Heating and bathing gas water heater for double volume and condensation heat exchange system

A heat exchange system and heat exchanger technology, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of energy consumption, environmental pollution, high cost, etc., and achieve fast and rapid heating temperature rise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

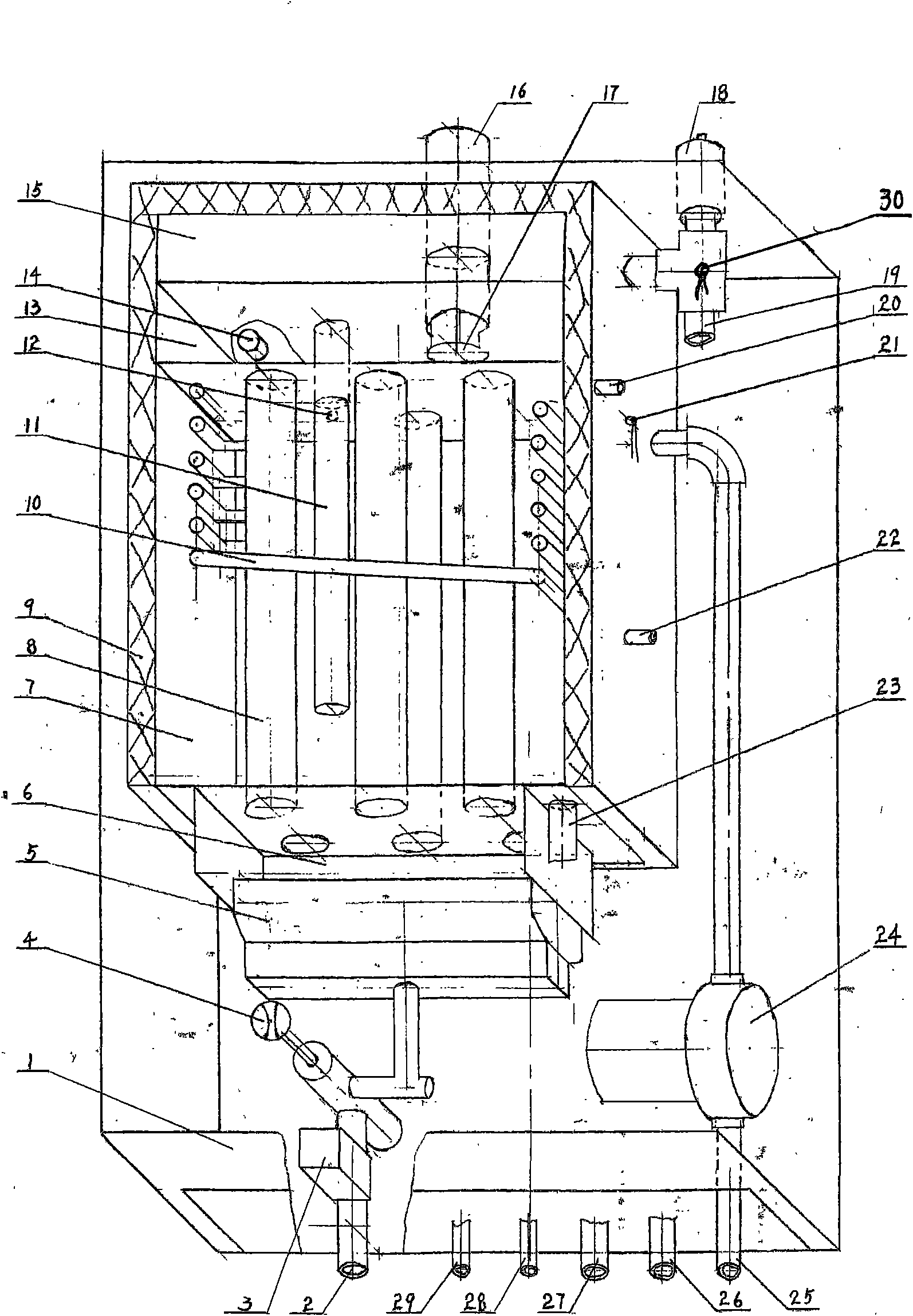

[0020] refer to figure 1 , the gas interface (2) enters the gas, the microcomputer controller (30) opens the normally closed solenoid valve (3), the gas adjustment valve (4) adjusts the gas volume according to the heating and domestic water conditions, the burner (5) and the second The first combustion chamber (6) burns, the lower volume heat exchanger (7) and the flame channel (8) receive heat and absorb heat, and the fireworks go to the second combustion chamber (13), and the combustion-supporting air entering the combustion-supporting air inlet (14) Mix and carry out the second combustion. In order to prevent low resistance of fireworks and waste of energy, a heat-absorbing plate (17) is made for wind resistance. After the upper volume heat exchanger (15) is heated again, the flue gas is naturally discharged from the chimney (16) Atmospheric; generally achieve full combustion of gas, full use of heat, and natural discharge into the atmosphere after the fireworks are fully ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com