Patents

Literature

342results about How to "Control heating temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

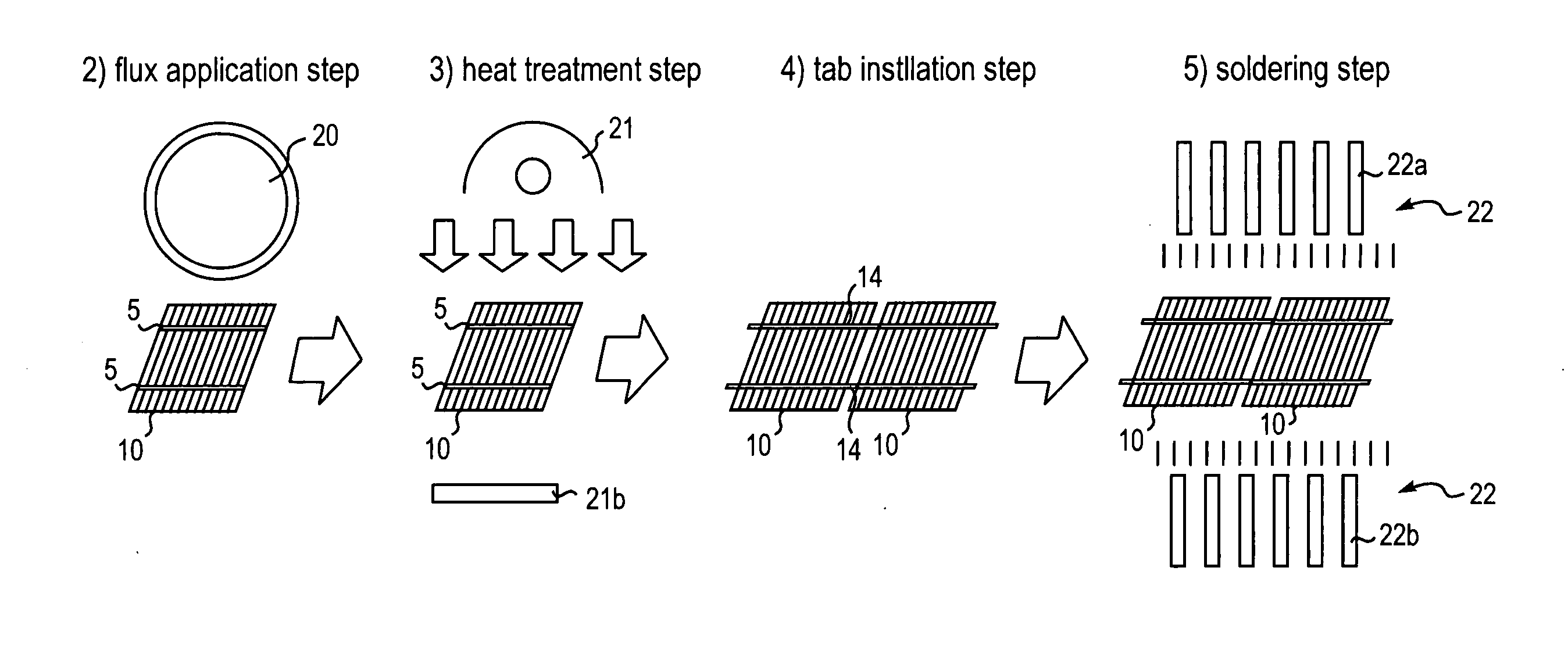

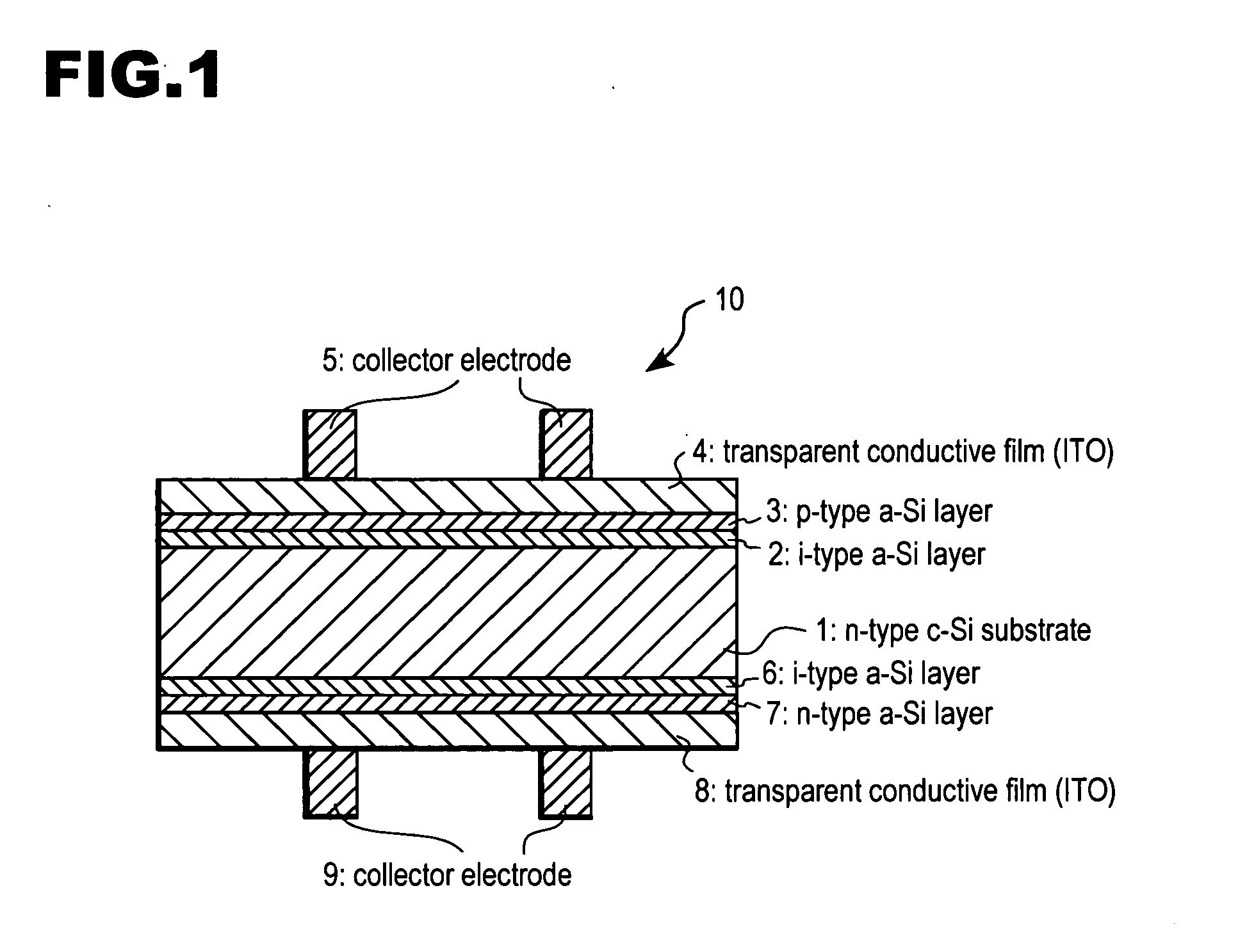

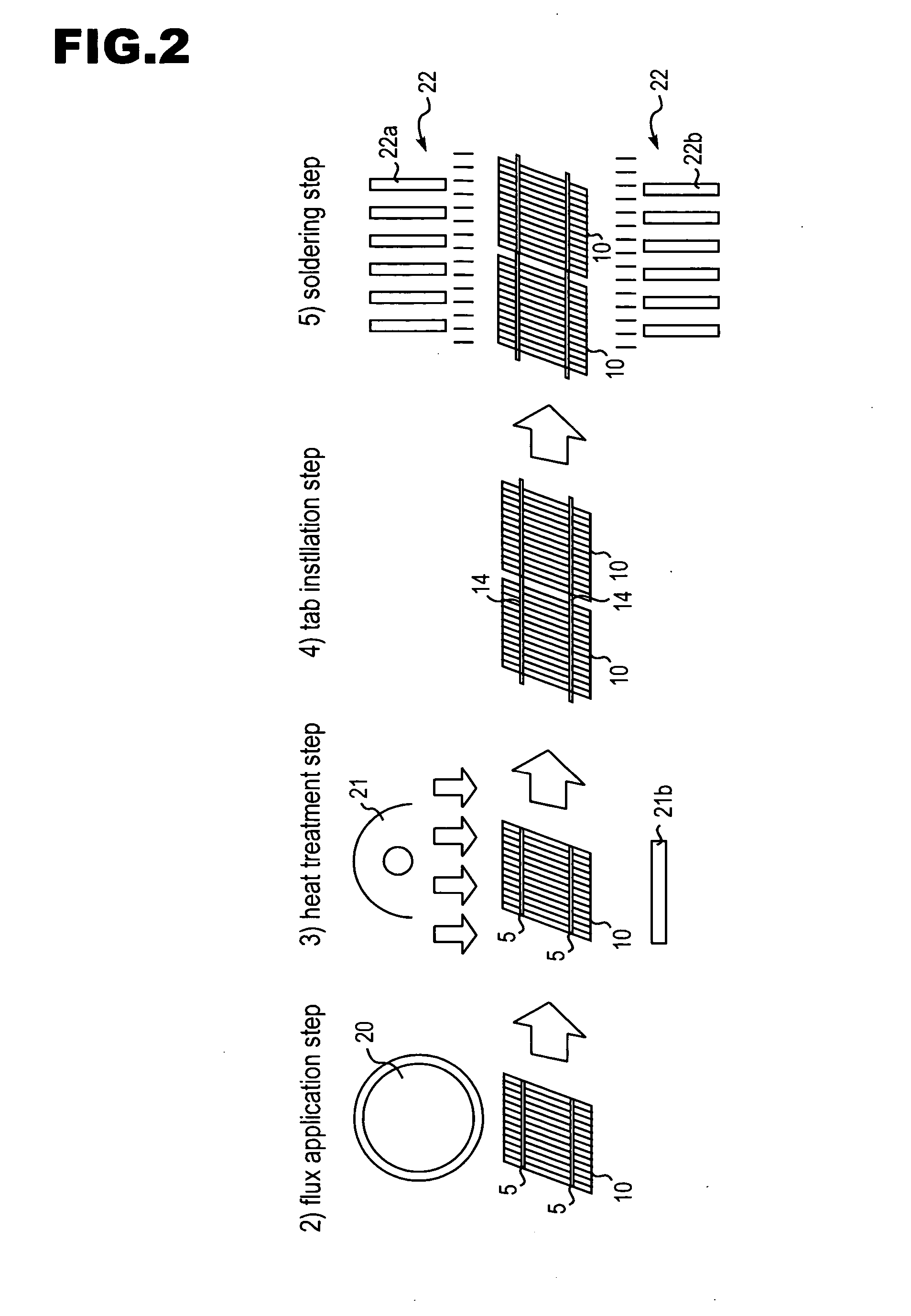

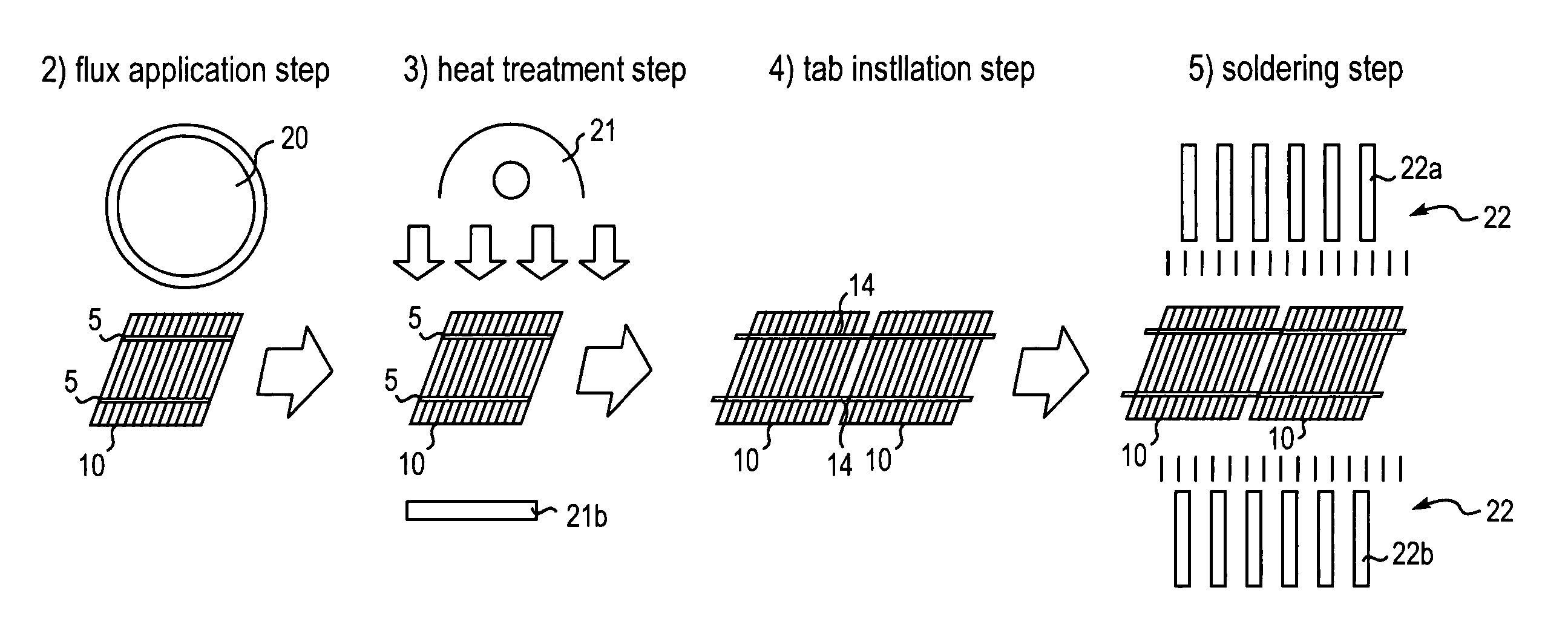

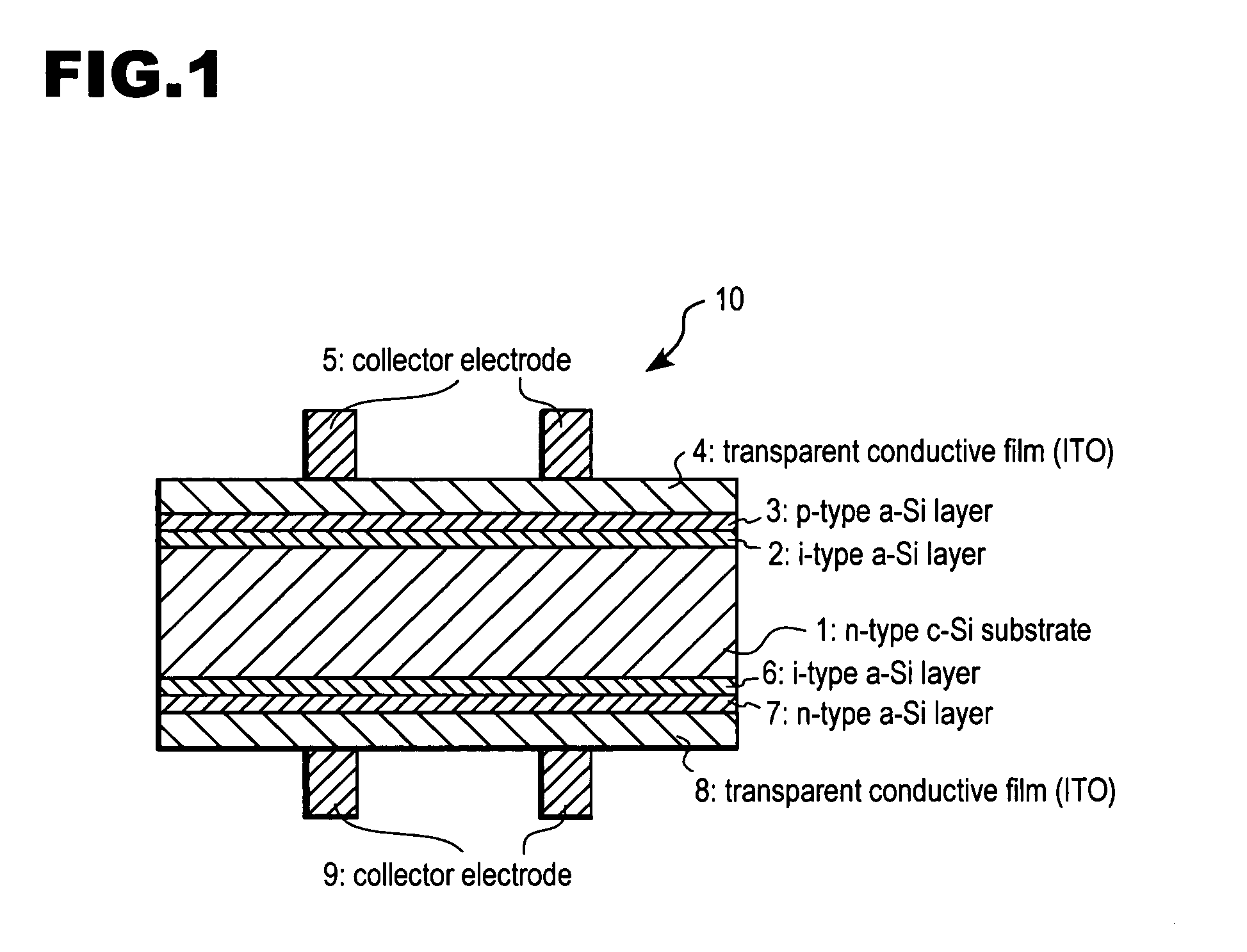

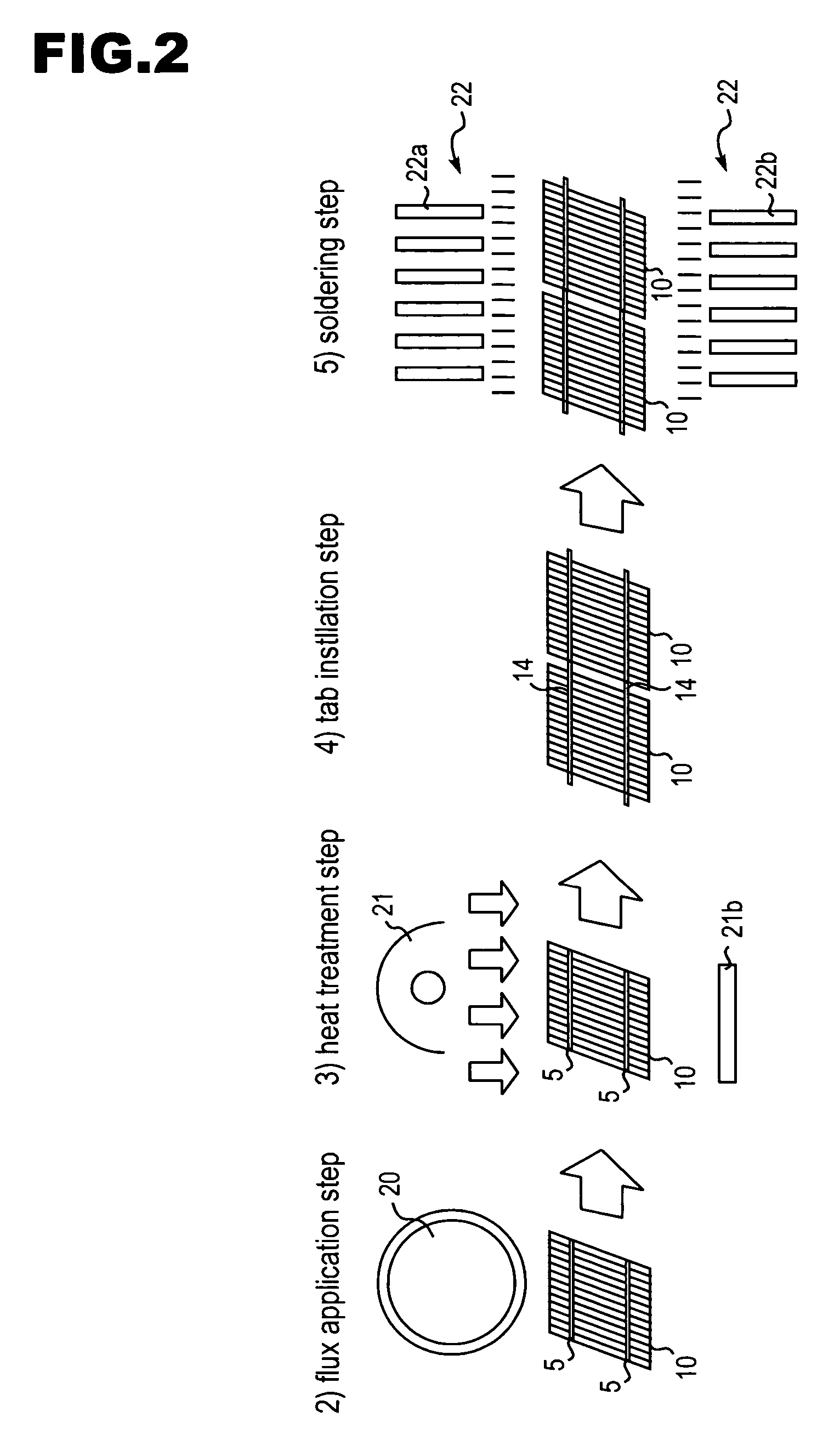

Method for manufacturing photovoltaic module

InactiveUS20060283496A1Improve interface propertiesIncrease productionFinal product manufacturePV power plantsHeterojunctionAmorphous silicon

This invention is made to improve the characteristics of a photovoltaic module in which a plurality of solar cells are electrically connected to each other with connecting members such as tabs or connecting leads. The present invention provides a method for manufacturing a photovoltaic module comprising a plurality solar cells each including a semiconductor heterojunction made by combining amorphous silicon and crystalline silicon and connecting members for connecting the plurality solar cells in which the connecting members are connected to the solar cells by soldering after a high-temperature heat treatment is applied to the solar cells, and the plurality of solar cells are electrically connected to each other with the connecting members.

