Cantilever woodworking center frame with chip removal

A technology of machining center and chip removal device, applied in the direction of wood processing appliances, manufacturing tools, multi-purpose machinery, etc., can solve the problems of cluttered configuration, hidden danger of operation safety, unsightly appearance, etc., to improve the overall layout, save manufacturing materials, shorten the The effect of pipe distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

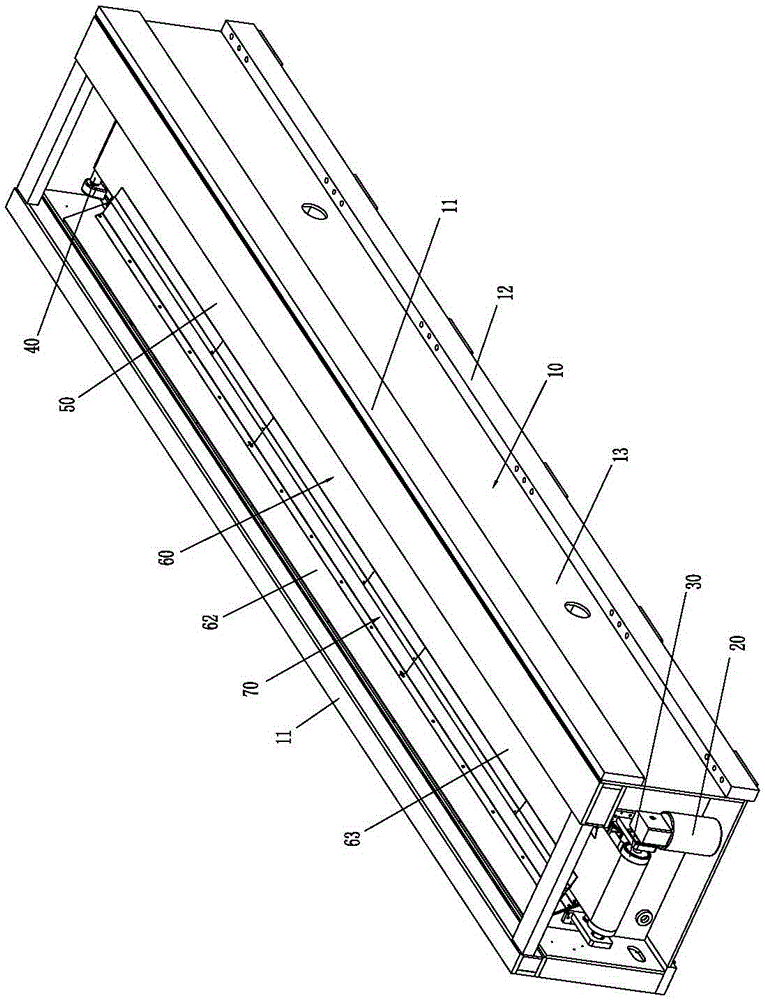

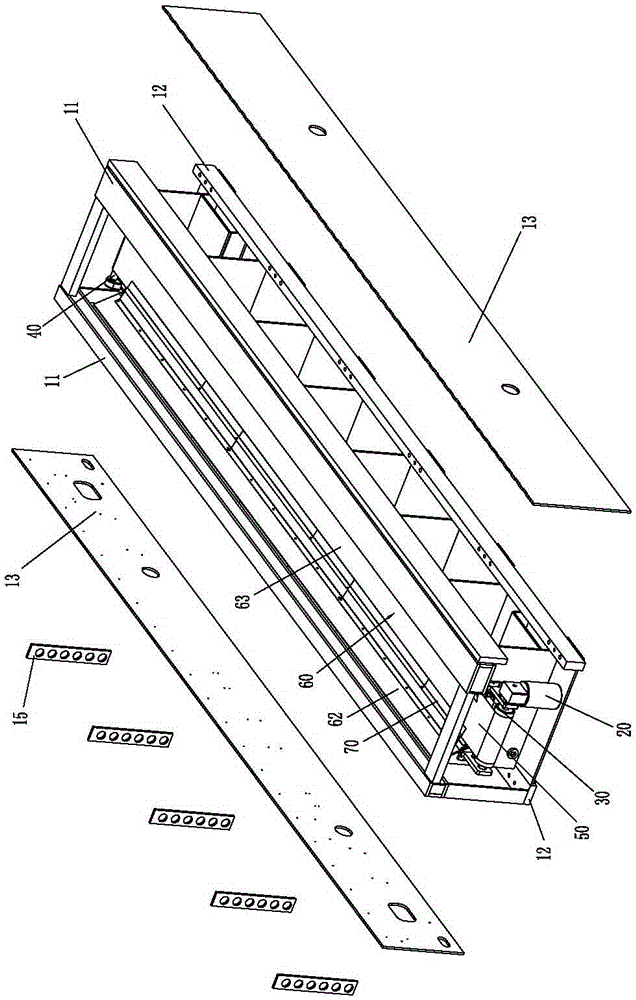

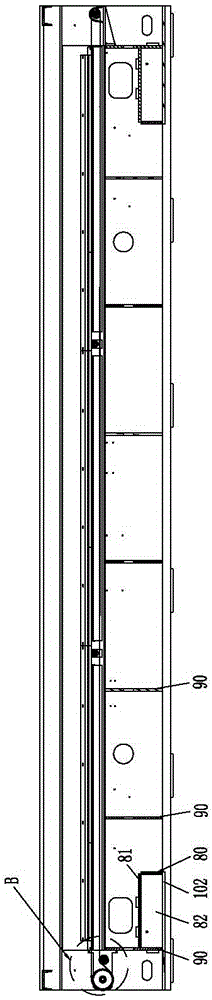

[0051] Please refer to Figure 1 to Figure 10 As shown, it shows the specific structure of the embodiment of the present invention, the frame of this kind of cantilever type wood processing center with chip removal device includes a frame body 10 and a motor 20 installed in the frame body 10, and a driving wheel 30 , Tension pulley 40, conveyor belt 50, chip flute body 60.

[0052]Wherein, a hollow cavity 101 is formed inside the frame body 10, and the hollow cavity 101 has an open upper end; in this embodiment, the frame body 10 includes two upper beams 11 and two lower beams 12 located on both sides, and A side steel plate 13 is connected between the upper and lower beams, a reinforcing rib 15 is added between the upper and lower beams on at least one side, and a bottom steel plate 14 is connected between the two lower beams 12; the upper and lower beams are made of steel plates It is welded, and the side steel plate 13, the bottom steel plate 14 and the reinforcing rib 15 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com