Patents

Literature

34results about How to "Increase alcohol yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

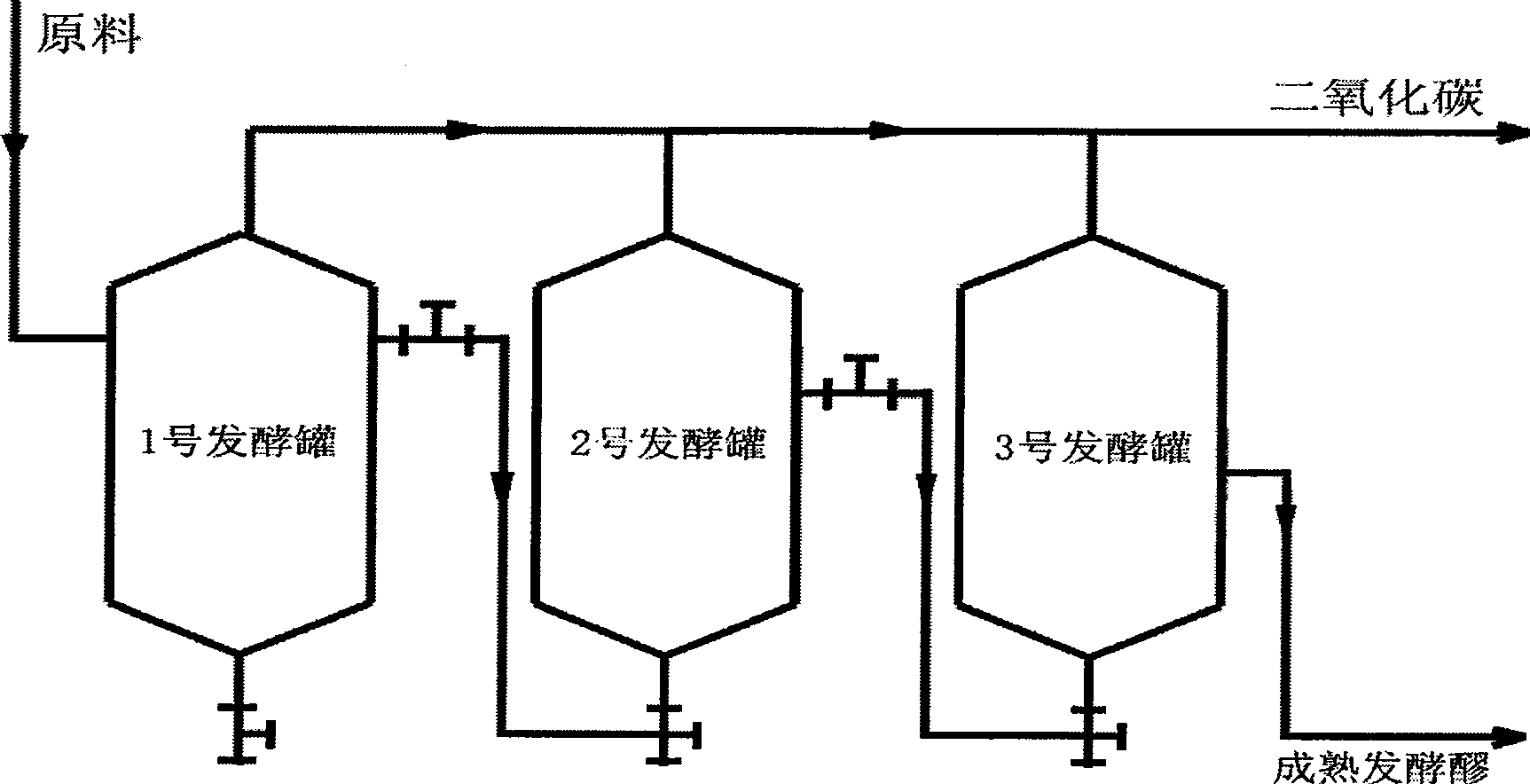

Wine brewing yeast strain and method for producing ethanol by efficient sugarcane juice fermentation

InactiveCN101434911AHighlight substantiveSignificant progressFungiBiofuelsFreeze-dryingContinuous flow

The invention relates to an excellent Saccharomyces cerevisiae gxas02 and a method for carrying out scale production of ethanol by utilizing the Saccharomyces cerevisiae gxas02 as a production strain and adopting sugar cane juice as a raw material. The strain is vacuum freeze-dried and collected in China Center for Type Culture Collection with the collection No. of CCTCC NO: M208110, the collection date is July 19, 2008, the strain is the Saccharomyces cerevisiae by identification, the strain is applicable to fermenting the ethanol by using the sugar cane juice, with fast speed, low residual sugar content, high temperature resistance and alcohol resistance. A production technology adopts a single concentration continuous flow processing technology, the sugar cane juice which is pressed but not concentrated or diluted is directly fermented under the conditions without using yeast reuse and fixed yeast technology, the continuous operation is carried out on a production line with daily production capacity of 10 tons of the ethanol, the effect is good, the fermentation time is 12-16h, alcohol degree reaches 8.6-9.4(V / V) and the residual sugar is 0.2-0.3g / 100ml. The invention is characterized by convenient implementation, high equipment utilization rate, high ethanol concentration of fermented mash, high sugar utilization rate which is close to the theoretical value, and the like, thereby reducing the costs for producing the ethanol.

