Patents

Literature

54results about How to "Reduce abnormal downtime" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sharing maintenance system ensuring normal operation of wind turbines and realization method thereof

ActiveCN102621971AReduce abnormal downtimeIncrease profitProgramme total factory controlRenewable energy source integrationCondition monitoringDiagnostic system

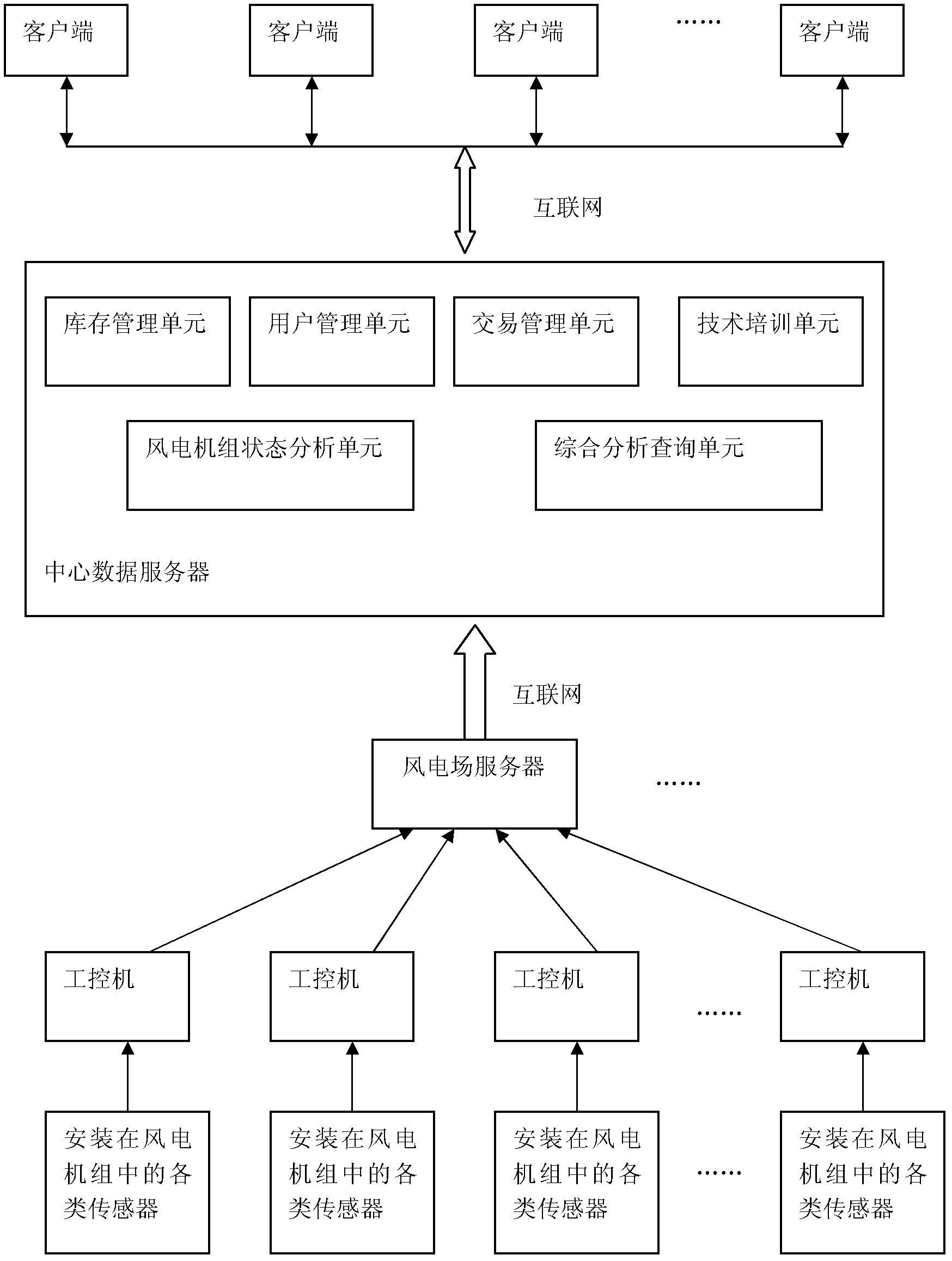

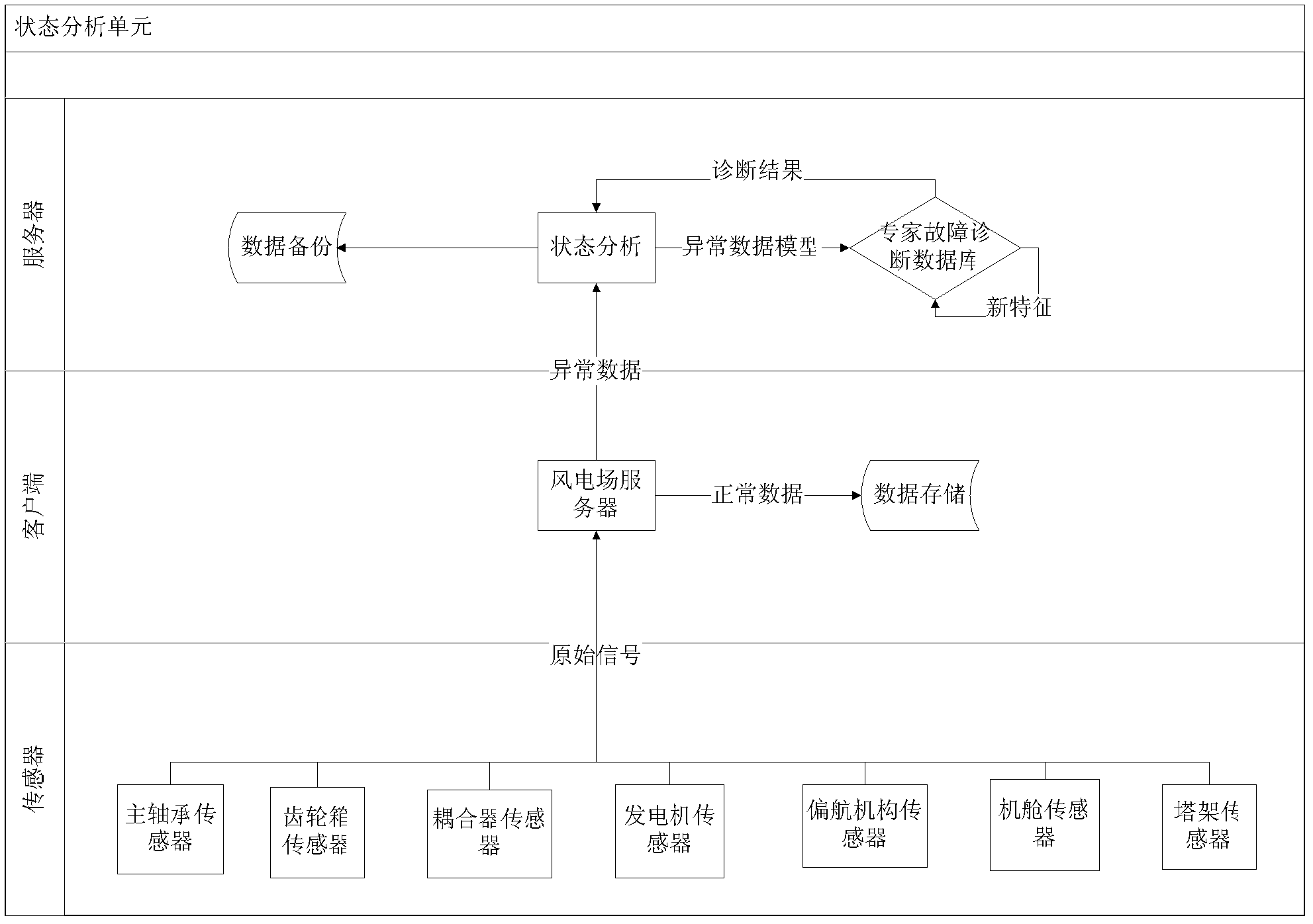

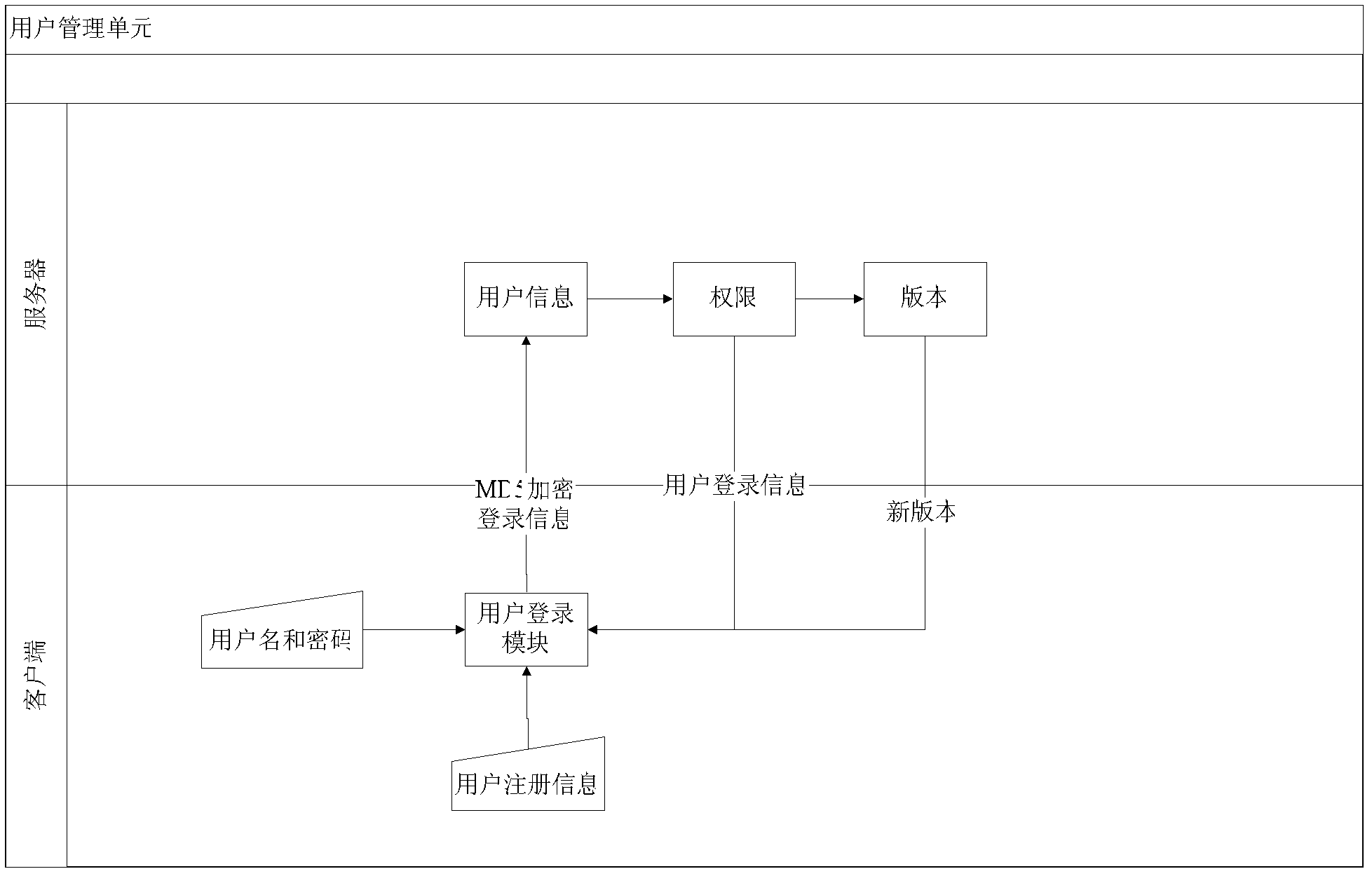

The invention relates to the field of wind power generation, and provides a sharing maintenance system ensuring normal operation of wind turbines and a realization method thereof. The sharing maintenance system can rapidly diagnose the failure state of the wind turbines and effectively solve the problems of difficult building of the spare parts store of each wind power plant and difficult technical training for maintenance personnel. The sharing maintenance system is characterized in that the system comprises a wind turbine state monitoring device and a central data server, wherein the central data server is mainly composed of a wind turbine state analyzing unit, a user management unit, an inventory management unit, a transaction management unit, a technical training unit and a comprehensive analysis inquiring unit. The central data server is provided with a client-side interactive interface, and a user can use the client-side interactive interface to operate on a client-side computer through a network. By adopting the system, the sharing and the regulation of spare part inventory among different wind power plants can be realized. The system provides a professional assurance for wind power plant hosts to rapidly diagnose the failure state of the system and produces a great promotion role for increasing the operation reliability, safety and economic benefit of the wind power plants.

