Ripple filling material with multiple layers of gas/liquid runners

A technology of corrugated packing and gas-liquid flow, applied in chemical/physical/physicochemical processes, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of reduced separation efficiency, increased resistance, loss of pressure drop and small efficiency , to achieve the effect of increasing flux, small resistance, improving heat transfer efficiency and separation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with specific examples. It should be understood that the described

[0024] The specific examples are only used to explain the present invention, not to limit the present invention.

[0025] The present invention provides a corrugated packing with multi-layered gas-liquid flow channels, and its shape can be cube, cuboid, cylinder, etc. This embodiment uses the cylindrical structure to describe the corrugated packing in detail.

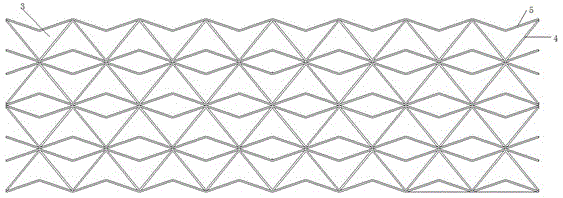

[0026] like Figure 4 As shown, the corrugated packing with multi-layer gas-liquid flow channel is composed of multiple packing blocks 1, and is fixed by bands 2 around the packing blocks 1.

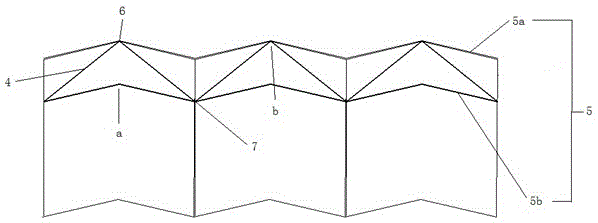

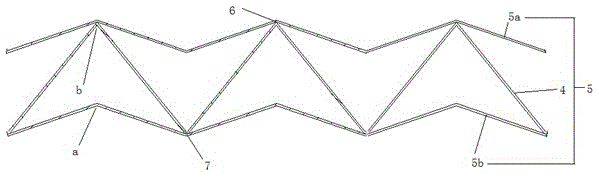

[0027] The cross-sectional structure of packing block 1 is as follows image 3 As shown, the packing block 1 is composed of a plurality of corrugated sheet units 3 superimposed.

[0028] like Figure 5 As shown, the directions of the gas-liquid channels of the two corrugate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com