Patents

Literature

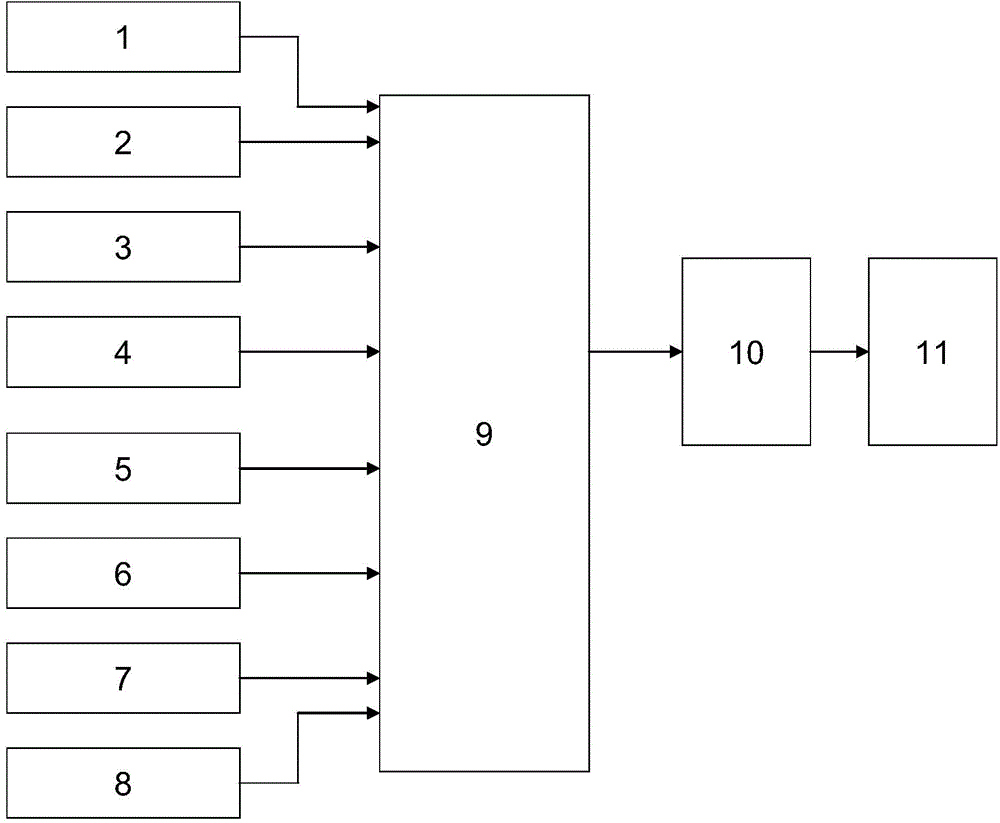

52results about How to "Ensure automatic control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

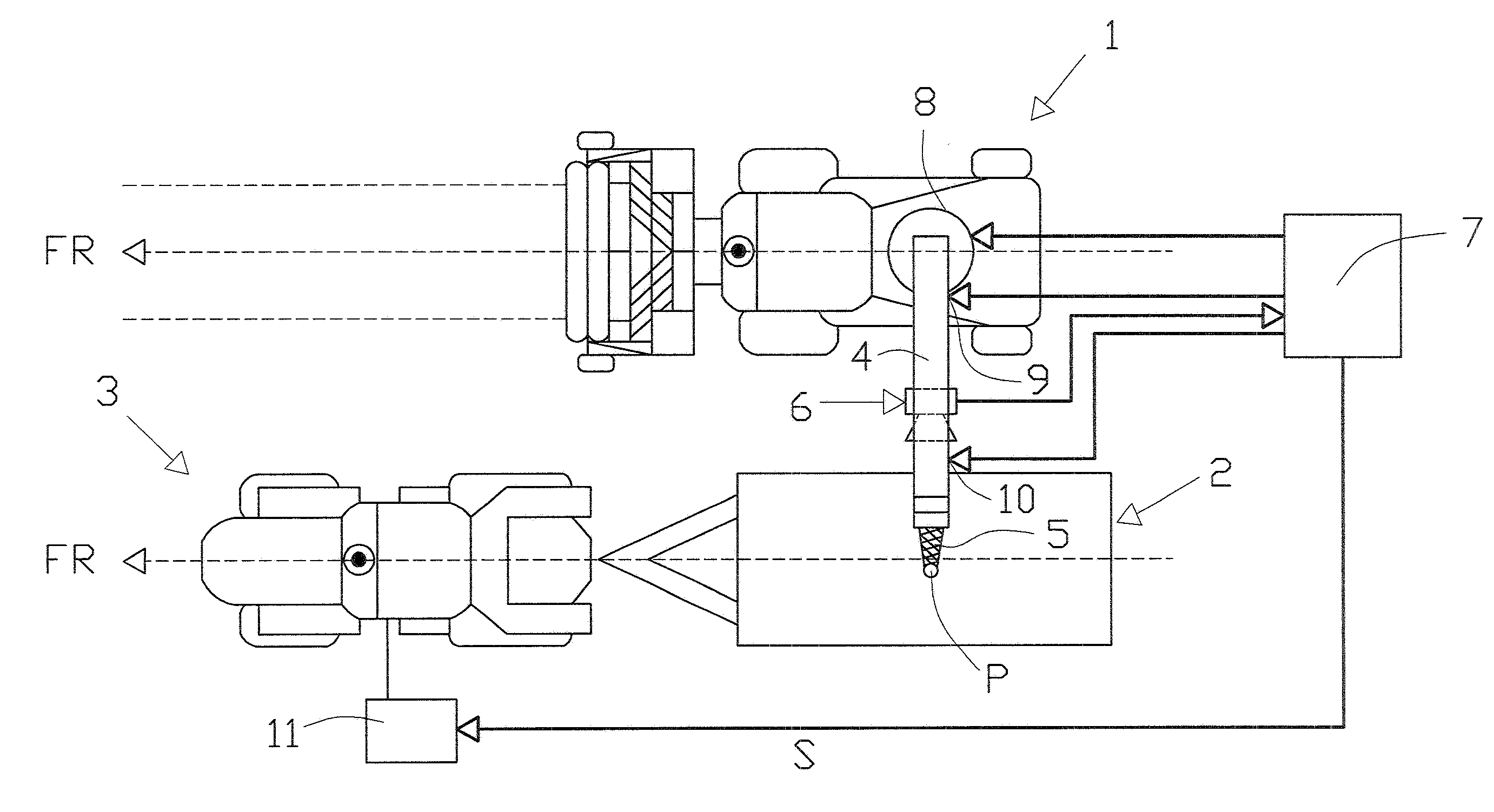

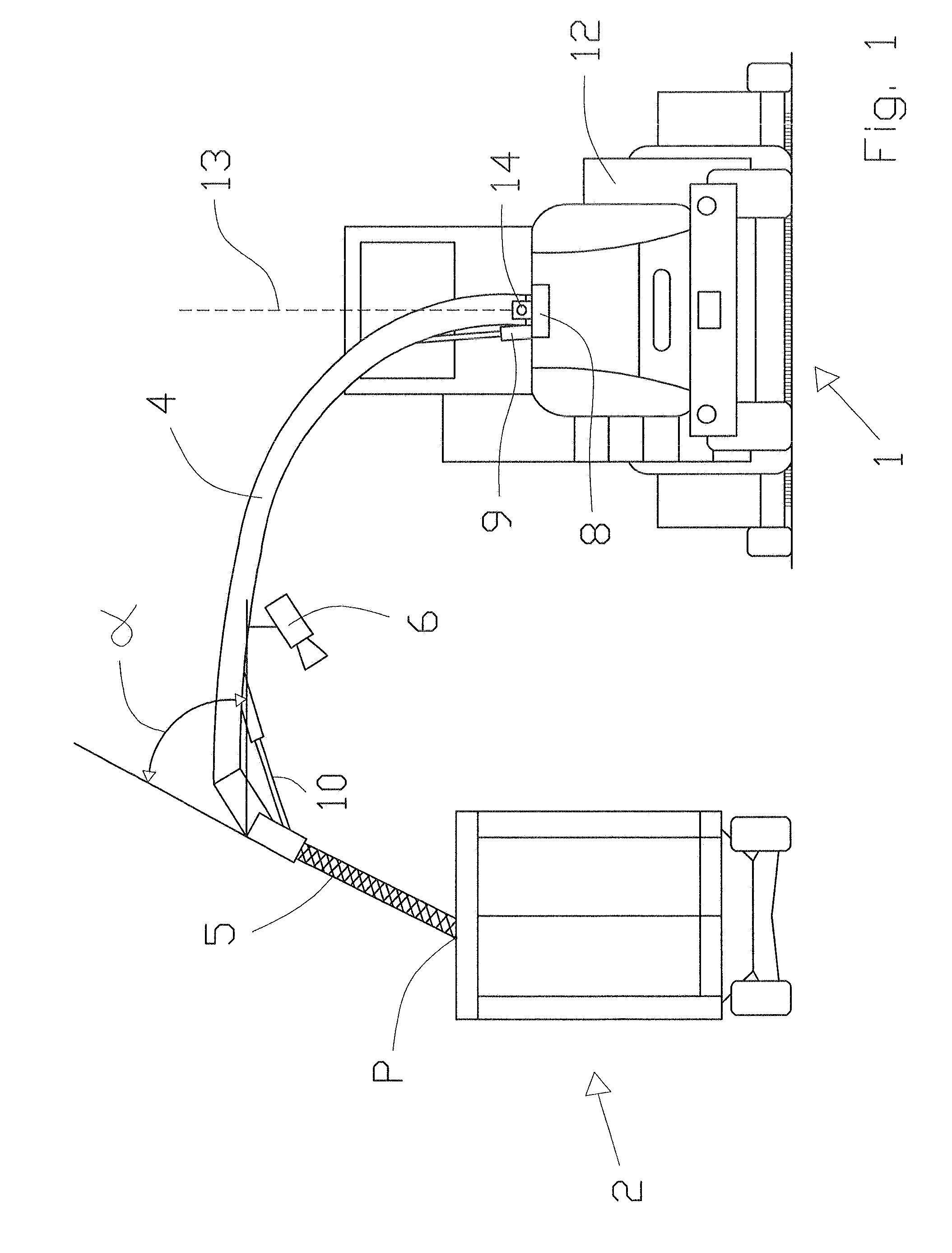

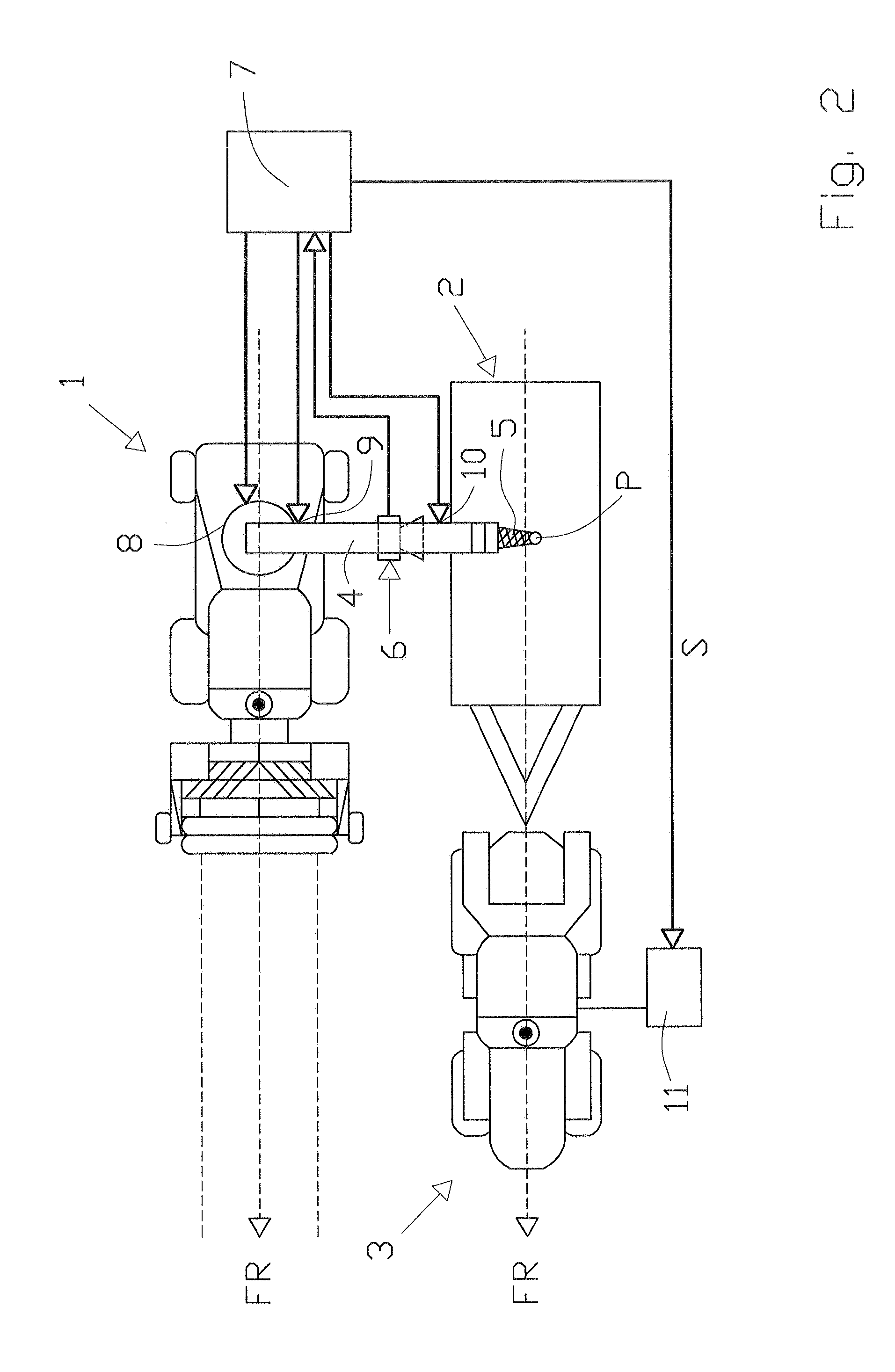

System and method for controlling crop transfer

InactiveUS20120263560A1Good reliefFast influenceMowersStorage devicesAgricultural scienceControl signal

A system for controlling crop transfer from a self-propelled agricultural harvesting machine into the loading container of a hauling vehicle includes a transfer device assigned to the harvesting machine from which the crop emerges in the form of a crop discharge flow and a detection device which detects the position of the loading container relative to the harvesting machine and transmits it to a control unit. The control unit actuates at least one actuator assigned to the transfer device in such a way that the crop discharge flow lands within the loading container in order to fill it with crop. The control unit generates a control signal (S) for the hauling vehicle that specifies a position of the hauling vehicle relative to the harvesting machine that is suitable for transfer into the loading container.

Owner:CLAAS SELBSTFAHRENDE ERNTEMASCHINEN GMBH

Loop control method of special thick steel at low temperature

InactiveCN102430591AEnsure automatic controlRealize automatic controlMeasuring devicesFlexible work arrangmentsLoop controlHeight difference

A loop control method of special thick steel at low temperature is disclosed, and aims to overcome the loop oscillation among precision rolling frames and ensure normal production of hot rolling. The method comprises the steps of: determining the control parameters of the loop among the frames by a first level computer according to the following formula if the target temperature at the strip steel precision rolling outlet is lower than 830 DEG C and the thickness of the product is greater than 7mm: Yn=Yn-1+Kp*{[1+TA / TN]*deltaYn-deltaYn-1}, wherein Yn is the additional quantity m / s of the loop height to the frame speed at sampling moment n; TA is program scanning time; TN is time of integration; Kp is proportional coefficient; deltaYn is loop height difference mm at sampling movement n; and transmitting downward by a second level computer to distinguish the loop tension set values of steels so as to give the torque of the loop.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

