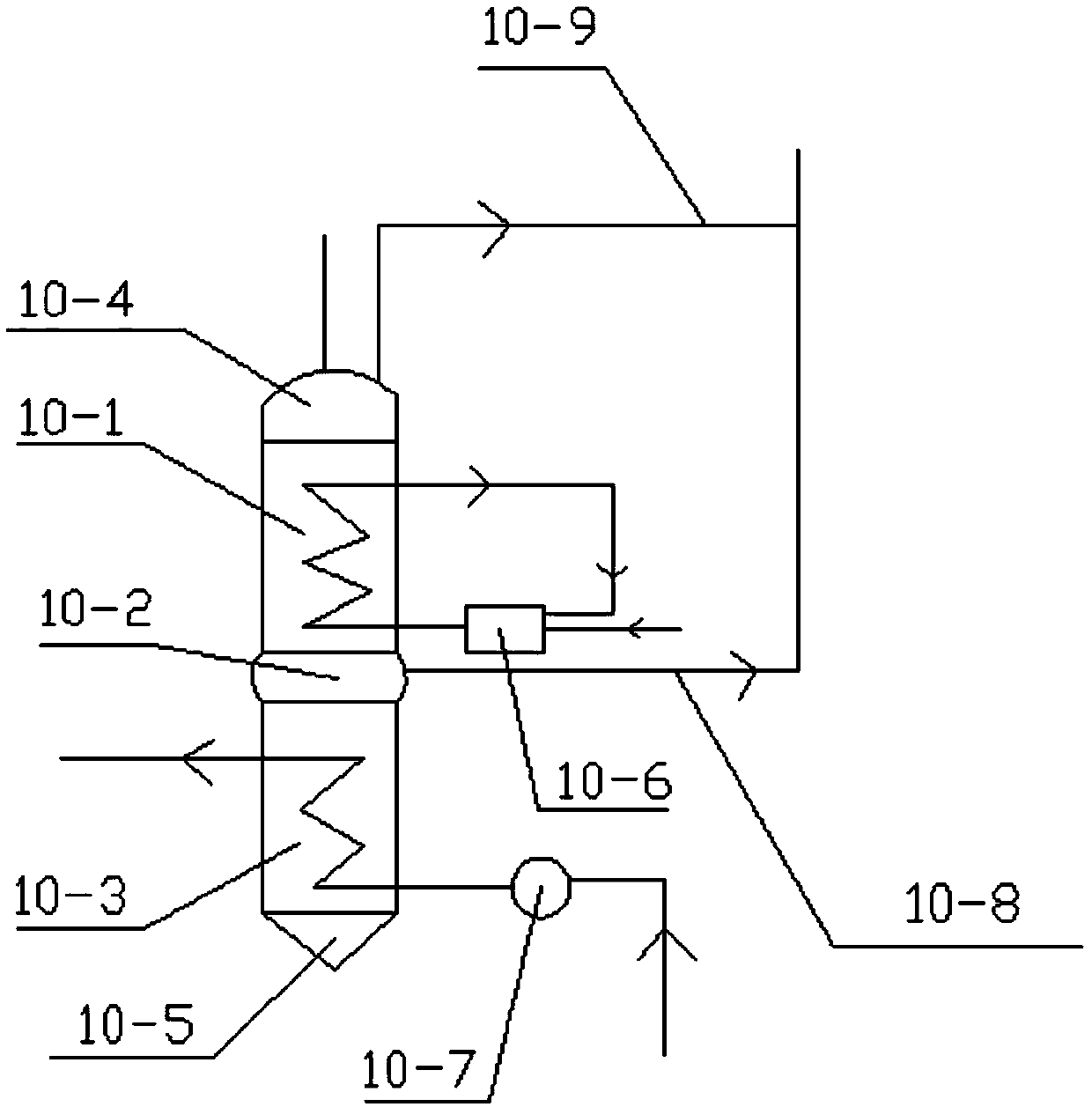

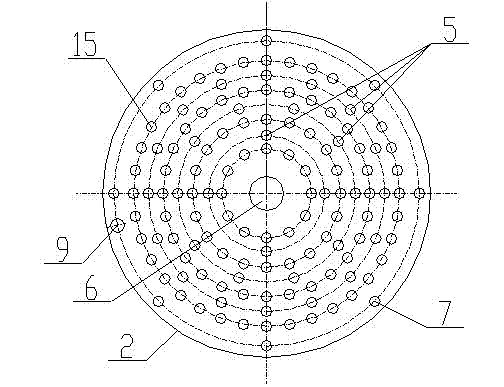

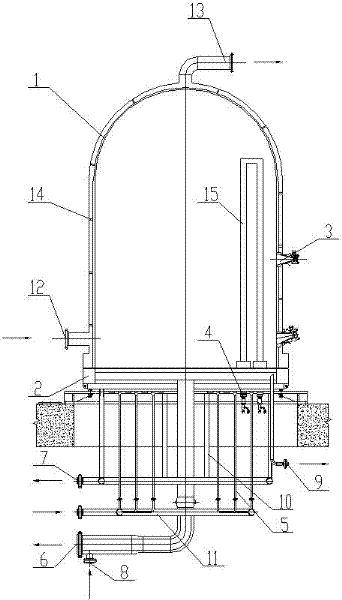

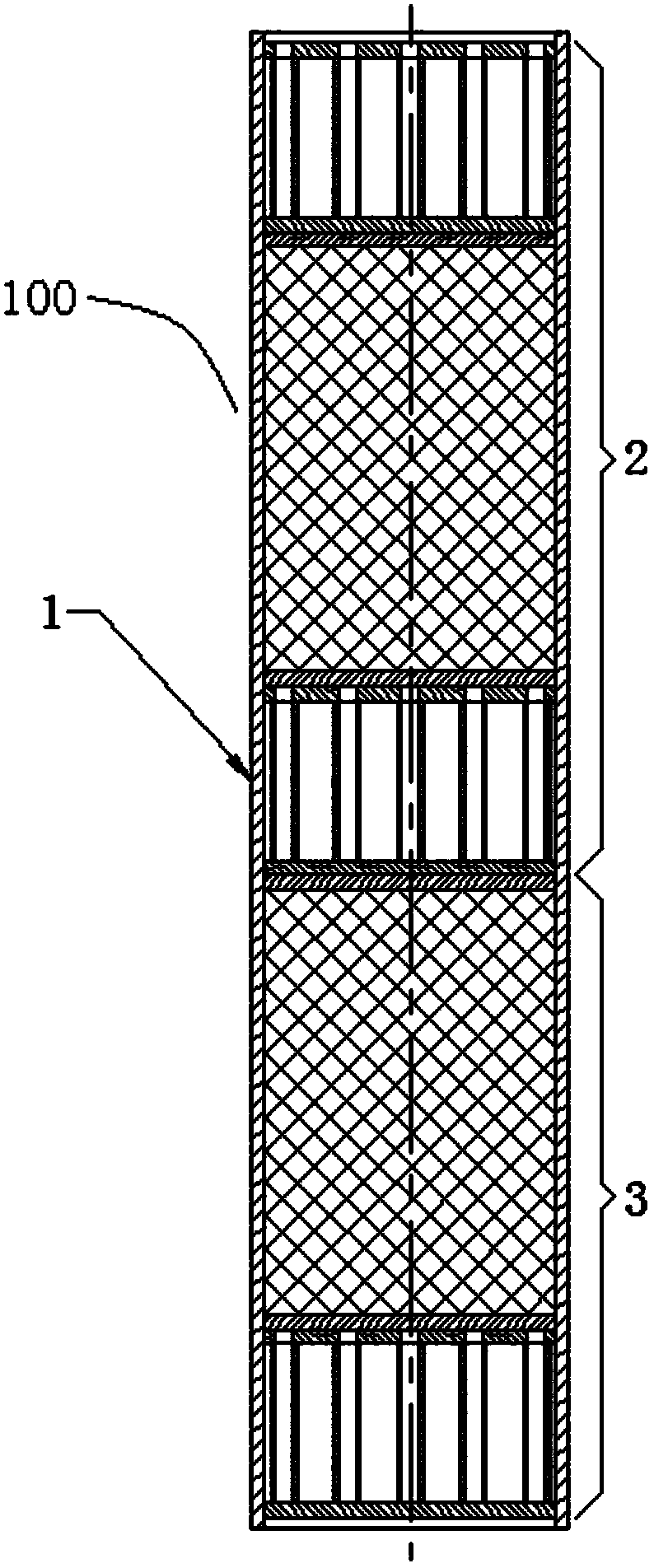

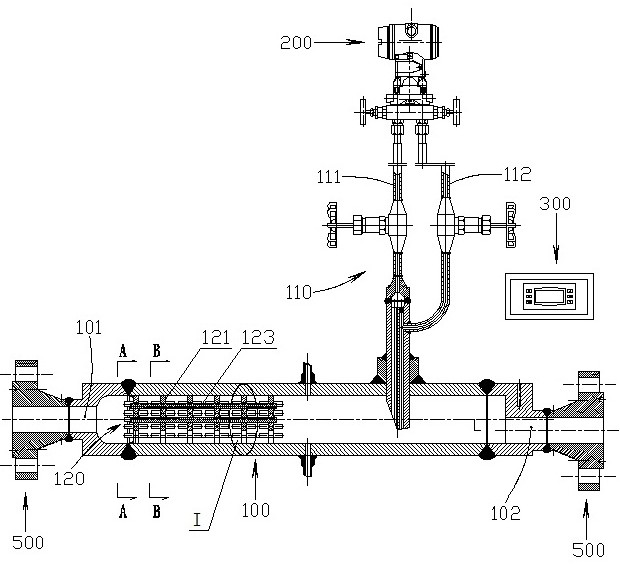

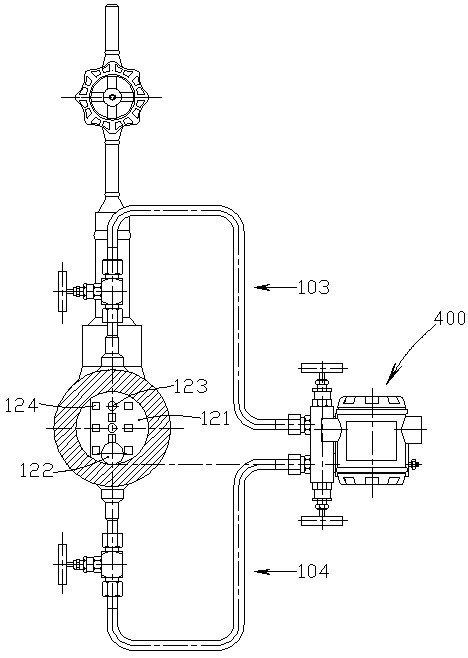

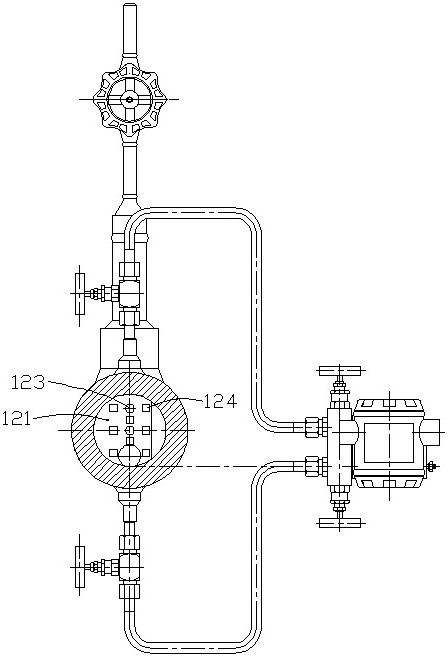

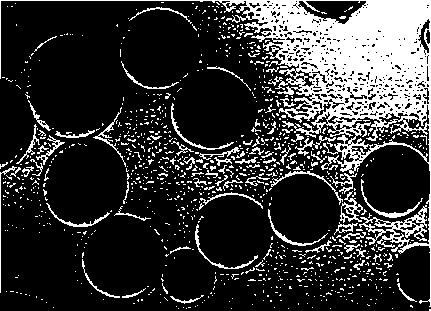

Combined type helium gas filtering sampling device for gas cooled reactor and installation method of device

ActiveCN103212250AFully depositedLarge filter areaDispersed particle filtrationNuclear energy generationMolecular sieveHelium

The invention relates to a combined type helium gas filtering sampling device for a gas cooled reactor and an installation method of the device. The combined type helium gas filtering sampling device is characterized by comprising a sleeve, at least two filter assemblies which are spaced along the axial direction and are fixed on the inner wall of the sleeve, and at least one molecular sieve assembly fixed between the two adjacent filter assemblies. The filtering sampling device provided by the invention adopts a sandwich combined type structure with the filter assemblies-the molecular sieve-the filter assembly, can fully filter fission product particles and graphite dust with different types and sizes carried by helium from a vapor generator, and can fulfill the purposes of multistage filtering, full deposition and adsorption of the fission product particles and graphite dust.

Owner:CHINERGY CO LTD

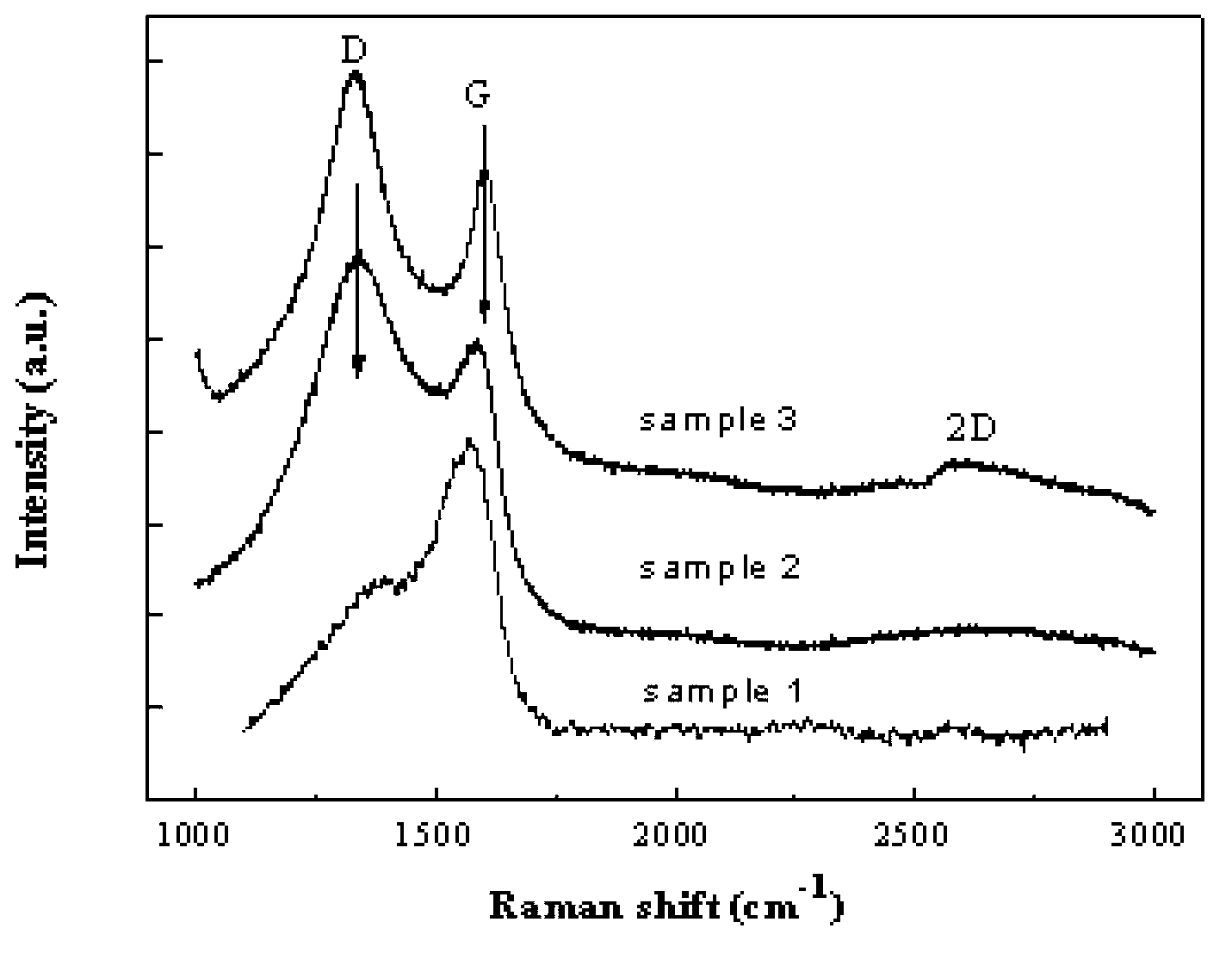

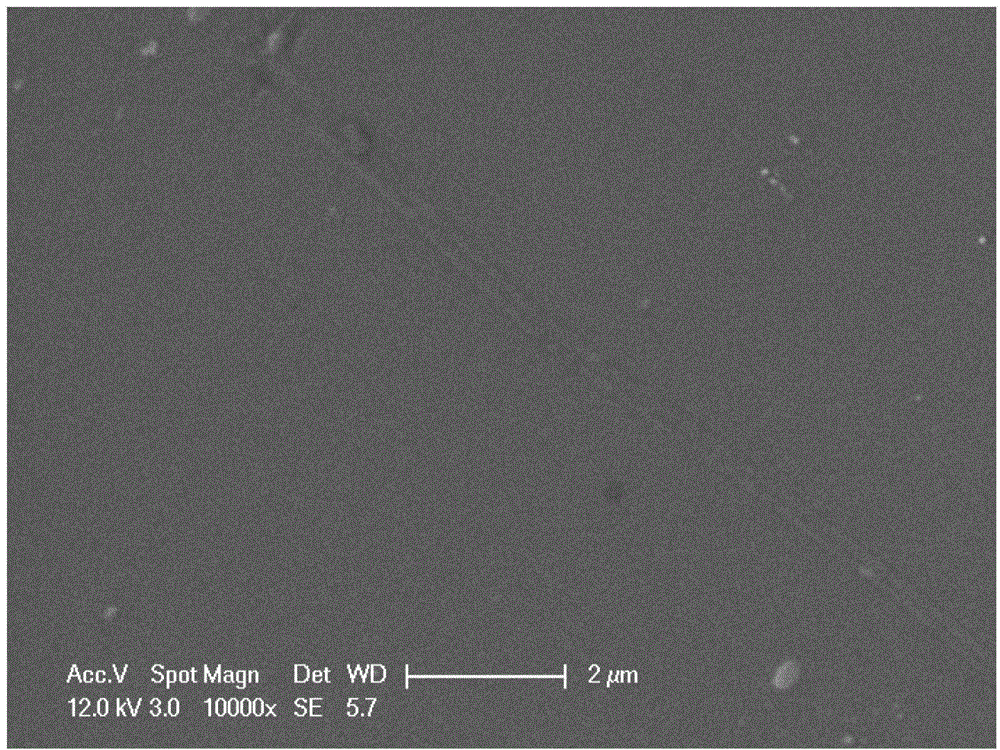

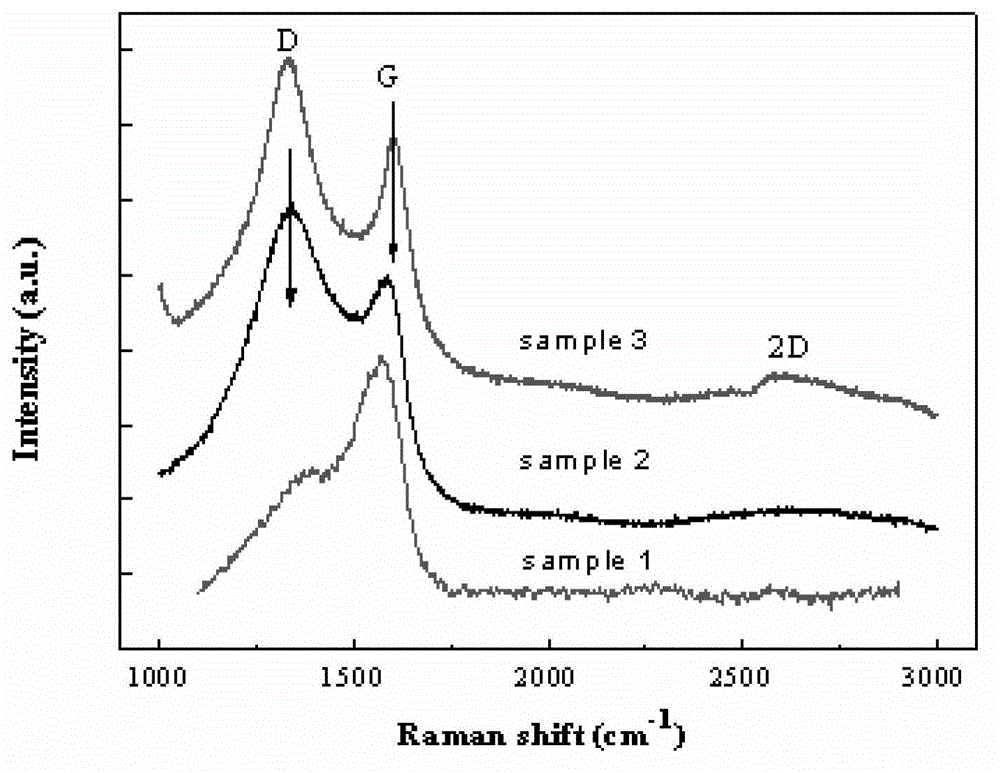

Method for preparing graphene or ultrathin carbon film by PVD (physical vapor deposition) technique

ActiveCN103266306AQuality improvementReduce formationChemical vapor deposition coatingCarbon filmElectric field

The invention provides a method for preparing a graphene or ultrathin carbon film by a PVD (physical vapor deposition) technique, which comprises the following steps: putting a substrate on a substrate rack in a deposition chamber, and carrying out glow cleaning on the substrate surface; introducing an acetylene-argon gas mixture into the gas mixture at 70-100 DEG C in an argon environment under the conditions of vacuum degree 0.5-1 Pa and the substrate voltage bias -200V; opening an anode layer ion source to ionize the gas mixture, wherein the voltage of the anode layer ion source is 300-500V in the ionization process, the acetylene is ionized to generate carbonous cations, and the cations bombards the substrate under the action of an electric field and deposits on the substrate; and after the deposition is finished, annealing under vacuum conditions for 1-2 hours, thereby preparing the graphene or ultrathin carbon film on the substrate surface after the annealing is finished. The method provided by the invention can satisfy the large-scale preparation of uniform-thickness graphene or ultrathin carbon films, and has important industrial application prospects.

