Intelligent hydraulic hoist

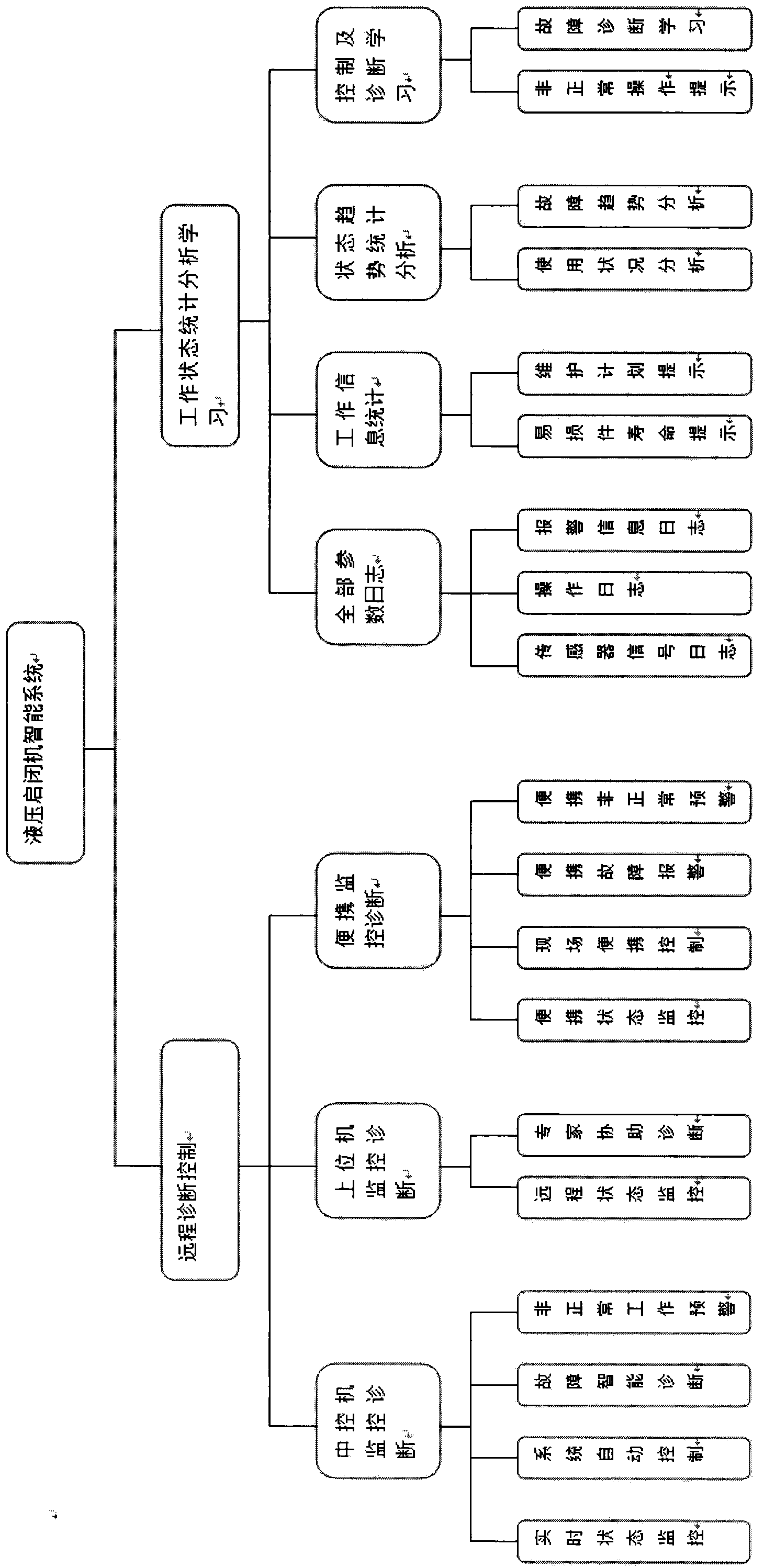

A technology of hydraulic hoist and hydraulic station, which is used in vertical lifting of ship machinery, machinery for lifting ships along slopes, hydraulic engineering, etc., can solve the problems of waste of maintenance, prone to errors, and inability to completely match the use conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

