Rubber-plastic seal ring with section seam, bonding method of section seam and vulcanization bonding die for section seam

A technology of vulcanization bonding and rubber sealing rings, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of increasing the mechanical connection structure of parts, long maintenance cycle, and high linear speed of sealing surface, so as to improve the sealing performance and service life, easy replacement and maintenance, and the effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

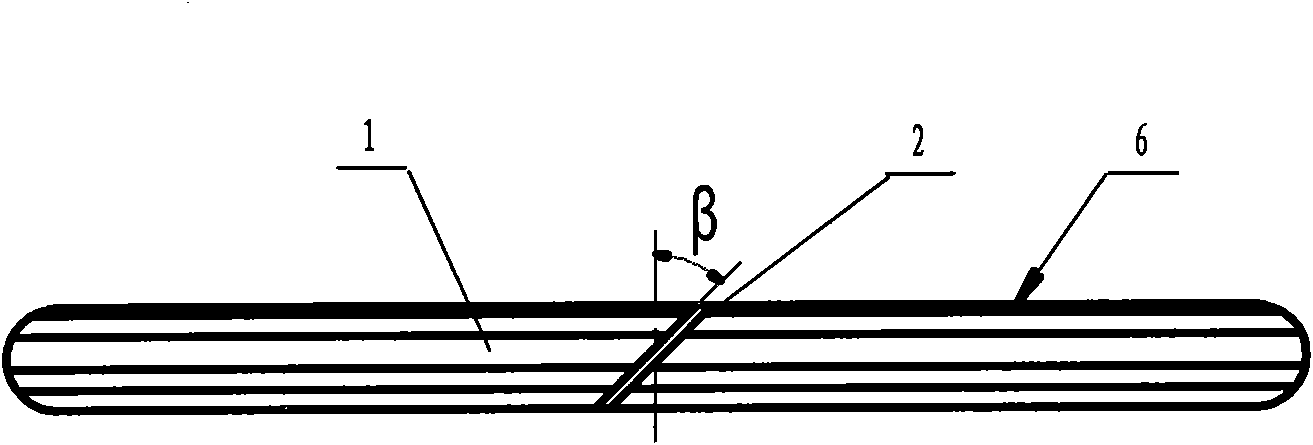

[0029] Such as figure 1 Shown is a rubber sealing ring with a slit. The sealing ring is a rubber lip-shaped sealing ring. An inclined slit 2 is cut on the annular sealing ring base 1, and the slit 2 seals the sealing ring base 1. Disconnect, so that the sealing ring can open the cut slit and fit on the rotating shaft from the radial direction. The section end surface of the cut slit 2 is an inclined section, and the angle between the inclined section end surface and the axis line of the rubber sealing ring is the section inclination angle β=45°, of course, the section inclination angle β can also be determined according to the structural size of the sealing ring , type, etc. to choose between 35 ° ~ 55 °. The cutting seam 2 can be obtained by cutting at the replacement and maintenance site, or it can be preset when making the sealing ring.