Owner:YICHANG HOUHUANG VACUUM TECH

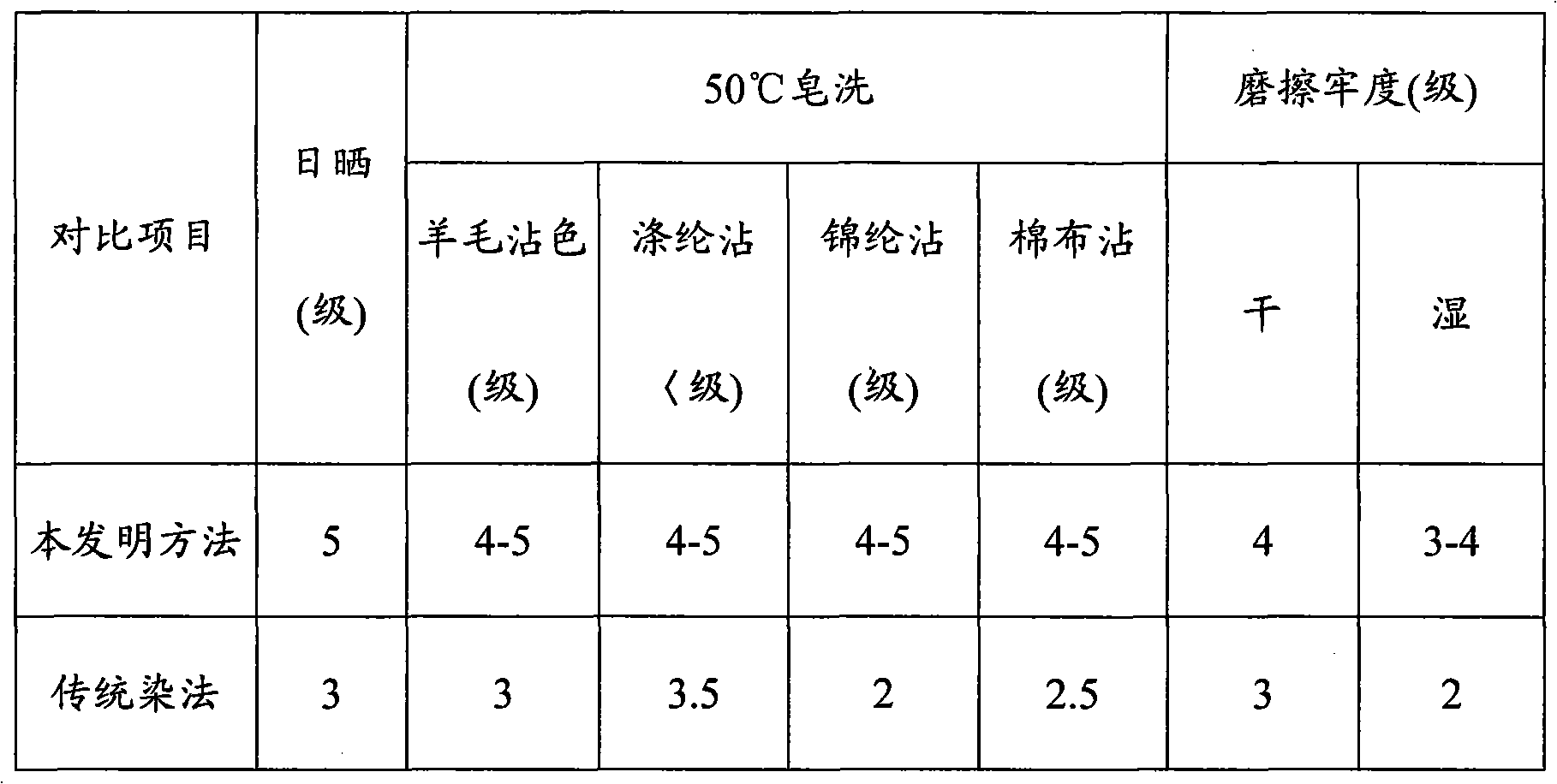

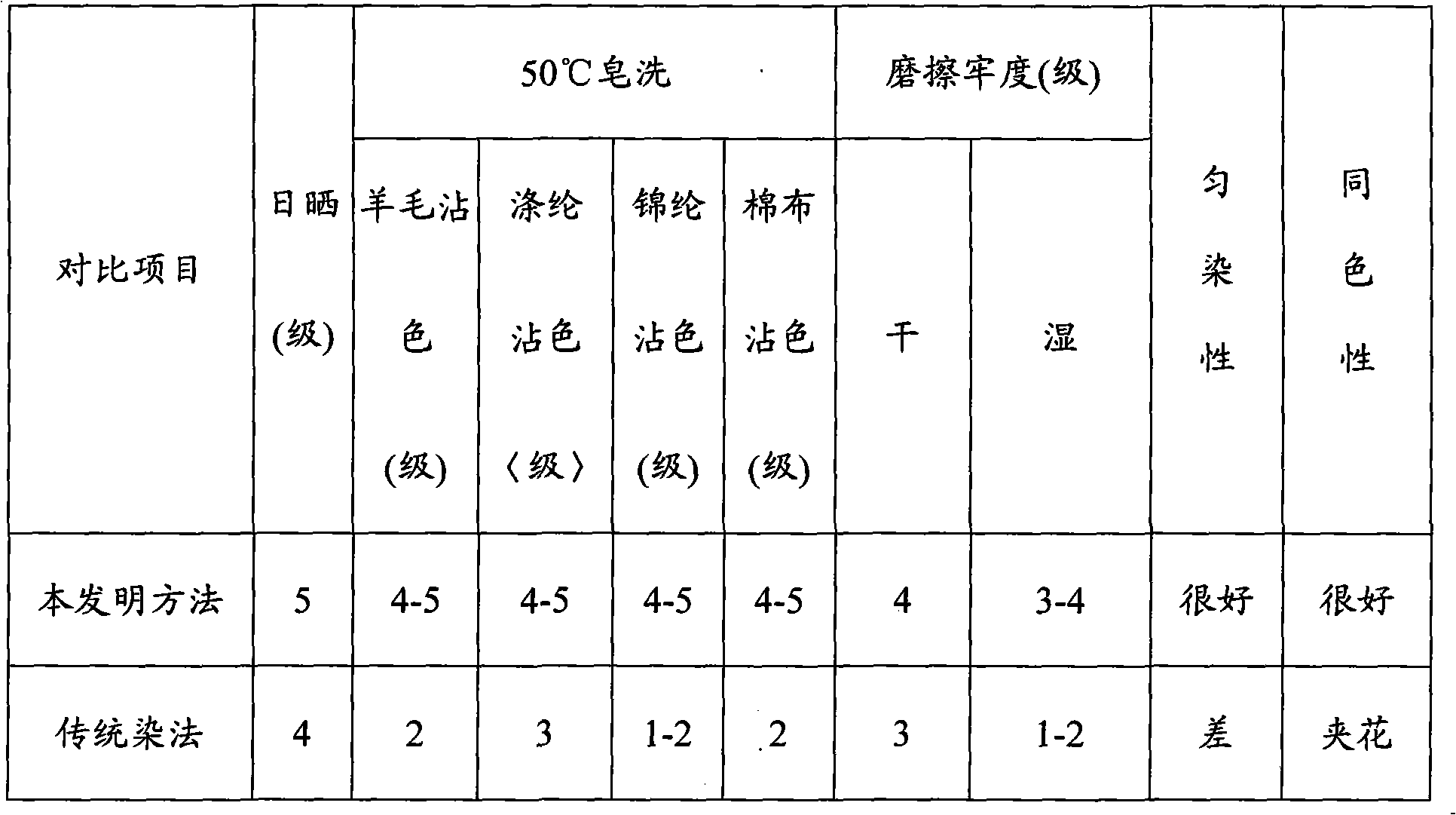

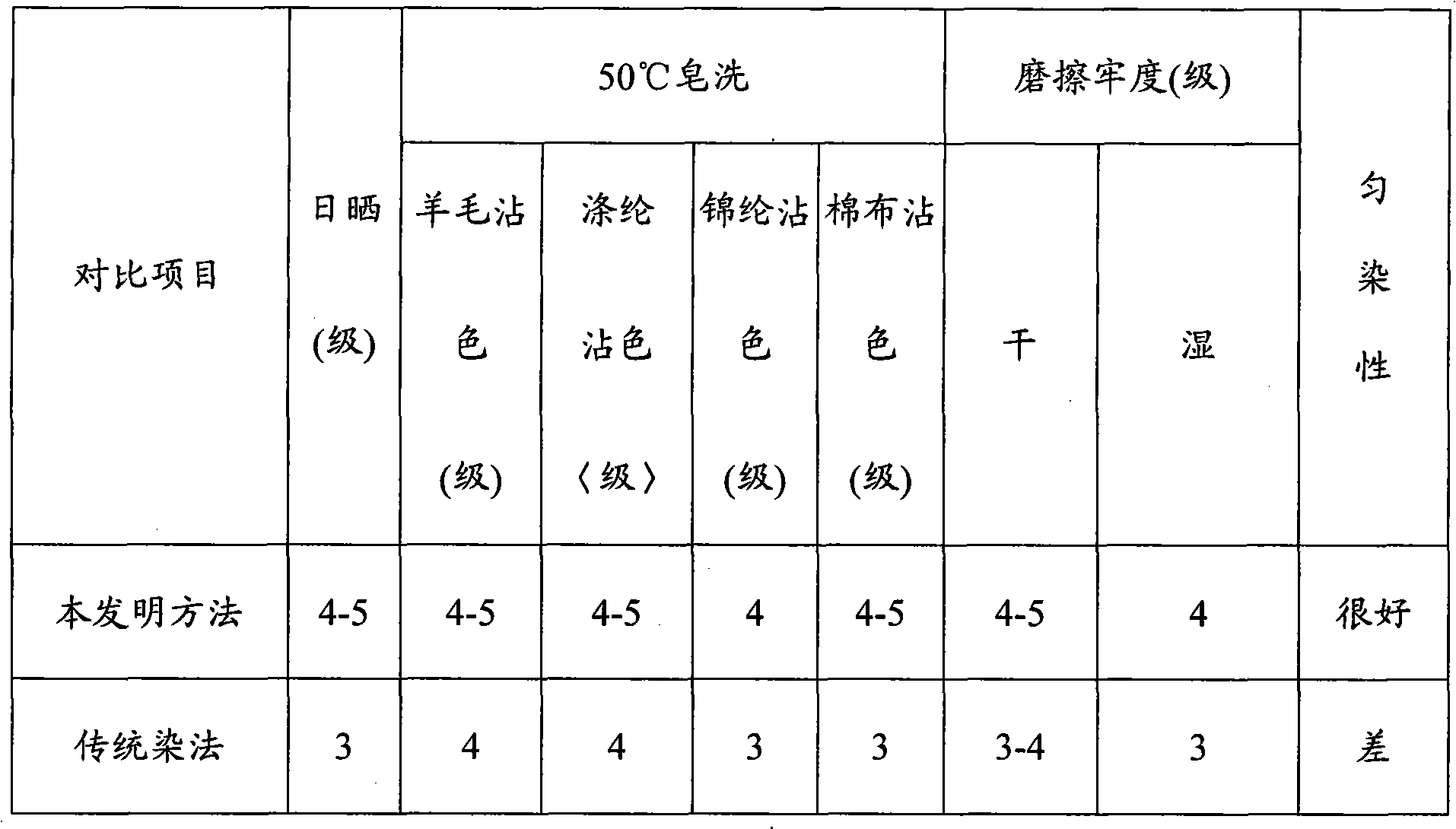

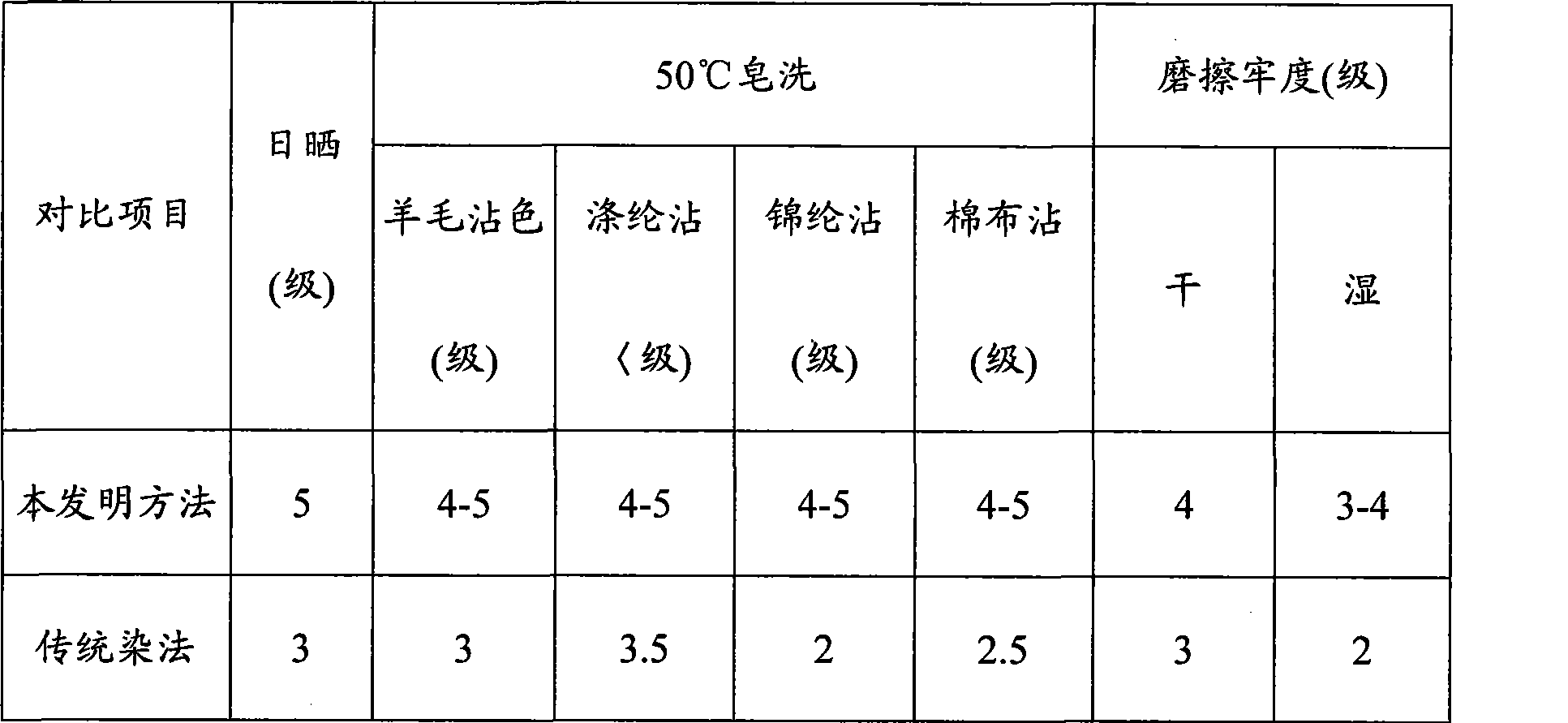

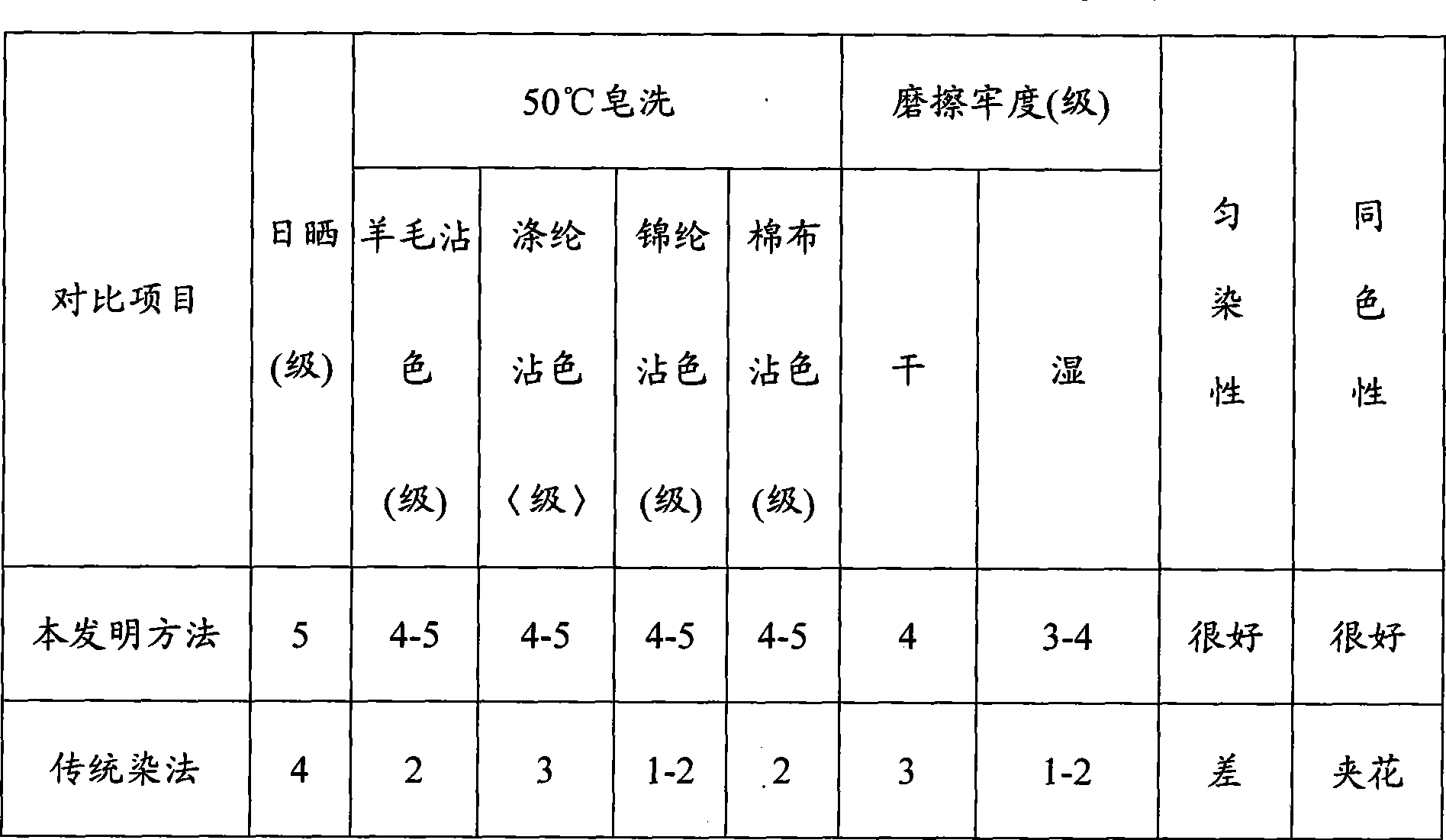

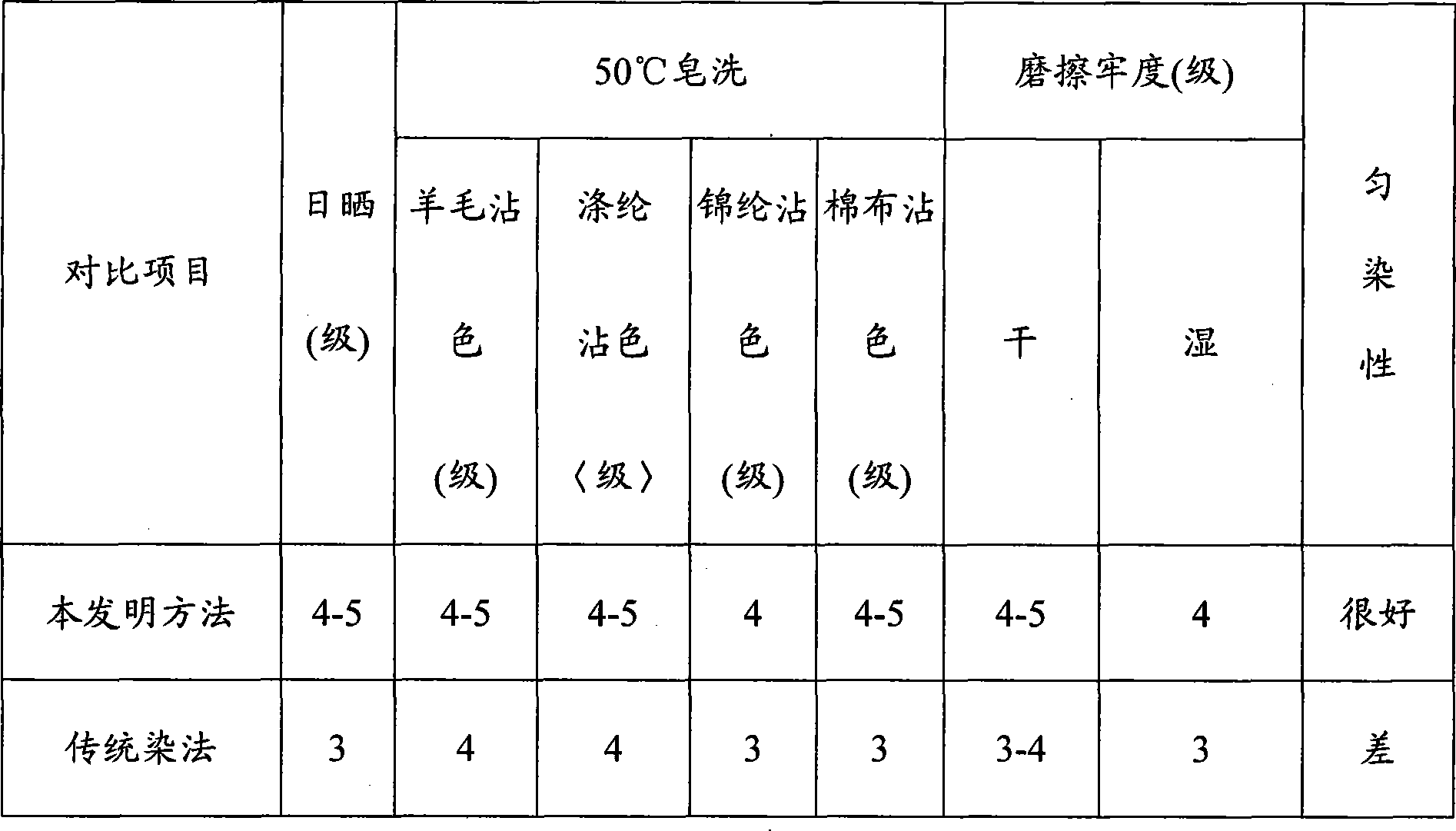

Pervasion auxiliary agent and application in dyeing course and degumming process thereof

InactiveCN101349019AImprove homochromaticityFully depositedDe-gumming silkDyeing processFiberPolymer science

The invention discloses a penetrating addition agent which comprises the following compositions in weight portion: 0.00018 to 0.0006 portion of laurocapam, 0.5 to 25 portions of myristyl lycine, 0.1 to 12 portions of dipropylene glycol methyl ether, 0.01 to 5 portions of N- methyl pyrrolidone, 0.05 to 2.5 portions of tri n butyl phosphate, 5 to 60 portions of diethylene glycol or butyl ether, 1 to 20 portions of phenylcarbinol and 1 to 3 portions of lignin sulfonic acid ammonium salt. The invention also discloses an application of the penetrating addition agent to the dyeing process and to the retting hemp process. The penetrating addition agent in the dyeing process ensures that the color yield and homochromatic properties of the double-component fiber are good, the leveling property is good and the 'white core' phenomenon is avoided.