Owner:GUANGXI ACAD OF SCI

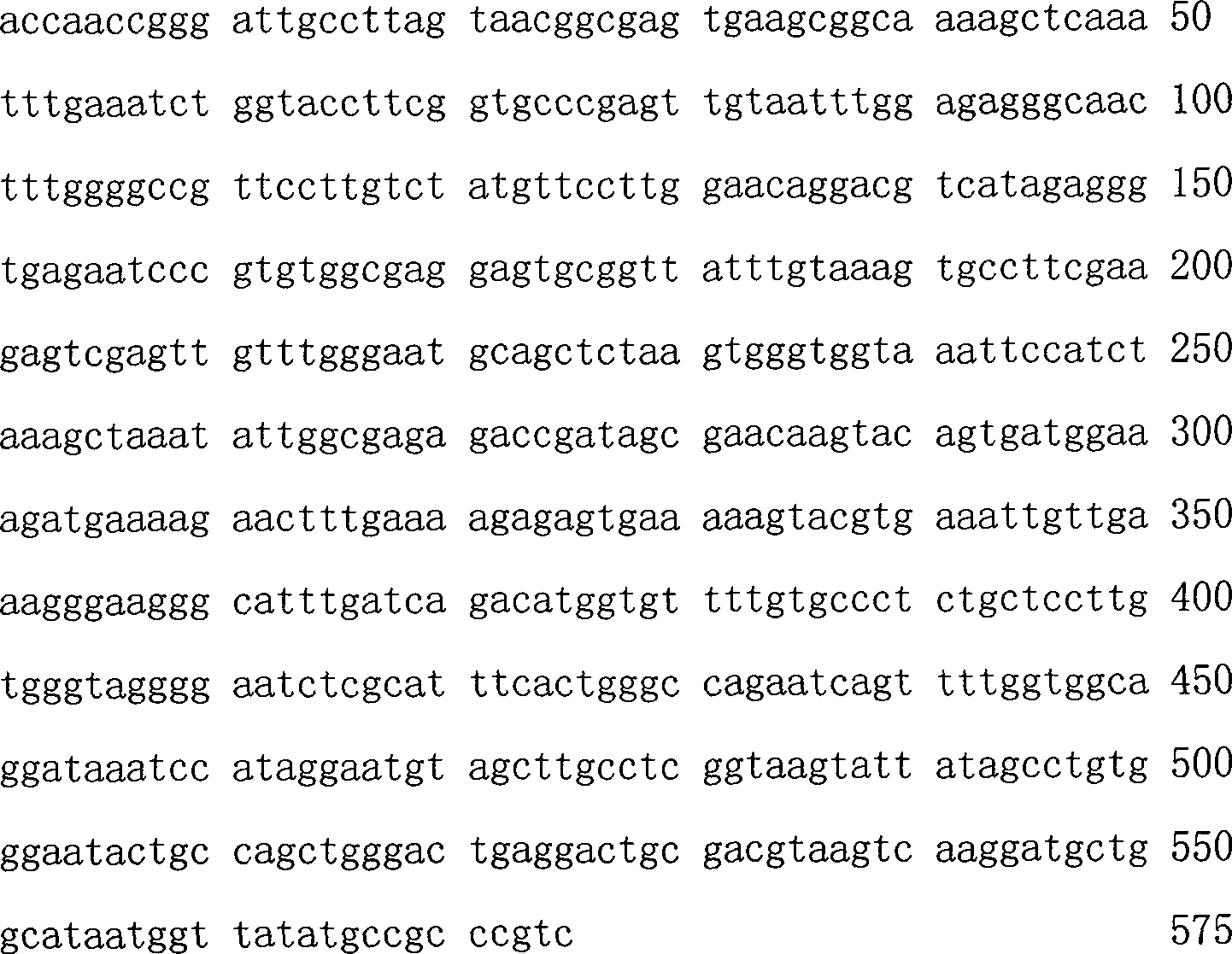

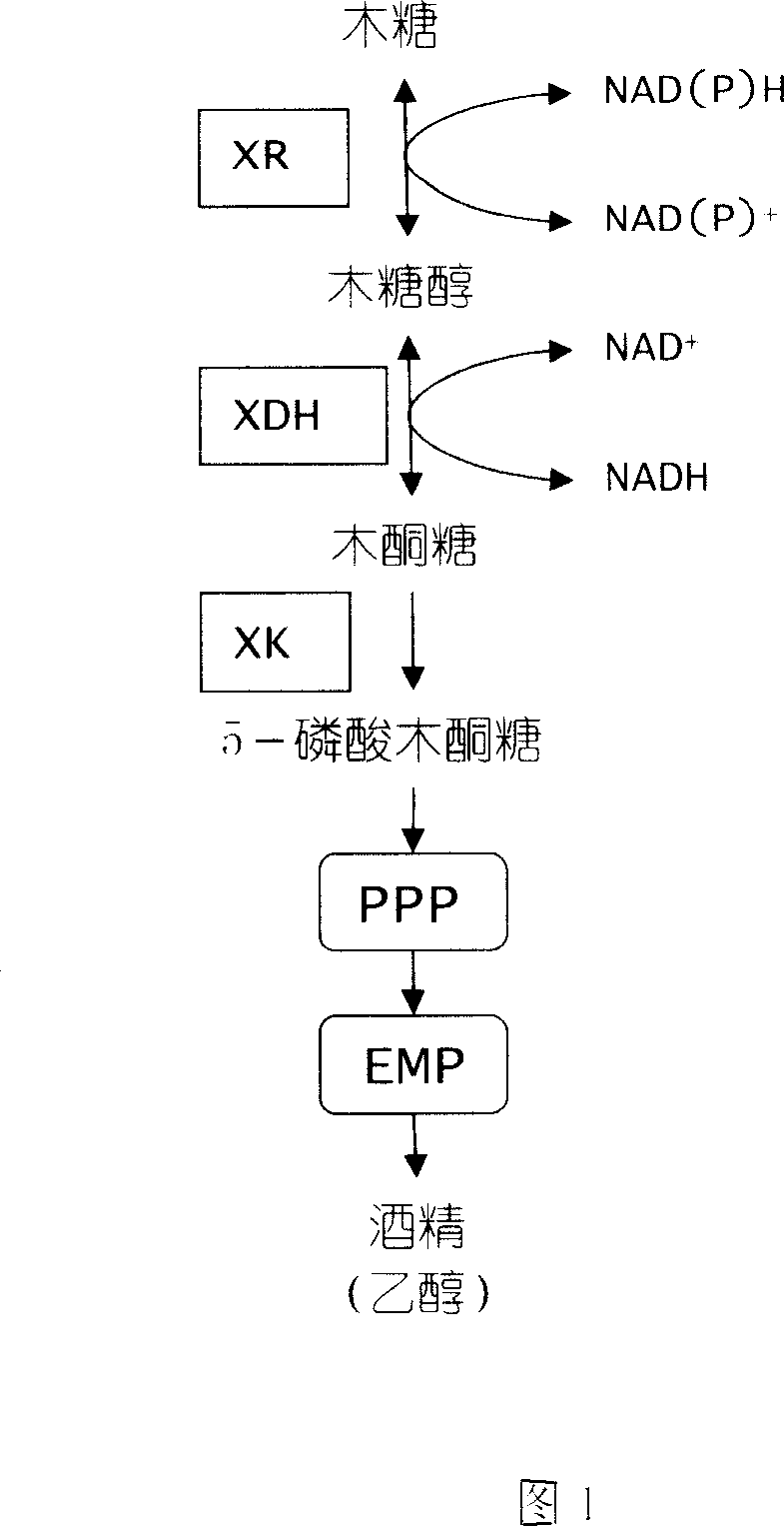

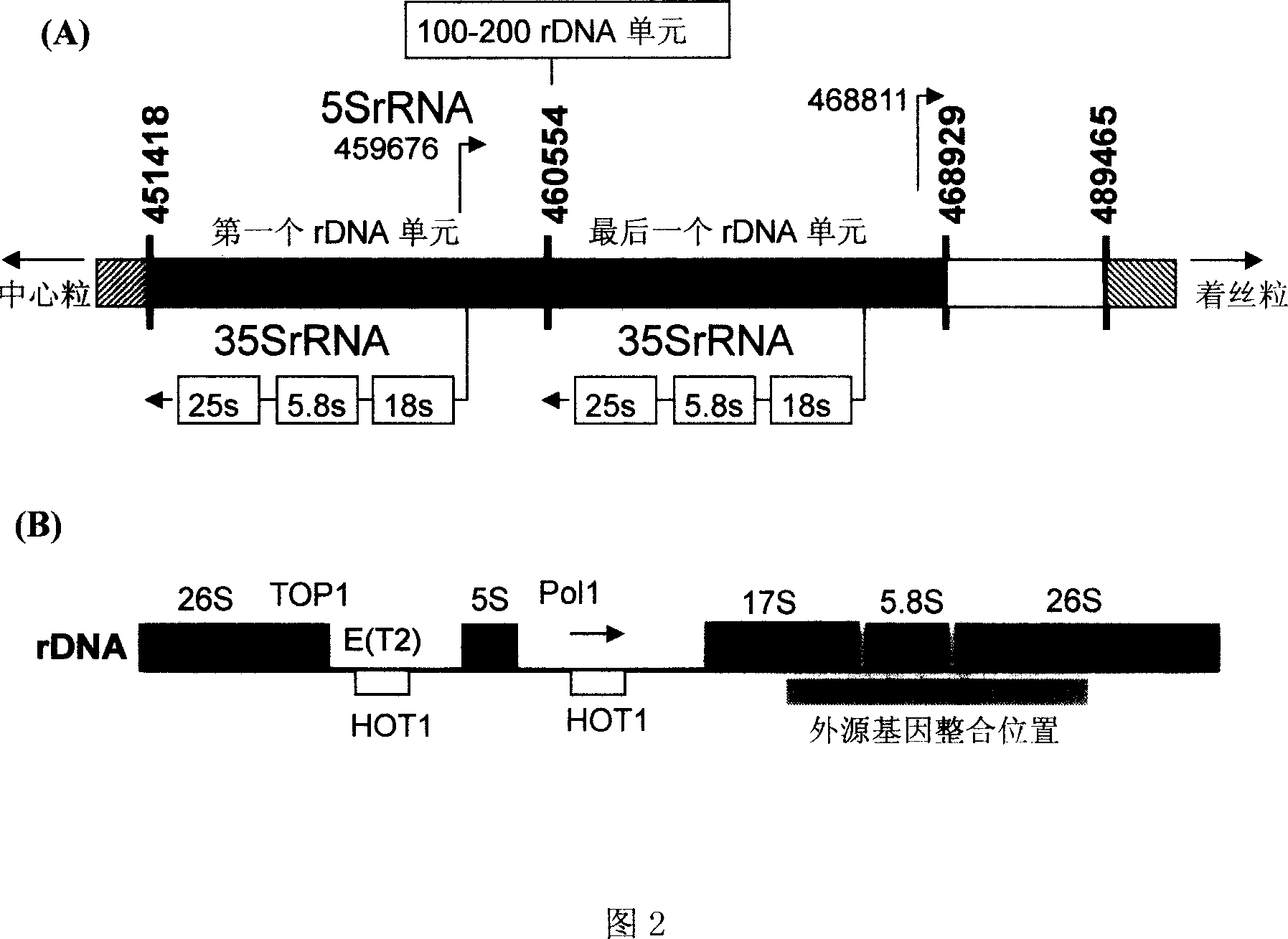

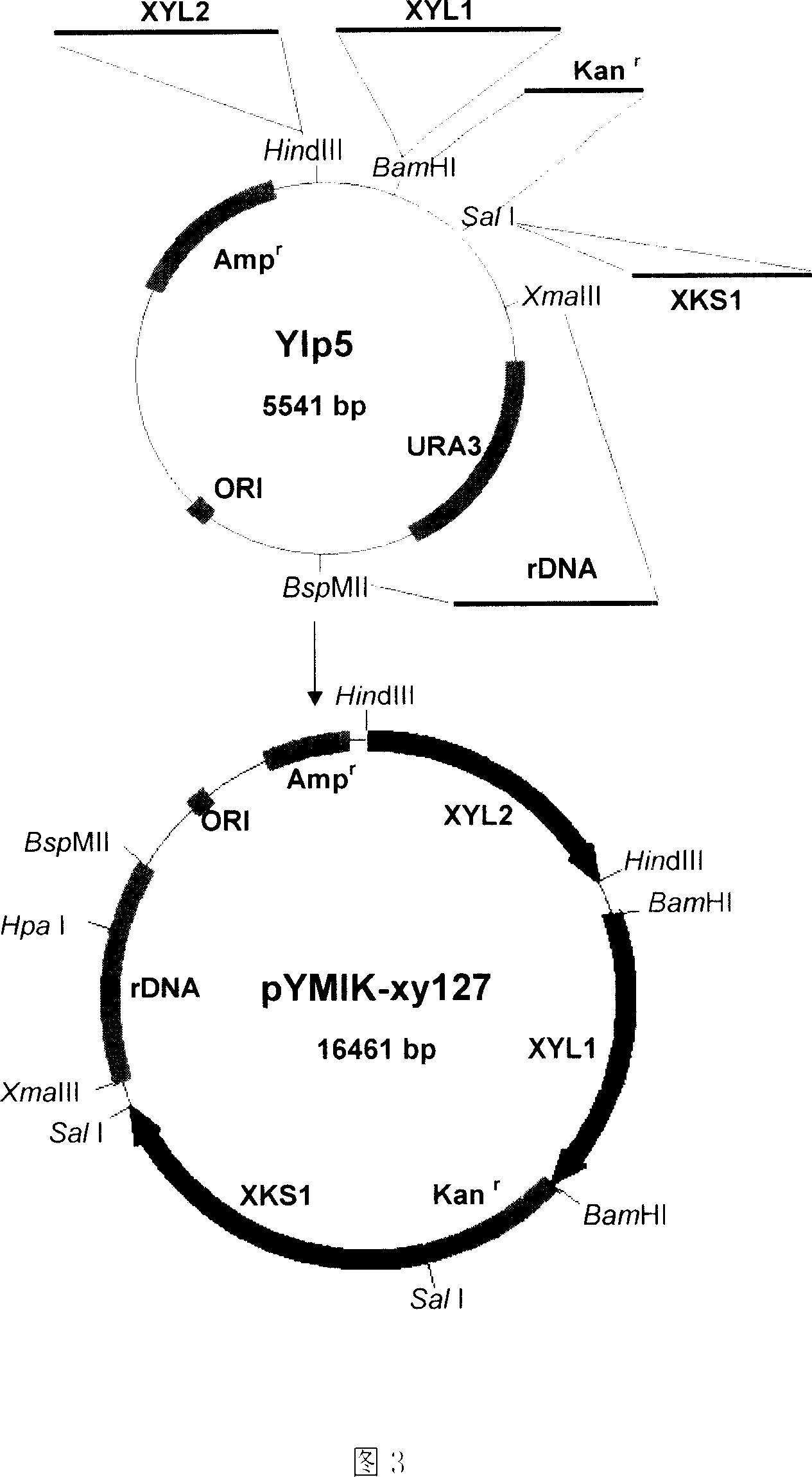

Process for producing alcohol by co-fermentation of glucose and xylose

The invention discloses a method for producing alcohol by co-fermenting glucose with recombinant Saccharomyces cerevisiae strains for industrial production. The invention comprises the steps of: (1) selecting recombinant Saccharomyces cerevisiae NAN127 (CGMCC No.1848), (2) slant-culturing, (3) culturing for seed, (4) enlargement-culturing, (5) fermenting, and (6) distilling to obtain alcohol. The method can utilize glucose and xylose in the medium at the same time, has the advantages of high utilization of xylose, high alcohol converting rate, and broad prospect in production alcohol with lignocellulose.

