Braze welding method of grease suction filter

An oil filter, brazing method technology, applied in welding equipment, installation/connection of lubricant purification devices, manufacturing tools, etc. Overall quality, good appearance quality, small deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

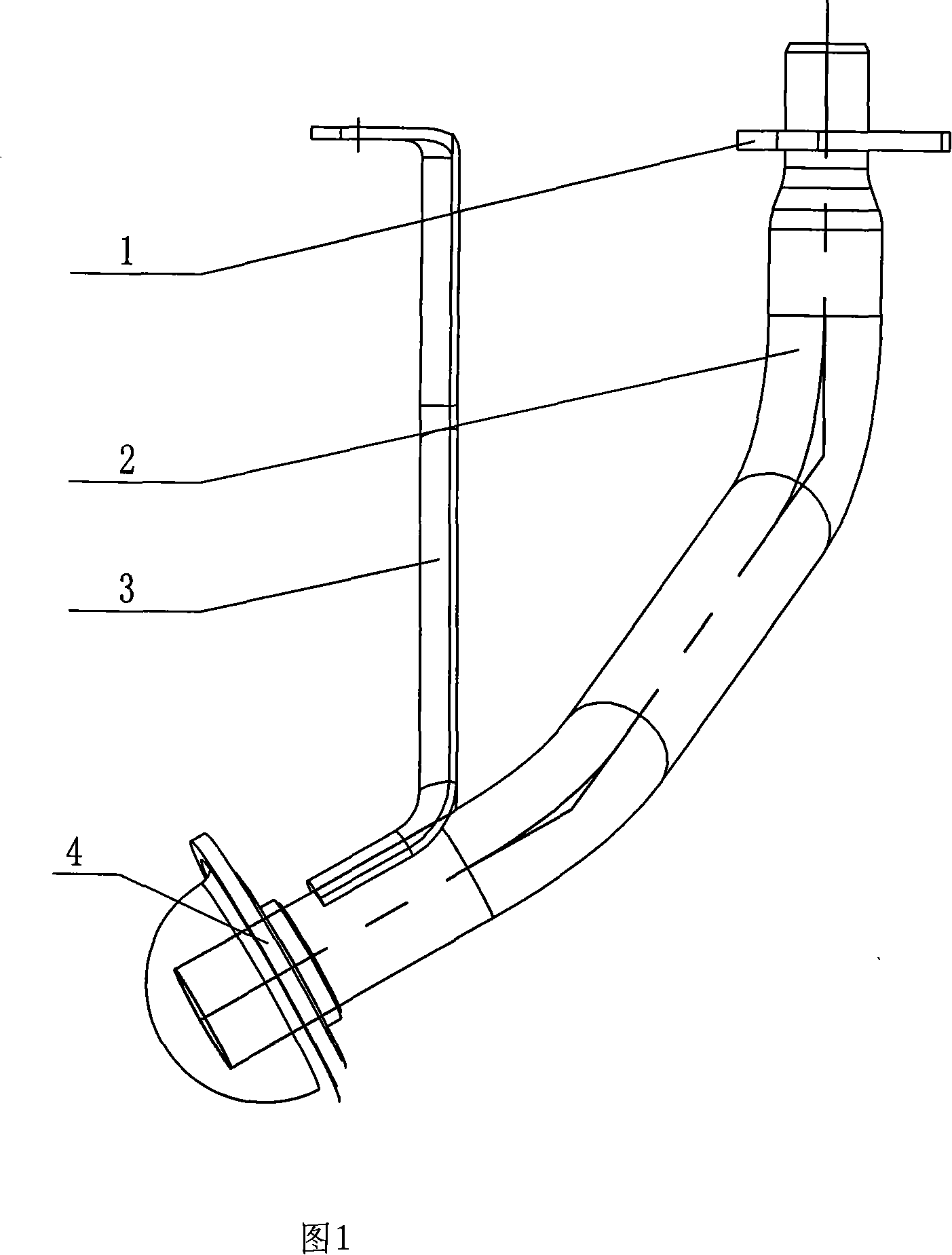

[0032] Let's take the processing of 474Q oil filter as an example:

[0033] First select the No. 10 cold-rolled steel plate, and use the traditional stamping process to form or press riveting to make the flange 1, the support piece 3, and the filter body 4 single parts, and use the welded pipe to make the oil pipe 2 through the necking forming process. Body parts, and then assemble them together as follows:

[0034] A. Use a heading machine to press-fit the flange 1 to one end of the oil pipe 2, and ensure that the fit gap is between 0.01 and 0.03mm;

[0035] B. Use a heading machine to press-fit the filter body 4 to the other end of the oil pipe 2, and ensure that the fit gap is between 0.01 and 0.03mm;

[0036] C. Place the support piece 3 on the outer wall of the oil pipe 2 close to the filter screen body 4, and spot weld the process hole at the lower end of the support piece 3 with a pressure arc welding machine, so that the filter screen body 4 and the oil pipe 2 are clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com