Owner:SHANGHAI TEXTILE GRP DETECTION STANDARD CO LTD

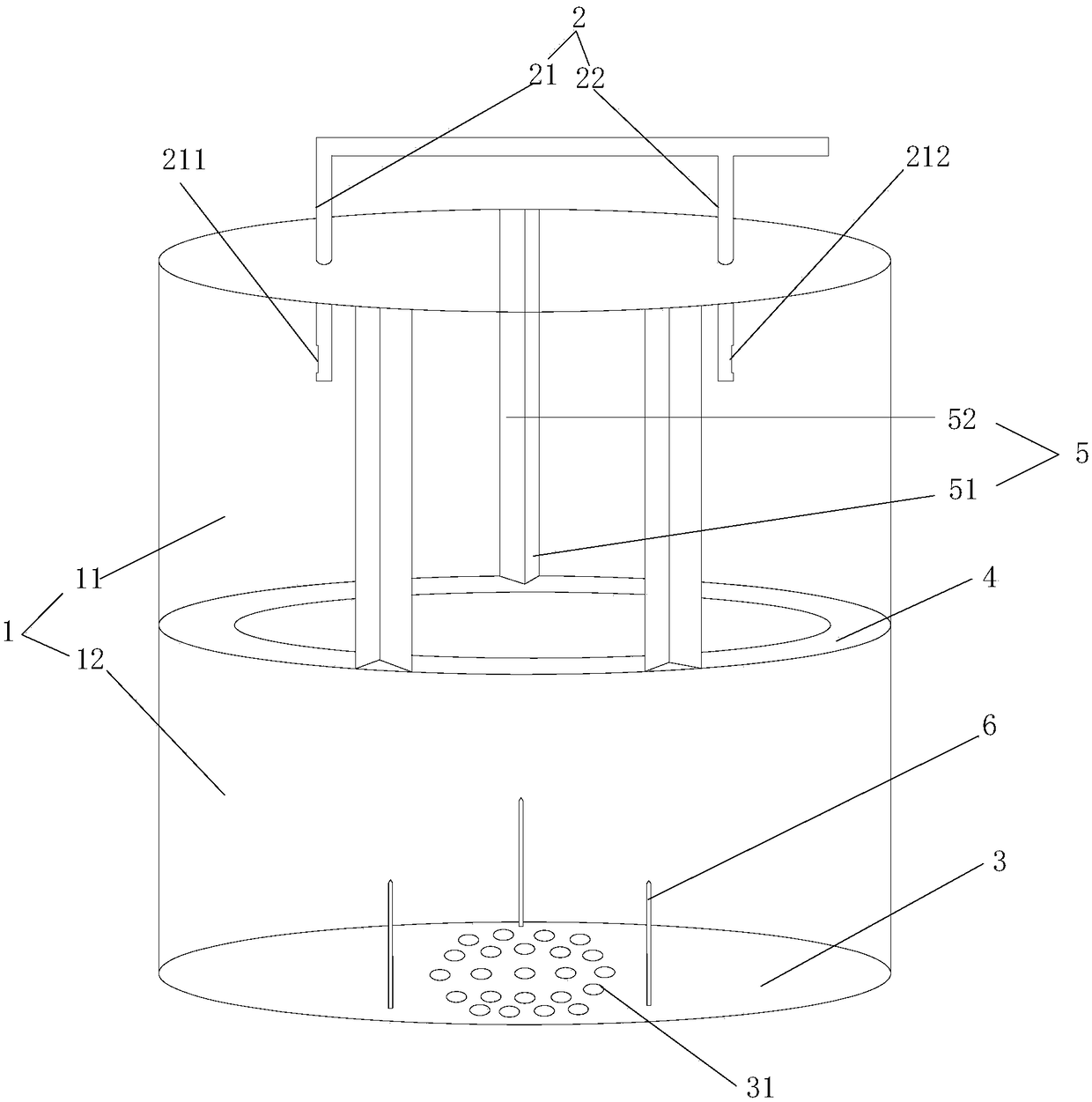

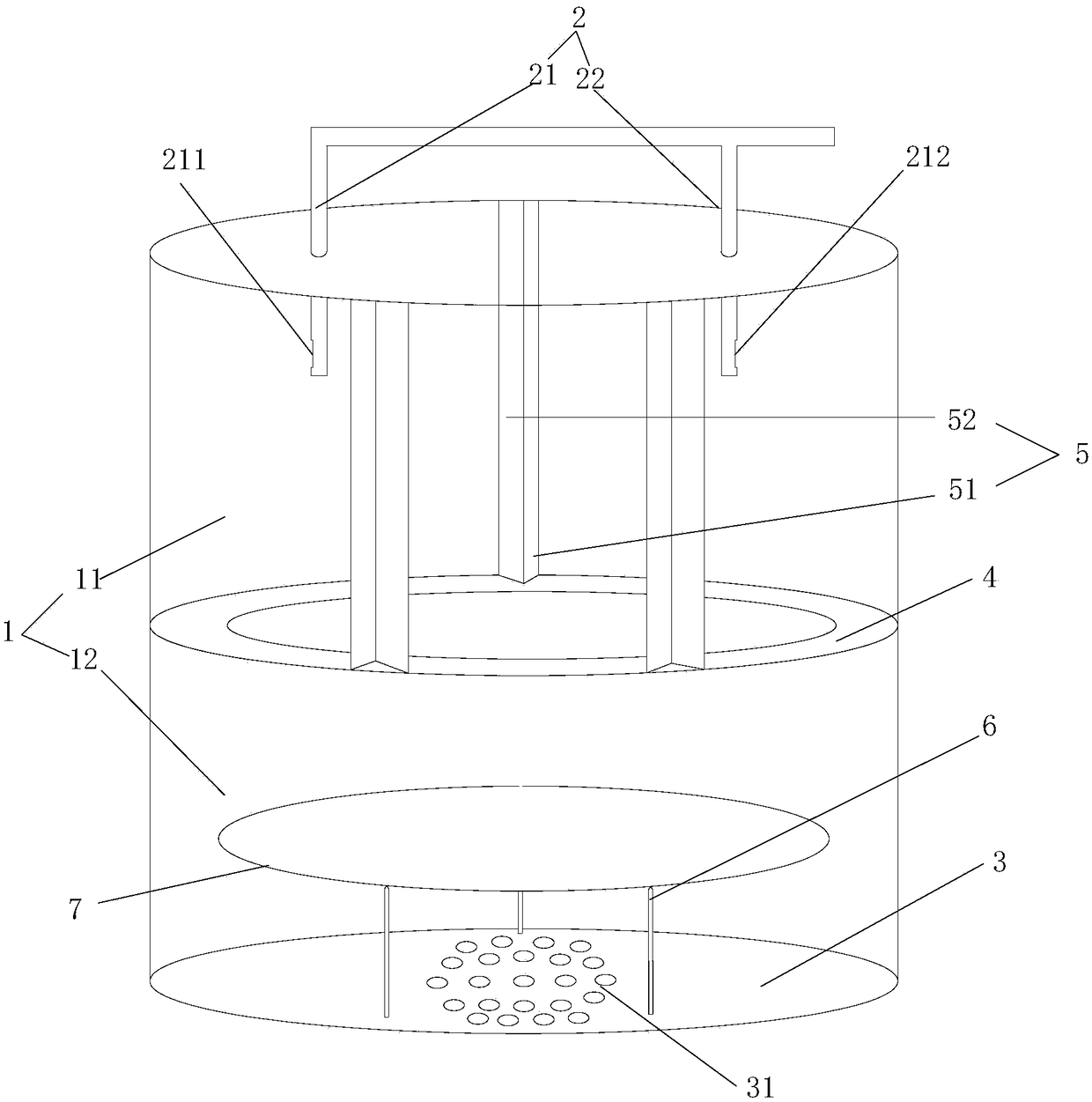

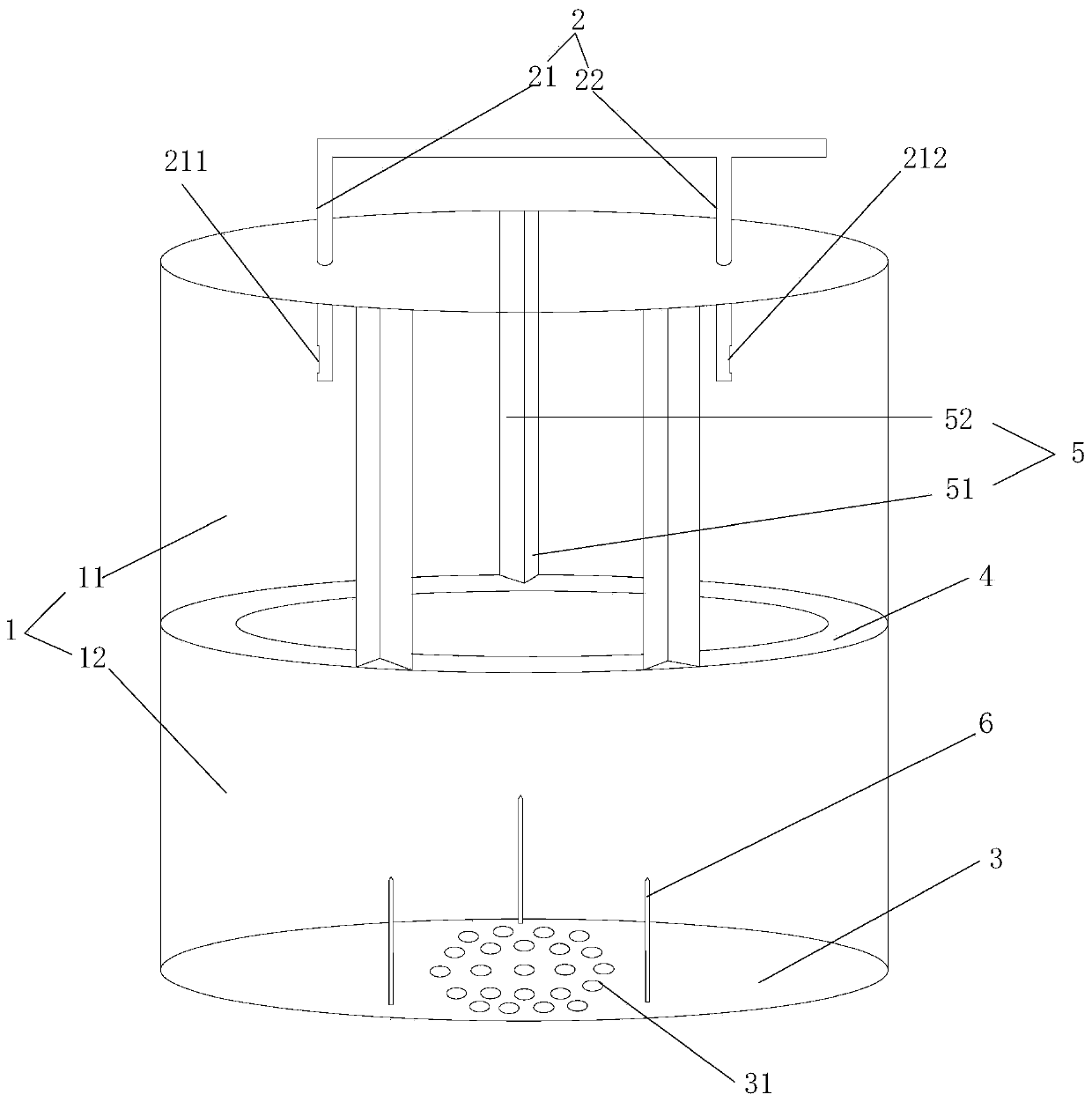

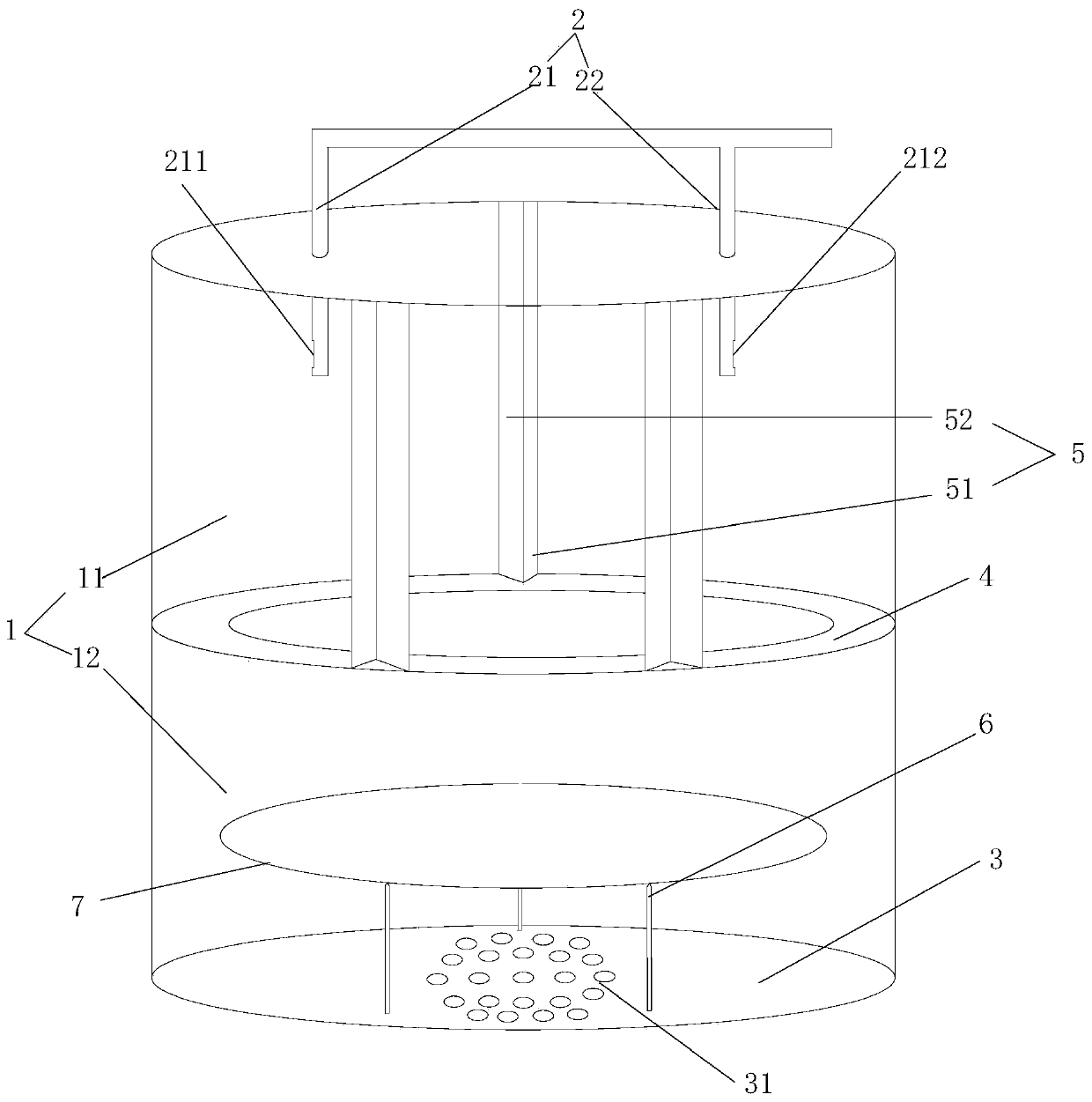

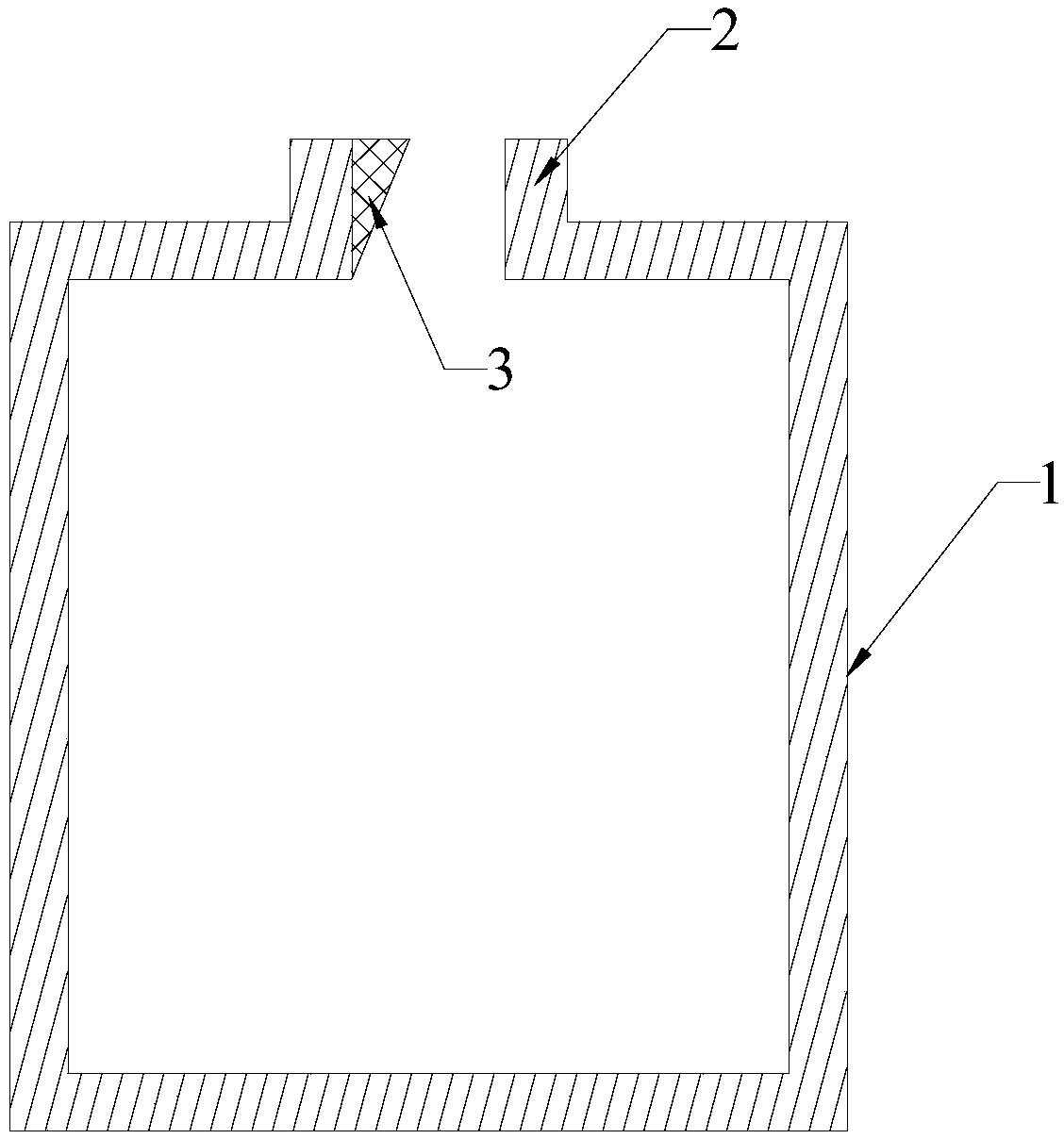

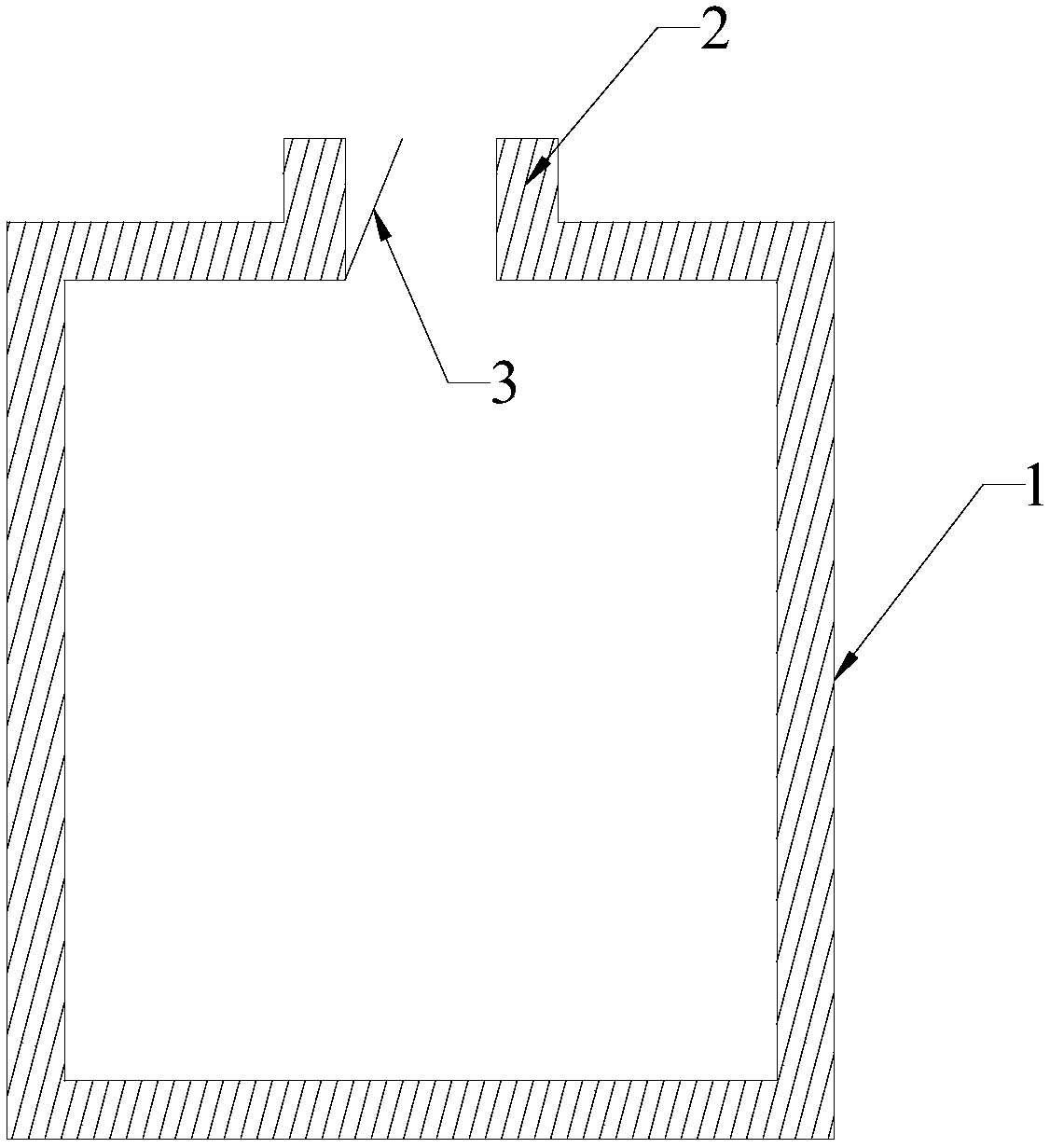

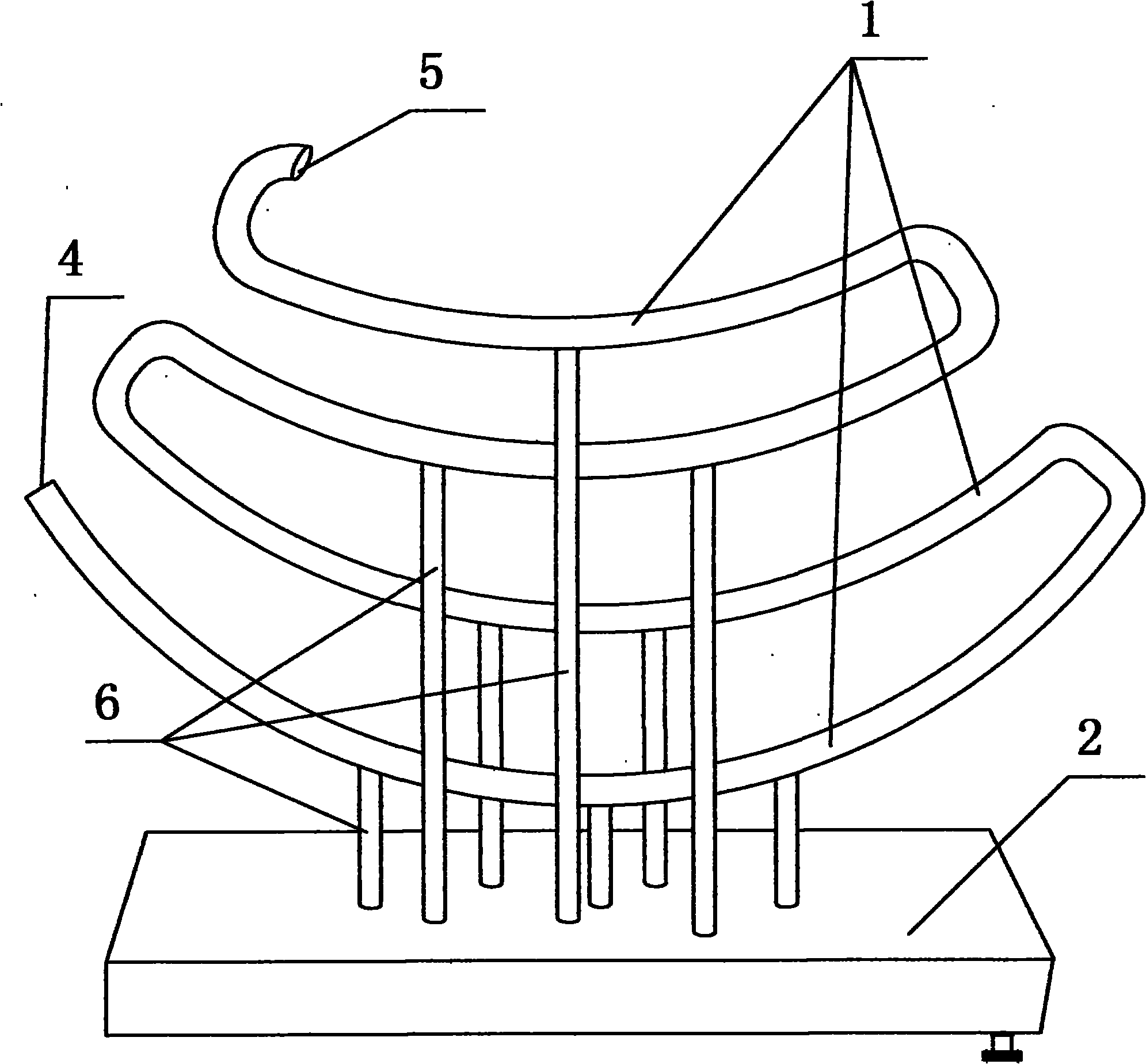

Device for preparing fully deposited silicon carbide coating by chemical vapor deposition

ActiveCN108546928AFlow adjustmentAvoid shockChemical vapor deposition coatingGas phaseChemical vapor deposition

The invention relates to a device for preparing a fully deposited silicon carbide coating by chemical vapor deposition, and belongs to the technical field of silicon carbide coating preparation. According to the main technical scheme, the device for preparing the fully deposited silicon carbide coating by the chemical vapor deposition includes a cavity, a support ring, gas flow interfering bodiesand supporting members. An air inlet device is arranged at the top of the cavity, and an air outlet device is arranged at the bottom of the cavity. The outer side wall of the support ring is connectedto the inner wall of the cavity, and the cavity is divided into an upper cavity and a lower cavity which communicate with each other in the middle. One ends of the gas flow interfering bodies are disposed on the support ring and arranged in the direction from the support ring to the top of the cavity, and the number of gas flow interfering bodies is greater than or equal to three. The supportingmembers are disposed at the bottom of the cavity for supporting a sample of a coating to be deposited and the sample is located in the lower cavity. The device for preparing the fully deposited silicon carbide coating by the chemical vapor deposition is capable of obtaining the fully deposited silicon carbide coating on the surface of the sample.