Owner:上海探能实业有限公司

Loop control method of special thick steel at low temperature

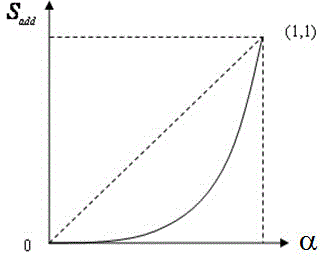

InactiveCN102430591AEnsure automatic controlRealize automatic controlMeasuring devicesFlexible work arrangmentsLoop controlHeight difference

A loop control method of special thick steel at low temperature is disclosed, and aims to overcome the loop oscillation among precision rolling frames and ensure normal production of hot rolling. The method comprises the steps of: determining the control parameters of the loop among the frames by a first level computer according to the following formula if the target temperature at the strip steel precision rolling outlet is lower than 830 DEG C and the thickness of the product is greater than 7mm: Yn=Yn-1+Kp*{[1+TA / TN]*deltaYn-deltaYn-1}, wherein Yn is the additional quantity m / s of the loop height to the frame speed at sampling moment n; TA is program scanning time; TN is time of integration; Kp is proportional coefficient; deltaYn is loop height difference mm at sampling movement n; and transmitting downward by a second level computer to distinguish the loop tension set values of steels so as to give the torque of the loop.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

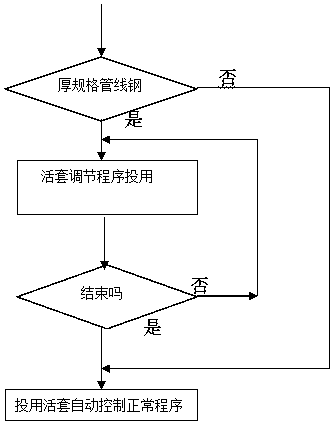

Movable sleeve control method for pipeline steel

ActiveCN103990652ADelay adjustment response speedMeet the control process requirementsTension/compression control deviceLine tubingStructural engineering

The invention provides a movable sleeve control method for pipeline steel, and belongs to the field of steel rolling. The method includes the steps that firstly, control parameters of movable sleeves between every two adjacent machine frames are determined through a first-stage computer and a second-stage computer according to the following formulas, wherein the target temperature of a strip steel finish rolling outlet is smaller than or equal to 810 DEG C, and the thickness of a finished product is larger than or equal to 8 mm; secondly, a table model of movable sleeve steel type tension coefficients is set up through the second-stage computer according to the requirements for process data and steel types, and steel type tension coefficients of different movable sleeves are obtained by looking up a table and sent out through the second-stage computer during rolling. By means of the movable sleeve control method, the hydraulic movable sleeves between the hot continuous rolling finish rolling machine frames are automatically controlled when the pipeline steel is rolled, the problem that the hydraulic movable sleeves between the hot continuous rolling finish rolling machine frames vibrate is solved when the pipeline steel is rolled, and abnormal shutdown time is shortened.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Method and device for avoiding abnormal shutdown of air conditioner caused by voltage leap and air conditioner

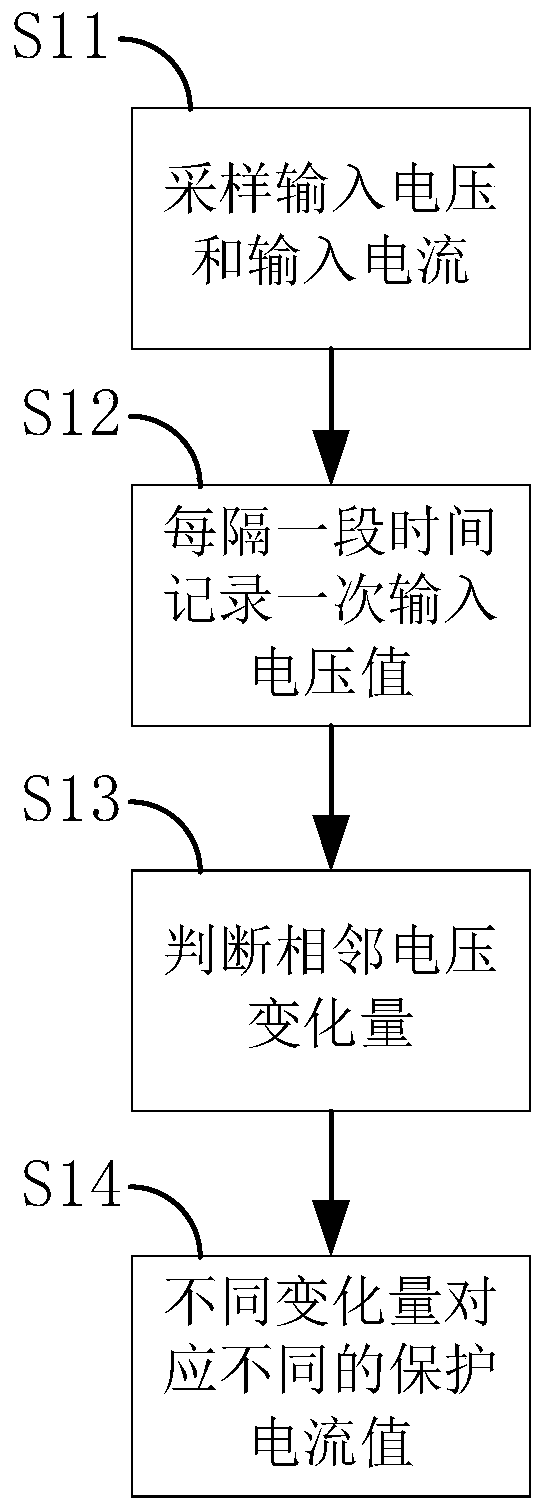

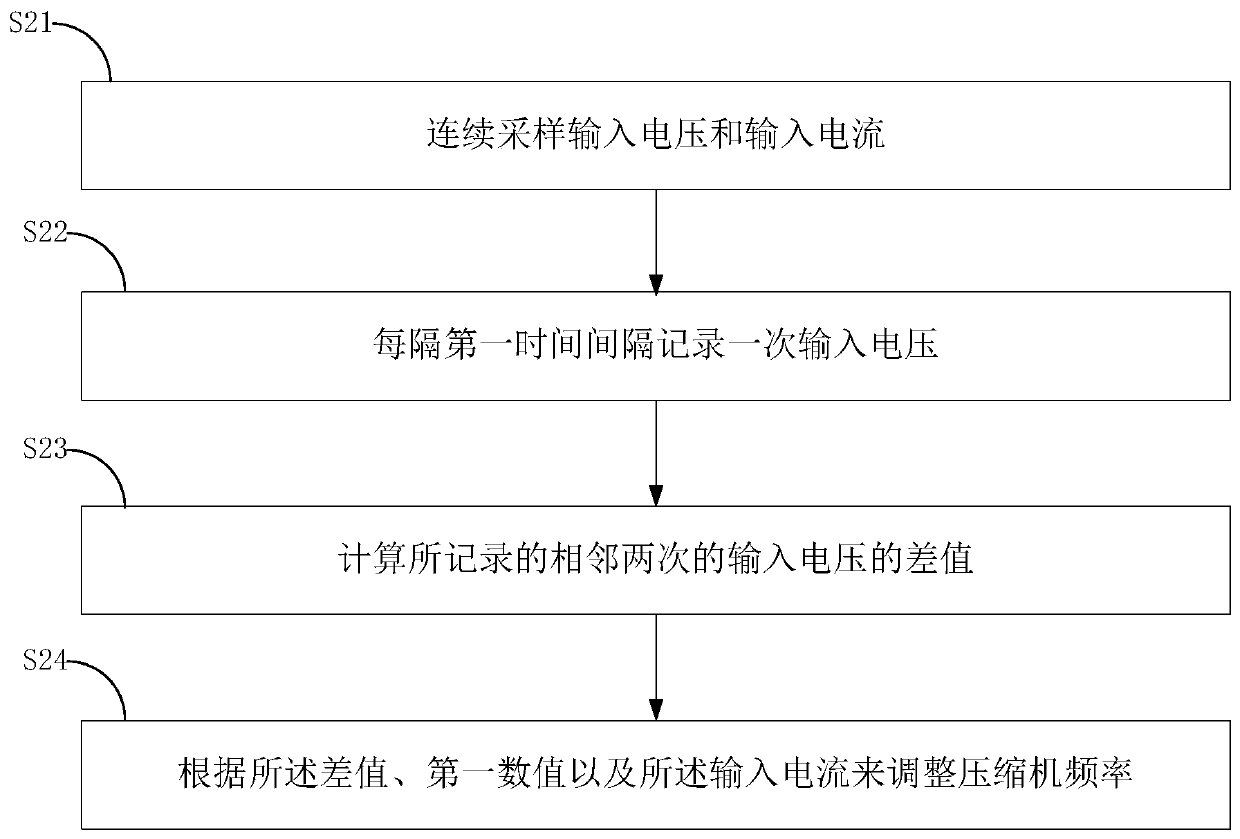

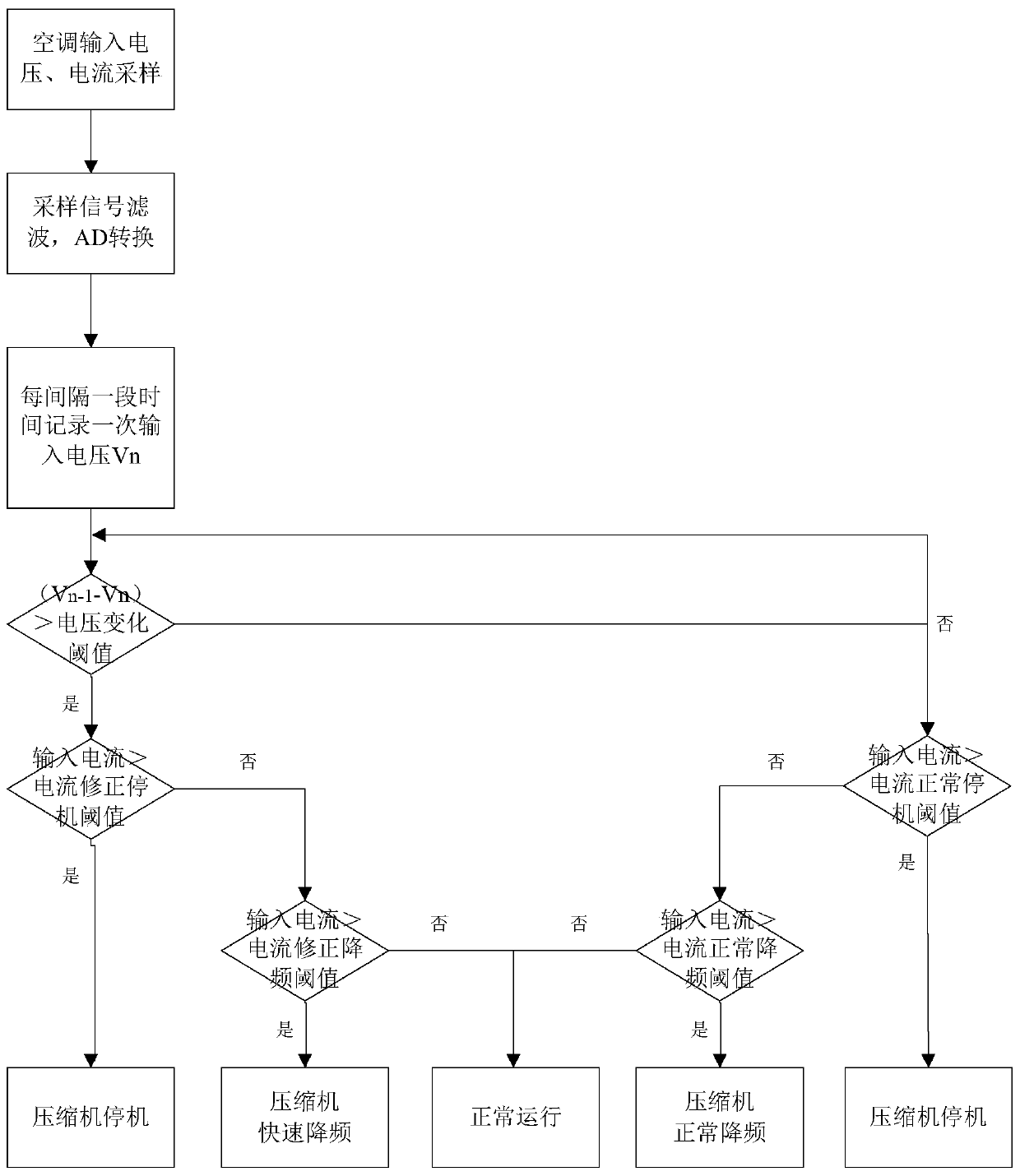

InactiveCN111219847AReduce abnormal downtimeImprove experienceMechanical apparatusSpace heating and ventilation safety systemsVoltage variationControl theory

The invention provides a method and device for avoiding abnormal shutdown of an air conditioner caused by voltage leap and the air conditioner, and relates to the technical field of air conditioners.The method includes the steps that input voltages and input currents are continuously sampled; the input voltages are recorded every first time interval; the difference between the recorded input voltages of every two consecutive times is calculated; and the compressor frequency is adjusted according to the difference, a voltage change threshold for comparison with the difference and the input currents. According to the method and device for avoiding the abnormal shutdown of the air conditioner caused by the voltage leap and the air conditioner, the current change is reflected through judgmentof the voltage change quantity within a certain time, different voltage change ranges correspond to different current protection values, and a compressor is controlled to reduce frequency and stop according to the voltage change so as to avoid abnormal shutdown of the compressor due to voltage fluctuations, so that the system operational stability is improved, and the user experience is improved.

