Preheating method for preventing cold rolling broken strip of high-grade non-oriented silicon steel

A technology of oriented silicon steel and high grade, which is applied in the direction of metal rolling, metal rolling, workpiece heating equipment, etc., can solve the problems of strong suppression of eddy current, influence on heating efficiency, and inability to install, etc., so as to achieve low equipment space requirements and improve heating Efficiency and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

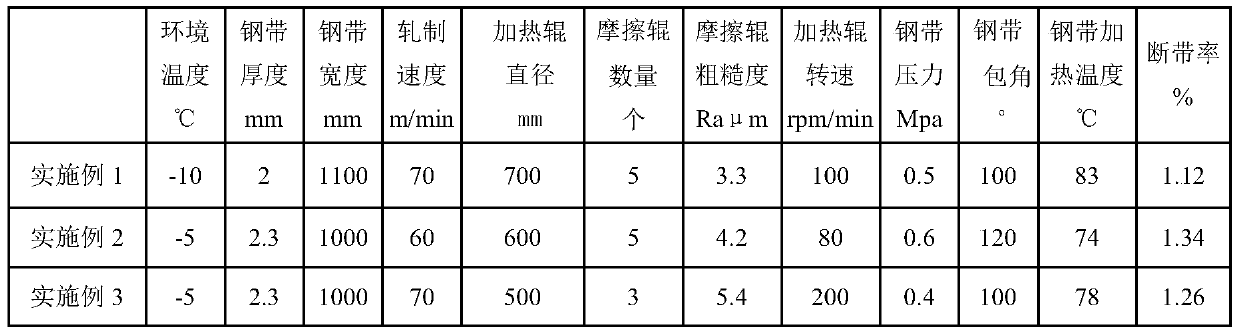

Examples

Embodiment Construction

[0020] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0021] The present invention describes a preheating method for avoiding high-grade non-oriented silicon steel cold-rolled strip breakage. The production process route of the cold-rolled non-oriented silicon steel is: molten iron desulfurization-converter smelting-RH refining-continuous casting-hot rolling-normal chemical - pickling - cold rolling - continuous furnace annealing - coating;

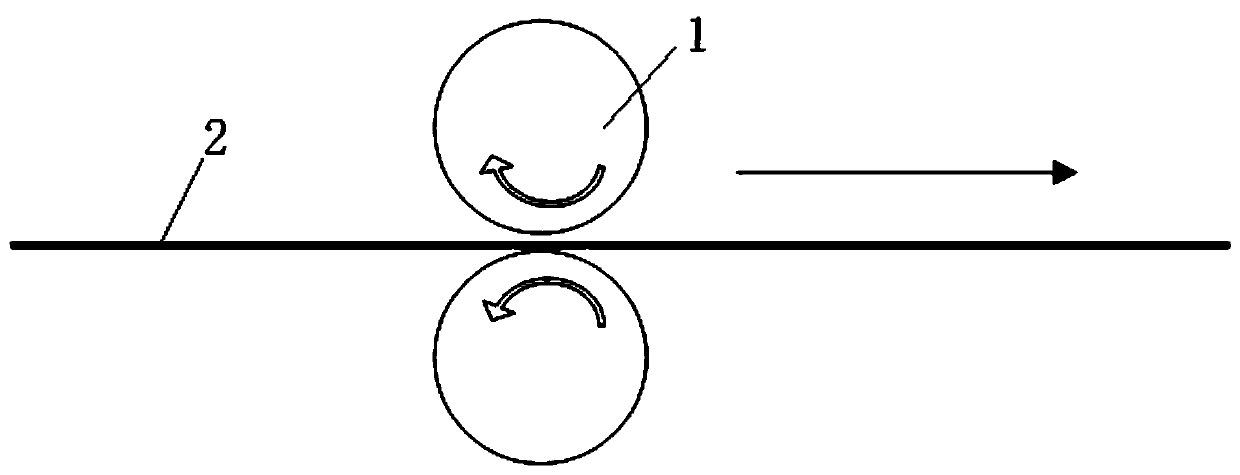

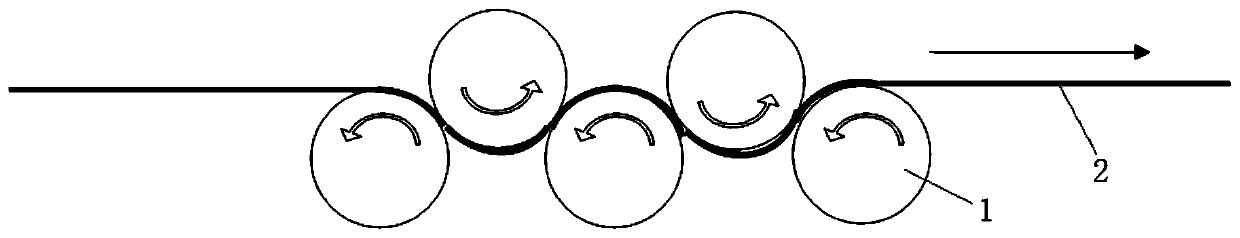

[0022] A friction heating roll 1 is arranged in front of the cold rolling mill, and the friction heating roll 1 and the steel strip 2 generate heat through friction and preheat the steel strip 2 through heat conduction; running in the opposite direction (e.g. figure 1 shown), or the tangential direction of the rotation of the friction heating roller 1 at the contact point of the two is the same as the running direction of the steel strip 2 but not synchronous w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com