Equipment maintenance intelligent control system and method

An intelligent control system and equipment technology, applied in the field of computer and network, can solve the problems that it is difficult to meet the requirements of metallurgical enterprises to reduce staff and increase efficiency, excessive purchase cost of spare parts, transitional maintenance and under-maintenance, etc., so as to reduce the possibility of abnormal shutdown and improve Efficiency and accuracy, the effect of reducing manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] For a more thorough understanding of the present invention, the present invention will now be described in detail with reference to some embodiments shown in the accompanying drawings. The invention may be practiced without parts or specific details. Well-known processing steps and / or structures are not described in detail herein. In addition, although the present invention has been described in conjunction with specific embodiments, the description does not limit the present invention to the described embodiments, and should not be taken as a limitation of the scope of protection claimed by the present invention.

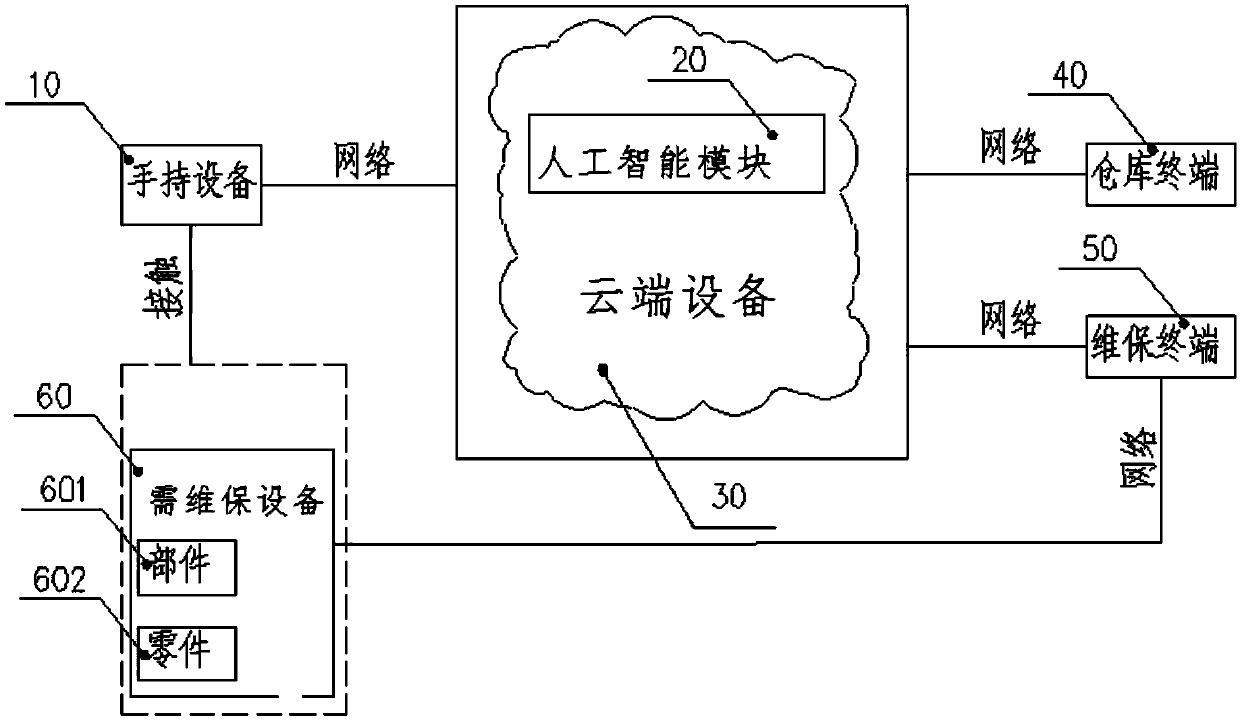

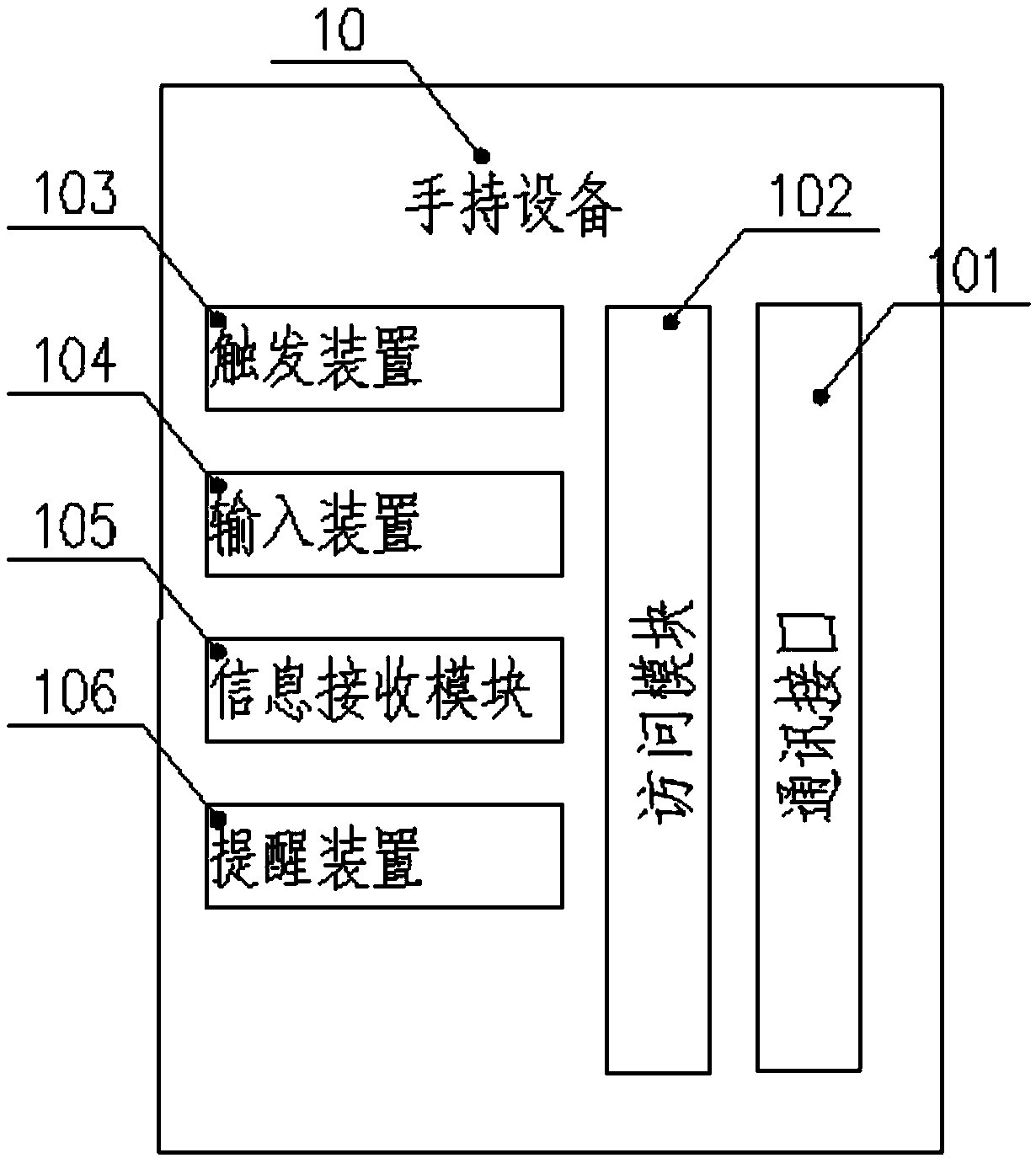

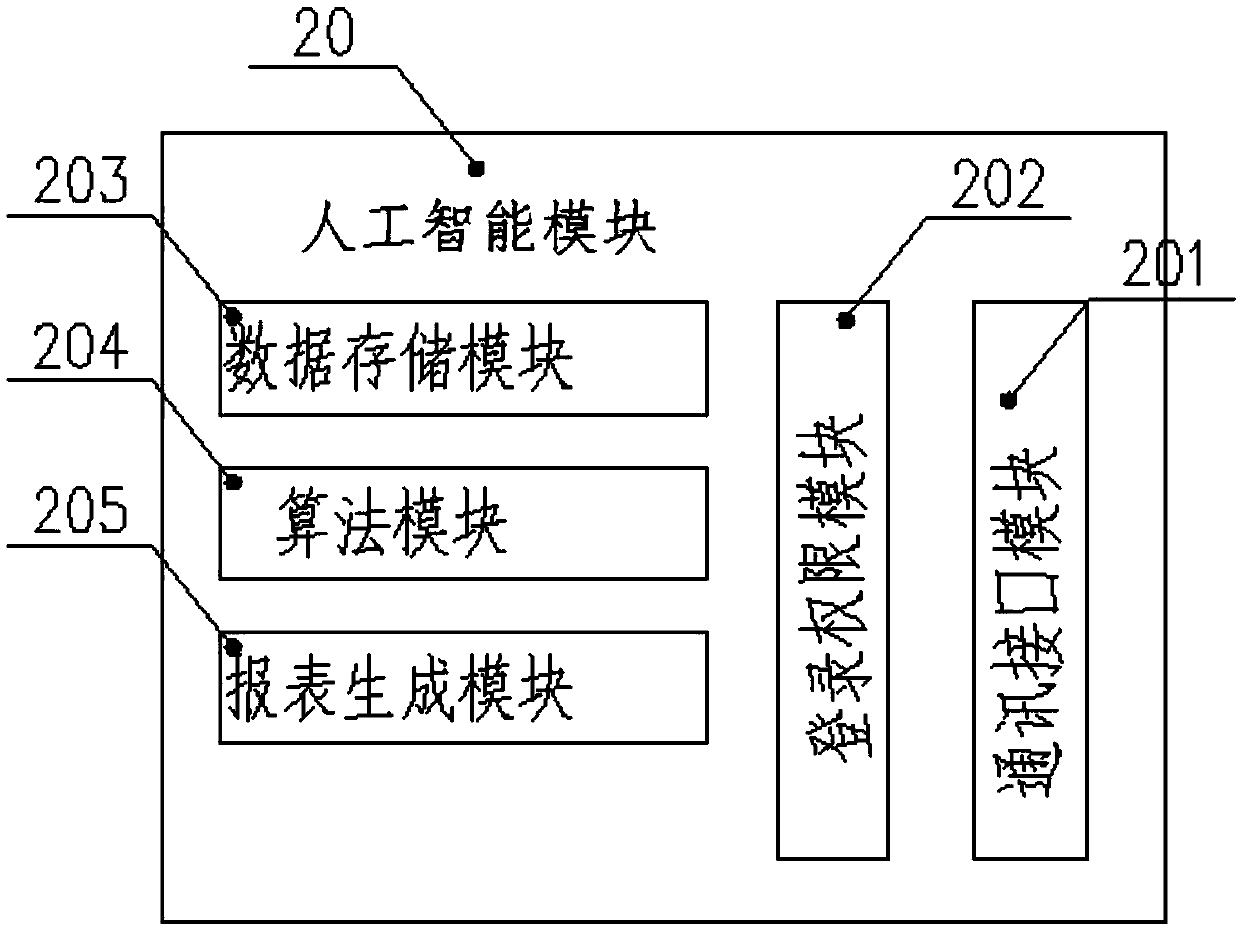

[0039] figure 1 The schematic diagram of the system modules of the illustrated embodiment includes an artificial intelligence module 20, a cloud device 30, a handheld device 10, a warehouse terminal 40, a maintenance terminal 50 and a maintenance device 60; wherein, the artificial intelligence module 20 runs on the On the cloud device 30, it is used for da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com