Paper machine light curtain safety production device

A technology for safe production and paper machine, applied in the direction of optical device exploration, etc., can solve the problems of non-adjustable height, high price, false triggering, etc., and achieve the effect of reducing abnormal shutdown, increasing control safety, and improving safety and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

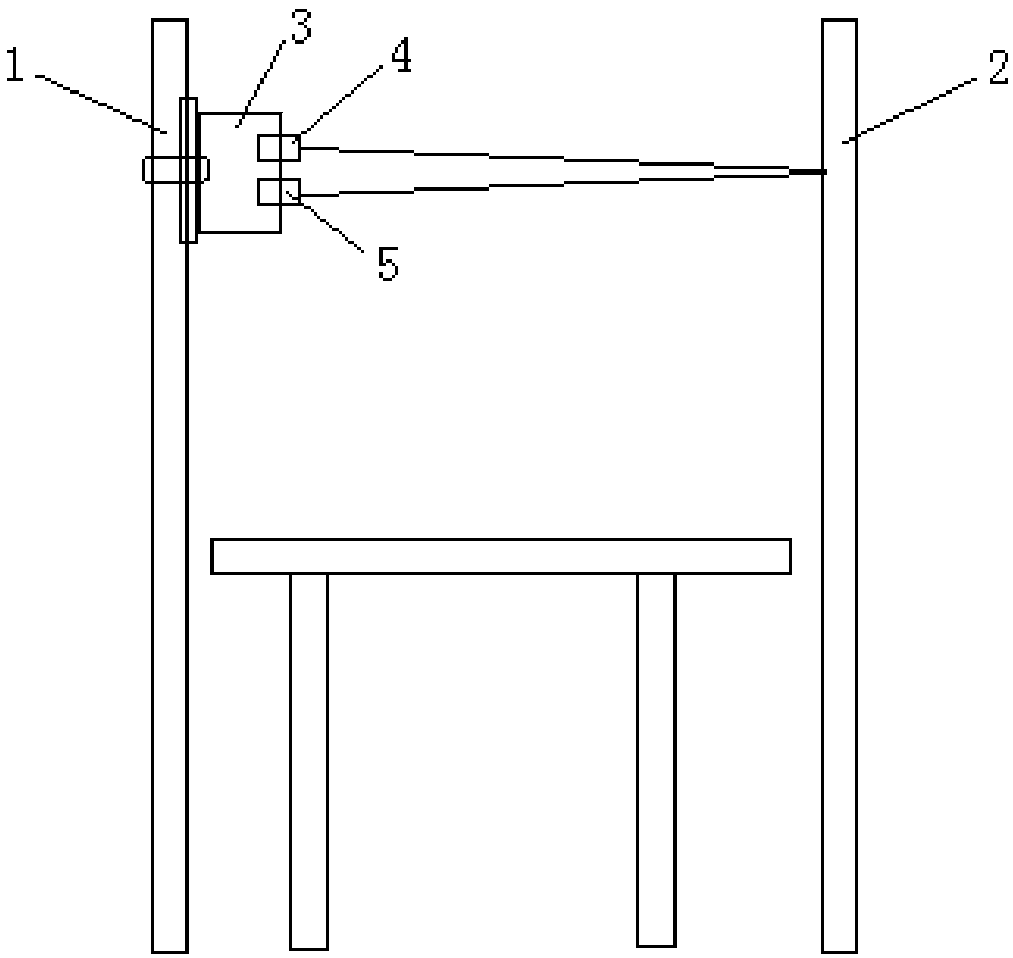

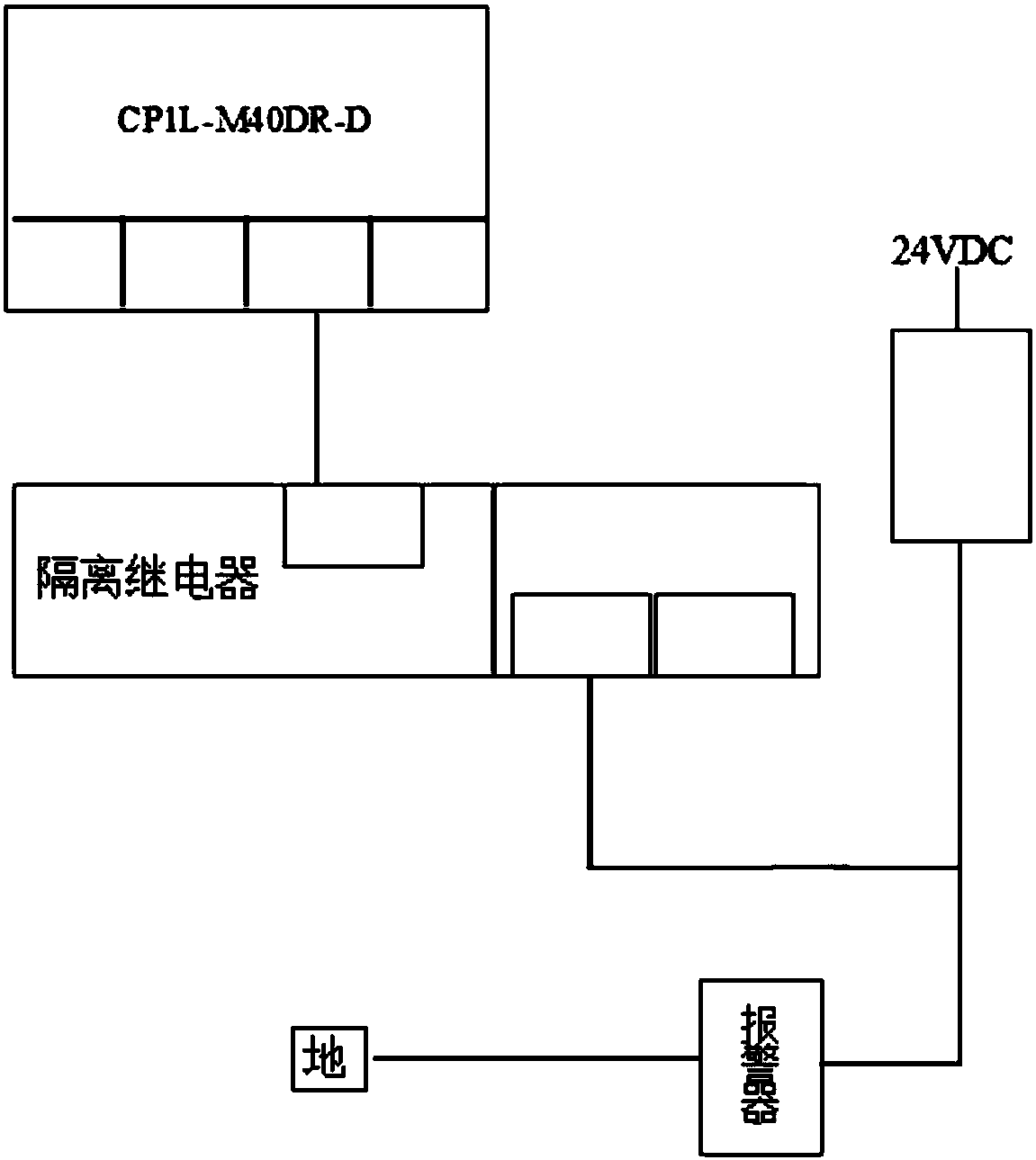

[0024] Such as figure 1 As shown, the present invention provides a light curtain safety production device for a paper machine, including:

[0025] Photoelectric sensor: It is a reflective plate photoelectric sensor, which is arranged on both sides of the paper roll frame of the paper machine. It includes a sensor body and a reflector arranged oppositely. The sensor body includes a vertical pole and an aluminum square installation on the top of the vertical pole. The box and the light-emitting device and the light-receiving device arranged in the mounting box, the infrared rays emitted by the light-emitting device are reflected by the reflector and received by the light-receiving device, and when blocked, a trigger signal is generated.

[0026] The side of the square mounting box facing the reflector is provided with a vertical slot for emitting and receiving infrared rays, and the light emitter and the light receiver are vertically arranged and aligned with the vertical slot.

[0027...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com