Owner:NINGBO AUX ELECTRIC +1

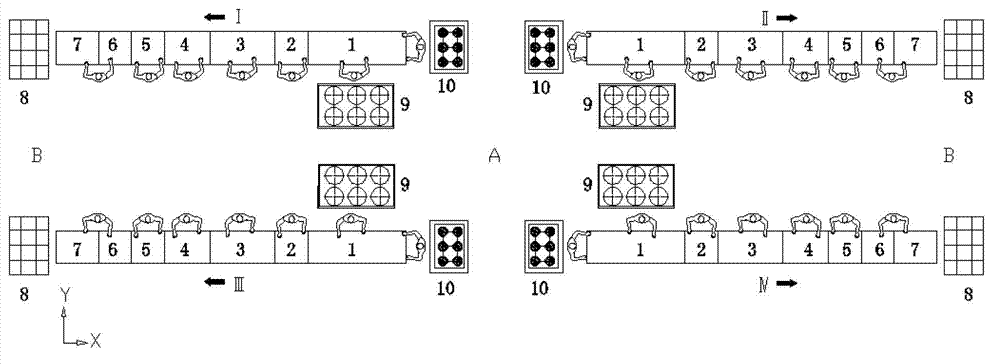

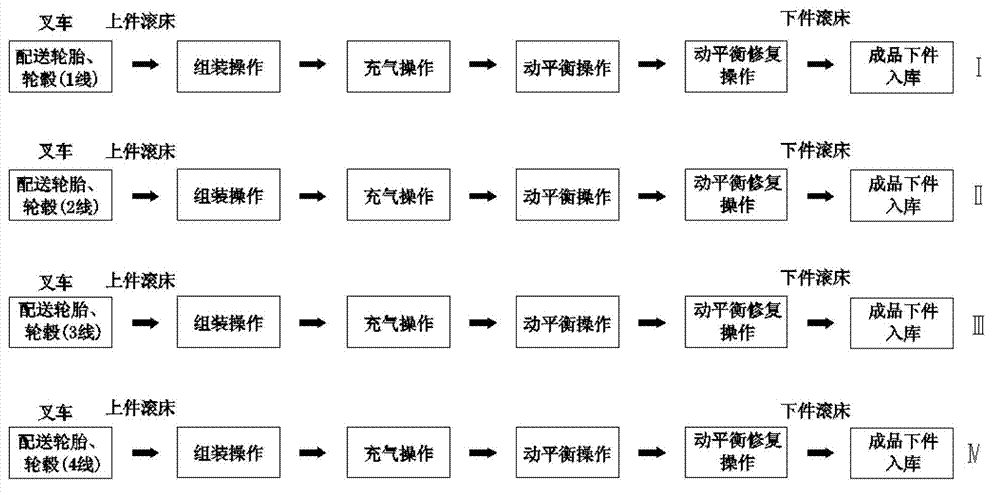

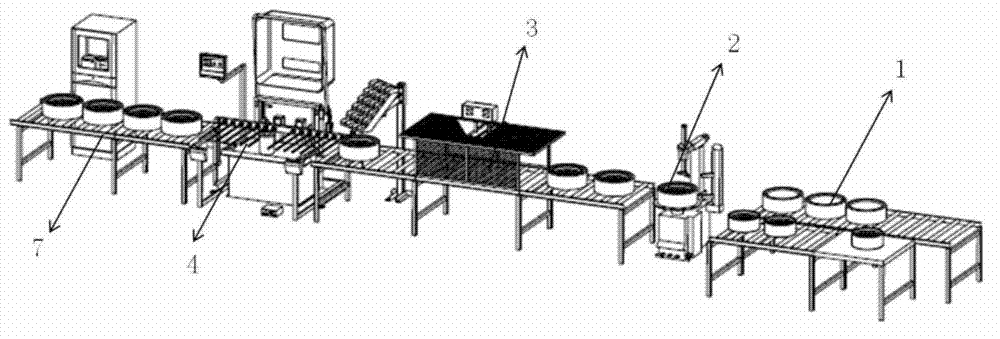

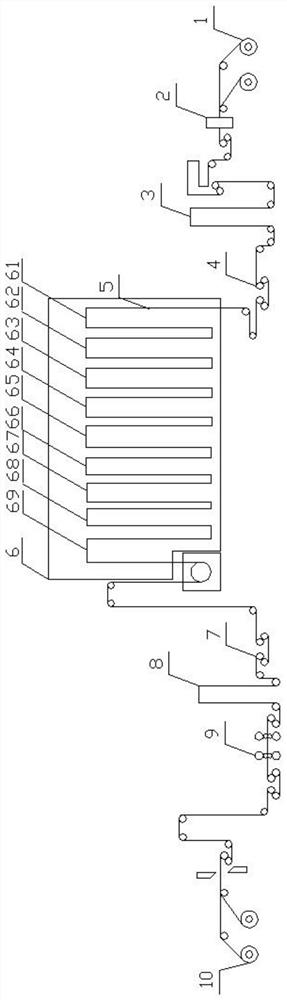

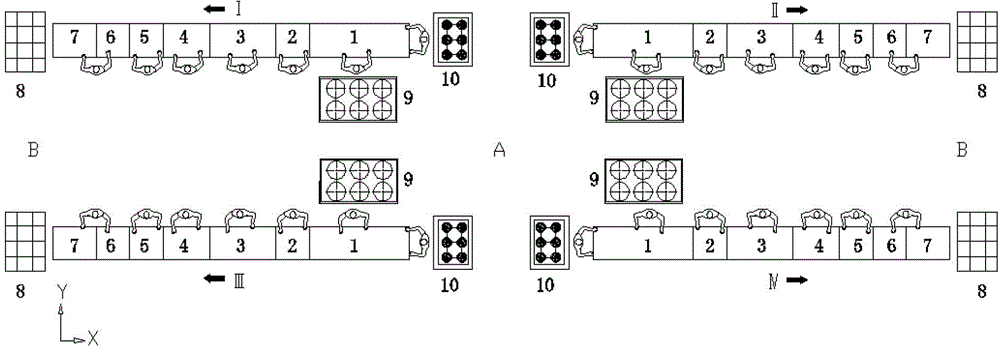

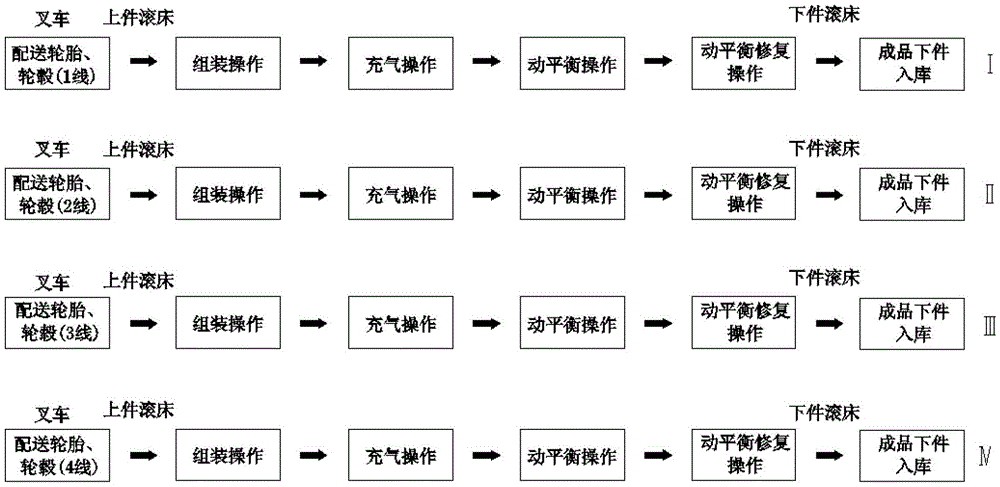

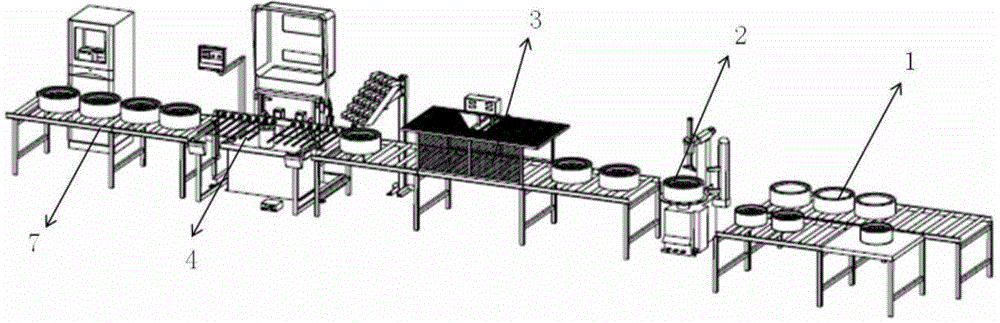

Manual assembly line layout for automobile tires

ActiveCN102756614AIncrease productivityLess investmentWheel assembling toolsBalancing machineAssembly line

The invention discloses a manual assembly line layout for automobile tires, belonging to the field of automobile tire assembly. The manual assembly line for the tires comprises more than two assembly lines, wherein each assembly line comprises a dismantling and assembling machine, an aerator, a balancing machine, a correction roller machine which are arranged in parallel along the Y-axis direction, and each assembly line is perpendicular to an assembly type part loading roller machine and an assembly type part unloading roller machine which are arranged along the X-axis direction. The manual assembly line layout has the advantages that the scattered part loading roller machines in the prior art are assembled into the part loading roller machine, the scattered part unloading roller machines in the prior art are assembled into the part unloading roller, the assembly type part loading roller machine and the assembly type part unloading roller machine are driven through a motor for transmission, the transmission spacing is carried out through an optoelectronic switch, and therefore, the convenience of manual assembly is increased, the production efficiency of the assembly line is improved, the operation region of a forklift is reduced, operating personnel are not needed in the production process, the cross operation of the forklift in the production process is eliminated, and the fluency of tire line physical distribution and the operation safety are increased. The length of equipment stations is shortened; and the effective usable areas of plants are increased.

Owner:CHERY AUTOMOBILE CO LTD

Control method for solving problem of rolling narrowing of silicon steel tail of hot-rolled steel strip

ActiveCN106391722ASolve the narrowing problemSolve the stability of hydraulic looperMetal rolling stand detailsRoll mill control devicesAutomatic controlInstability

The invention relates to the field of automatic control for finish rolling of a rolling line for continuous-hot-rolled strips. According to a control method for solving the problem of rolling narrowing of the silicon steel tail of a hot-rolled steel strip, a control procedure for adjusting the loop moment and the compensation speed is developed during silicon steel rolling by fully utilizing the characteristics of advancement and operability of the computer control technique, the hidden danger of movement abnormities of a loop is eliminated, the equipment fault time is shortened, the problem of rolling narrowing, caused by instability of the loop, of the tail of the steel strip is solved, the product quality is improved, and good benefits are achieved. The control method is suitable for control over a finish rolling machine for the hot-rolled steel strip.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

