Preparation method of high-temperature resistant microencapsulation turmeric essential oil biological bacteriostatic agent

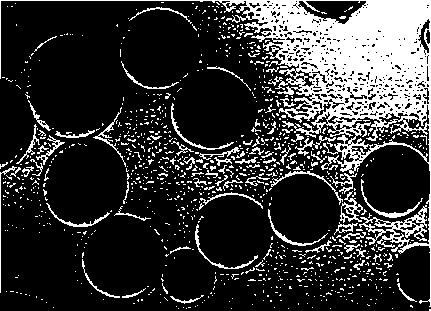

A technology of biological antibacterial agent and turmeric essential oil, which is applied in capsule delivery, pharmaceutical formula, food science, etc., can solve the problems of inability to protect turmeric essential oil, easy water absorption, swelling and rupture, unstable microcapsules, etc., and achieve cost-effective consumption Safe, excellent interface properties, good effect of sphericity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] 1. Using gelatin and peach gum as wall materials, dissolve 1g of gelatin and 1g of peach gum in 400mL of water at 40°C to obtain a wall material solution;

[0016] 2. Add 1g of turmeric essential oil into the wall material solution, and emulsify with a high-speed dispersing homogenizer, the emulsification speed is 10000rpm, and the time is 3min, to obtain an emulsion;

[0017] 3. Transfer the emulsion to a three-necked flask, in a water bath at 40°C and a stirring speed of 300rpm, drop in acetic acid with a mass concentration of 10% to adjust the pH to 4.0, and perform a complex coagulation reaction for 10 minutes to form a suspension of microcapsules; ice Cool the bath to 10°C, then adjust the pH to 5.0, add 0.25 g of glutaminase (enzyme activity: 80 U / g), perform curing treatment at room temperature for 8 hours, and filter with suction to obtain wet turmeric essential oil microcapsules;

[0018] 4, wet turmeric essential oil microcapsules, carry out spray drying proce...

Embodiment 2

[0021] 1. Using gelatin and peach gum as the wall material, dissolve 1.33g of gelatin and 0.67g of peach gum in 600mL of water at 60°C to obtain a wall material solution;

[0022] 2. Add 4g of turmeric essential oil into the wall material solution, and emulsify with a high-speed dispersing homogenizer, the emulsification speed is 8000rpm, and the time is 5min, to obtain an emulsion;

[0023] 3. Transfer the emulsion to a three-necked flask, in a water bath at 50°C and a stirring speed of 200 rpm, drop in acetic acid with a mass concentration of 5% to adjust the pH to 3.7, and carry out a complex coagulation reaction for 5 minutes to form a suspension of microcapsules; ice Cool the bath to 15°C, then adjust the pH to 6.0, add 0.665g glutaminase (enzyme activity: 40U / g), solidify at room temperature for 9 hours, and filter with suction to obtain wet turmeric essential oil microcapsules;

[0024] 4. The wet turmeric essential oil microcapsules are spray-dried. The air inlet tempe...

Embodiment 3

[0027] 1. Using gelatin and peach gum as wall materials, dissolve 0.67g of gelatin and 1.33g of peach gum in 2000mL of 80°C water to obtain a wall material solution;

[0028] 2. Add 0.34g of turmeric essential oil into the wall material solution, and emulsify with a high-speed dispersing homogenizer, the emulsification speed is 12000rpm, and the time is 4min to obtain an emulsion;

[0029] 3. Transfer the emulsion to a three-necked flask, in a water bath at 35°C and a stirring speed of 500 rpm, drop in acetic acid with a mass concentration of 15% to adjust the pH to 4.2, and carry out a complex coagulation reaction for 20 minutes to form a suspension of microcapsules; ice Cool the bath to 0°C, then adjust the pH to 7.0, add 0.067g of transglutaminase (enzyme activity: 60U / g), perform curing treatment at room temperature for 10 hours, and filter with suction to obtain wet complex coagulated turmeric essential oil microcapsules;

[0030] 4. The wet turmeric essential oil microca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com