Owner:CHINA BUILDING MATERIALS ACAD

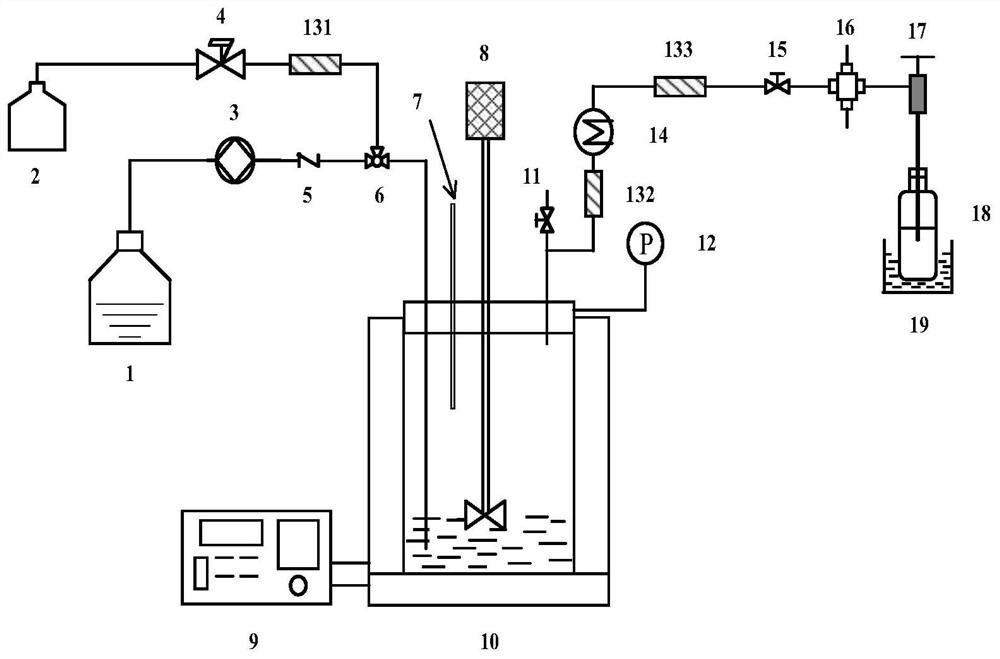

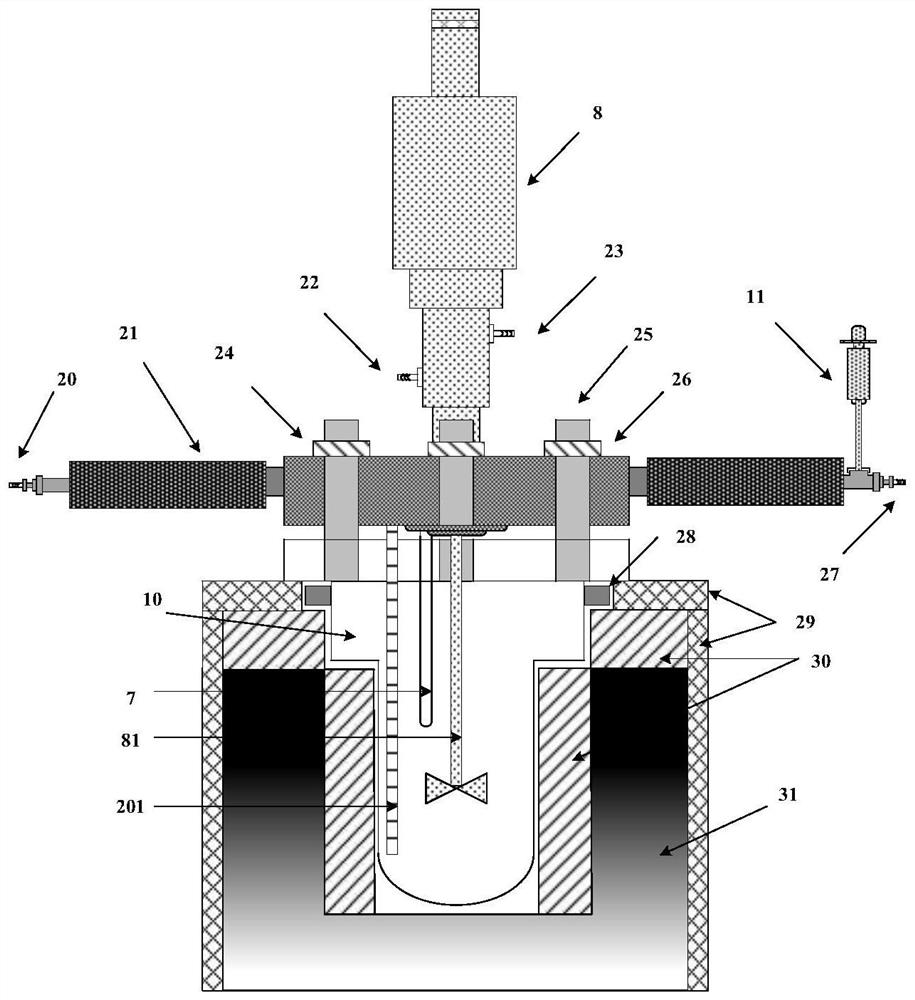

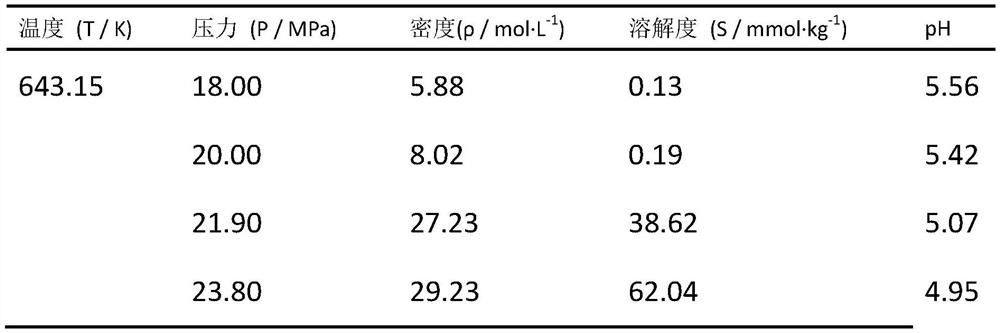

Flowing type high-temperature high-pressure solubility online measuring device and measuring method thereof

InactiveCN111624235AWell mixedStable temperatureAnalysis by thermal excitationMaterial resistanceFluid phaseControl system

The invention discloses a flowing type high-temperature high-pressure solubility online measuring device and a measuring method thereof. The system comprises a feeding system, a balance kettle, a sampling system and a pressure control system. A Hastelloy C276 material is adopted as the balance kettle body so that the balance kettle body can resist a high temperature of 823K and a high pressure of35MPa, and a stable phase balance state can be obtained in a relatively large temperature and pressure range; the reasonable feeding system ensures that reagents entering the balance kettle are consistent in composition and are uniformly mixed; a precise temperature and pressure control system and a mechanical stirring device ensure that a fluid phase in the balance kettle is fully balanced; the reasonable sampling system ensures that the phase balance of the flow system is not influenced in the sampling process, the high-voltage conductivity detection pool can detect the conductivity of the sample on line, and the solubility data of the fluid is further obtained.

Owner:XI AN JIAOTONG UNIV

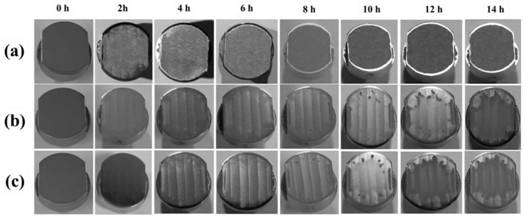

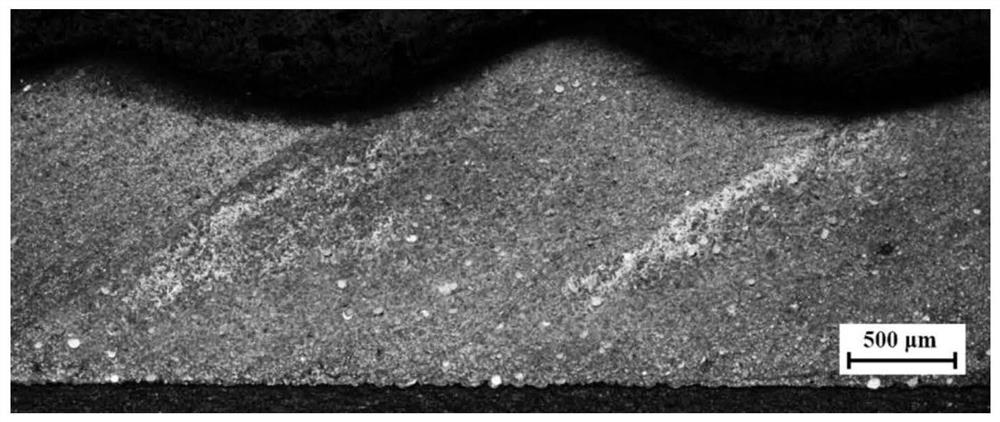

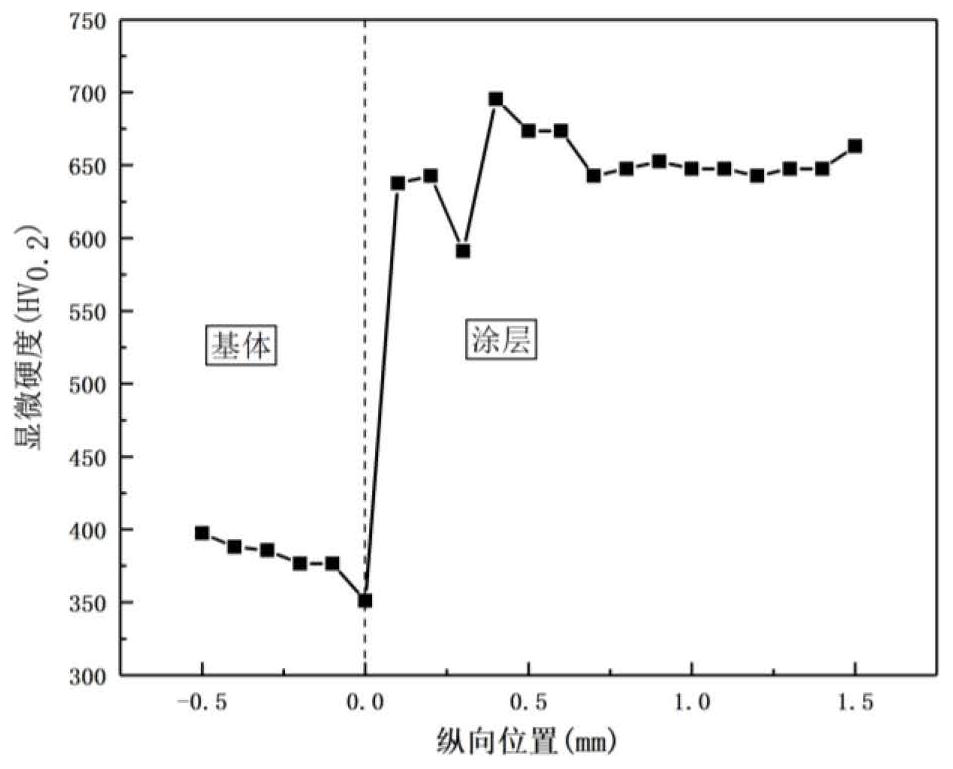

Preparation method of cobalt-based anti-cavitation coating of plastic deposition based on work hardening

InactiveCN111793795ALow critical speedImprove anti-cavitation performancePressure inorganic powder coatingCoated surfaceRobotic arm

A preparation method of a cobalt-based anti-cavitation coating of plastic deposition based on work hardening comprises the steps that an oxidization film on the surface of a metal matrix is removed, oil dirt and residual impurities on the surface are removed through cleaning, and after the metal matrix is dried in air, the matrix is fixed to a workbench; (2) powder is placed in a vacuum drying boxto be dried, and after being dried, the powder is cooled to room temperature to be placed in a powder feeder; (3) the carrier gas kind, the carrier gas pressure, the preheating temperature and the powder feeding rotating speed are set in a cold spraying panel; (4) laser power is set in a laser control panel; (5) a mechanical arm is started, the spraying coating lap-joint rate and the scanning speed are input, the mechanical arm is adjusted, so that a cold spraying nozzle is perpendicular to the surface of the matrix, and the angle of a laser head is adjusted, so that laser spots coincide withspraying powder spots; (6) equipment is started, and supersonic-speed laser deposition experimenting is carried out in the matrix; and (7) after processing is completed, the coating on the surface ofthe metal matrix is subjected to aftertreatment, and the surface of the coating is leveled.

Owner:ZHEJIANG UNIV OF TECH

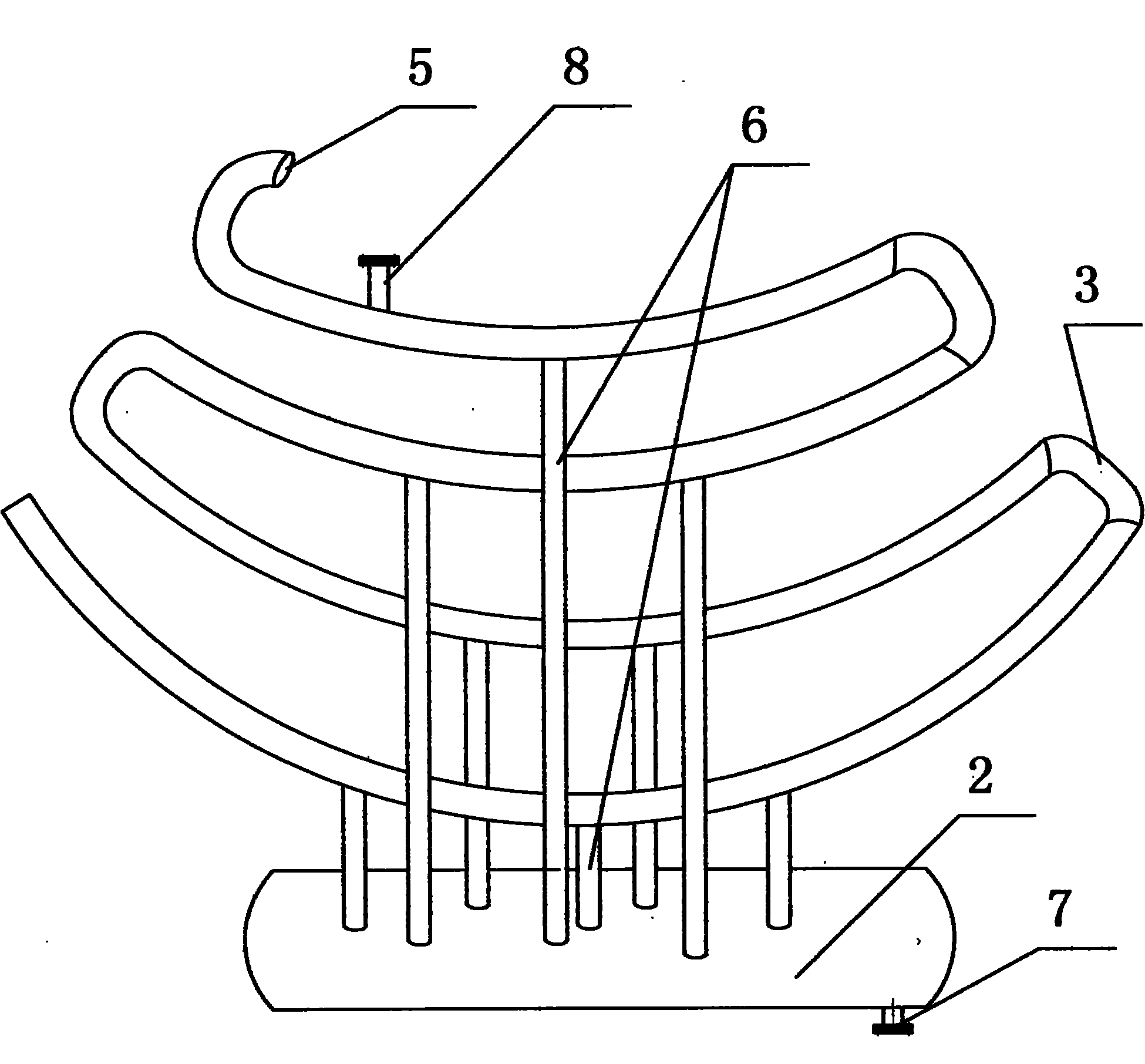

Device for preparing fully deposited silicon carbide coatings by chemical vapor deposition

ActiveCN108546928BFlow adjustmentAvoid shockChemical vapor deposition coatingCarbide siliconChemical vapor deposition

The invention relates to a device for preparing a fully deposited silicon carbide coating by chemical vapor deposition, and belongs to the technical field of silicon carbide coating preparation. According to the main technical scheme, the device for preparing the fully deposited silicon carbide coating by the chemical vapor deposition includes a cavity, a support ring, gas flow interfering bodiesand supporting members. An air inlet device is arranged at the top of the cavity, and an air outlet device is arranged at the bottom of the cavity. The outer side wall of the support ring is connectedto the inner wall of the cavity, and the cavity is divided into an upper cavity and a lower cavity which communicate with each other in the middle. One ends of the gas flow interfering bodies are disposed on the support ring and arranged in the direction from the support ring to the top of the cavity, and the number of gas flow interfering bodies is greater than or equal to three. The supportingmembers are disposed at the bottom of the cavity for supporting a sample of a coating to be deposited and the sample is located in the lower cavity. The device for preparing the fully deposited silicon carbide coating by the chemical vapor deposition is capable of obtaining the fully deposited silicon carbide coating on the surface of the sample.

Owner:CHINA BUILDING MATERIALS ACAD

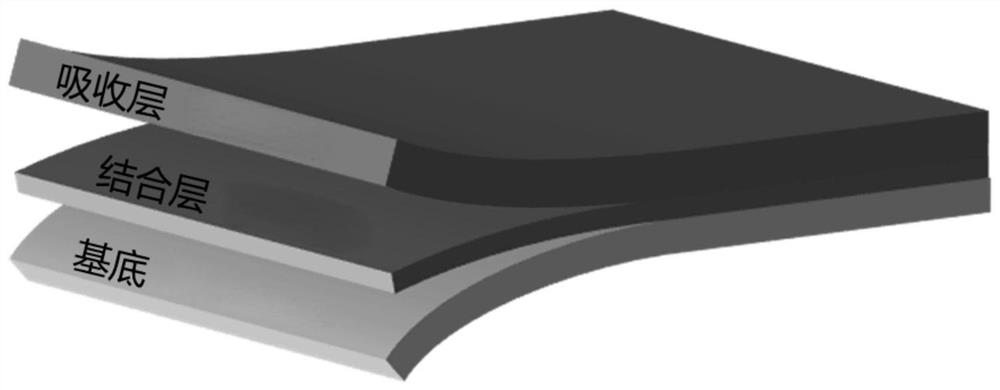

Carbon-based micro-nano photo-thermal coating layer and preparation method thereof

ActiveCN114054318ASimple structureExcellent superhydrophobic propertiesSpecial surfacesCoatingsIr reflectionMicro nano

The invention discloses a carbon-based micro-nano photo-thermal coating layer and a preparation method thereof, and belongs to the field of solar photo-thermal conversion, wherein the carbon-based micro-nano photo-thermal coating layer comprises a film-coated substrate, and the surface of the substrate is sequentially spin-coated with RTV-1 and deposited with candle ash; the carbon-based micro-nano photo-thermal coating layer is characterized in that metal aluminum is used as an infrared reflecting layer of the film-coated substrate, and has the function of reducing the infrared emissivity of the coating layer; the RTV-1 layer is a deposition layer and has the function of enhancing the binding force of a carbon nanoparticle coating layer; and the carbon-based micro-nano layer is a candle ash deposition layer and has the functions of absorbing solar radiation and improving the absorption performance of the surface. The prepared carbon-based micro-nano photo-thermal coating layer has high absorptivity and low emissivity, the photo-thermal conversion efficiency of a flat plate type heat collector can be greatly improved, preparation is simple, and the actual cost is relatively low when the method is applied.