Owner:SHANDONG UNIV

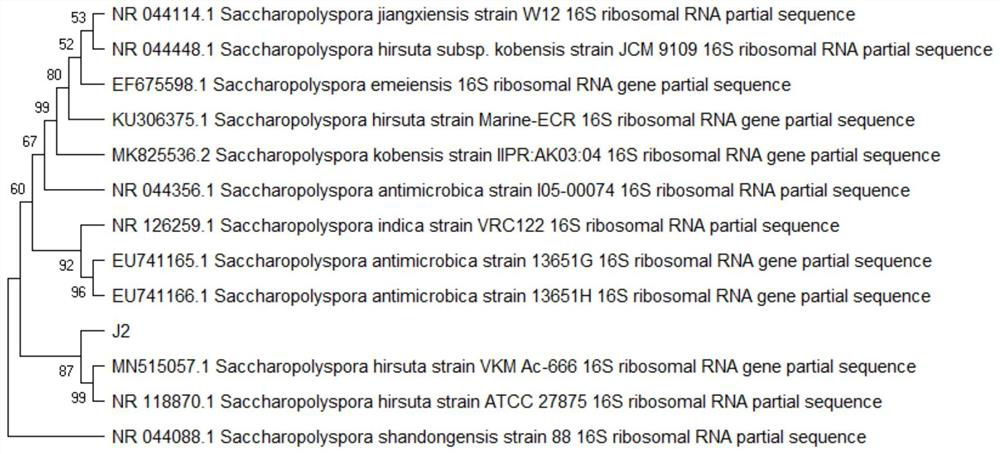

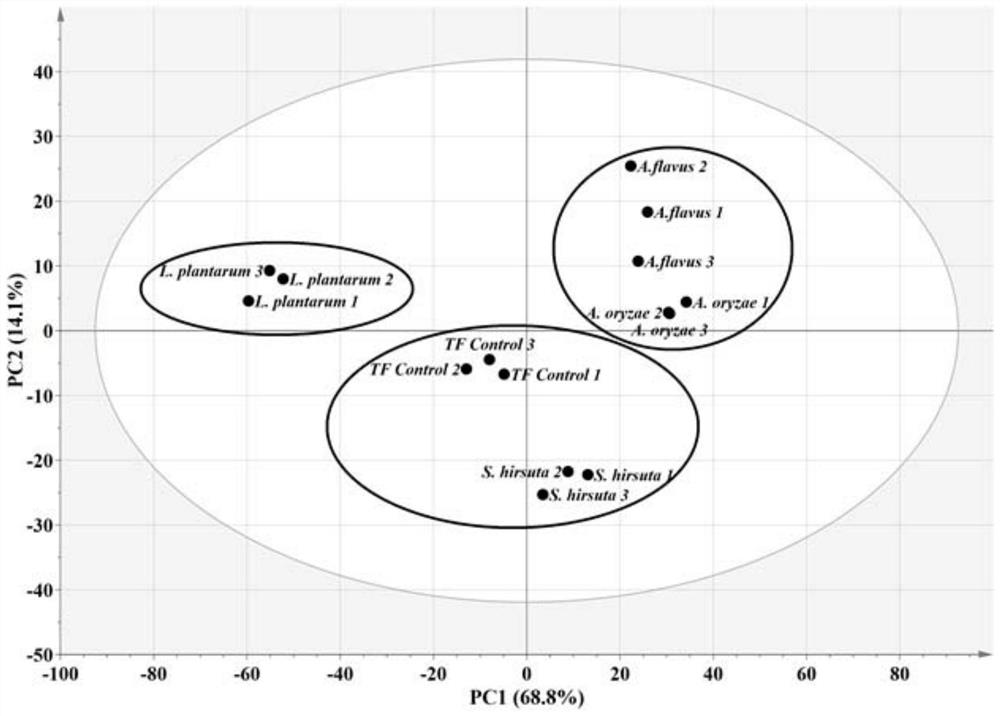

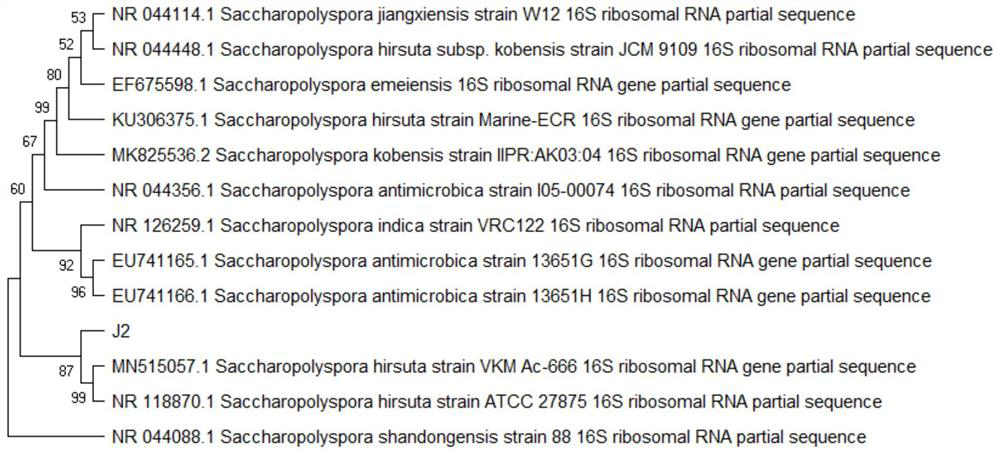

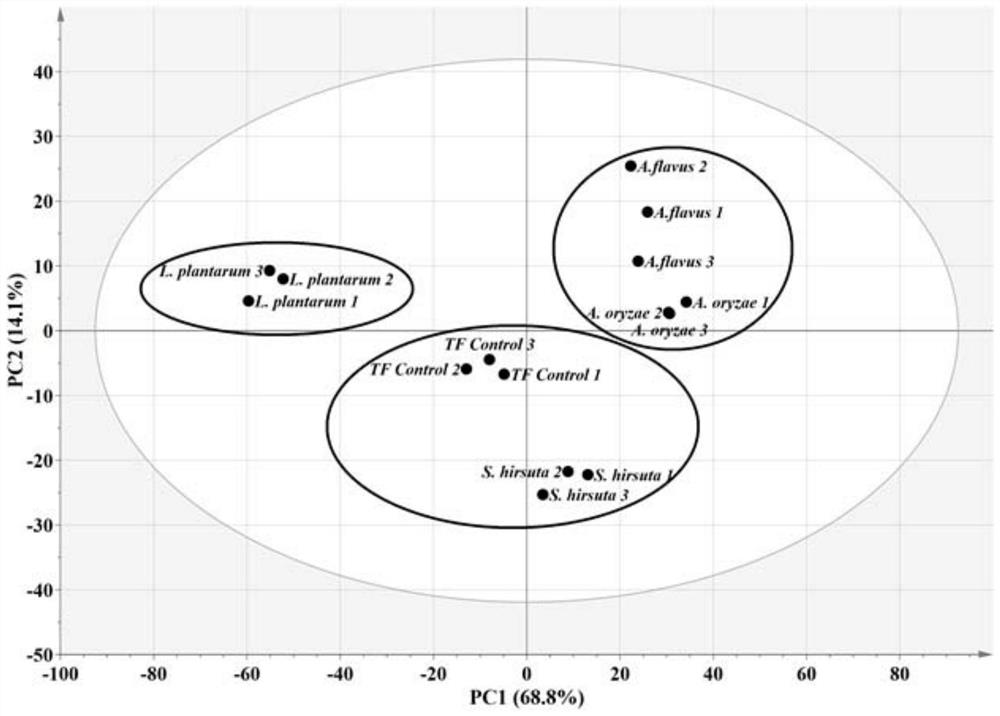

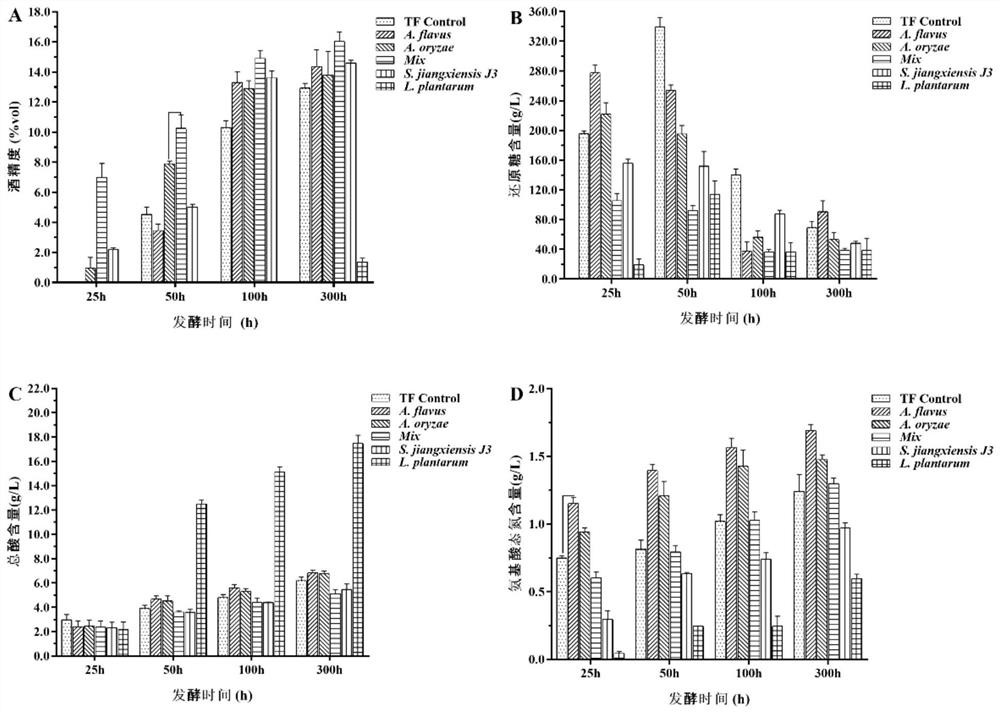

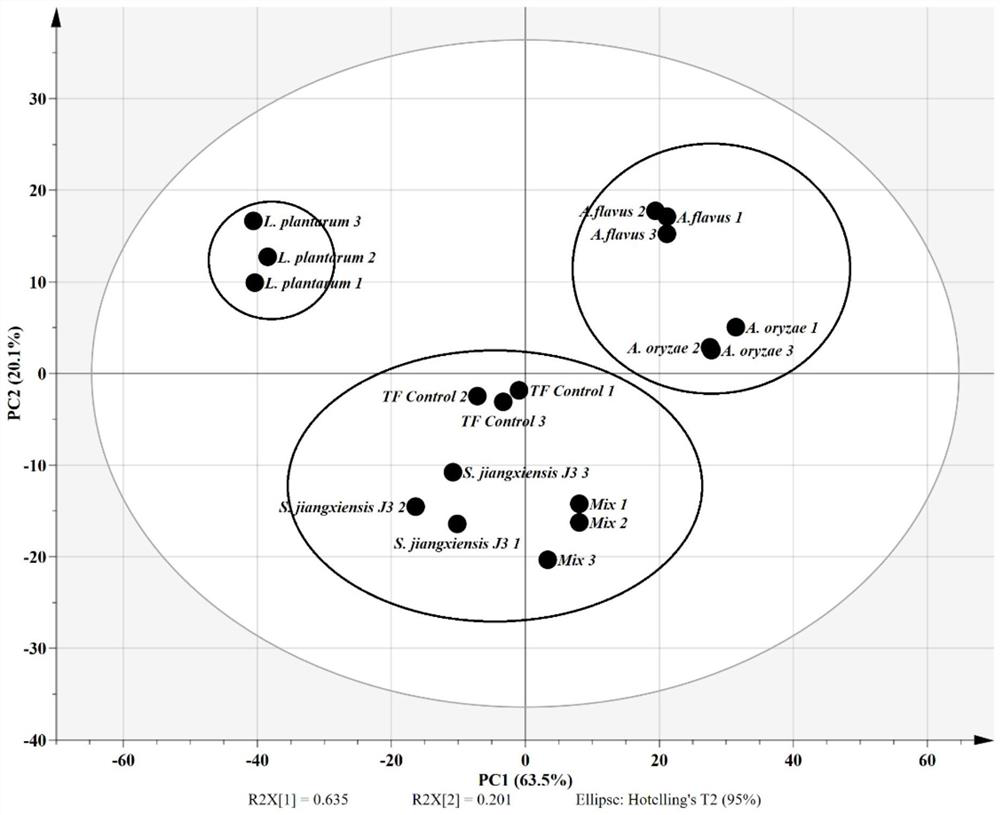

Saccharopolyspora for decreasing biogenic amine and application of saccharopolyspora

ActiveCN111961615ADoes not affect normal fermentationHigh in amino acidsBacteriaMicroorganism based processesBiotechnologyNutritive values

The invention discloses saccharopolyspora for decreasing biogenic amine and application of the saccharopolyspora, and belongs to the technical field of food fermentation. Saccharopolyspora hirsute J2capable of decreasing the content of the biogenic amine is screened from wheat koji and is applied to a brewing process of liquors (white spirits and yellow rice wine), fermented sausages or soy sauce, so that the content of the biogenic amine can be decreased, meanwhile, the content of amino acids can be increased, the nutrition value of a fermented product can be increased, and therefore, the saccharopolyspora is capable of improving the quality and safety of fermented foods and has wide application prospects.

Owner:JIANGNAN UNIV

Composite enzyme of saccharification and nutrition dedicated to alcohol and fuel ethanol, and application

This invention relates to a special diastatic nutritive complex zyme specially used in alcohol and fuel alcohol including the following components in weight percentage: compound cellulose: 10-20%, pectic enzyme; 3-7%, proteinase: 5-15%, debranching enzyme: 5-15%, phytase: 5-15%, beta-amylase: rest. This invention adds the said diastatic nutritive complex zyme into the being saccharificated materials at one run at the diastatic stage. This invented multizyme reagent compound recipe can replace the beta-amylase in the current technology.