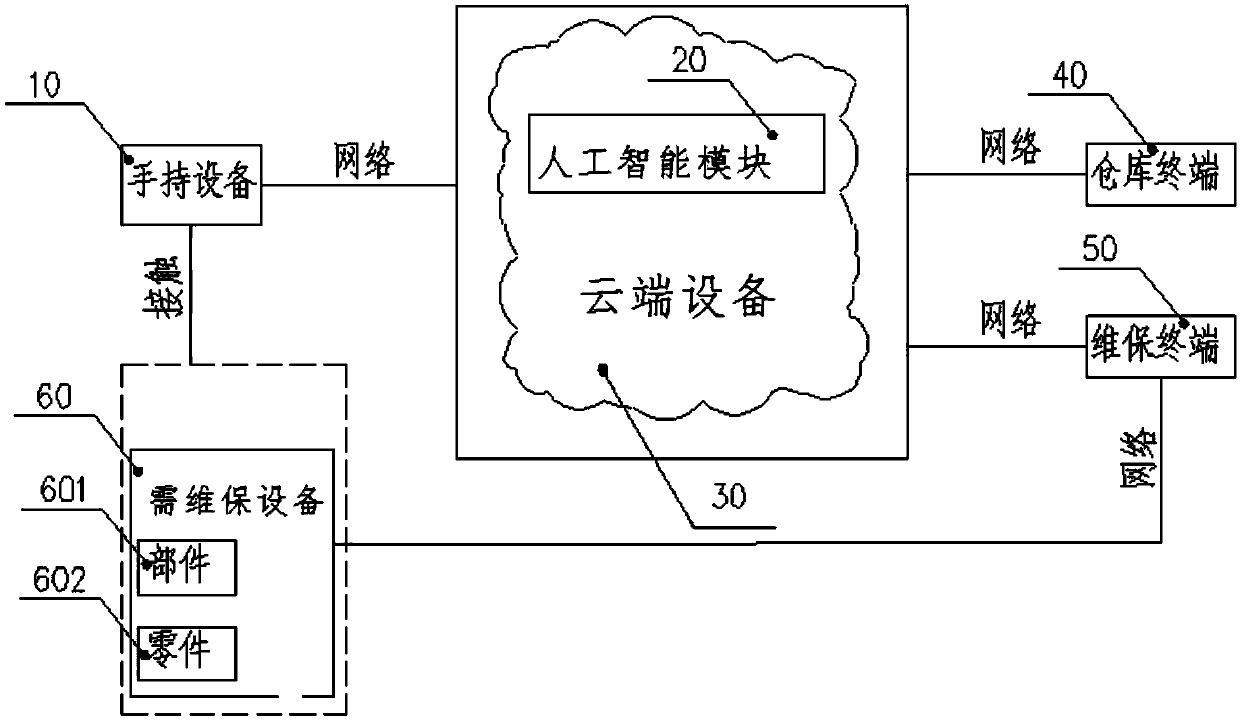

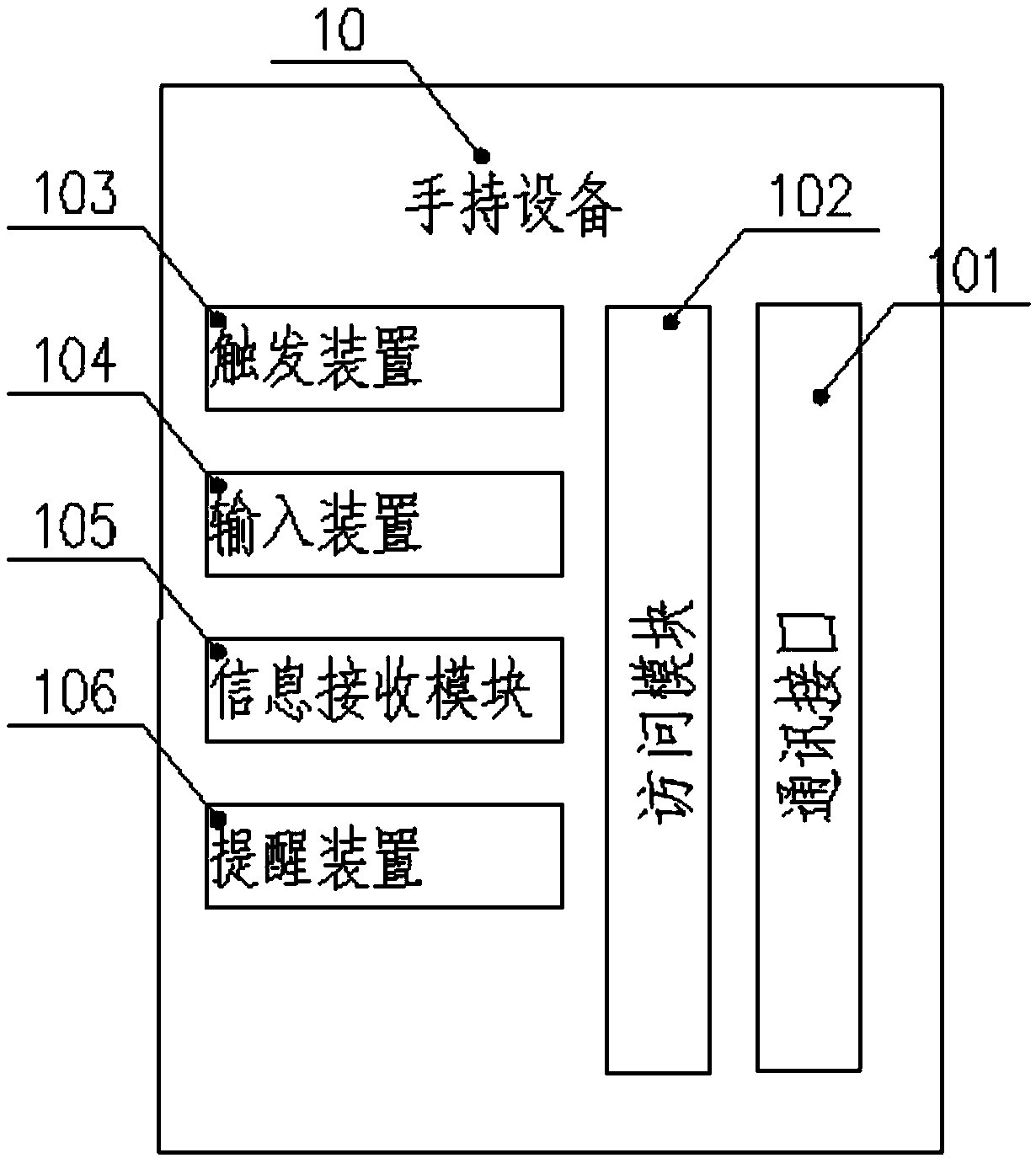

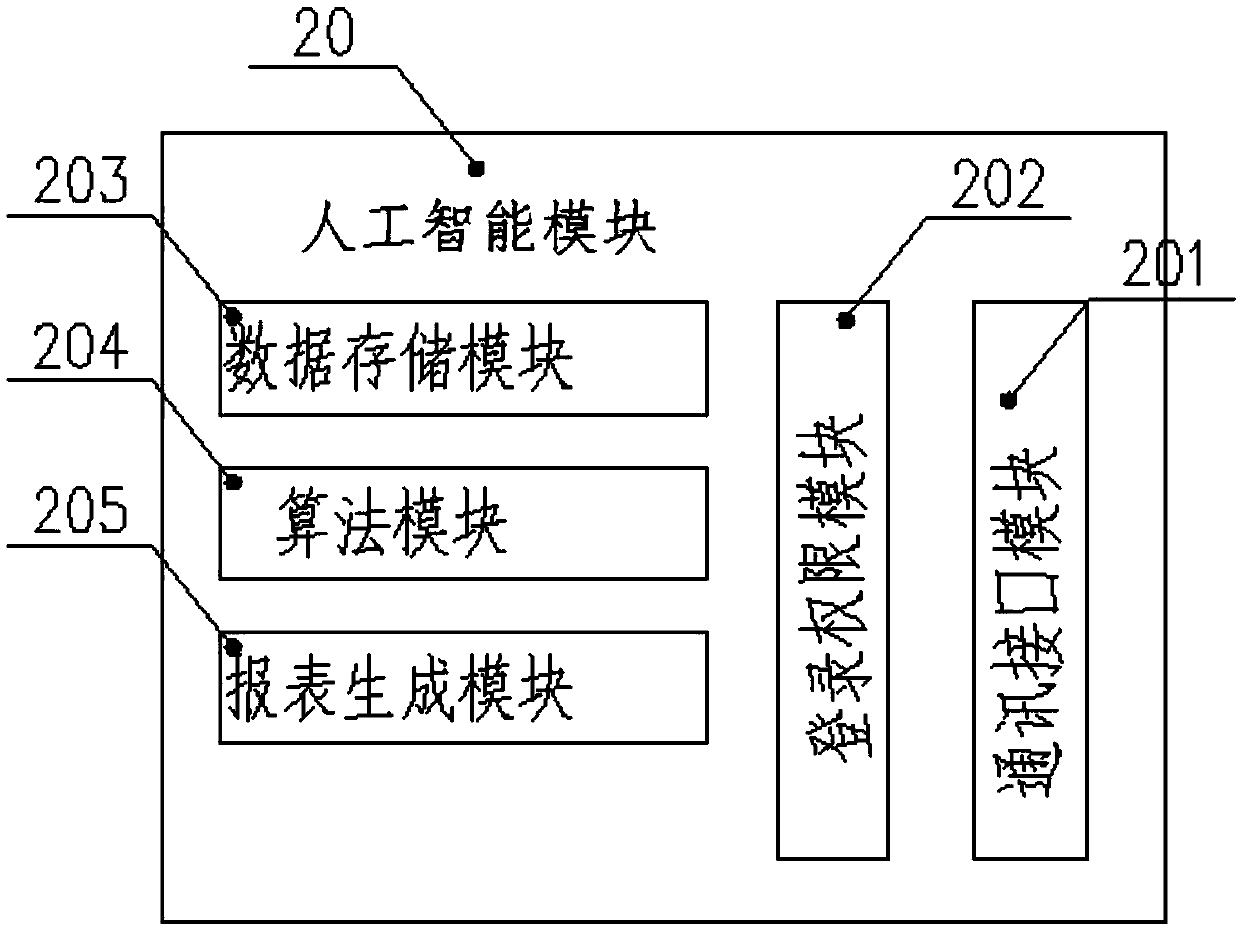

Equipment maintenance intelligent control system and method

InactiveCN109615090AReduce consumptionReduce abnormal downtimeResourcesLogisticsComputer moduleHand held devices

The invention provides an equipment maintenance intelligent control system and method. The system comprises an artificial intelligence module, a cloud device, a handheld device, a warehouse terminal and a maintenance terminal, wherein the artificial intelligence module is mounted on the cloud device; the handheld device communicates with the artificial intelligence module through a network; the warehouse terminal communicates with the artificial intelligence module through a network; the maintenance terminal communicates with the artificial intelligence module through a network; and the maintenance terminal communicates with equipment needing maintenance through a network. According to the method, by utilizing the system, an artificial intelligence module predicts faults which may occur inequipment needing maintenance through an artificial intelligence algorithm, deduces reasons of the faults and predicted spare part requirements, and carries out corresponding processing. Equipment maintenance resources are configured through intelligent technical means, maintenance efficiency and accuracy are improved, manpower and spare part consumption is reduced, and benefits are very obvious.

Owner:CONTINUOUS CASTING TECH ENG OF CHINA

Control method of head shearing speed of flying shears for hot continuously rolled band steel

InactiveCN106077805AEnsure consistencySolve the effect of actual speedShearing control devicesSlip coefficientEngineering

The invention provides a control method of the head shearing speed of a pair of flying shears for hot continuously rolled band steel and belongs to the technical field of metallurgy. The control method comprises the steps that firstly, an HMD60 hot metal detector is installed at the position 3 meters away from the flaying shears; secondly, the head shearing speed of the flying shears is set to be 0.8 m / s- 1.5 m / s; thirdly, no band steel exists in the area of the flying shears, the speed of a roller way in the area of the flying shears is 0.8 m / s- 1.5 m / s; and fourthly, when the band steel passes through the area of the flying shear, the speed of the roller way in the area of the flying shear is the product of the F0 machine frame speed actual value and the F0 machine frame backward slip coefficient. By the adoption of the control method of the head shearing speed of the pair of flying shears for the hot continuously rolled band steel, the influence of frequent change of the speed of the roller way on the actual band steel speed is eliminated, and the problem of the influence of faults of a laser velocimeter on production operation is also solved; and the stability of band steel head shearing control is achieved, and fault time is shortened.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

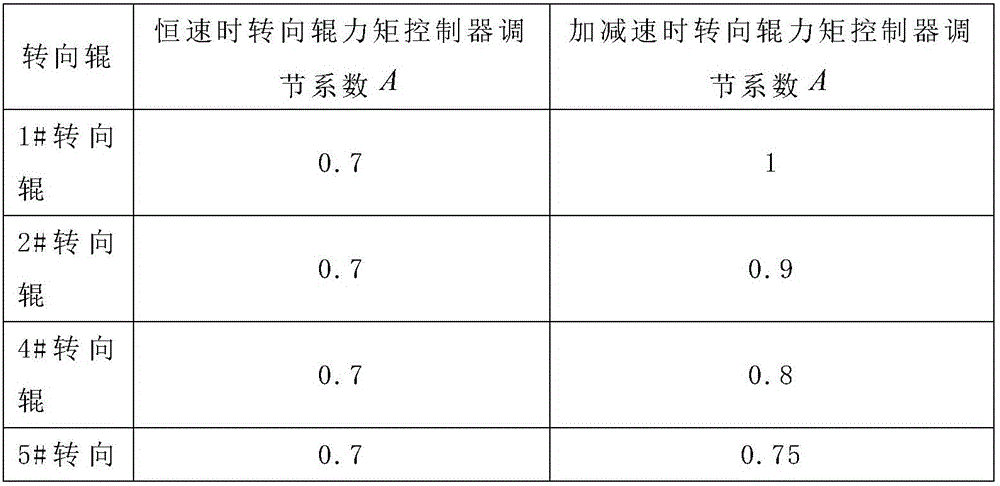

Variable coefficient loop control method

InactiveCN104259220ARealize automatic controlAssurance controlTension/compression control deviceAutomatic controlLoop control

The invention discloses a variable coefficient loop control method. When a strip steel treatment line runs, a control chip selects coefficients of a loop winch torque adjuster according to the thickness and the yield strength of strip steel, a loop winch transmission device adjusts torque output of a loop winch according to the torque adjuster coefficients transmitted by the control chip, so that the tension of the strip steel in a loop area on the treatment line is controlled. The formula includes Qn=A*GAIN*DEVn+A*GAIN*(T0 / Tn-1)*DEVn-1+Qn-1. The variable coefficient loop control method has the advantage that automatic control can be realized in acceleration and deceleration and in a steady state.

Owner:武钢集团有限公司

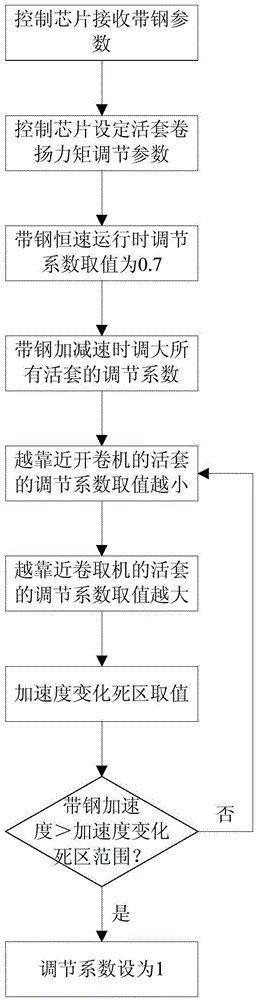

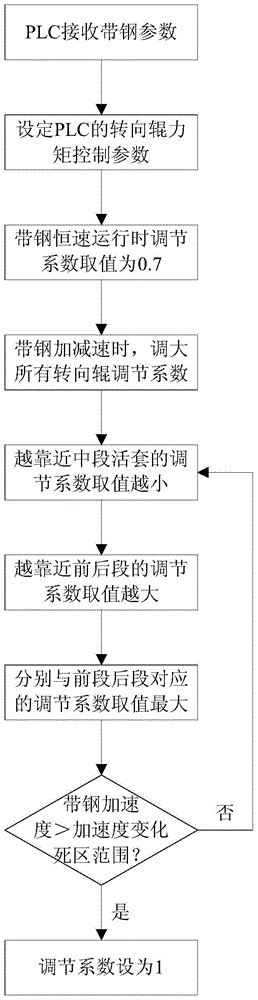

Loop control method capable of ensuring tension stability of strip steel processing line

InactiveCN104858244AStable controlStable productionTension/compression control deviceLoop controlStrip steel

The invention discloses a loop control method capable of ensuring tension stability of a strip steel processing line. The loop control method comprises the following steps of step1, controlling a chip to receive and process yield strength and thickness parameters of operation strip steel in the processing line; step2, setting the adjustment parameter Qn of loop winching torque according to the above parameter control chip; step3, setting a minimum value as an adjustment coefficient A when operating the strip steel on the processing line at constant speed; when the strip steel is accelerated and decelerated, increasing the adjustment coefficient A corresponding to the loop winch; when the accelerated speed of the accelerated and decelerated strip steel is beyond the change dead zone range of the accelerated speed, setting the adjustment coefficient A of the loop winch as a maximum value. According to the loop control method, the loop can be precisely controlled during deceleration and acceleration, and tension deviation in the loop area can be solved, the strip steel processing line can be normally produced, the quality of the strip steel product is improved, and thus the loop control method can be widely applied to the control field of the strip steel processing line.

Owner:武钢集团有限公司

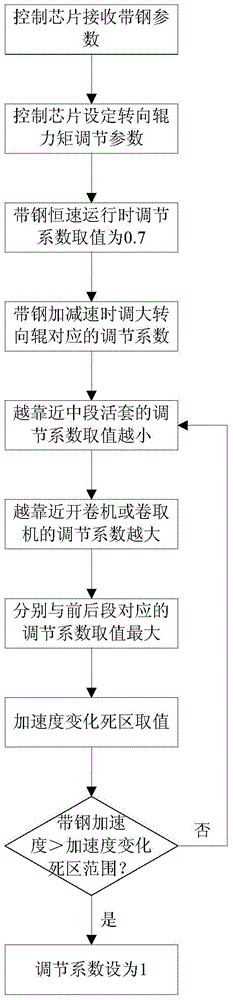

Method for controlling turning rollers on processing line

InactiveCN104907340AFix stability issuesGuaranteed uptimeRoll mill control devicesFlexible work arrangmentsEngineeringStrip steel

The invention discloses a method for controlling turning rollers on a processing line. The method comprises the first step of causing a control chip to receive yield strength and thickness parameters of running strip steel on the processing line; the second step of causing the control chip to set a turning roller torque adjusting parameter Qn according to the parameters; the third step of setting the regulation coefficient A as the minimum value when the strip steel on the processing line runs at a constant speed; when the strip steel is accelerated or decelerated, turning up the regulation coefficient A corresponding to all the turning rollers; and when the strip steel in acceleration or deceleration exceeds the acceleration change dead area range, setting the regulation coefficient A of all the turning rollers as the maximum value. The method has the advantages of guaranteeing accurate control of the turning rollers in acceleration or deceleration, solving the problem of tension fluctuation between the turning rollers, guaranteeing normal production of the strip steel processing line and improving strip steel product quality; and the method can be widely applied to the field of strip steel processing line control.

Owner:武钢集团有限公司

Novel cold heading wire coating process

The invention relates to a novel cold heading wire coating process. The novel cold heading wire coating process is characterized by comprising the following steps that lubricants are added into a mold box of a drawing machine to replace common drawing powder and smeared on the surface of a cold heading wire through a finished product wire drawing step. The lubricants include, by weight, 40-80% of liquid sodium stearate, 5-15% of transformer oil, 5-15% of refined mineral oil, 5-15% of petroleum sulfonate and 5-15% of lanolin magnesium soap. The novel cold heading wire coating process has the following advantages that (1) powder does not accumulate on the surface of a product produced through the process, abnormal closedown can be reduced, and the use amount of cold heading oil is also reduced; (2) part of problems caused by bad phosphorization can be solved through the product produced through the process; and (3) the cold heading wire produced through the process has a better antirust function; and meanwhile, the abnormal closedown time of cold heading can be shortened.