Owner:SHAANXI UNIV OF SCI & TECH

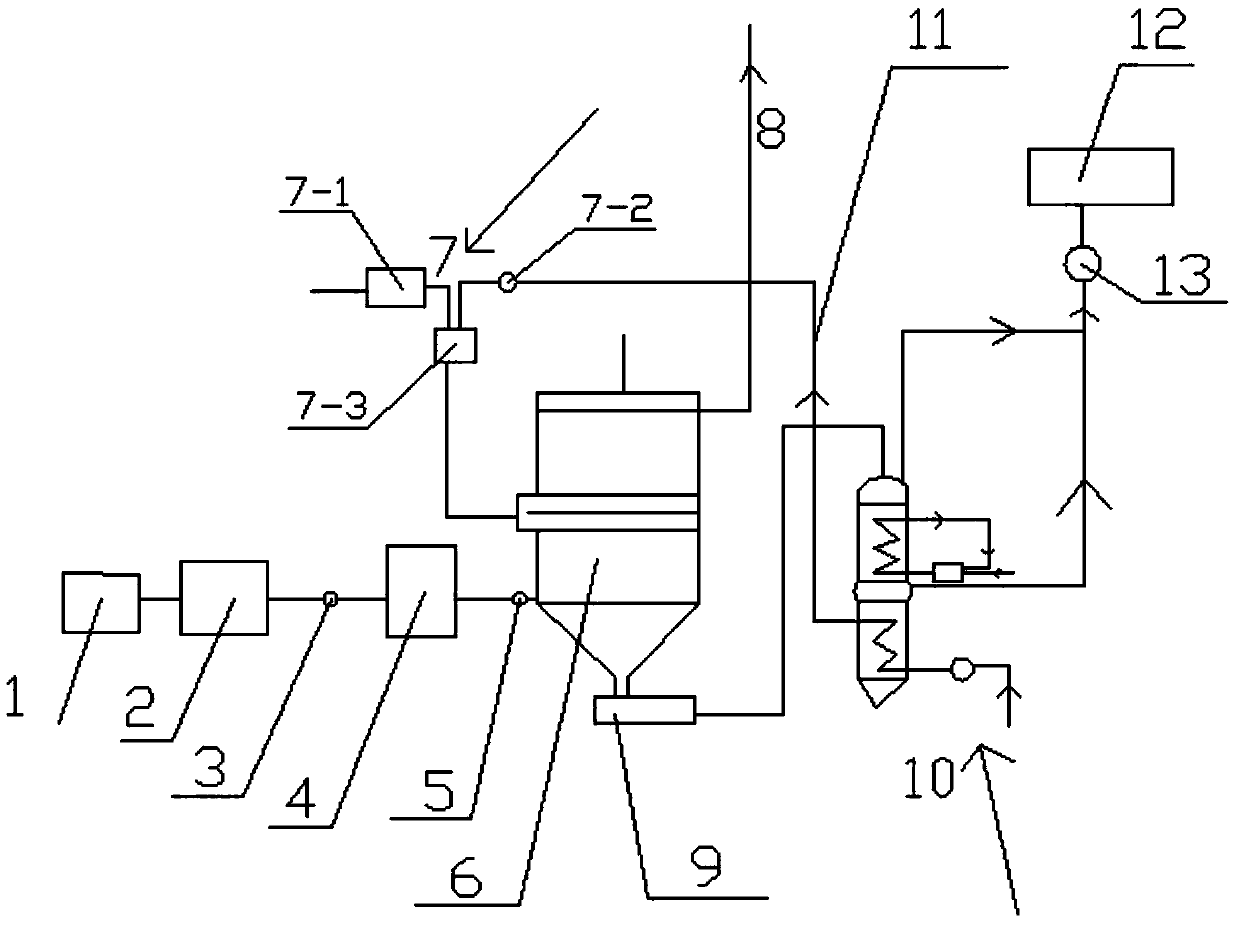

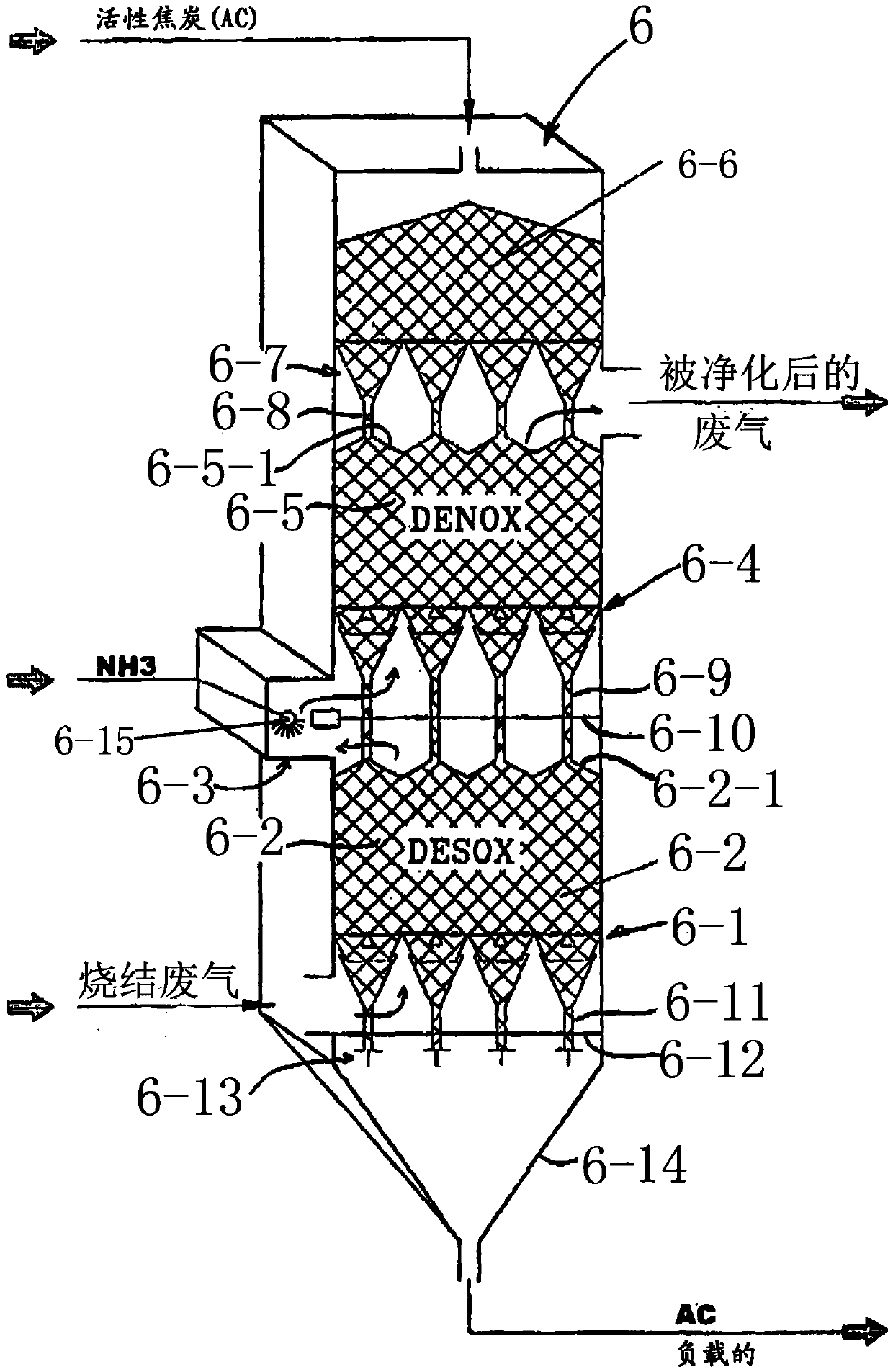

Method and device for treating solid combustion exhaust gas

PendingCN110813050AEasy to provideTo offer comfortCombination devicesGas treatmentExhaust gasExhaust fumes

The invention discloses a method and device for treating solid combustion exhaust gas. The method for treating the solid combustion exhaust gas includes the steps of removing at least major amount ofSOX and possibly other pollutants, pre-removing of NOX and removing of NOX and / or other reaction products. The device for treating the solid combustion exhaust gas includes a moving bed reactor for removing SOX, NOX and possibly other pollutants in the solid combustion exhaust gas, a NH3 supply unit and a regeneration unit for an adsorbent; and after air cooled by the adsorbent in the regenerationunit flows out of a cooling section of the regeneration unit, the air can be introduced into a dilution fan in the NH3 supply unit. According to the method and device for treating the solid combustion exhaust gas, simple and convenient production of NH3 can be realized, recycle of gas during the regeneration of the adsorbent is realized, and the gas during regeneration of the adsorbent can be used in the NH3 supply unit.

Owner:BEIJING ZHTD ENVIRONMENTAL PROTECTION TECH CO LTD

Double-tube electrolytic dephosphorization device

PendingCN111039475AReduce adhesionFully removedWater contaminantsTreatment involving filtrationElectrolysisReducer

The invention discloses a double-tube electrolytic dephosphorization device, which comprises a water inlet, a water outlet, a filter pipe and at least two metal sleeves which are vertically arranged and are sequentially connected in series. Each metal sleeve comprises a water inlet tee joint, a water outlet tee joint, a metal outer pipe, a metal inner pipe, a concentric reducer and a precipitationpipe. Ports of the water inlet tee joint are respectively communicated with the water inlet, the bottom end of the metal outer pipe and the top end of the precipitation pipe; ports of the water outlet tee joint are respectively connected with the top end of the metal outer pipe, the bottom end of the concentric reducer and the water inlet tee joint of the next metal sleeve; the top end of the metal inner pipe is sleeved in the concentric reducer, and the bottom end of the metal inner pipe is arranged at the bottom end of the precipitation pipe; a filter element is arranged in the filter pipe;the water outlet is arranged at the top end of the filter pipe; the metal outer pipe is connected with a power anode; and the metal inner pipe is connected with a power cathode. The device has the advantages of simple and feasible structure, low manufacturing cost, convenience in use and maintenance and good electrolysis effect.

Owner:GUANGZHOU NEWEARTH ENVIRONMENTAL PROTECTION IND

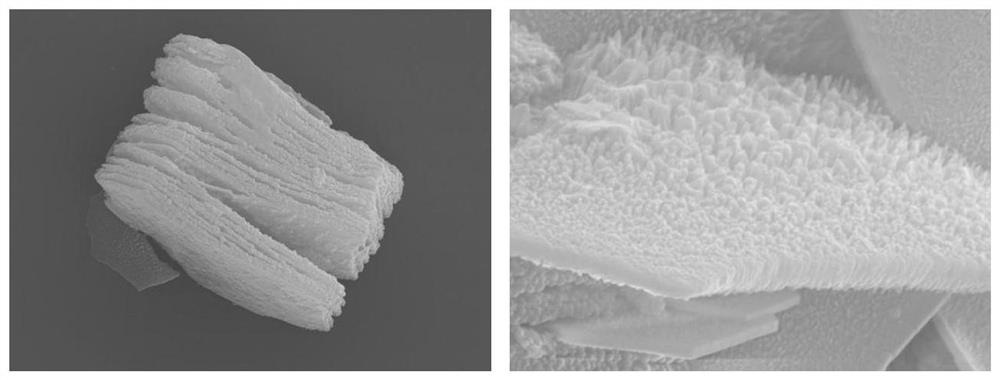

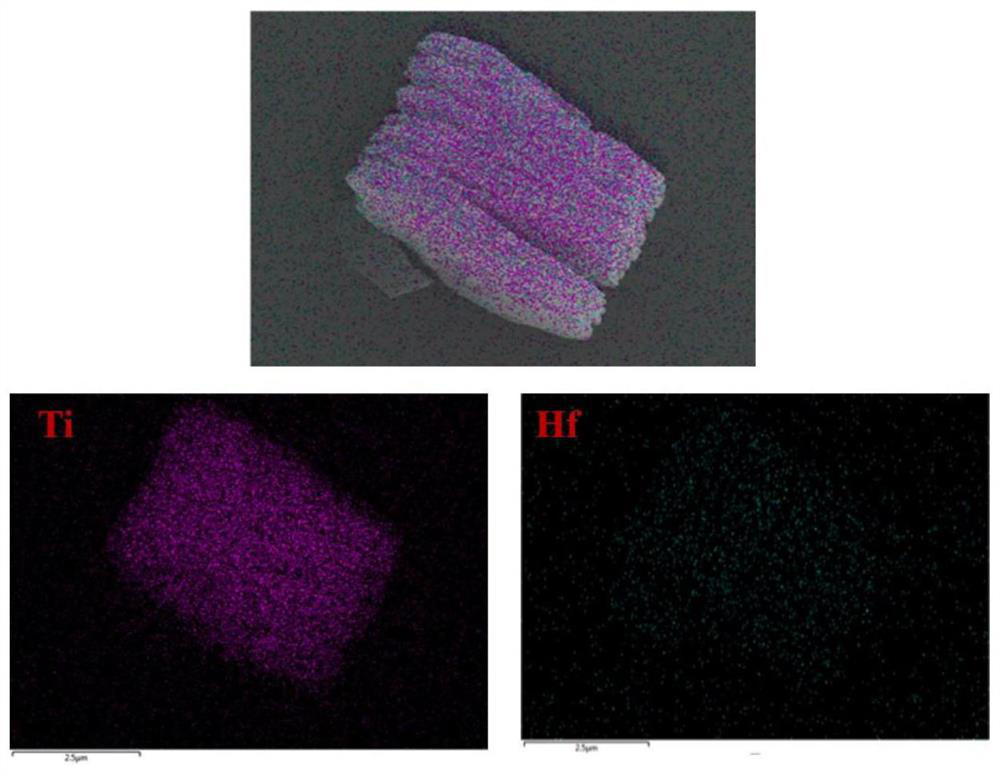

Total dose irradiation resistant SOI (Silicon On Insulator) device and preparation method thereof

ActiveCN113990846AEffective shieldingSimple manufacturing processSemiconductor/solid-state device detailsSolid-state devicesResin matrixEngineering

The invention discloses a total dose irradiation resistant SOI device and a preparation method thereof, and belongs to the field of radiation protection materials. The problems that an existing high-low Z alternate laminated coating process is complex, multiple times of coating and drying are needed, consumed time is long, and the protection capacity is limited are solved. And the technical problem that flexibility cannot be realized is solved. The preparation method comprises the following steps: etching an MAX-phase ceramic matrix to obtain a Ti3C2Tx material with a layered structure, depositing high-Z metal into the Mxene layered structure through an atomic layer deposition technology to obtain a composite material, mixing the composite material with a resin matrix, and coating the mixture on the surface of an SOI device to obtain a radiation protection coating. The material disclosed by the invention can be used in the fields of radiation-proof clothes in life, medical treatment and protection required in nuclear reaction.

