Evaporation source device

An evaporation source and evaporator technology, which is applied in vacuum evaporation plating, ion implantation plating, metal material coating processes, etc., can solve the problems of waste, reduce material utilization, and change in evaporation rate, and achieve utilization high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

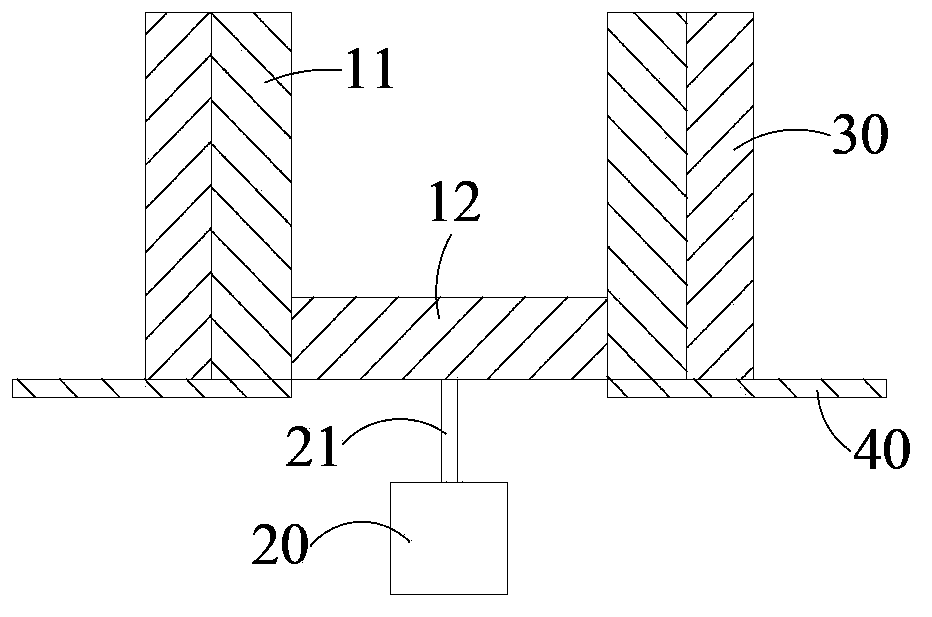

[0047] like figure 1 and figure 2 As shown, the first embodiment of the evaporation source device of the present invention is set in a vacuum chamber (not shown in the figure), and is used for evaporating a thin film on a substrate (not shown in the figure). The evaporation source device includes an evaporator, a lifter and a heater.

