Coaxial hole processing cutter

A technology for machining tools and coaxial holes, used in manufacturing tools, metal processing equipment, milling cutters, etc., can solve problems such as low efficiency and low hole coaxiality, and achieve high machining hole accuracy, high coaxiality, and replacement. Simple and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, further describe the technical solution of the present invention.

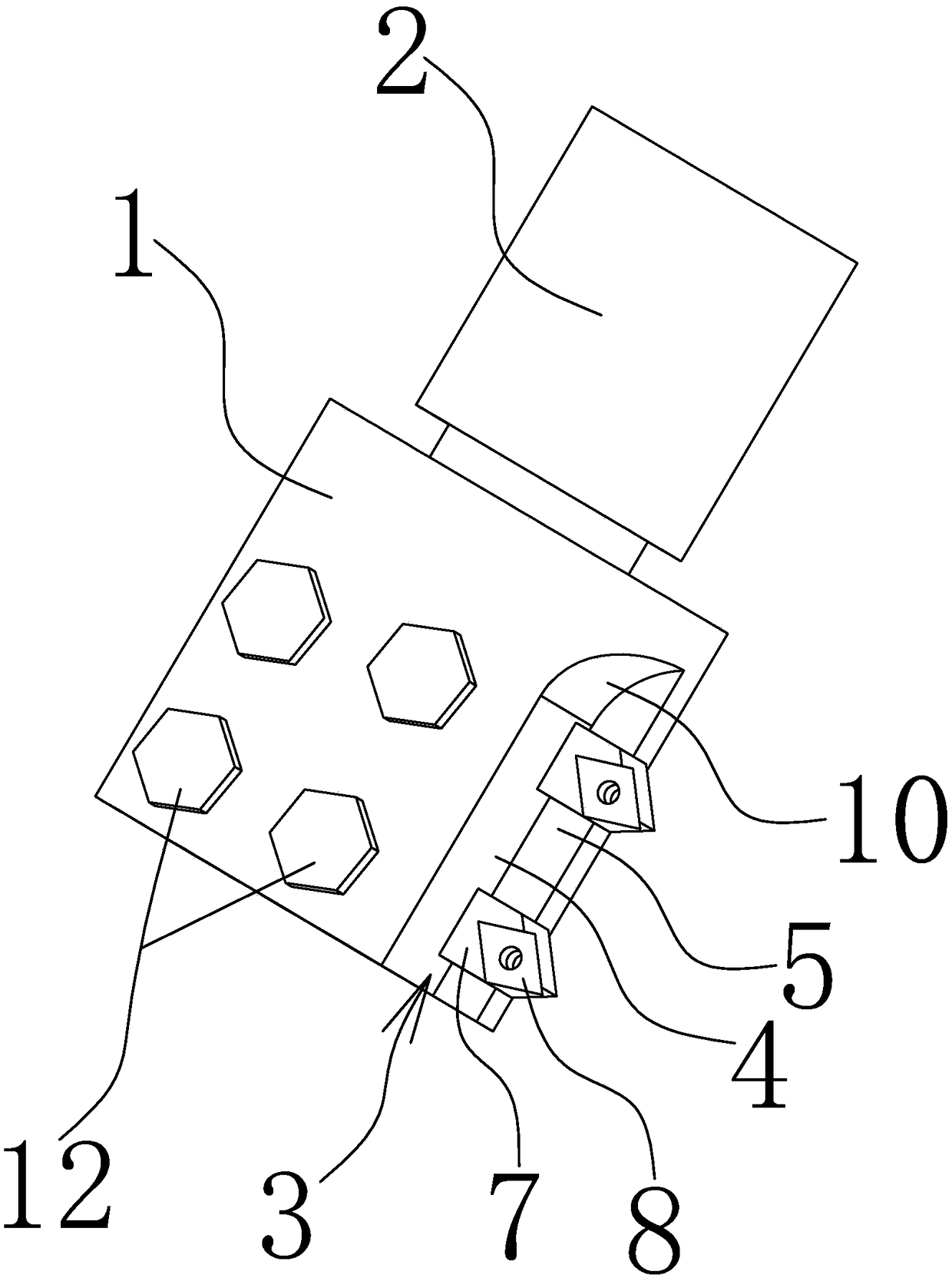

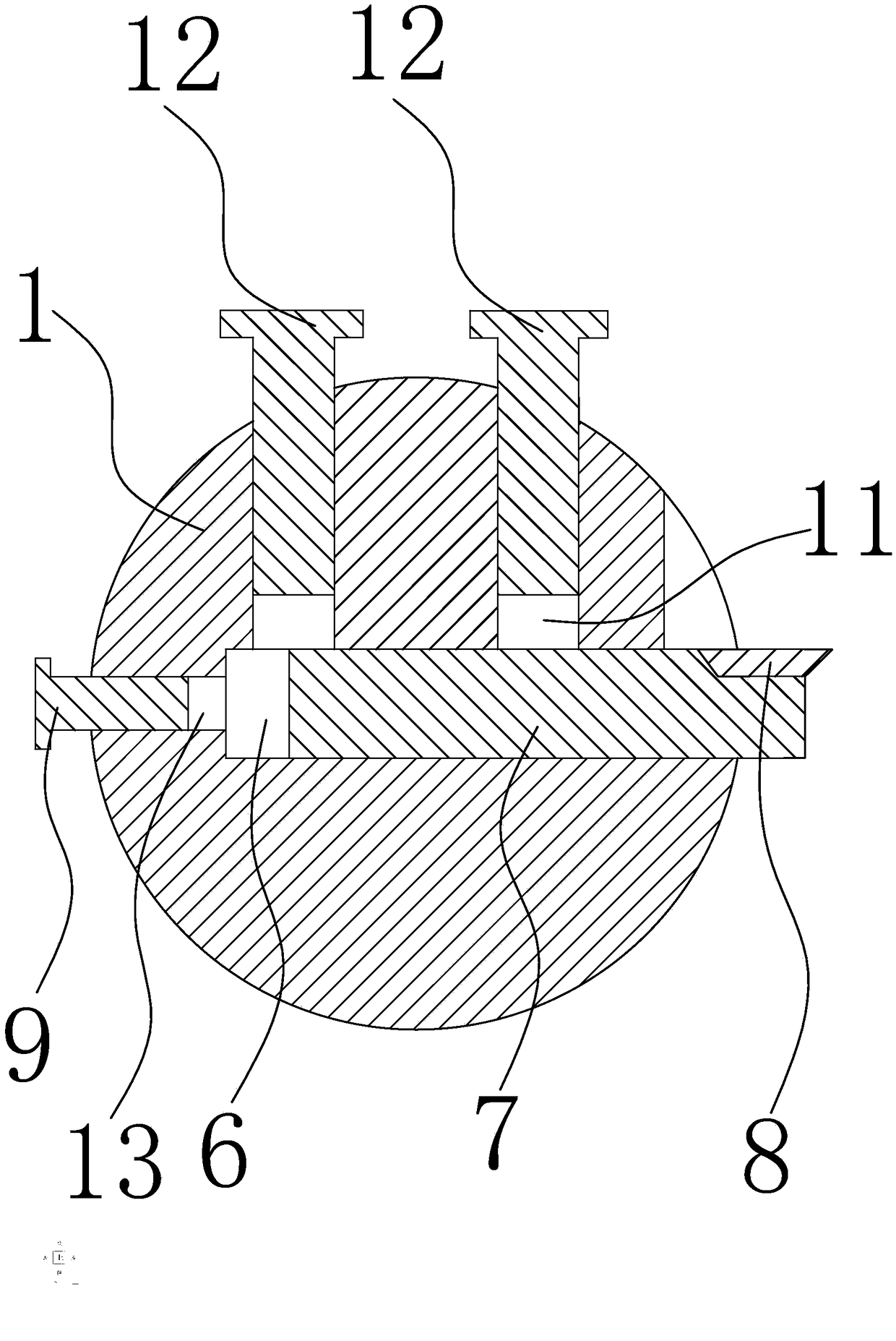

[0019] Such as Figures 1 to 2 , a coaxial hole processing cutter, the cutter includes a cutter body and a handle, characterized in that: the handle is connected to the cutter body, the handle and the cutter body are integrally formed, and the cutter body is vertically provided with a knife The head groove, the cutter head groove includes a chip removal surface and a cutter head surface, and a chip guide surface is also provided on the cutter body, and the chip guide surface is curved in an arc shape, and one end of the chip guide surface is connected to the chip removal surface The other end of the chip guide surface is connected to the side wall of the cutter body, and the cutter body is provided with a number of installation holes at intervals in the transverse direction. As a preference...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com