Owner:郭峰

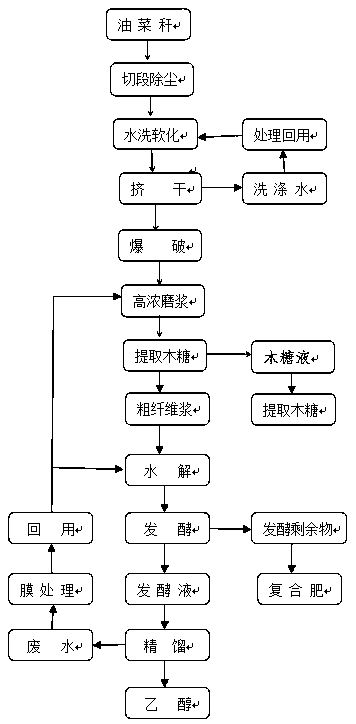

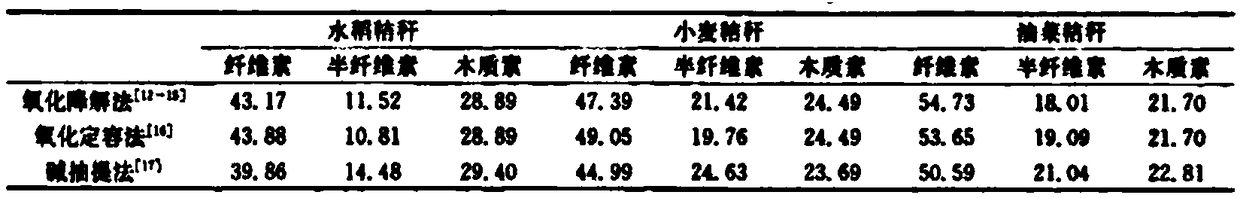

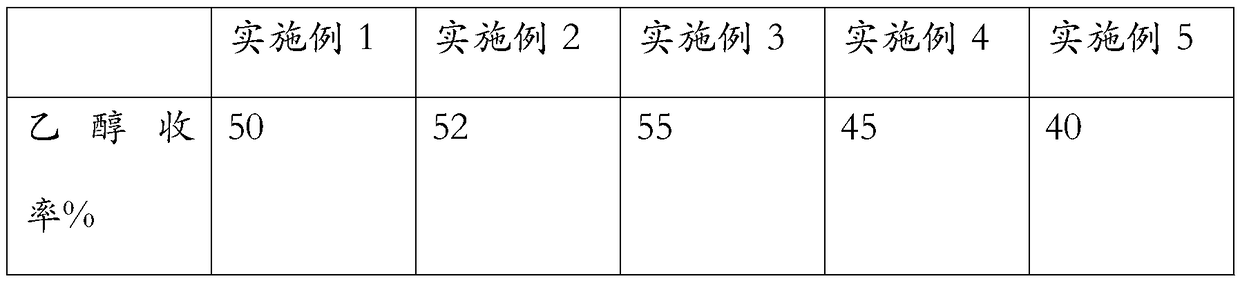

Method for resourceful full-mass utilization of rape stalks

ActiveCN109136293AReduce dosagePromote hydrolysis reactionSugar derivativesBiofuelsWastewaterHydrolysis

The invention belongs to the field of xylose extracted by explosion and ethanol prepared by fermentation, and particularly relates to a method for resourceful full-mass utilization of rape stalks. Themethod comprises the following steps: pretreating raw materials at first; then preparing a compound fertilizer by screw extruded explosion, xylose extraction, impurity removal by hydrolysis, enzymolysis fermentation process and fermentation residues; and treating and reusing waste water. Resourceful full-mass utilization of the rape stalks is realized, the production cost for fermenting ethanol is reduced, and a production process is environmentally friendly.