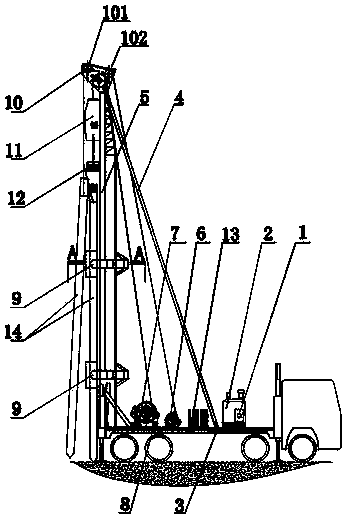

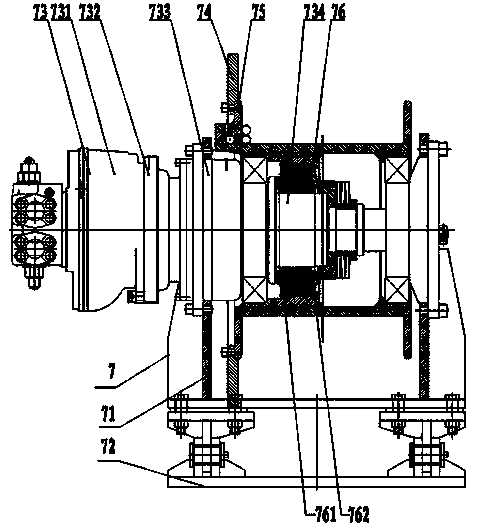

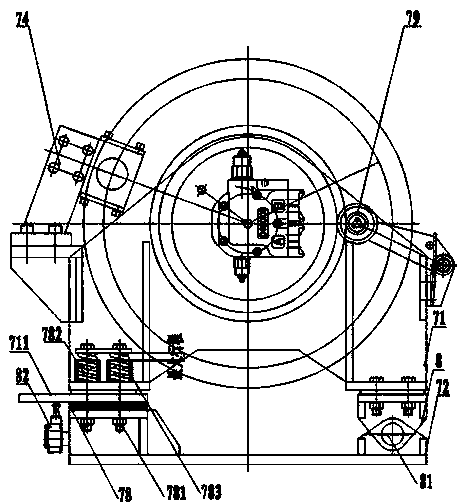

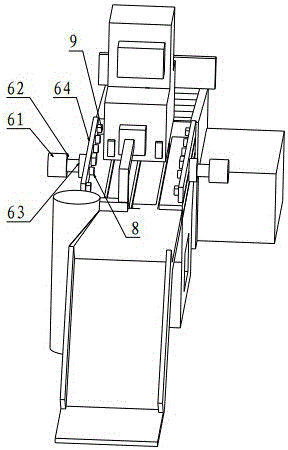

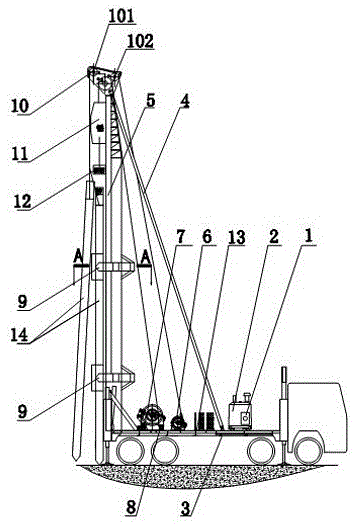

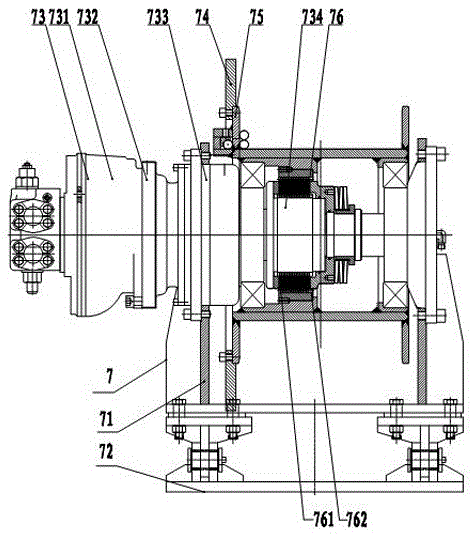

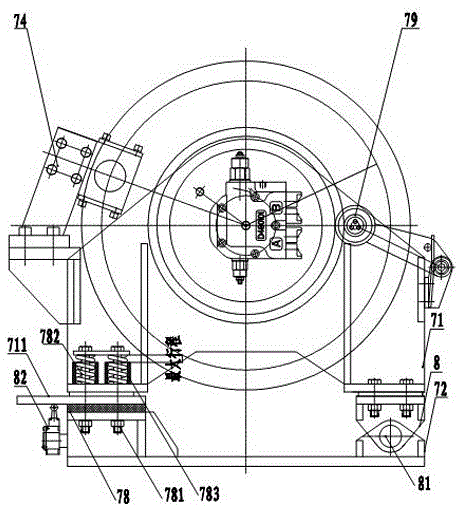

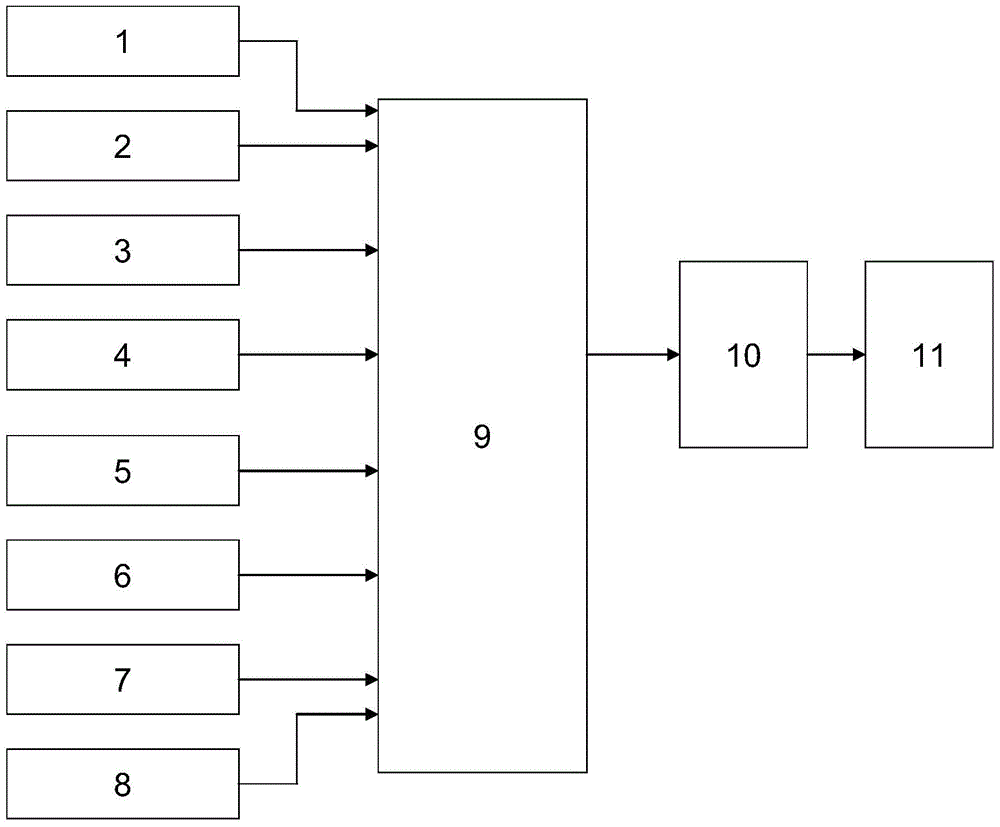

Full-automatic hydraulic piling machine using freely-lowering winch for driving heavy hammer

ActiveCN103422505AEliminate pollutionPromote environmental protectionBulkheads/pilesAutomatic controlControl system

The invention discloses a full-automatic hydraulic piling machine using a freely-lowering winch for driving a heavy hammer. The full-automatic hydraulic piling machine comprises a hydraulic control system and an electric circuit control system. The full-automatic hydraulic piling machine is provided with a pile lifting winch, the freely-lowering heavy hammer winch and automatic pile clamping mechanisms. The pile lifting winch and the freely-lowering heavy hammer winch are connected with a pile lifting control oil circuit and a heavy hammer control oil circuit respectively. The pile lifting control oil circuit and the heavy hammer control oil circuit are arranged in a hydraulic control system oil circuit in parallel. An automatic control rack hinge mechanism is arranged on the freely-lowering heavy hammer winch and connected with a PLC in the electric circuit control system. The automatic pile clamping mechanisms are arranged on a piling machine main arm, and a pile clamping system of the automatic pile clamping mechanisms is connected with the PLC. A diesel hammer is not needed for the automatic piling machine, a pile is automatically positioned, the piling process is fully automatic from beginning of the piling, operation is easy, labor is saved, efficiency is high, cost is low, and economic benefits are high.

Owner:INI HYDRAULIC

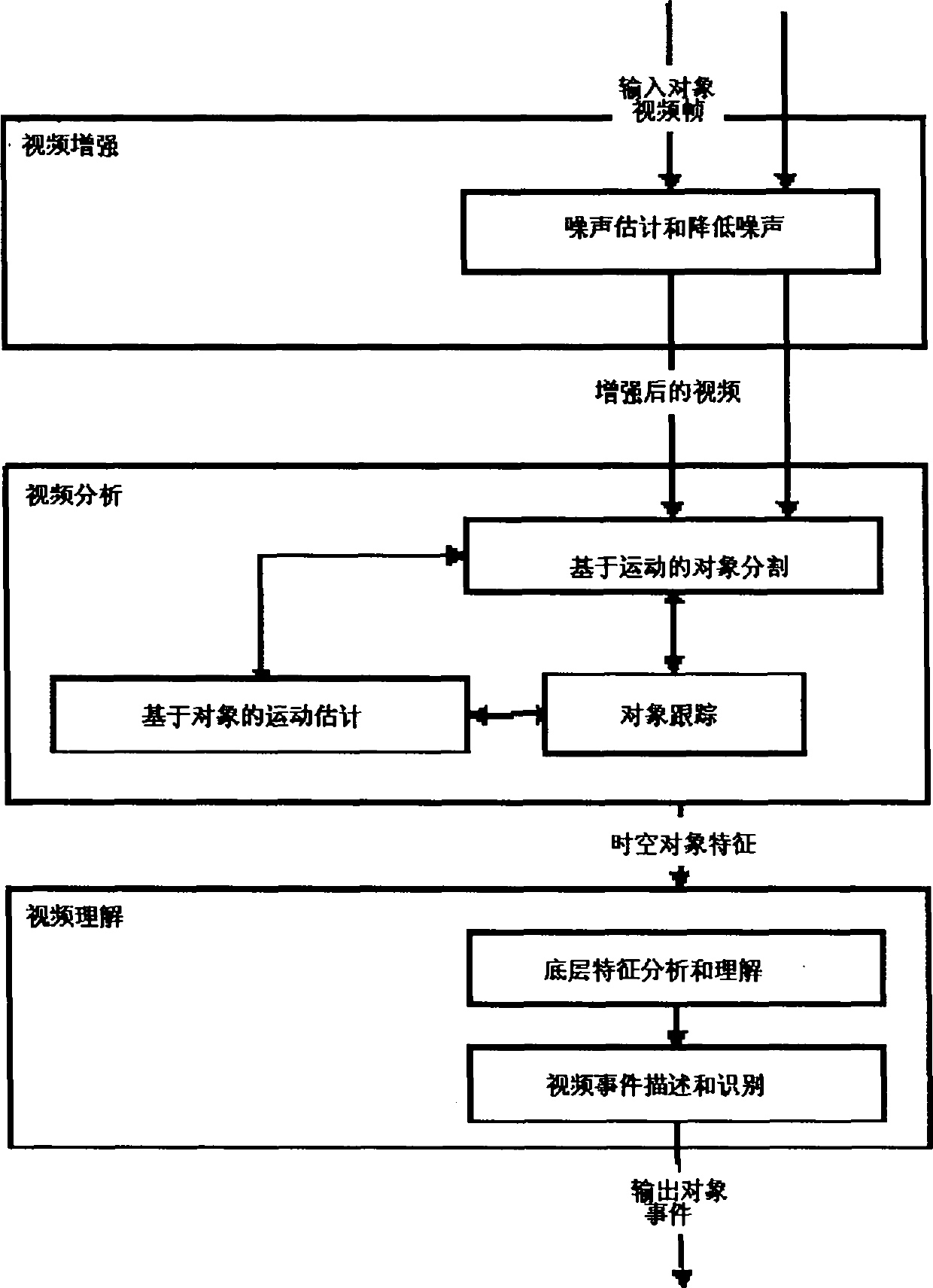

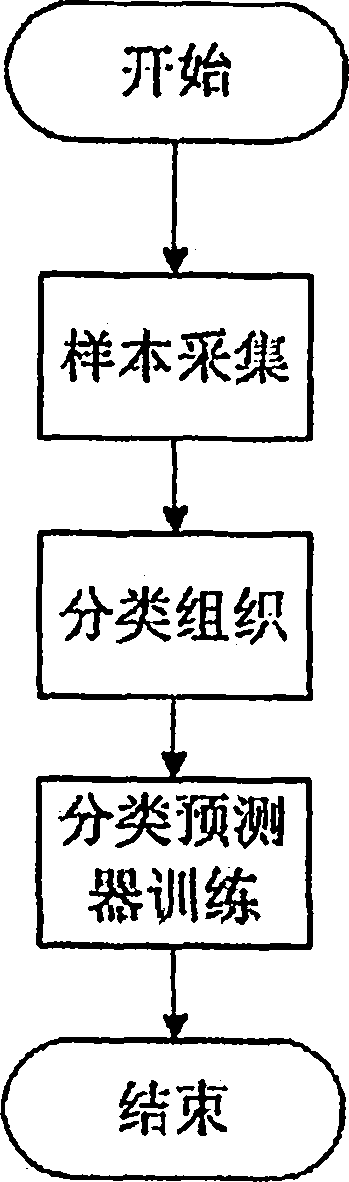

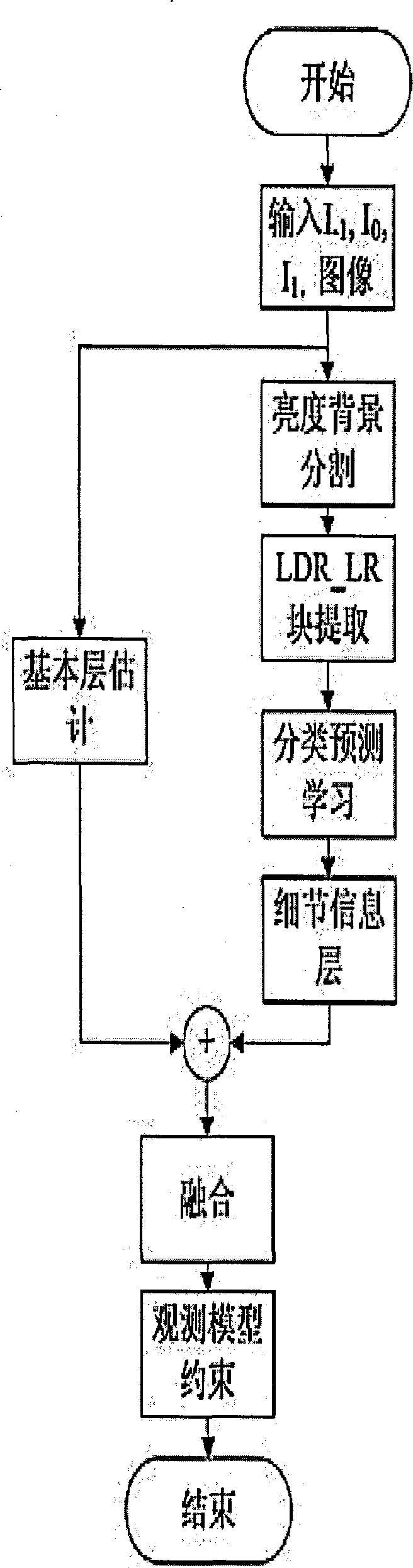

Digital image processing method

InactiveCN103747189AWide range of typesHigh precisionImage enhancementTelevision system detailsAutomatic controlVideo image

The invention relates to a digital image processing method which comprises the following steps: successively carrying out video enhancement, video analysis and video understanding on highway video images acquired by a camera. As for the video enhancement, multiple low-resolution images of the same scene and with different exposure parameters are reconstructed into high-quality images with highlight brightness dynamic range and high resolution, thus providing high-quality video images for the video analysis level and raising reliability of video processing results. As for the video analysis, detection is carried out through moving objects, and space-time object characteristics of video ground and middle levels are extracted by motion estimation and target tracking video analytic algorithms so as to provide inferential basis for event identification in high-level video processing. As for the video understanding, identification of surveillance video events is completed by analyzing and understanding the space-time object characteristics provided by the video analysis level. According to the invention, types of detection events are broader and precision is higher. Through correct identification of events, automatic control of highways is ensured.

Owner:NANYANG INST OF TECH

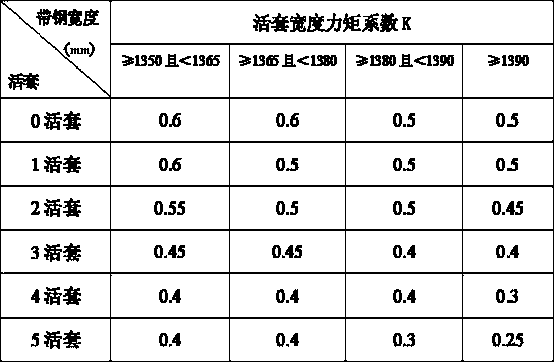

Movable sleeve control method for pipeline steel

ActiveCN103990652ADelay adjustment response speedMeet the control process requirementsTension/compression control deviceLine tubingStructural engineering

The invention provides a movable sleeve control method for pipeline steel, and belongs to the field of steel rolling. The method includes the steps that firstly, control parameters of movable sleeves between every two adjacent machine frames are determined through a first-stage computer and a second-stage computer according to the following formulas, wherein the target temperature of a strip steel finish rolling outlet is smaller than or equal to 810 DEG C, and the thickness of a finished product is larger than or equal to 8 mm; secondly, a table model of movable sleeve steel type tension coefficients is set up through the second-stage computer according to the requirements for process data and steel types, and steel type tension coefficients of different movable sleeves are obtained by looking up a table and sent out through the second-stage computer during rolling. By means of the movable sleeve control method, the hydraulic movable sleeves between the hot continuous rolling finish rolling machine frames are automatically controlled when the pipeline steel is rolled, the problem that the hydraulic movable sleeves between the hot continuous rolling finish rolling machine frames vibrate is solved when the pipeline steel is rolled, and abnormal shutdown time is shortened.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