Owner:SANYO ELECTRIC CO LTD

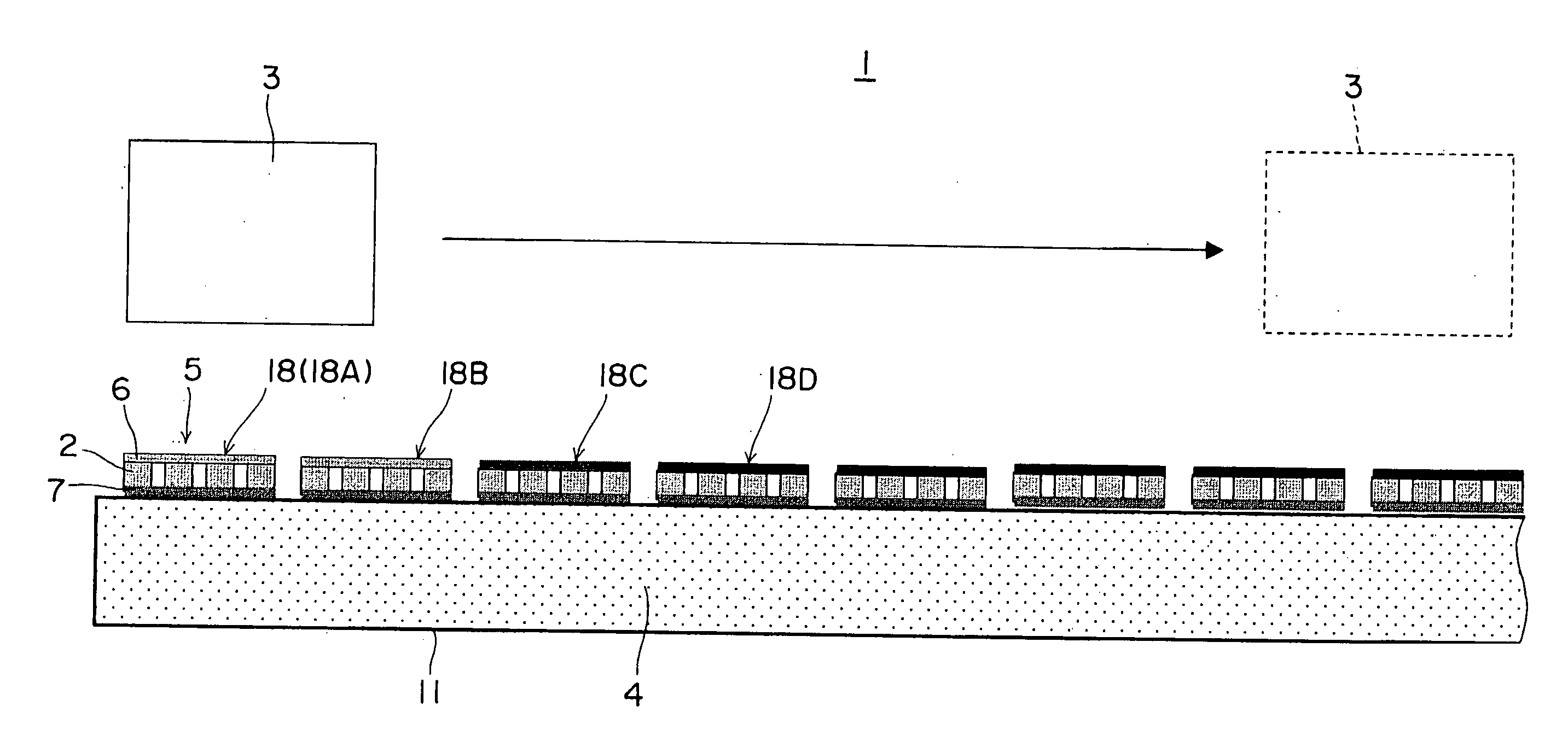

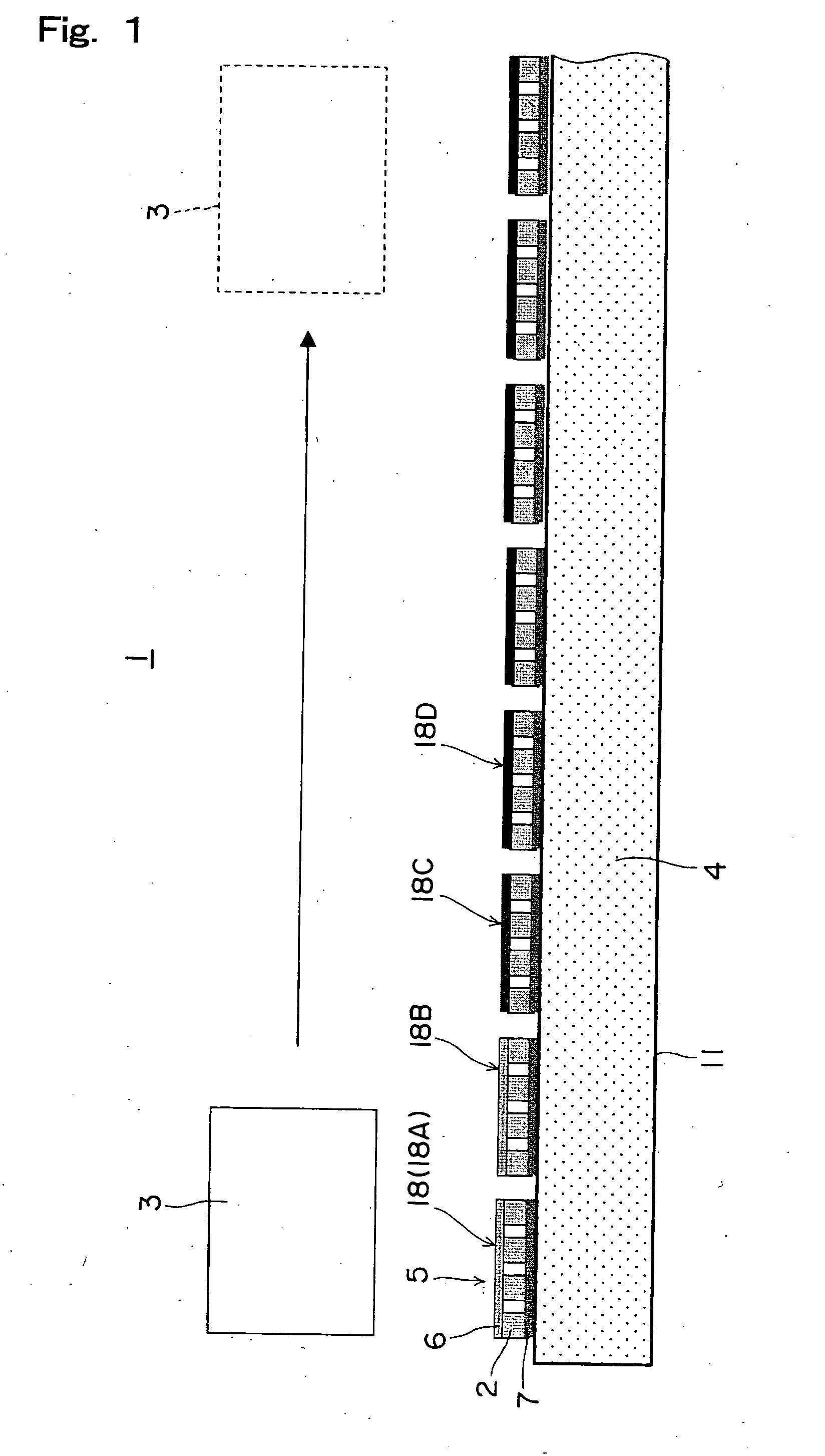

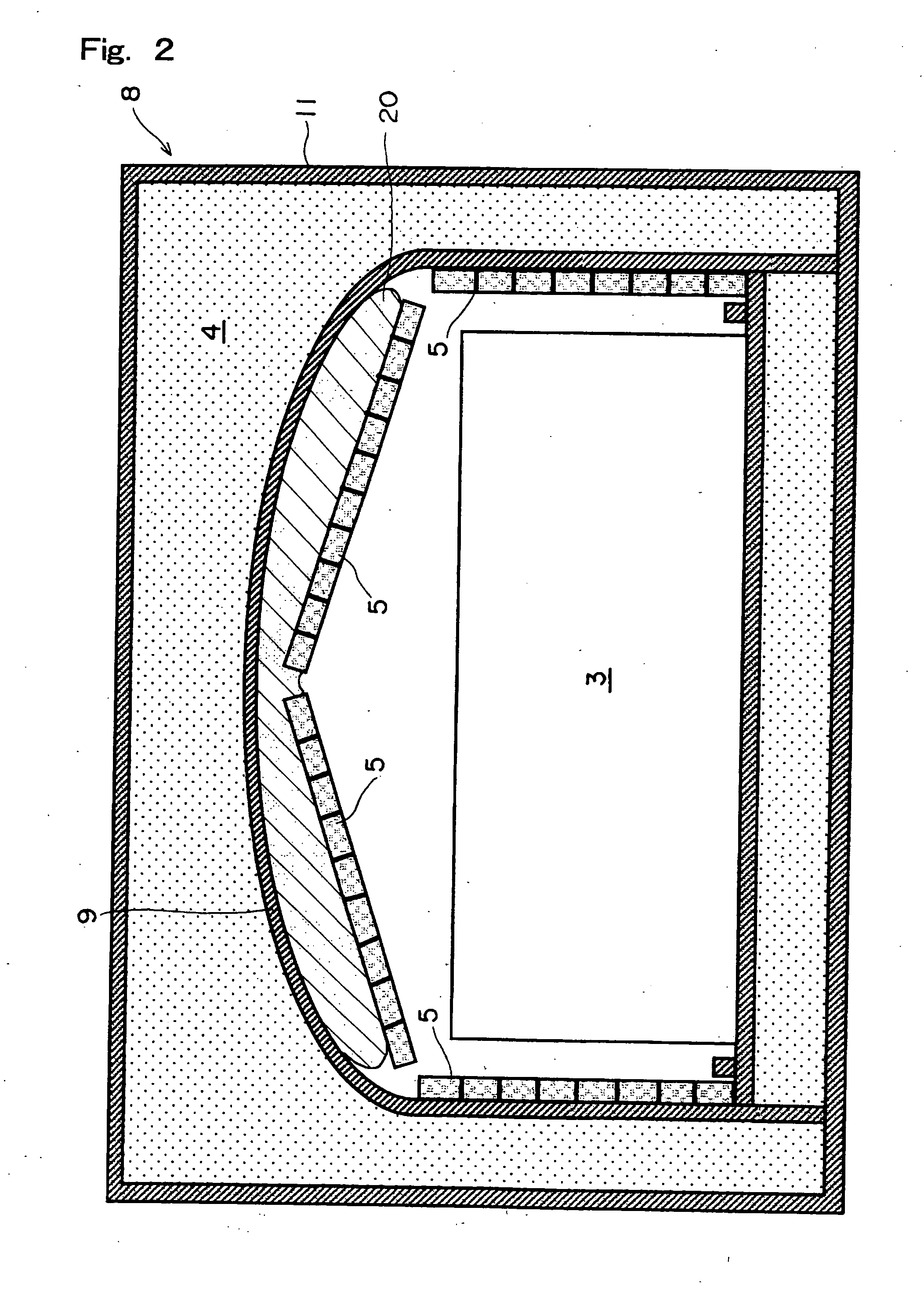

Thermoelectric Conversion System and of Increasing Efficiency of Thermoelectric Conversion System

InactiveUS20080023056A1Control quantityKeep soundnessThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentEmissivityTemperature difference

The present invention relates to a thermoelectric conversion system for receiving heat by radiation from a heat source and an efficiency improving method of the thermoelectric conversion system, the system including at least one thermoelectric conversion module 5 having at least a pair of thermoelectric elements 2, a heat receiving zone 6 placed not to contact a heat source 3 for receiving heat by radiation from the heat source 3 and a radiating zone 7 positioned on an opposite side to the heat receiving zone 6 and cooled by a coolant 4, generating electric power by a temperature difference between the heat receiving zone 6 and the radiating zone 7, a continuous or divided heat receiving surface 18 formed by one or a plurality of surfaces facing the heat source 3 of the heat receiving zone 6, and each of the heat receiving surface 18 is given a different quantity of heat from the heat source 3, the system comprising the heat receiving surface 18 has a plurality of different emissivities according to the quantity of heat received from the heat source 3.

Owner:CENTRAL RESEARCH INSTITUTE OF ELECTRIC POWER INDUSTRY +1

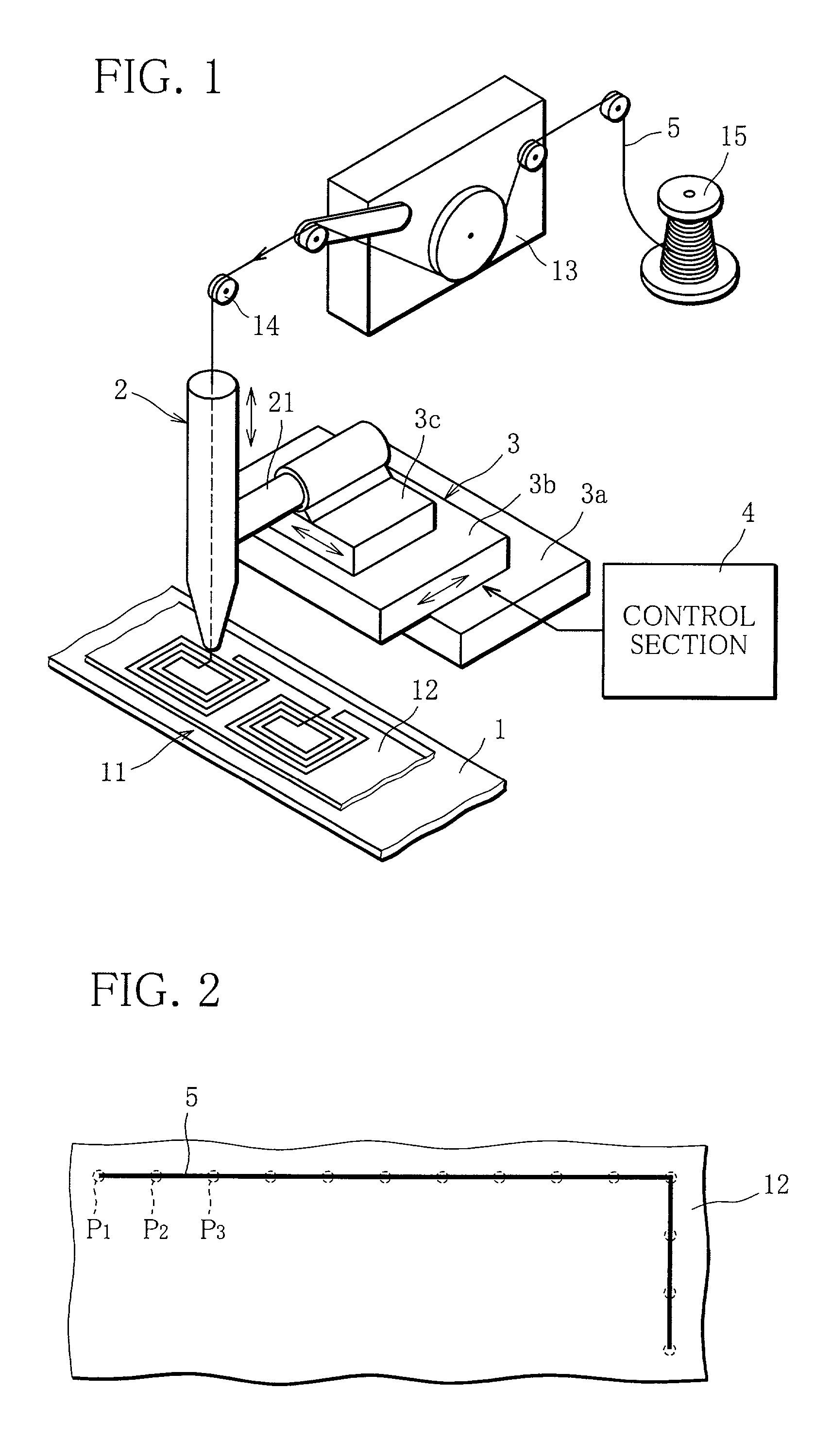

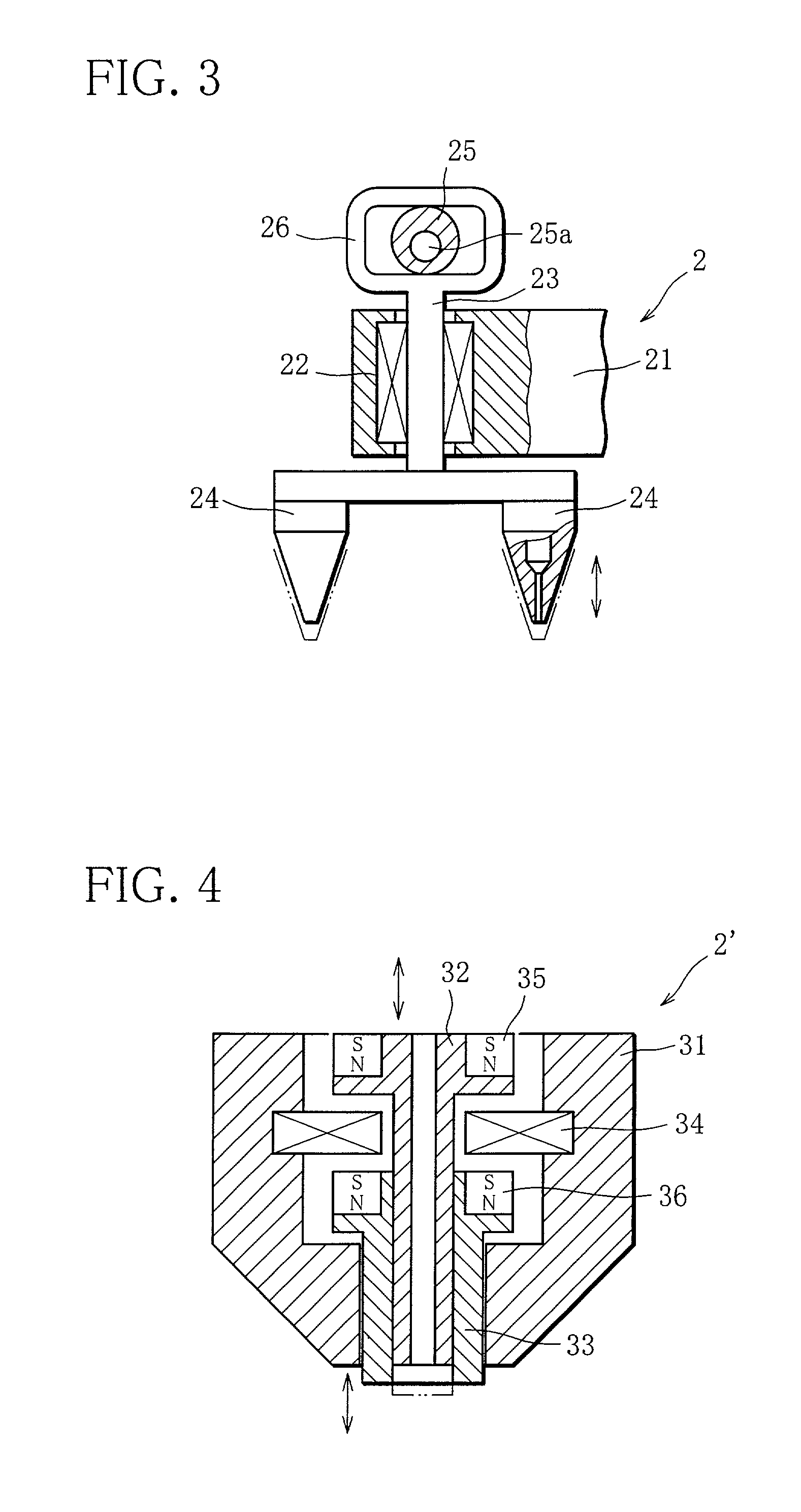

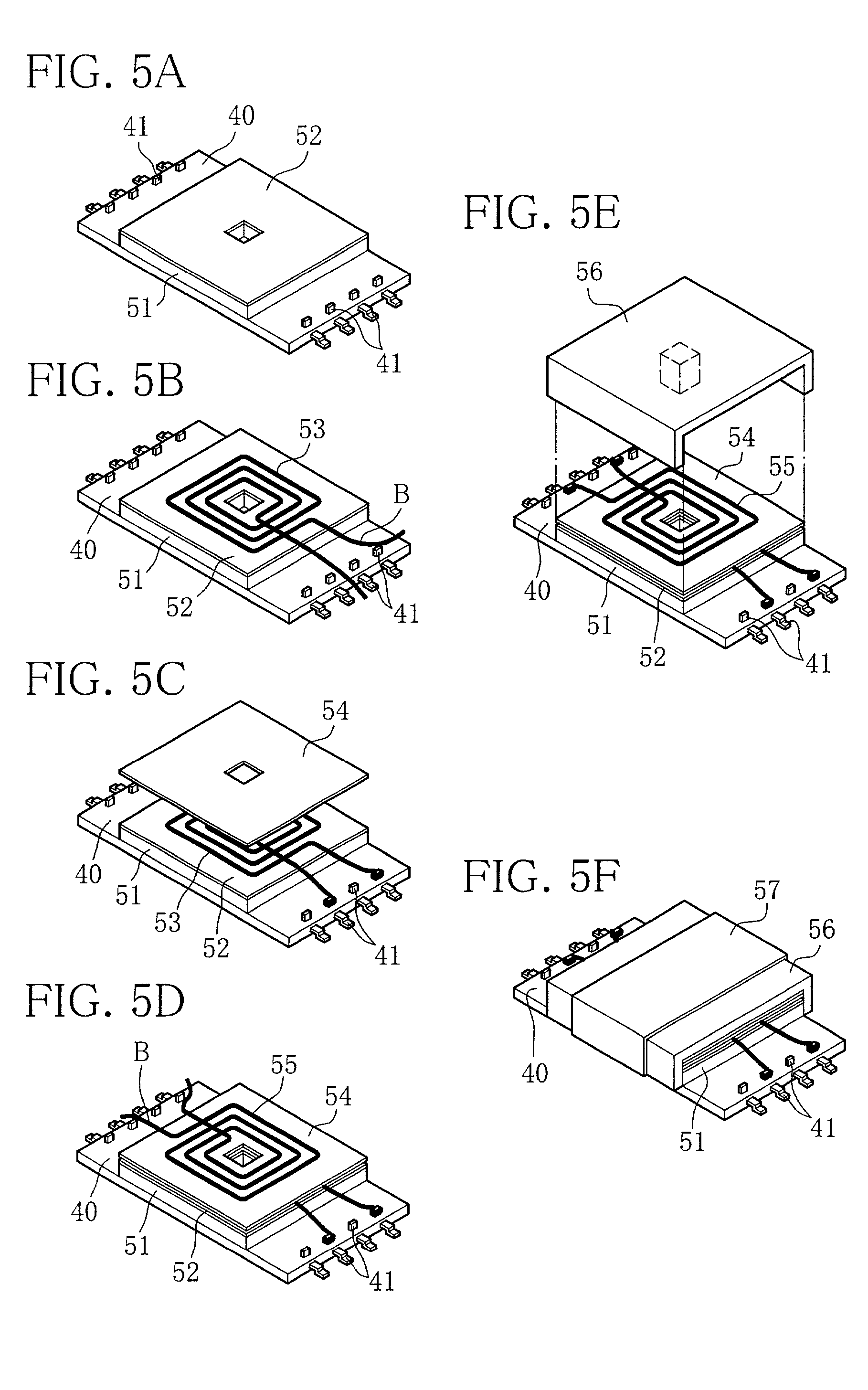

Wiring method and wiring apparatus

InactiveUS20010011413A1Low costImprove reliabilityMechanical working/deformationSemiconductor/solid-state device detailsElectrical conductorReciprocating motion

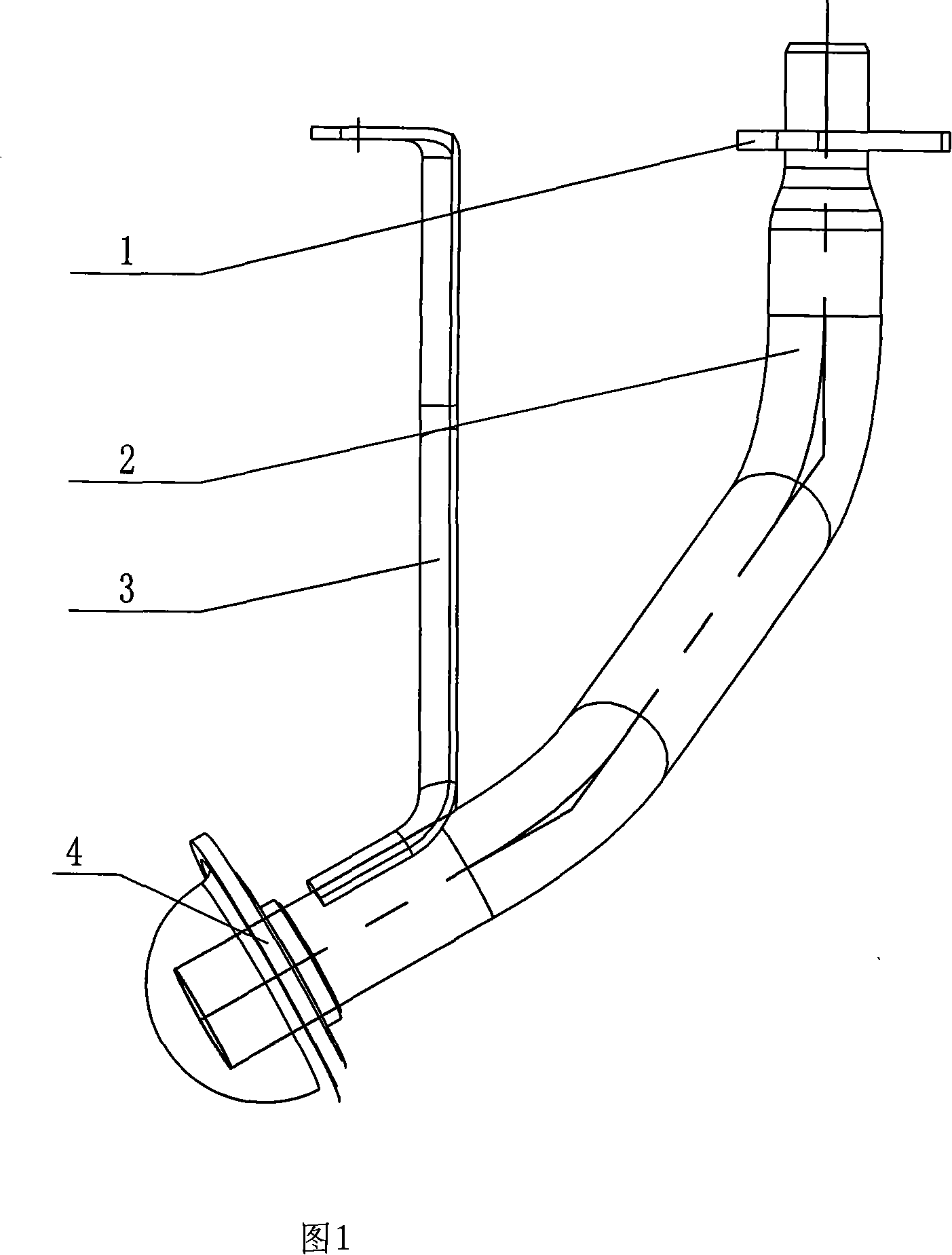

A wiring method is provided, in which a wire conductor is stuck on a surface of a substrate by causing a three-dimensional relative movement between a wiring head (2) for guiding the wire conductor (5) and the substrate (11) such that the wiring head relatively moves along an adhesive layer (12) on the surface of the substrate and the wiring head and the adhesive layer intermittently come close to each other for point contact. A wiring apparatus for carrying out the wiring method includes a table (1) for supporting the substrate, a wiring head arranged for reciprocating motion between a close position in which the wiring head can be in point contact with the adhesive layer and a distant position in which the wiring head is most distant from the adhesive layer, and a moving mechanism (3) for causing a translational motion of the wiring head along the surface of the substrate under the control of a control section (4). The wire conductor is stuck onto the surface of substrate point by point, to be laid thereon, whereby a planar transformer, an antenna coil or a conductor pattern is formed on the substrate.

Owner:FURUKAWA ELECTRIC CO LTD

Red soup hotpot base material and preparation method thereof

The invention provides a red soup hotpot base material, which comprises 20 to 30 parts of vegetable oil, 5 to 15 parts of salt, 30 to 45 parts of hot pepper, 15 to 30 parts of thick broad-bean sauce, 1 to 5 parts of spice and 3 to 10 parts of internal heat clearing material. Compared with the prior art, the formula of the red soup hotpot base material provided by the invention is reasonable, and the formula has no components which affect the nutritional components and the mouthfeel with one another. Therefore, the red soup hotpot base material is hot, spicy, fresh, delicious, unique in flavor and proper in mouthfeel. In addition, because the internal heat clearing material is added in the formula, a user does not suffer from internal heat after the red soup hotpot base material is used. The invention also provides a preparation method of the red soup hotpot base material.

Owner:甘丘平

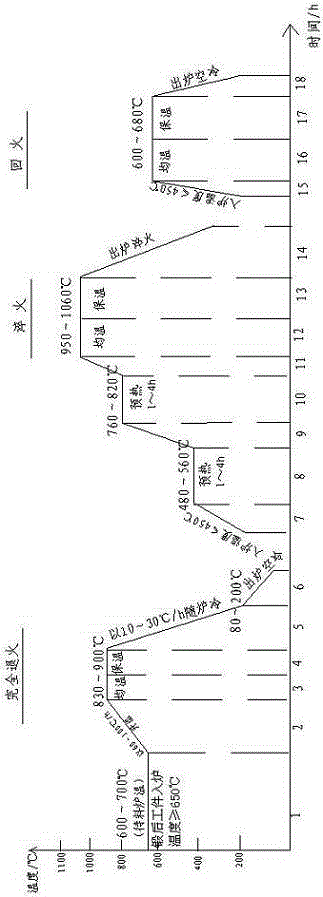

Heat treatment method of high-chromium martensitic stainless steel

ActiveCN102719627ASufficient quenching and cooling intensityAvoid crackingMartensitic stainless steelQuenching

The invention relates to a stainless-steel heat treatment technology, in particular to a heat treatment method of high-chromium martensitic stainless steel. The heat treatment method comprises the following steps of: 1) annealing; 2) preheating; 3) quenching; and 4) tempering. The heat treatment method has the following advantages that 4Cr16Mo stainless steel heat treatment process comprises the following procedures of: (1) complete annealing, controlling the furnace entering temperature after forging, the heating speed, the heating temperature, the insulating time and the furnace cooling speed; (2) quenching heating, controlling the preheating temperature, the heating speed, the heating temperature and the insulating time; (3) quenching cooling, adopting a gap-cooling mode of air-liquid-air-liquid-air-liquid, the quenching stress is furthest reduced while ensuring that a workpiece obtains enough quenching cooling severity and obtains a martensitic structure, and the cracking of the workpiece caused by excessive stress is avoided; and (4) tempering, strictly controlling the tempering furnace-entering time, tempering heating temperature and the insulating time, the structure transformation is complete, the quenching stress is eliminated, and fine and uniform tempering sorbite is obtained.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

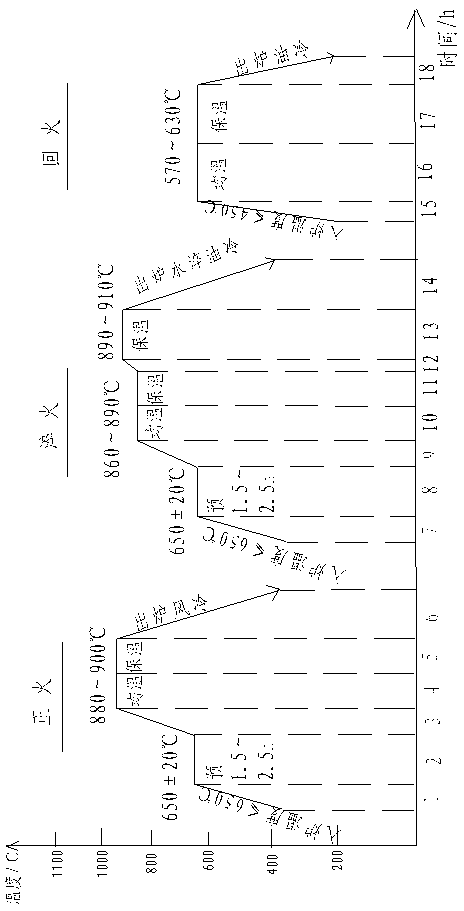

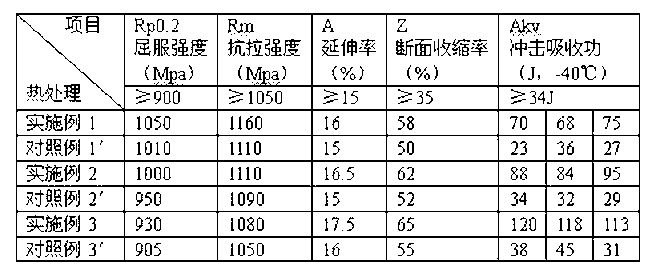

Thermal treatment technology for improving low-temperature impact toughness of 25Cr2Ni4MoV steel forging

The invention belongs to the technical field of production of steel forging products used at low temperature, relating to a thermal treatment technology requiring higher low-temperature impact toughness, and particularly relating to a thermal treatment technology for improving the low-temperature impact toughness of a 25Cr2Ni4MoV steel forging. The thermal treatment technology comprises the following steps of: (1) normalizing heating; (2) normalizing cooling; (3) quenching heating; and (4) quenching cooling. The thermal treatment technology provided by the invention effectively improves the low-temperature impact toughness and prolongs the service life of a product while guaranteeing the material strength.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

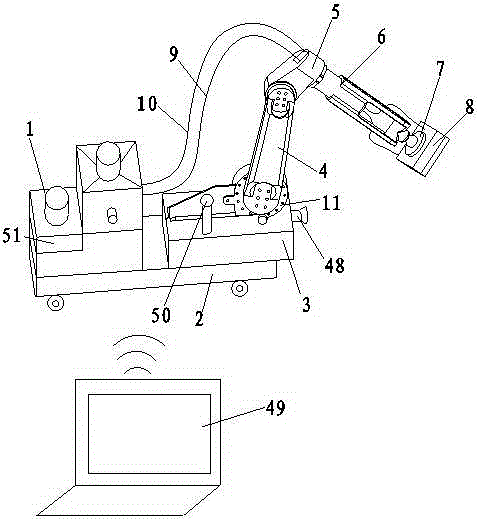

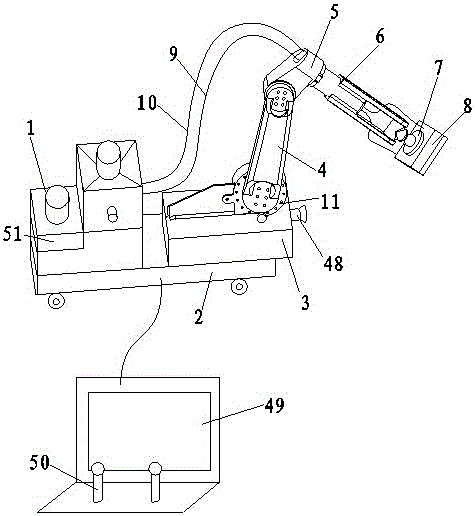

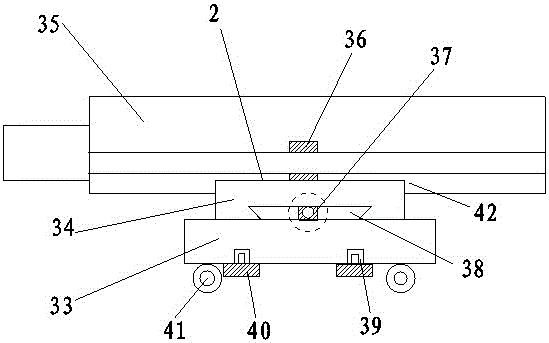

Spraying robot with automatic visual tracking function

The invention discloses a spraying robot with an automatic visual tracking function. The spraying robot comprises a conveying device, a moving device, an adjusting base, a large arm, a transition arm, a third arm, a rotary connector and a painting device. The adjusting base is mounted on the moving device, a mounting seat is mounted on the upper surface of the adjusting base and is hinged to the large arm, the large arm is hinged to the transition arm, the transition arm is hinged to the third arm, the rotary connector is arranged at the front end of the third arm, and the painting device is mounted at the front end of the rotary connector. The spraying robot has the advantages that tailing materials can be recycled, accordingly, the cost can be saved, surrounding edges can be fitted, and environmental pollution due to falling of the tailing materials in construction sites can be prevented; the spraying robot has the automatic visual tracking function, accordingly, construction personnel and equipment are separated from one another during site operation construction, and automatic construction can be implemented; fitting intensity of the painting device and walls can be adjusted at any time by the aid of load pressure sensors, and accordingly good plastering and tailing material recycling effects can be realized.