Owner:SICHUAN GOLDEN ELEPHANT SINCERITY CHEM CO LTD

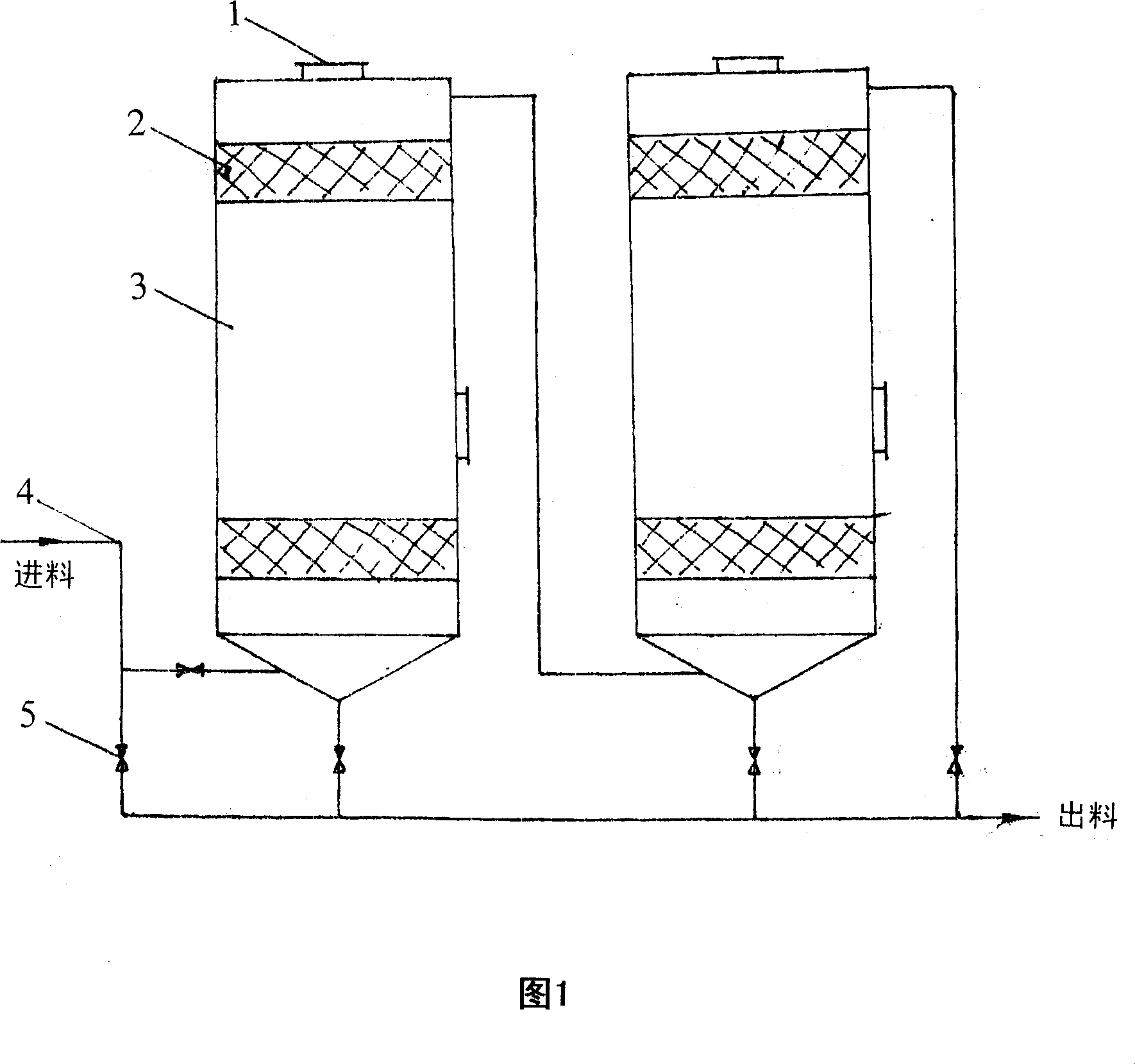

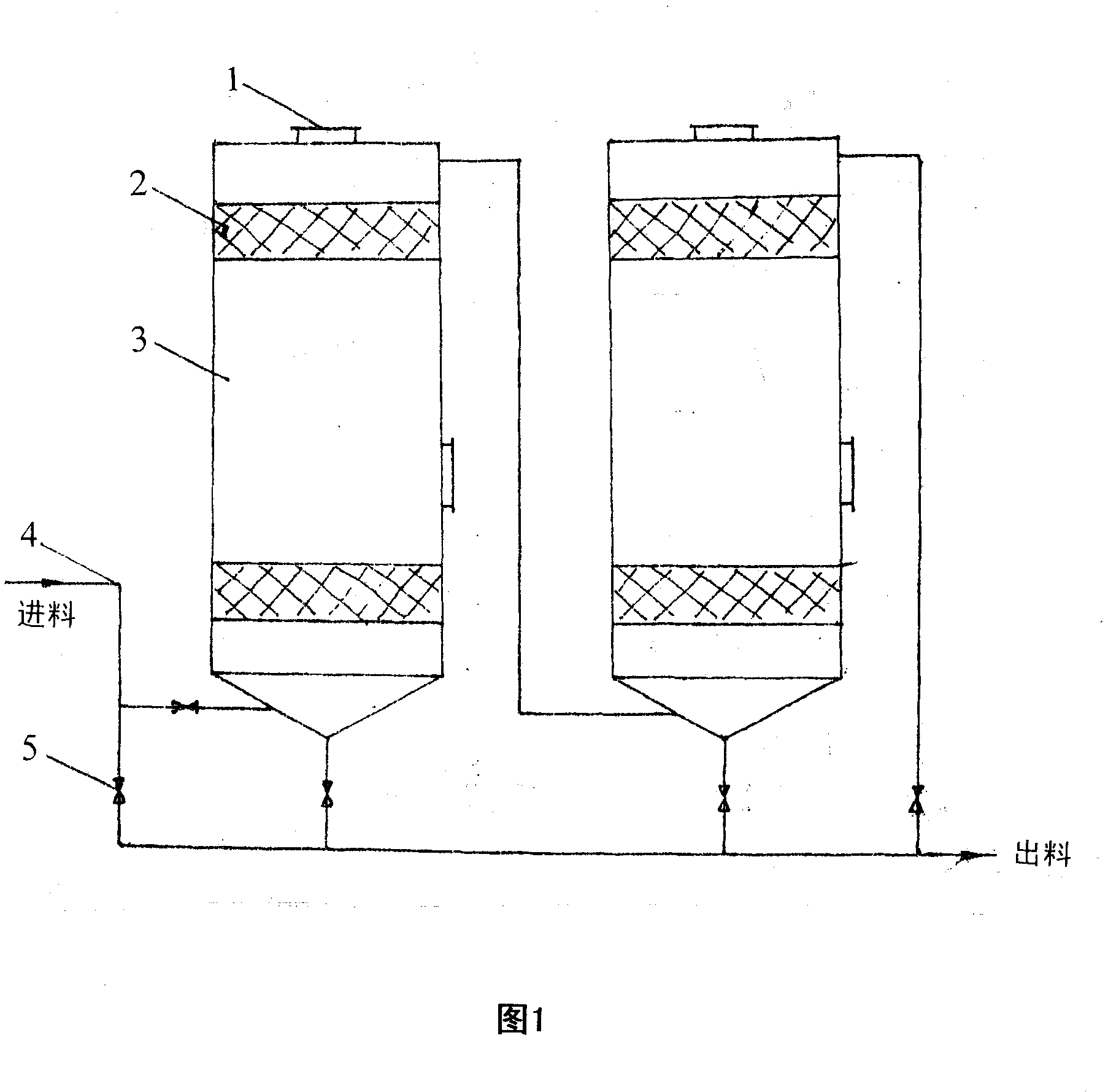

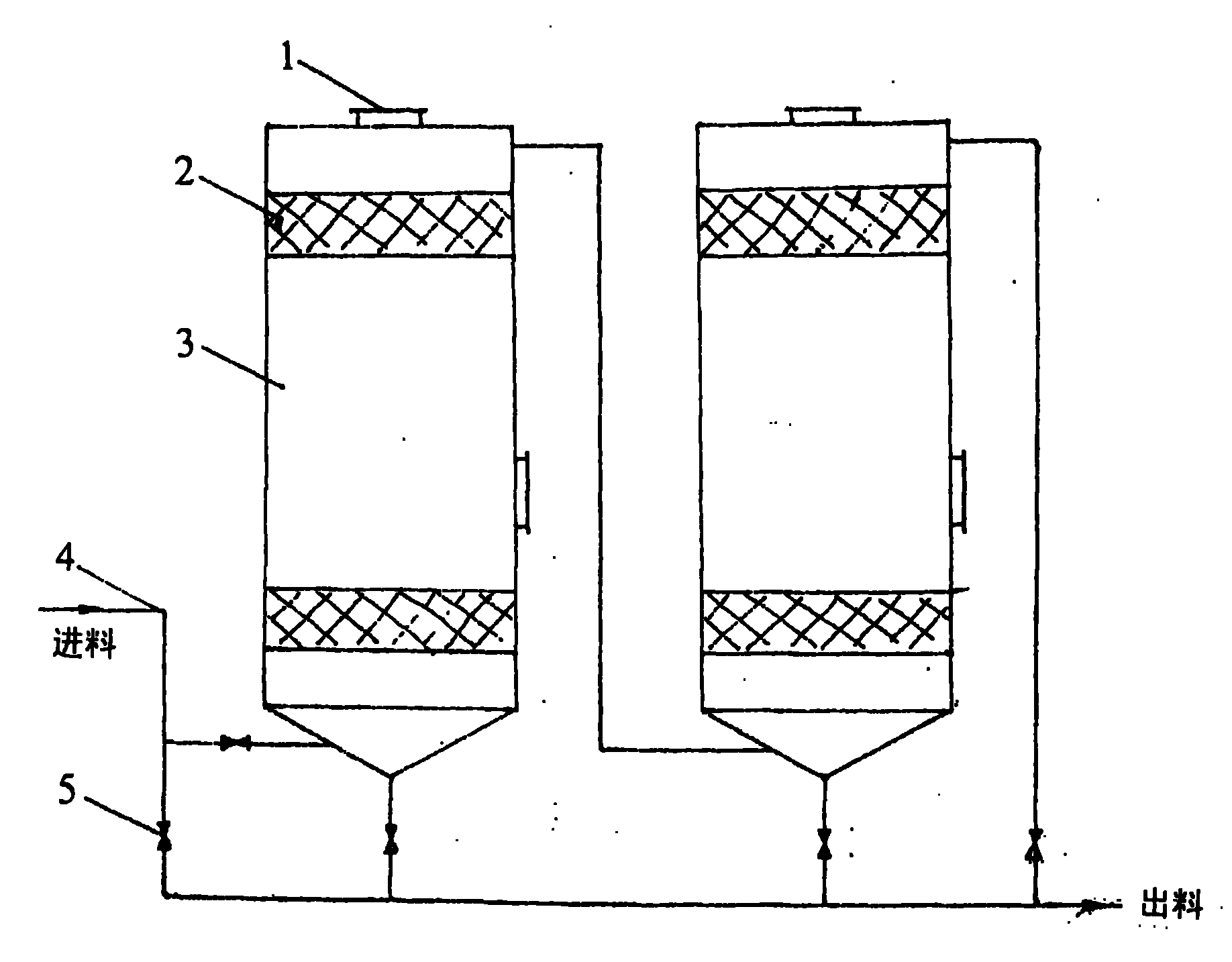

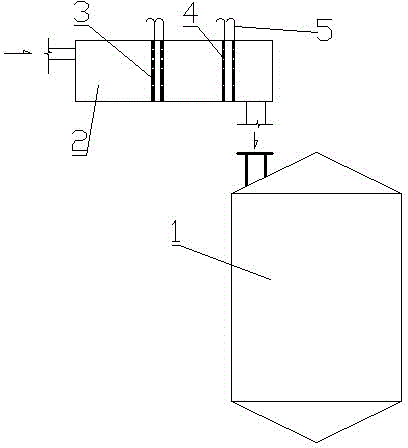

Alcohol output increasing method and device

InactiveCN1986820AWide variety of sourcesLow priceBioreactor/fermenter combinationsBiological substance pretreatmentsFiberPectinase

The present invention relates to alcohol producing fermentation process and apparatus with starch as material. After biological enzyme active catalyst on carrier is set inside some container, turbid liquid with starch is made to stay in the container to contact with the catalyst for 30-60 min. The biological enzyme active catalyst includes pectinase in 8-15 wt%, cellulase in 10-20 wt% and trace elements, and the carrier is porous material, with the pectinase and cellulase being obtained through strain fermentation. The present invention has increased alcohol yield.