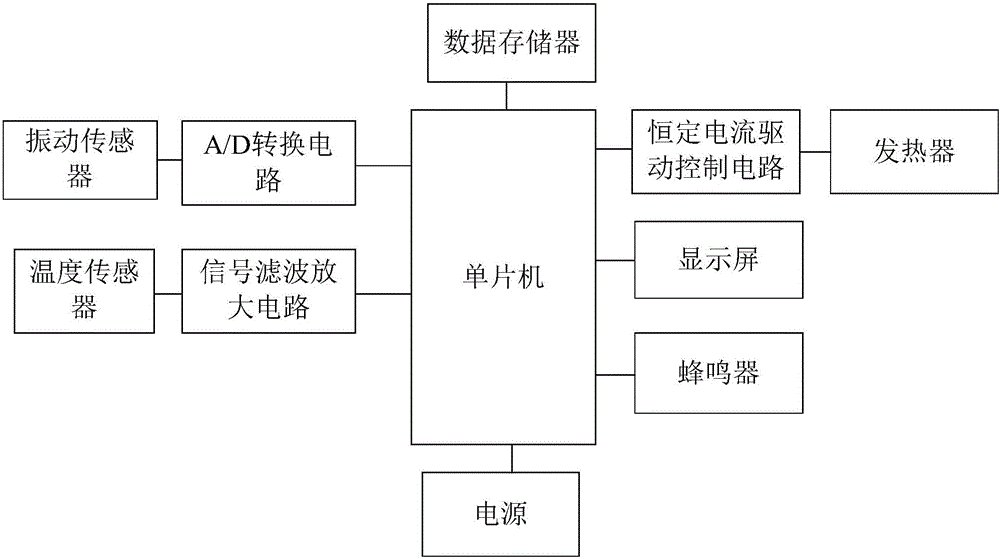

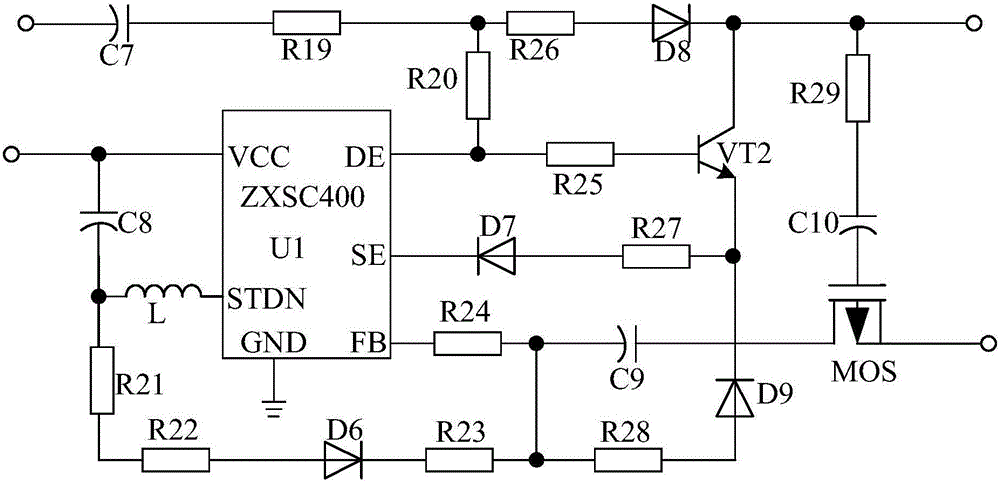

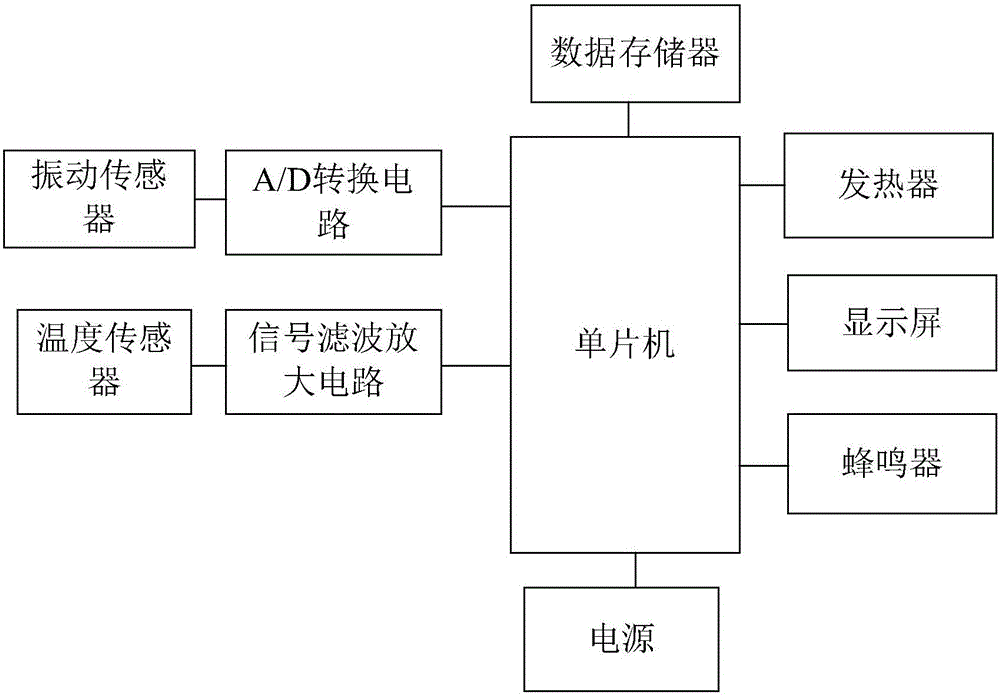

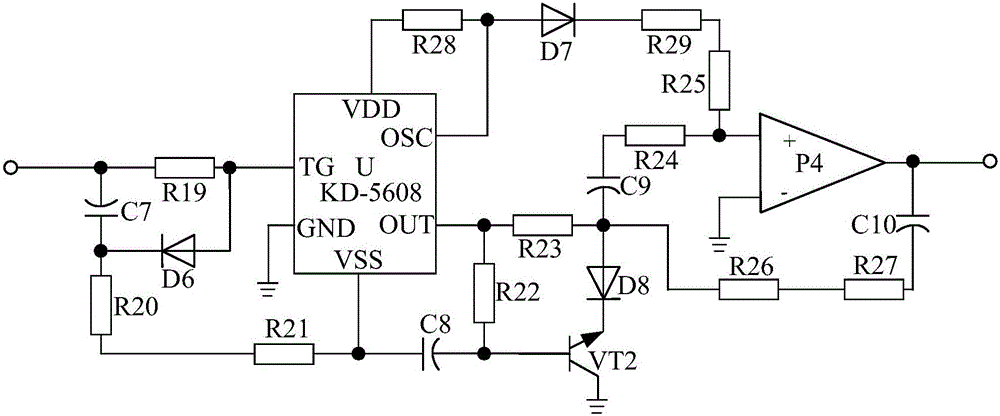

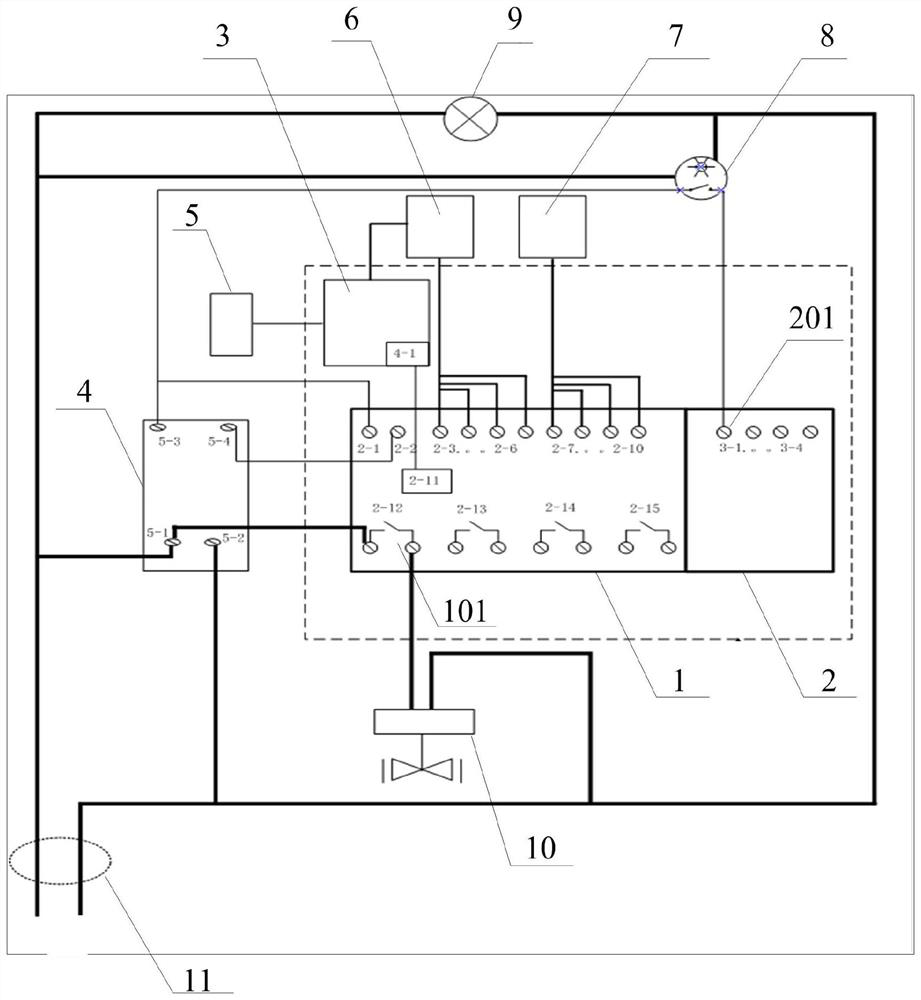

Multi-circuit processing type temperature intelligent control system

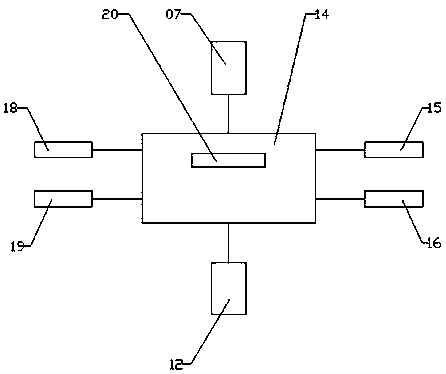

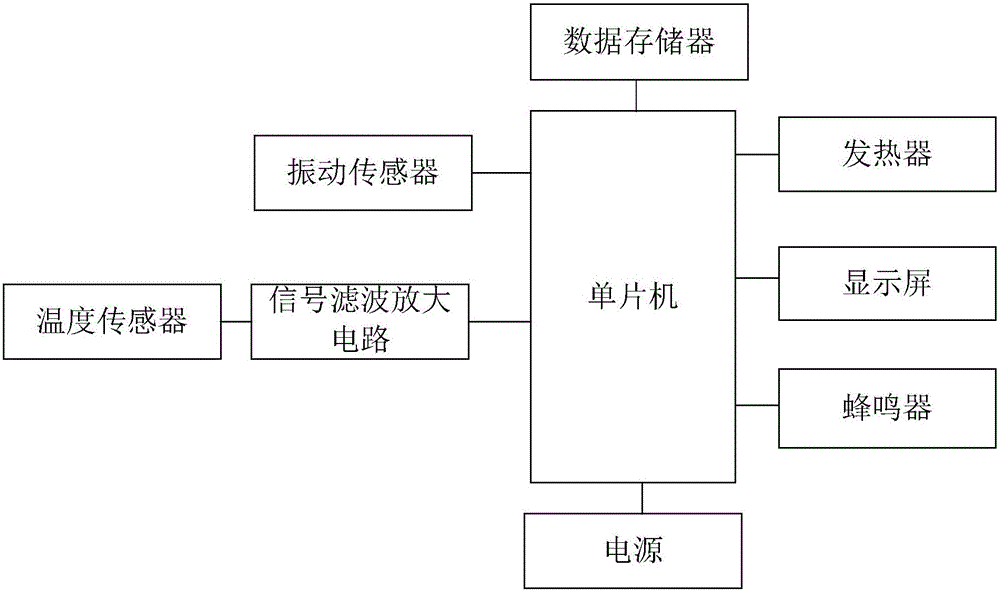

InactiveCN105867467AControl heating temperatureEnsure automatic controlAuxillary controllers with auxillary heating devicesMicrocontrollerProcessing type

The invention discloses a multi-circuit processing type temperature intelligent control system, which includes a single-chip microcomputer, a buzzer connected to the single-chip microcomputer, a data memory, a display screen, a power supply, a constant current drive control circuit, an A / D conversion circuit and a signal filter An amplifier circuit, a vibration sensor connected to the input end of the A / D conversion circuit, a heater connected to the output end of the constant current drive control circuit, and a temperature sensor connected to the input end of the signal filter amplifier circuit. The vibration frequency information of the pot body collected by the vibration sensor and the temperature information of the soup in the pot detected by the temperature sensor are analyzed and processed by the single-chip microcomputer. Certain, so that the soup in the pot maintains a certain temperature, and at the same time, effectively saves power resources.

Owner:CHENGDU JUHUICAI TECH

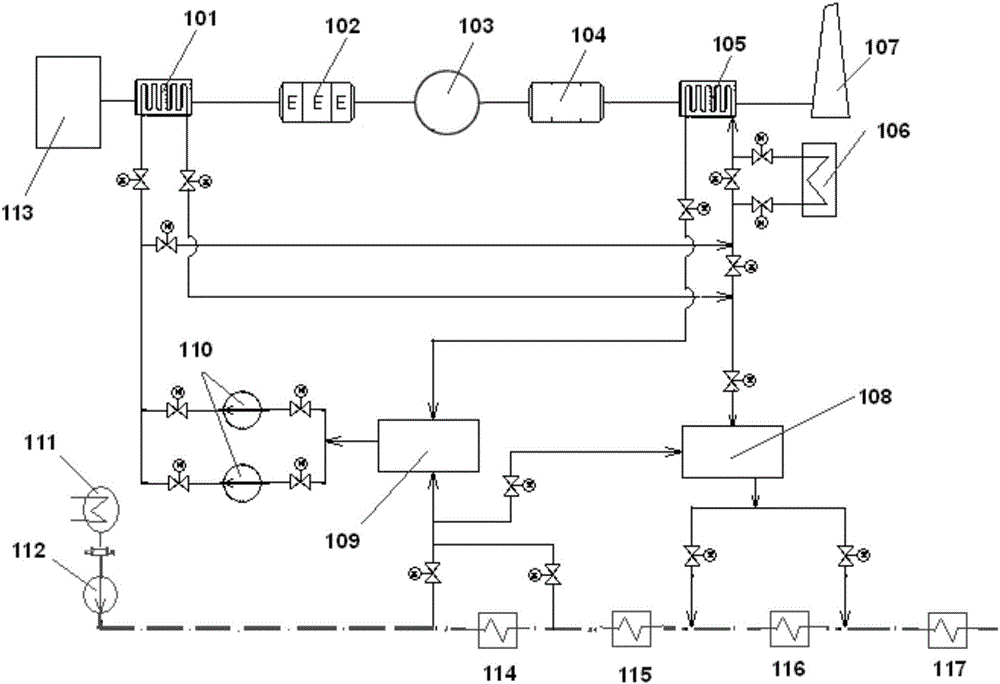

Open lower temperature waste heat utilization system of ultra-clean emission coal-fired unit

PendingCN106765265AAvoid condensationAvoid Low Temperature CorrosionFeed water supplyCombustion technology mitigationGas heaterGas cooler

The invention discloses an open lower temperature waste heat utilization system of ultra-clean emission coal-fired unit, and relates to a steady controllable open MGGH system. A water outlet of a gas cooler is communicated with a gas-gas heater and a water inlet of waste heat recovery hot water mixer through pipeline systems with valves respectively, and the water inlet pipeline of the gas-gas heater is also provided with an auxiliary steam heater; the water outlet of the gas-gas heater is communicated with the water inlet of the gas cooler through a circulating water and make-up water mixer, a variable frequency booster pump and the pipeline systems with the valves; the water inlet of the circulating water and make-up water mixer is also communicated with a condensation water pipeline, and the water outlet of the waste heat recovery hot water mixer is communicated with a low-temperature heating system pipeline through at least two pipelines with the valves. In the invention, the problems that the inlet gas temperature of an electrostatic precipitator and chimney inlet gas temperature are difficult to control, the low-temperature heating adjustment of the unit is difficult to control and the disturbance is severe due to poor heat exchange effect of a plate heat exchanger in the existing MGGH technology are solved.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

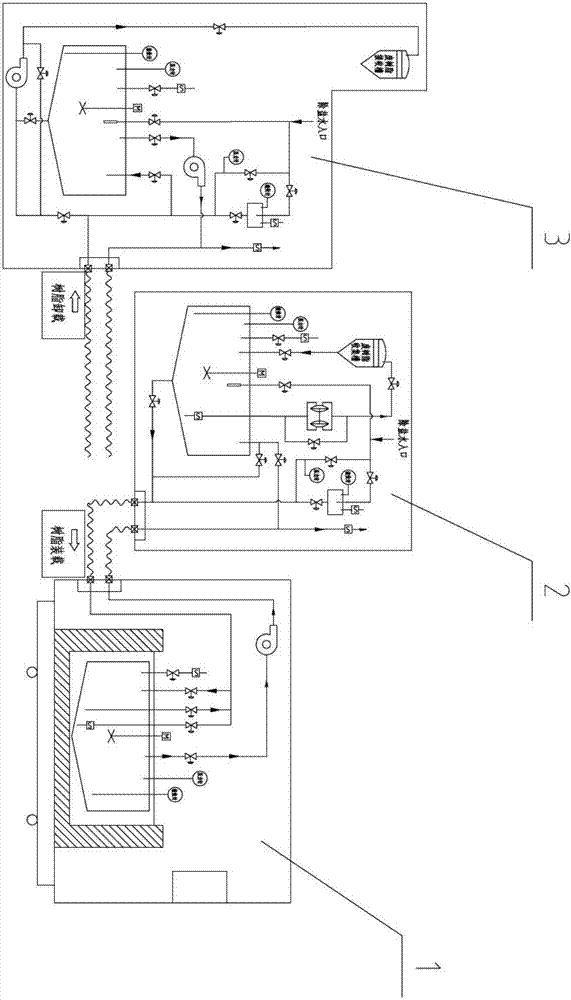

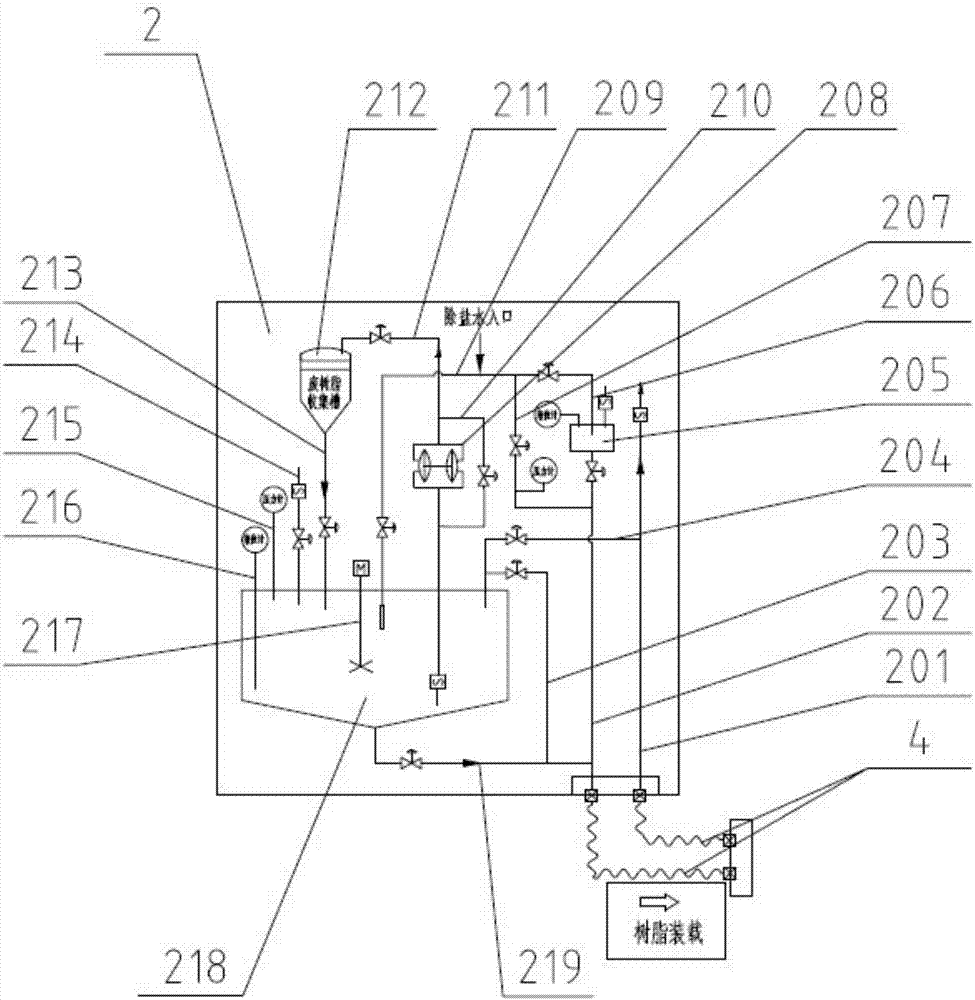

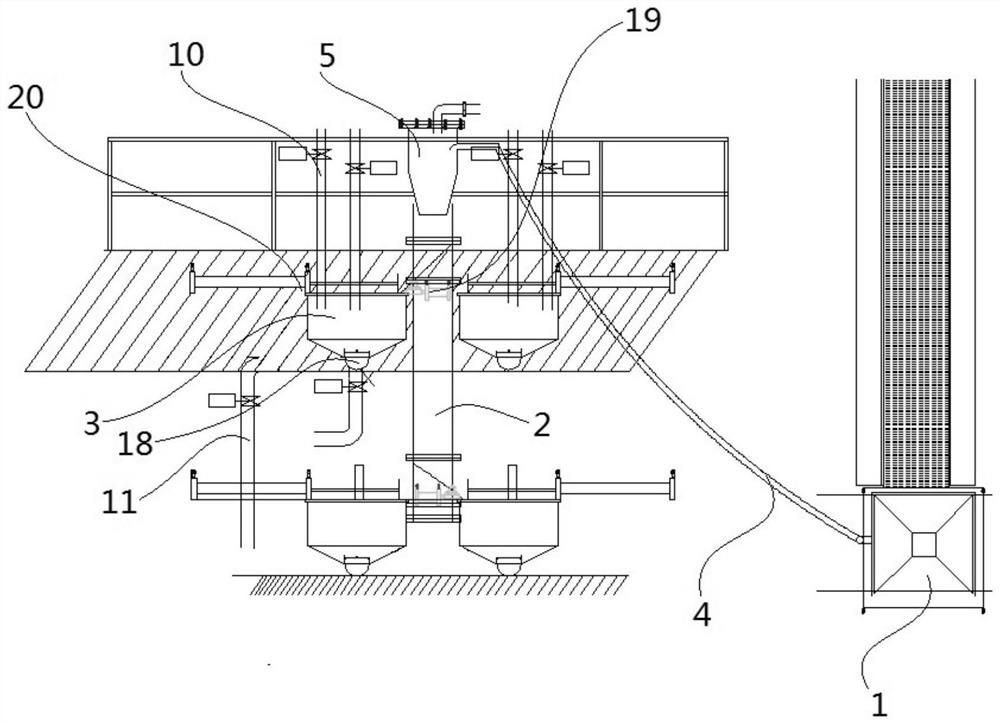

Loading, unloading and transferring apparatus for nuclear power plant spent resin and transferring method thereof

ActiveCN107293343AAvoid depositionReduce the risk of radiationPortable shielded containersNuclear engineeringRadioactive waste

The invention discloses a loading, unloading and transferring apparatus for nuclear power plant spent resin and a transferring method thereof, and belongs to the technical field of safety transfer of radioactive wastes. The loading, unloading and transferring apparatus for nuclear power plant spent resin comprises a shielding transporter, a loading connector device and an unloading connector device; in unloading, the shielding transporter is connected with the loading connector device through a hose; in unloading, the shielding transporter is connected with the unloading connector device through a hose. The loading, unloading and transferring method for nuclear power plant spent resin is good in safety and high in efficiency, and enables the pollution risk due to leakage and radiation danger in personnel's operation to be effectively decreased.

