Process and device for recovering gluten from starch slurry

A gluten and process technology, which is applied to the process of recovering gluten from slurry and the field of devices used, can solve the problems of clogging heat exchange equipment, affecting normal production, low gluten extraction rate, etc., to ensure sanitation and smooth progress, reduce The effect of blocking the number of heat exchange equipment and improving the yield of alcohol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

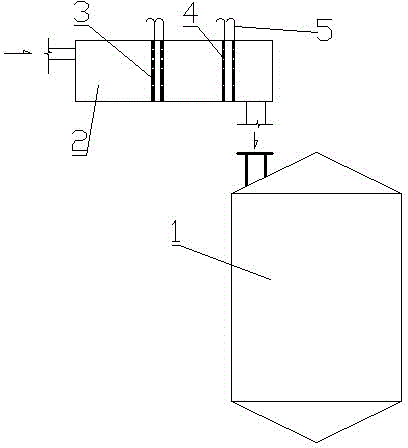

[0027] Before the liquefaction tank 1, a filter tank 2 is arranged, and 2 coarse filter screens and 2 fine filter screens are movably installed in the filter tank 2; the gap between the coarse filter screen 3 is 2 mm, and the gap between the fine filter screen 4 is 1 mm.

[0028] A handle 5 is arranged on the filter net in the opening direction of the filter tank 2 .

[0029] According to the amount of gluten in the concentrated slurry, the filtered gluten can be recovered in time by artificial means, and the amount of gluten entering the liquefaction tank can be controlled, thereby achieving the purpose of stabilizing alcohol production, reducing production costs, and improving economic benefits.

[0030] Before the transformation: clean the heat exchanger twice a week, 2 people each time, 3 hours, use about 0.5 tons of steam, the cost is 200 yuan, the shutdown affects production for 3 hours, according to 2000 yuan / h, the cost is 6000 yuan, a total of 12400 Yuan;

[0031] Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com