Owner:安徽东坚仓储货架制造有限公司

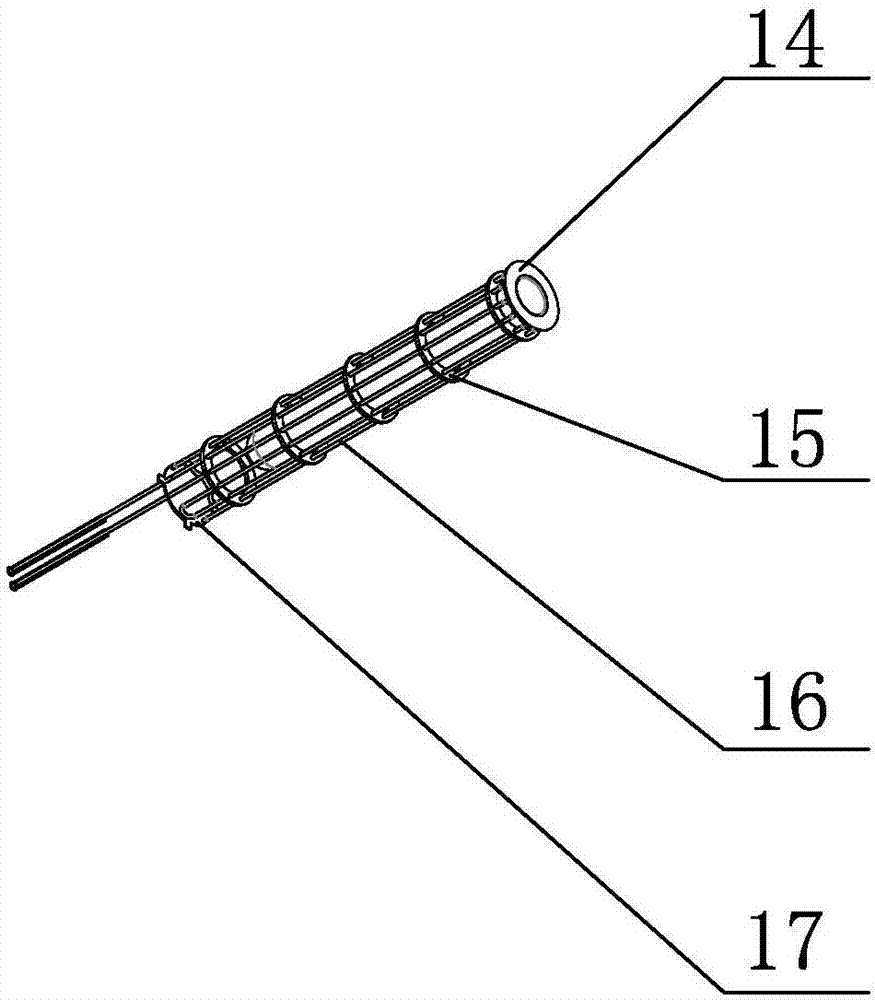

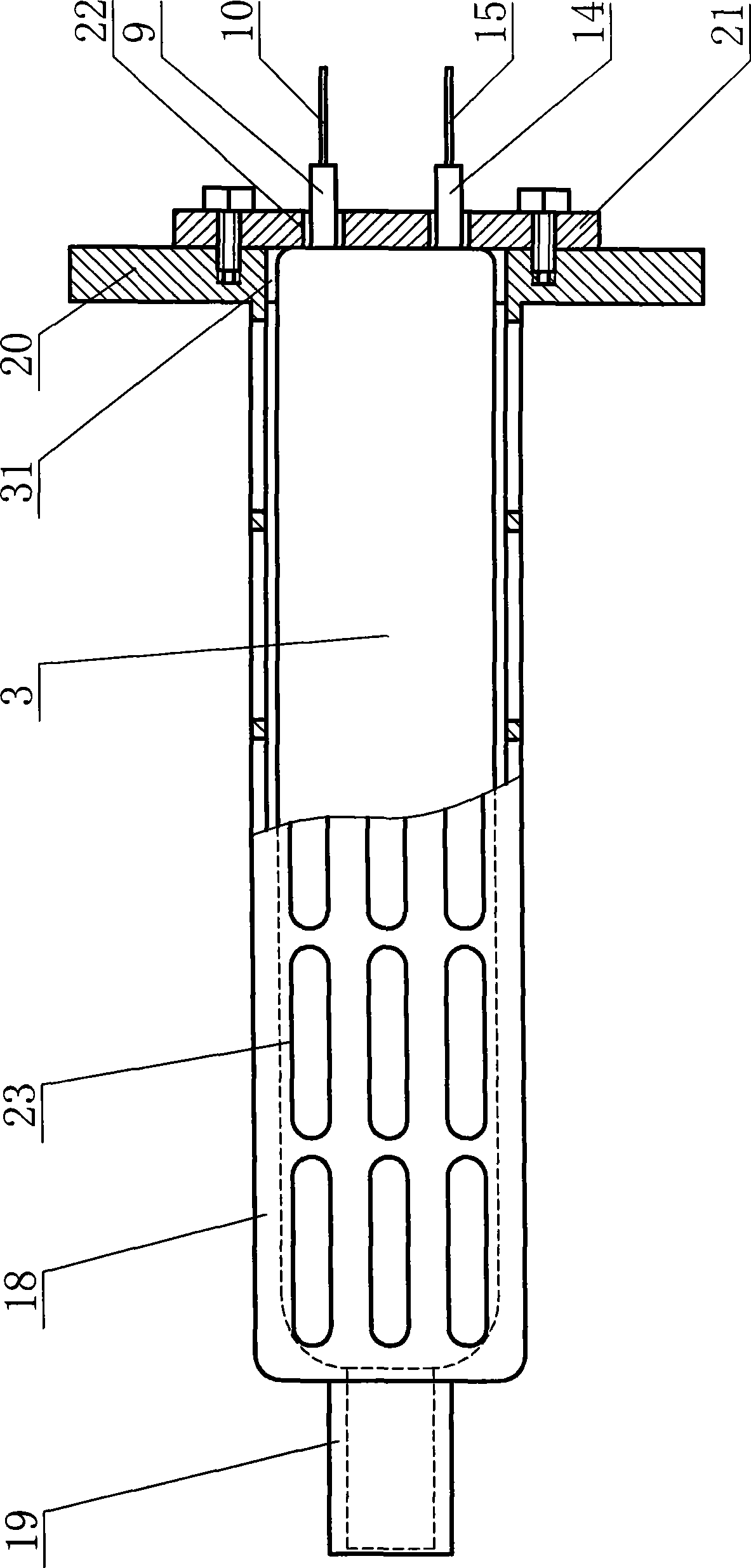

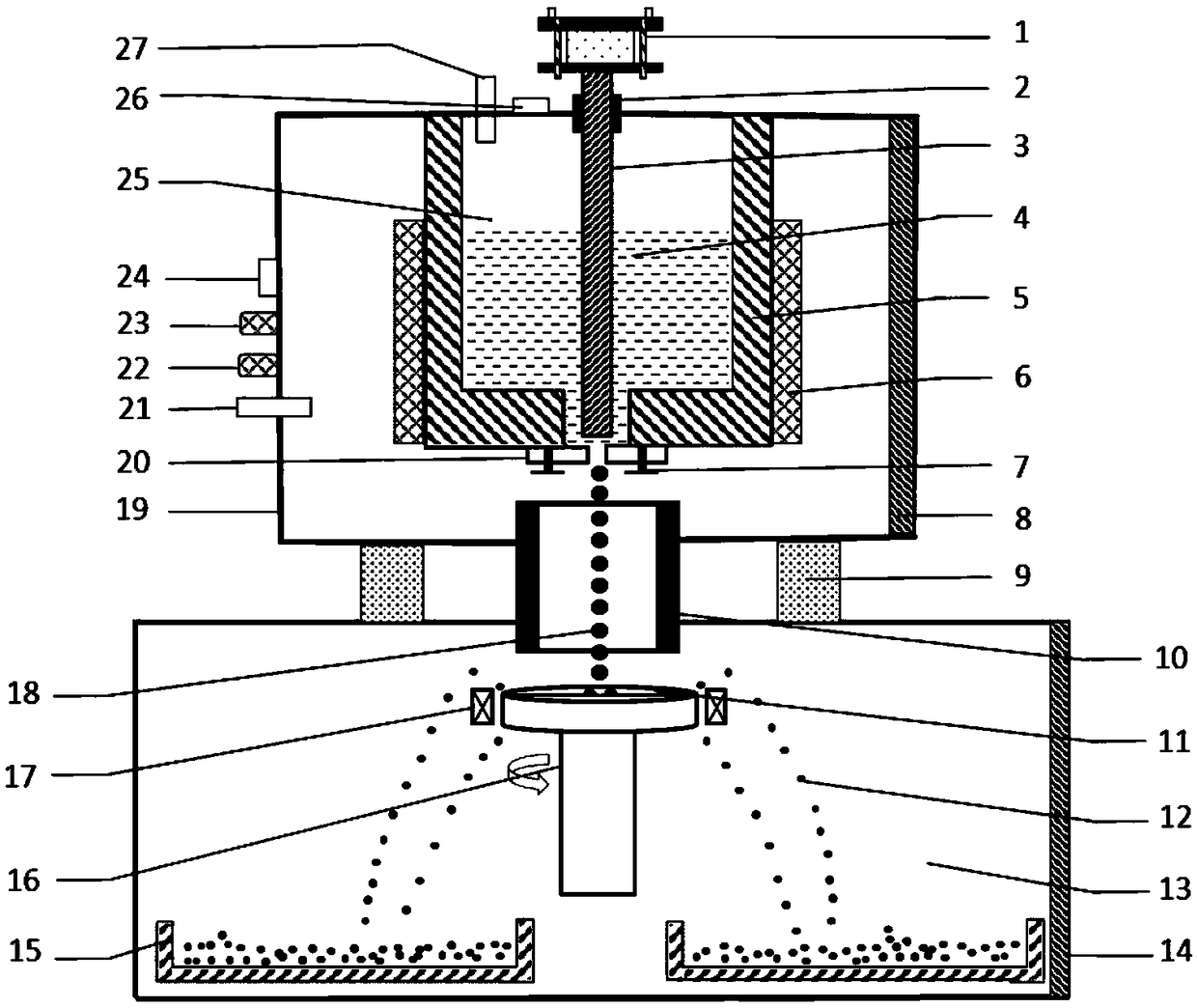

Low-temperature vacuum evaporation source

PendingCN107217236AEfficient exclusionTo achieve the purpose of coolingVacuum evaporation coatingSputtering coatingWater circulationOrganic compound

The invention discloses a low-temperature vacuum evaporation source. The low-temperature vacuum evaporation source comprises a heating system, a cooling system, a temperature measuring system, a control system and a connecting assembly. An electrode in the device is electrified to heat a lamp filament of the heating system, and when the temperature of the lamp filament reaches the sublimation temperature of substances in a crucible, a source substance starts to be evaporated, gas molecules obtained through evaporation are transmitted to a to-be-coated base body in a vacuum cavity, and evaporation of alkaline metal and an organic compound can be achieved. A real-time evaporation temperature of a thermocouple of the temperature measuring system is conducted and detected through an electric couple wire. Cooling water is led into a water inlet pipe of the cooling system, the crucible is cooled through water circulation in a cooling cover, and the low-temperature evaporation effect is achieved. A rotation baffle on a crucible opening can adjust and control whether the substances obtained through evaporation conduct coating on the base body or not through a manual rod.

Owner:DALIAN JIAOTONG UNIVERSITY

Method for manufacturing photovoltaic module

InactiveUS7754962B2Control heating temperatureImprove output characteristicsPV power plantsFinal product manufactureHeterojunctionAmorphous silicon

This invention is made to improve the characteristics of a photovoltaic module in which a plurality of solar cells are electrically connected to each other with connecting members such as tabs or connecting leads. The present invention provides a method for manufacturing a photovoltaic module comprising a plurality solar cells each including a semiconductor heterojunction made by combining amorphous silicon and crystalline silicon and connecting members for connecting the plurality solar cells in which the connecting members are connected to the solar cells by soldering after a high-temperature heat treatment is applied to the solar cells, and the plurality of solar cells are electrically connected to each other with the connecting members.

Owner:SANYO ELECTRIC CO LTD

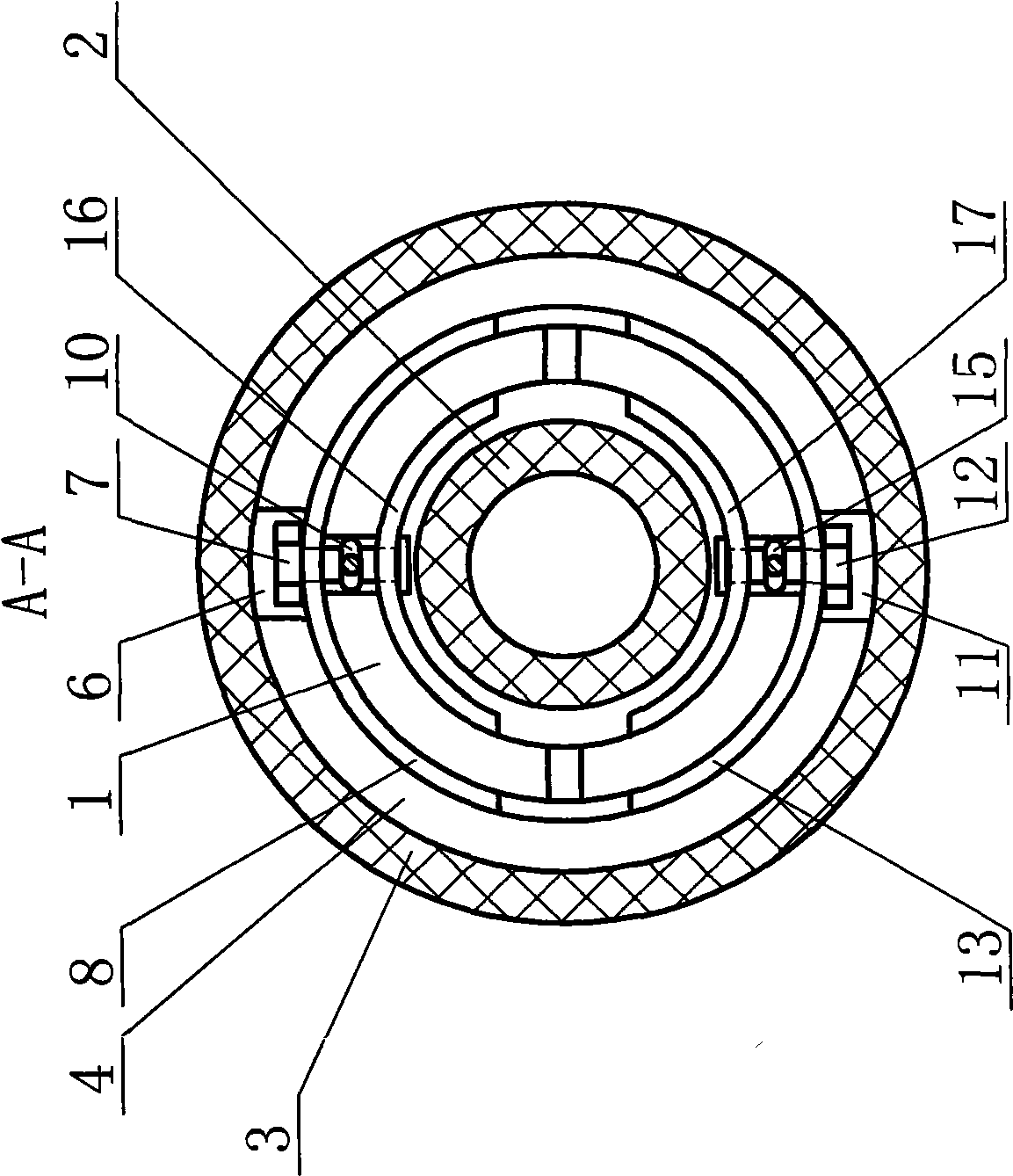

Infrared radiation ceramic heater

InactiveCN101505554AHeating up fastReduce consumptionImmersion heating arrangementsHeating element shapesFiberCarbon fibers

The invention discloses an infrared radiation ceramic heater, which comprises a quartz outer tube and a quartz inner tube, wherein two ends of the quartz outer tube and two ends of the quartz inner tube are connected in a melted and closed mode respectively; a cavity is arranged between the inner wall of the quartz outer tube and the outer wall of the quartz inner tube and provided with a silicon carbon rod inside; the diameter of a through hole in the middle of the quartz inner tube is more than or equal to the length of the quartz outer tube; electrodes are arranged at the ends of the silicon carbon rod; and a silicon dioxide pad is arranged on the outer wall or the inner wall of the ends of the silicon carbon rod. The infrared radiation ceramic heater is mainly used for medium heating of heaters, can also be used for heating in industrial production, and is particularly applicable to heaters adopting water circulation. The product can directly heat water to make the water temperature rise rapidly, water absorbs heat through the quartz outer tube and the quartz inner tube, the heat efficiency is high, because the infrared radiation rate is larger than 97 percent, the energy consumption is low, and compared with the prior silicon fiber wire heating and electrothermal tube heating, the heating mode saves energy by 38 to 45 percent. The infrared radiation ceramic heater has the advantages of long service life along with thoroughly overcoming the defect of easy failures of electric heating and carbon fiber heating.

Owner:周存文

Non-annealed cold forging steel hot-rolled wire rod and production method thereof

The invention discloses a non-annealed cold forging steel hot-rolled wire rod and a production method thereof. The method comprises the steps of continuous casting, heating, rolling, spinning and cooling. The non-annealed cold forging steel hot-rolled wire rod comprises 0.29-0.38wt% of C, 0.15-0.30wt% of Si, 0.70-0.90wt% of Mn, 0.03wt% or less of P, 0.03wt% or less of S, 0.30wt% or less of Cr, 0.0008-0.0050wt% of B, and the balance of Fe and residual elements. In the heating step, continuous cast billets are heated to 1100-1190DEG C; in the rolling step, the initial finish rolling temperature is 965-995DEG C; in the spinning step, the spinning temperature is 960-990DEG C; and in the cooling step, the cooling speed is 0.5-1.5DEG C / s. The method realizes production of the non-annealed cold forging steel hot-rolled wire rod through optimally designing chemical components, controlling the heating temperature, the initial finish rolling temperature, the spinning temperature and the cooling speed and controlling the amount and the grain size of ferrite by using present devices and technologies without increasing investment or production cost, so the non-annealing production and cost reduction demands of downstream users are met, and pollution of annealing to environment is avoided.

Owner:XINGTAI IRON & STEEL

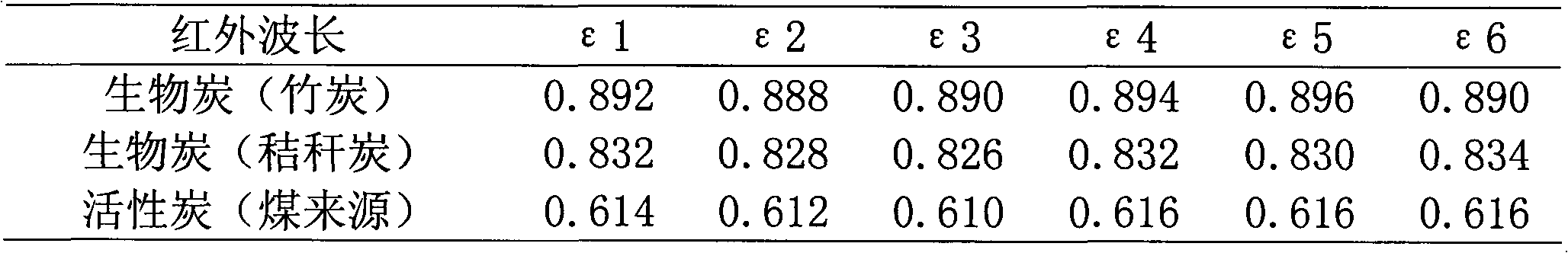

Medical self-heating far infrared hot compress bag

InactiveCN102846425AAvoid restrictionsAchieve ease of useLight therapyTherapeutic coolingExternal energyCutaneous microcirculation

The invention belongs to the field of medical devices, and relates to a medical self-heating far infrared hot compress bag for physiotherapy and health care. A heating agent in the medical self-heating far infrared hot compress bag contains biochar which can efficiently emit suitable far infrared rays. The biochar has appropriate granularity, and can be activated char and inactivated char or a mixture of the activated char and the inactivated char for realizing the balance of heating temperature, time and far infrared ray releasing. The inner bag of the hot compress bag consists of a plurality of small bags which are isolated from each other, perforations are arranged between the small bags for partitioning, and the small bags can be torn off according to the requirements. The outer bag of the hot compress bag can be a vacuumized sealed package and is provided with a self-sealing strip, and the unused part can be put in the outer bag and sealed. The medical self-heating far infrared hot compress bag is low in price, convenient to carry and easy to use, does not need an external energy source, and can satisfy the requirements on treatment at any time, long-term health care and people of remote regions. The biochar can also take the functions of absorbing sweat and odor and regulating skin microcirculation. The inner bag is specially designed to be fit with the shape of an afflicted part and avoids waste, and the usability is further improved through the seal-sealing design and vacuumization of the outer bag.