Owner:AEROSUN CORP

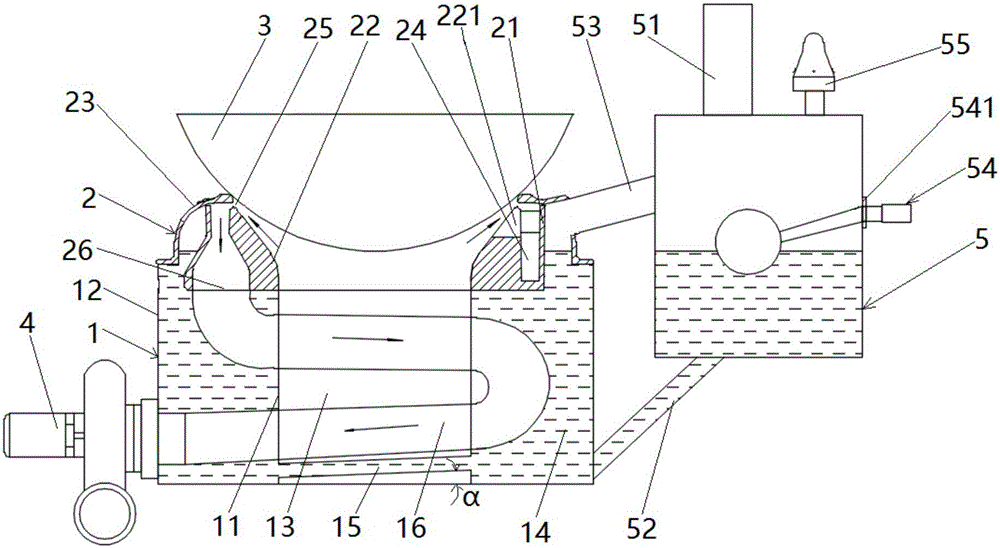

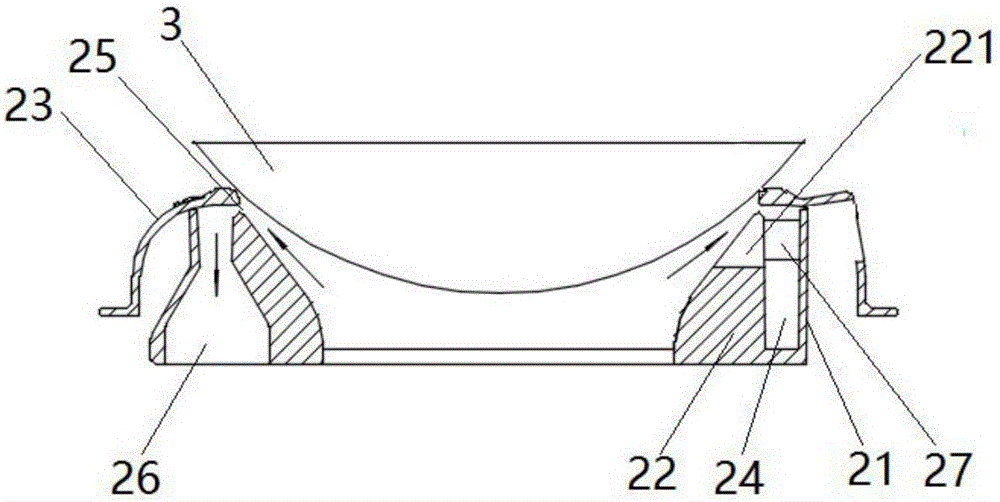

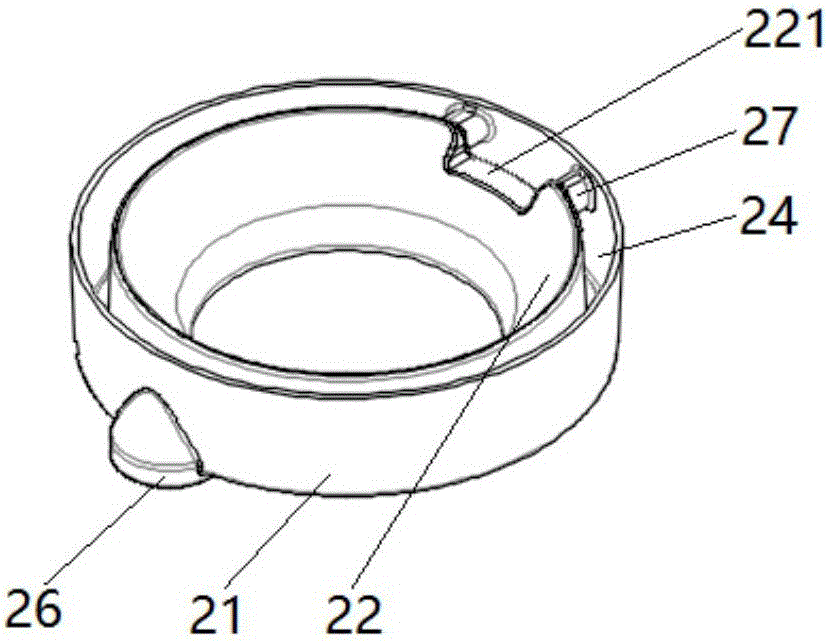

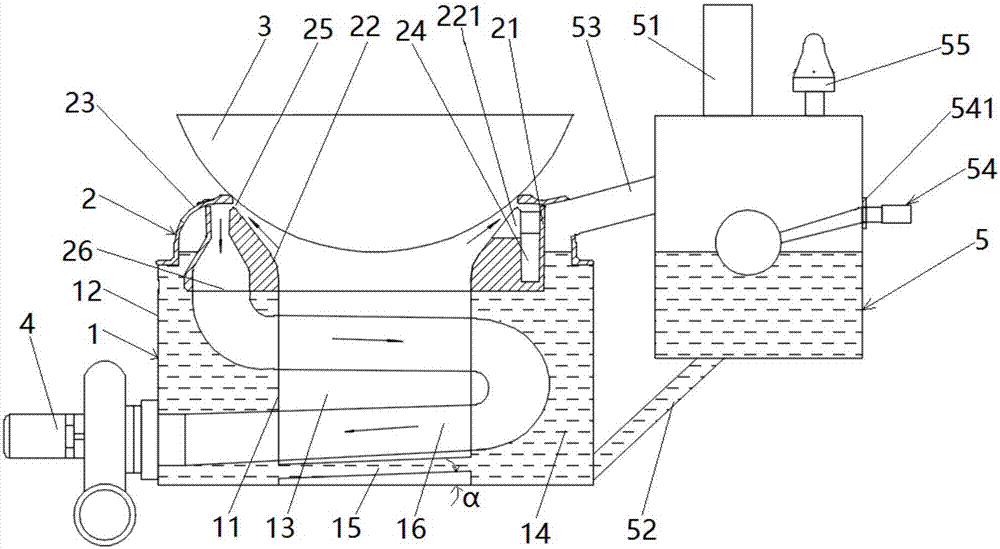

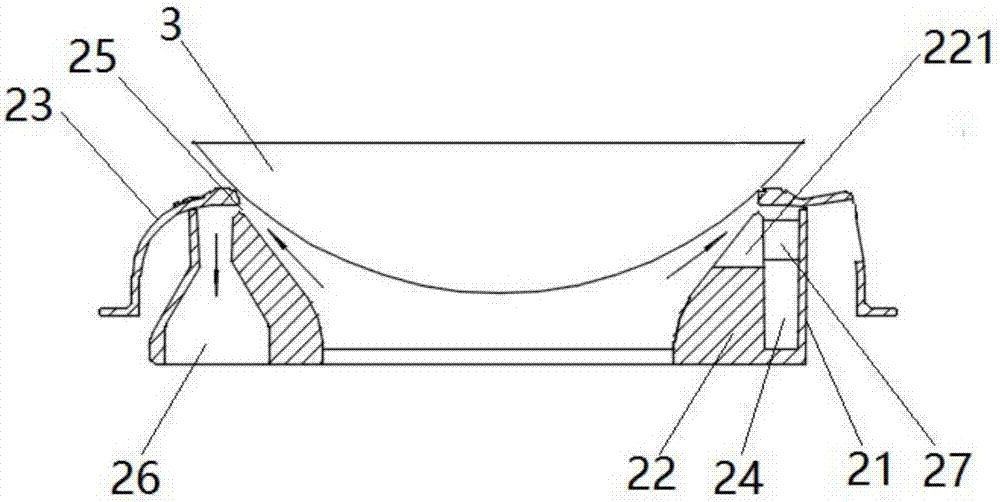

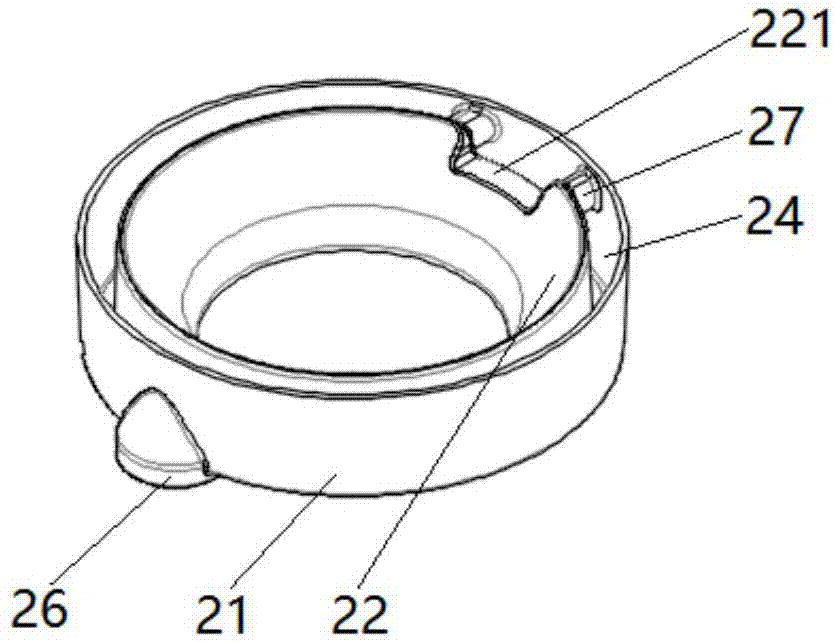

Cooking range generating steam by using waste heat

ActiveCN105841502AAchieve efficient recyclingGood promotion prospectDomestic stoves or rangesCooking fumes removalAutomatic controlEngineering

The invention relates to a cooking range generating steam by using waste heat. The cooking range a furnace body, a furnace head and a water tank, wherein the furnace body is combined by an inner furnace wall and an outer furnace wall; a hollow region surrounded by the inner furnace wall is a hearth; a plurality of tubular fire bars are uniformly arranged below the hearth at intervals in the furnace body; the furnace head comprises an outer furnace ring, an inner furnace ring and a pot body supporting ring; the lower end of the inner furnace ring is connected to the inner furnace wall; the lower end of the pot body supporting ring is connected to the outer furnace wall; a cavity among the inner wall furnace, the outer wall furnace and the furnace head is a heating cavity; a coil surrounding the hearth is arranged in the heating cavity; a steam pipe communicating with the top of the heating cavity is arranged in the upper part of the water tank; a water outlet pipe communicating with the bottom of the heating cavity is arranged in the lower part of the water tank; a gas outlet pipe is arranged on the top of the water tank; a water inlet is formed between the steam pipe and the water outlet pipe on the water tank; and a float ball water inlet valve is arranged on the water inlet. The cooking range provided by the invention realizes efficient recovery of smoke heat and automatic control of water inflow in a stove using process.

Owner:JIANGSU SHENGONG STOVE CO LTD

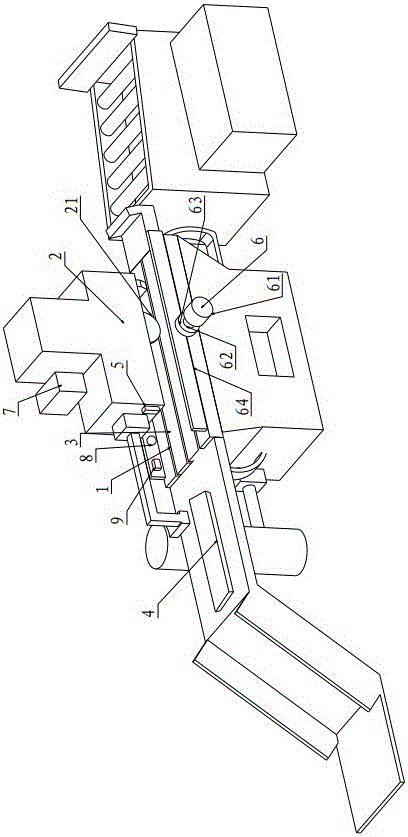

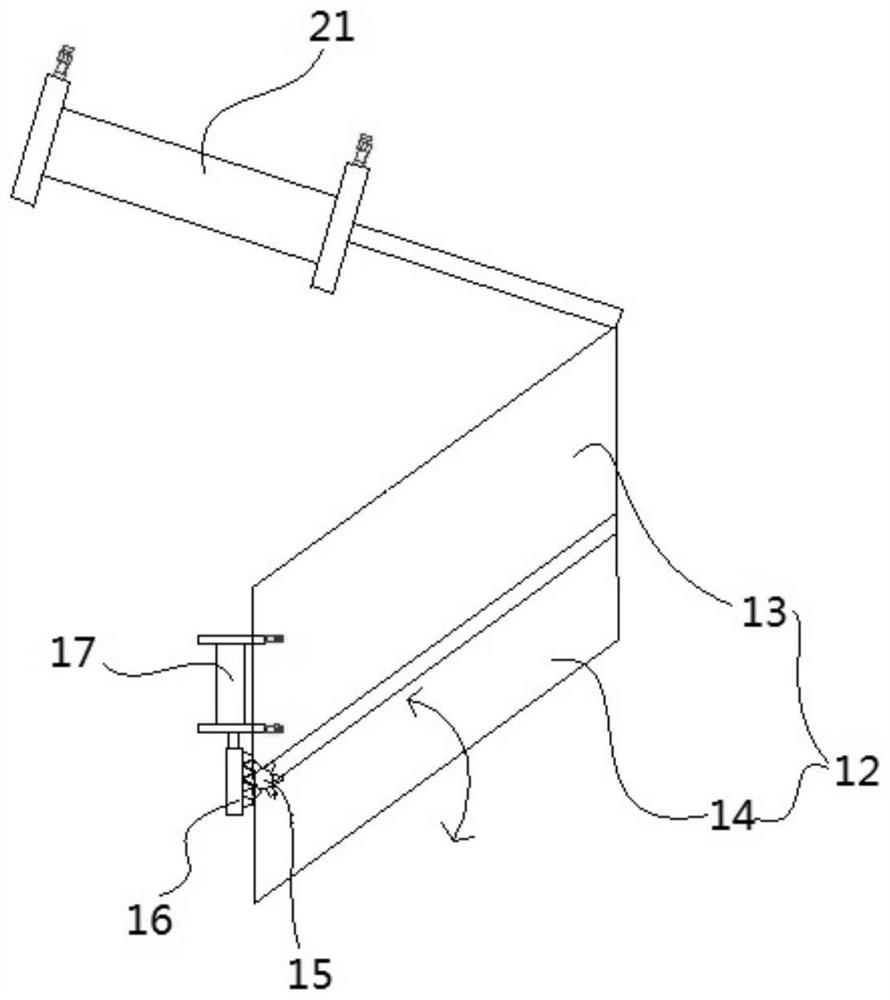

Bilateral longitudinal sectioning slicer for bamboo products

ActiveCN105150317AAchieve precise positioningEnsure automatic controlCane mechanical workingProgrammable logic controllerEngineering

The invention discloses a bilateral longitudinal sectioning slicer for bamboo products. The bilateral longitudinal sectioning slicer comprises a working table, a cutting device and a conveying belt, wherein the conveying belt is arranged at the right center position of the working table; the slicer also comprises two infrared positioning devices, two automatic pushing devices, a programmable logic controller and at least two displacement sensors; the two infrared positioning devices are arranged on the cutting device; each infrared positioning device is used for positioning the positions of longitudinal cutting openings in the bamboo products; the at least two displacement sensors are connected to one automatic pushing device respectively; each displacement sensor is used for measuring and transmitting edge positions of the bamboo products to the programmable logic controller; the programmable logic controller is used for controlling each automatic pushing device to adjust the positions of the bamboo products on the conveying belt. According to the bilateral longitudinal sectioning slicer for bamboo products, the quality of the bamboo products at the positions of slicing openings, thereby improving the cutting efficiency and quality; the waste of the bamboo products is avoided.

Owner:宣城宏宇竹业有限公司

Intelligent agricultural water-saving valve

PendingCN108413103AReasonable designSimple structureOperating means/releasing devices for valvesWater savingAutomatic control

The invention relates to an intelligent agricultural water-saving valve. The intelligent agricultural water-saving valve comprises a valve seat, a valve cover and a valve chamber, wherein a fixed plate is arranged above the valve seat in parallel; a circular hole is formed in the middle of the valve seat; a plurality of supporting posts are uniformly arranged at the periphery of the circular holeof the valve seat; the supporting posts are fixedly connected with the valve seat and the fixed plate; the valve chamber is arranged on the fixed plate; a drive device is arranged in the valve chamber; the drive device sequentially passes through the bottom of the valve chamber and the fixed plate, and is connected with the valve cover; the valve cover is positioned above the circular hole of thevalve seat; a battery and a controller are further arranged in the valve chamber; the valve cover is in sealing contact with the valve seat; when the valve cover is positioned on a lower limiting position, the valve is closed and the valve cover is separated from the valve seat; and when the valve cover is positioned on an upper limiting position, the valve is opened. The intelligent agriculturalwater-saving valve is reasonable in design, is simple in structure, can automatically control opening / closing of the valve according to water level of a farmland, performs farmland water level regulation, and avoids water resource loss as a result of unmanned management of farmland irrigation, so that farmland irrigation water is greatly saved.