Owner:黄荣胜

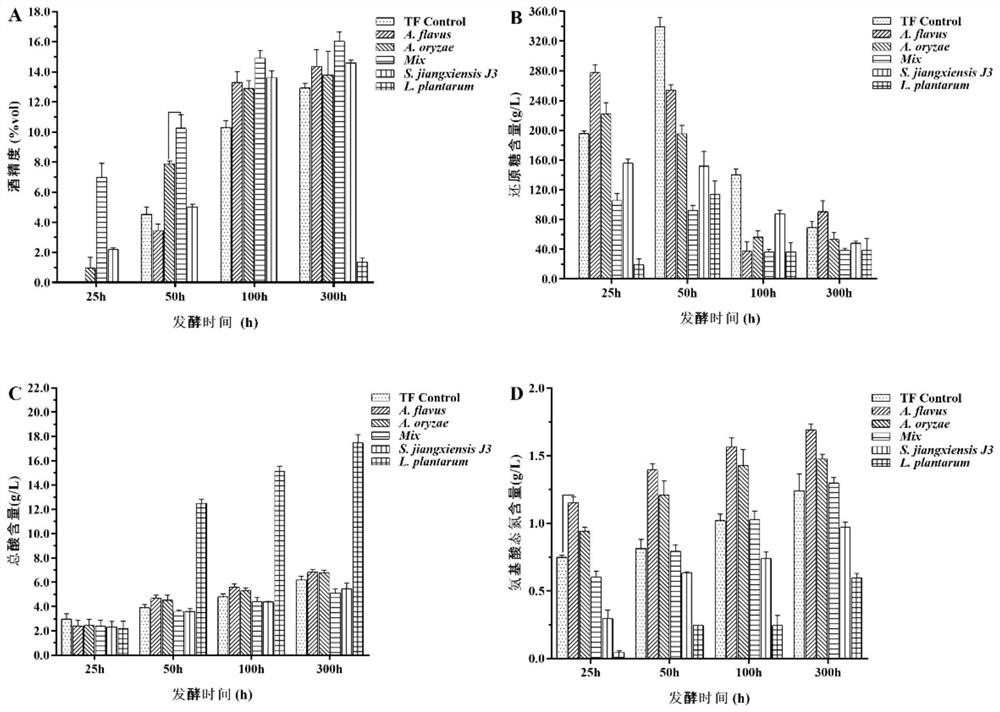

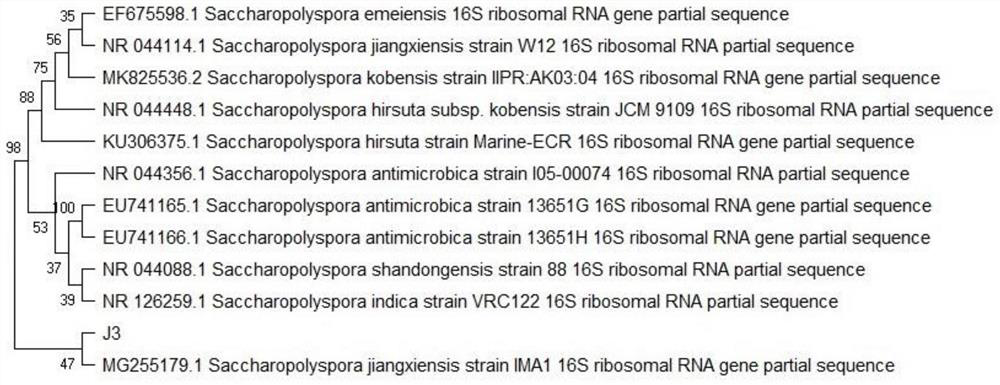

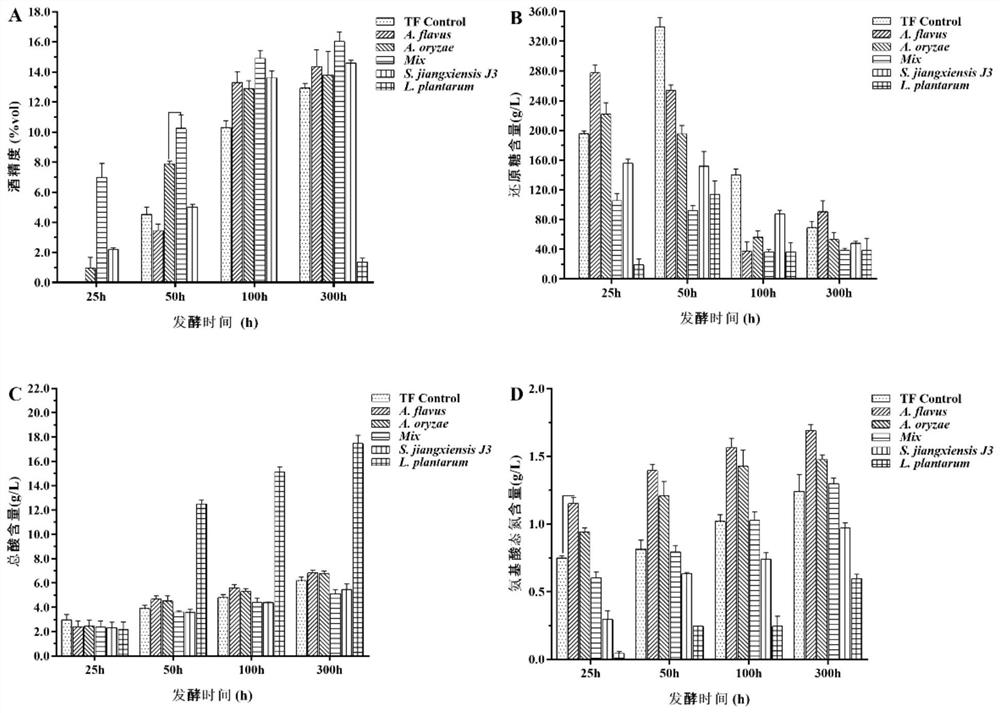

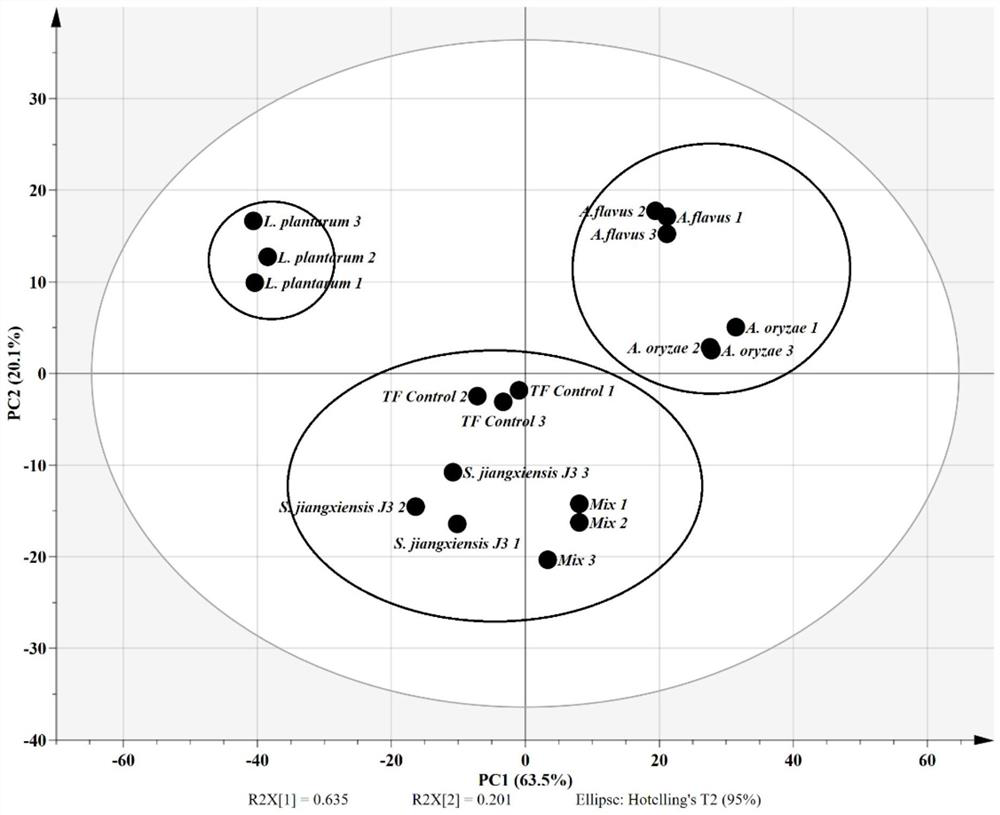

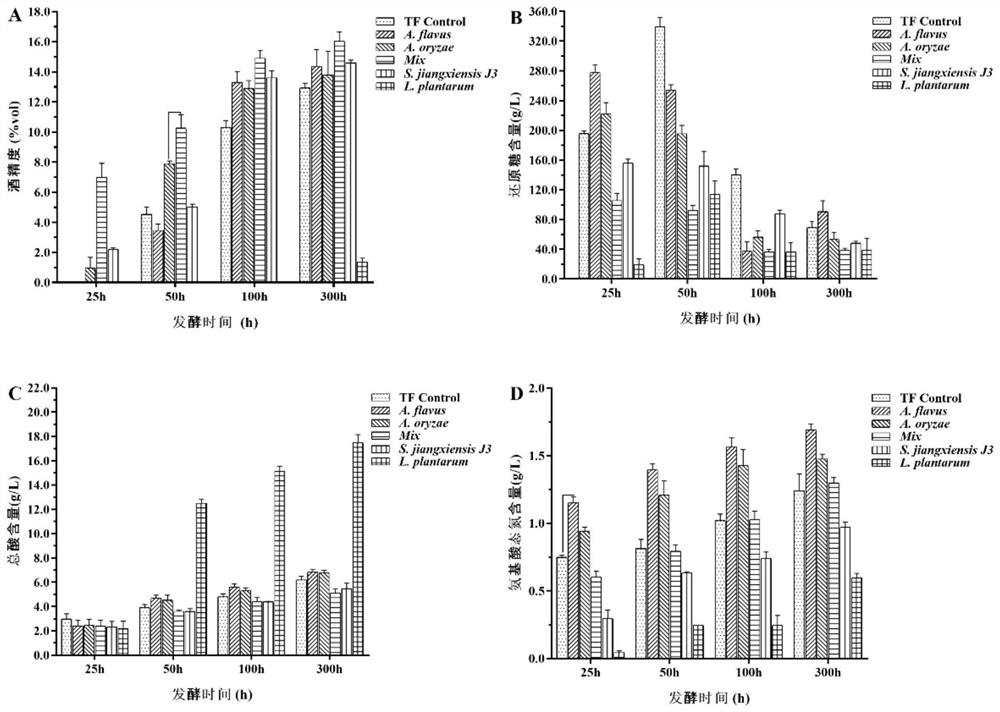

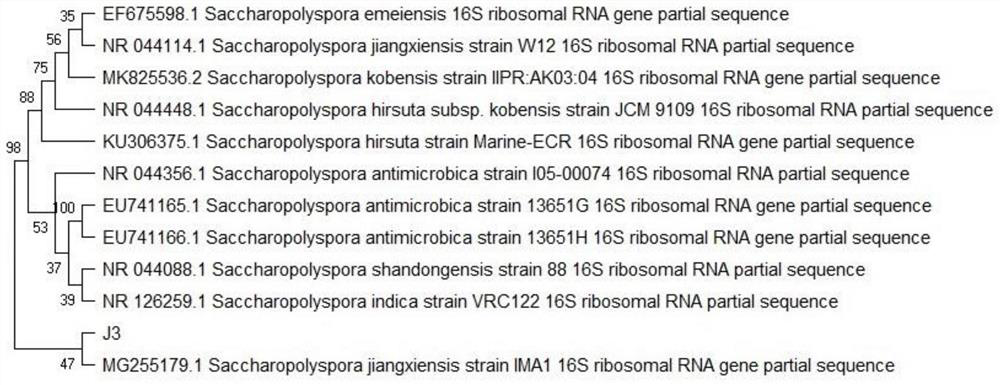

Saccharopolyspora jiangxiensis and applications thereof in food

ActiveCN111979146ADoes not affect normal fermentationHigh in amino acidsTobacco treatmentBacteriaBiotechnologyMicrobiology