Owner:HARBIN INST OF TECH

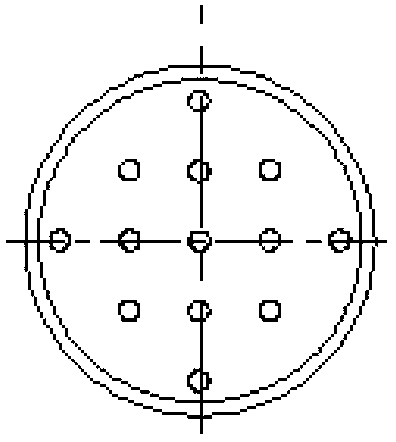

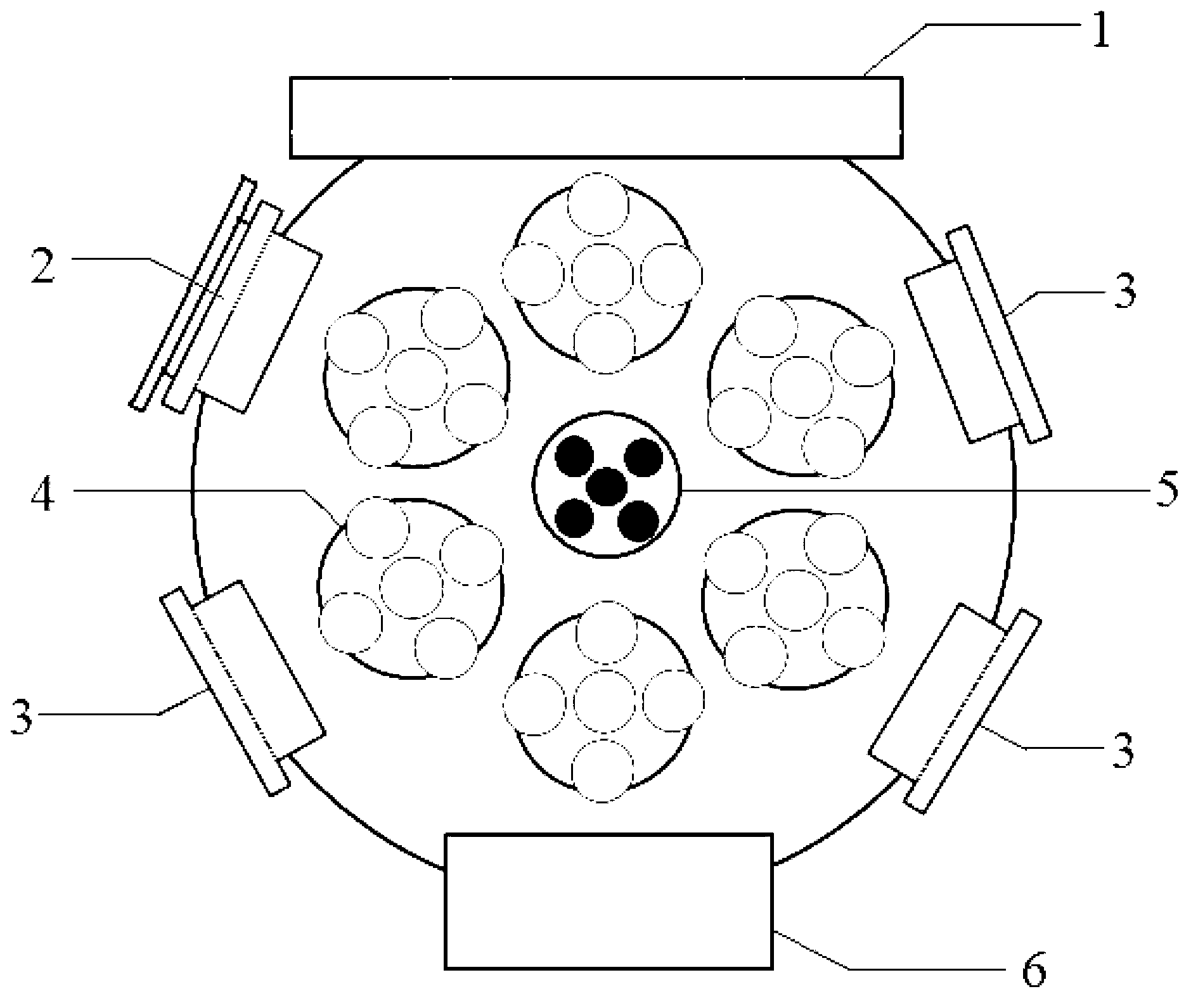

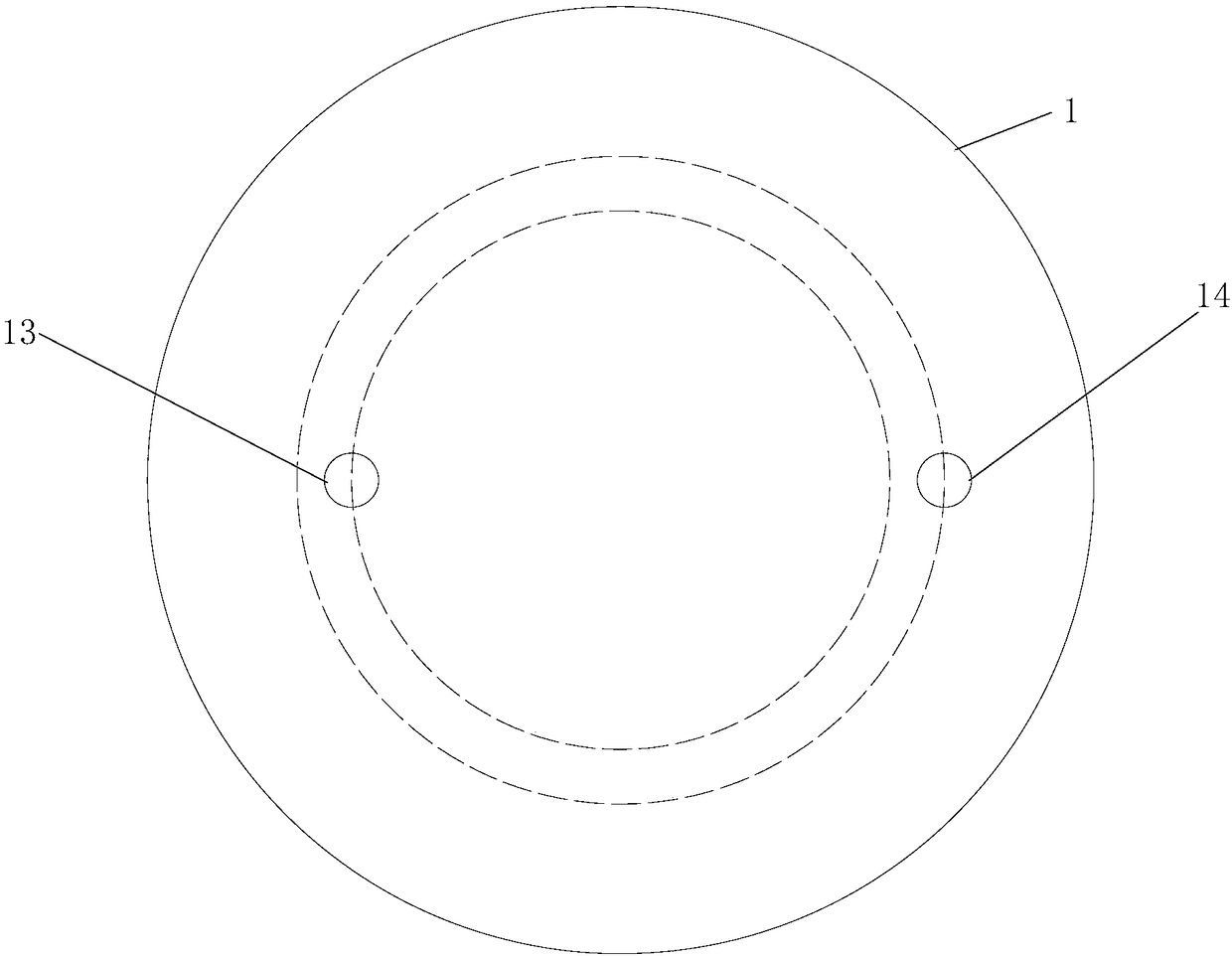

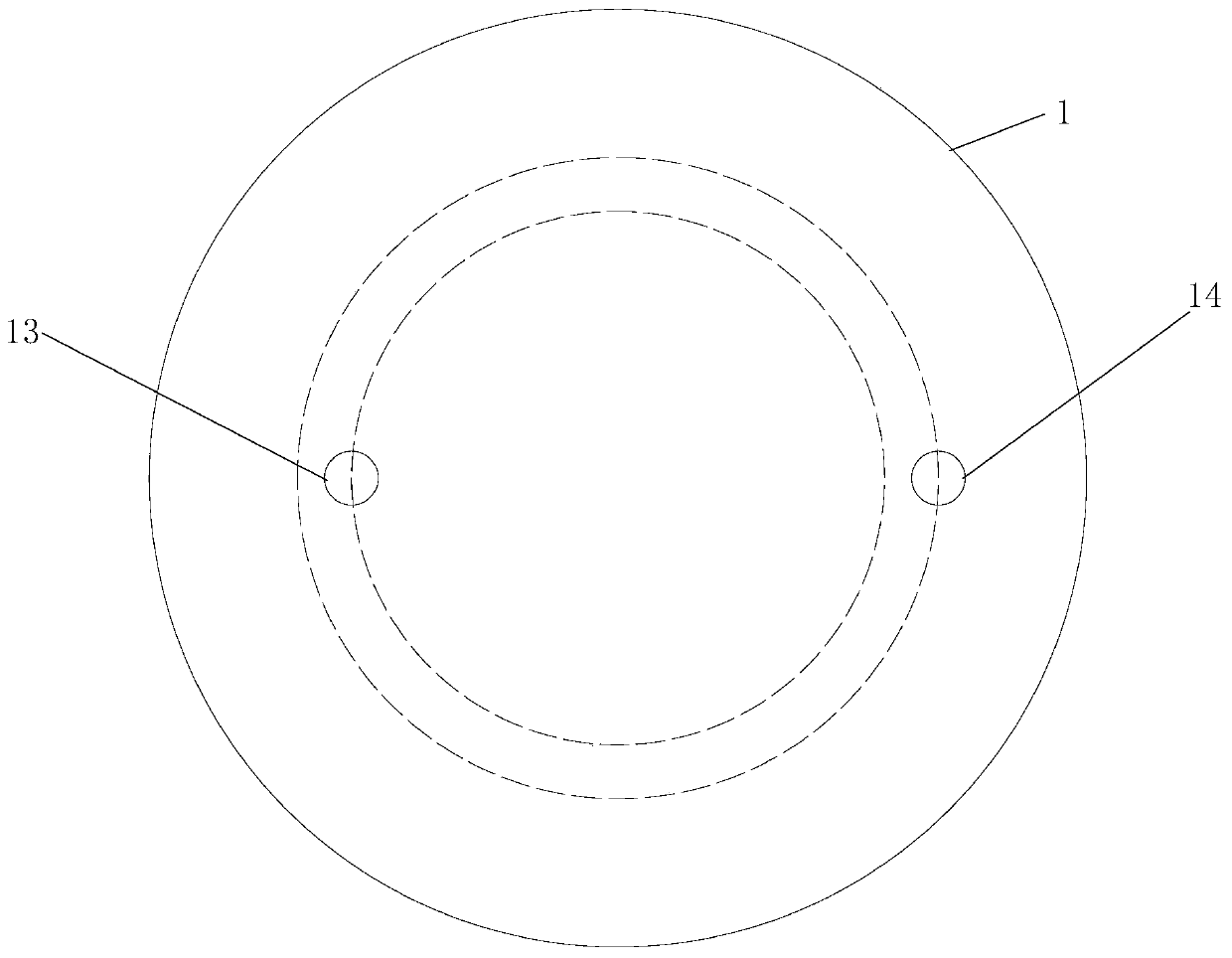

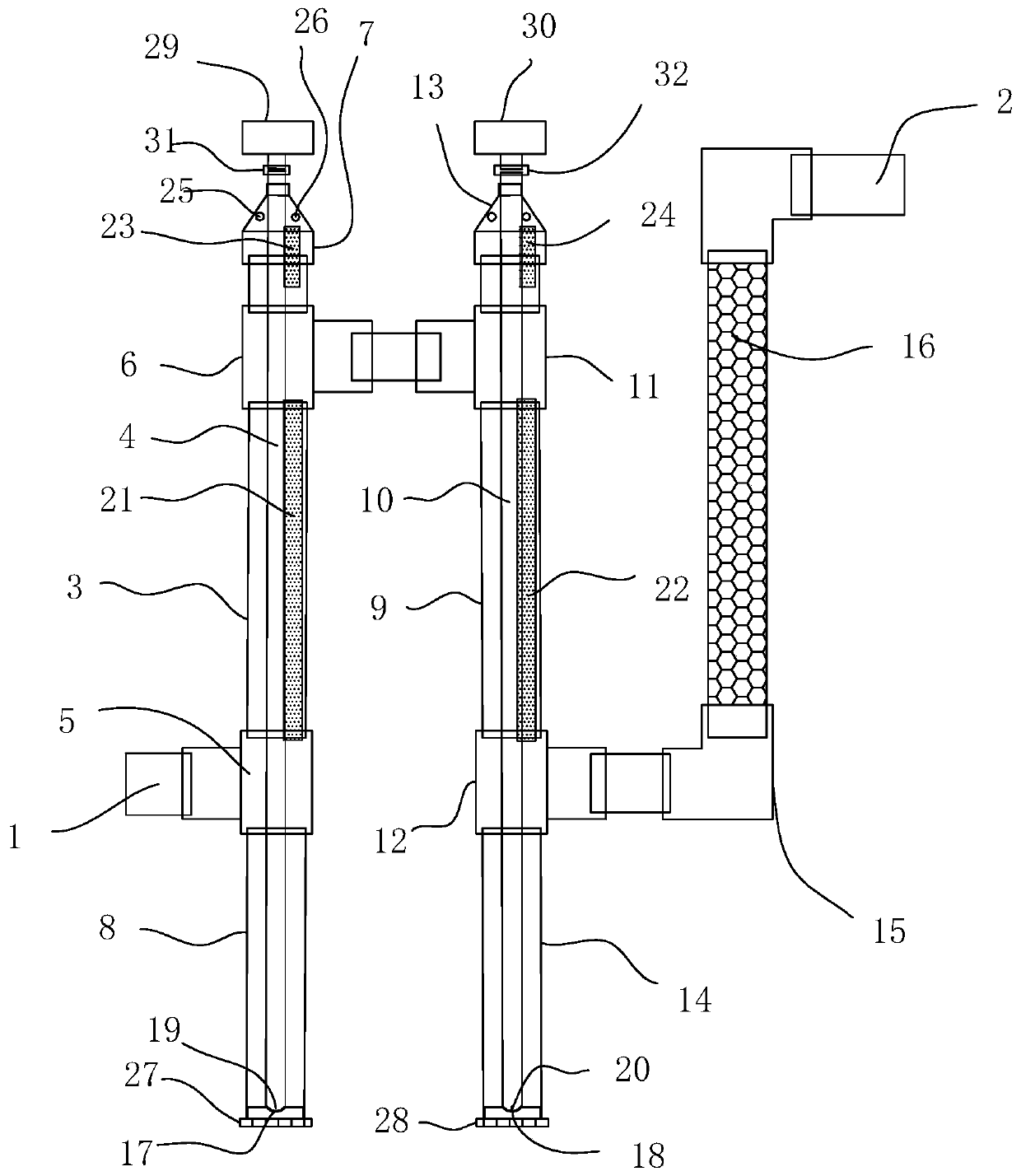

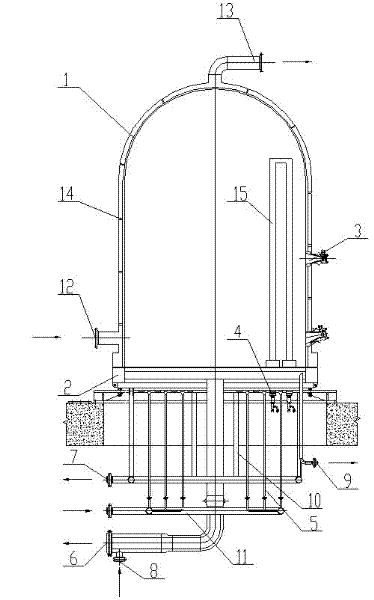

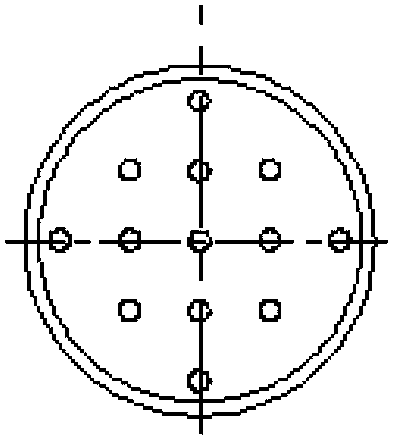

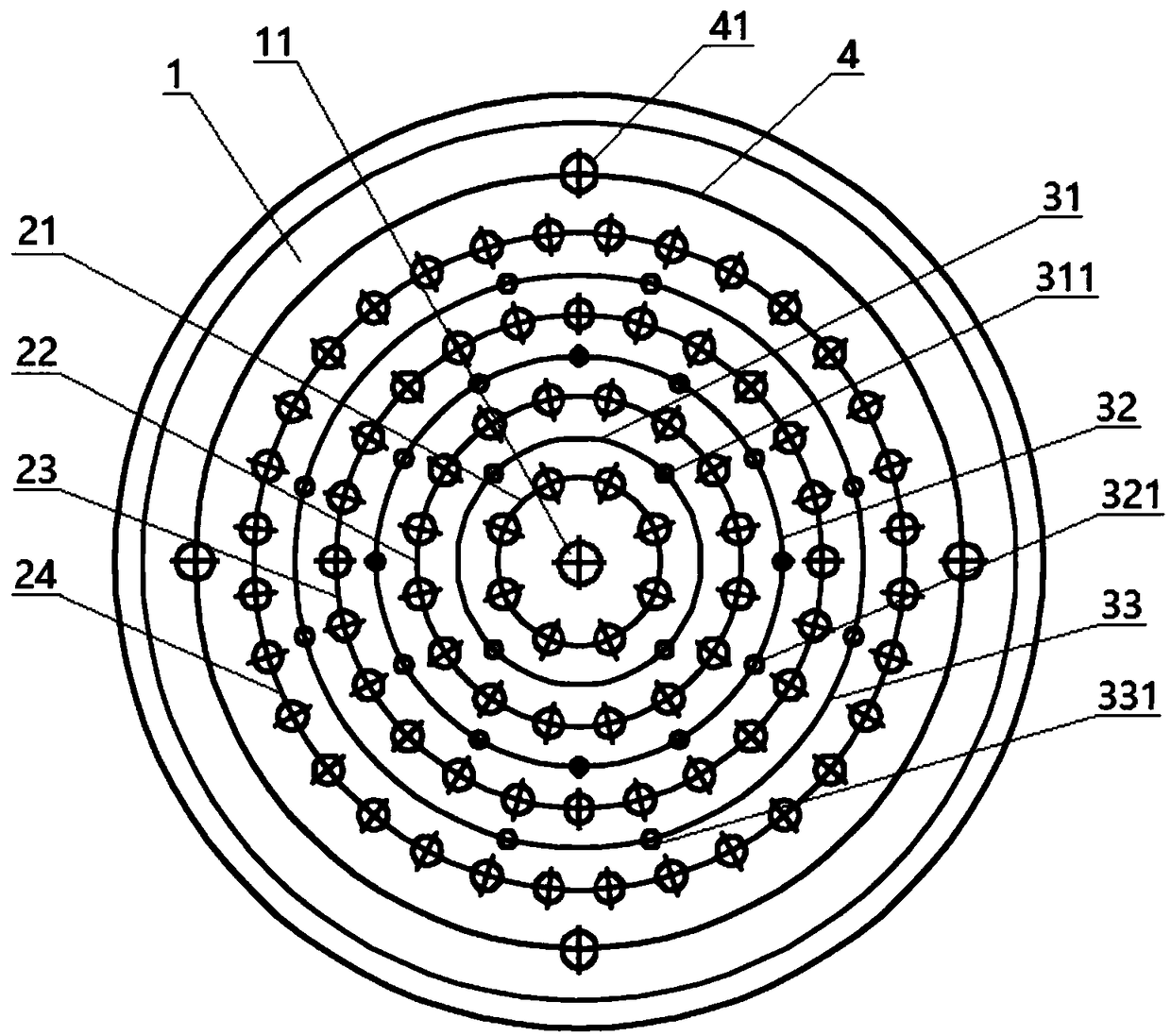

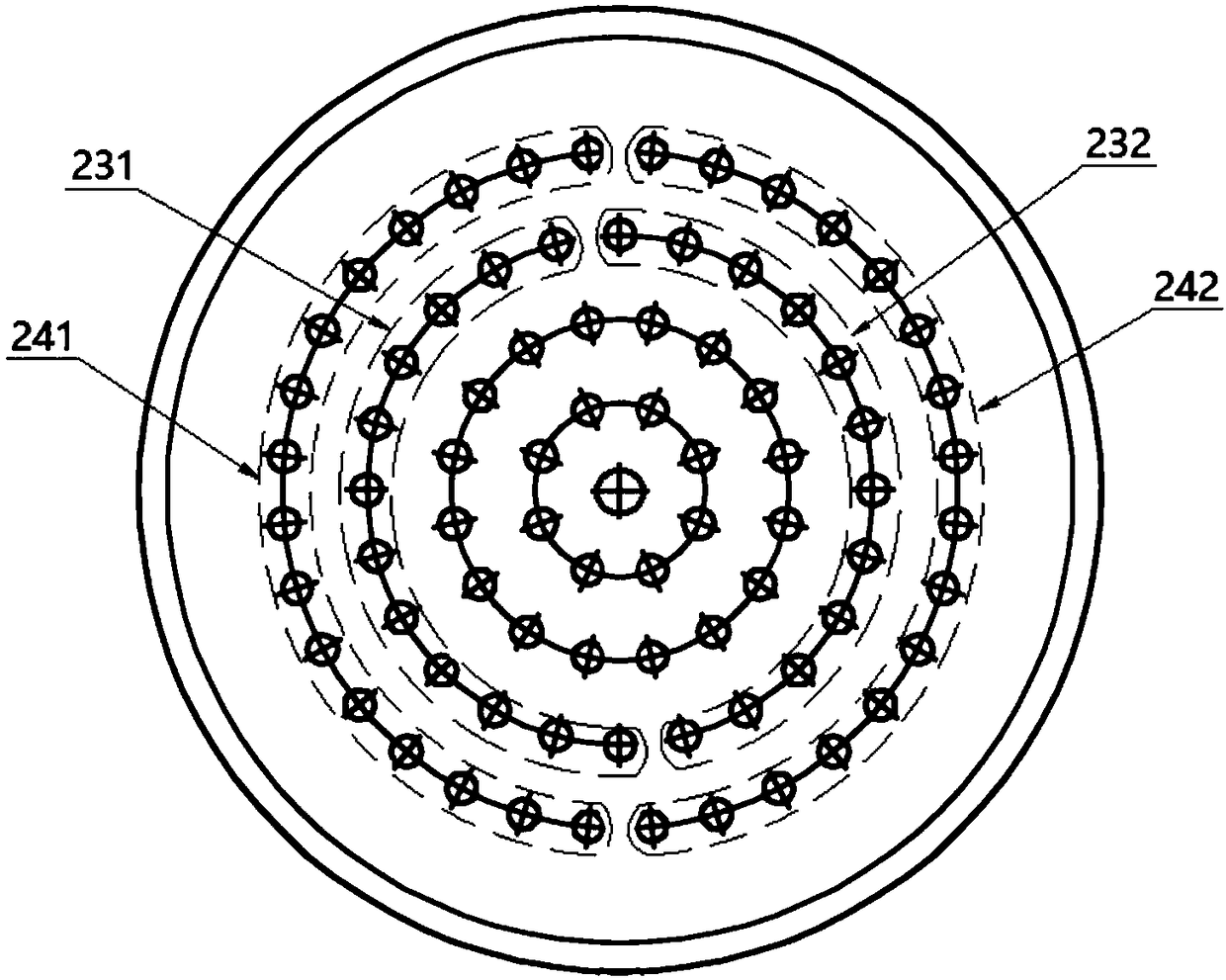

Polycrystalline silicon reduction furnace with 48 pairs of rods

InactiveCN102392299AReduce energy costsReduce manufacturing costPolycrystalline material growthElectrochemical responseChemical reaction

The invention relates to a polycrystalline silicon reduction furnace with 48 pairs of rods, especially to a reduction furnace for manufacturing polysilicon by electrochemical reaction. The polycrystalline silicon reduction furnace provided by the invention comprises a furnace body (1) and a chassis (2) and is characterized in that the furnace body (1) is equipped with a cooling water jacket; the chassis (2) is provided with a water-cooled structure; and 48 pairs of electrodes, namely 96 electrodes, are uniformly arranged on four circles of the chassis (2), wherein the outermost circle of the chassis (2) is provided with 18 pairs of electrodes (4); the second circle is equipped with 14 pairs of electrodes (4); the third circle is provided with 10 pairs of electrodes (4); the innermost circle is provided with 6 pairs of electrodes (4); and anode and cathode of the electrodes (4) are arranged one by one at intervals on the chassis (2). The polycrystalline silicon reduction furnace provided by the invention has a reasonable internal structure layout. The output of a single polycrystalline silicon reduction furnace is raised in comparison with that of a present reduction furnace. The invention can be used to greatly reduce the relative production power consumption of polysilicon per kilogram and relatively decrease the comprehensive energy consumption and production cost of polysilicon.