Owner:如皋市农田水利试验站 +1

A hydraulic fully automatic pile driver with a free lowering hoist to drive a heavy hammer

ActiveCN103422505BEliminate pollutionPromote environmental protectionBulkheads/pilesFree fallingAutomatic control

The invention discloses a full-automatic hydraulic piling machine using a freely-lowering winch for driving a heavy hammer. The full-automatic hydraulic piling machine comprises a hydraulic control system and an electric circuit control system. The full-automatic hydraulic piling machine is provided with a pile lifting winch, the freely-lowering heavy hammer winch and automatic pile clamping mechanisms. The pile lifting winch and the freely-lowering heavy hammer winch are connected with a pile lifting control oil circuit and a heavy hammer control oil circuit respectively. The pile lifting control oil circuit and the heavy hammer control oil circuit are arranged in a hydraulic control system oil circuit in parallel. An automatic control rack hinge mechanism is arranged on the freely-lowering heavy hammer winch and connected with a PLC in the electric circuit control system. The automatic pile clamping mechanisms are arranged on a piling machine main arm, and a pile clamping system of the automatic pile clamping mechanisms is connected with the PLC. A diesel hammer is not needed for the automatic piling machine, a pile is automatically positioned, the piling process is fully automatic from beginning of the piling, operation is easy, labor is saved, efficiency is high, cost is low, and economic benefits are high.

Owner:INI HYDRAULIC

Intelligent control device and method for walking of coal mining machine

InactiveCN104533413AGuaranteed to workImprove work efficiencySlitting machinesCurrent transducerAutomatic control

The invention provides an intelligent control device and method for walking of a coal mining machine. The intelligent control device and method are suitable for coal mining machines. The intelligent control device comprises a coal cutting roller motor current transducer, a coal mining machine traction motor current transducer, a roller rotation-speed transducer, a stress transducer, a vibration transducer installed on a coal cutting rocker arm, a laser sensor, a hall switch, a sensor controlling upward displacement of a hydraulic shaft, a master controller, a variable frequency driver and a traction motor. All the components of the intelligent control device are used for detecting all parts of the coal mining machine, and the coal mining machine is controlled to only operate through monitor data. The mechanical failures caused when the coal mining machine is in contact with rock stratums or faults in the coal cutting process are avoided. Meanwhile, it is guaranteed that automatic control over the process that automatic control over reciprocating coal cutting by a coal face of the coal mining machine is achieved.

Owner:CHINA UNIV OF MINING & TECH

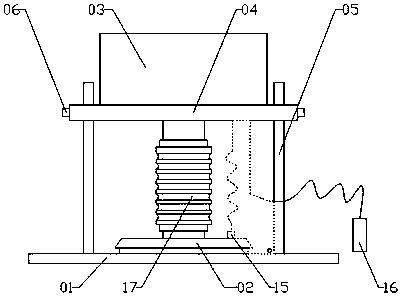

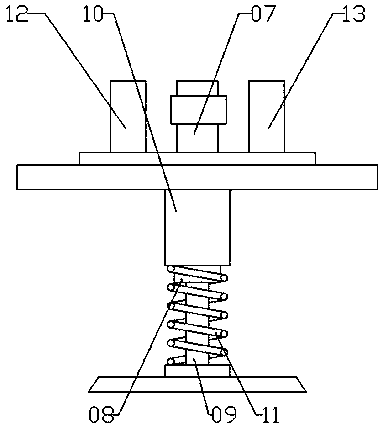

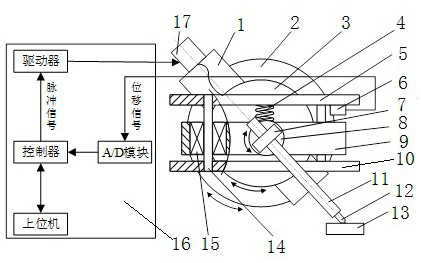

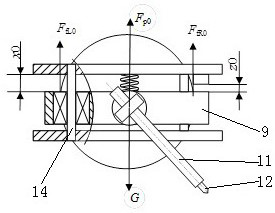

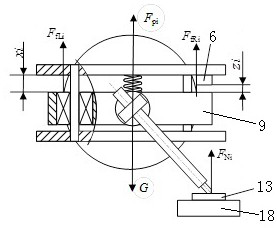

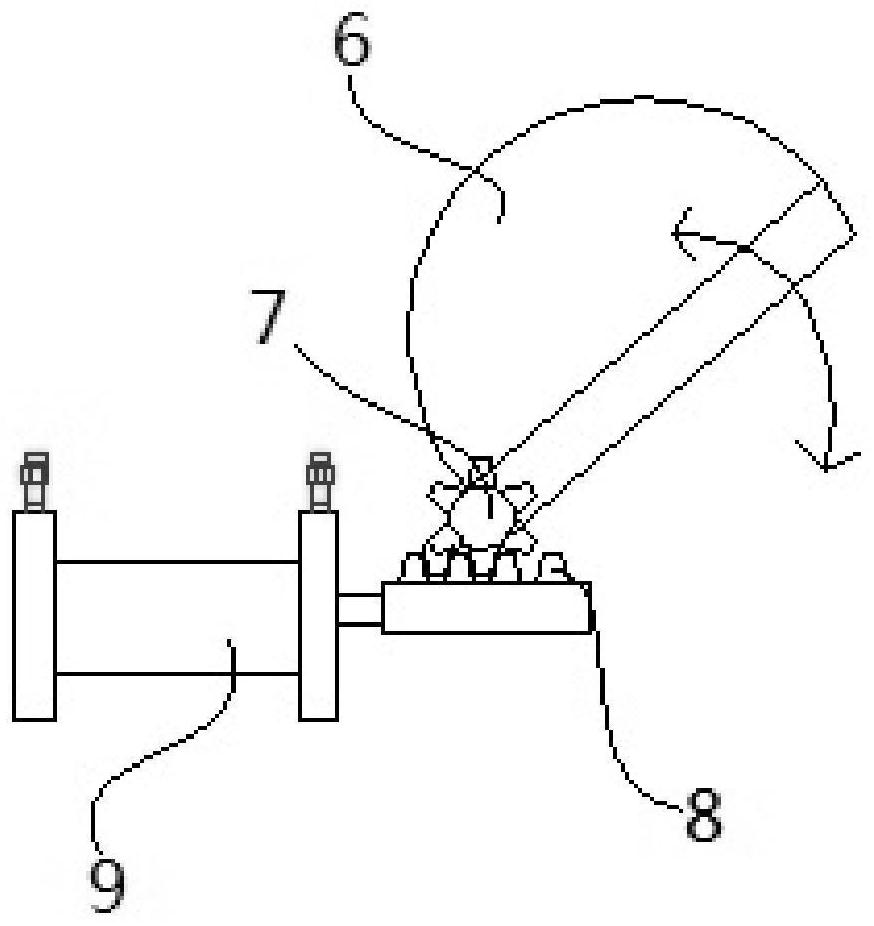

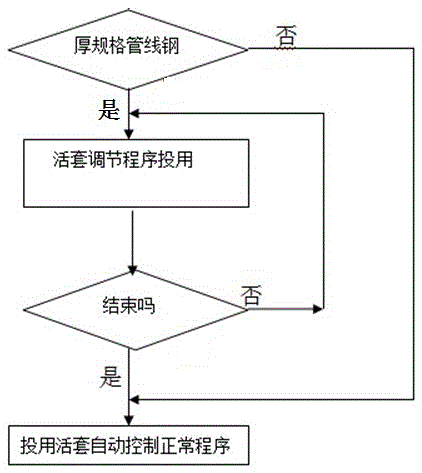

Automatic control device and control method for converting contact force into displacement during electric spark deposition bead weld

ActiveCN112756743ARealize closed-loop controlHigh strengthWelding accessoriesAutomatic controlLoop control

The invention relates to an automatic control device and control method for converting contact force into displacement during electric spark deposition bead weld. The automatic control device mainly comprises a feeding mechanism, a floating elastic mechanism, a gun clamping mechanism, a welding gun, an electric control system and the like and converts the contact force between an electrode and a workpiece into displacement of a floating sliding table. A non-contact displacement sensor is adopted for detection, conversion from tension and pressure measurement to displacement measurement is achieved, the strength of a mechanical system is improved, and measurement of micro contact force can be achieved. The contact force between the electrode and the workpiece is determined according to the displacement of the floating sliding table, a controller and the feeding mechanism are used for controlling the electrode to move along the axis of the electrode, closed-loop control over the contact force is achieved, and vibration between the electrode and the workpiece can be reduced through spring damping of the floating elastic mechanism; and the stability and reliability of automatic control of the contact force between the electrode and the workpiece in the deposition process are remarkably improved.

Owner:HENAN UNIV OF SCI & TECH

System for statistical analysis and learning on working state of hydraulic hoist

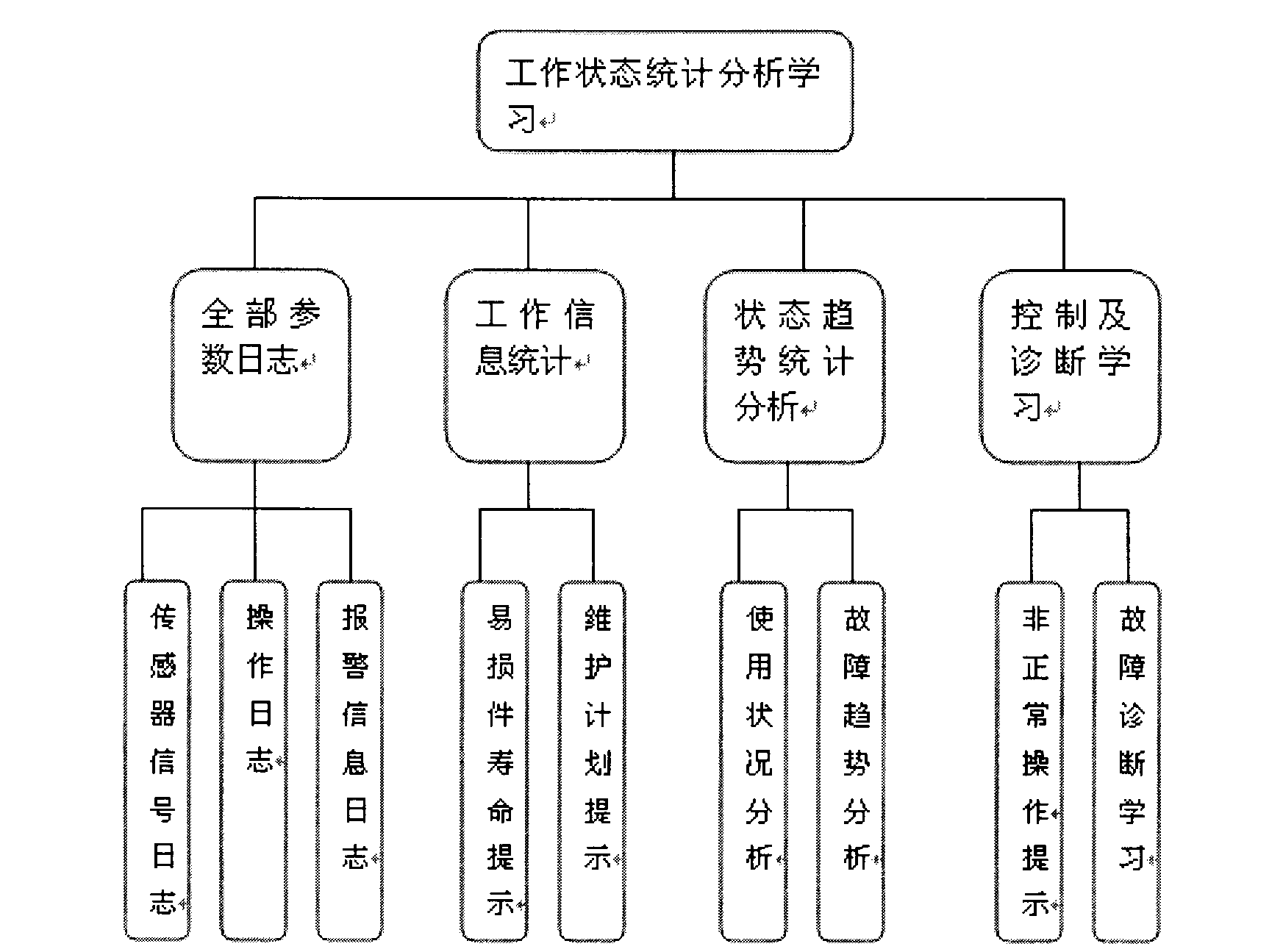

InactiveCN103676802AEnsure automatic controlGuaranteed full-time monitoringTotal factory controlSpecial data processing applicationsAlarm messageStatistical analysis

The invention relates to a system for statistical analysis and learning on working state of a hydraulic hoist. The system comprises functional modules of sensor signal log, an operation log, alarm information log, quick-wear part service life prompting, maintenance plan prompting, application state analysis, fault trend analysis, abnormal operation prompting and fault diagnosis learning. Through the adoption of the system, overall statistical analysis on the operation state, the learning on manual operation action, early warm prompting on abnormal operation, intelligent management on equipment application and maintenance and practical analysis and calculation on the service life of a quick-ware part are provided. The invention provides the overall hydraulic hoist working state statistical analysis and learning system, comprehensive handling on the equipment condition is ensured, and operation and maintenance on the hydraulic hoist with low cost and reliability are achieved.