Owner:袁暾 +1

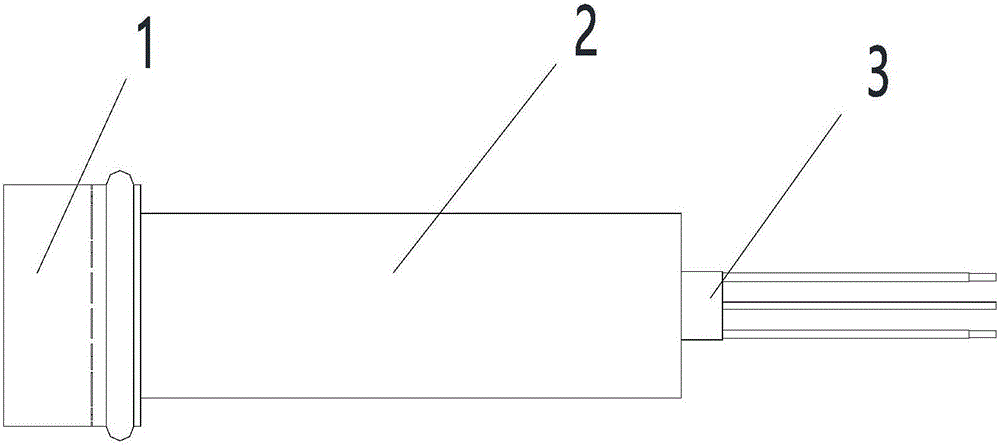

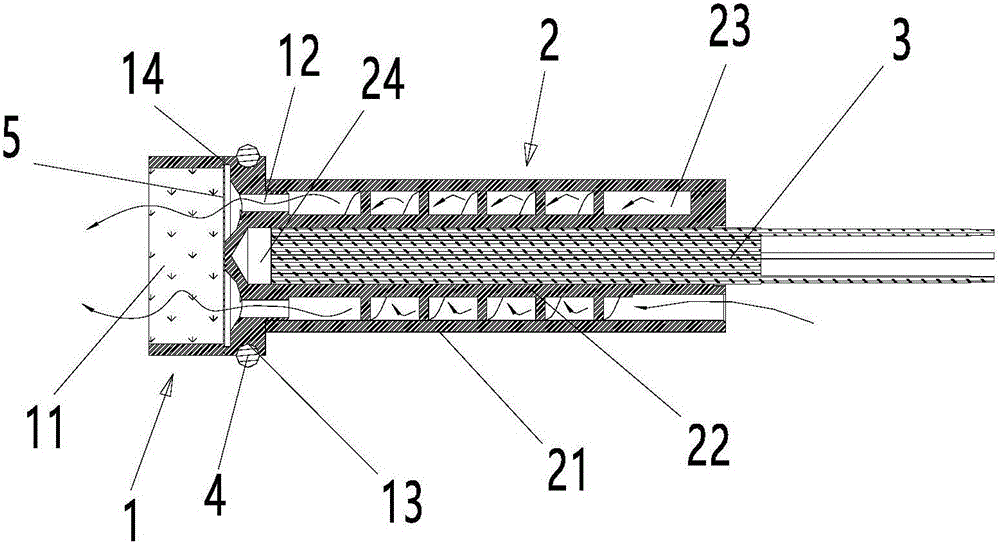

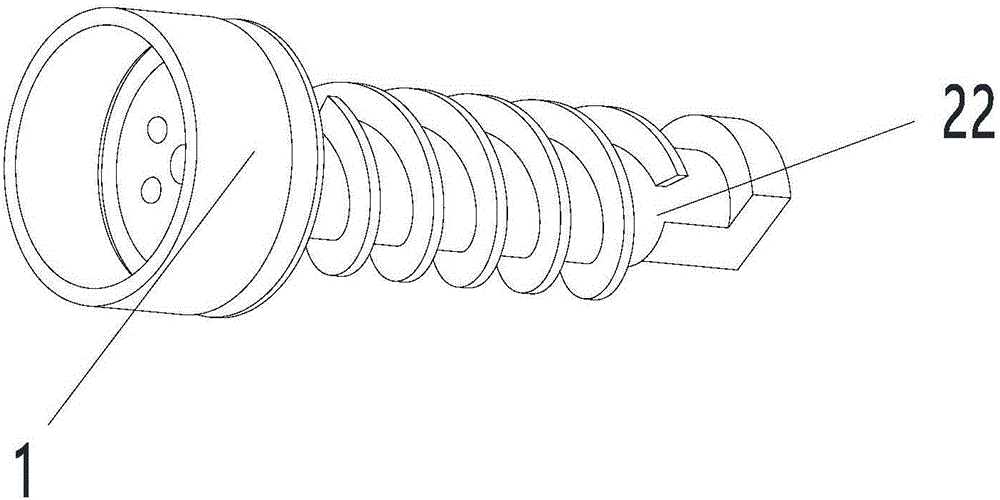

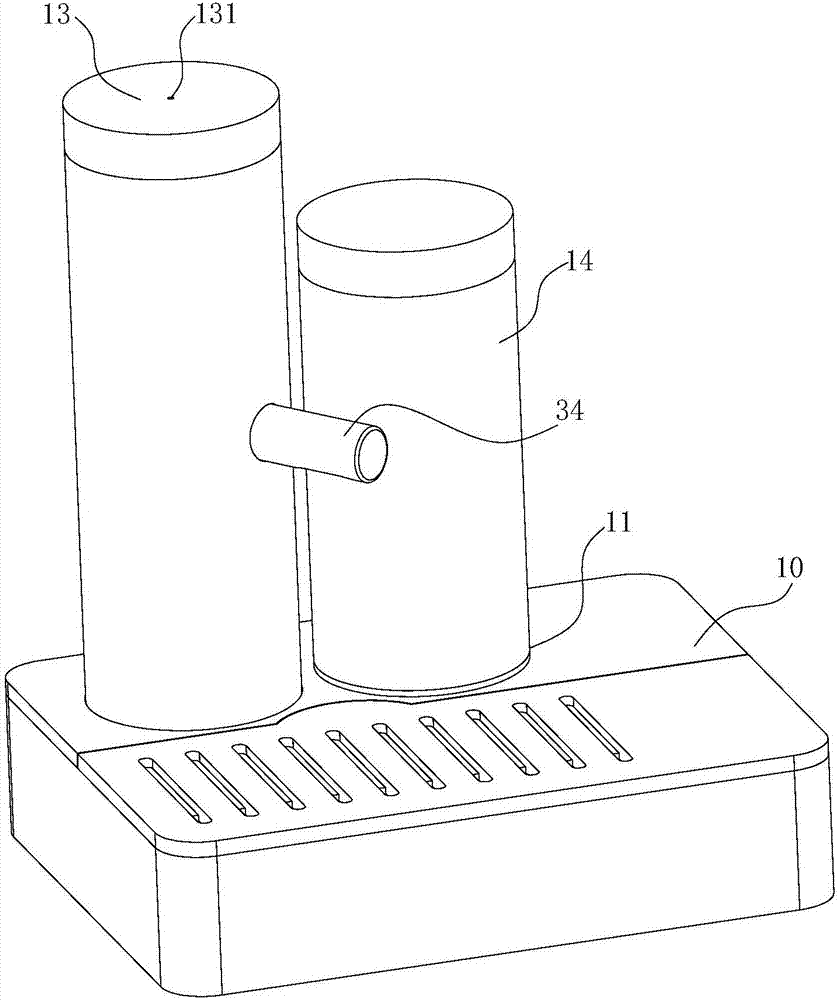

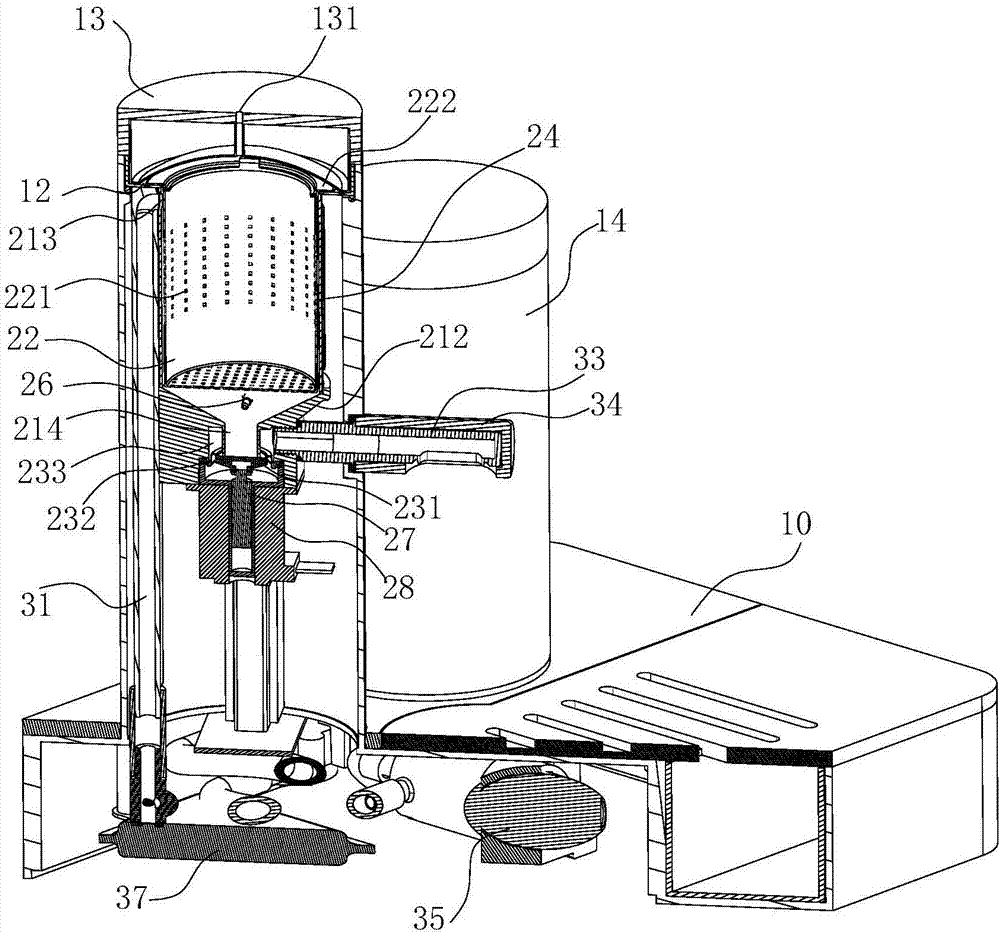

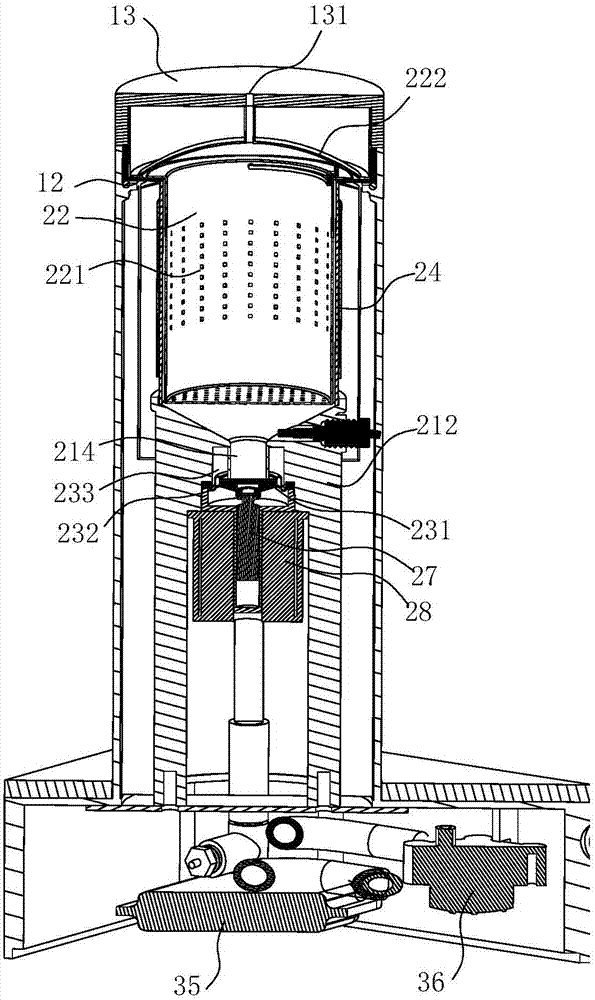

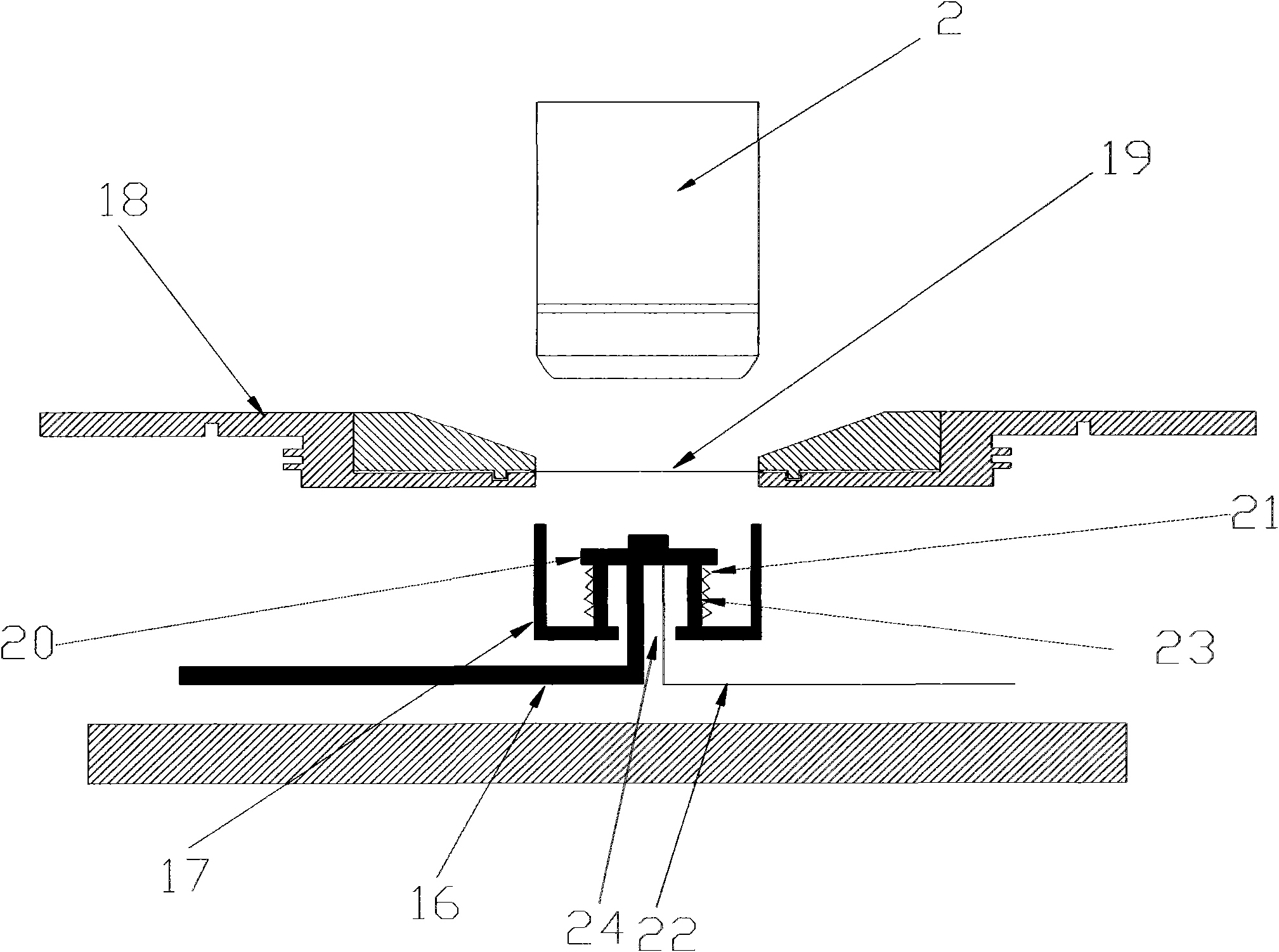

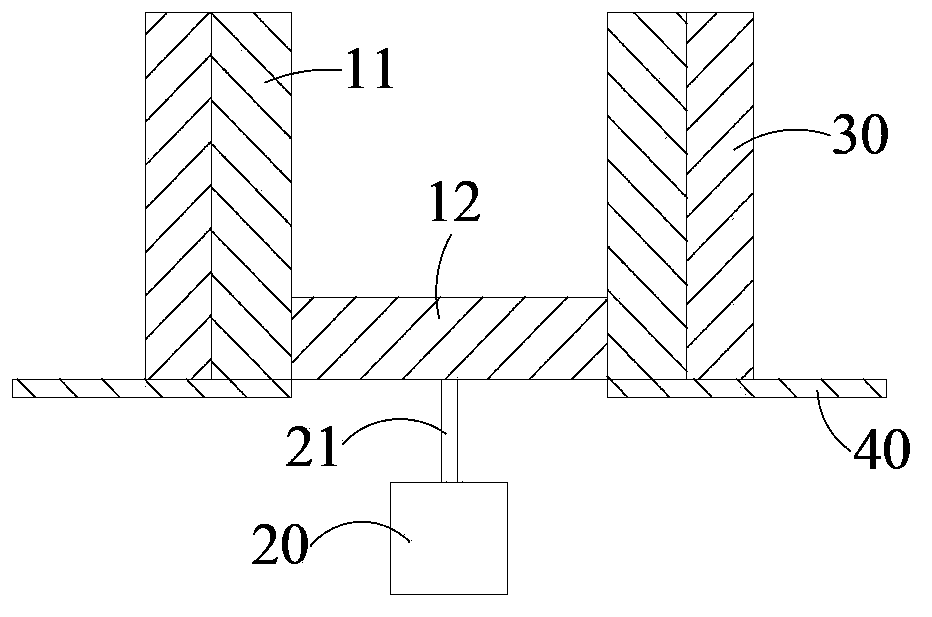

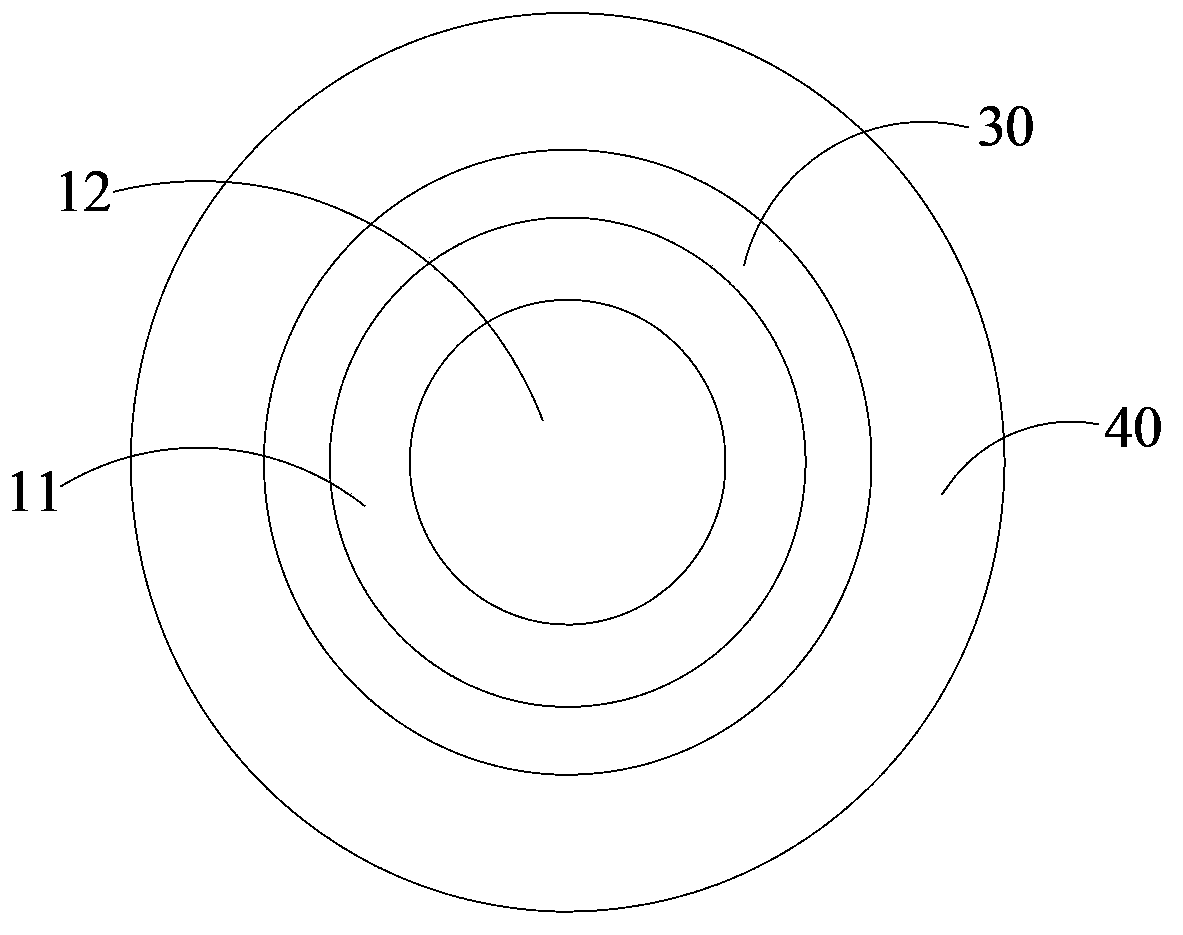

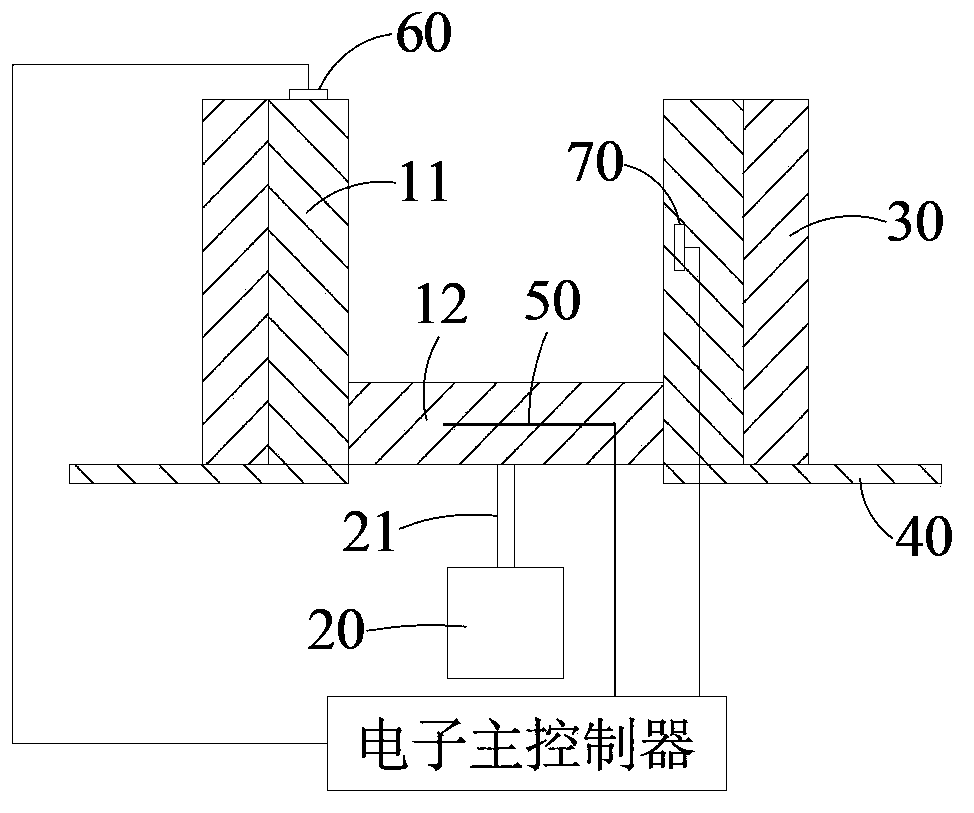

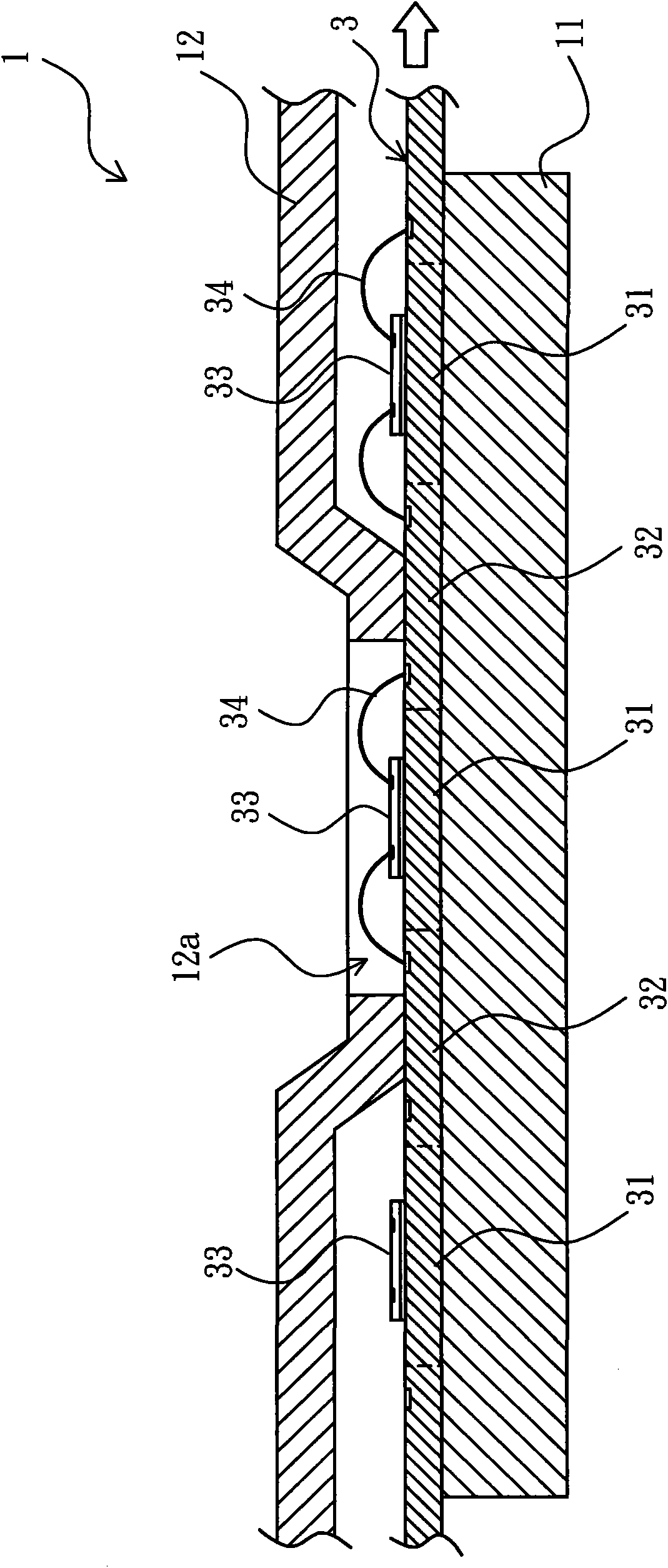

Baking device

InactiveCN105768234AControl heating temperatureReduce condensationTobacco devicesEngineeringElectronic cigarette

The invention provides a baking device. The device comprises a smoke pan (1) and an air inlet structure (2) at one end of the smoke pan (1), wherein the air inlet structure (2) comprises an air inlet passage (23), the smoke pan (1) comprises a smoke cavity (11) and an air inlet hole (12) for communicating the smoke cavity (11) and the air inlet channel (23). The baking device further comprises a heating device (3), wherein the heating device (3) is used for heating the air inlet passage (23) and the smoke pan (1). Through the adoption of the baking device provided by the invention, the heating device (3) capable of heating the air inlet passage is additionally arranged, the entered air can be pre-heated while passing through the air inlet passage (23) as long as the air passes through the air inlet passage (23), and then then air enters the smoke pan (1). Therefore, the baking device has the function of preheating the induced air, and is capable of improving the mouthfeel of the cured tobacco when being used for baking the electronic cigarette.

