Embedded unit curtain wall window easy to install and adjust

A unit curtain wall, installation and adjustment technology, applied in the direction of walls, buildings, building components, etc., can solve the problems of difficult installation accuracy and quality assurance, complicated installation process, and large combined width and size, and achieve simple and easy installation quality control, on-site Simple and convenient installation, beautiful internal and external visual effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

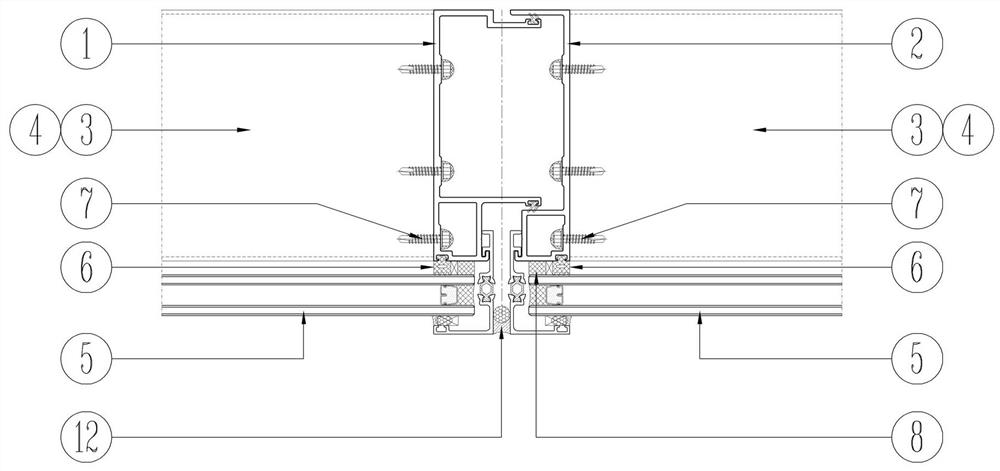

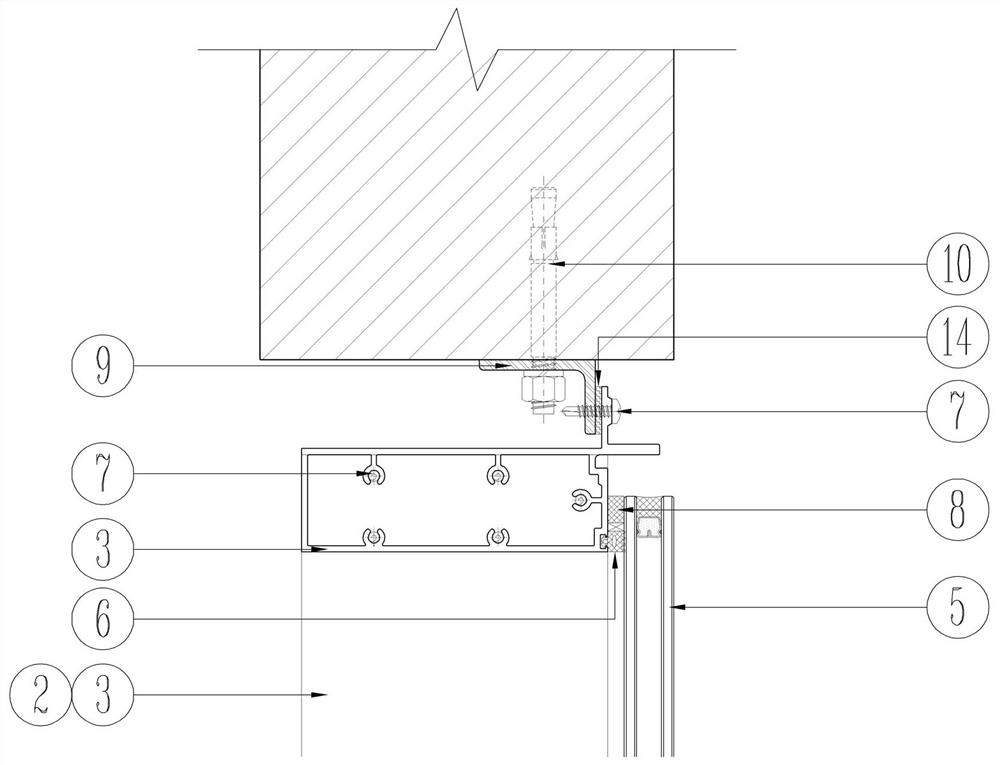

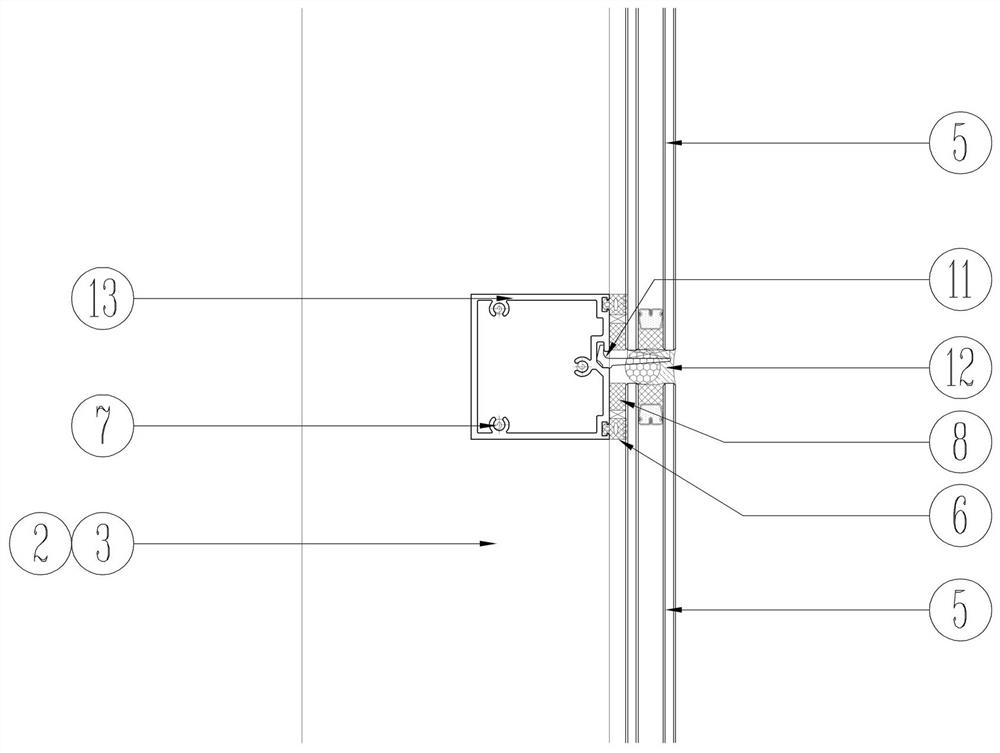

[0019] exist figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 Among them, firstly, the profile sections of the upper beam 3, the middle beam 13, and the lower beam 4 have screw grooves, and their two ends are fixedly connected to the right side of the left column 1 of the unit curtain wall window and the right column 2 of the unit curtain wall window with stainless steel screws 7 respectively. On the left, the window block frame that makes up the unit curtain wall. Then press the rubber strip 6 into the notch of the profiles around the window panel frame of the unit curtain wall, and the glass panel 5 is connected and fixed on the outer end of the window keel frame of the unit curtain wall through double-sided stickers + structural glue 8 around the glass panel 5, and the middle beam 13 and the lower beam 4 Aluminum alloy brackets 11 are inserted into the notch of the profile to support the glass panel 5. The upper and lower ends of the mid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com