Owner:JIANGSU CHENGUANG SUNDE HYDRAULIC EQUIP

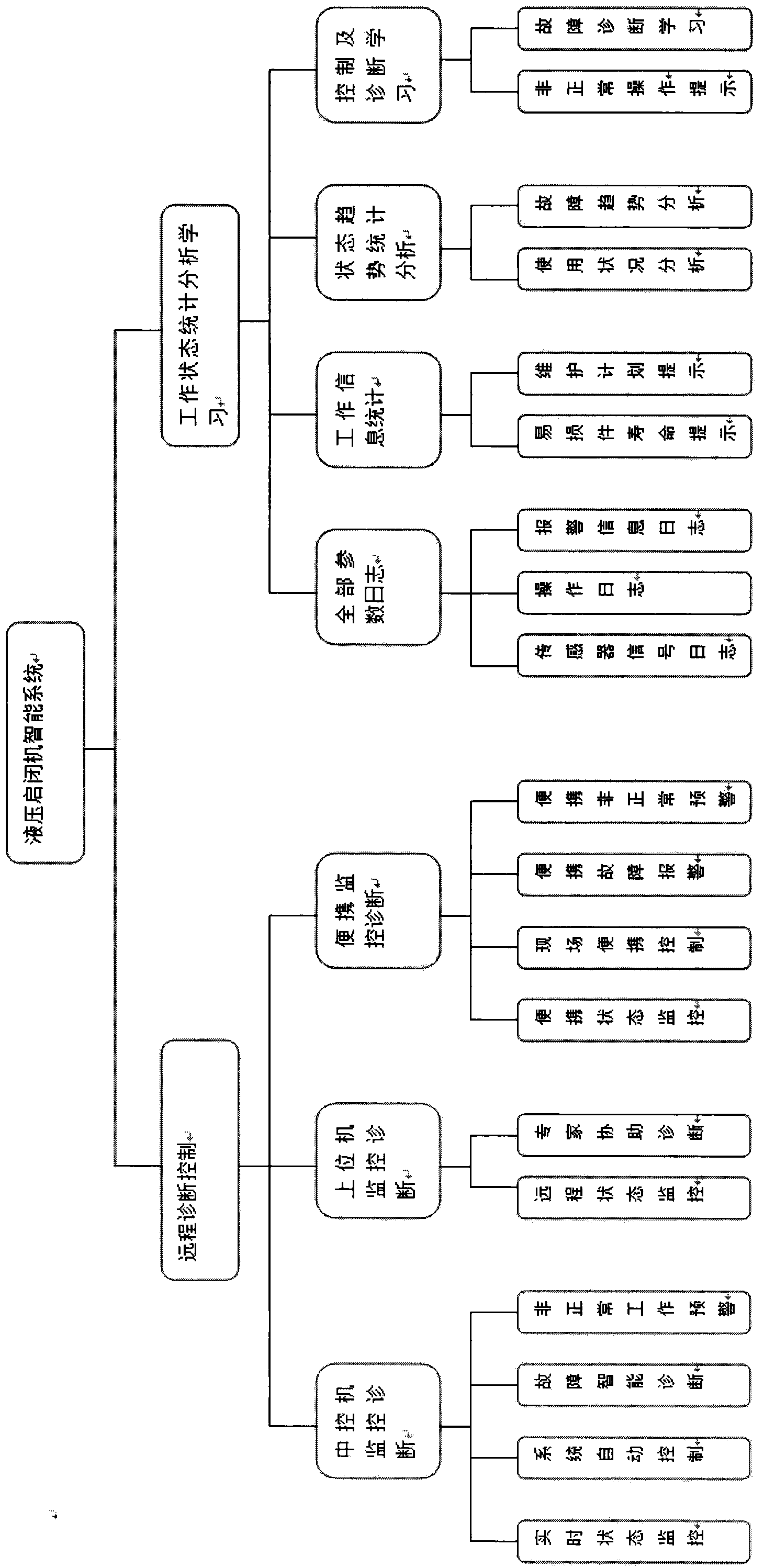

Intelligent hydraulic hoist

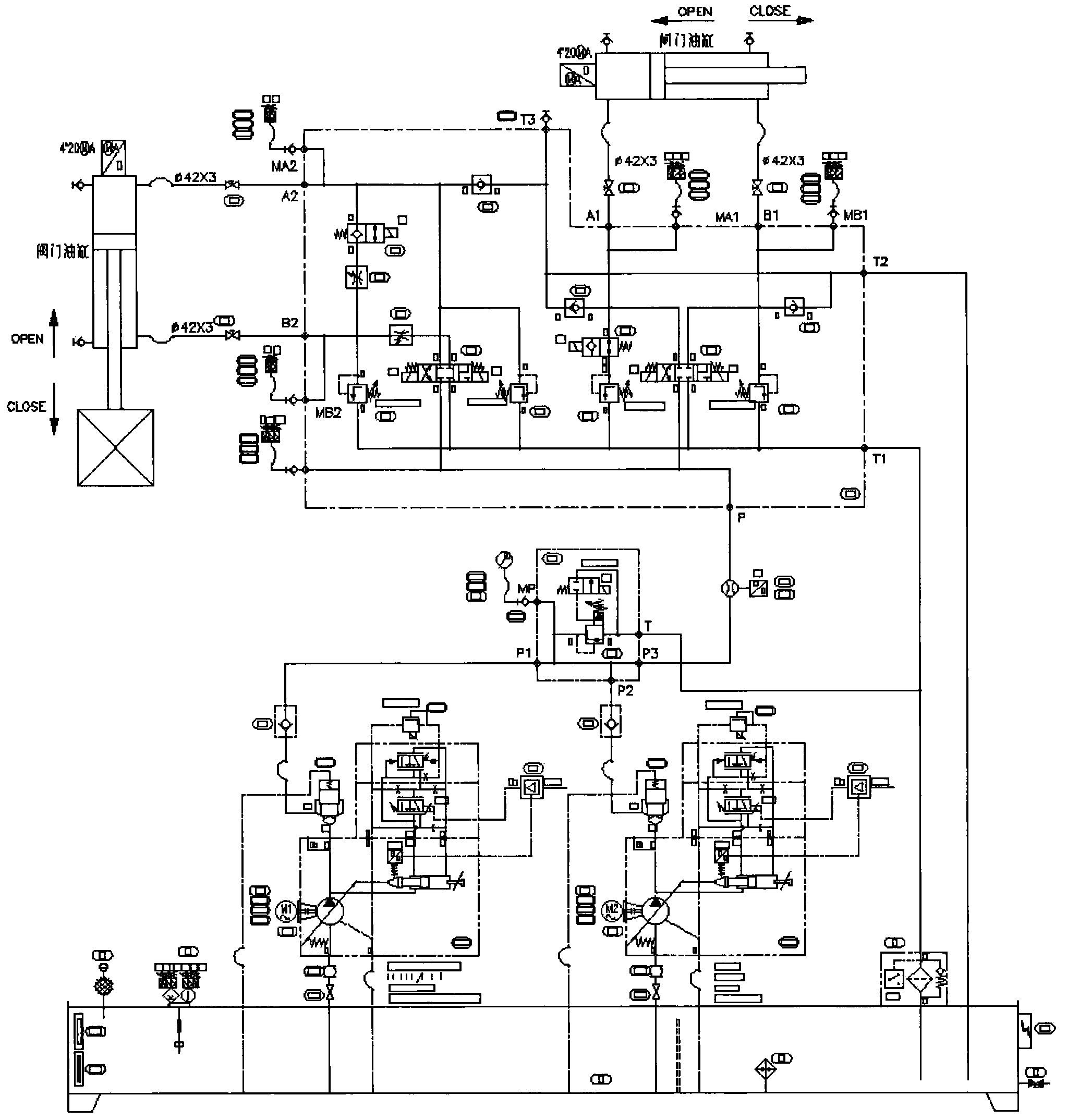

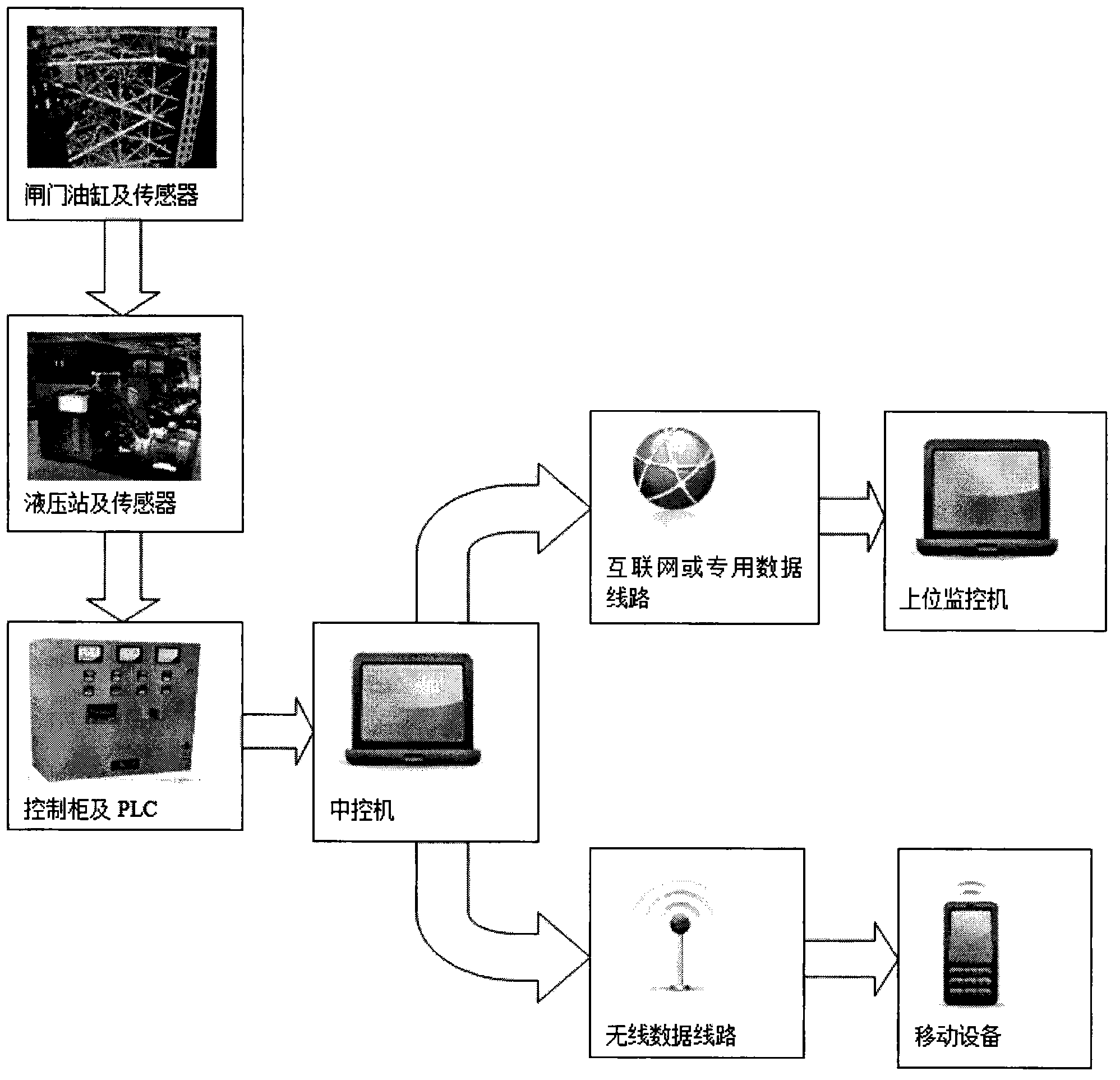

InactiveCN103669295AGood operabilityGood maintenance planBarrages/weirsInclined ship-liftingTime domainHydraulic cylinder

The invention relates to an intelligent hydraulic hoist which comprises a hydraulic cylinder, a hydraulic station, a control cabinet, a centralized control machine, an upper monitor and mobile equipment. The intelligent hydraulic hoist achieves operation condition real-time remote monitoring, operation abnormal condition and fault remote diagnosis and operation instruction automatic control. Monitoring data and prompting and alarming information are transmitted to the upper monitor through the Internet or a special data line, and the monitoring data and the prompting and alarming information are transmitted to the upper monitor through a wireless data line or mobile short messages. The intelligent hydraulic hoist is wholly intelligent and digitized, automatic control over operation is guaranteed, full time domain monitoring of working conditions is achieved, intelligent remote diagnosis of faults and abnormal operation is achieved, and an intelligent guarantee is provided for normal operation.

Owner:JIANGSU CHENGUANG SUNDE HYDRAULIC EQUIP

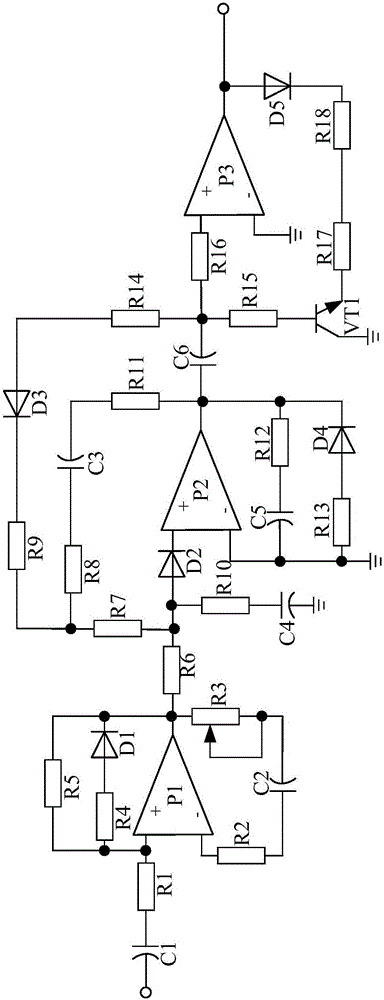

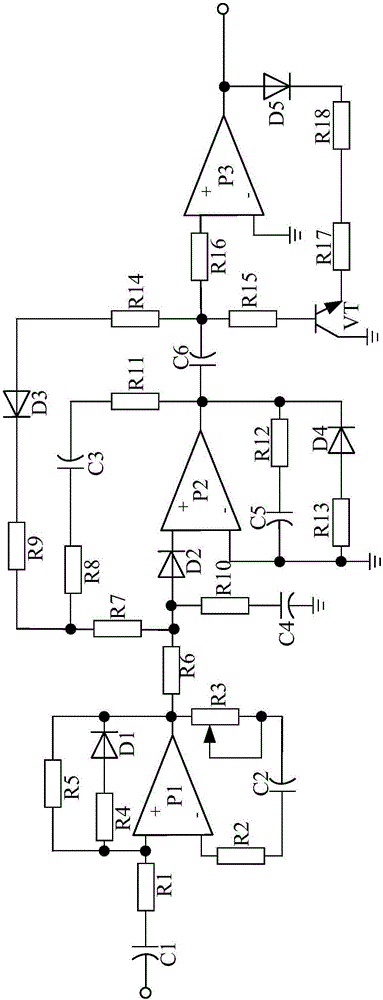

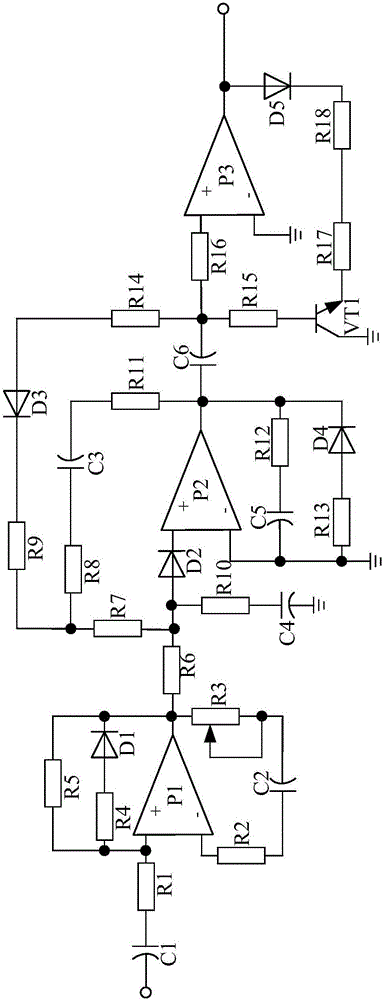

Intelligent temperature control system

InactiveCN105867468AControl heating temperatureEnsure automatic controlAuxillary controllers with auxillary heating devicesMicrocontrollerTemperature control

The invention discloses an intelligent temperature control system which comprises a single-chip microcomputer, a buzzer, a data memory, a vibration sensor, a power supply, a heater, a display screen and a signal filtering and amplifying circuit, wherein the buzzer, the data memory, the vibration sensor, the power supply, the heater, the display screen and the signal filtering and amplifying circuit are connected with the single-chip microcomputer. The intelligent temperature control system further comprises a temperature sensor which is connected with the signal filtering and amplifying circuit. The signal filtering and amplifying circuit comprises a signal acquiring circuit of which the input end is connected with the temperature sensor, and a double-order filtering and amplifying circuit of which the output end is connected with the output end of the signal acquiring circuit. The output end of the double-order filtering and amplifying circuit is connected with the single-chip microcomputer. According to the intelligent temperature control system, pot body vibration frequency information which is acquired by the vibration sensor and in-pot soup temperature information that is acquired by the temperature sensor are analyzed through the single-chip microcomputer. The intelligent temperature control system can effectively and automatically adjust heating temperature of the heater so that the temperature of the heater is constant, thereby keeping the temperature of the soup in the pot to a certain temperature and furthermore effectively saving electric power resource.

Owner:CHENGDU JUHUICAI TECH

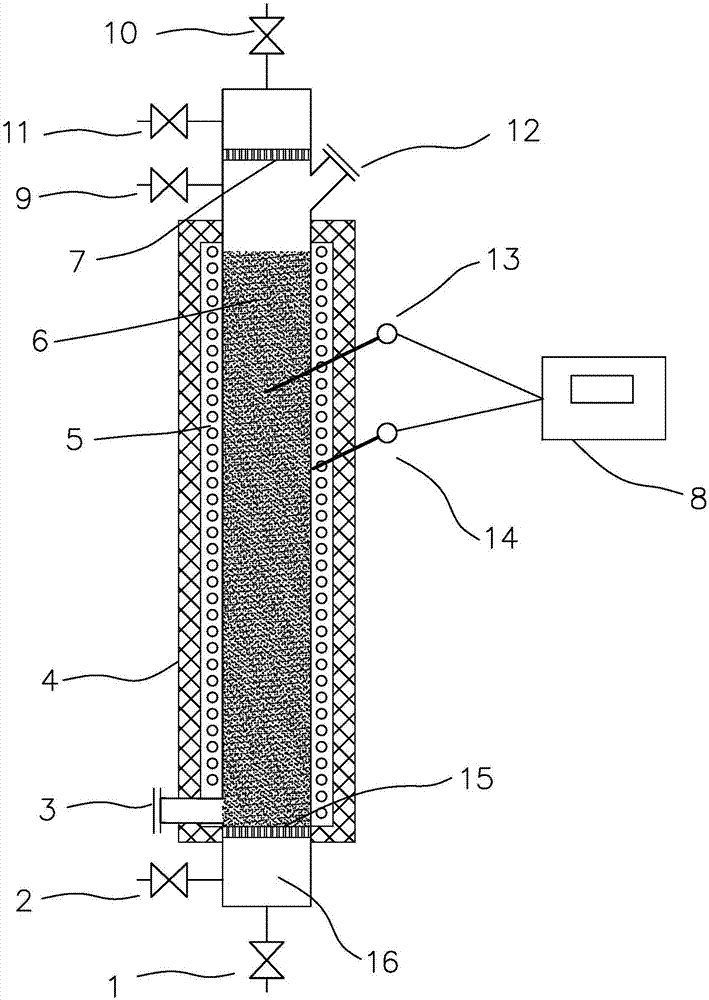

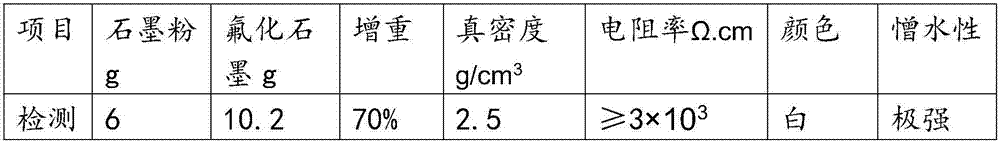

Fluorinated graphite tubular reactor

ActiveCN107128896AEnsure automatic controlWidely used valueChemical industryCarbon fluoridesPhysical chemistryGraphite

The invention relates to a fluorinated graphite tubular reactor which comprises a reactor body. The reactor body is internally provided with a gas mixing chamber, a lower filter layer, a reaction cavity and an upper filter layer sequentially from bottom to top. The lower portion of the gas mixing chamber is provided with a nitrogen inlet and a fluorine gas inlet; both the lower filter layer and the upper filter layer are sintered filter sieves; a heater is arranged on the outer side of the reaction cavity; an emptying valve is arranged at the top of the reactor body. The fluorinated graphite tubular reactor has advantages that high fluorination efficiency is achieved due to completeness in contact of graphite and fluorine gas; by arbitrary stacking of graphite in the reactor, the graphite layer thickness is increased, the utilization rate of the reaction cavity is high, and yield of each reactor is increased; in a production process, after fluorination in each reactor is finished, heating stopping of the reactor body is avoided in processes of discharging, new material replacement and supplementation, so that halting-free continuous production is realized, and operation efficiency is improved.

Owner:洛阳森蓝化工材料科技有限公司

An intelligent control device and method for coal mining machine travel

InactiveCN104533413BGuaranteed to workImprove work efficiencySlitting machinesCurrent transducerAutomatic control

Owner:CHINA UNIV OF MINING & TECH

Intelligent temperature control system based on A/D conversion circuit

InactiveCN105867457AControl heating temperatureEnsure automatic controlTemperatue controlMicrocomputerTemperature control

The invention discloses an intelligent temperature control system based on an A / D conversion circuit, which includes a single-chip microcomputer, a buzzer connected to the single-chip microcomputer, a data memory, a power supply, a heater, a display screen, an A / D conversion circuit and a signal filter Amplifying circuit, a vibration sensor connected to the input end of the A / D conversion circuit, and a temperature sensor connected to the input end of the signal filter amplification circuit; the output end of the A / D conversion circuit is connected to the single-chip microcomputer; the The output end of the signal filtering and amplifying circuit is connected with the single chip microcomputer. The vibration frequency information of the pot body collected by the vibration sensor and the temperature information of the soup in the pot detected by the temperature sensor are analyzed and processed by the single-chip microcomputer. Certain, so that the soup in the pot maintains a certain temperature, and at the same time, effectively saves power resources.