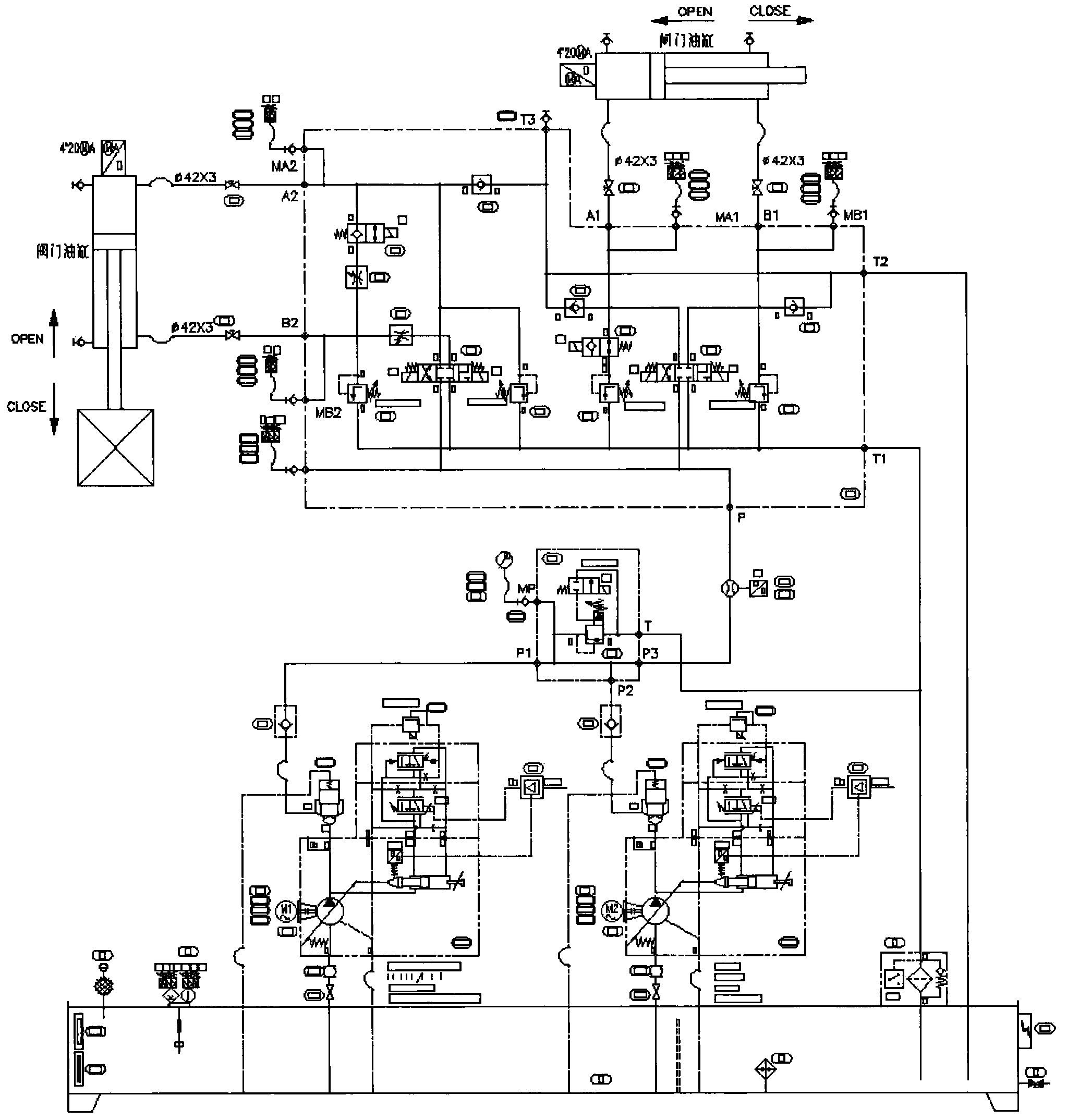

Method used

Image

Examples

Embodiment 1

[0037] The present invention is as follows to the discovery processing step of oil pollution:

