Automatic tea maker and automatic tea making method

A tea making machine, automatic technology, applied in kitchen utensils, home utensils, beverage preparation devices, etc., can solve the problems of heat loss, affecting the effect of tea brewing, affecting the precise control of water temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

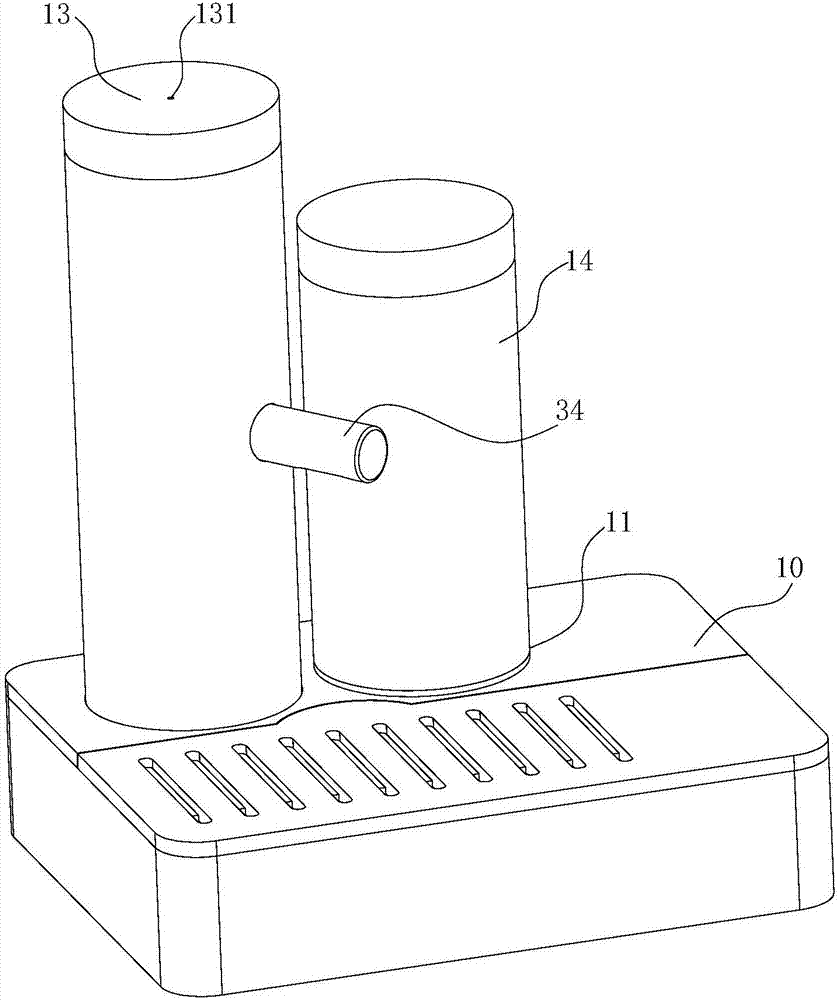

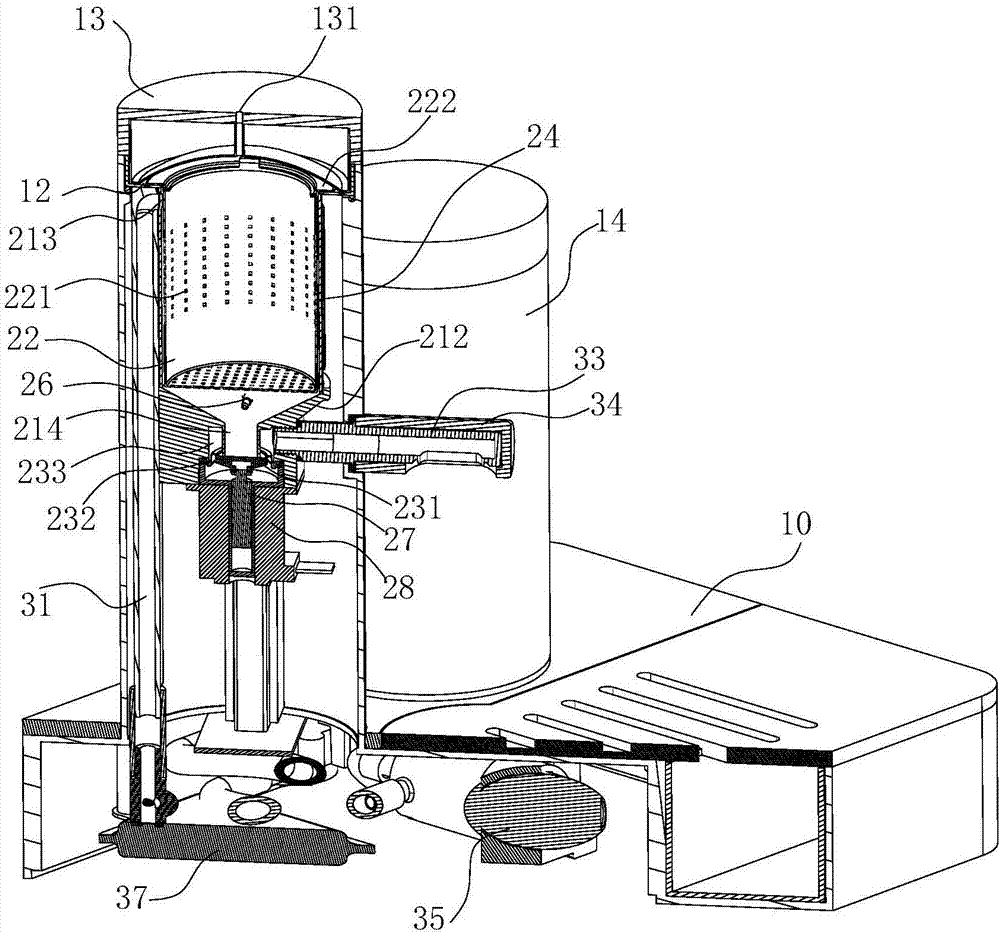

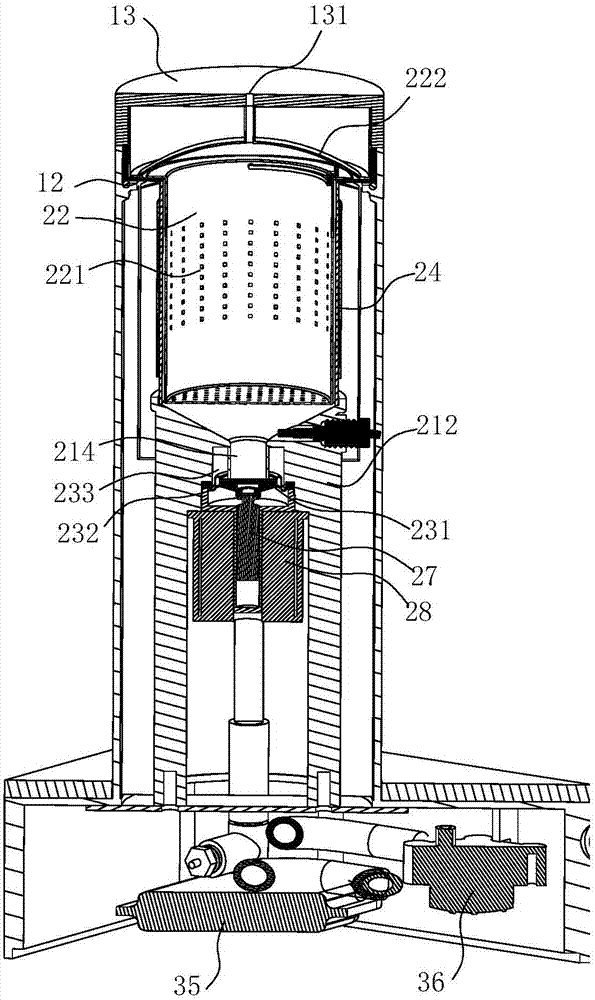

[0166] Such as Figure 1 to Figure 6 Shown, a kind of automatic tea making machine includes and also includes seat body 10, water tank body 14, tea making cup 21, and water tank body 14 and tea making cup 21 are all provided with water inlet 213, water outlet 214, water The water outlet 214 of the box body 14 communicates with the water inlet 213 of the tea cup 21 through the water inlet pipe 31, and the second heating element 37 is arranged on the water inlet pipe 31, and the first heating element 37 is arranged on the tea cup 21. The element 24; the tea cup 21 is made of heat-conducting material, and at least part of the water inlet pipe 31 located between the second heating element 37 and the tea cup 21 is also made of heat-conducting material, and the water inlet pipe 31 It is in thermal contact with the first heating element 24 and the tea cup 21 .

[0167] The tea cup 21 has a metal tube 211 and a lower seat 212, the metal tube 211 is cylindrical and upright, the first ...

Embodiment 2

[0232] Automatic tea making method: the terminal receives the download instruction; the terminal transmits the download instruction and its identification code to the server; the server compares the received identification code with the stored identification code, if the two match, the server will The tea making method data corresponding to the download instruction is transmitted to the terminal; the terminal receives the tea making method data, and transmits the tea making method data and the identification code to the automatic tea making machine; the automatic tea making machine sends the received identification code Compared with the stored identification code, if the two match, the automatic tea making machine receives and stores the tea making method data. After receiving the tea making instruction, the stored tea making method data is retrieved, and tea is made according to the tea making method data of the tea making method data.

[0233] In this embodiment, the method...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com