Device and method for cleaning external surface of portal heat exchanger

A technology for cleaning devices and heat exchangers, which is applied to cleaning heat transfer devices, flushing, lighting and heating equipment, etc., can solve problems such as hidden safety hazards, increased rental costs, and low operating efficiency, and can reduce the use frequency of cranes, reduce Construction cost and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

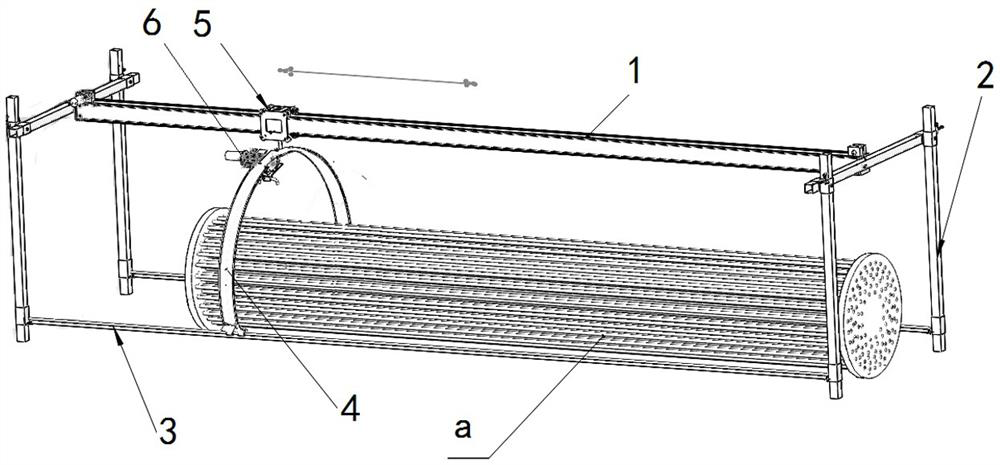

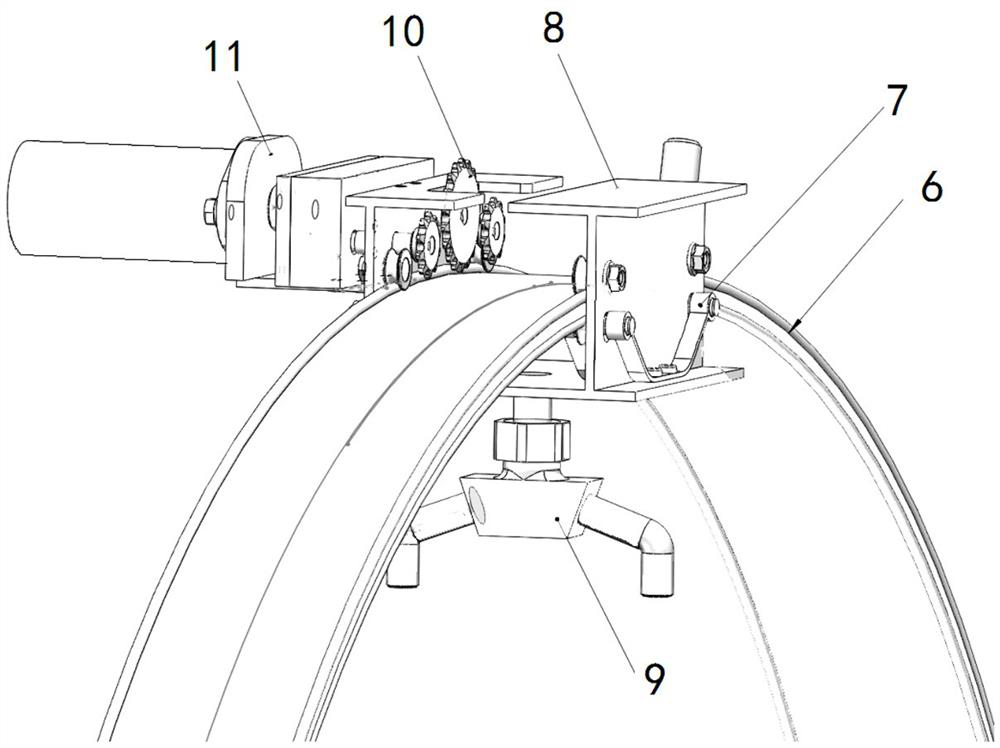

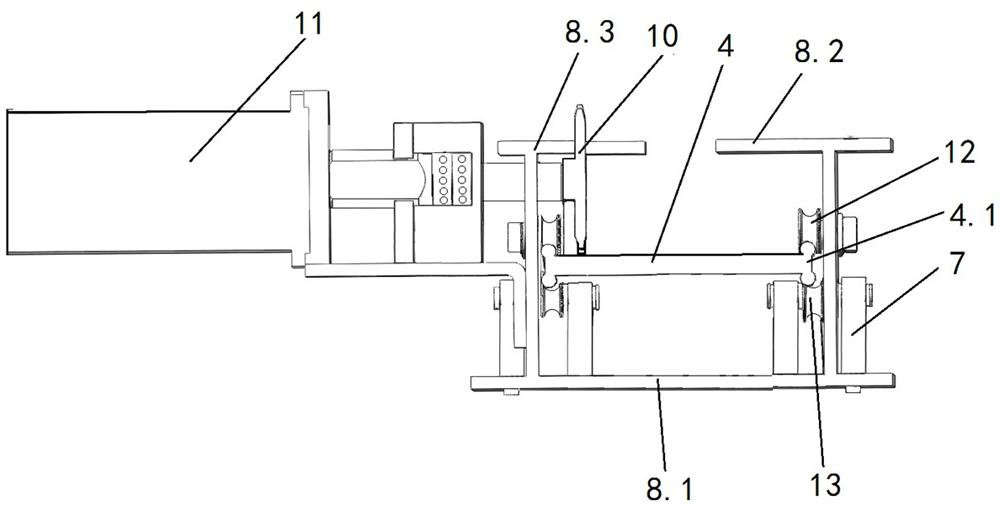

[0023] Embodiment 1, a cleaning device for the outer surface of a portal heat exchanger mentioned in the present invention, including a longitudinal beam 1, a door frame 2, a linear guide rail 3, an arc plate device 4, a longitudinal beam moving mechanism 5, and an arc plate moving device 6 , two or more sets of door frames 2 are added on the outside of the heat exchanger a, a longitudinal beam 1 is installed on the upper part between two or more sets of door frames 2, and two linear guide rails 3 are installed on the lower part , the arc plate device 4 is installed between the longitudinal beam 1 and the linear guide rail 3, and the upper part of the arc plate device 4 is movably connected with the longitudinal beam 1 through the longitudinal beam moving mechanism 5, and the lower part is movably connected with the linear guide rail 3, and the arc plate device 4 is It has a semi-circular structure and is arranged above the heat exchanger a, and the arc plate device 4 is provid...

Embodiment 2

[0033] Embodiment 2, the difference between the present invention and embodiment 1 is:

[0034] Arc plate also can adopt two symmetrical short-arc long arc plates to be hung on the longitudinal beam moving mechanism 5 both sides on the longitudinal beam 1, and the cleaning head at this moment can be two sets of simultaneous cleaning from both sides.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com