Owner:JOYETECH EURO HLDG

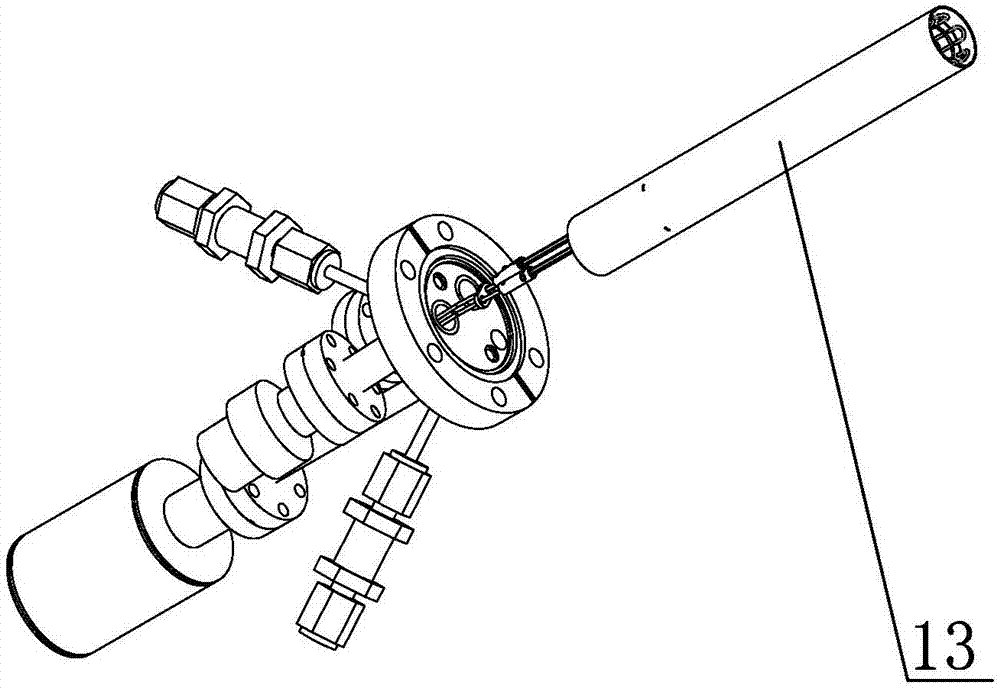

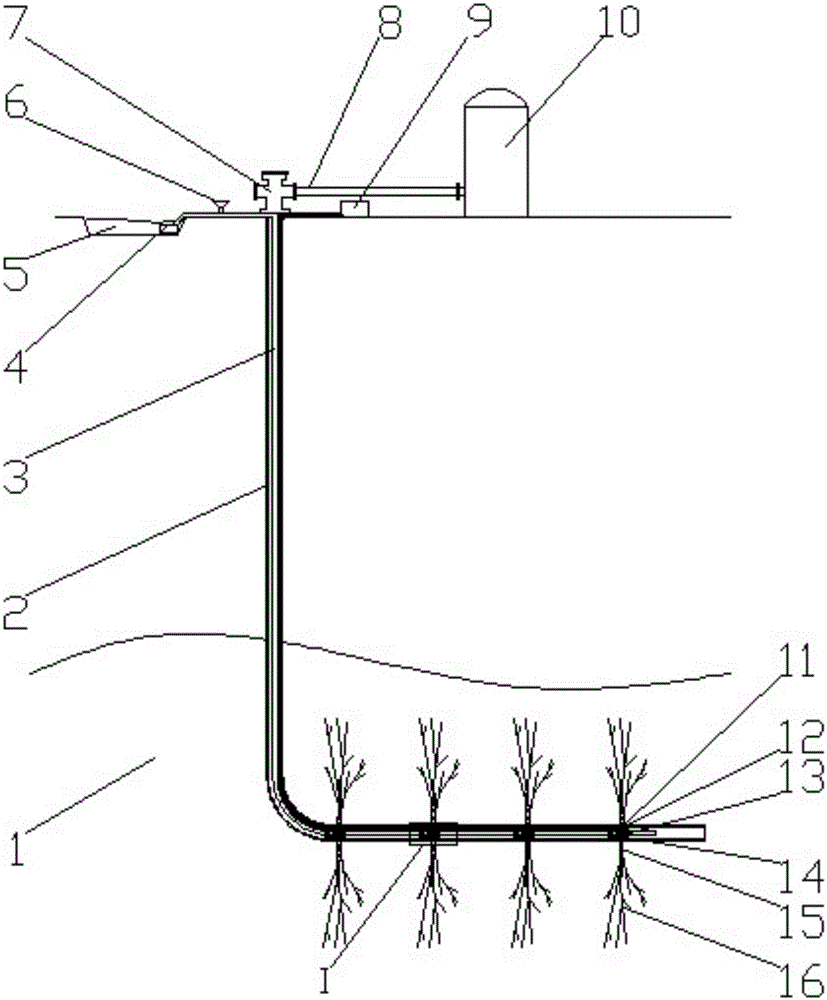

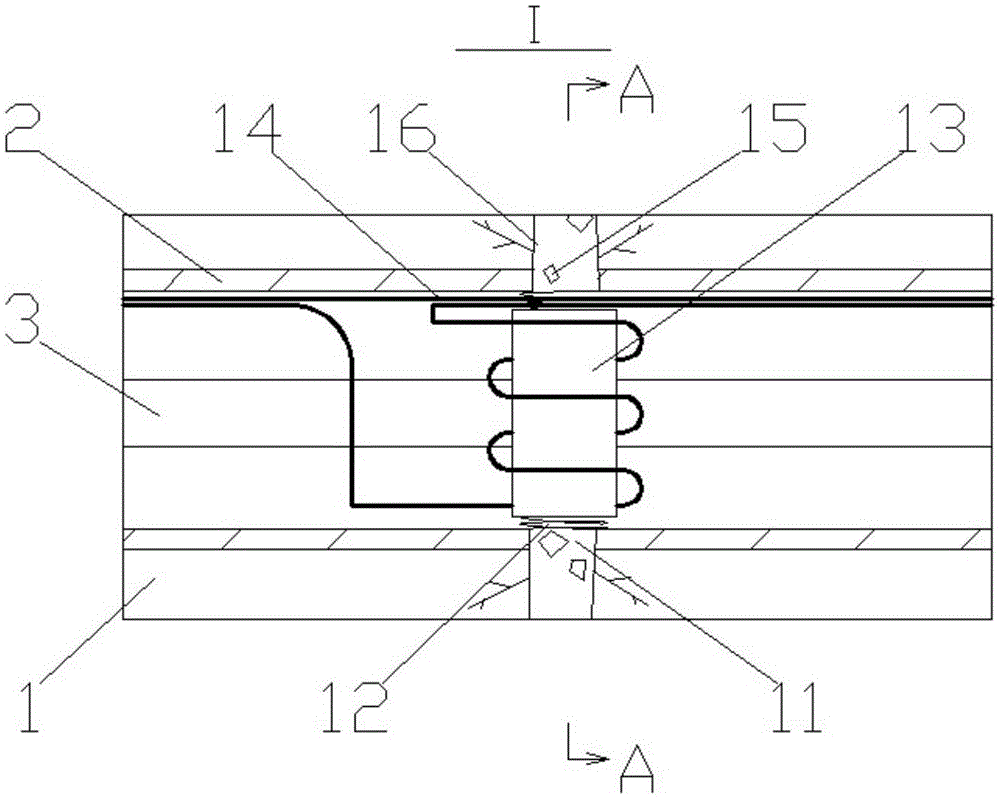

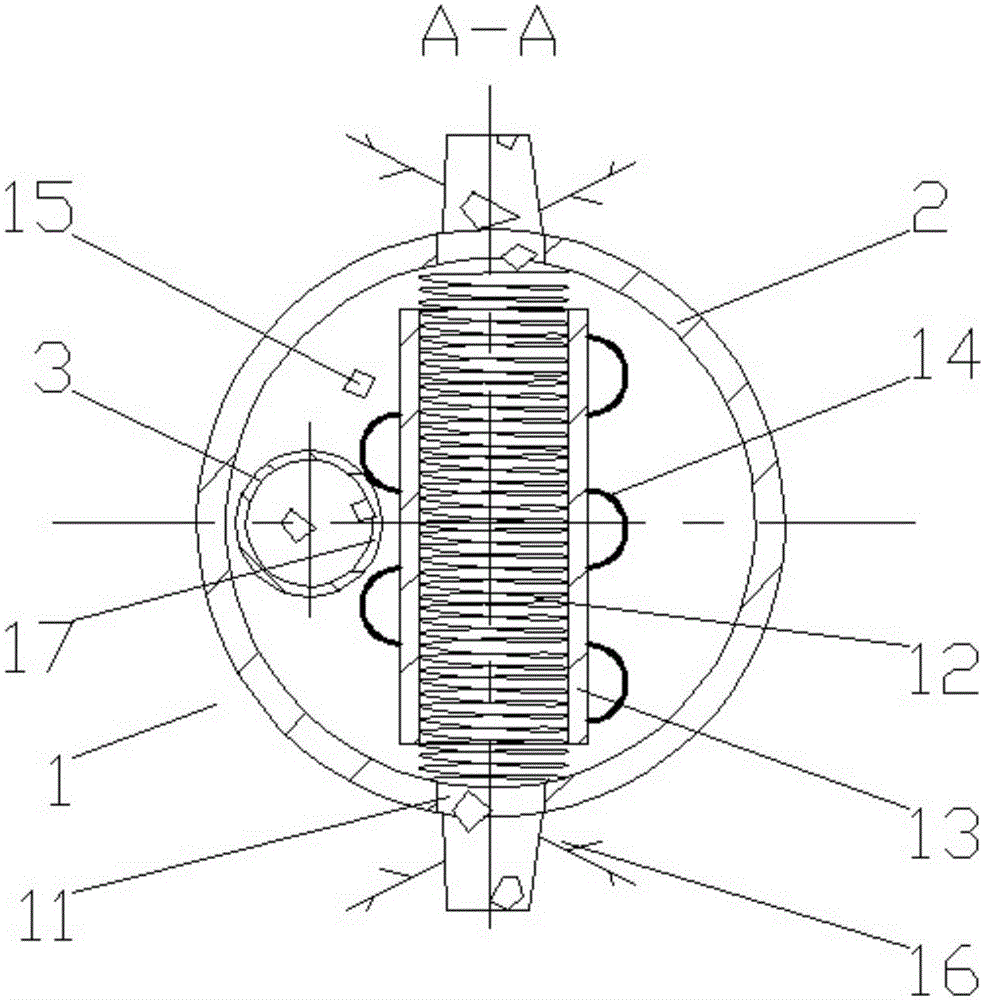

Rock stratum steam fracturing device applied to shale gas exploitation

The invention discloses a rock stratum steam fracturing device applied to shale gas exploitation. The device is formed by a shaft, a liquid delivery pipe, a submersible pump, a reservoir, an emery feeding hole, an air pump, a gas transmission line, an alternating current power supply, a gas storage tank, perforations, a limiting spring, a metal rod, a guide wire, and an emery particle and water outlet, wherein the submersible pump is used for delivering clear water and emery particles in the reservoir to the horizontal shaft by the liquid delivery pipe, symmetric perforations are uniformly distributed in the horizontal shaft, the metal rod is arranged at the perforations, the middle of the metal rod is of a hollow structure, the limiting spring passes through the metal rod and is stuck at the wall of the shaft to limit and fix the metal rod. The guide wire is wound on the metal rod, alternating current is introduced to the guide wire, and the air pump is arranged at the outlet of the shaft so as to collect natural gas produced by fracturing into the gas storage tank. According to the rock stratum steam fracturing device, a method of quickly generating a large amount of steam to facture rock by electromagnetic induction heating is adopted, and requirement for a large amount of water resource is avoided; because fracturing fluid is not needed, pollution to the underground environment can be avoided.

Owner:BEIJING UNIV OF CHEM TECH

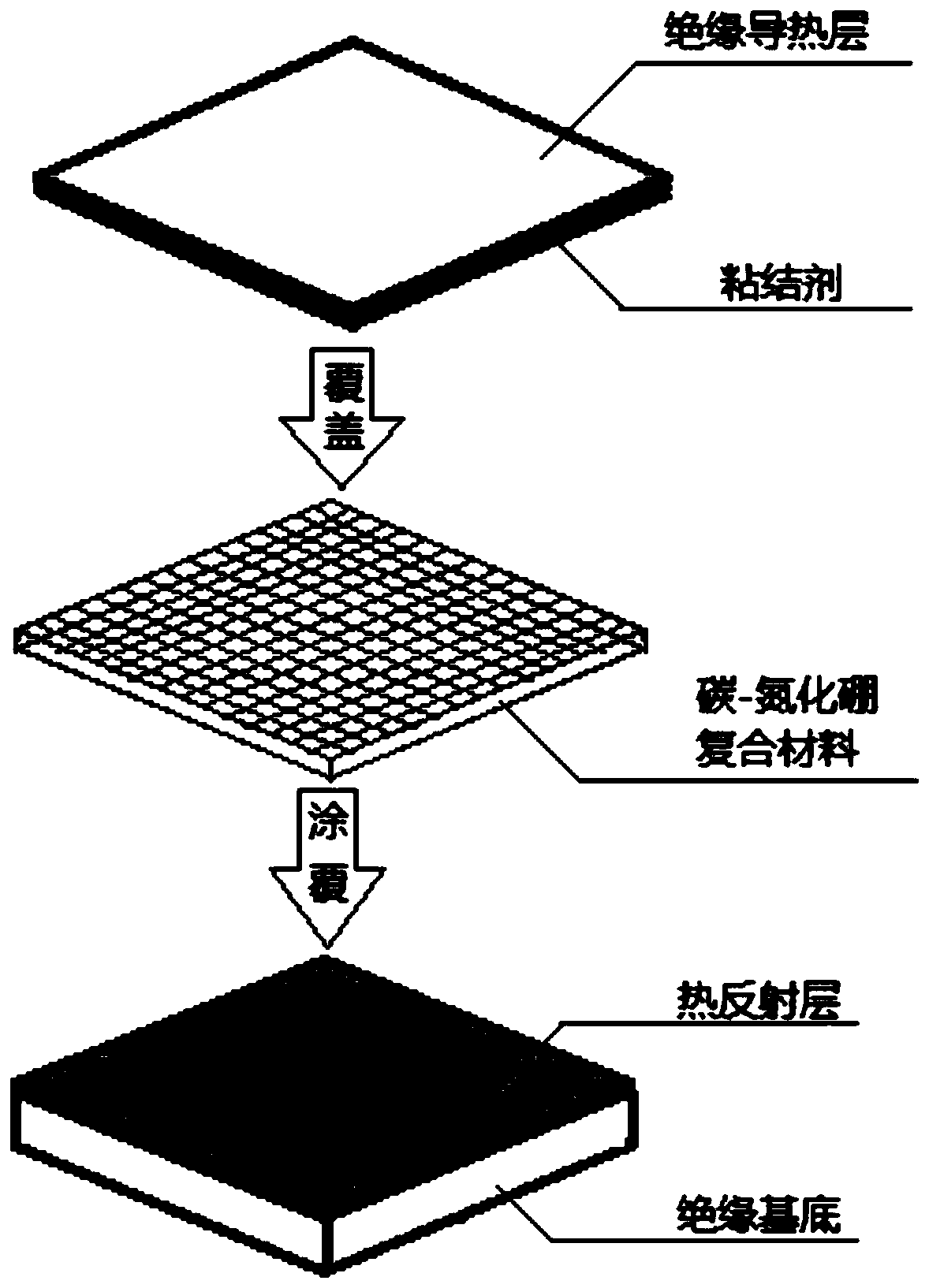

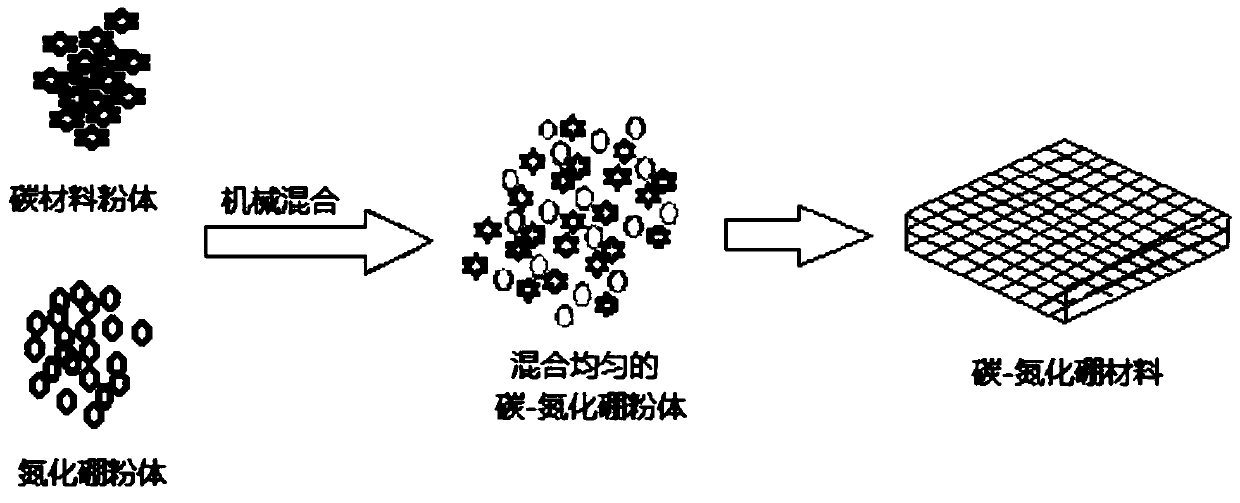

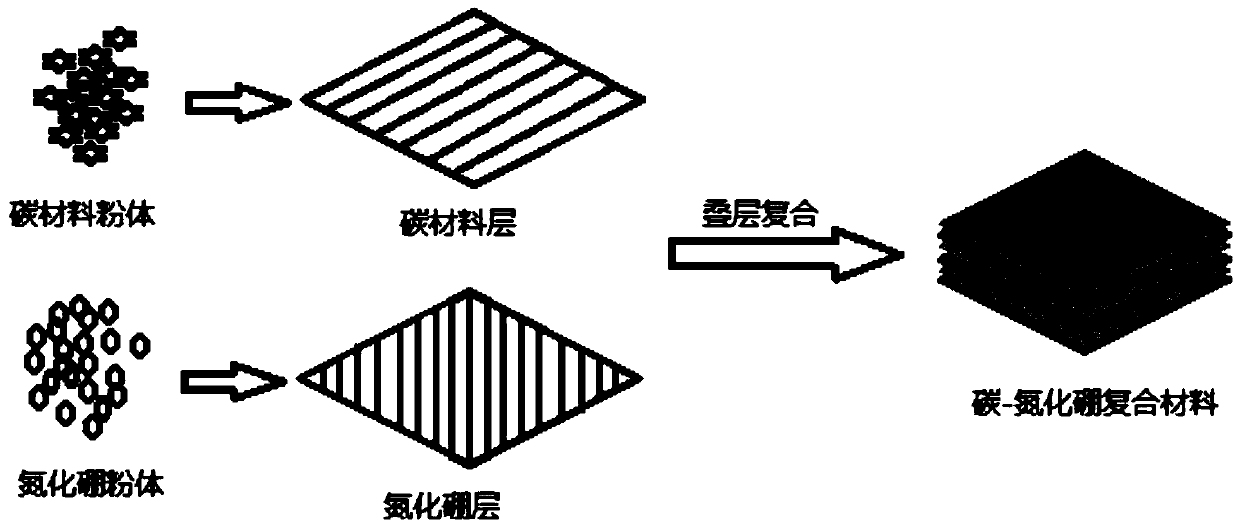

High-temperature heating film and preparation method thereof

InactiveCN109890094AImprove insulation performanceFast conductionHeating element materialsCompound aBoron nitride

The invention discloses a high-temperature heating film and a preparation method thereof. The high-temperature heating film sequentially comprises an insulation base, a heat reflection layer, a heating layer and an insulation heat conduction layer from bottom to top; and the heating layer is made of a carbon-boron nitride composite material. The preparation method comprises the steps of: attachingthe reflection layer to the insulation base; then compounding a carbon raw material with boron nitride to prepare the carbon-boron nitride composite material; then coating the carbon-boron nitride composite material on the reflection layer; and finally, covering the insulation heat conduction layer to prepare the high-temperature heating film. The heating film disclosed by the invention has the advantages of high electric heat conversion rate, high heating temperature, wide application range, safety and environmental protection.

Owner:XI AN JIAOTONG UNIV

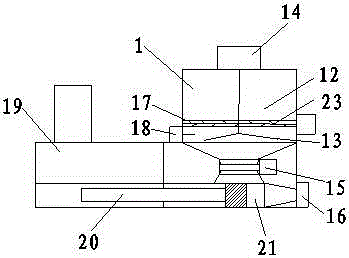

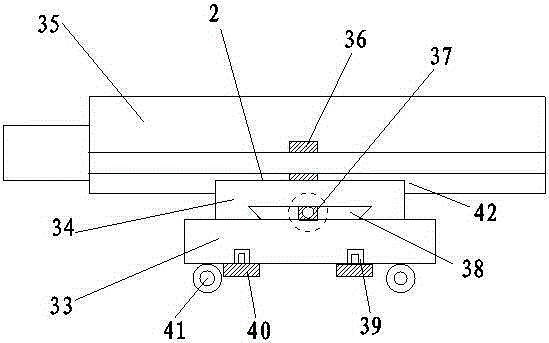

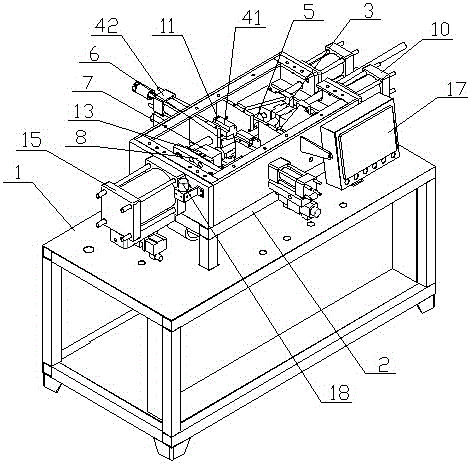

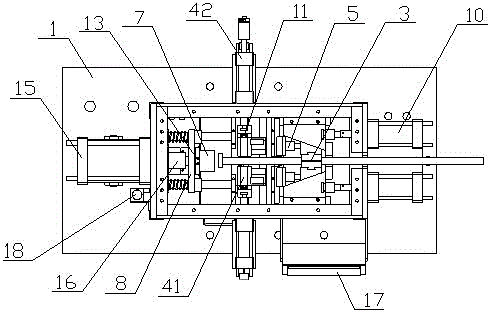

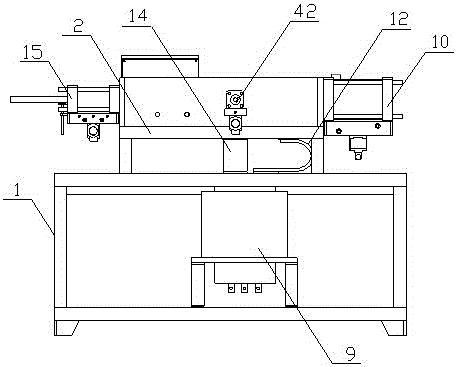

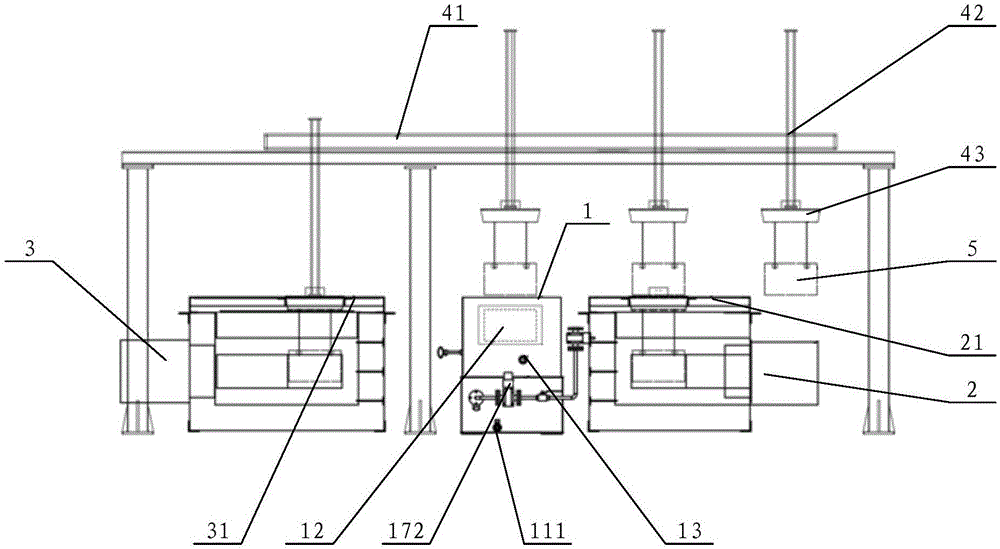

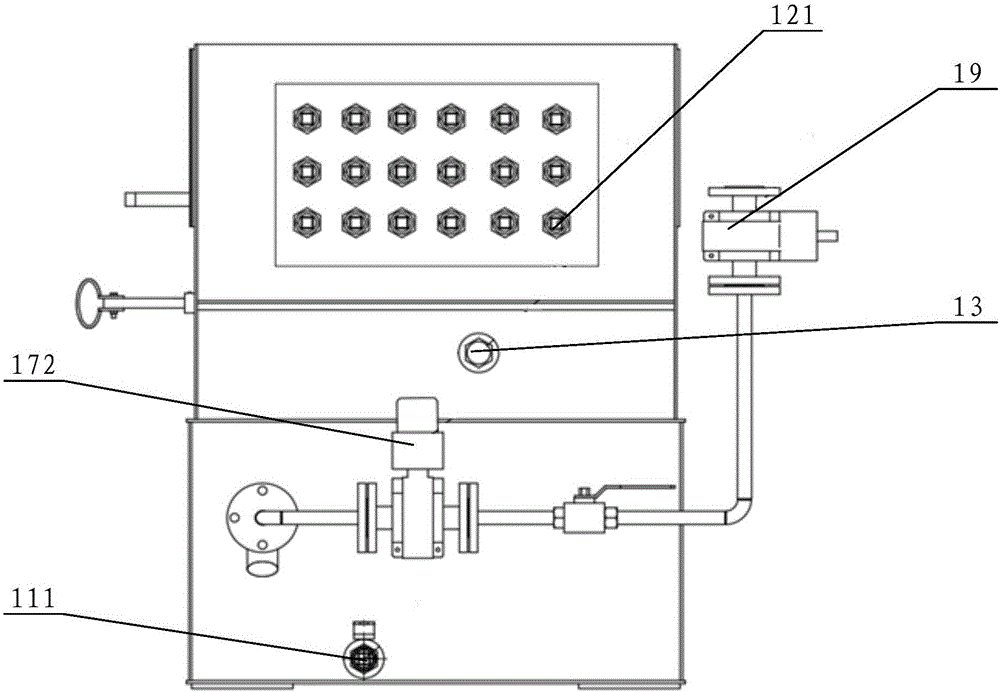

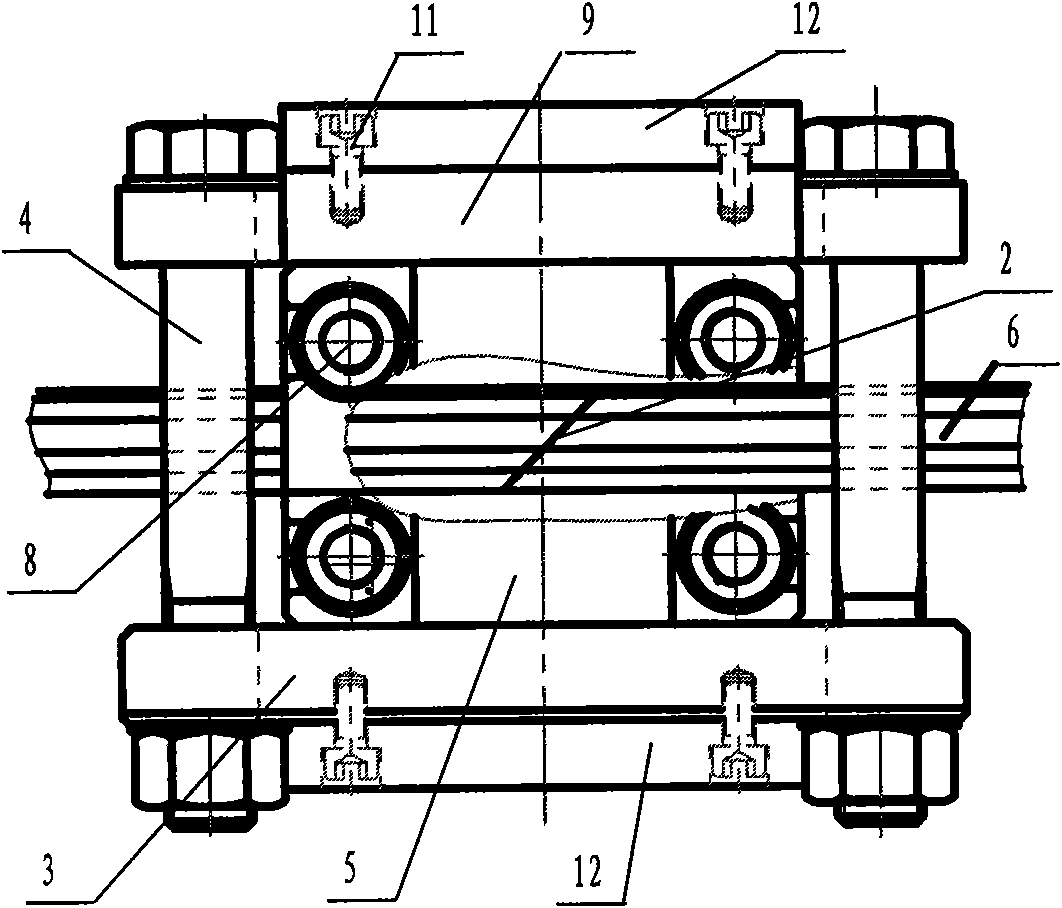

Heated upsetting processing device for ends of steel reinforcements

The invention discloses a heated upsetting processing device for the ends of steel reinforcements. The heated upsetting processing device comprises a base, a supporting frame, a rear-end clamp, a front-end clamp, guiding pressing seats, an upsetting mold, an upsetting electrode, an upsetting frame, a transformer and a control box. The rear-end clamp comprises a sliding seat, two pressing blocks, two rear-end clamping blocks, two linear sliding rails and two sliding rail mounting seats. Each guiding pressing seat comprises a guide rail, a sliding block, a fixed plate, a movable bar and a guide sleeve. The front-end clamp comprises two clamping electrodes and two front-end clamping hydraulic cylinders. The upsetting electrode is connected with the inner side of a connecting plate at the front end of a mounting frame through the upsetting frame. The transformer and the control box are arranged on a lower panel of the base. A control panel is arranged on the outer side of the mounting frame. The control panel is connected with the control box. The heated upsetting processing device has the advantages that the steel reinforcements can be effectively clamped, and the steel reinforcements are enabled to be accurately positioned during the upsetting process, so that the upsetting quality of the ends of the steel reinforcements is ensured, and the upsetting efficiency of the ends of the steel reinforcements is effectively improved.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