Owner:CHENGDU JUHUICAI TECH

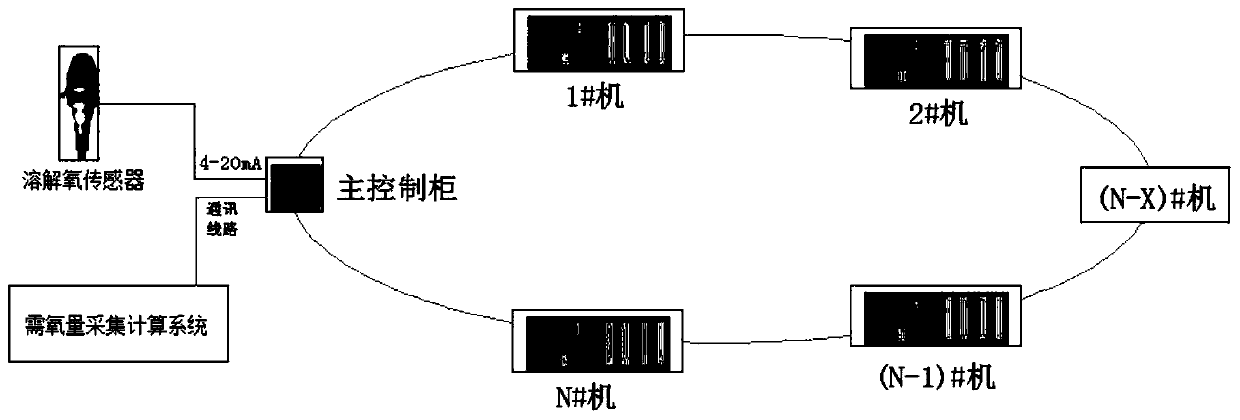

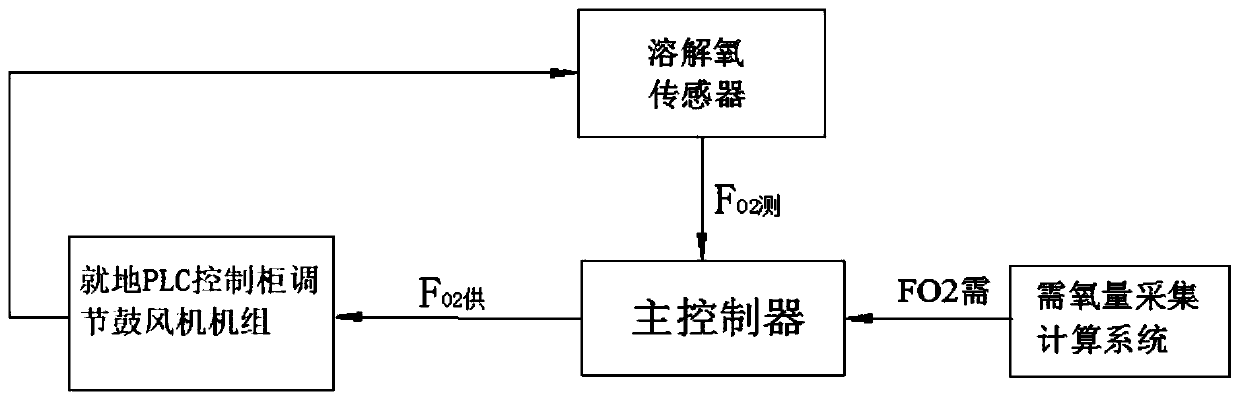

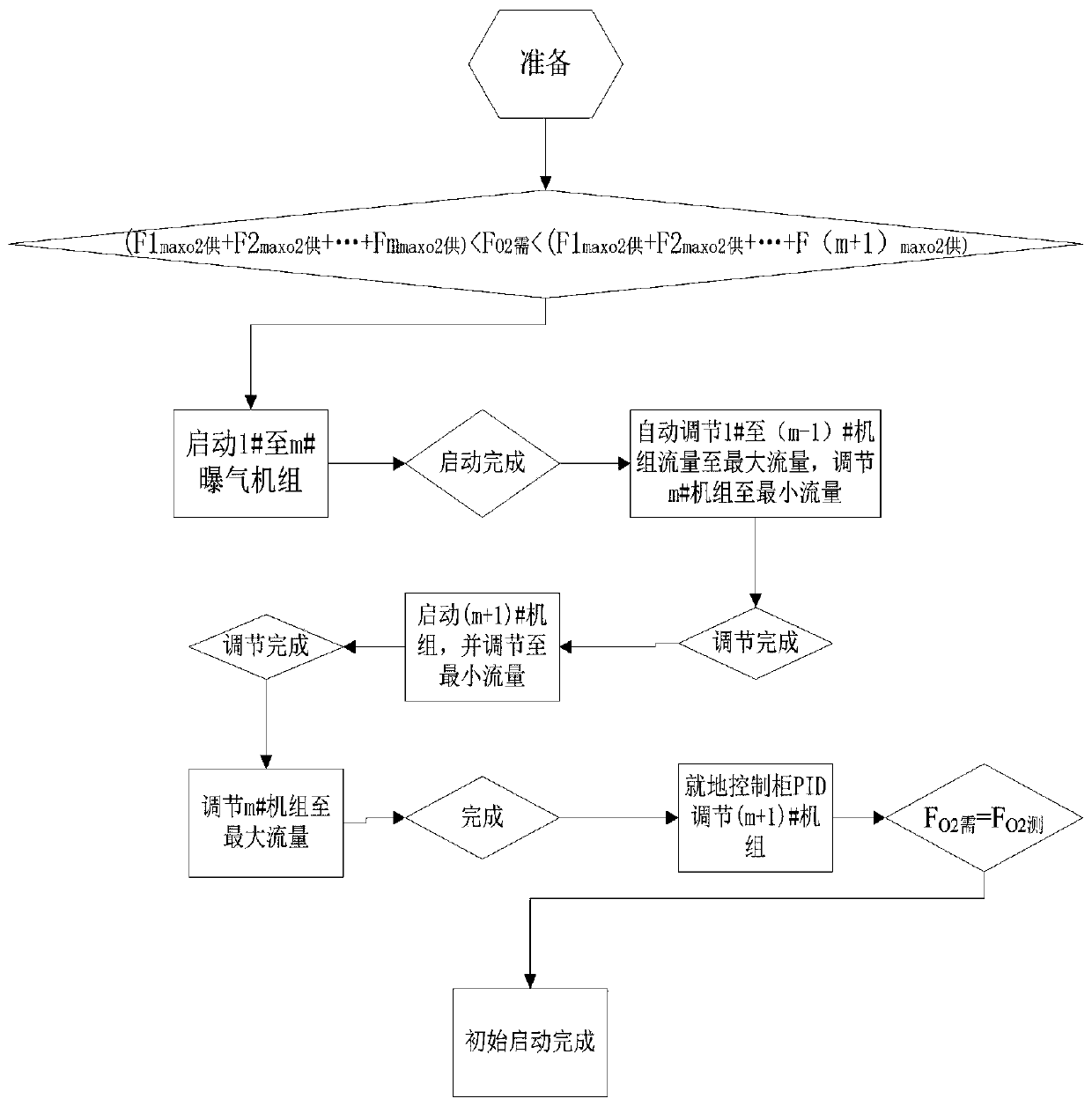

Automatic joint debugging system for multiple air blower units and control method thereof

InactiveCN109814374AQuick responseAccurate adjustmentWater aerationSustainable biological treatmentComputing systemsEngineering

The invention discloses an automatic joint debugging system for multiple air blower units and a control method thereof. The system includes several air blower units, a main control cabinet, a dissolved oxygen sensor and an oxygen demand acquisition and calculation system, wherein the dissolved oxygen sensor and the oxygen demand acquisition and calculation system are connected with the main control cabinet respectively. Each air blower unit is provided with a local PLC control cabinet for controlling the air blower unit, the local PLC control cabinet is connected with the main control cabinetthrough optical fiber, the dissolved oxygen sensor is used for measuring the oxygen amount of sewage, the oxygen demand acquisition and calculation system is used for collecting various parameter values of sewage and calculate the oxygen demand of sewage and sending the oxygen demand of sewage to the main control cabinet, the main control cabinet includes a PLC, and a PID control algorithm is integrated on the PLC controller. The main control cabinet regulates the oxygen supply of the multiple air blower units by controlling the oxygen supply of one air blower unit through the local PLC control cabinet.

Owner:CHONGQING JIANGJIN SHIPBUILDING IND

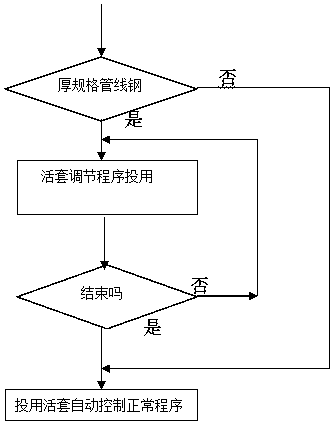

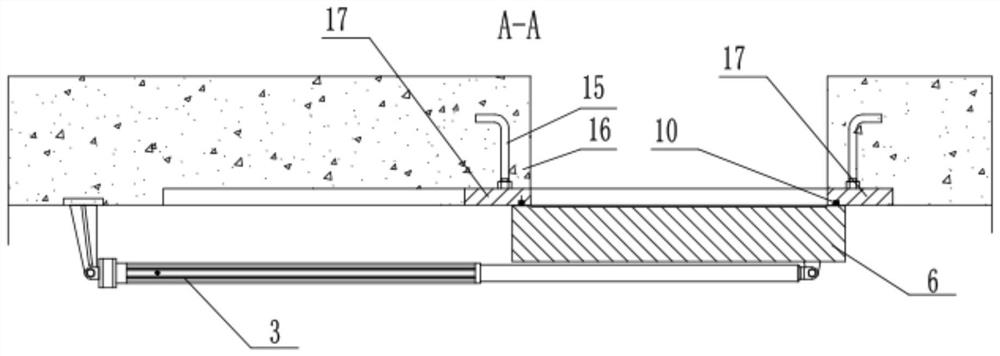

Steel loop control method for low-temperature wide material finishing mill frame of hot continuous rolling mill

InactiveCN105499278AEnsure automatic controlSolve problems such as vibrationMass flow control deviceMetal rolling arrangementsLoop controlAutomatic control

The invention relates to the field of hot continuous rolling low-temperature wide material special steel loop control, in particular to a steel loop control method for a low-temperature wide material finishing mill frame of a hot continuous rolling mill. The steel loop control method for low-temperature wide material finishing mill frame of the hot continuous rolling mill is characterized in that whether low-temperature wide material special band steel is rolled or not is judged; if so, a loop control technology is used until the rolling is completed; otherwise, a normal loop automatic control procedure is used; when the outlet temperature of a finishing mill frame of the band steel is lower than or equal to 850 DEG C, and meanwhile, the width is greater than or equal to 1350mm, the low-temperature wide material special band steel is rolled. The steel loop control method has the advantages that a low-temperature wide material special steel loop control technology is developed; the automatic control of a hydraulic loop during low-temperature wide material band belt rolling is ensured; during the low-temperature wide material band belt rolling, the problems of hydraulic loop oscillation between hot continuous rolling finishing mill frames, and the like are solved.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Stoves that use waste heat to generate steam

ActiveCN105841502BEvenly distributedReduce lossDomestic stoves or rangesCooking fumes removalAutomatic controlInlet valve

The invention relates to a cooking range generating steam by using waste heat. The cooking range a furnace body, a furnace head and a water tank, wherein the furnace body is combined by an inner furnace wall and an outer furnace wall; a hollow region surrounded by the inner furnace wall is a hearth; a plurality of tubular fire bars are uniformly arranged below the hearth at intervals in the furnace body; the furnace head comprises an outer furnace ring, an inner furnace ring and a pot body supporting ring; the lower end of the inner furnace ring is connected to the inner furnace wall; the lower end of the pot body supporting ring is connected to the outer furnace wall; a cavity among the inner wall furnace, the outer wall furnace and the furnace head is a heating cavity; a coil surrounding the hearth is arranged in the heating cavity; a steam pipe communicating with the top of the heating cavity is arranged in the upper part of the water tank; a water outlet pipe communicating with the bottom of the heating cavity is arranged in the lower part of the water tank; a gas outlet pipe is arranged on the top of the water tank; a water inlet is formed between the steam pipe and the water outlet pipe on the water tank; and a float ball water inlet valve is arranged on the water inlet. The cooking range provided by the invention realizes efficient recovery of smoke heat and automatic control of water inflow in a stove using process.

Owner:JIANGSU SHENGONG STOVE CO LTD

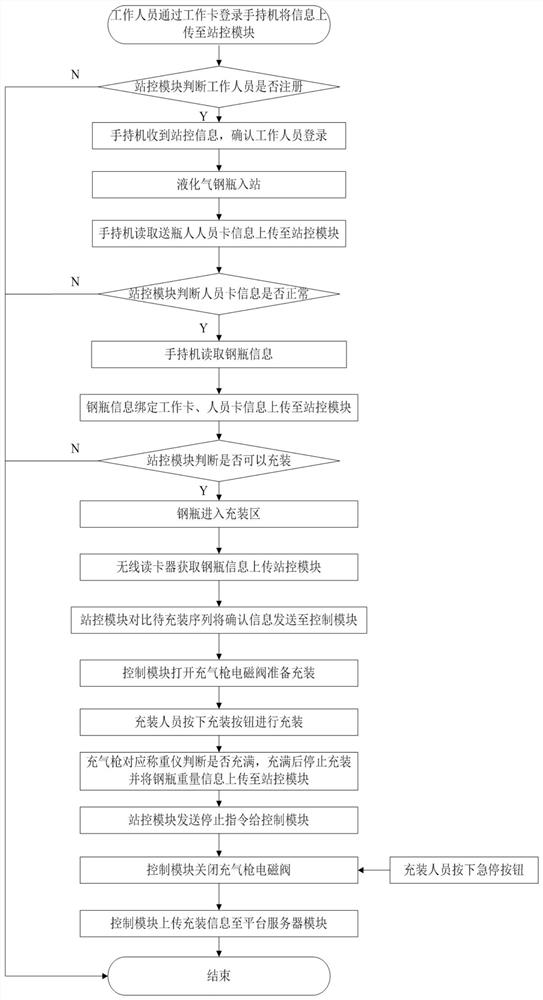

Filling control system and method for liquefied petroleum gas steel cylinder

PendingCN114484269AStandardize the operation processStrengthen supervisionVessel mounting detailsData processing applicationsControl systemCard reader

The invention discloses a filling control system and method for a liquefied petroleum gas steel cylinder. The system comprises a handset, a wireless card reader, a station control module and a control module, the handset and the wireless card reader are respectively in wireless communication connection with the station control module; the handset is used for collecting personal information of a worker and steel cylinder information and binding the personal information with the steel cylinder information; the wireless card reader is used for reading steel cylinder information; the station control module is used for verifying personal information of workers and steel cylinder information, sorting steel cylinders according to the read steel cylinder information and distributing filling positions for the steel cylinders; the control module is provided with a filling gun electromagnetic valve control port, and the filling gun electromagnetic valve control port is electrically connected with a filling gun electromagnetic valve. According to the filling control system of the liquefied petroleum gas steel cylinder, supervision on workers is enhanced, the operation process of the steel cylinder filling process is standardized, and potential safety hazards are reduced.