Owner:无锡翱天钢丝制品有限公司

Hot continuous rolled strip steel coiling dual detection method

InactiveCN106513445AEliminate detection inaccuraciesRealize automatic controlMeasuring devicesMetal rolling arrangementsAutomatic controlLaminar cooling

The invention discloses a hot continuous rolled strip steel coiling dual detection method and belongs to the field of automatic control over the coiling temperature of hot continuous rolled strip steel. The method is characterized in that two temperature detectors are arranged at an outlet of laminar cooling equipment and located between the laminar cooling equipment and a coiling machine, wherein the two temperature detectors meet the following conditions that (1) the distance between the detectors and a rolling center line in the horizontal direction is no larger than 4 meters, (2) the distance between the detectors and the rolling center line in the vertical height direction is no larger than 3 meters, and (3) the two temperature detectors have different detection angles, with the horizontal line as a reference, the detection angle of one temperature detector is 35-45 degrees, the detection angle of the other temperature detector is 35-40 degrees, and two temperature detection values T1 and T2 are input into a first-stage controller simultaneously. The situation that strip steel temperature detection is affected when water exists on the strip steel locally is eliminated, stability of control over strip steel coiling temperature is achieved, the product performance and the qualified rate are improved, and good benefits are gained.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

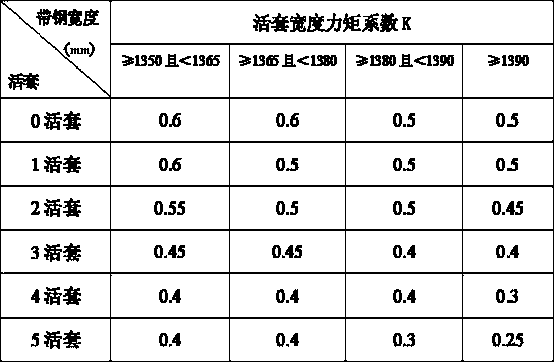

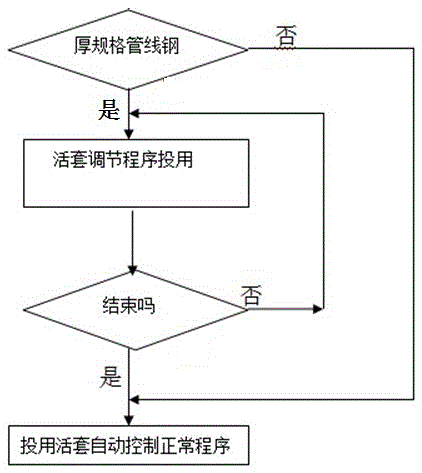

Steel loop control method for low-temperature wide material finishing mill frame of hot continuous rolling mill

InactiveCN105499278AEnsure automatic controlSolve problems such as vibrationMass flow control deviceMetal rolling arrangementsLoop controlAutomatic control

The invention relates to the field of hot continuous rolling low-temperature wide material special steel loop control, in particular to a steel loop control method for a low-temperature wide material finishing mill frame of a hot continuous rolling mill. The steel loop control method for low-temperature wide material finishing mill frame of the hot continuous rolling mill is characterized in that whether low-temperature wide material special band steel is rolled or not is judged; if so, a loop control technology is used until the rolling is completed; otherwise, a normal loop automatic control procedure is used; when the outlet temperature of a finishing mill frame of the band steel is lower than or equal to 850 DEG C, and meanwhile, the width is greater than or equal to 1350mm, the low-temperature wide material special band steel is rolled. The steel loop control method has the advantages that a low-temperature wide material special steel loop control technology is developed; the automatic control of a hydraulic loop during low-temperature wide material band belt rolling is ensured; during the low-temperature wide material band belt rolling, the problems of hydraulic loop oscillation between hot continuous rolling finishing mill frames, and the like are solved.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Additional given value control method of hot-continuous-rolling thin-specification running sleeve and idle sleeve

ActiveCN104550260AFix stability controlEasy to adjustTension/compression control deviceMetal rolling arrangementsAutomatic controlStrip steel

The invention relates to an additional given virtual sheathing control method of a hot continuous rolling thin-specification movable sleeve, belonging to the field of hot continuous rolling automatic control. The method is characterized in that when the thickness of strip steel is less than 2.0mm and the strip steel rolling force load value of a rack adjacent to the strip steel is larger than the target value (300-500 tons), the rack is confirmed to bite steel in a tracking way. When the actual torque of the strip steel is less than the set torque of the strip steel, the final value given by a servo valve is calculated by a controller, and a first stage computer control signal channel acts on the servo valve, so that the servo valve acts. After the method is adopted, off tracking and waste rolling which are caused by virtual sheathing of the movable sleeve can be eliminated, and the great hidden danger of damage to mechanical equipment can be avoided, so that the failure time is reduced, the product quality is improved, and good benefit is obtained.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Control method for load relay of hot continuous rolling thin-specification rolling frame

ActiveCN104324952ARealize automatic controlEliminates significant potential for damageRoll mill control devicesMeasuring devicesControl engineeringEngineering

The invention discloses a control method for a load relay of a hot continuous rolling thin-specification rolling frame. When the thickness of a strip steel finished product is smaller than or equal to 1.6 millimeters, the switch-on / off of the frame load relay is judged according to a frame rolling pressure value; the frame rolling pressure value is equal to the sum of the detection values of pressure detection devices on both sides. According to the method, a frame rolling load relay signal control program is developed specific to a rolling thin specification by making full use of the characteristics of advancement and operability of a computer control technology, the control problem and the major potential hazard of damage to mechanical equipment caused by signal abnormality of the frame load relay are solved and eliminated, the failure time is shortened, the product quality is enhanced, and a good benefit is achieved. The method is suitable for controlling the frame of a hot rolled strip finishing mill.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

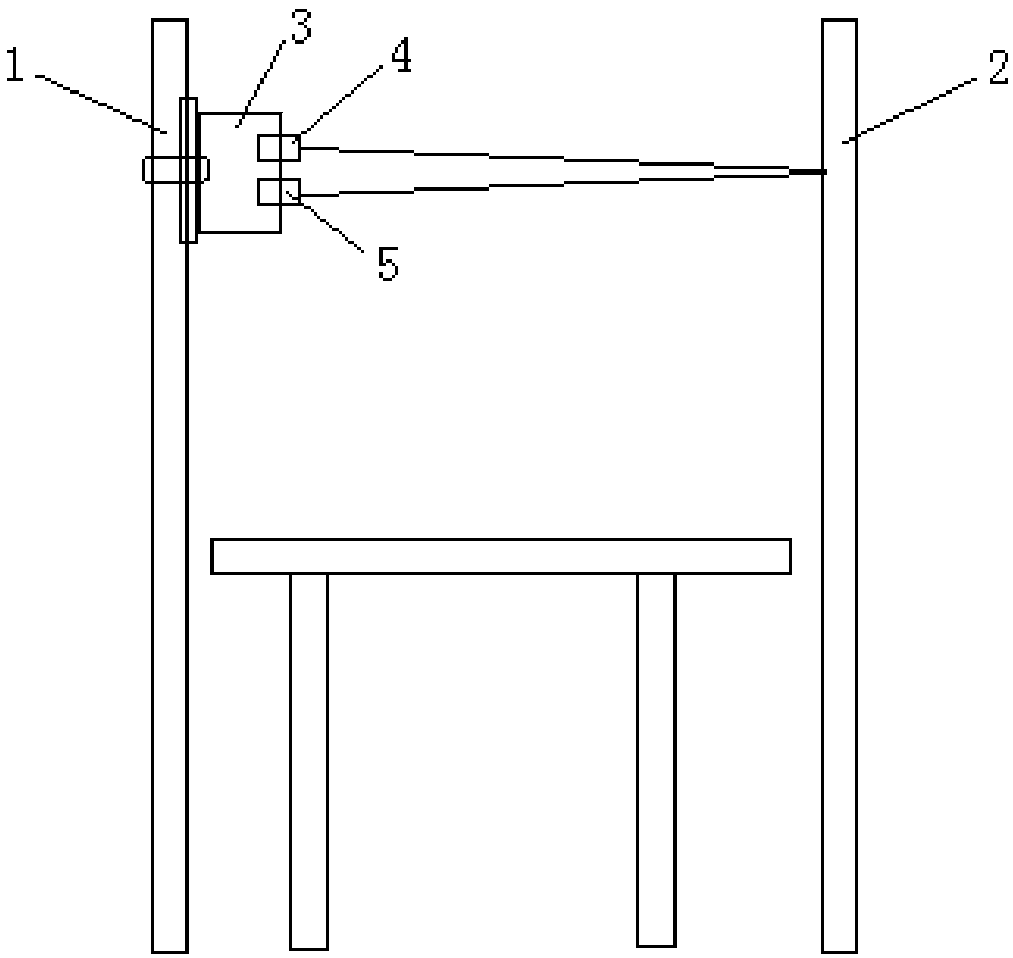

Paper machine light curtain safety production device

PendingCN110058321AReduce abnormal downtimeImprove handling safetyOptical detectionEngineeringReflective layer

The invention relates to a paper machine light curtain safety production device. The device comprises a photoelectric sensor and a triggering control circuit, wherein the photoelectric sensor is a reflective-plate photoelectric sensor, is arranged at the two sides of a column paper rolling frame of a paper machine and comprises a sensor body and a reflective plate which are arranged oppositely; and the triggering control circuit uses a triggering signal of the reflective-plate photoelectric sensor as a switching action signal to control a rolling part of the paper machine to shut down and givean alarm. Compared with the prior art, the device has the advantages of being safe, reliable and capable of preventing a malfunction, etc.

Owner:上海东冠纸业有限公司

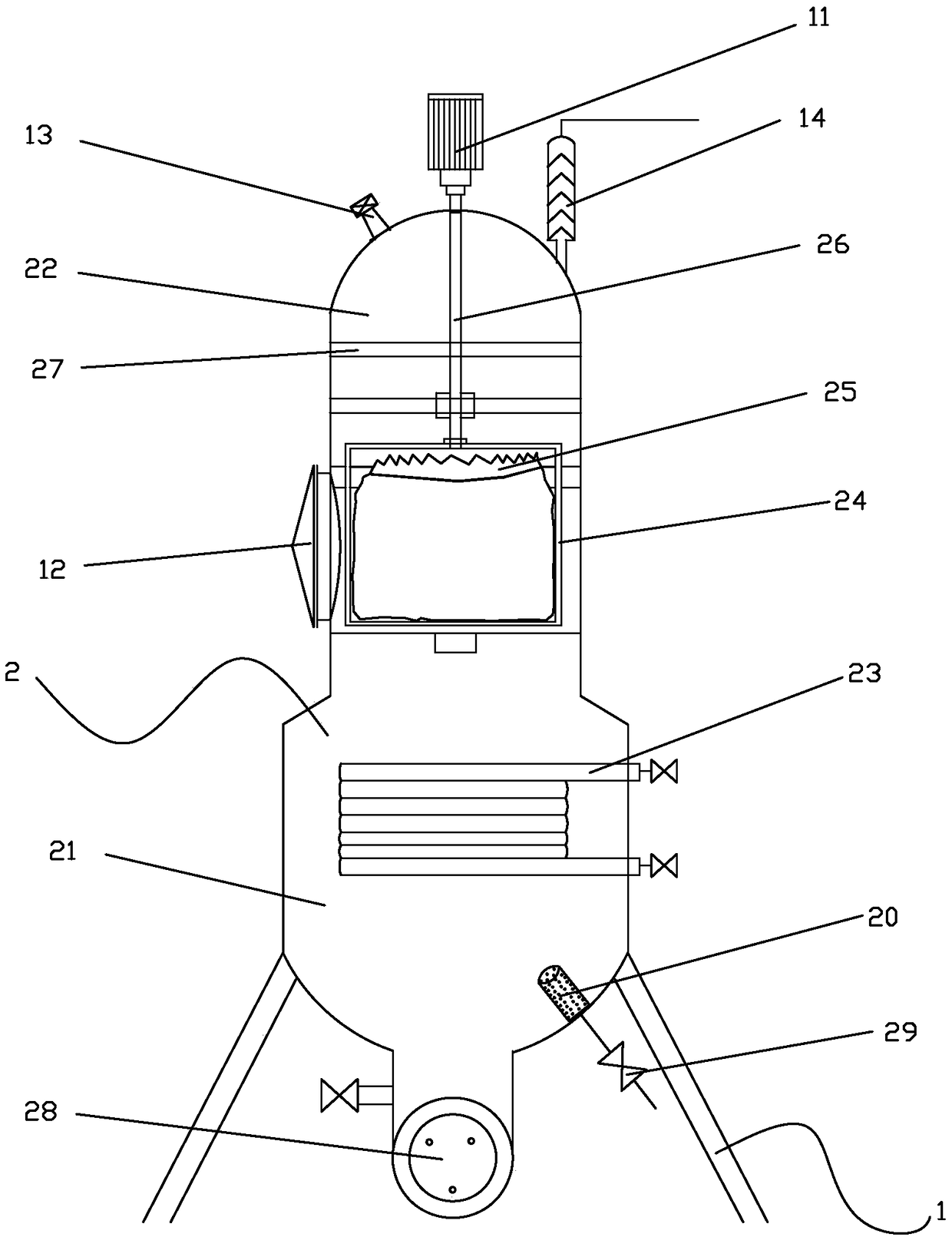

Fruit and vegetable vacuum frying device capable of quickly replacing filter screen

InactiveCN109122749AConvenient to take togetherAvoid it happening againOil/fat bakingEngineeringHanging basket

The invention discloses a fruit and vegetable vacuum frying device capable of quickly replacing a filter screen. The device comprises a frame. The frame is provided with an upper portion warehouse. The upper portion warehouse comprises a lower portion warehouse for storing oil and an operation area which is used for dehydrating and frying the fruits and vegetables and is arranged above the lower portion warehouse and is connected to the lower portion warehouse. A hanging basket used for hanging the fruits and vegetables for dehydration and frying is arranged in the operation area. The filter screen used for placing the fruits and vegetables and preventing fragments from falling into the lower portion warehouse is arranged in the hanging basket. The outer edge contour size of the filter screen is smaller than the inner diameter size of the operation area. By using the fruit and vegetable vacuum frying device capable of quickly replacing the filter screen, the filter screen is arranged in the hanging basket in the vacuum frying dehydration operation area and can be quickly replaced. Fruit and vegetable fibers are prevented from blocking an oil circulation pipeline, equipment abnormalshutdown is reduced, and continuous production operation is facilitated.

