Heated upsetting processing device for ends of steel reinforcements

A processing device and upsetting technology, applied in the field of hot processing of steel bars, can solve the problems of poor steel bar clamping effect, low production efficiency, poor temperature control, etc., and achieve the effects of avoiding bending, good clamping effect and energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

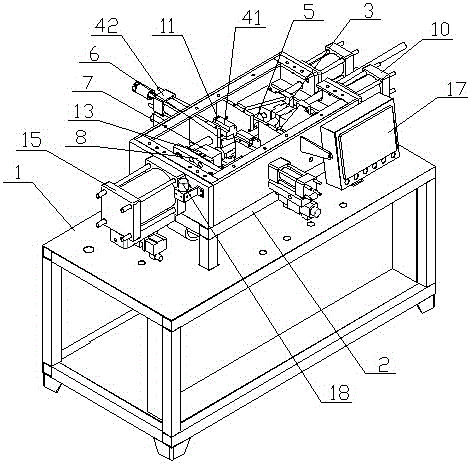

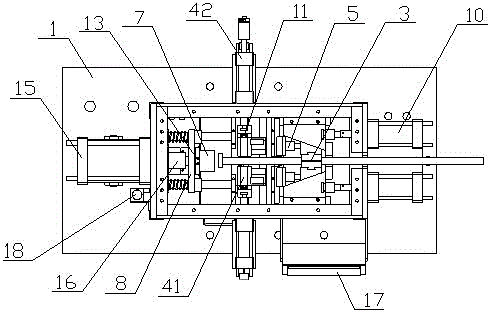

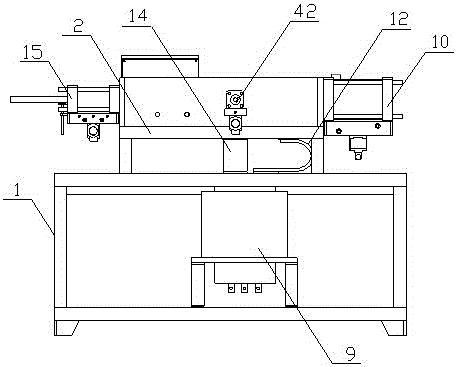

[0029] Example: see Figure 1 to Figure 6 , a steel bar end heating upsetting processing device, including a machine base 1, a support frame 2, a rear end clamp 3, a front end clamp, a guide pressing seat 5, an upsetting mold 6, an upsetting electrode 7, an upsetting frame 8, Heating electrode, transformer 9 and control box. The base 1 includes an upper panel and a lower panel, and the support frame 2 is arranged on the upper panel, and the support frame 2 includes feet and a rectangular support frame, and the four corners of the support frame are respectively fixedly connected to the upper panel by a foot, Two ends and two sides of the supporting frame are respectively vertically provided with a mounting plate, and the four mounting plates are connected successively to form a rectangular mounting frame.

[0030] The rear end clamp 3 is installed in the installation frame and is close to the rear end of the installation frame; the rear end clamp 3 includes a sliding seat 31, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com