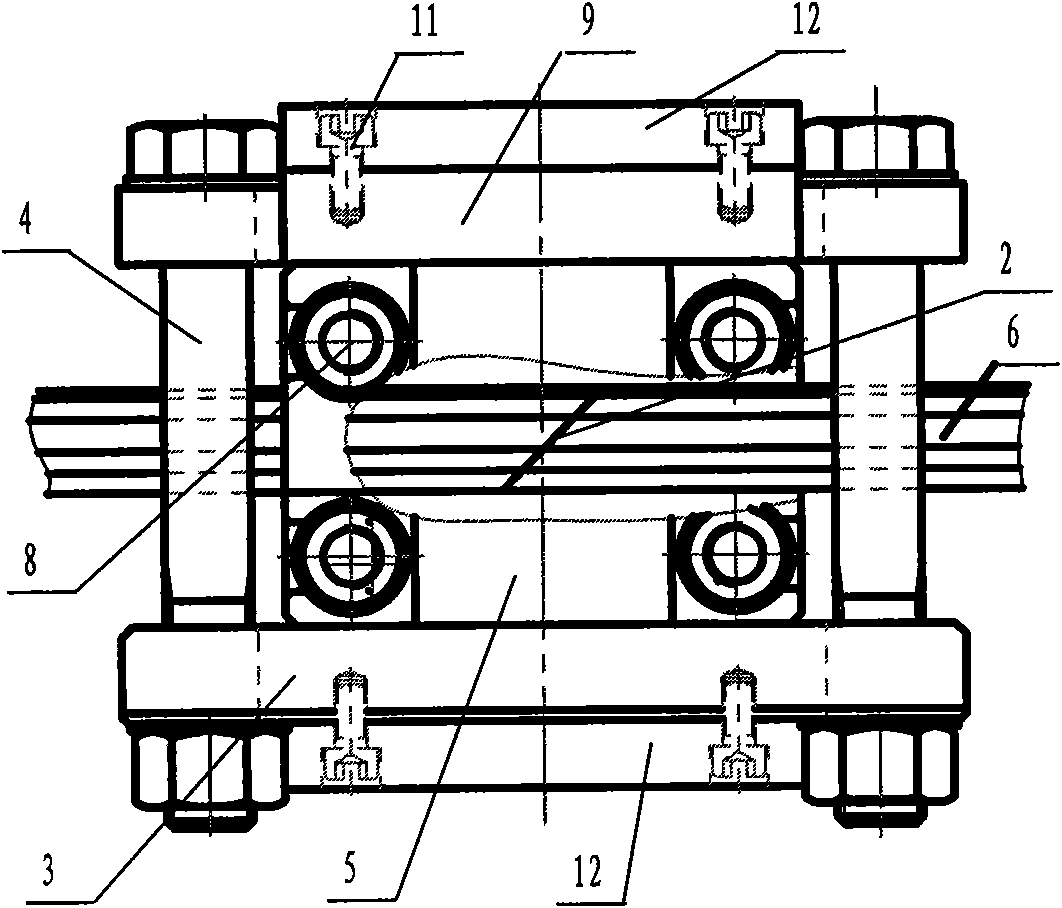

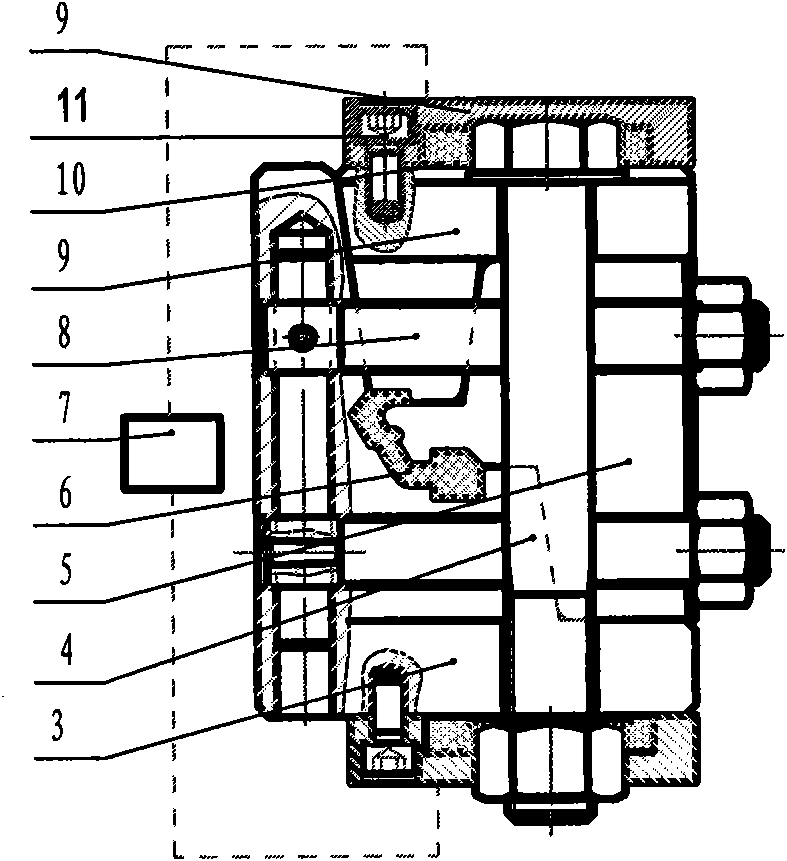

[0030] Such as figure 2 , image 3 The shown special slit vulcanization bonding mold includes a lower formwork 3, an upper formwork ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com