Thermal treatment technology for improving low-temperature impact toughness of 25Cr2Ni4MoV steel forging

A technology for low temperature impact toughness and steel forgings, which is applied in the field of steel forging product production and can solve the problems of inability to meet usage requirements and poor impact toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

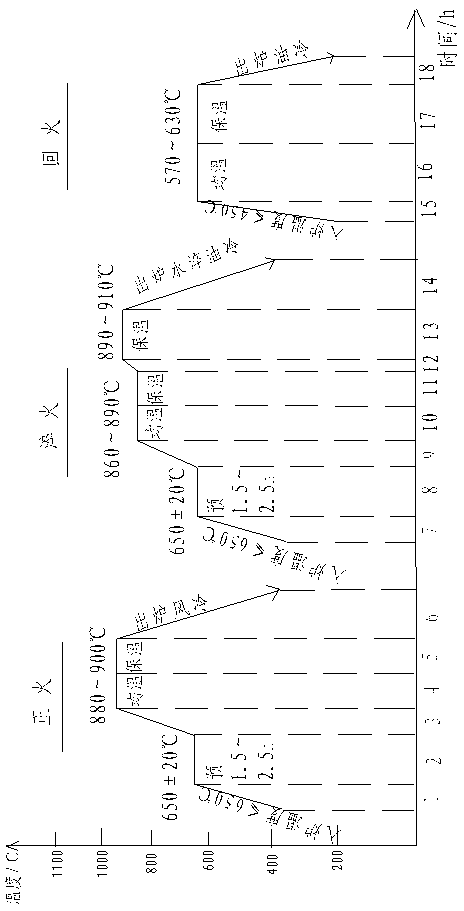

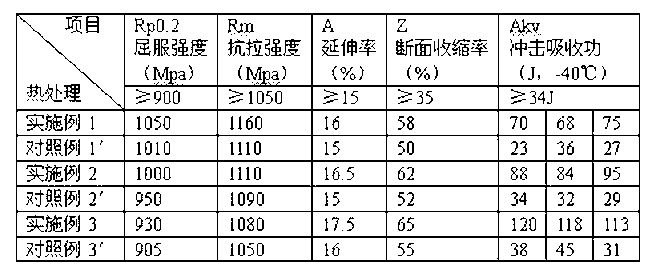

[0018] Embodiment 1: The selected diameter is 440mm; the chemical composition is: C=0.22~0.30%, Si=0.15~0.30%, Mn≤0.50%, Ni=3.25~4.00%, Cr=1.40~2.00%, Mo=0.30~ 0.60%, V=0.05~0.15%, Cu≤0.20%, S≤0.015%, P≤0.015%; the steel type is 25Cr2Ni4MoV forgings. The heat treatment process is carried out by normalizing + quenching and tempering, such as figure 1 As shown, normalize first, preheat at 630°C for 2.5 hours, then raise the temperature to the normalizing temperature of 880°C, and the holding time is 1.2 hours / 100mm. After normalizing, four axial-flow blowers are placed on both sides of the upper and lower platforms respectively, and are sprayed directly onto the workpiece from multiple directions to force the workpiece to cool evenly and rapidly, so as to refine the grain and uniform structure and composition, and prepare for quenching. Prepare. After normalizing, adopt quenching and tempering treatment process, preheat at 630°C for 2.5 hours, then raise the temperature to que...

Embodiment 2

[0019] Embodiment 2: The selected diameter is 440mm; the chemical composition is: C=0.22~0.30%, Si=0.15~0.30%, Mn≤0.50%, Ni=3.25~4.00%, Cr=1.40~2.00%, Mo=0.30~ 0.60%, V=0.05~0.15%, Cu≤0.20%, S≤0.015%, P≤0.015%; the steel type is 25Cr2Ni4MoV forgings. The heat treatment process is carried out by normalizing + quenching and tempering, such as figure 1 As shown, normalize first, preheat at 650°C for 2 hours, then raise the temperature to the normalizing temperature of 890°C, and the holding time is 1.1 hours / 100mm. After normalizing, four axial-flow blowers are placed on both sides of the upper and lower platforms respectively, and are sprayed directly onto the workpiece from multiple directions to force the workpiece to cool evenly and rapidly, so as to refine the grain and uniform structure and composition, and prepare for quenching. Prepare. After normalizing, adopt quenching and tempering treatment process, preheat at 650°C for 2 hours, then raise the temperature to quenchi...

Embodiment 3

[0020] Embodiment 3: The selected diameter is 440mm; the chemical composition is: C=0.22~0.30%, Si=0.15~0.30%, Mn≤0.50%, Ni=3.25~4.00%, Cr=1.40~2.00%, Mo=0.30~ 0.60%, V=0.05~0.15%, Cu≤0.20%, S≤0.015%, P≤0.015%; the steel type is 25Cr2Ni4MoV forgings. The heat treatment process is carried out by normalizing + quenching and tempering, such as figure 1 As shown, normalize first, preheat at 670°C for 1.5 hours, then raise the temperature to the normalizing temperature of 900°C, and the holding time is 1 hour / 100mm. After normalizing, four axial-flow blowers are placed on both sides of the upper and lower platforms respectively, and are sprayed directly onto the workpiece from multiple directions to force the workpiece to cool evenly and rapidly, so as to refine the grain and uniform structure and composition, and prepare for quenching. Prepare. After normalizing, adopt quenching and tempering treatment process, preheat at 670°C for 1.5 hours, then raise the temperature to quench...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com