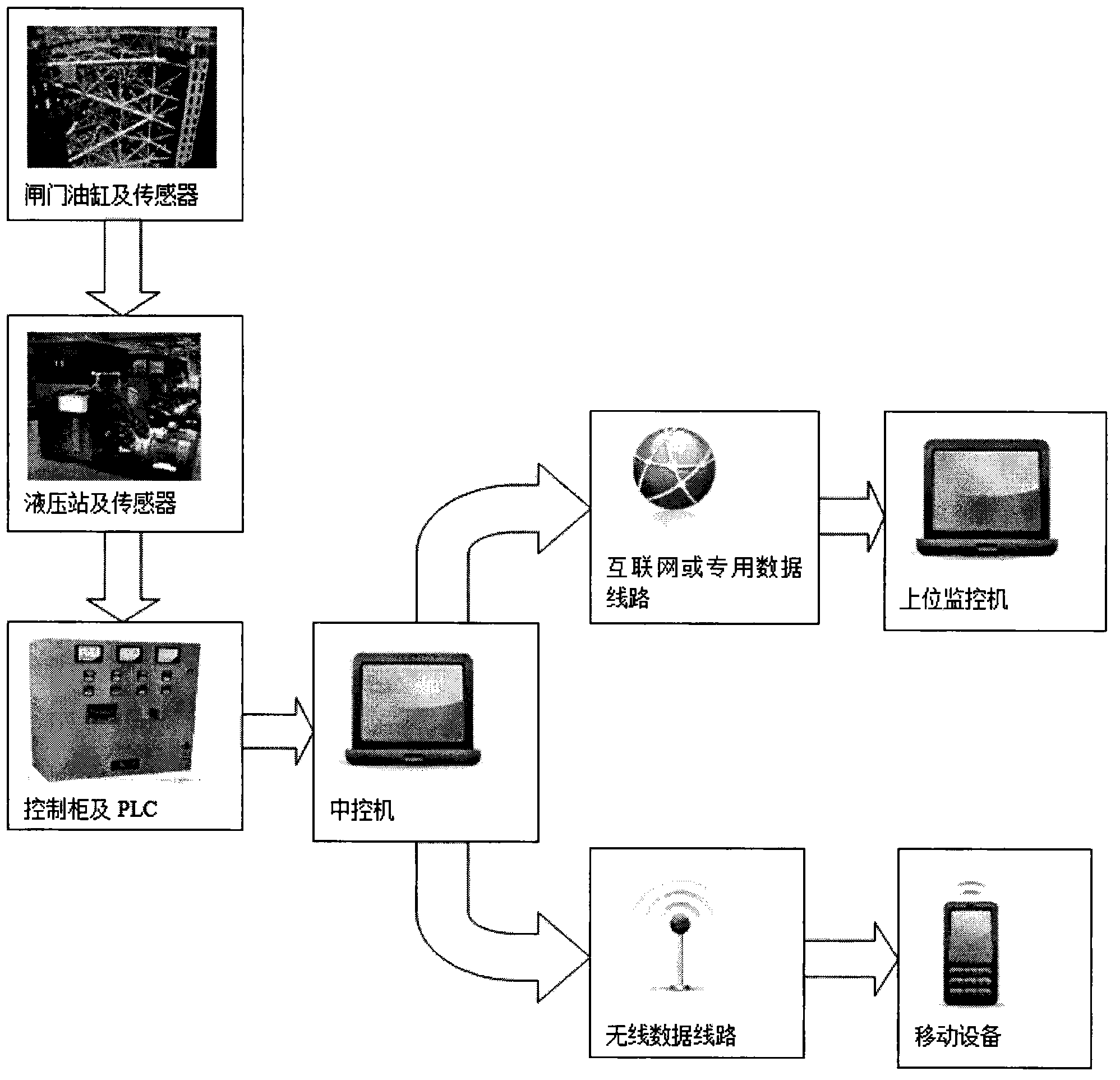

[0038] During operation, the oil resistance and oil transparency sensors feed back the data of oil conductivity and oil transmittance in real time. When the conductivity exceeds the set threshold and the light transmittance is lower than the set threshold, the central control system will give the oil Pollution alarm and reminder to check and replace the oil, and send the warning information to the upper monitoring machine and portable equipment, and send a short message to the set mobile phone number at the same time.

[0039] When only the conductivity exceeds the set threshold, the central control computer system will analyze the historical data log. If the recent conductivity data shows a continuous upward trend, the central control computer system will give an oil pollution alarm and prompt to check and replace the oil, and will warn The information is sent to the host monitorin...

Embodiment 2

[0042] The present invention controls the automatic deviation correction of the gate during installation, commissioning and maintenance as follows:

[0043] Select automatic gate deviation correction on the on-site portable control device, the system checks the cylinder stroke position data, and controls all cylinders to move synchronously to the half-extended state; the system checks the gate level sensor data, judges the deviation on both sides according to the sensor data, and slowly lifts the low side cylinder to The sensor gives the level data; it gives a prompt that the gate deviation is in place, wait for confirmation, and after confirmation, set the stroke positions of the cylinders on both sides to bind synchronously.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com