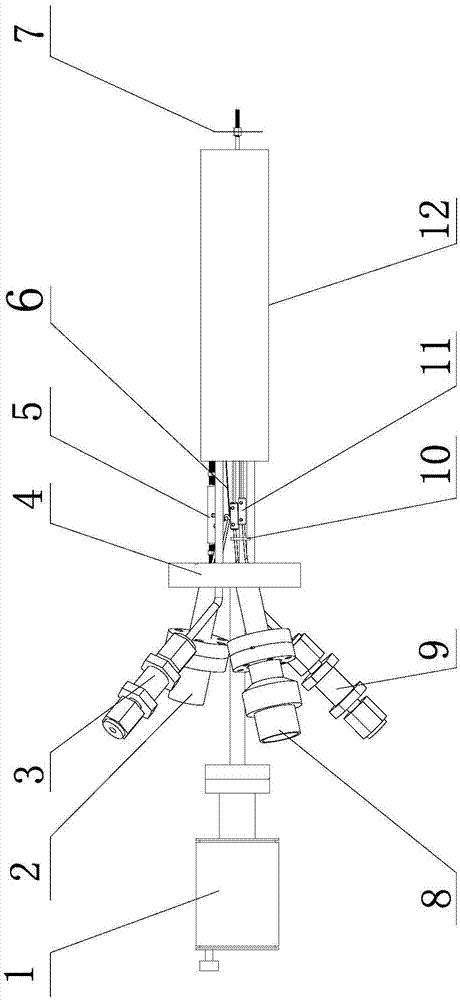

Device and method for preparing spherical metal powder for 3D printing

The invention provides a device and method for preparing spherical metal powder for 3D printing. The device for preparing the spherical metal powder comprises a shell, a crucible and a collecting bin,wherein the crucible is arranged in the shell, and the collecting bin is arranged on the lower portion of the shell. The device for preparing the spherical metal powder for the 3D printing is characterized in that a rotating disc arranged in a powder collection area is of a inlaying structure, materials with poor thermal conductance are selected as a substrate part of the rotating disc, metal materials with a wetting angle less than 90 degrees with liquid drops are selected to be inlayed into a main part to be used as an atomized plane, and a ventilation hole is formed in the rotating disc. The invention further discloses a method for preparing the spherical metal powder for the 3D printing, a pulse microporous injection method and a centrifugal atomization method are mainly combined, a rotating disc structure is matched, and the surface of the rotating disc is subjected to induction heating, so that molten metal breaks through a split mode of traditional molten metal, a fibrous splitmode which can be realized only when an atomization medium is an aqueous solution or an organic solution is realized, high melting point metal powder which meets requirements is prepared, the particle size is fine and grain size is controllable, the sphericity is high, no satellite droplet is achieved, the mobility and the spreadability are good, and the preparation method is suitable for industrialized production.

Owner:DALIAN UNIV OF TECH +1

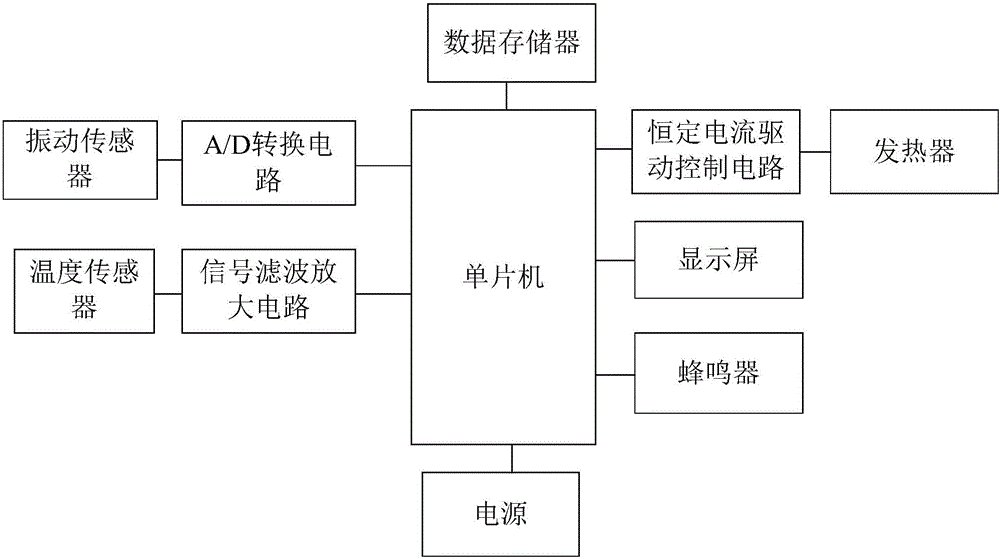

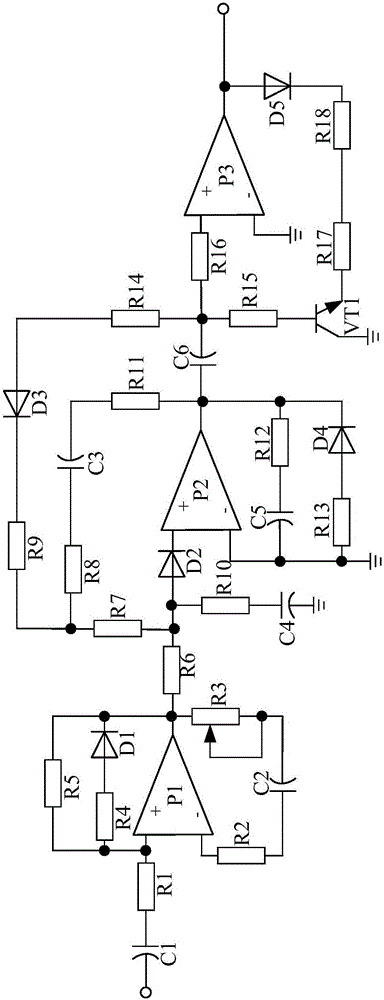

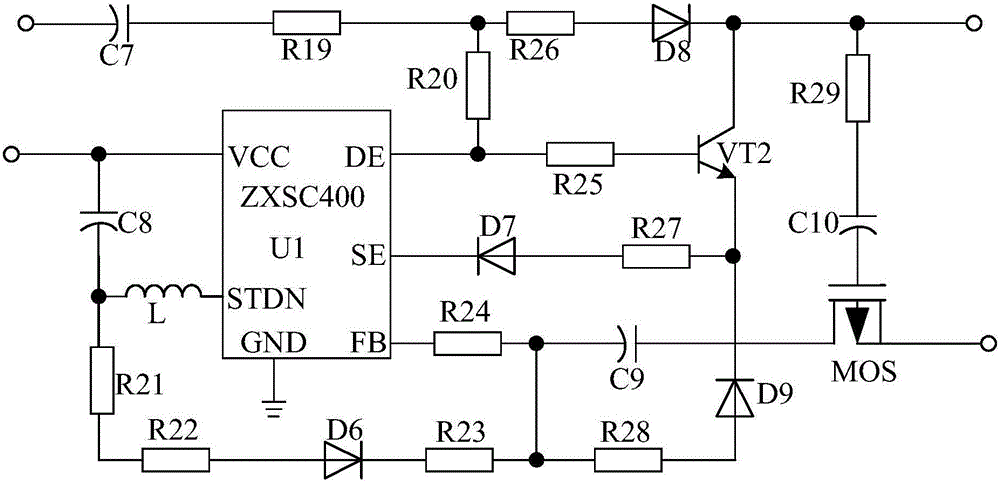

Multi-circuit processing type temperature intelligent control system

InactiveCN105867467AControl heating temperatureEnsure automatic controlAuxillary controllers with auxillary heating devicesMicrocontrollerProcessing type

The invention discloses a multi-circuit processing type temperature intelligent control system, which includes a single-chip microcomputer, a buzzer connected to the single-chip microcomputer, a data memory, a display screen, a power supply, a constant current drive control circuit, an A / D conversion circuit and a signal filter An amplifier circuit, a vibration sensor connected to the input end of the A / D conversion circuit, a heater connected to the output end of the constant current drive control circuit, and a temperature sensor connected to the input end of the signal filter amplifier circuit. The vibration frequency information of the pot body collected by the vibration sensor and the temperature information of the soup in the pot detected by the temperature sensor are analyzed and processed by the single-chip microcomputer. Certain, so that the soup in the pot maintains a certain temperature, and at the same time, effectively saves power resources.

Owner:CHENGDU JUHUICAI TECH

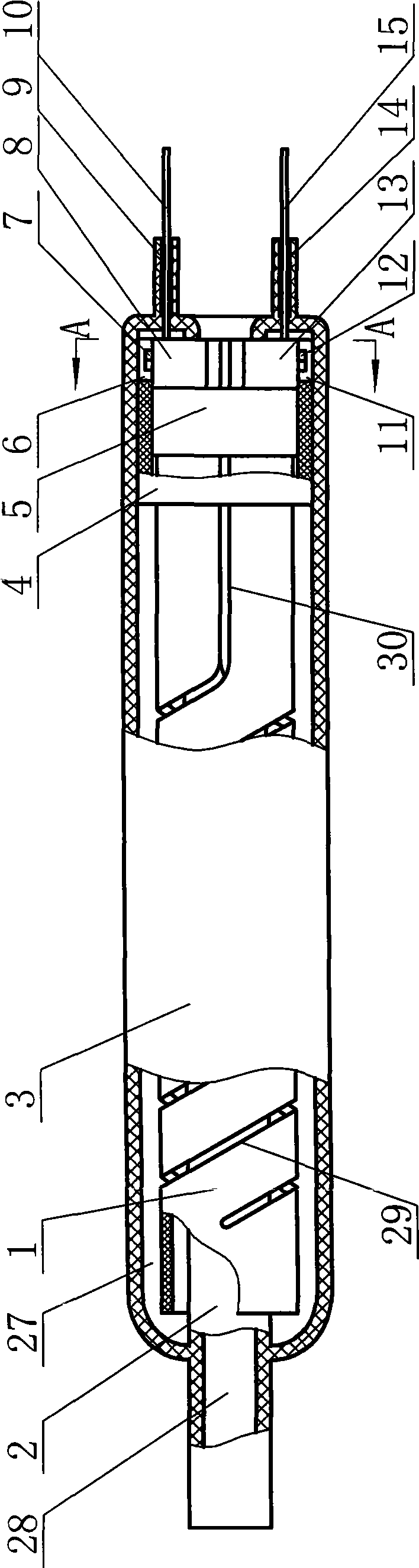

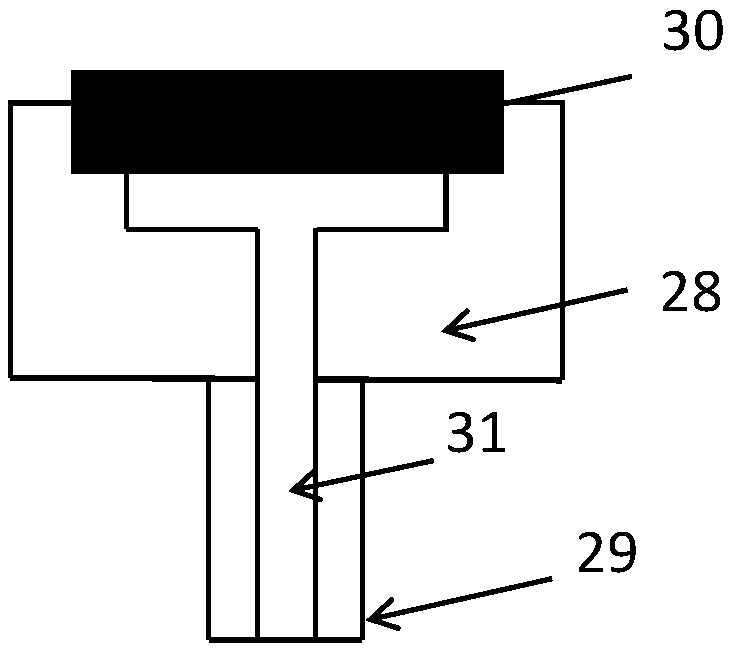

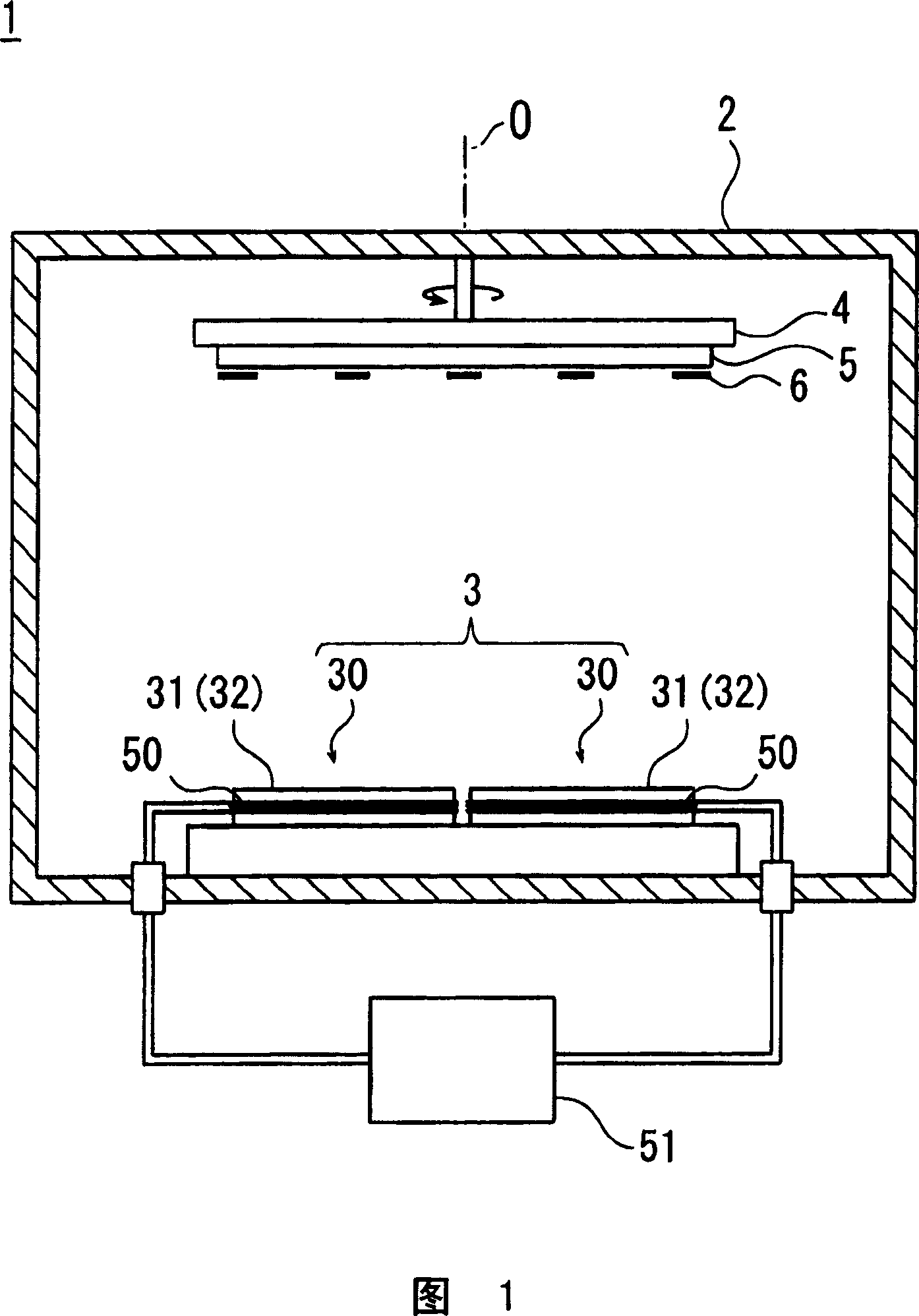

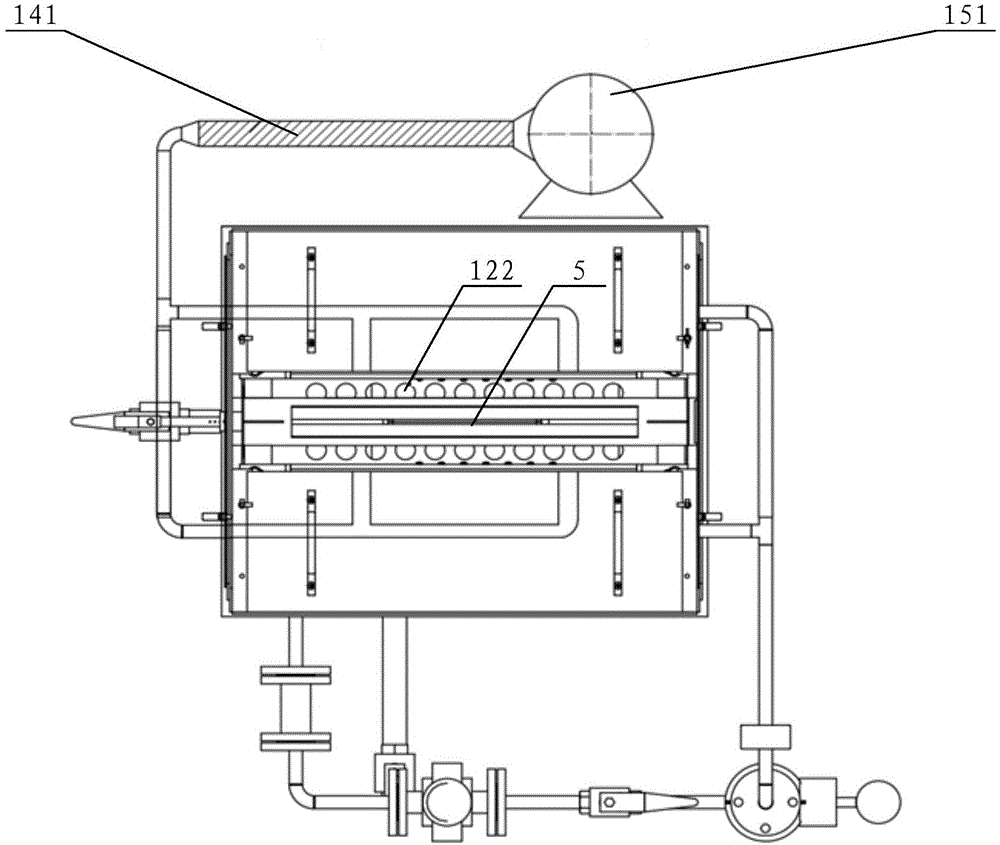

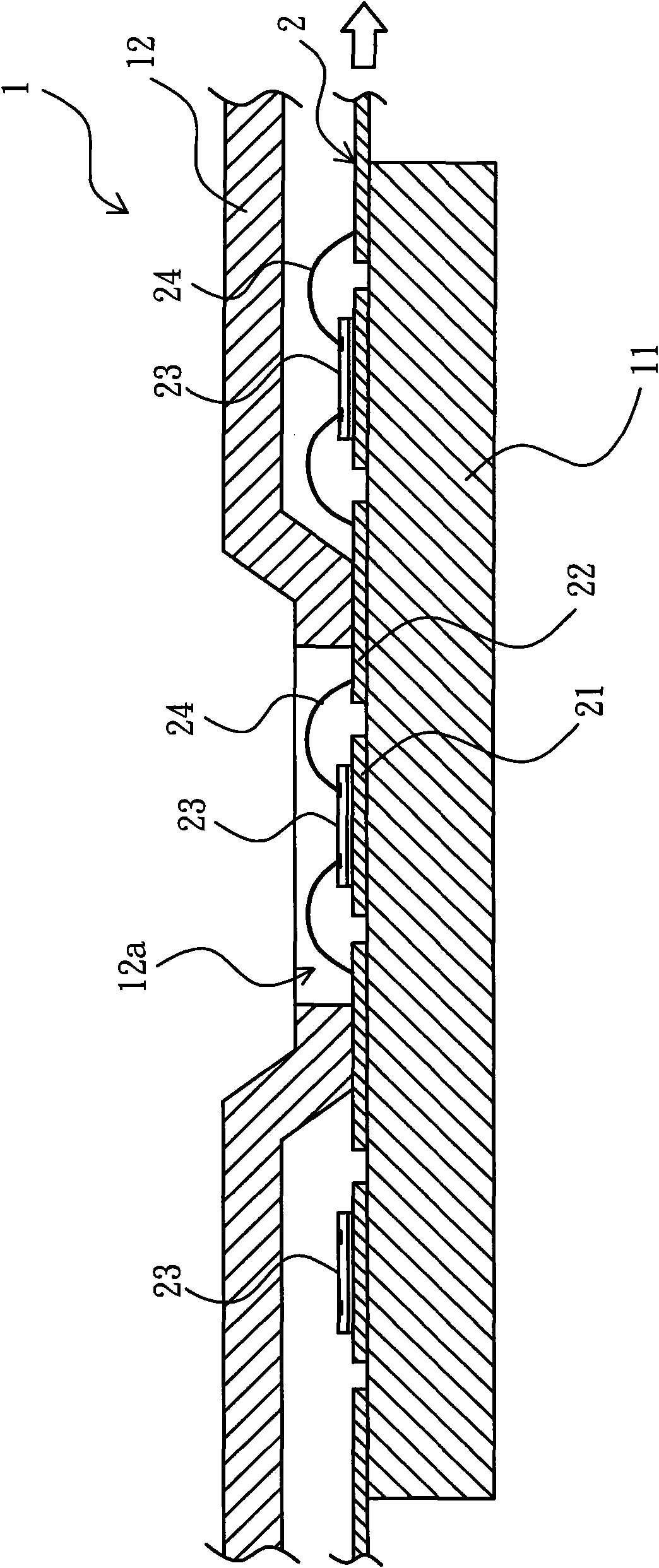

Organic material evaporation source and organic vapor deposition device

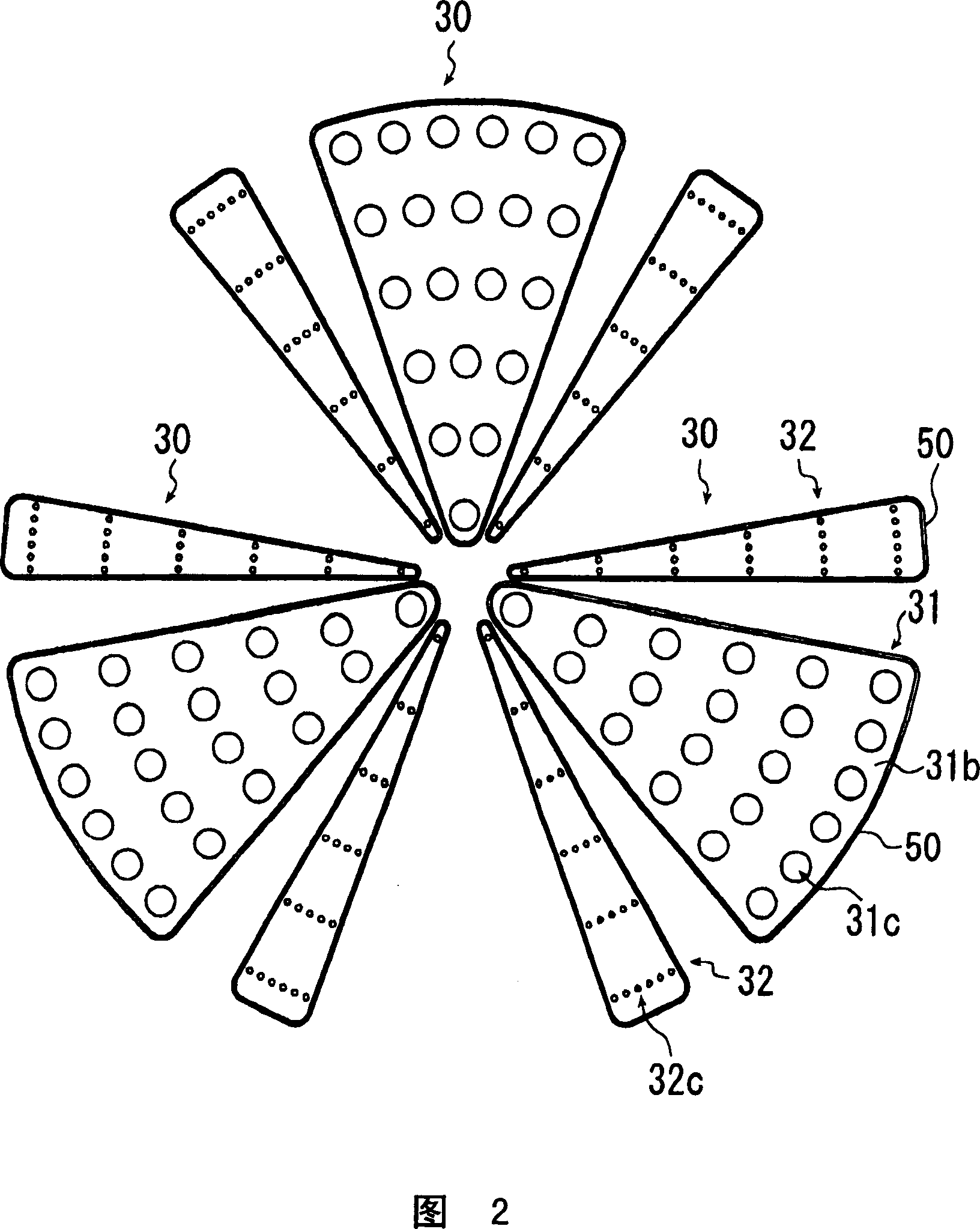

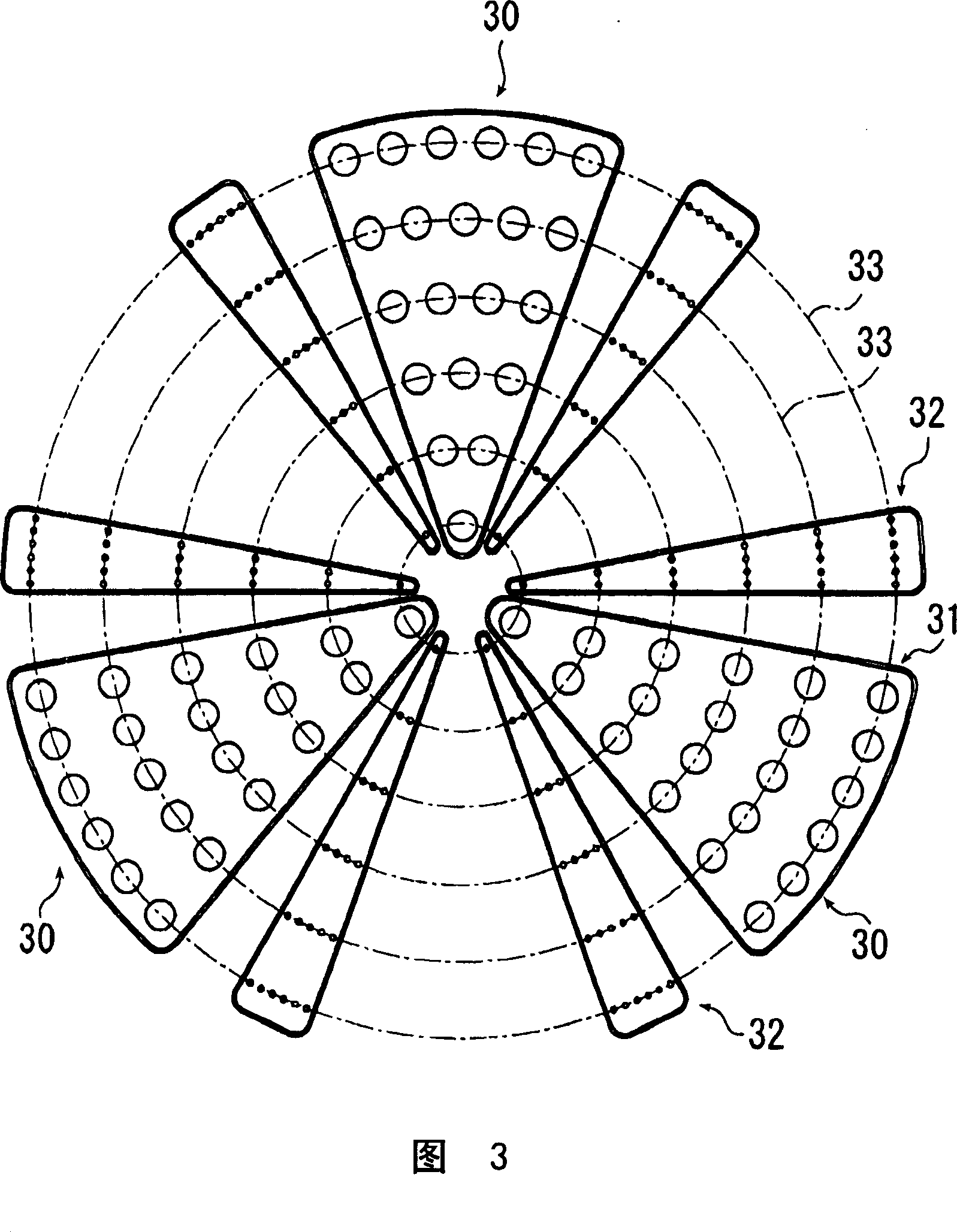

InactiveCN1950536AUniform film thickness distributionControl heating temperatureElectroluminescent light sourcesSolid-state devicesVaporizationMembrane thickness

An organic material evaporation source capable of forming a membrane having a uniform membrane thickness distribution with respect to a large-sized substrate and capable of controlling heating temperature and evaporation rate during vapor deposition accurately and with good responsiveness; and an organic vapor deposition device using the source. A vaporization source comprises a vessel main body (31a) having a heating section consisting of a high frequency induction coil (50) and receiving a predetermined organic material, and a lid (31b) having a vaporization port (31c) for the vapor of the organic material to pass therethrough. The arrangement is such that the amount of vapor of the organic material discharged from the vaporization port (31c) in the lid (31b) steadily increases with respect to a two-dimensional position with a predetermined reference position used as a basis.