Owner:新疆西北星信息技术有限责任公司

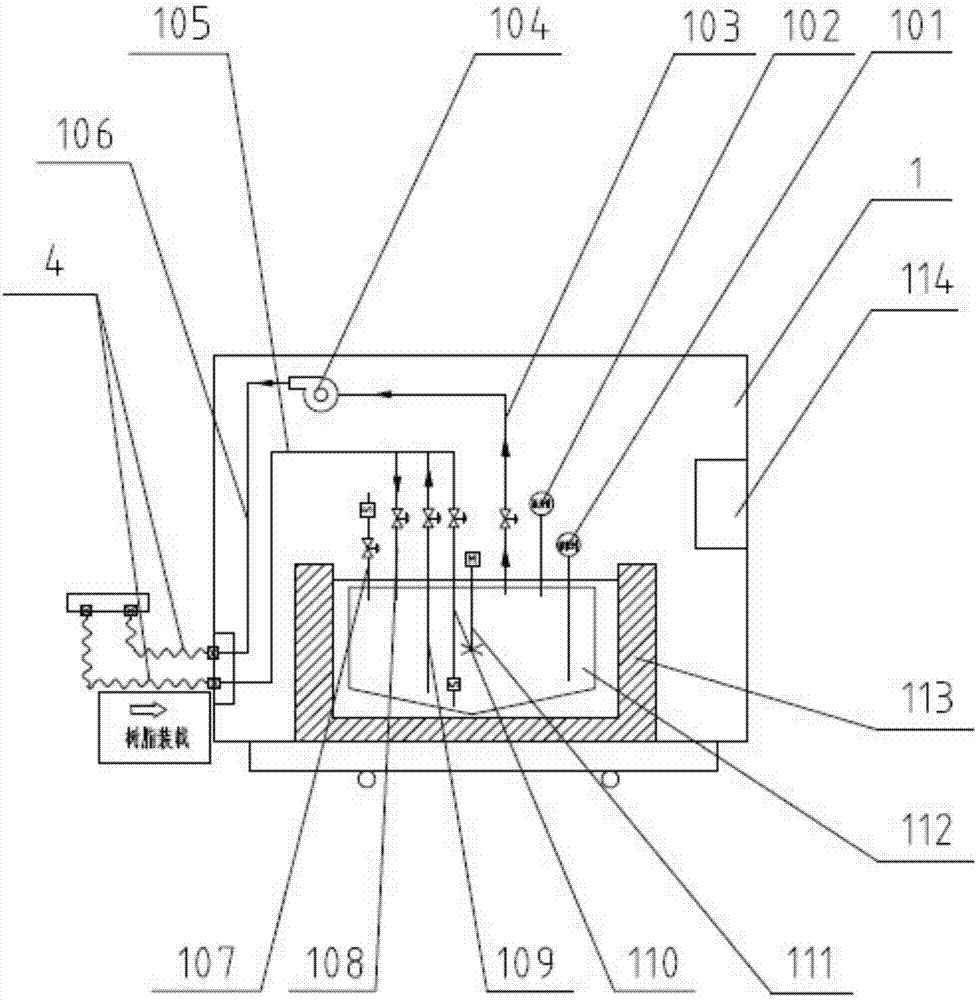

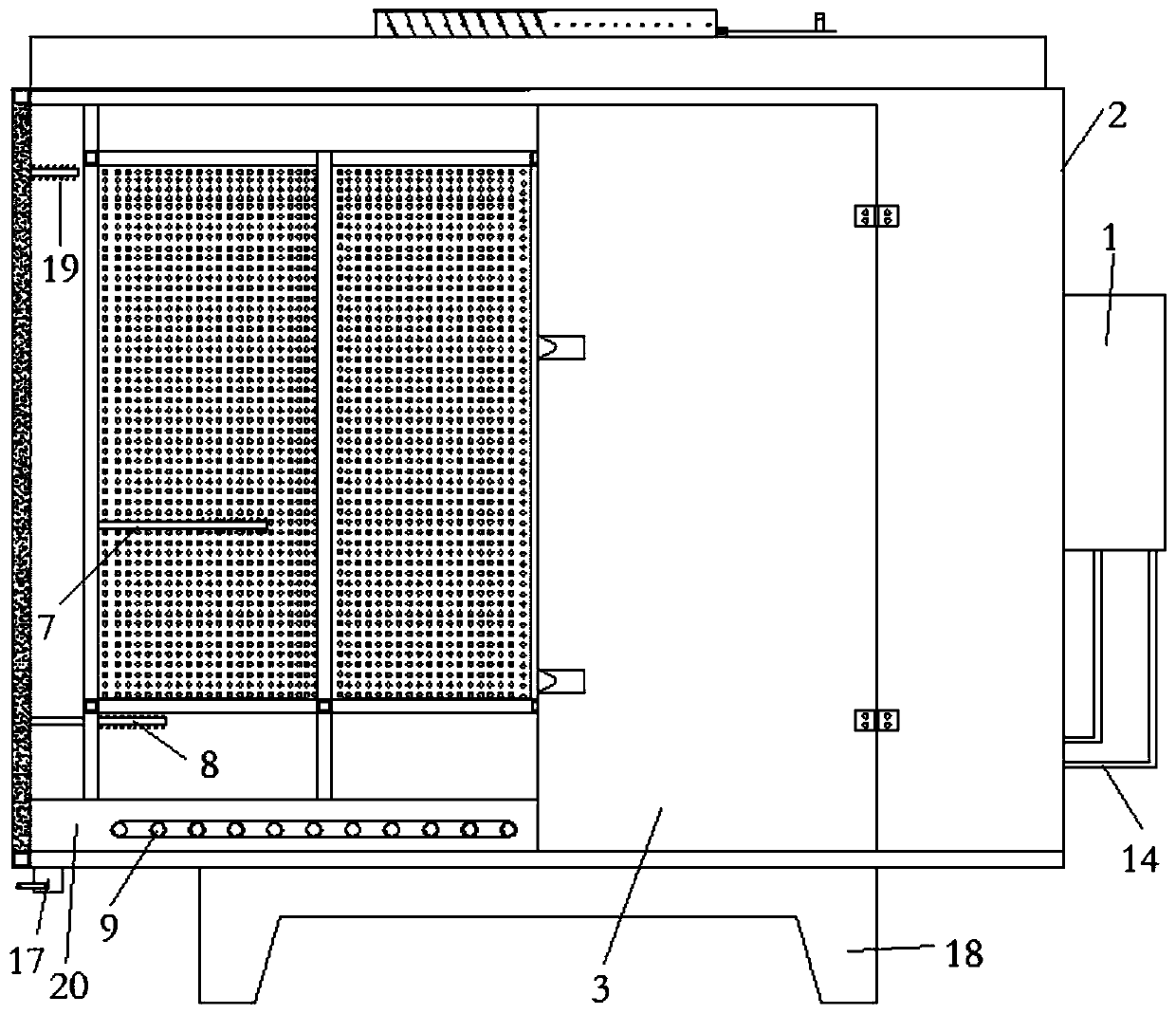

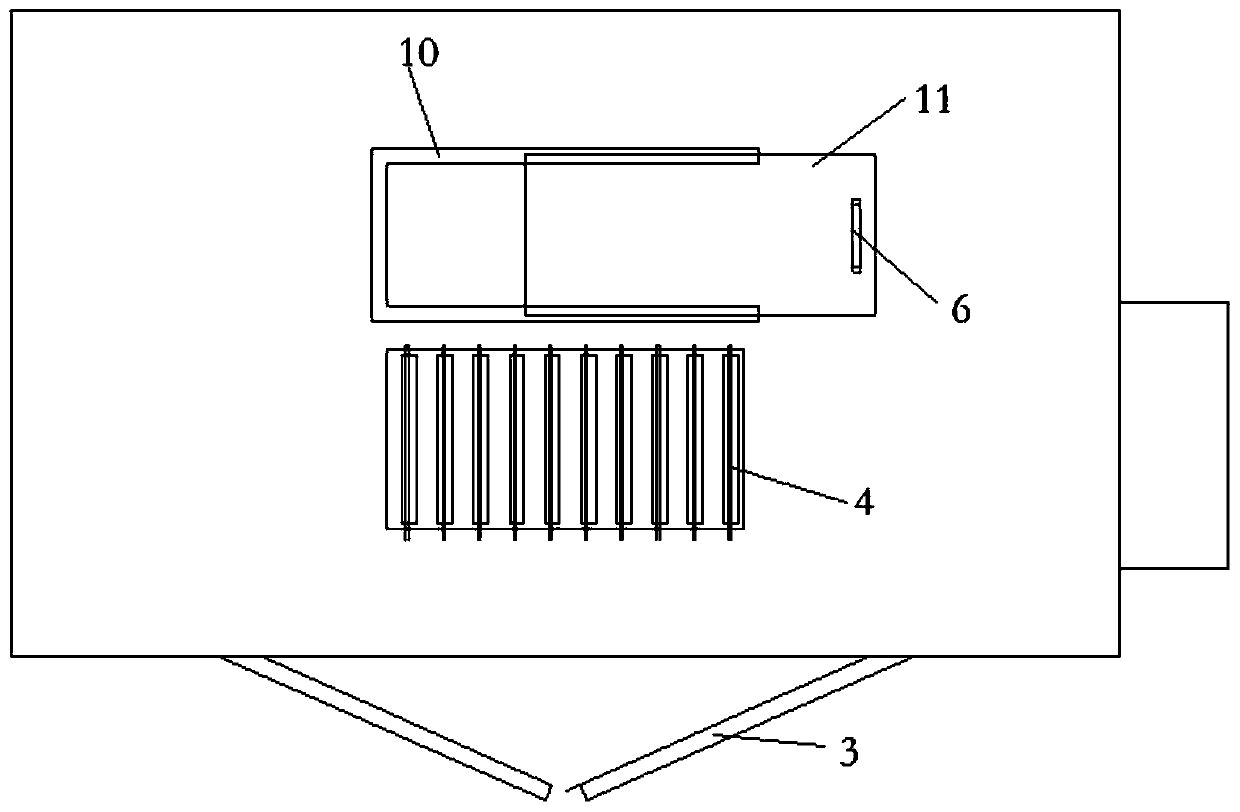

Box-type piling machine for dark green tea

PendingCN109874884APrevent drynessGuaranteed qualityPre-extraction tea treatmentTemperature controlGreen tea

The invention discloses a box-type piling machine for dark green tea. The box-type piling machine comprises a box body, a feeding mechanism, a humidity control mechanism, a temperature control mechanism, a piling mechanism and a controller. The feeding mechanism comprises a feeding port, and the feeding port is formed in the top of a shell; the piling mechanism comprises a piling bin, a bracket and a piling temperature sensor, wherein the piling bin is positioned in the box body, the top of the piling bin is open, and the piling bin comprises an inner bin baseplate and inner bin side walls; the piling temperature sensor is fixed to the corresponding inner bin side wall in the piling bin; the humidity control mechanism comprises a ventilation window and a humidity sensor; the ventilation window is mounted on the top of the shell, and the temperature control mechanism comprises a box temperature sensor, a heat exchange element and a heater, wherein the heat exchange element is mounted onthe inner side of the bottom of the shell; the piling bin is positioned right above the heat exchange element, the humidity sensor and the box temperature sensor are both mounted in the box body andpositioned outside the piling bin, and the humidity sensor, the ventilation window, the box temperature sensor and the heater are separately connected with the controller. The piling machine has a simple structure and can meet the requirements of traditional piling fermentation.

Owner:HUAZHONG AGRI UNIV +1

Soaking and conveying system for walnut kernels

ActiveCN114751194ASoaking achievedImprove working environmentCharge manipulationFood shapingWorking environmentProcess engineering

The invention provides a walnut kernel soaking and conveying system, and belongs to the technical field of food processing, and the walnut kernel soaking and conveying system comprises a surge bin suitable for storing walnut kernels subjected to alkali washing and astringency removal; the multiple soaking bins are communicated with the buffering bin, the interiors of the soaking bins are communicated with a water inlet pipeline and a water outlet pipeline, and discharging openings suitable for discharging walnut kernels are formed in the soaking bins; a discharging control assembly is arranged at the communication position of the soaking bin and the buffering bin and comprises a gate plate with an opening position and a closing position and a driving assembly suitable for controlling the gate plate to be switched between the opening position and the closing position. According to the soaking and conveying system for the walnut kernels, operators are saved, meanwhile, the labor intensity is greatly reduced, the effects of protecting ground facilities and reducing potential safety hazards are achieved, the working environment of a workshop is improved to a certain degree, and the temperature of the working environment is reduced to a certain degree.

Owner:HEBEI YANGYUAN ZHIHUI BEVERAGE

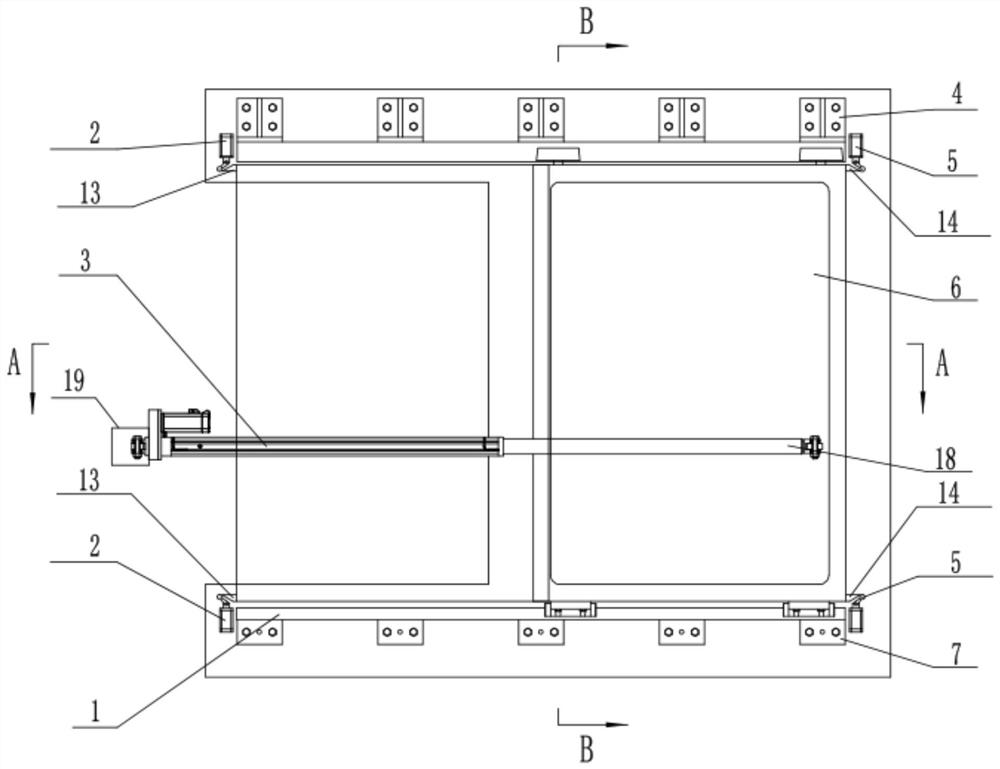

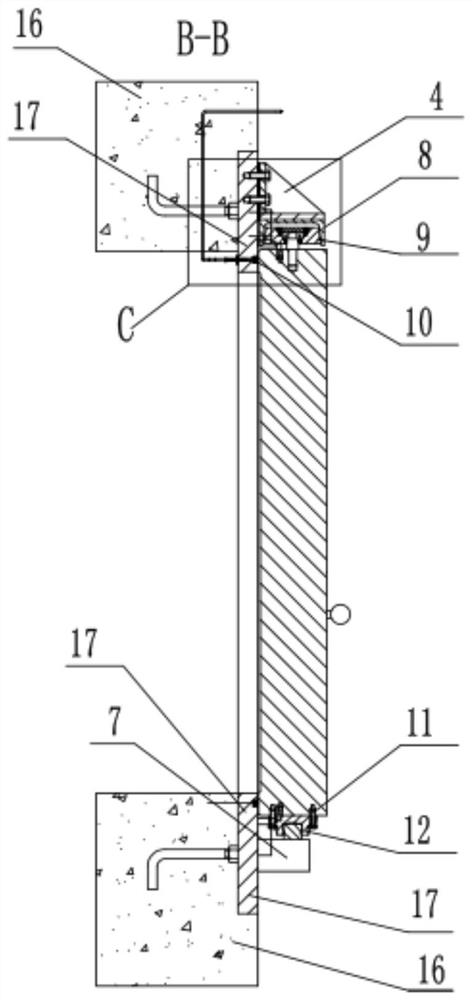

Structure and control method of shielded airtight door

ActiveCN110206469BImprove working environmentReduce workloadPower-operated mechanismSealing arrangementsElectric machineryStructural engineering

The invention discloses a shielded and sealed door structure. The shielded and sealed door structure is arranged in a access passage of a workshop or a factory for shielding and sealing required by the nuclear industry, the end, provided with a motor, of an electric push rod is fixed to a wall, the end, provided with a telescopic push rod, of the electric push rod is fixed to a door plate, and theelectric push rod is used for driving the reciprocating horizontal moving motion of the door plate; an upper guide rail is connected with the upper end edge of the door plate in a rolling mode, a lower guide rail is slidably connected with the lower end edge of the door plate, the upper guide rail and the lower guide rail are fixed to the wall body, an opening travel switch is arranged on the wall body at the limiting position where the door plate is completely opened, and a closed travel switch is arranged on the wall body at the limiting position where the door plate is completely closed; and when the door plate is completely closed, the door plate is connected with walls of the periphery of the access passage through an elastic sealing part in a sealing mode. The shielded and sealed door structure aims to solve the problem that a sealing door in the prior art has the heavy weight and is not prone to opening and closing manually, and has the technical effects that the automatic opening and closing of the sealing door is achieved, the workload of the manual operation is reduced, and the shielding and sealing effect is good.

Owner:CHINA NUCLEAR POWER ENG CO LTD

A looper control method for pipeline steel

ActiveCN103990652BEnsure automatic controlRealize automatic controlTension/compression control deviceLine tubingAutomatic control

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Automatic control device and control method for contact force transfer displacement of electrospark deposition surfacing welding

ActiveCN112756743BRealize closed-loop controlHigh strengthWelding accessoriesAutomatic controlLoop control

The invention relates to an automatic control device and a control method for the displacement displacement of the contact force of EDM surfacing, wherein the automatic control device is mainly composed of a feed mechanism, a floating elastic mechanism, a gun clamp mechanism, a welding torch and an electric control system, and the electrode and the workpiece The contact force between them is transformed into the displacement of the floating slide table, and the non-contact displacement sensor is used for detection, which realizes the transformation from tension pressure measurement to displacement measurement, which not only improves the strength of the mechanical system, but also realizes the measurement of tiny contact force; according to the floating The displacement of the sliding table determines the contact force between the electrode and the workpiece, and the controller and the feed mechanism are used to control the movement of the electrode along its axis to realize the closed-loop control of the contact force. The spring damping of the floating elastic mechanism can reduce the distance between the electrode and the workpiece. The vibration between the electrode and the workpiece significantly improves the stability and reliability of the automatic control of the contact force between the electrode and the workpiece during the deposition process.

Owner:HENAN UNIV OF SCI & TECH

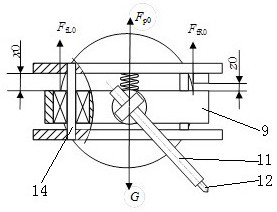

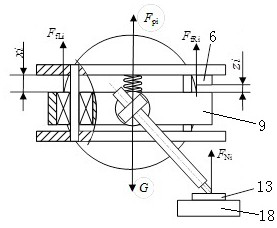

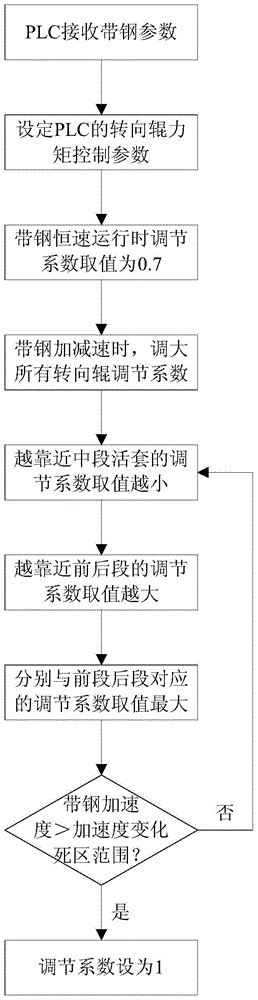

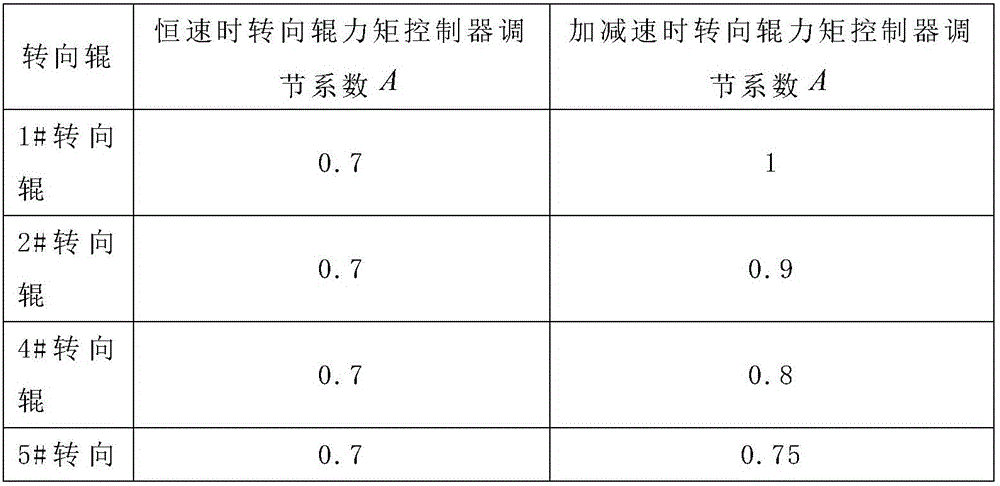

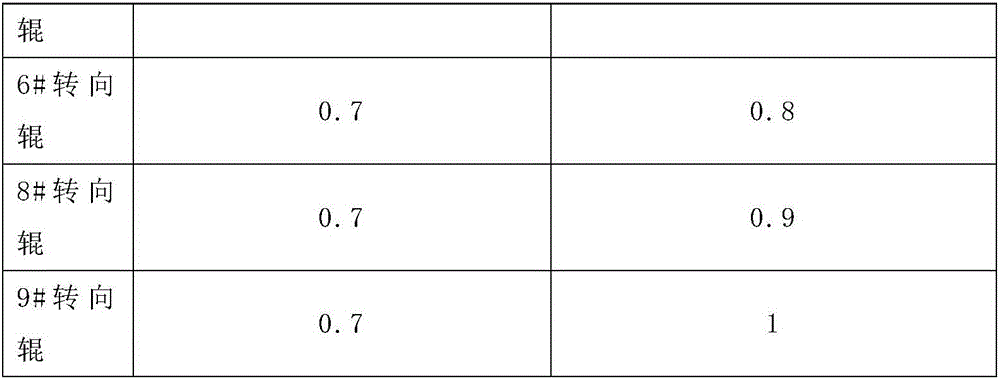

Steering roller control method to ensure stable strip steering on processing line

ActiveCN104492820BRealize automatic controlSolve problems such as steering oscillationRoll mill control devicesMetal rolling arrangementsStrip steelUltimate tensile strength

The invention discloses a steering roller control method for guaranteeing steering stability of strip steels on a treatment line. The method comprises the following steps: (1) a PLC receives the yield strengths and the thickness parameters of the strip steels operating on the treatment line; (2) the steering roller moment control parameters Qn of the PLC are set according to the parameters; (3) when the strip steels operate on the treatment line with constant speed, steering roller moment controllers are controlled through setting the adjusting coefficients A as the minimum value; when the strip steels operate with decreased speed or increased speed, the adjusting coefficients A of all the steering roller moment controllers are increased; and when the accelerations of the strip steels operating with decreased or increased speed are beyond the acceleration change dead area range, the adjusting coefficients A of all the steering roller moment controllers are set as the maximum value. The method can guarantee the steering stability of steering rollers and prevent the influence of the steering oscillation on the product quality, and can be widely applied to the technical field of strip steel production.

Owner:通用电气(武汉)自动化有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com