Owner:JIANGYONG COUNTY LAOSHITOU CHARACTERISTIC AGRI DEV

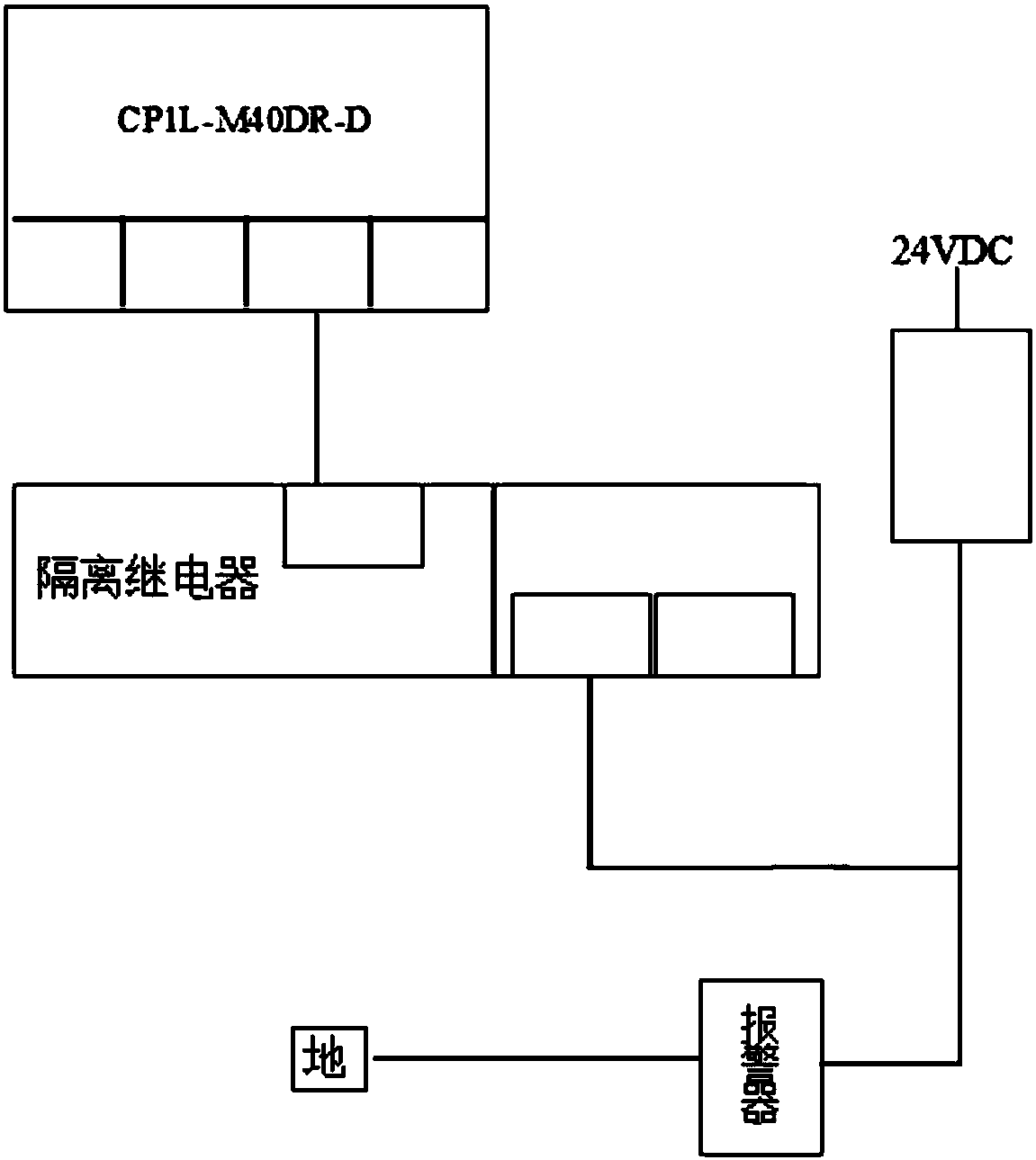

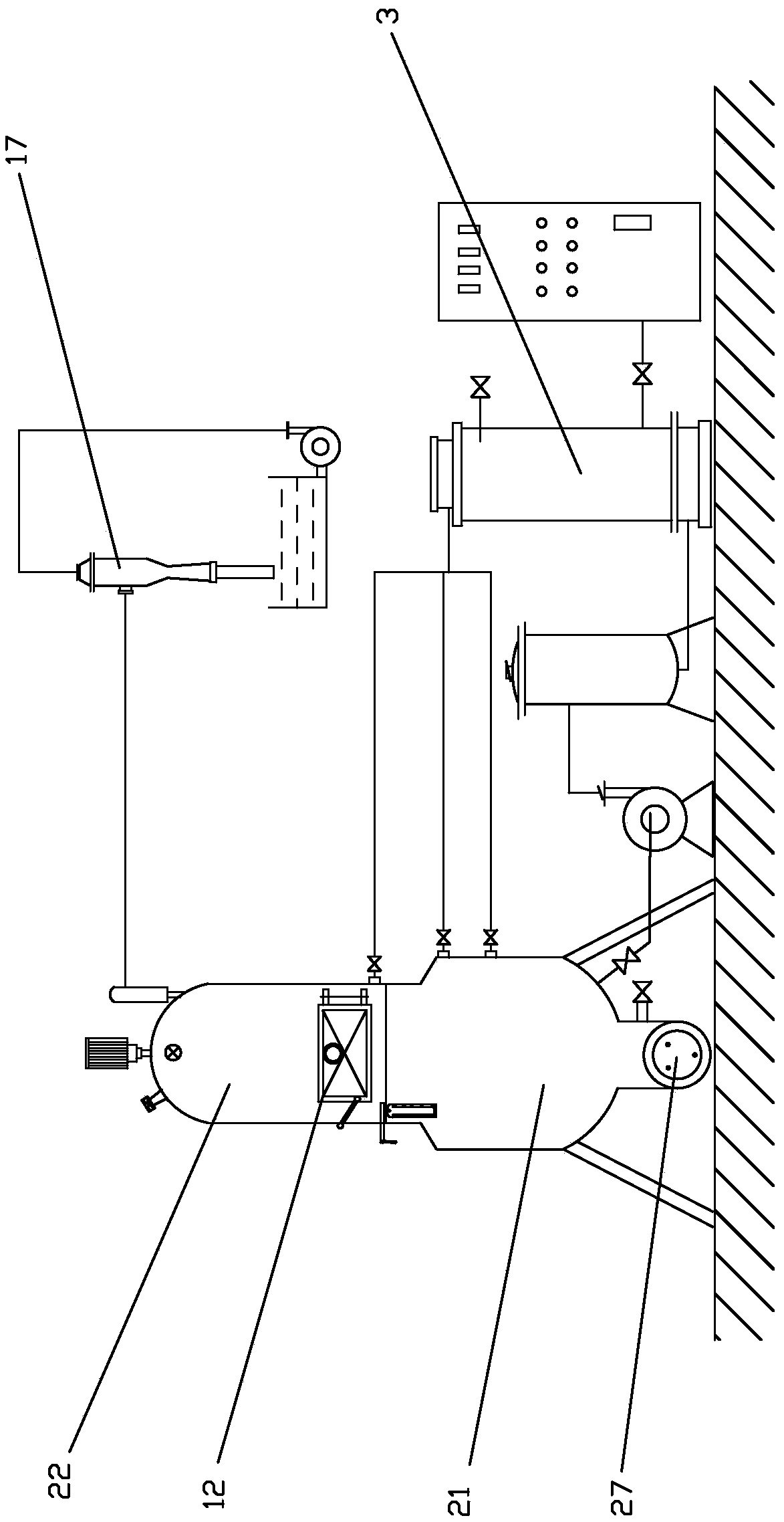

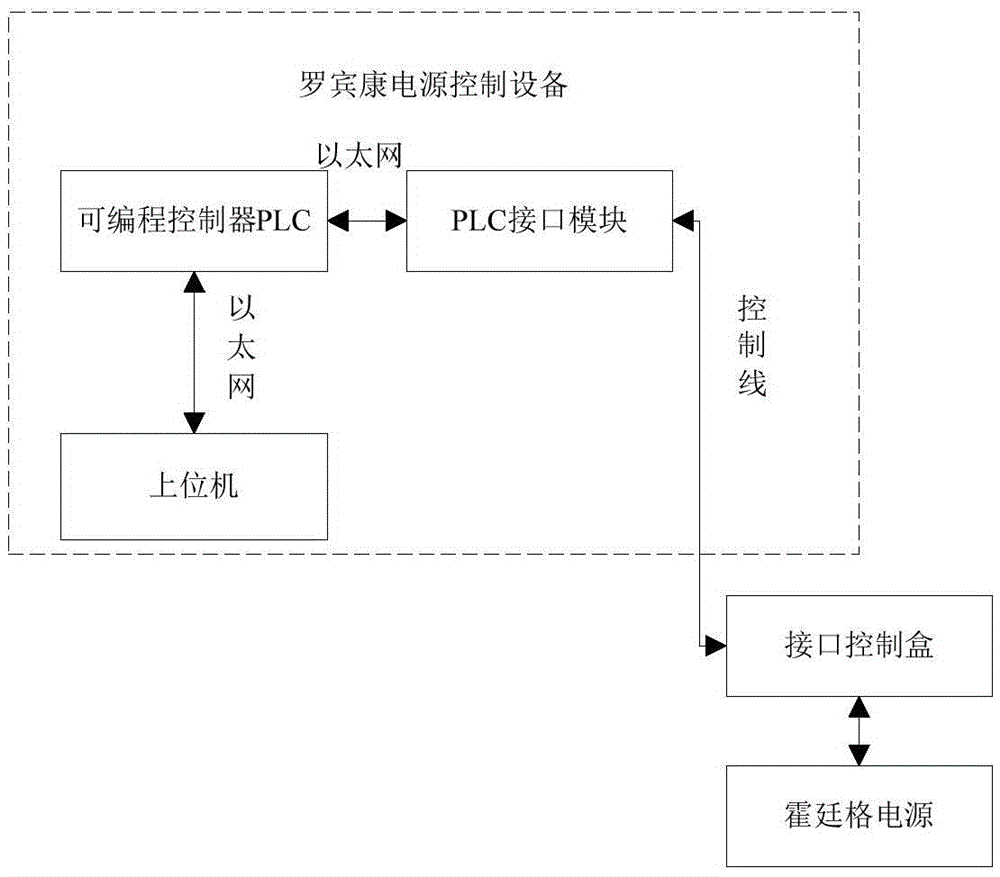

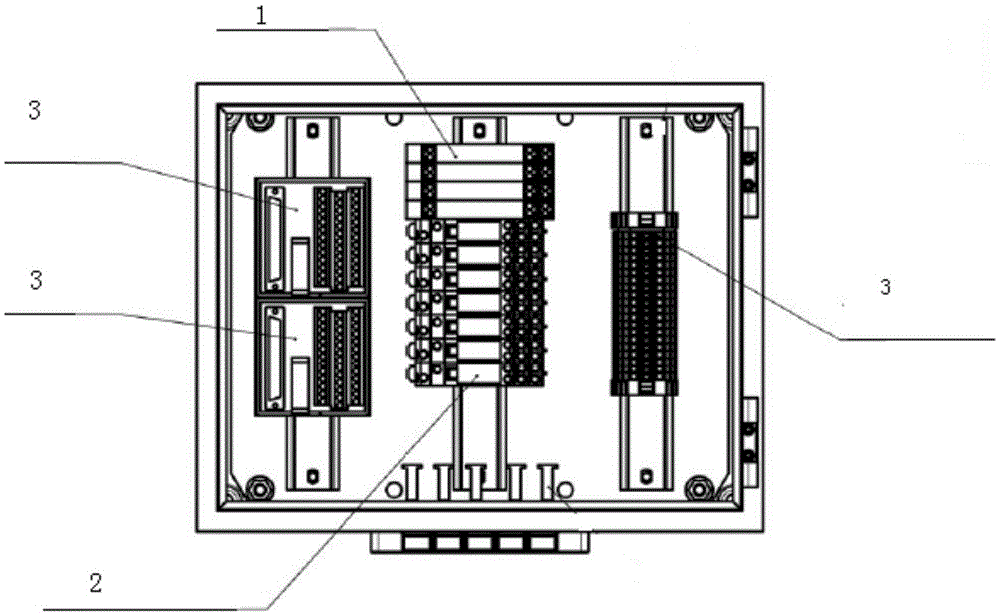

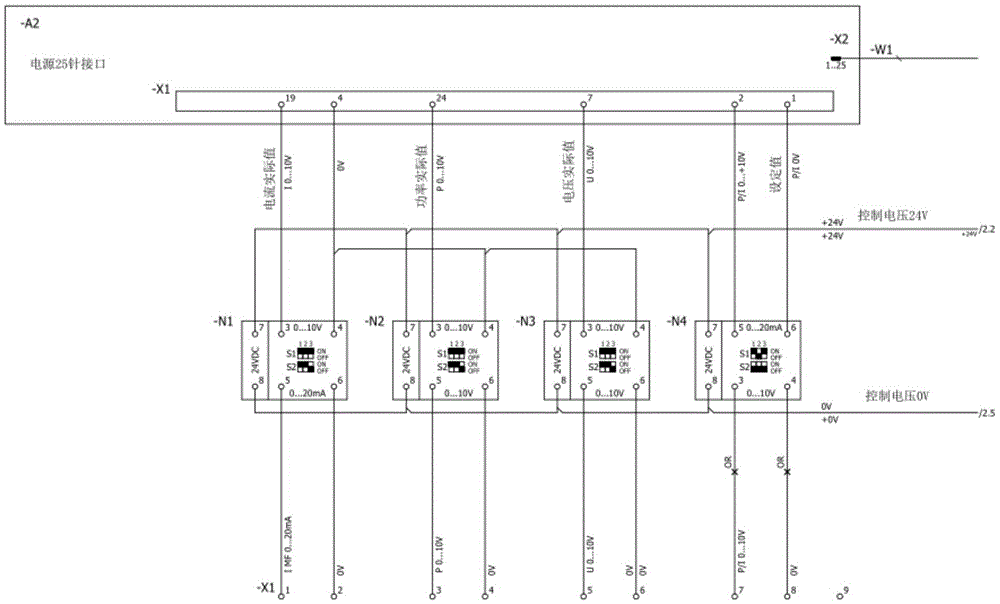

Huttinger power control system

ActiveCN105467924AAchieve substitutionControl signal stableProgramme control in sequence/logic controllersControl systemPower control system

The invention provides a Huttinger power control system, which comprises a Robicon power control device, an interface control box and a Huttinger power supply. The Robicon power control device is electrically connected with the interface control box; the interface control box is electrically connected with the Huttinger power supply; a current / voltage analog quantity transition module, a relay module and a terminal block are arranged in the interface control box; the power supply transition control system changes a transition parameter of the current / voltage analog quantity transition module, the quantity of the current / voltage analog quantity transition module and the quantity of the relay module to convert different power control signals. Through adoption of the Huttinger power control system, the Robicon power supply is replaced; after isolating signals, a control signal is stable and an abnormal fault is reduced; the investment cost is reduced; the Robicon power supply can be replaced normally; the problems of aging Robicon power supply circuits and frequent faults are solved; faults time of the power supply is reduced; and normal production is guaranteed.