Owner:ULVAC INC

Quenching experimental device and quenching experimental method

InactiveCN106834634AReduce stressEasy to shapeFurnace typesHeat treatment process controlAlloyHigh pressure

The invention discloses a quenching experimental device and a quenching experimental method, relates to the technical fields of aluminum alloy heat treatment equipment and technology simulation machines, and aims at solving the technical problems that a conventional quenching experimental device easily leads to reduction of plate shape quality and comprehensive mechanical properties of aluminum alloy plate strips. The quenching experimental device comprises a cooling mechanism; the cooling mechanism comprises a water tank; an upper region of the water tank is provided with a cooling nozzle assembly, the cooling nozzle assembly is provided with at least two rows of nozzles, the nozzles comprise water nozzles for spraying water and gas nozzles for injecting gas, and the nozzles adopt a cooling way of high-pressure inclined injection; a lower region of the water tank is provided with a heater for heating cooling water in the water tank; the air inlets of the gas nozzles communicate with a frequency conversion fan through an air supply pipeline, and an interface of the air supply pipeline is provided with a first pressure sensor, a first flowmeter and a first valve.

Owner:NORTHEASTERN UNIV

Automatic tea making method

ActiveCN107007147AShorten the pipeline distanceReduce distanceBeverage vesselsTime informationMachine control

The invention discloses an automatic tea making method. An automatic tea making machine receives a tea making instruction; the automatic tea making machine records or obtains current tea making time number information, all previous tea making time information and all previous tea making temperature information; the automatic tea making machine obtains current tea making time information and current tea making temperature information according to the current tea making time number information, all the previous tea making time information and all the previous tea making temperature information; the automatic tea making machine controls current tea making time and temperature according to the current tea making time information and the current tea making temperature information. According to the automatic tea making method, based on previous brewing time variables, adjusting parameter variables for next brewing water temperature and soaking duration can be established, intelligent brewing parameter indicators generated with brewing time at intervals in an interactive mode are formed, and the quality of tea water is improved.

Owner:GUANGZHOU XIAOHAI ELECTRONICS PROD

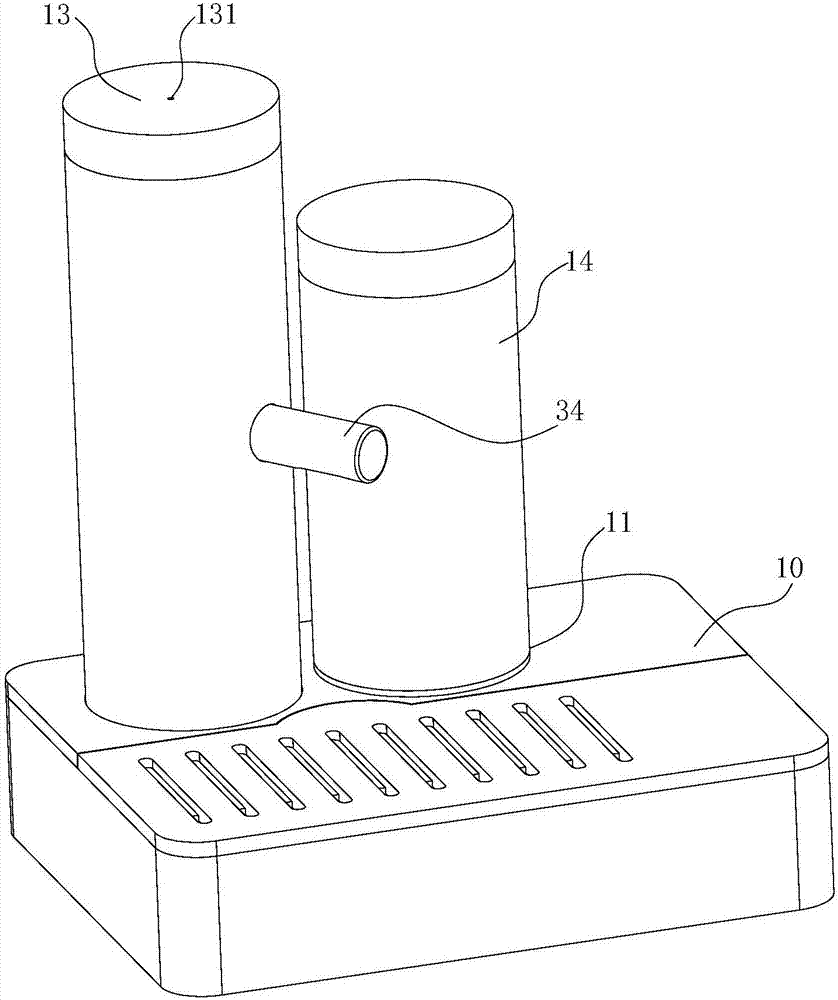

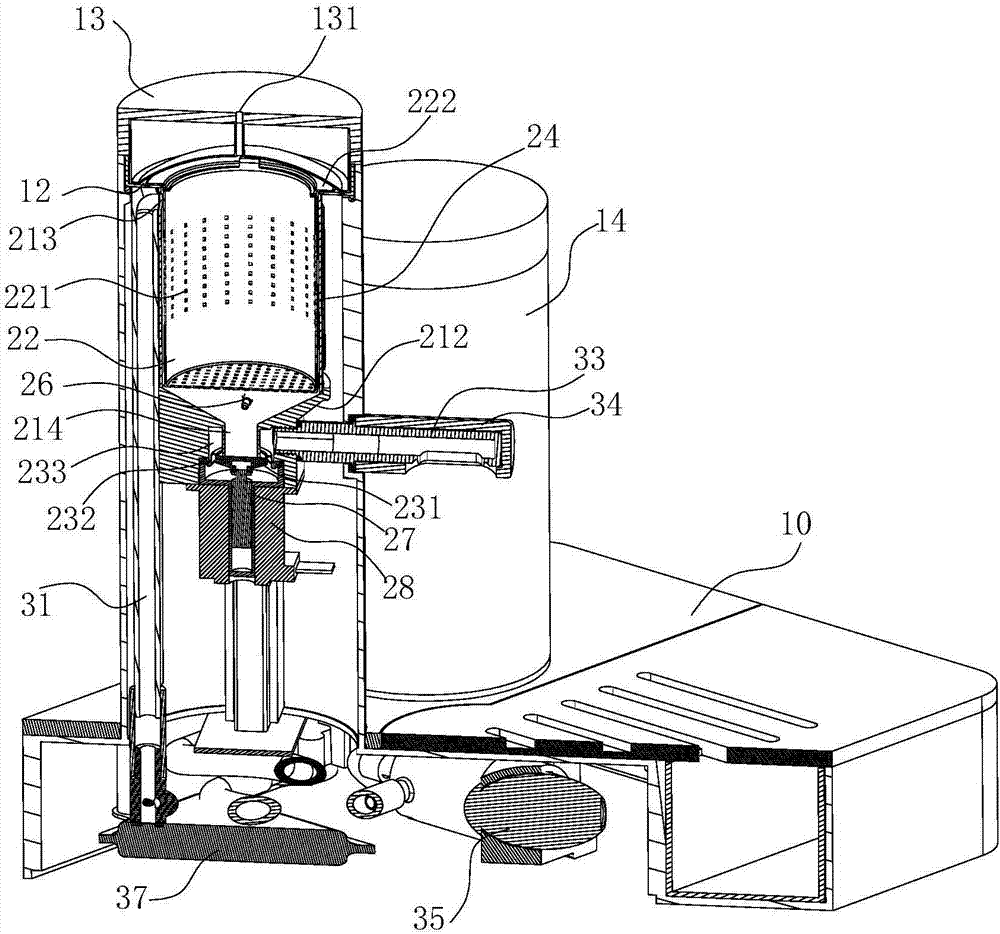

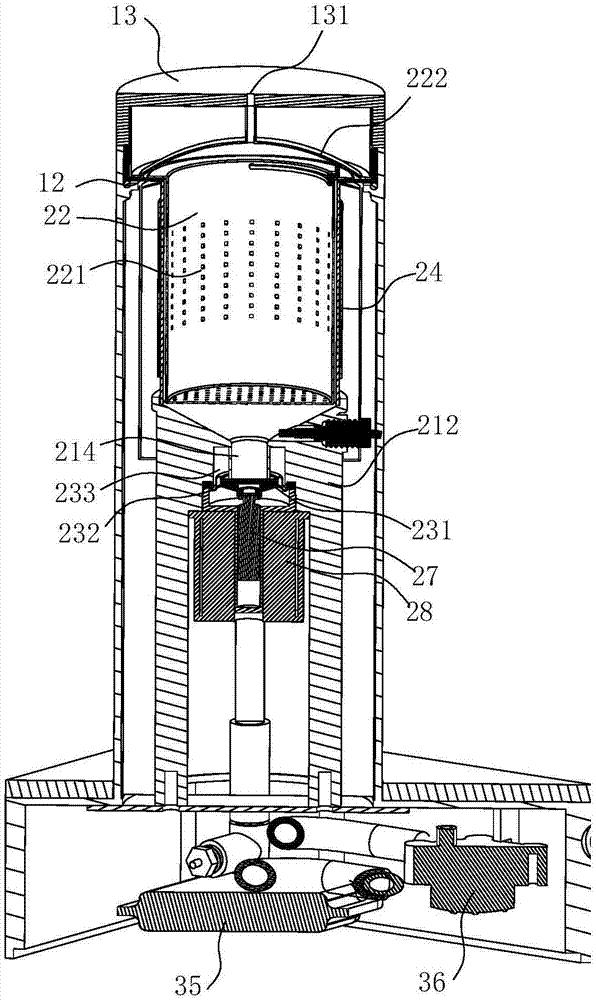

Automatic tea maker and automatic tea making method

ActiveCN106993944AShorten the pipeline distanceReduce distanceClimate change adaptationBeverage vesselsHeat conductingHeat losses

The invention discloses an automatic maker and an automatic tea making method. The automatic maker comprises a water tank body and a tea making cup; a water inlet and a water outlet are arranged on the water tank body and the tea making cup, the water outlet of the water tank body is connected with the water inlet of the tea making cup through a water inlet pipeline; a second heating element is arranged on the water inlet pipeline, and a first heating element is arranged on the tea making cup; the tea making cup is made of heat conducting material, and at least a part of the water inlet pipeline between the second heating element and the tea making cup is also made of heat conducting material; the water inlet pipeline forms heat conducting contact with at least one of the first heating element, the second heating element, and the tea making cup. The automatic maker can keep corresponding temperature of the water inlet pipeline, avoid heat loss when the hot water heated by the second heating element is conveyed to the tea making cup, thus water temperature in the tea making cup meets the setting temperature, and the accurate control of tea making water temperature is reached, and the tea quality is improved.

Owner:GUANGZHOU XIAOHAI ELECTRONICS PROD

Spraying device achieving remote video manipulation

The invention discloses a spraying device achieving remote video manipulation. A spraying robot comprises a feeding device, a moving device, an adjusting base, a big arm, a transition arm, a ternary arm, a rotating connector and a painting device. The adjusting base is installed on the moving device. An installation seat is installed on the upper surface of the adjusting base and hinged to the big arm. The big arm is hinged to the transition arm. The transition arm is hinged to the ternary arm. The front end of the ternary arm is provided with the rotating connector. The front end of the rotating connector is provided with the painting device. The spraying device achieving remote video manipulation has the advantages that tailings can be recycled, cost is saved, and an attached surrounding edge is arranged and prevents the situation that because the tailings fall off in a construction site, the environment is polluted; the spraying device can be remotely controlled, construction personnel and on-site device operation are separated, and therefore operation safety is facilitated; the attachment intensity of the painting device to a wall can be adjusted at any time through a load pressure sensor, and good plastering and tailing recovering effects are achieved.

Owner:安徽通成五金制品科技有限公司

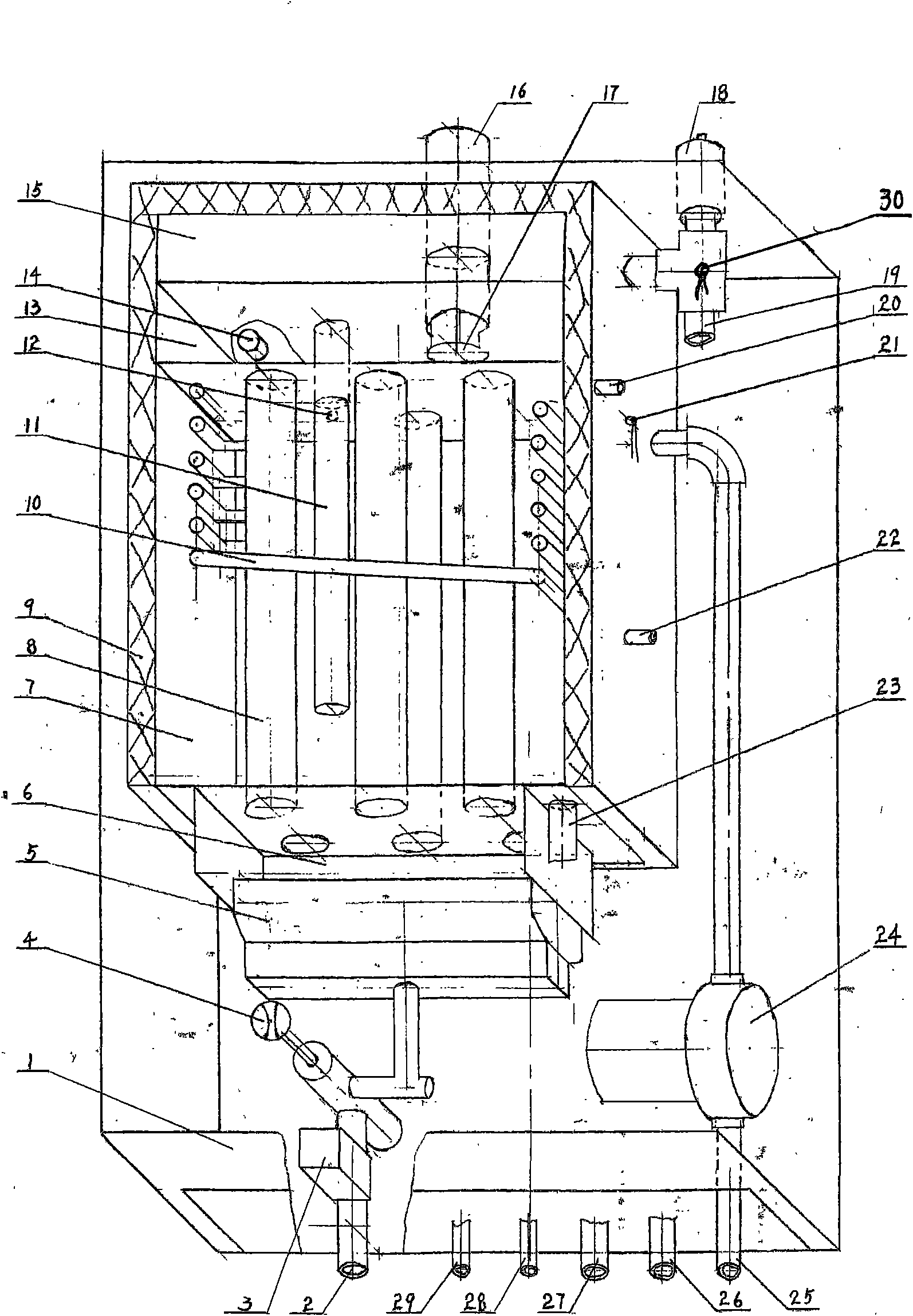

Heating and bathing gas water heater for double volume and condensation heat exchange system

InactiveCN101832633AHeating up fastNot affected by temperatureWater heatersThermal energyCombustion chamber

The invention discloses a heating and bathing wall-mounted gas furnace for a 'double volume + condensation heat exchange system', which comprises a shell, a microcomputer controller, a normally closed solenoid valve, a combustor, a first combustion chamber, a second combustion chamber, a lower honeycomb-shaped or parallel circular tube grate-shaped condensation volume heat exchanger and the like so as to form a heating and bathing combustor which has the advantages of forcedly changing hot water flow rule, fully utilizing heat energy, fully combusting gas, having large heat exchange area, long stroke and no resistance, not needing cleaning a flue in lifetime, supplying heating and bathing domestic water, and singly supplying bathing water in summer. The heating and bathing wall-mounted gas furnace saves energy by 30 percent and saves cost by about 60 percent than concentrated heating, saves energy and cost by over 60 percent than a pipeline type wall-mounted gas furnace, saves energy and cost by about 65 percent than the electric energy, and saves cost by 40 percent than honeycomb briquette heating. Because the gas furnace is ignited by gas electronically, so the heating can be started and stopped at any time, and the trouble of making a fire by coal and briquettes and pollution are eliminated; therefore, the heating and bathing wall-mounted gas furnace is an energy-saving and clean heating and bathing water heater which can be opened and closed at any time or fixed time.

Owner:岳书才

Braze welding method of grease suction filter

InactiveCN101108434ASmall amount of deformationInhibit sheddingSoldering apparatusPressure lubricationWeld seamEngineering

The invention is an engine oil suction filter soldering assembly method, which uses traditional pressing technics forming or rivet pressing technics to produce a flange plate (1), a supporting piece (3) and a filtering net (4), use a weld seam pipe to produce an oil pipe (2) by the tube sinking forming technics, then arrange the flange plate (1) and the filtering net (4) at the two ends of the oil pipe (2), the supporting plate (3) the outer wall of the oil pipe 2 close to the filtering net 2, then, lay the installed engine oil suction filter in an air protecting braze welding furnace stably to proceed braze welding in furnace. By the method in the invention, the prepared product not only has good and appearance and quality, even welding line, fixed welding, and is beautiful, but also doesn't need galvanizing, which prevents after effect of the zinc layer peeling off and improves the whole quality of the product.