Owner:SHUANGLIANG NEW ENERGY EQUIP

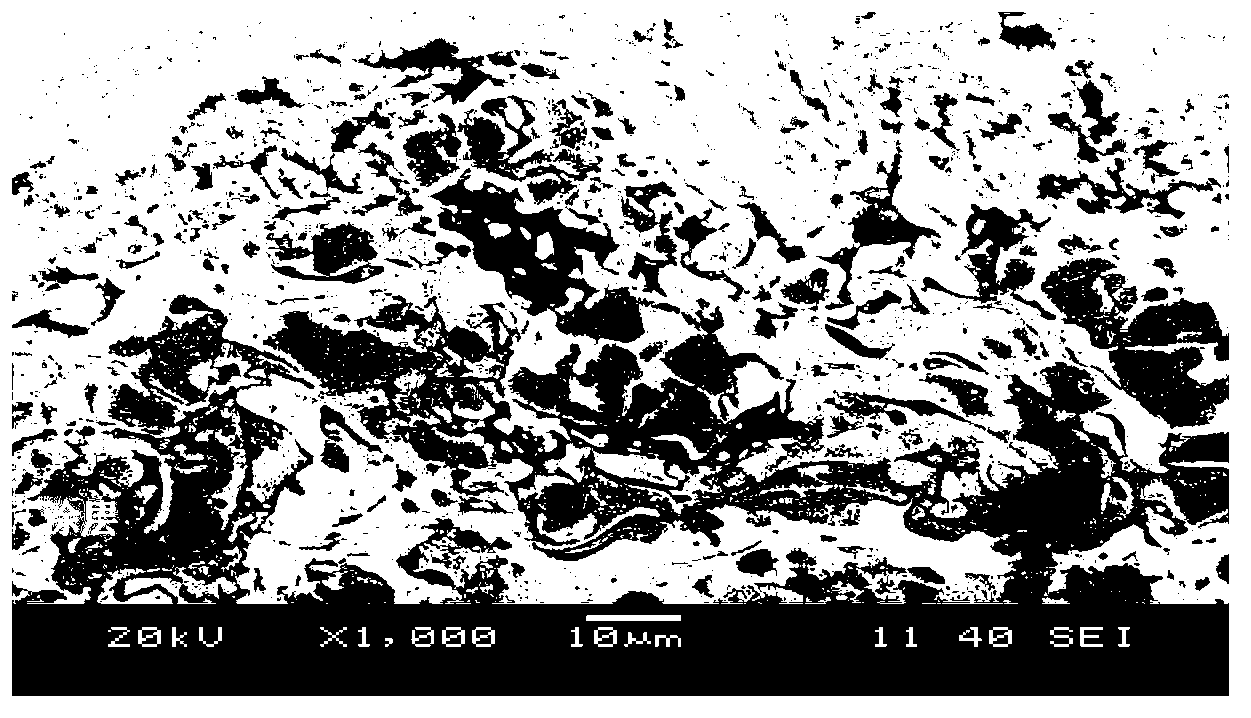

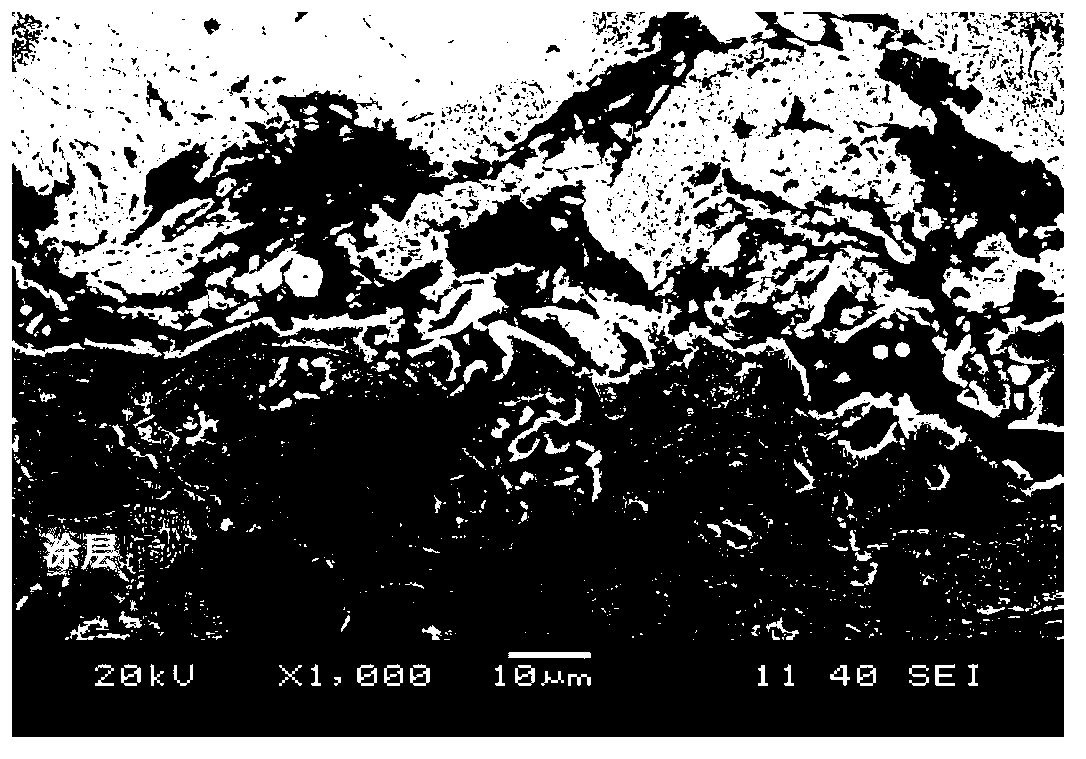

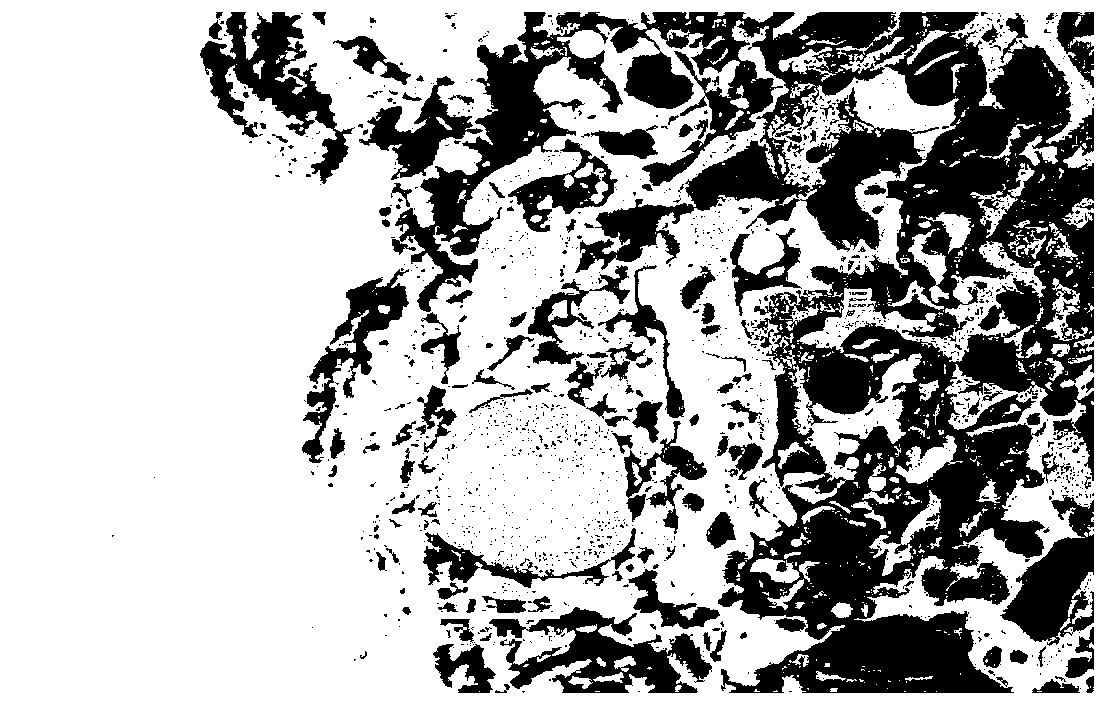

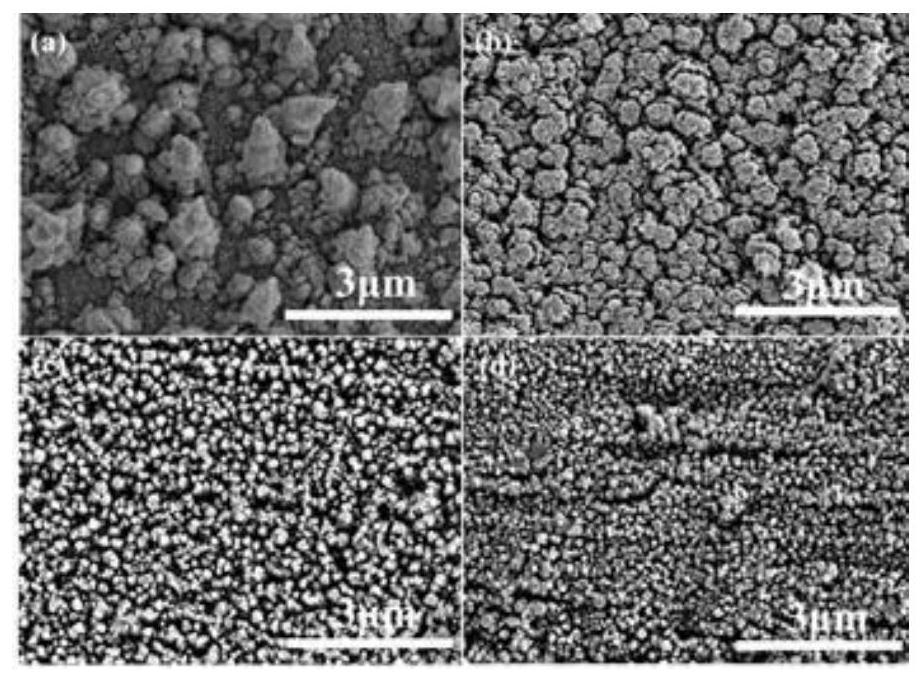

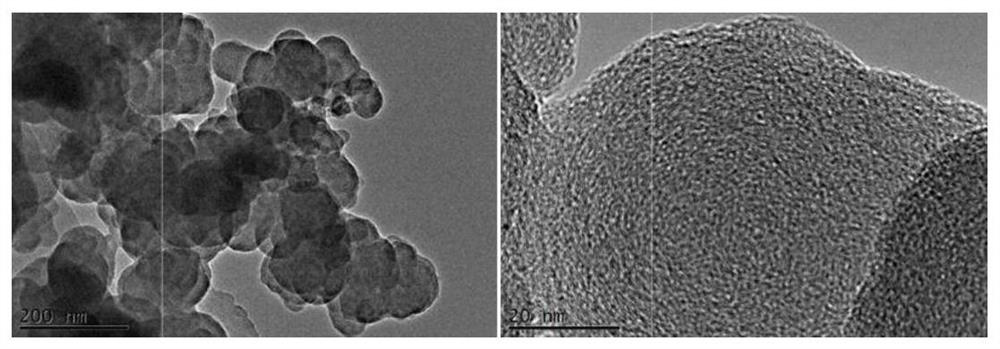

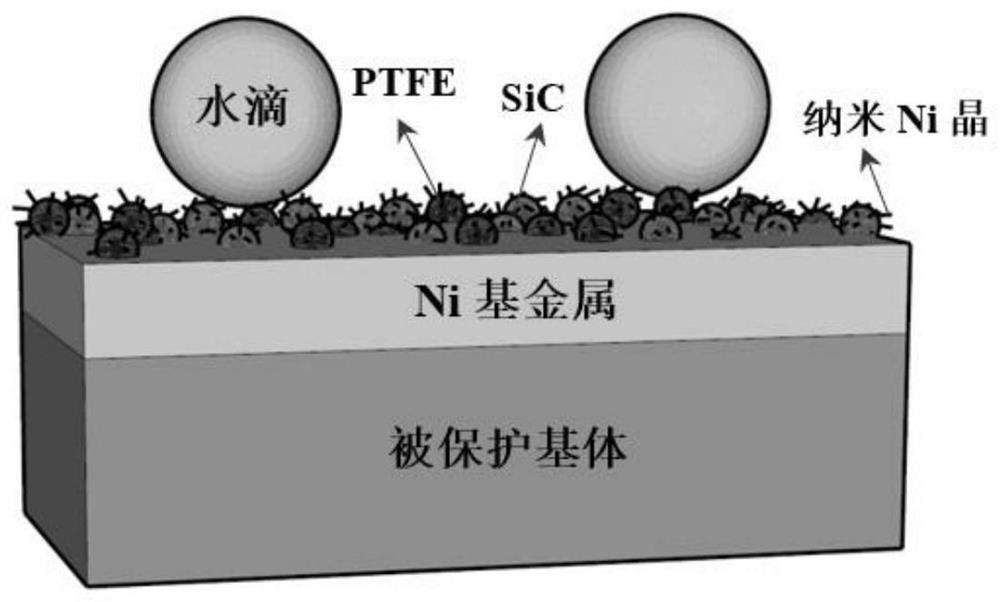

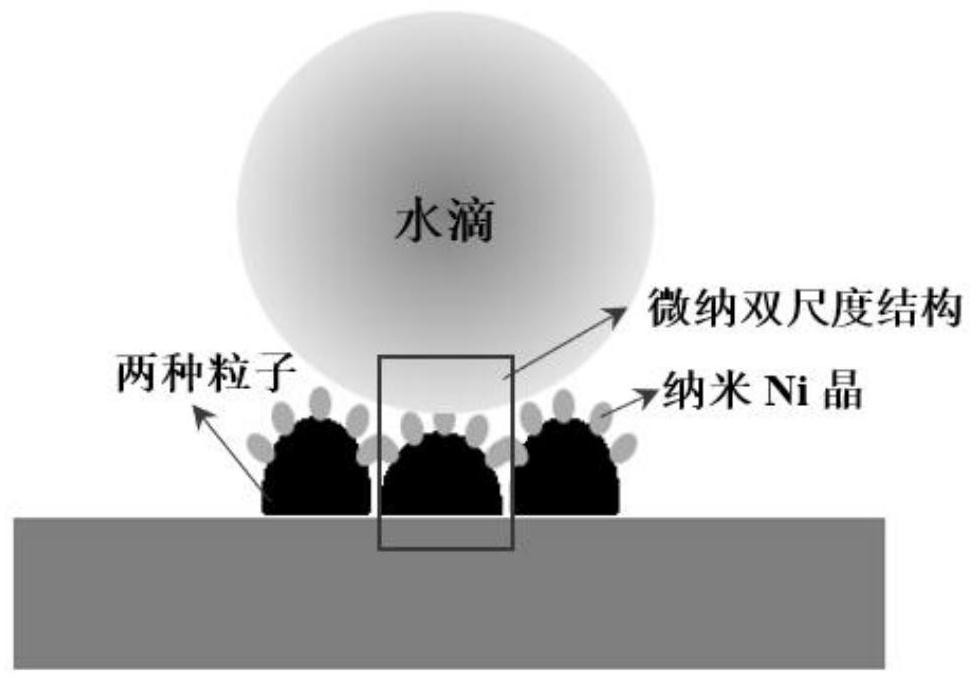

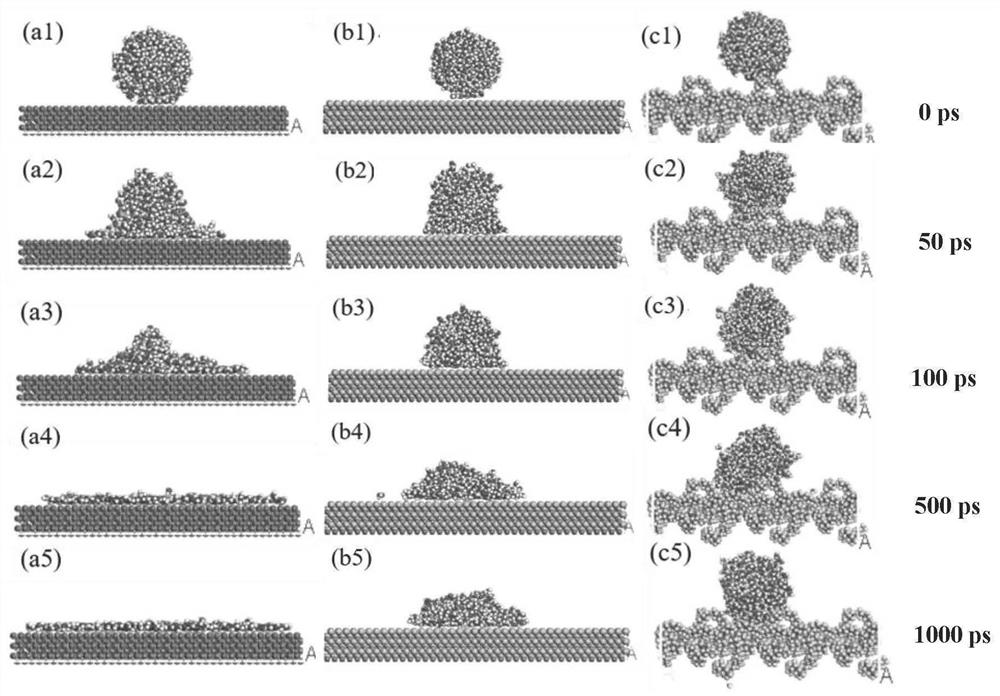

A kind of ni-ptfe-sic superhydrophobic anticorrosion coating and preparation method thereof

ActiveCN113445107BLow self-lubricationReduce hardnessElectrolytic coatingsNanoparticleHigh wear resistance

The invention relates to the technical field of super-hydrophobic coatings, and provides a Ni-PTFE-SiC super-hydrophobic anti-corrosion coating and a preparation method thereof. The invention adds PTFE and SiC nanoparticles into the nickel-based plating solution, utilizes the low surface energy and low friction coefficient of PTFE and the high hardness and high wear resistance of SiC, and prepares Ni-PTFE-SiC on the metal substrate by electrodeposition Super-hydrophobic anti-corrosion coating, no need to use low surface energy substances for secondary modification of the coating. The super-hydrophobic anti-corrosion coating has a micro-nano dual-scale structure, including a nickel metal layer and PTFE and SiC nanoparticles embedded in the nickel metal layer. Nickel crystals are adsorbed on the nanoparticles, and a large number of micro-pores can be formed between the micro-nano dual-scale structure. Trapping air makes the coating achieve good hydrophobicity. After testing, the Ni-PTFE-SiC super-hydrophobic anti-corrosion coating has a good anti-corrosion effect on the substrate, and has excellent mechanical stability and durability.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Combined type helium gas filtering sampling device for gas cooled reactor and installation method of device

ActiveCN103212250BFully depositedLarge filter areaDispersed particle filtrationNuclear energy generationMolecular sieveHelium

The invention relates to a combined type helium gas filtering sampling device for a gas cooled reactor and an installation method of the device. The combined type helium gas filtering sampling device is characterized by comprising a sleeve, at least two filter assemblies which are spaced along the axial direction and are fixed on the inner wall of the sleeve, and at least one molecular sieve assembly fixed between the two adjacent filter assemblies. The filtering sampling device provided by the invention adopts a sandwich combined type structure with the filter assemblies-the molecular sieve-the filter assembly, can fully filter fission product particles and graphite dust with different types and sizes carried by helium from a vapor generator, and can fulfill the purposes of multistage filtering, full deposition and adsorption of the fission product particles and graphite dust.

Owner:CHINERGY CO LTD

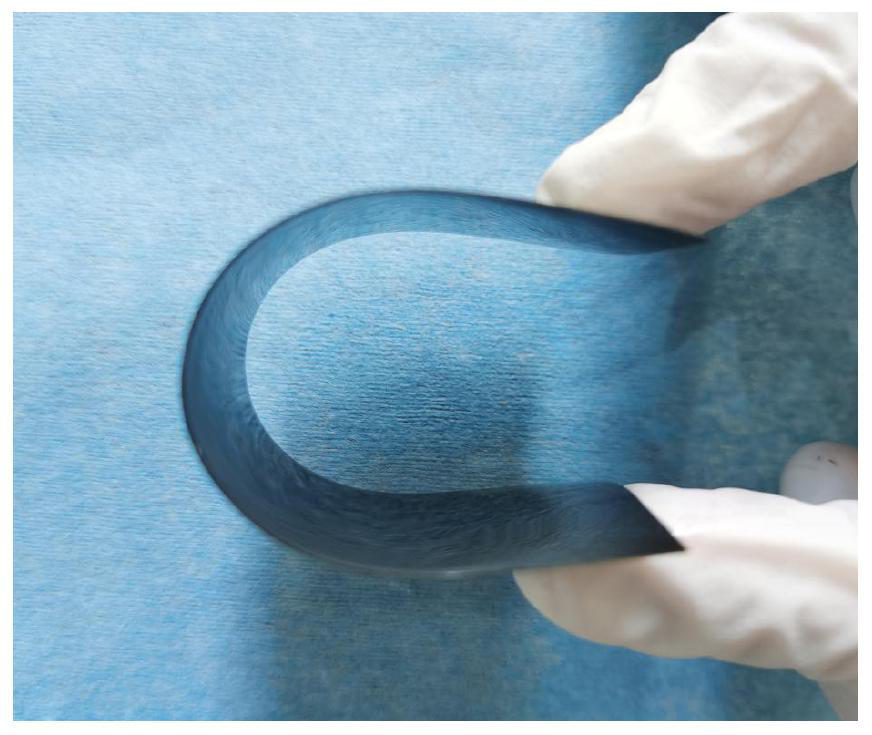

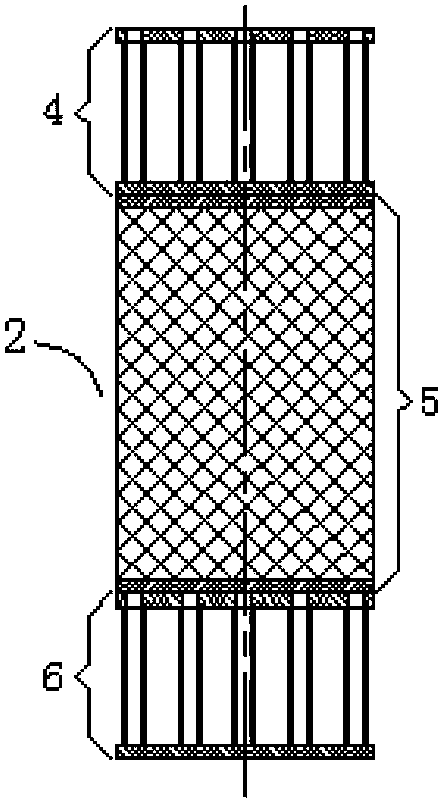

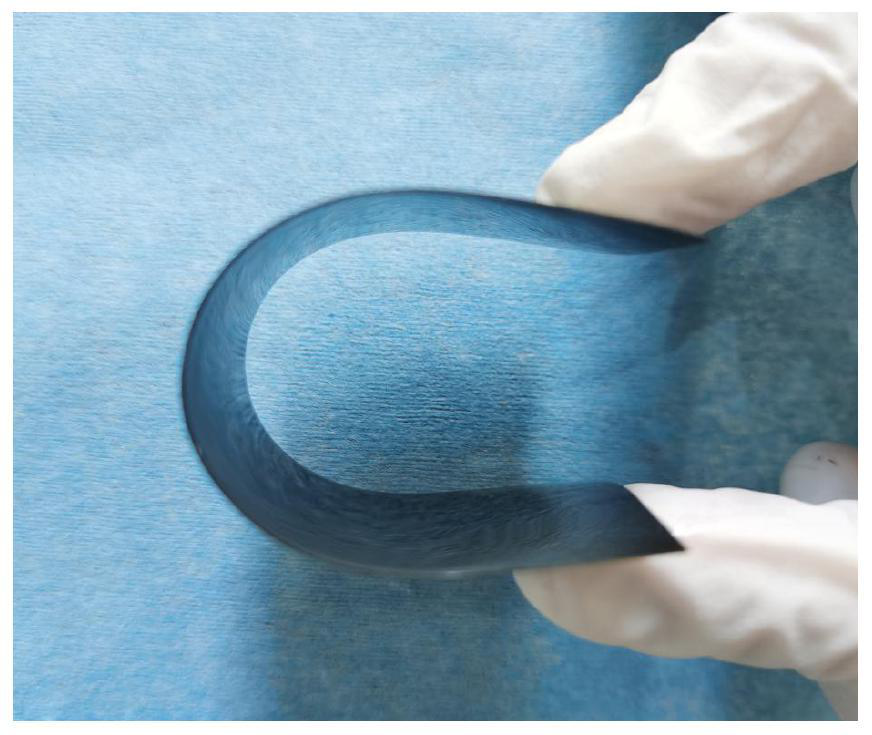

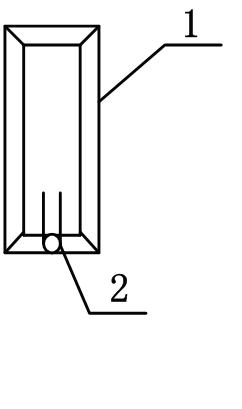

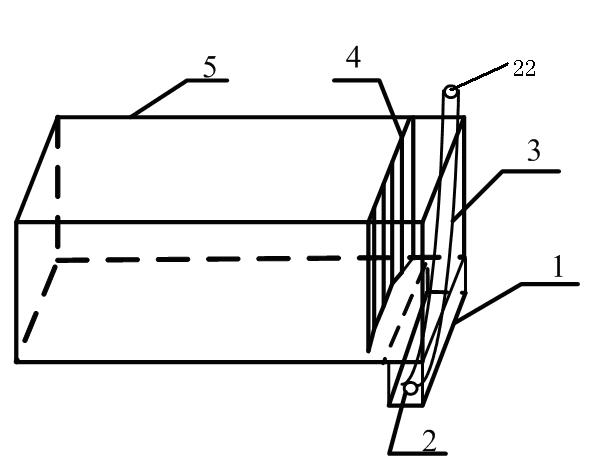

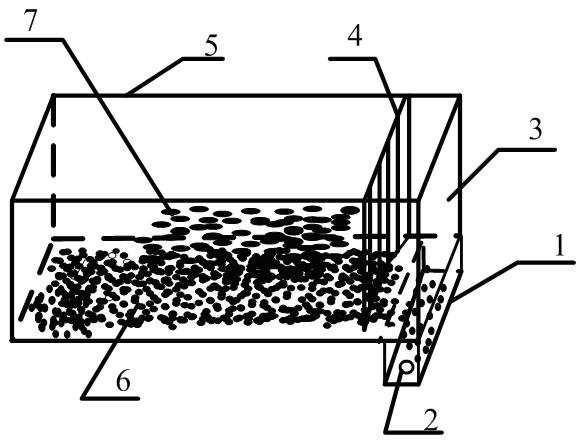

Water treatment deposition filter

ActiveCN101843991BFully depositedLow costSettling tanks feed/dischargeSedimentation settling tanksSlagFilter effect

The invention discloses a water treatment deposition filter which comprises filter pipes and a slag depositing tank and is characterized in that each filter pipe is a arc-shaped pipe of which the two ends are high and the middle is low; the arc-shaped pipes of which the two ends are high and the middle is low are connected and arranged from bottom to top, and two adjacent arc-shaped pipes of which the two ends are high and the middle is low are respectively arranged on a layered structure formed between an upper layer and a lower layer; a water inlet is formed at one end of a arc-shaped pipe at the undermost layer, and the other end of the arc-shaped pipe at the undermost layer is connected with a arc-shaped pipe at the last second layer; the arc-shaped pipe at the last second layer is connected with a arc-shaped pipe at the last third layer; the outlet of a arc-shaped pipe at the uppermost layer is directly used as a water outlet, or the outlet of the arc-shaped pipe at the uppermostlayer is connected with a water outlet pipe of which the water outlet port is used as the water outlet; deposition supporting pipes which are arranged at the middle concave parts of each layer of arc-shaped pipes of which the two ends are high and the middle is low are connected and communicated into the slag depositing tank positioned at the lower part of the arc-shaped pipe at the undermost layer; and a deposited slag discharging valve is arranged at the lower part of the slag depositing tank. The water treatment deposition filter has simple structure and better filtering effect by testing,and achieves the drinking water quality standard.

Owner:FUJIAN MINQING FONDA ECOLOGICAL AGRI GRAND VIEW GARDEN CO LTD

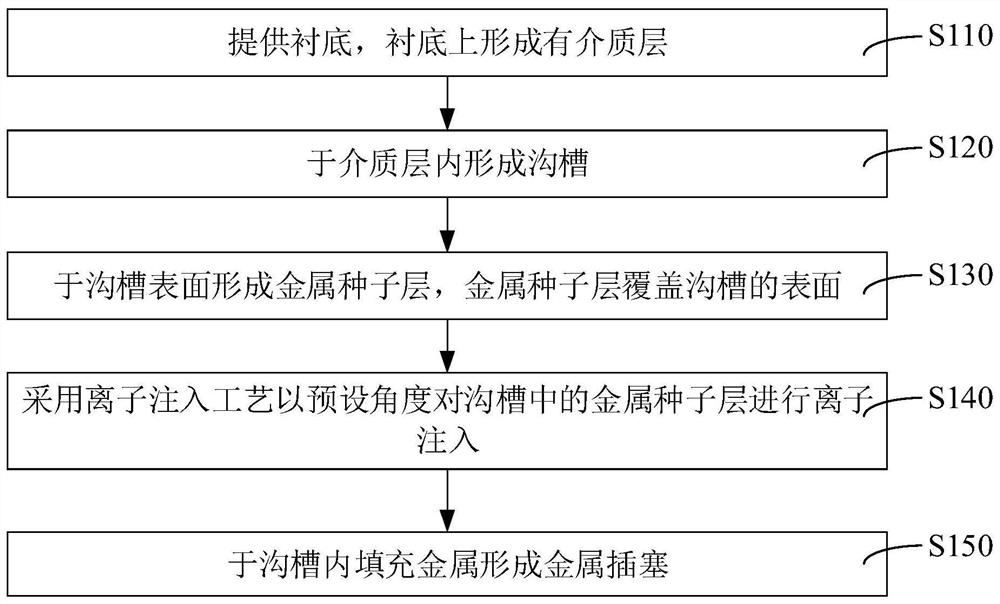

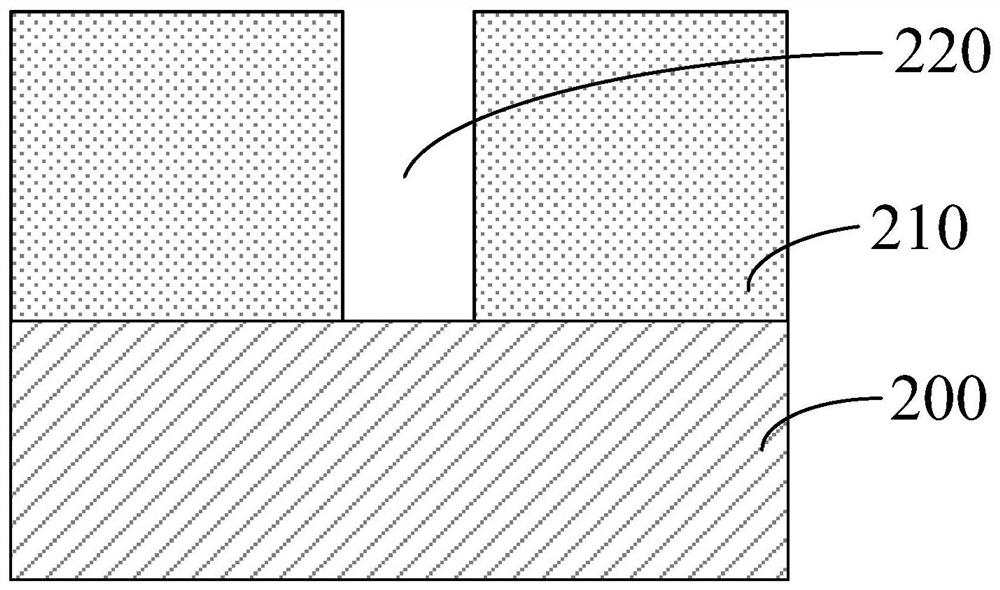

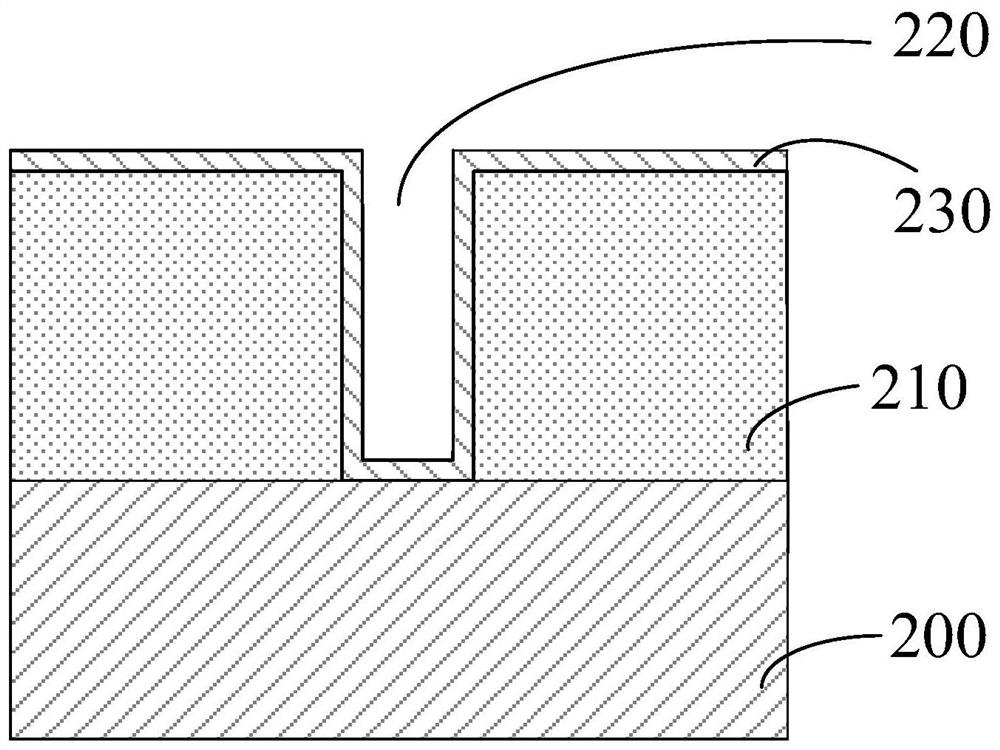

Semiconductor structure and preparation method thereof

InactiveCN112736030AInhibition of nucleationReduce the rate of formationSemiconductor/solid-state device detailsSolid-state devicesSemiconductor structureIon implantation

The invention relates to a semiconductor structure and a preparation method thereof. According to the preparation method of the semiconductor structure, the passivation area of metal in a groove is accurately controlled through ion implantation, then the forming rate of the metal in the groove is reduced, and the forming rate of the metal in the passivation layer is controlled to be slower than that of the metal in the seed layer, so sufficient deposition of the metal in the groove can be promoted, and when the groove with a high depth-to-width ratio is filled, the defects of gaps, holes and the like can be avoided. Meanwhile, a reaction area can be directly defined through ion implantation, the forming area of the metal passivation layer can be accurately controlled, and the control capacity of the technological process is enhanced; and moreover, the metal passivation layer can be used as a barrier layer without adding a removal step, so that the preparation process is simplified.