Owner:天津南玻节能玻璃有限公司

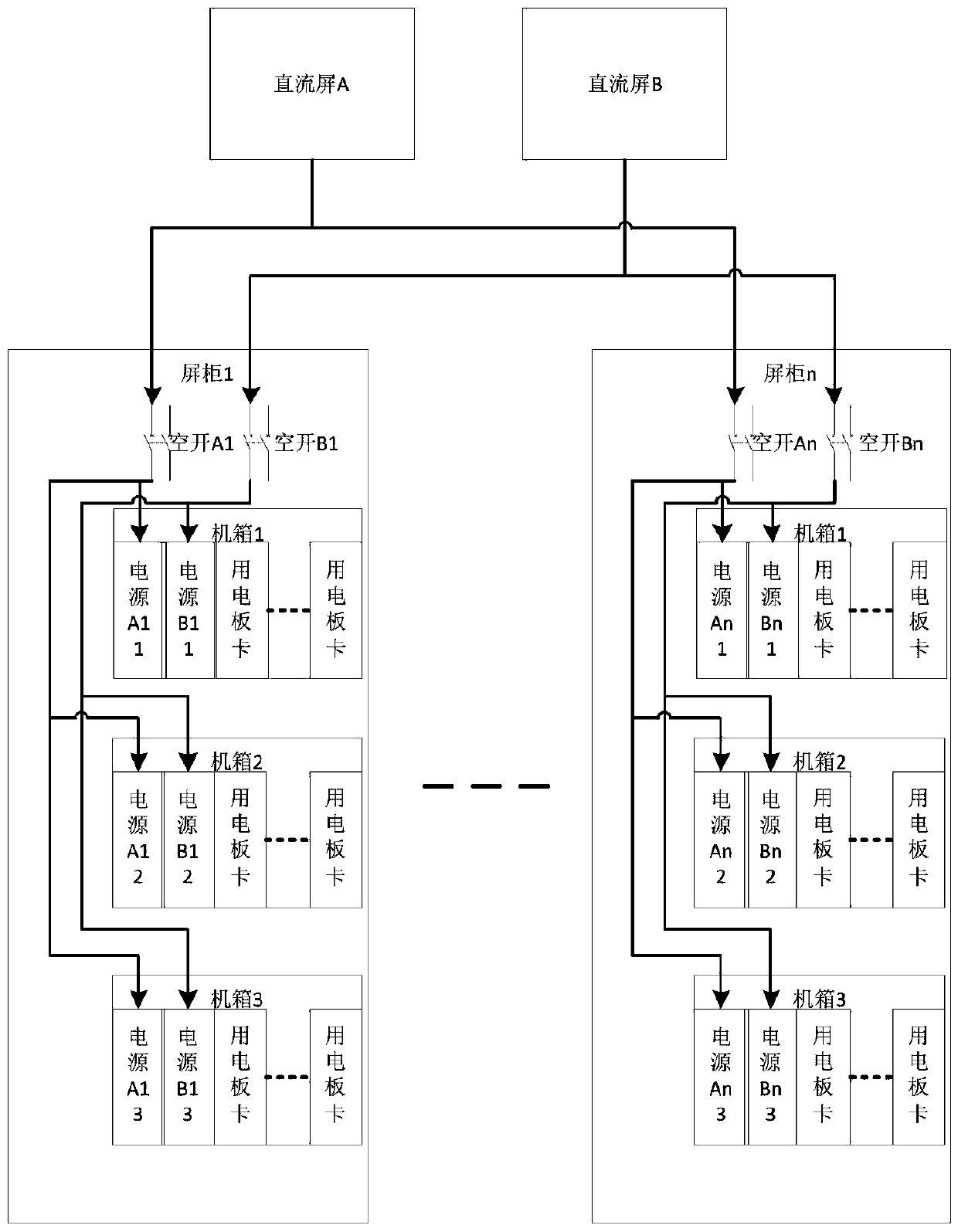

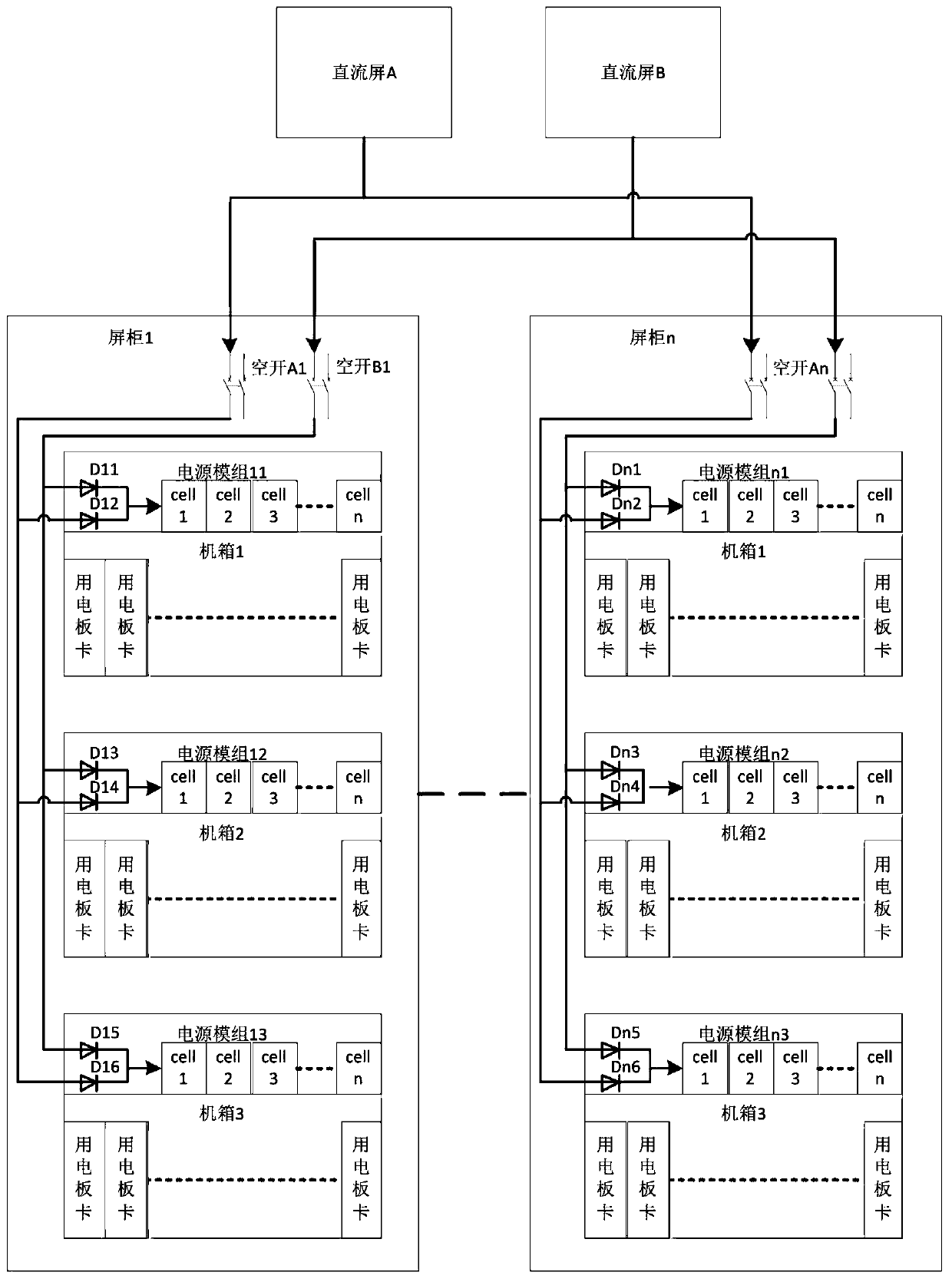

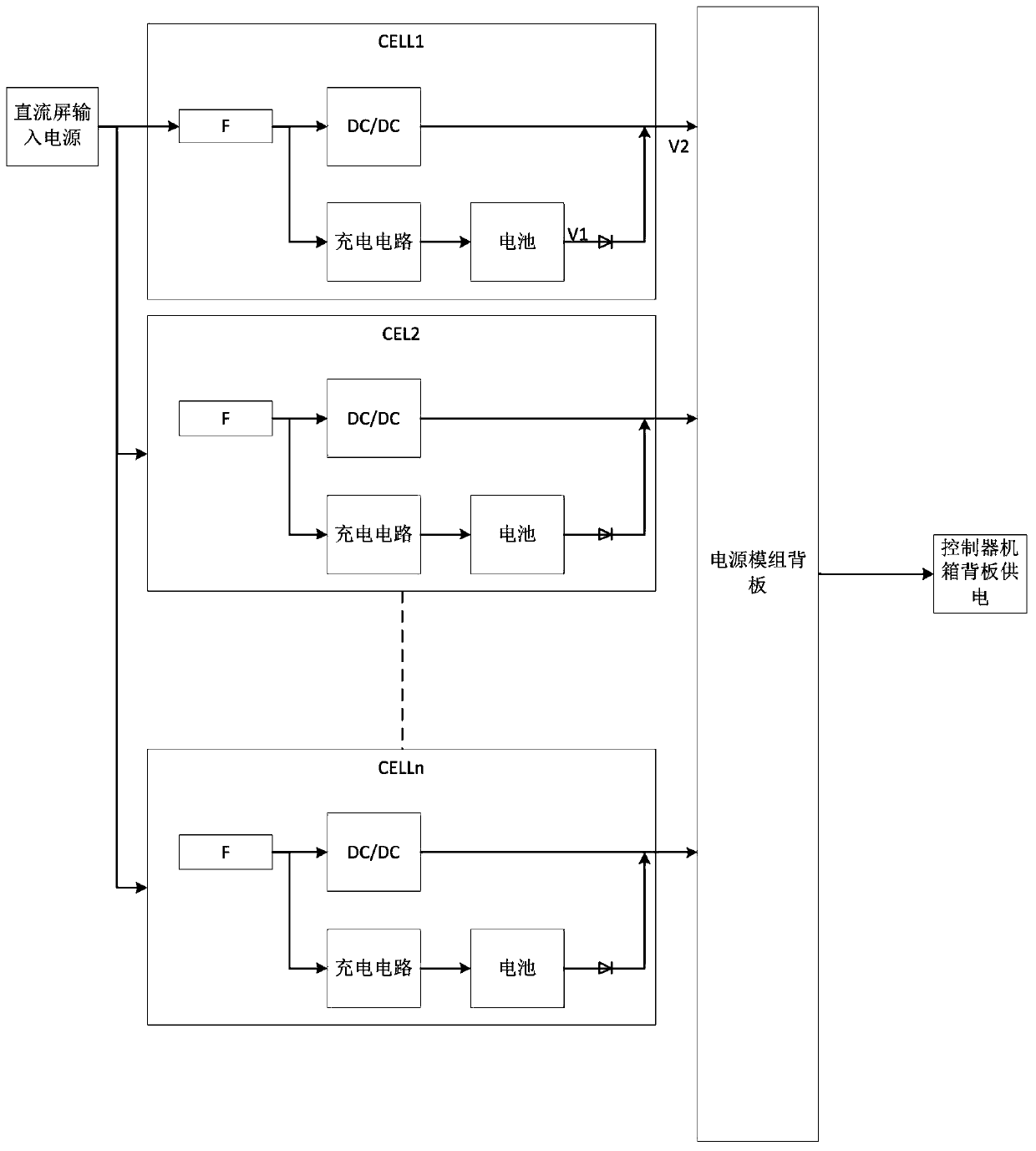

High-reliability power supply method of converter valve controller

PendingCN110912176AReduce abnormal downtimeReduce riskElectric power transfer ac networkEmergency power supply arrangementsControl engineeringControl theory

The invention provides a high-reliability power supply method of a converter valve controller. A converter valve controller case in each converter valve control screen cabinet is provided with a powersupply module. The power supply module is independently arranged in a shell matched with the case. The power supply module is composed of a plurality of modular power supplies, and the power, the internal circuit, the boundary dimension and the interface of each modular power supply are completely the same. Two paths of direct-current power supplies are used for supplying power, and the module power supply can work normally under the condition that any path of direct-current power supply is electrified. A combinable modular power supply mode is provided by improving a power supply mode of anexisting converter valve controller, so that the problems of poor compatibility and complex production management of a power panel caused by different power requirements of the converter valve controller are solved, and the overall reliability of a power supply system is improved through multi-power-supply power supply.

Owner:CSG EHV POWER TRANSMISSION +1

Additional given control method of hot continuous rolling silicon steel movable sleeve

ActiveCN104209341ARealize automatic controlEliminates significant potential for damageTension/compression control deviceAutomatic controlStop time

The invention relates to an additional given control method of a hot continuous rolling silicon steel movable sleeve, belonging to the field of metallurgical rolling. According to the method, when the given torque of strip steel is judged to be larger than the actual torque of the strip steel by a controller, the movable sleeve of the strip steel is proved to have the phenomenon of virtual sheathing; the controller is used for controlling a servo valve in a point-to-point way by a transformation channel; the additional given value calculated by the controller and the value given by the servo valve are correspondingly transformed into current values by the transformation channel; the current is applied to the servo valve by a cable, so that the servo valve acts. After the method is adopted, the finish rolling movable sleeve can be automatically controlled, off tracking and pack rolling which are caused by virtual sheathing of the strip steel movable sleeve can be eliminated, the great hidden danger of damage to equipment can be avoided, and abnormal stop time is shortened.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

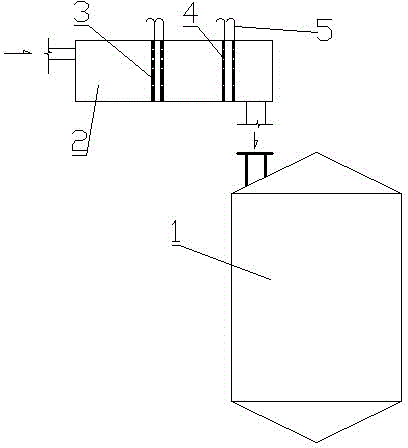

Process and device for recovering gluten from starch slurry

ActiveCN102974146AHigh extraction rateReduce the number of blocked heat exchange equipmentBioreactor/fermenter combinationsBiological substance pretreatmentsAlcohol productionEconomic benefits

The invention belongs to the technical field of flour milling, and particularly relates to a process and device for recovering gluten from starch slurry. A starch slurry filtering tank is additionally arranged in front of a feeding opening of a liquefaction tank in a gluten workshop; and the gluten in the starch slurry can be filtered through a two-stage filtering screen, and can be pumped into the liquefaction tank. The filtered gluten is recovered in time by a manual method according to the content of the gluten in the thick slurry, so that the amount of the gluten entering the liquefaction tank can be controlled, and furthermore, the purposes of stabilizing alcohol production, reducing production cost and improving economical benefits can be realized.