Owner:CHONGQING SHENGMATIAN MACHINE MFG

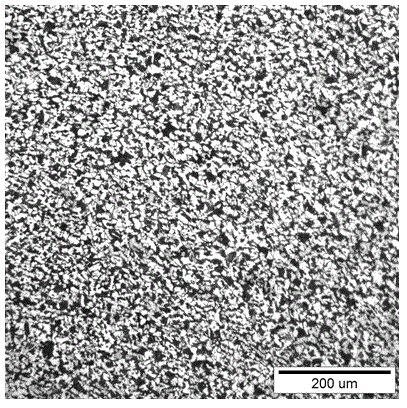

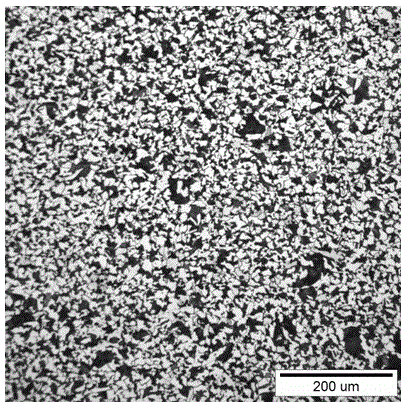

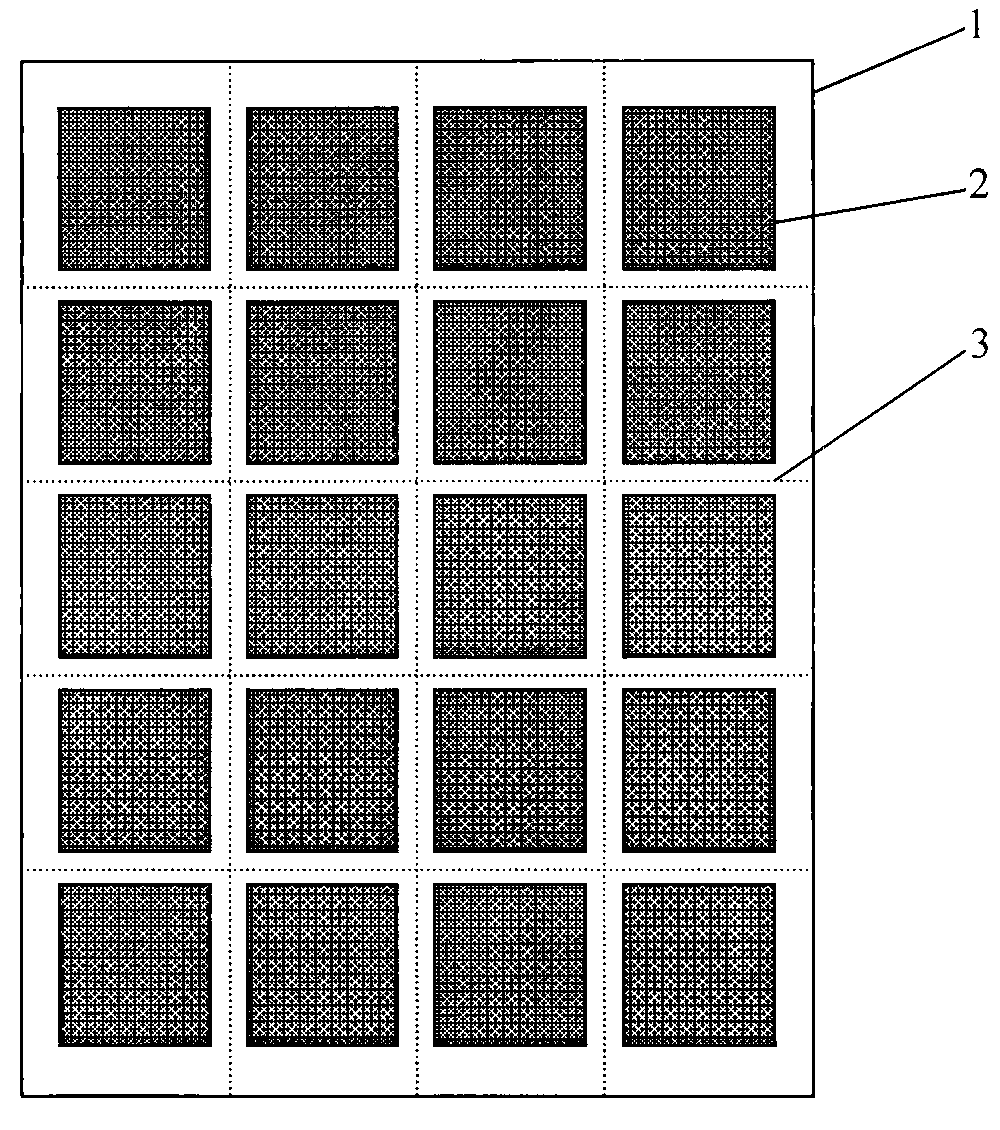

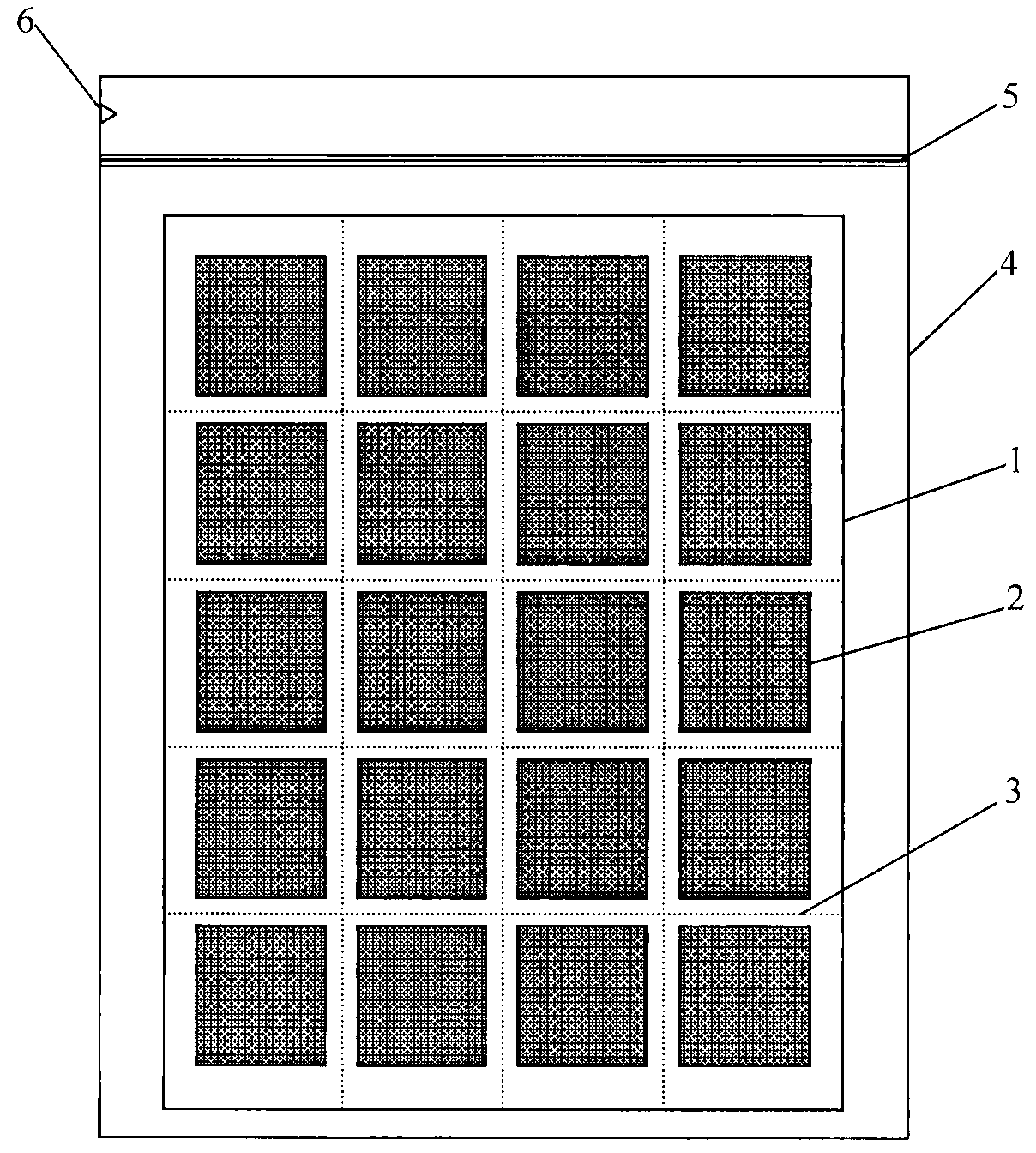

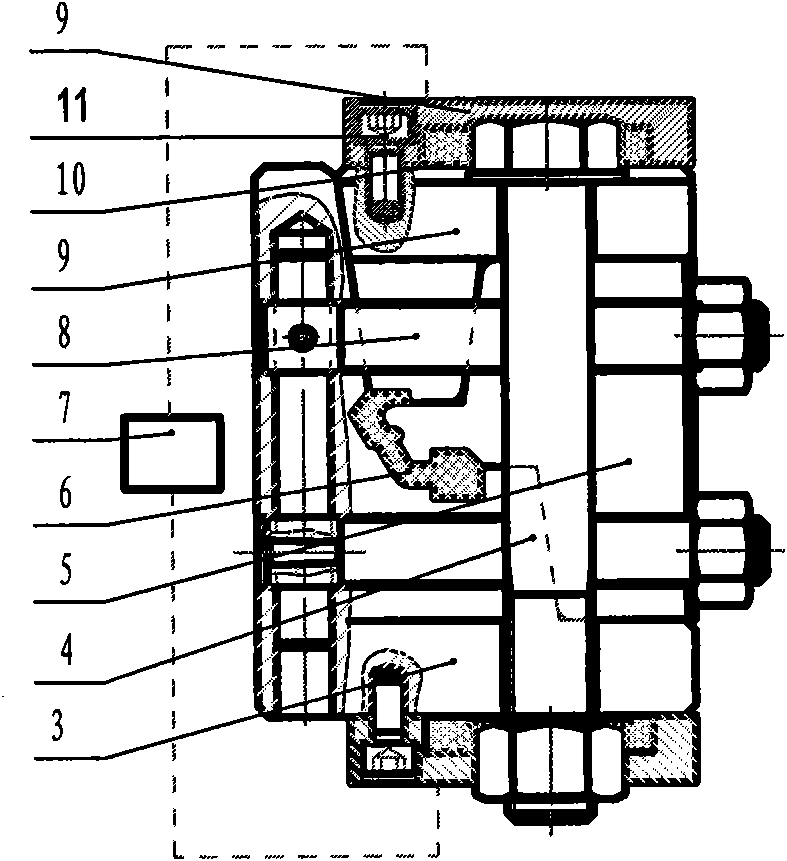

High-resolution high-temperature metallographic structure analyzer

InactiveCN101839846AControl the heating rateControl heating temperatureMaterial analysis by optical meansWater circulationImage analysis

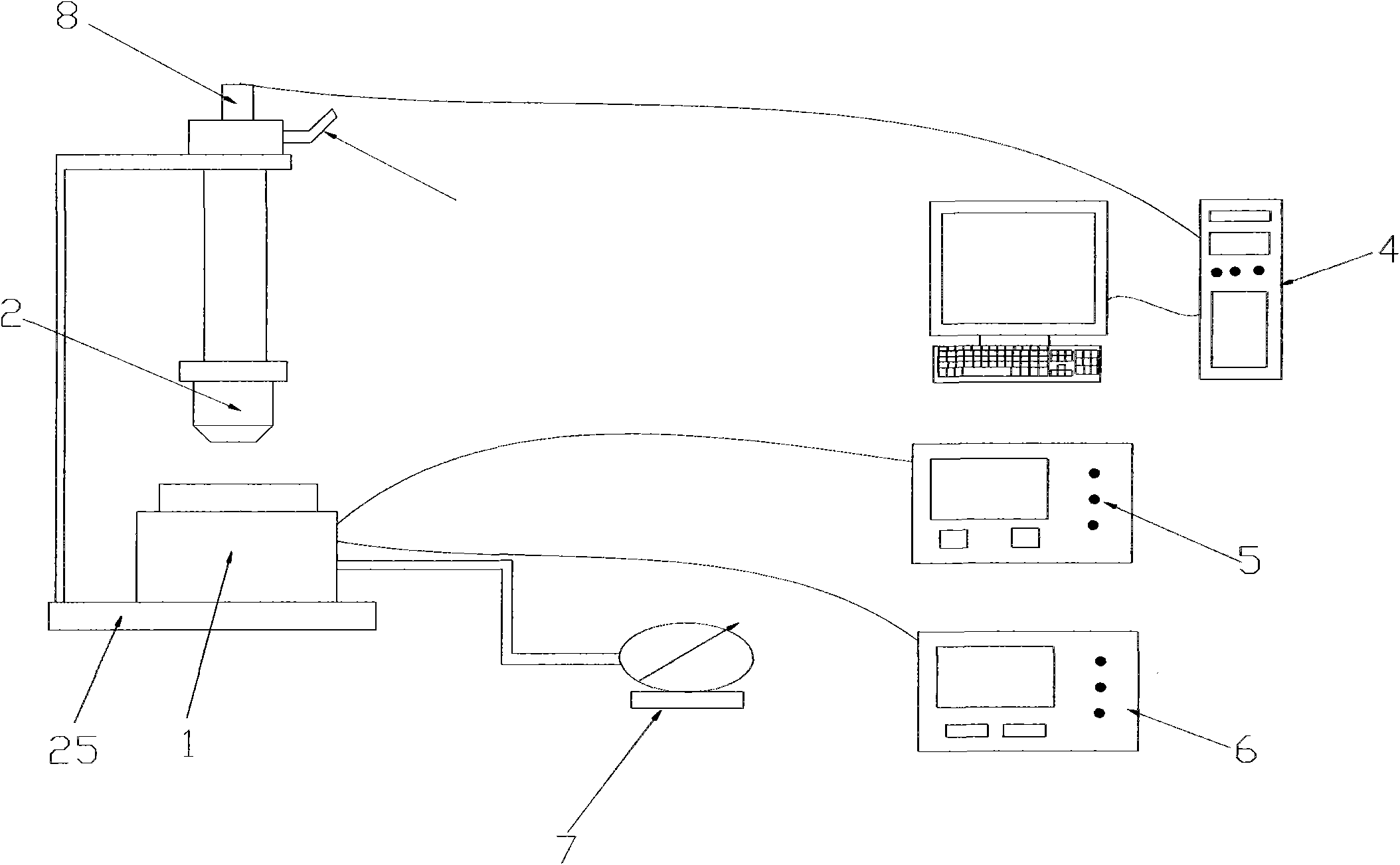

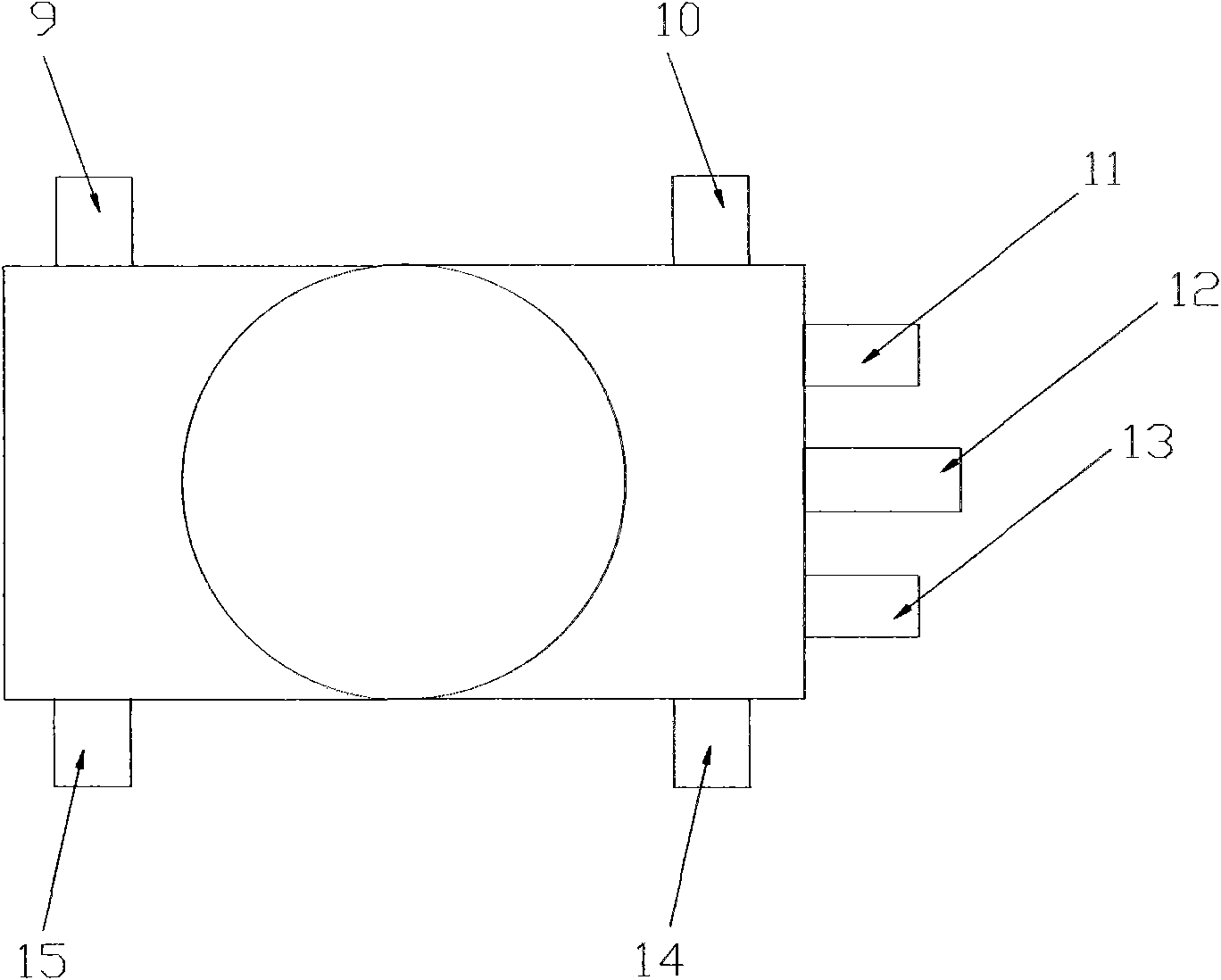

The invention relates to the technical field of metalloscopes, in particular to a high-resolution high-temperature metallographic structure analyzer which comprises a metalloscope equipped with a digital camera head, a hot stage, a cooling water circulation system of a window, a cooling water circulation system of a warm stage upper cover and a microcomputer embedded with an image analysis system. The analyzer is characterized in that the signal output end of the digital camera head is connected with the signal input end of the microcomputer, and the outer wall of the hot stage is respectively provided with a cooling water inlet, a liquid nitrogen cooling opening, a vacuum interface, a heating power supply interface, a thermocouple interface, a cooling water outlet and a reserved function interface. Compared with the prior art, by the invention, cooling speed and heating speed can be shown by numerical values and can be controlled more visually and conveniently; and in addition, the flow rate of the cooling water can be controlled in an intelligent way. The internal vacuum degree of the hot stage of the device can reach 10-3Pa, which can prevent a metal sample from being oxidized at high temperature. The reserved function interface of the device greatly widens the application scope of the high-temperature metalloscope.

Owner:SHANGHAI UNIV OF ENG SCI

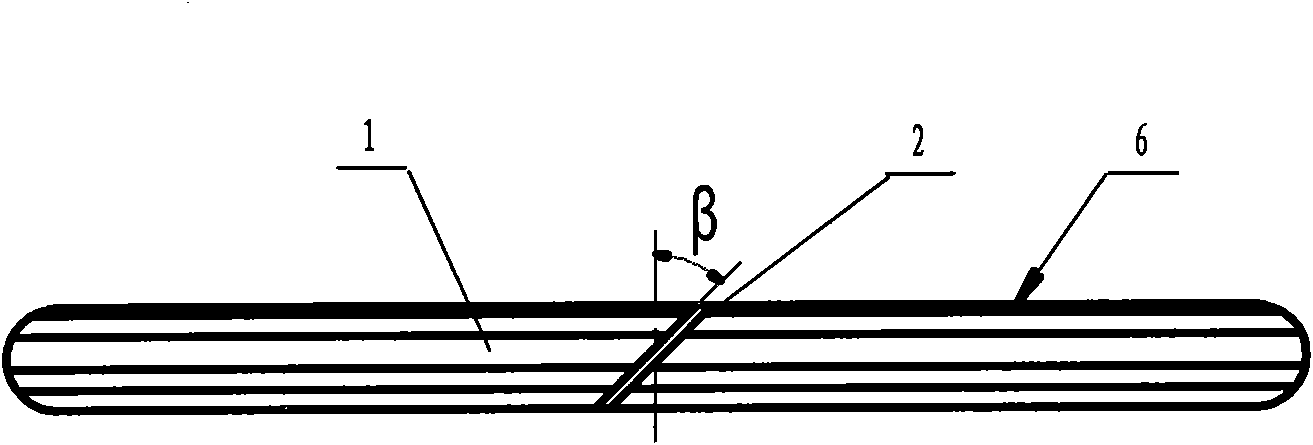

Rubber-plastic seal ring with section seam, bonding method of section seam and vulcanization bonding die for section seam

InactiveCN102042409AEasy replacement and maintenanceGood adhesionEngine sealsVulcanizationFree cooling

The invention discloses a rubber seal ring with a section seam. The rubber sealing ring comprises an annular seal ring substrate, the inclined section seam is arranged on the seal ring substrate, the seal ring substrate is cut off by the section seam, and the section inclination angle beta of the section seam is equal to 35 degrees-55 degrees. The bonding steps of the section seam are as follows: roughening, cleaning and air-drying the section seam; uniformly distributing heat vulcanization bonding agent on the section and drying; butting bevel end surfaces, then placing into a preheated vulcanization bonding die and exerting pressure on the two bevel end surfaces so as to enable the two opposite bevel end surfaces to be close to each other; heating and keeping for a certain period of time; and naturally cooling down to room temperature and then removing the die. The vulcanization bonding die for the section seam at least comprises an upper die plate and a lower die plate, wherein the upper die plate and the lower die plate are connected through an axial pressurization screw rod, a rubber seal ring cavity is formed between the upper die plate and the lower die plate which are mutually jointed, electric heaters and temperature measuring devices are arranged on the upper die plate and the lower die plate, and the temperature measuring devices are mutually electrically connected with a temperature controller.

Owner:东台市远洋船舶配件有限公司

Evaporation source device

InactiveCN104294217AAvoid or reduce residueIncrease profitVacuum evaporation coatingSputtering coatingEvaporationEngineering

The invention provides an evaporation source device, which is arranged in a vacuum chamber and used for evaporation of film to a substrate. The evaporation source device comprises an evaporator and at least one lifter. The evaporator is used for evaporation of evaporation material placed therein, and comprises a cylinder body and a cylinder seat. The cylinder body is fixedly mounted to the vacuum chamber, the cylinder seat is slidably coupled to the inner wall of the cylinder body. The lifting device is connected to the cylinder seat and used for driving the cylinder seat to move along the cylinder body. In the invention, the evaporator adopts a split structure, and the cylinder seat can be driven by the lifter to move up and down along the cylinder wall. With the usage of evaporation materials, the cylinder seat is rising gradually, so that the distance between the evaporation material and the substrate remains approximately constant to avoid or reduce the residue of evaporation material in the bottom of the evaporator. Accordingly, the evaporation source device provided by the invention can realize high utilization rate of evaporation material.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

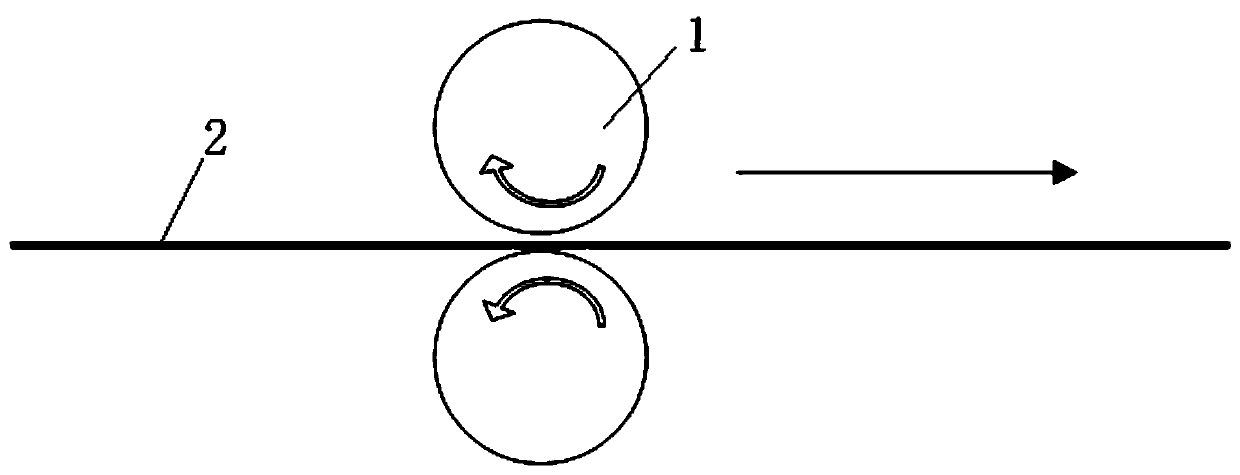

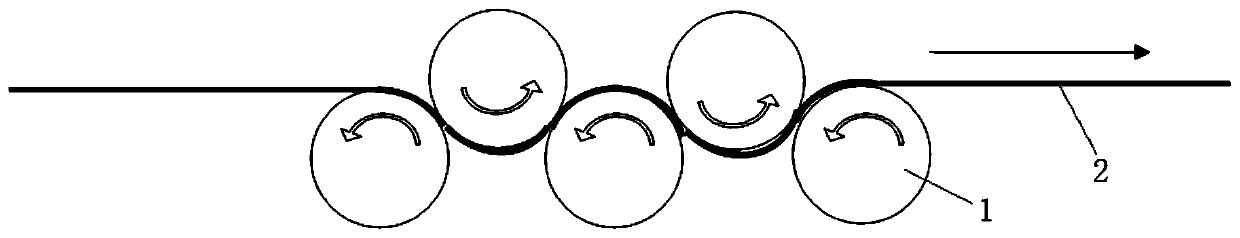

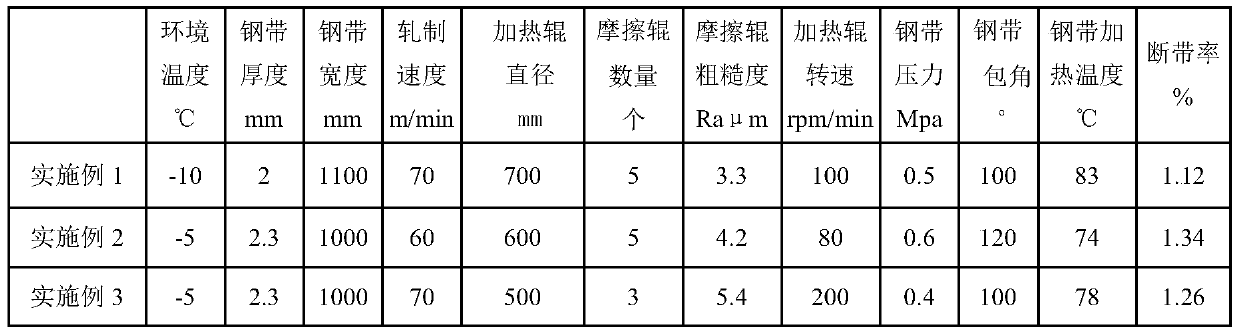

Preheating method for preventing cold rolling broken strip of high-grade non-oriented silicon steel

InactiveCN110369525AImprove heating efficiencyControl heating temperatureWork heating devicesMetal rolling arrangementsBreakage rateContact position

The invention relates to a preheating method for preventing cold rolling broken strip of high-grade non-oriented silicon steel. A friction heating roller is arranged in front of a cold rolling mill, and the friction heating roller and a steel strip generate heat through friction to preheat the steel strip through a heat conduction mode; the rotating tangential direction of the friction heating roller at the contact position of the friction heating roller and the steel strip is opposite to the running direction of the steel strip, or the rotating tangential direction of the friction heating roller at the contact position of the friction heating roller and the steel strip is the same as the running direction of the steel strip but the friction heating roller and the steep strip are differentfrom each other in the running speed; and the friction heat is generated through relative movement, and the heating temperature is controlled by controlling the roughness of the surface of the friction heating roller, the running speed of the friction heating roller and the steel strip and the pressure of the friction heating roller on the steel strip. With the method provided by the invention, at ambient temperature of minus 15 DEG C to 20 DEG C, the strip breakage rate is less than 5%.

Owner:ANGANG STEEL CO LTD

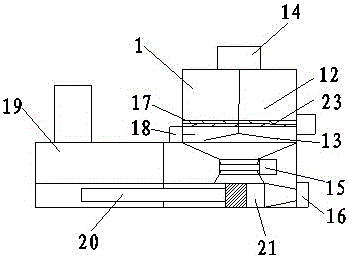

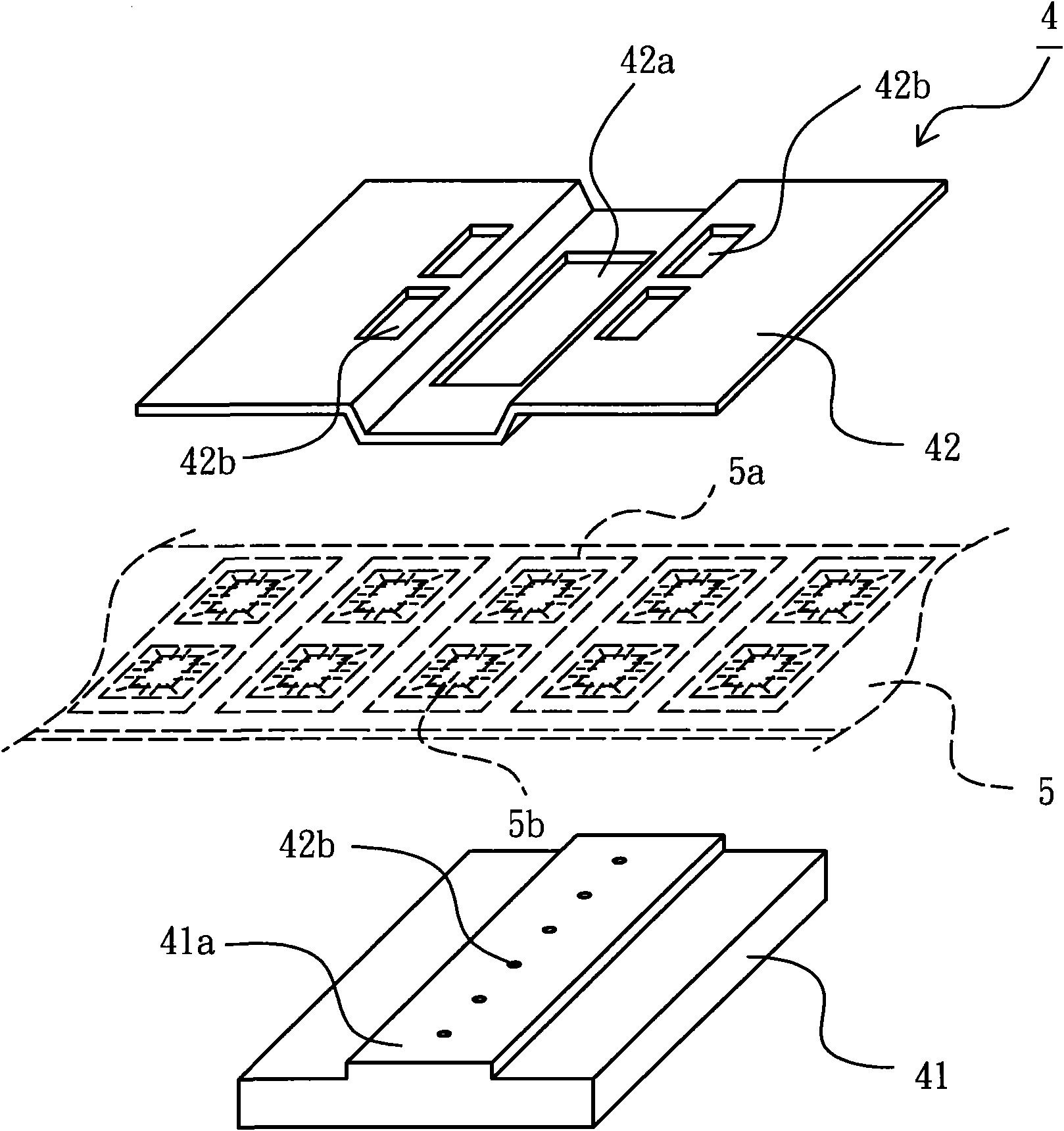

Heating device for semiconductor packaging wire bonding process and fixture thereof

InactiveCN102136442AInstant exclusionQuality improvementSolid-state devicesSemiconductor/solid-state device manufacturingHeating timeSemiconductor package

The invention discloses a heating device for a semiconductor packaging wire bonding process and a fixture thereof. The heating device comprises a heating block and a fixture. The heating block comprises a convex part which is convexly arranged on the upper surface of the heating block and used for bearing a wire bonding operation area of a packaging carrier; the fixture is positioned above the heating block and used for clamping the packaging carrier; and the packaging carrier is clamped and positioned between the heating block and the fixture. The fixture comprises a wire bonding window and at least an exhaust port. The wire bonding window exposes the wire bonding operation area on the packaging carrier; and the exhaust port is arranged at least one side of the wire bonding window. Therefore, the heating device can perform centralized heating on the wire bonding operation area by use of the convex part so as to reduce the heating time and prevent metal oxidation of the surface on the wire bonding position caused by excessive heating, and can exhaust organic volatile gas generated by wire bonding through the exhaust port so as to avoid pollution on the surface of the wire bonding position.

Owner:ASE ASSEMBLY & TEST SHANGHAI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com