Owner:CHANGXIN MEMORY TECH INC

A method for preparing graphene or ultra-thin carbon film with PVD technology

ActiveCN103266306BQuality improvementReduce formationChemical vapor deposition coatingCarbon filmOptoelectronics

Owner:YICHANG HOUHUANG VACUUM TECH

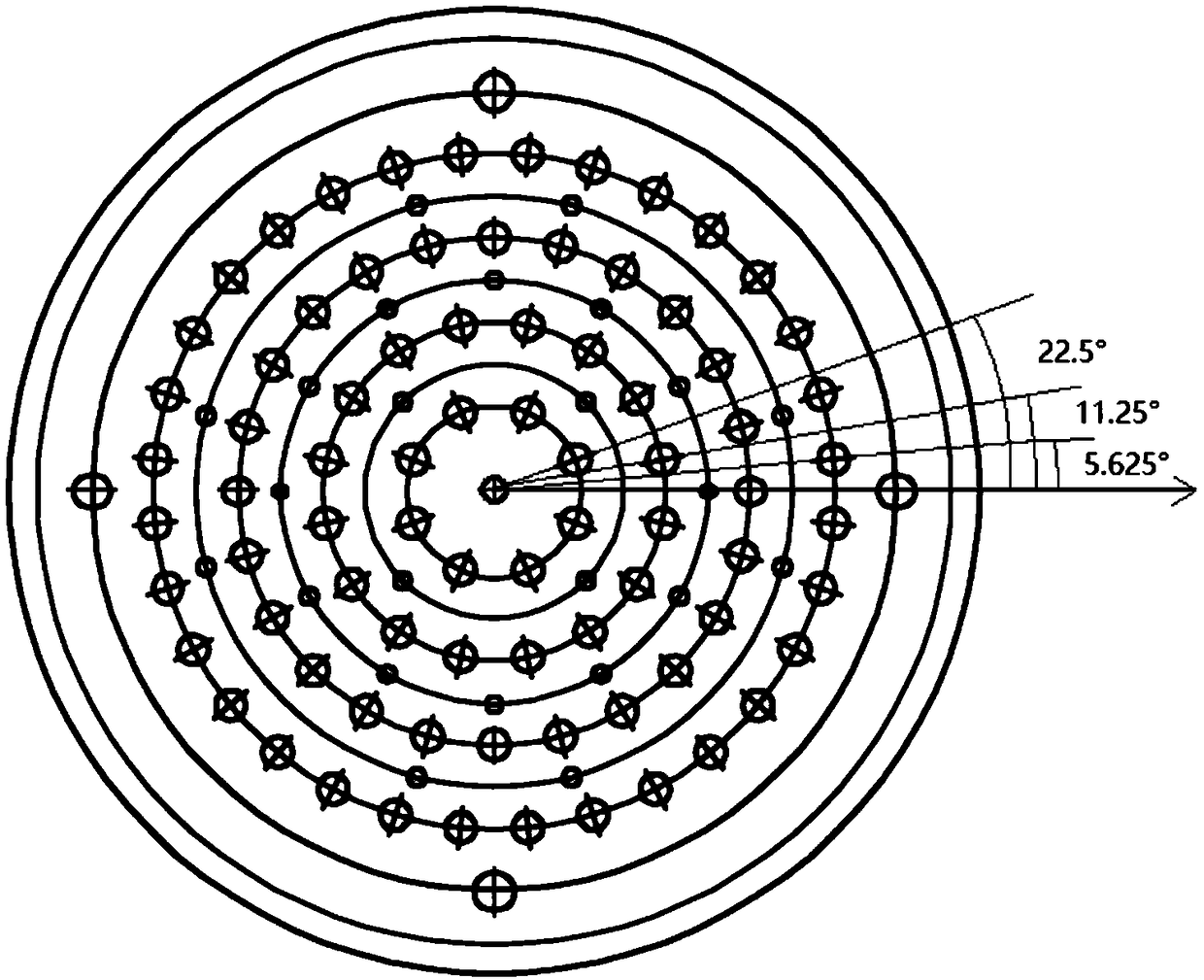

Efficient and energy-saving reducing furnace chassis and polycrystalline silicon reducing furnace

PendingCN108773846AUniform depositionFully depositedChemical industrySilicon compoundsRe engineeringMaterials science

The invention discloses an efficient and energy-saving reducing furnace chassis. The efficient and energy-saving reducing furnace chassis comprises a chassis, wherein a central feeding hole is formedin the chassis, n electrode ring layers and n-1 feeding ring layers are arranged on the chassis, and n is an positive integer more than or equal to 4; the electrode ring layers and the feeding ring layers are arranged at intervals by taking the central feeding hole as a round center; each feeding ring layer is provided with at least four feeding holes; the nth electrode ring layer is provided with4n pairs of electrodes according to the counting of the electrode ring layers from inside to outside; each two adjacent electrodes of the same electrode ring layer are arranged in an equal interval manner; and a discharging ring layer is arranged outside the nth electrode ring layer and is provided with at least two discharging holes, and the two discharging holes are formed in the discharging ring layer in an equal interval manner. By redesigning the layout of the electrodes and feeding holes on and in the reducing furnace chassis, the temperature field and gas field for reaction in a reducing furnace are improved, and meanwhile, the raw material conversion rate is increased, and the production cost is lowered. The invention further provides a polycrystalline silicon reducing furnace including the efficient and energy-saving reducing furnace chassis.

Owner:内蒙古通威高纯晶硅有限公司

Method for Harmless Treatment and Recycling of Chromium Slag and Metallurgical Waste

ActiveCN101942571BAchieve recyclingEfficient use ofSolid waste disposalProcess efficiency improvementMetallurgical slagAdhesive

The invention discloses a method for innocently treating and recycling chromium residues and a metallurgical waste material. The method comprises the following steps of: preparing balls by taking chromium residues to be treated as a raw material and taking pulverized coal, coke powder, gravitationally collected dust or iron-making washing dust as a reducing agent and an adhesive; preparing compound small balls from the adhesive and the balls by taking the dust in a metallurgical iron-containing waste material as a spherical shell raw material on a sintering production line or a pellet production line; putting the compound small balls separately or together with an agglomerate raw material or a pellet raw material into a sintering machine and sintering the mixture into agglomerate or pellet; and allowing the balls to form a reducing atmosphere in the spherical shell at a sintering or baking high temperature so as to realize the pretreatment of the chromium residues and further putting the agglomerate or the pellet into a blast furnace to treat the chromium residues completely. The conventional sintering and blast furnace treatment are adopted on the premise of not changing the overall oxidation atmosphere of sintering, the chromium residues are treated effectively and the dust in the metallurgical iron-containing waste material is utilized effectively, so that the method is economical, environmentally-friendly and easy to implement.

Owner:CHONGQING ANGRUIYUE SCI & TECH

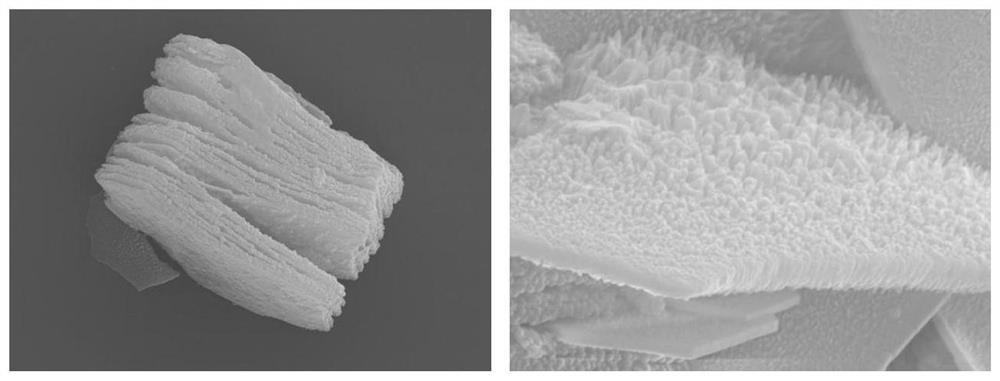

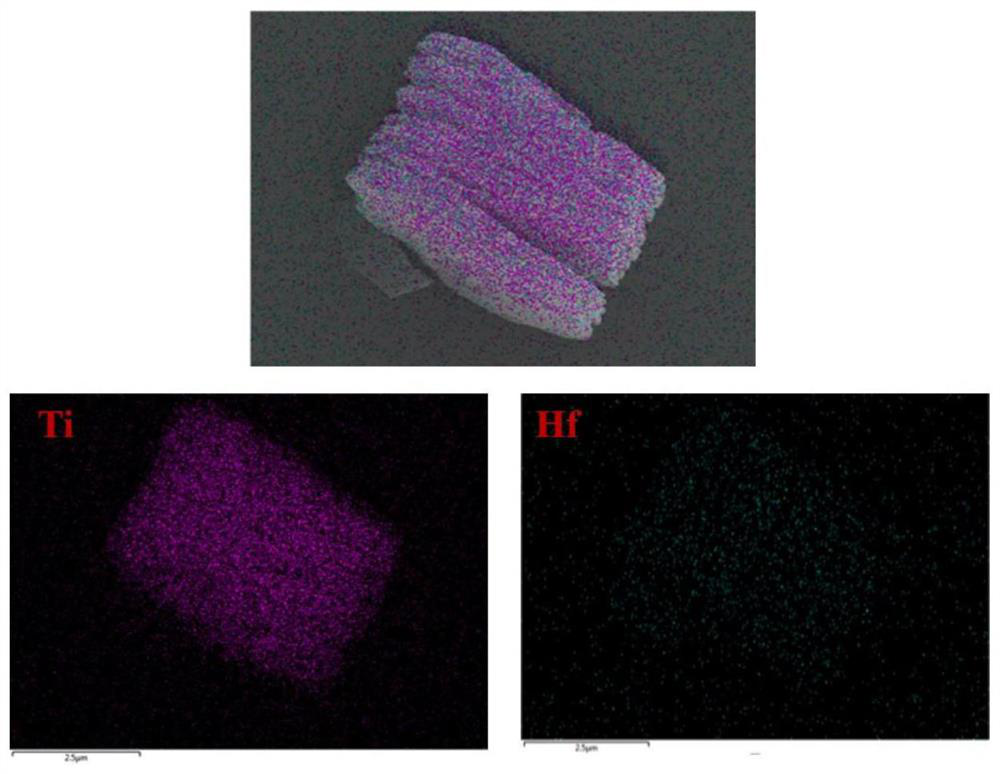

A kind of soi device resistant to total dose irradiation and preparation method thereof

ActiveCN113990846BEffective shieldingSimple manufacturing processSemiconductor/solid-state device detailsSolid-state devicesResin matrixEngineering

An SOI device resistant to total dose irradiation and a preparation method thereof belong to the field of radiation protection materials. The present invention solves the problems that the current high and low Z alternately laminated coating process is complicated, needs to be coated and dried for many times, takes a long time, and has limited protection capability; it also cannot realize the technical problem of flexibility. In the present invention, the MAX phase ceramic matrix is etched to obtain a layered structure of Ti 3 C 2 T x Then, the high-Z metal is deposited into the Mxene layered structure by atomic layer deposition technology to obtain the composite material, and the composite material is mixed with the resin matrix and then coated on the surface of the SOI device to obtain the radiation protection coating. The material of the present invention can be used for radiation protection suits in daily life, medical aspects, and required and protective fields in nuclear reactions.

Owner:HARBIN INST OF TECH

Dehydrating device and dehydrating method

ActiveCN102188842AFully depositedReduce moisture contentSettling tanks feed/dischargeSedimentation settling tanksWater contentSlurry

The invention relates to a dehydrating device and a dehydrating method. The dehydrating device comprises a tank body (5), wherein one side of the bottom of the tank body (5) is provided with a bottom settling tank (1); the side wall of the bottom settling tank is provided with a water outlet (2); and a floater baffle plate (4) is arranged in the tank body (5) and at the front end opposite to the bottom settling tank (1). The bottom settling tank is arranged at the bottom of the tank body, so slurry or ore pulp can be more fully settled, and the water content of a solid material can be effectively reduced. The floater baffle plate is arranged, so the whole device can more effectively prevent floating wastes from being settled, and water brought by the floating wastes is greatly reduced; meanwhile, the device has a simple structure, the using method is simple, and energy and manpower are saved because a water pump is not required to be used.

Owner:YUNNAN DAHONGSHAN PIPELINE

Recycling treatment process of electroplating rinse water

PendingCN114538674AReduce metal cationsAchieve recyclingWater contaminantsDispersed particle separationIndustrial waste waterRinse water

The invention belongs to the technical field of industrial wastewater treatment, and particularly relates to a recycling treatment process of electroplating rinse water. The method at least comprises the following steps: (1) electro-deposition: filling electroplating rinse water into a liquid storage barrel, then sucking the electroplating rinse water into an electro-deposition tank of an electro-deposition device, and adsorbing metal cations in the electroplating rinse water to a cathode in an electro-deposition manner; and (2) circulation: discharging the electroplating rinse water subjected to the first electrodeposition to a liquid storage barrel, sucking the electroplating rinse water into an electrodeposition tank of the electrodeposition device again, and adsorbing residual metal ions in the electroplating rinse water to a cathode in an electrodeposition mode again. The method can greatly reduce the cation content in the electroplating rinse water, realizes water recovery, can obtain an electrodeposited metal layer at the cathode, and realizes metal recycling.

Owner:东莞市盛德电解设备科技有限公司

Natural gas flow measuring device for water-containing natural gas transmission pipeline

PendingCN112284465AEfficient separationImprove accuracyVolume/mass flow by differential pressureFlow transducerMechanics

The invention discloses a natural gas flow measuring device for a water-containing natural gas transmission pipeline; the natural gas flow measuring device is provided with a measuring pipe, a first differential pressure transmitter, a flow totalizer and a second differential pressure transmitter, wherein the measuring pipe is provided with a Pitotbar flow sensor; a top pressure guide pipe and a bottom pressure guide pipe which are communicated with the interior of the measuring pipe are symmetrically arranged on the top wall and the bottom wall of the measuring pipe, and are connected with the input end of the second differential pressure transmitter; the signal output end of the second differential pressure transmitter is connected with the signal input end of the flow totalizer; an airinlet hole and an air outlet hole at two ends of the measuring pipe are respectively connected with pipeline joints which can be in butt joint with the water-containing natural gas transmission pipeline; the inner diameter of each pipeline joint is equal to that of the water-containing natural gas transmission pipeline, and the inner diameter of the measuring pipe is larger than that of each pipeline joints. After the device is applied, the flow of natural gas in the water-containing natural gas transmission pipeline can be relatively accurately measured.

Owner:海南毕托巴科技研究院有限公司

Preparation method of high-temperature resistant microencapsulation turmeric essential oil biological bacteriostatic agent

ActiveCN102885378BImprove interface propertiesRapid depositionFood preservationCapsule deliveryBiotechnologyAcetic acid

The invention discloses a preparation method of a high-temperature resistant microencapsulation turmeric essential oil biological bacteriostatic agent, which comprises the following steps of: dissolving gelatin and peach gum in a wall material to obtain a wall material solution; adding turmeric essential oil into the wall material solution, and emulsifying and dispersing at high speed to obtain emulsion; and stirring the emulsion in a constant temperature waterbath, regulating a pH value by using acetic acid, performing complex coacervation reaction, and forming microcapsule suspension liquid; cooling, regulating the pH value by using NaOH solution, adding glutamine transaminase, solidifying, leaching, drying, and thus obtaining turmeric essential oil microcapsule. The wall material is available, and the turmeric essential oil microcapsule has stable quality, is low in cost, and is safe to eat. The turmeric essential oil microcapsule has characteristic of controlling releasing in high-temperature and high-humidity environments, and turmeric essential oil has an effect of resisting bacteria in a high-temperature environment.

Owner:BOHAI UNIV

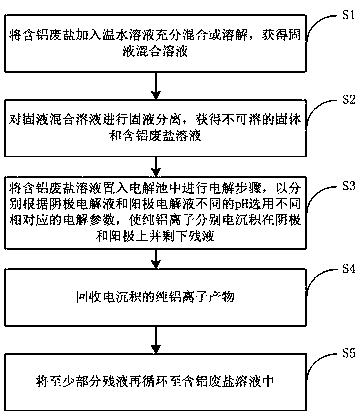

Treatment method for aluminum-containing waste salt

PendingCN109825713AEasy to handleFully recyclePhotography auxillary processesProcess efficiency improvementAluminum IonSewage treatment

The invention discloses a treatment method for aluminum-containing waste salt, and relates to the technical field of sewage treatment. The treatment method comprises the steps that the aluminum-containing waste salt is added into a warm aqueous solution to be fully mixed or dissolved, and a solid-liquid mixed solution is obtained; solid-liquid separation is carried out on the solid-liquid mixed solution, and insoluble solid and an aluminum-containing waste salt solution are obtained; the aluminum-containing waste salt solution is placed in an electrolytic cell for performing electrolysis, different corresponding electrolysis parameters are selected according to different pHs of cathode liquor and anode liquor, pure aluminum ions are electrodeposited on the anode and the cathode, and residual liquid is left; an electrodeposited pure aluminum ion product is recovered; and at least a part of residual liquid is recycled into the aluminum-containing waste salt solution. The treatment methodhas the advantage of high deposition efficiency, and realizes effective treatment of recycling of the aluminum-containing waste salt.

Owner:航天国环技术集团有限公司

Crucible for point evaporation source

InactiveCN109666898AFully depositedAvoid wastingVacuum evaporation coatingSputtering coatingCrucibleEvaporation

The invention relates to the technical field of evaporation processes, in particular to a crucible for a point evaporation source. The crucible comprises a crucible body which is hollow inside. An opening is formed in the top end of the crucible body, and a flow guiding part is arranged on the side wall where the opening is located. The flow guiding part is arranged on the side wall where the opening of the crucible body is located, the spraying angle of evaporation objects in the crucible body can be adjusted through the included angle formed between the flow guiding part and the horizontal plane, the evaporation objects are fully deposited on a substrate, and the situation that cleaning troubles and waste of the evaporation objects are caused by the fact that the wall of a cavity is plated with the evaporation objects is avoided.

Owner:FUJIAN HUAJIACAI CO LTD

Water treatment deposition filter

ActiveCN101843991AFully depositedLow costSettling tanks feed/dischargeSedimentation settling tanksSlagFilter effect

The invention discloses a water treatment deposition filter which comprises filter pipes and a slag depositing tank and is characterized in that each filter pipe is a arc-shaped pipe of which the two ends are high and the middle is low; the arc-shaped pipes of which the two ends are high and the middle is low are connected and arranged from bottom to top, and two adjacent arc-shaped pipes of which the two ends are high and the middle is low are respectively arranged on a layered structure formed between an upper layer and a lower layer; a water inlet is formed at one end of a arc-shaped pipe at the undermost layer, and the other end of the arc-shaped pipe at the undermost layer is connected with a arc-shaped pipe at the last second layer; the arc-shaped pipe at the last second layer is connected with a arc-shaped pipe at the last third layer; the outlet of a arc-shaped pipe at the uppermost layer is directly used as a water outlet, or the outlet of the arc-shaped pipe at the uppermost layer is connected with a water outlet pipe of which the water outlet port is used as the water outlet; deposition supporting pipes which are arranged at the middle concave parts of each layer of arc-shaped pipes of which the two ends are high and the middle is low are connected and communicated into the slag depositing tank positioned at the lower part of the arc-shaped pipe at the undermost layer; and a deposited slag discharging valve is arranged at the lower part of the slag depositing tank. The water treatment deposition filter has simple structure and better filtering effect by testing, and achieves the drinking water quality standard.

Owner:FUJIAN MINQING FONDA ECOLOGICAL AGRI GRAND VIEW GARDEN CO LTD

Pervasion auxiliary agent and application in dyeing course and degumming process thereof

InactiveCN101349019BImprove homochromaticityFully depositedDe-gumming silkDyeing processFiberDiethylene glycol

The invention discloses a penetrating addition agent which comprises the following compositions in weight portion: 0.00018 to 0.0006 portion of laurocapam, 0.5 to 25 portions of myristyl lycine, 0.1 to 12 portions of dipropylene glycol methyl ether, 0.01 to 5 portions of N- methyl pyrrolidone, 0.05 to 2.5 portions of tri n butyl phosphate, 5 to 60 portions of diethylene glycol or butyl ether, 1 to 20 portions of phenylcarbinol and 1 to 3 portions of lignin sulfonic acid ammonium salt. The invention also discloses an application of the penetrating addition agent to the dyeing process and to the retting hemp process. The penetrating addition agent in the dyeing process ensures that the color yield and homochromatic properties of the double-component fiber are good, the leveling property is good and the 'white core' phenomenon is avoided.

Owner:SHANGHAI TEXTILE GRP DETECTION STANDARD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com