Owner:BINZHOU ZHONGYU FOOD

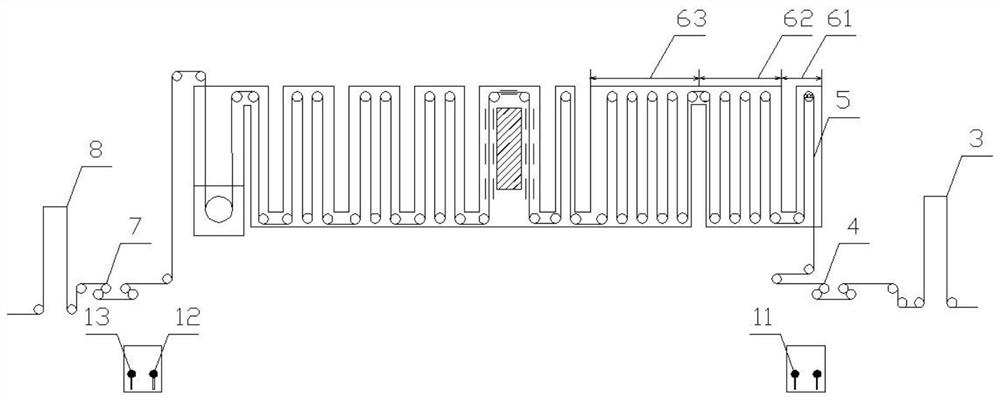

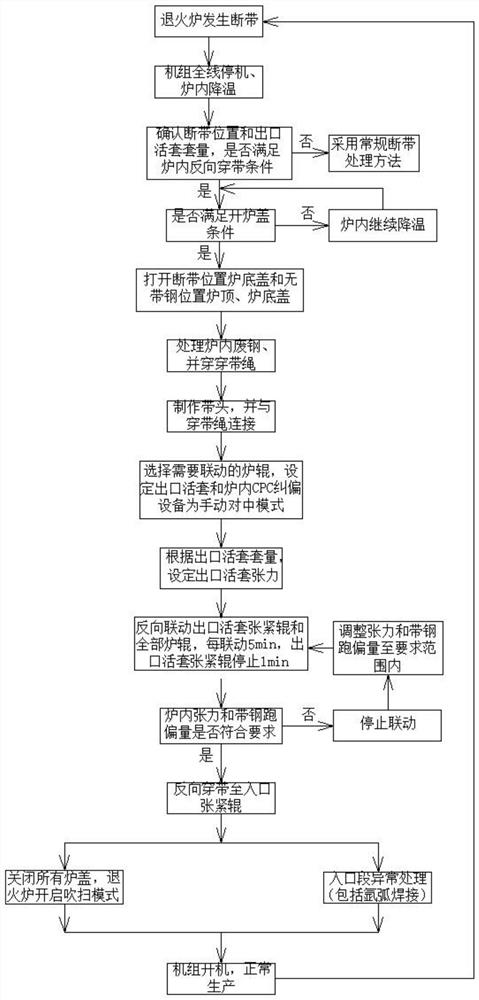

Control method of reverse belt threading in vertical continuous annealing furnace

ActiveCN109576481BRealize reverse threadingImprove the efficiency of threading operationsFurnace typesHeat treatment process controlFurnace temperatureContinuous annealing

The invention relates to a vertical continuous annealing furnace interior reverse belt penetrating control method. The control method comprises the following steps that S1, a unit is stopped, and an annealing furnace is switched to the cooling mode; S2, the belt breaking position in the furnace is determined, whether the looping quantity of an outlet loop is enough or not is determined, and whether a reverse belt penetrating operation method is adopted or not is decided; S3, when the temperature of the furnace is decreased to the furnace cover opening temperature or below, according to the belt breaking condition in the furnace, a corresponding furnace cover is opened, steel scrap processing and rope penetrating operation are conducted, and a belt head is manufactured at the tail of a broken belt and connected with a belt penetrating rope; S4, a furnace roller needing to be subjected to linkage is selected; S5, according to the looping quantity of the outlet loop, the tension of the outlet loop is set, and belt steel in the furnace is tightened by adopting an outlet tensioning roller of the annealing furnace; S6, the outlet tensioning roller and the furnace roller are operated forreverse full linkage, and in-furnace reverse belt penetrating operation is conducted till the tail of the belt penetrates to an inlet tensioning roller of the annealing furnace; S7, all the furnace covers are closed, and the blow sweeping mode of the annealing furnace is started; and S8, the unit is started for normal production.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

A looper control method for pipeline steel

ActiveCN103990652BEnsure automatic controlRealize automatic controlTension/compression control deviceLine tubingAutomatic control

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

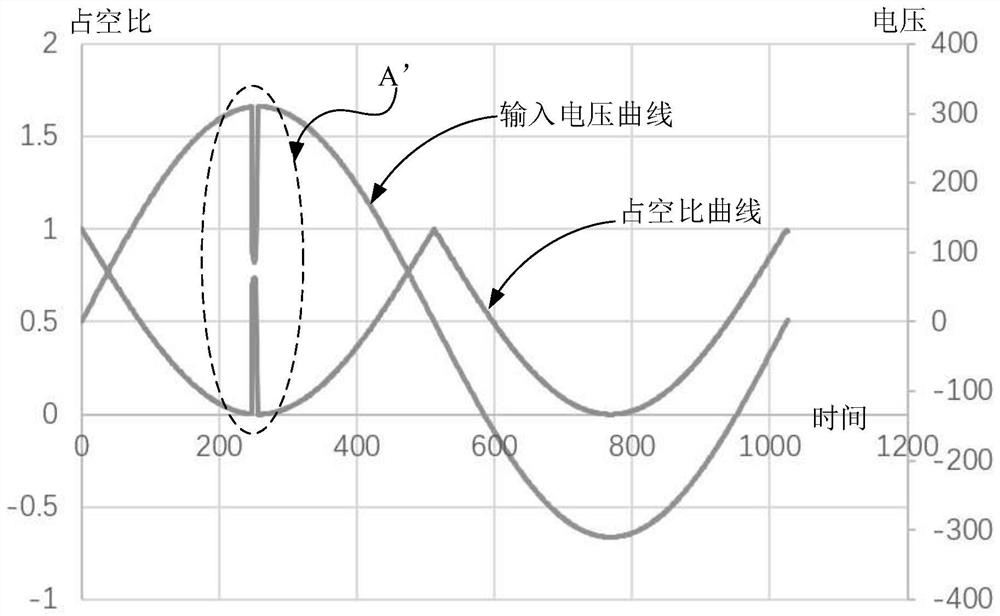

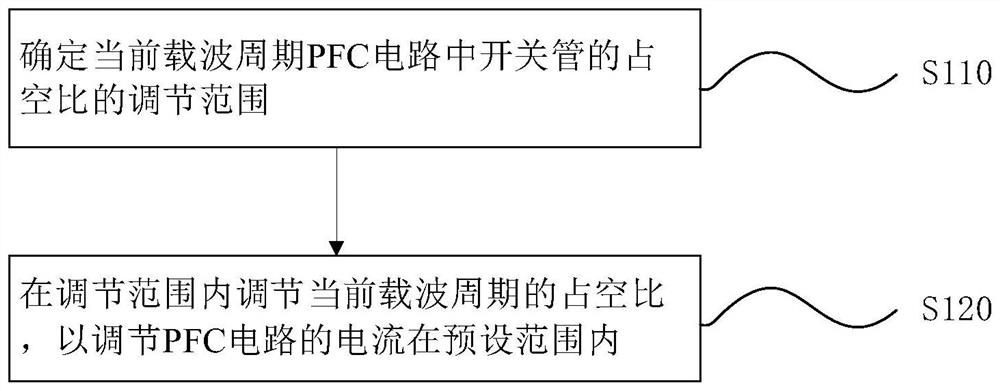

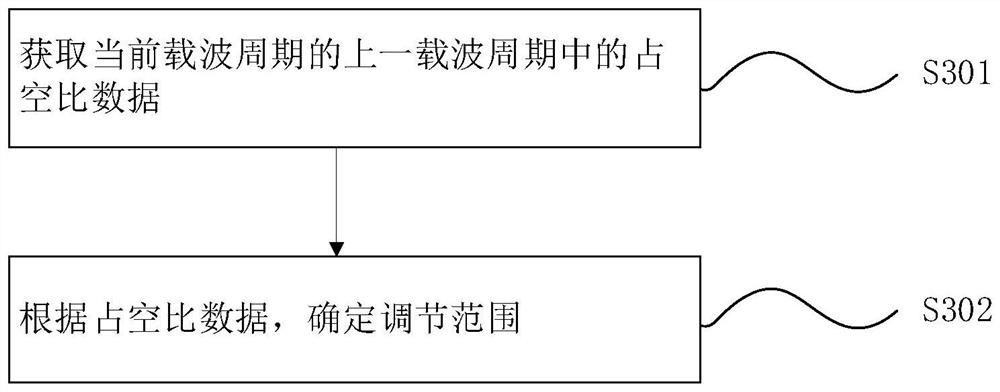

Circuit protection method and device, electrical equipment and storage medium

PendingCN114362495AGuaranteed uptimeReduce abnormal downtimeEfficient power electronics conversionPower conversion systemsPower gridHemt circuits

The invention relates to a circuit protection method and device, electrical equipment and a storage medium. The method comprises the steps that the adjustment range of the duty ratio of a switching tube in a PFC circuit in the current carrier period is determined; and adjusting the duty ratio of the current carrier cycle in the adjustment range so as to adjust the current of the PFC circuit to be in a preset range. According to the method disclosed by the invention, the adjustment of the duty ratio of the switching tube is always within the set adjustment range, and the increase amplitude of the duty ratio does not exceed the adjustment range in the scene of voltage abrupt change, so that the current of the PFC circuit is always under the overcurrent threshold, and the electrical equipment can stably operate without shutdown on the premise of protecting the electrical equipment. Therefore, abnormal shutdown of the electrical equipment caused by instability of a power grid is effectively reduced, and the user experience is improved.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

Steering roller control method to ensure stable strip steering on processing line

ActiveCN104492820BRealize automatic controlSolve problems such as steering oscillationRoll mill control devicesMetal rolling arrangementsStrip steelUltimate tensile strength

The invention discloses a steering roller control method for guaranteeing steering stability of strip steels on a treatment line. The method comprises the following steps: (1) a PLC receives the yield strengths and the thickness parameters of the strip steels operating on the treatment line; (2) the steering roller moment control parameters Qn of the PLC are set according to the parameters; (3) when the strip steels operate on the treatment line with constant speed, steering roller moment controllers are controlled through setting the adjusting coefficients A as the minimum value; when the strip steels operate with decreased speed or increased speed, the adjusting coefficients A of all the steering roller moment controllers are increased; and when the accelerations of the strip steels operating with decreased or increased speed are beyond the acceleration change dead area range, the adjusting coefficients A of all the steering roller moment controllers are set as the maximum value. The method can guarantee the steering stability of steering rollers and prevent the influence of the steering oscillation on the product quality, and can be widely applied to the technical field of strip steel production.

Owner:通用电气(武汉)自动化有限公司

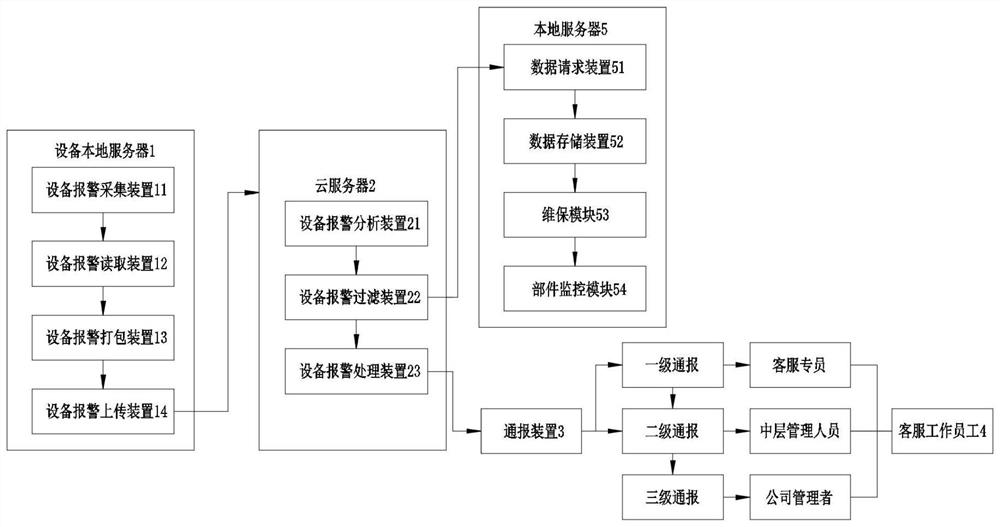

Equipment after-sales service system and method based on cloud service

The invention discloses an equipment after-sales service system based on cloud service. The equipment after-sales service system comprises an equipment local server, a cloud server and a notification device, wherein the equipment local server is in data connection with the cloud server, and is used for collecting alarm information of the equipment and uploading the alarm information to the cloud server; the cloud server is in data connection with the notification device, and is used for analyzing and comparing the acquired data, so that unimportant alarm information or information which does not need to be processed is abandoned, whereas the important alarm information or information needing to be processed in time is sent to the notification device; the notification device is in data connection with customer service staff, and sending the important alarm information or information needing to be processed in time to after-sales service employees; the customer service staff makes processing and guidance in time. According to the invention, an equipment manufacturer can receive alarm information in time and process the alarm information in time, so that loss caused by shutdown of a user is reduced; in addition, the vulnerable parts or parts of the equipment can be improved.

Owner:DONGGUAN KE YAO EQUIP CO LTD

A car tire manual assembly line layout

ActiveCN102756614BIncrease productivityLess investmentWheel assembling toolsBalancing machineAssembly line

The invention discloses a manual assembly line layout for automobile tires, belonging to the field of automobile tire assembly. The manual assembly line for the tires comprises more than two assembly lines, wherein each assembly line comprises a dismantling and assembling machine, an aerator, a balancing machine, a correction roller machine which are arranged in parallel along the Y-axis direction, and each assembly line is perpendicular to an assembly type part loading roller machine and an assembly type part unloading roller machine which are arranged along the X-axis direction. The manual assembly line layout has the advantages that the scattered part loading roller machines in the prior art are assembled into the part loading roller machine, the scattered part unloading roller machines in the prior art are assembled into the part unloading roller, the assembly type part loading roller machine and the assembly type part unloading roller machine are driven through a motor for transmission, the transmission spacing is carried out through an optoelectronic switch, and therefore, the convenience of manual assembly is increased, the production efficiency of the assembly line is improved, the operation region of a forklift is reduced, operating personnel are not needed in the production process, the cross operation of the forklift in the production process is eliminated, and the fluency of tire line physical distribution and the operation safety are increased. The length of equipment stations is shortened; and the effective usable areas of plants are increased.

Owner:CHERY AUTOMOBILE CO LTD

Process and device for recovering gluten from starch slurry

ActiveCN102974146BHigh extraction rateReduce the number of blocked heat exchange equipmentBioreactor/fermenter combinationsBiological substance pretreatmentsAlcohol productionEconomic benefits

The invention belongs to the technical field of flour milling, and particularly relates to a process and device for recovering gluten from starch slurry. A starch slurry filtering tank is additionally arranged in front of a feeding opening of a liquefaction tank in a gluten workshop; and the gluten in the starch slurry can be filtered through a two-stage filtering screen, and can be pumped into the liquefaction tank. The filtered gluten is recovered in time by a manual method according to the content of the gluten in the thick slurry, so that the amount of the gluten entering the liquefaction tank can be controlled, and furthermore, the purposes of stabilizing alcohol production, reducing production cost and improving economical benefits can be realized.

Owner:BINZHOU ZHONGYU FOOD

Speed control method of looper false frame in hot continuous rolling thin gauge steel mill

ActiveCN105665450BRealize automatic controlEliminates significant potential for damageRoll speed control deviceSheet steelAdditional values

A speed control method for a loop virtual sleeving rack of a hot continuous rolling thin-steel-plate rolling mill is characterized in that when a rack loop torque deviation value is larger than or equal to 2000 Nm, the final speed reference value of the rack is correspondingly reduced; and when the rack loop actual torque is larger than or equal to set torque 1000 Nm (that is the torque when the rack loop torque deviation value is smaller than or equal to -1000 Nm), an integral control formula is applied to enable the torque to quit out of the above speed additional value. According to the method, off tracking, rolling rejects and major risks to mechanical equipment due to loop virtual sleeving are eliminated, the failure time is shortened, the product quality is improved, and good benefits are achieved.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com