The preparation method of the acoustic sensor

A sound sensor, wet etching technology, applied in the direction of sensors, electrostatic transducer microphones, manufacturing microstructure devices, etc., can solve the problems affecting the performance of the sound sensor 1, and achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The present invention provides a kind of preparation method of acoustic sensor, comprises the following steps:

[0040] Step S11, providing a substrate;

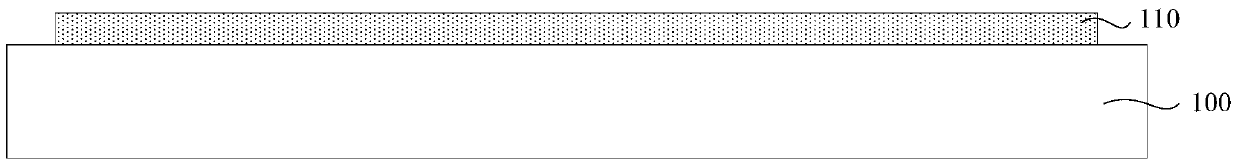

[0041] Step S12, forming a first sacrificial layer on the substrate, the first sacrificial layer is a ring structure with a sacrificial layer opening, and the material of the first sacrificial layer is a material that can be removed by wet etching;

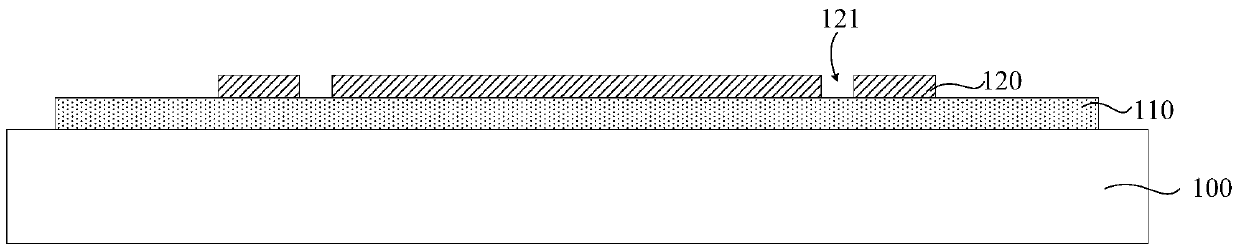

[0042] Step S13, forming a second sacrificial layer, the second sacrificial layer covers the first sacrificial layer and the opening of the sacrificial layer, and the material of the second sacrificial layer is a material that can be removed by an ashing process;

[0043] Step S14, sequentially forming a vibrating electrode, a third sacrificial layer, a fixed electrode film and a protective layer on the second sacrificial layer, the material of the third sacrificial layer is a material that can be removed by an ashing process, and the protective layer layer sealing the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com