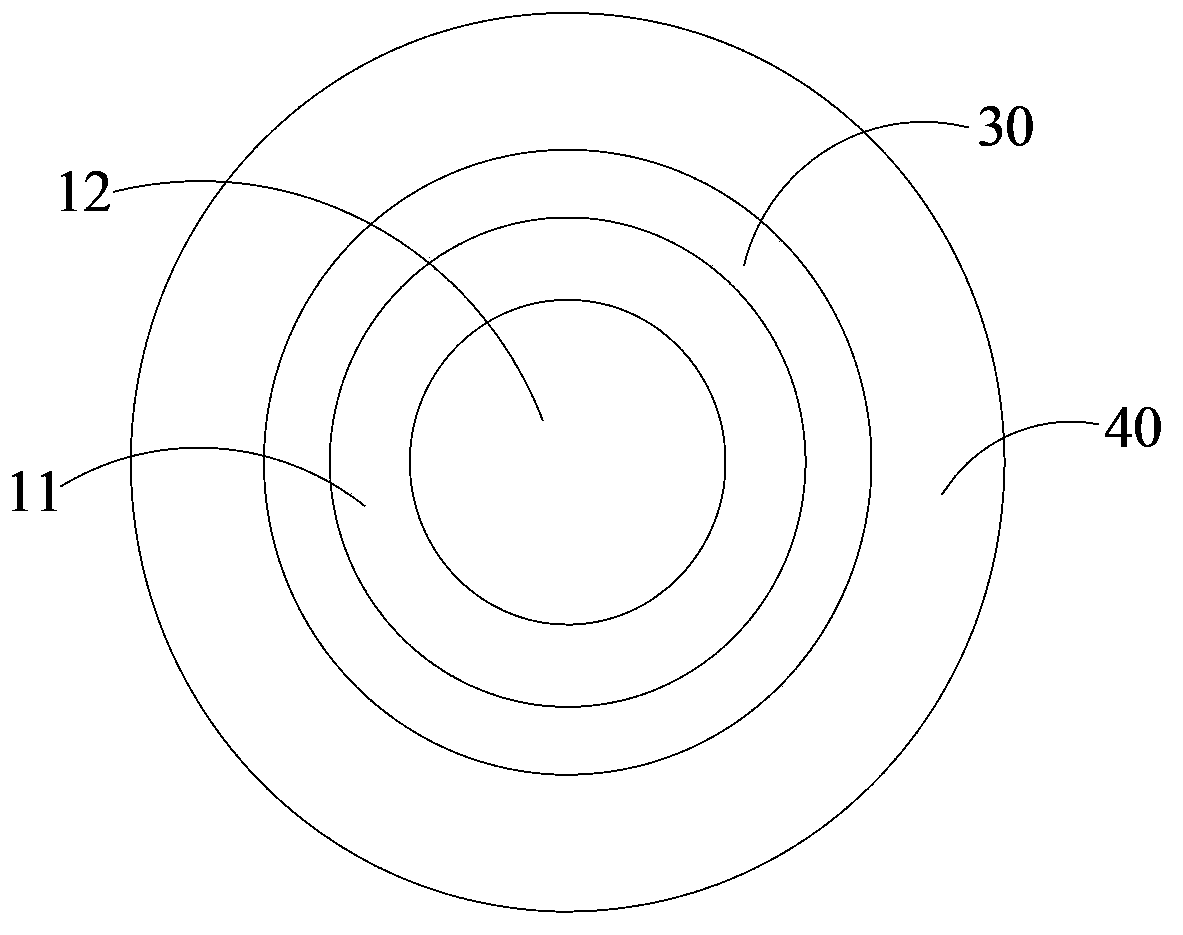

[0048] The evaporator is used to evaporate the evaporation material placed in it, and can be made of titanium or white iron. In the first embodiment, the evaporator is a split structure, including a cylinder body 11 and a cylinder base 12 .

[0049] The cylinder 11 is fixedly installed in the vacuum chamber, for example, a baffle 40 is fixed in the vacuum chamber, and the bottom of the cylinder 11 is fixed on the upper surface of the baffle 40 . The top opening of the cylinder 11 is aligned with the substrate, and the cylinder 11 may be a cylinder with a circular cross section, or a straight cylinder with a square cross section or other shap...

Embodiment 2

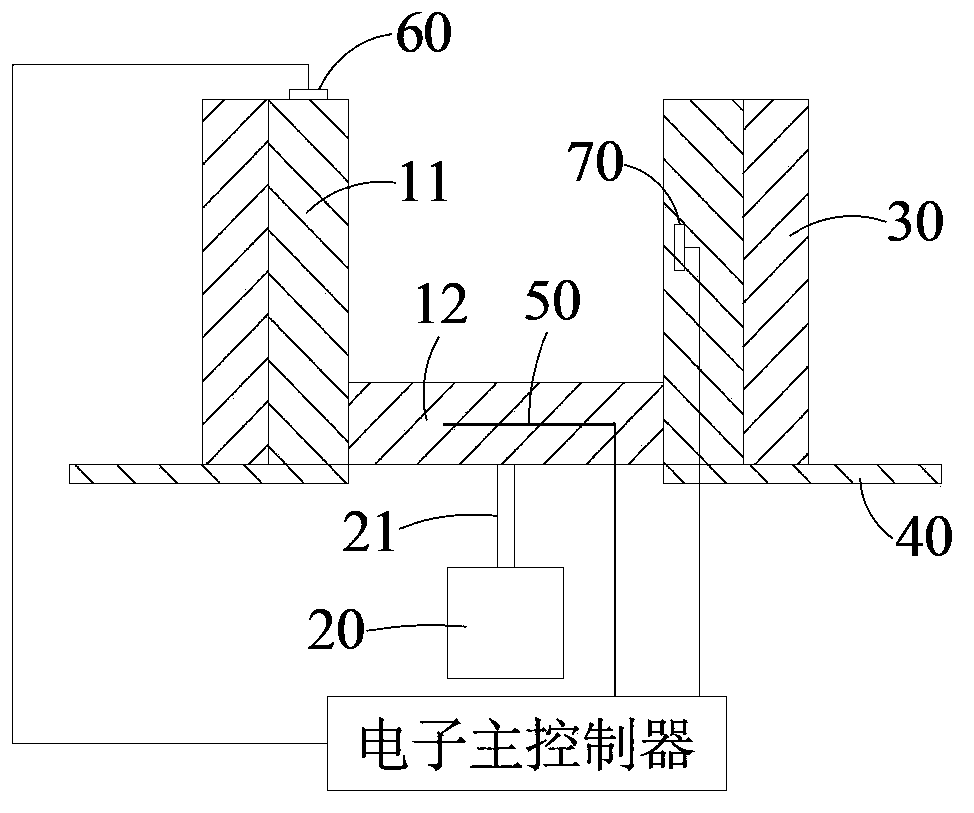

[0055] like image 3 As shown, the second embodiment of the evaporation source device of the present invention adds a controller and an electronic main console on the basis of the first embodiment, the controller can be installed in the electronic main console, and the electronic main console is installed on the baffle 40 below, that is to say, the evaporator is separated from the electronic main console by the baffle plate 40 .

[0056] The controller is used to control the lifter to drive the cylinder base to slide at a constant speed along the barrel. Of course, under the control of the controller, the cylinder base 12 can also slide at a non-uniform speed, but adjusted according to the evaporation parameters.

[0057] In addition, the controller also includes a first temperature sensor 50 arranged on the cylinder base 12, the first temperature sensor 50 is used to sense the temperature data of the cylinder base 12, the controller receives the measured temperature data of t...

Embodiment 3

[0061] like Figure 4 and Figure 5 As shown, the structure of the third embodiment of the evaporation source device of the present invention is basically the same as that of the first embodiment. Nozzles (not shown). At this time, preferably, two linear motors 20 are used, and the ends of the output shafts 21 of the two linear motors 20 are symmetrically connected to the bottom surface of the barrel base 12 . When the cylinder bottom 12 needs to rise or fall, the two linear motors 20 extend or retract the output shafts 21 at the same time. Certainly linear motor 20 also can be replaced by air cylinder or oil cylinder, and at this moment the piston rod end of air cylinder or oil cylinder is symmetrically connected to cylinder base 12 bottom surfaces.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com