The present invention discloses saccharopolyspora jiangxiensis and applications thereof in food and belongs to the technical field of food fermentation. The saccharopolyspora jiangxiensis J3 is screened from wheat koji and deposited in China Center for Type Culture Collection on April 30, 2020, and has the deposit number of CCTCC NO:M 2020104. The strain is applied to a food fermentation system and results show that the strain does not affect normal fermentation of food, has effects of reducing content of biogenic amines in fermented alcoholic beverages, fermented food and fermented seasoningproducts, and has broad application prospects in the field of food brewing.

Owner:JIANGNAN UNIV

Production method of black rice yellow wine

PendingCN112760181AImprove qualityHigh nutritional valueAlcoholic beverage preparationBiotechnologyYield (wine)

The invention discloses a production method of black rice yellow wine. Black rice is used as a fermentation raw material, contains a large amount of anthocyanidin, and has a relatively thick rice skin layer which is not beneficial to dissolution of the anthocyanidin. A dissolution rate of the anthocyanidin is improved through soaking and pre-gelatinization after soaking. Rice soaking water of black rice is applied to fermentation, so that discharge of wastewater is reduced, the environment is protected, loss of the anthocyanin is reduced, a utilization rate of the anthocyanin is increased, chromaticity of wine liquid is increased, caramel color does not need to form specially, and cost is reduced. Cellulase is added into rice mash for fermentation production of yellow wine and beneficial to damage of a black rice aleurone layer, promotes dissolution and enzymolysis of starch and protein in black rice, and improves a raw material conversion rate and the wine yield. An increase of a dissolution rate of the protein is beneficial to increase of the content of amino acid nitrogen in the product. The flavor of the yellow wine is improved.

Owner:HEFEI UNIV OF TECH

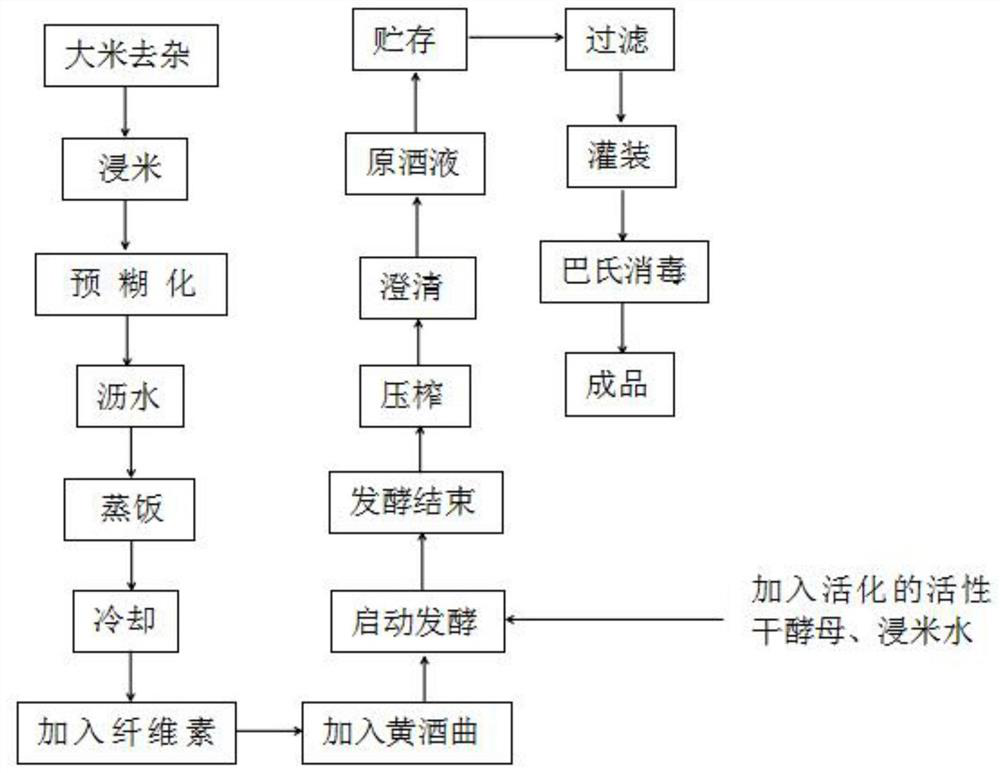

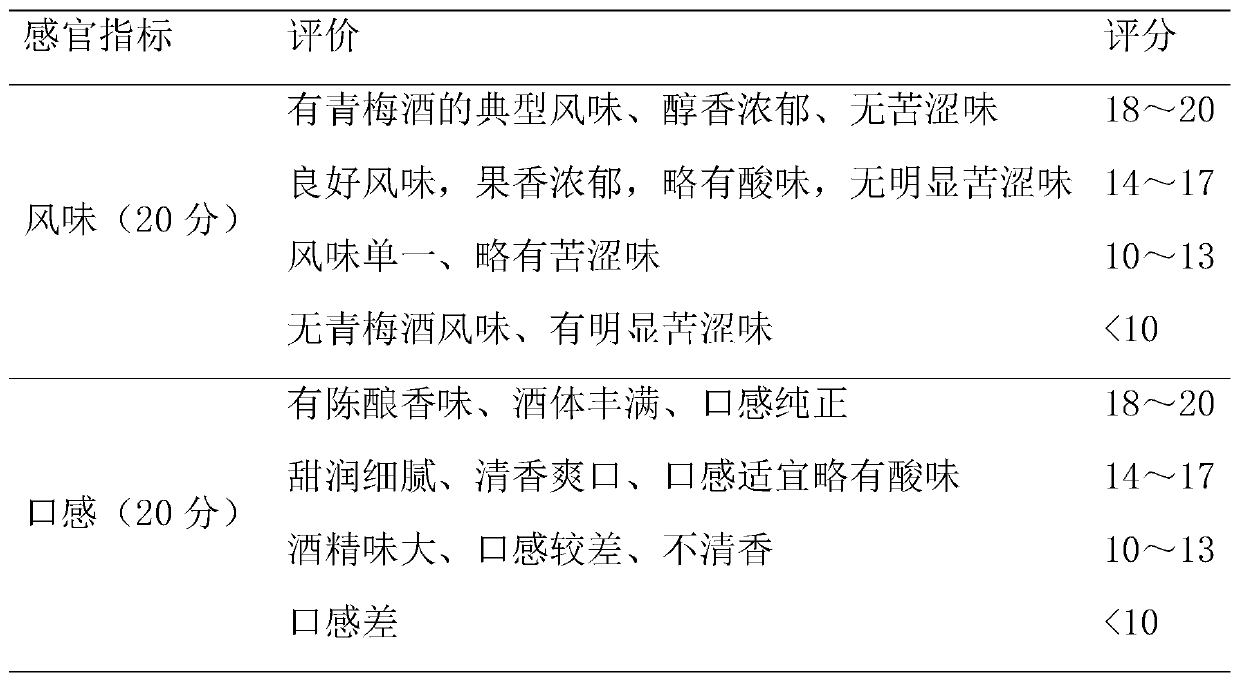

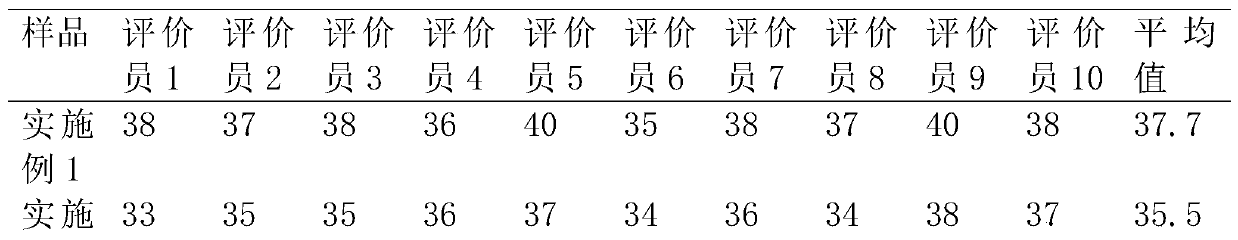

Green plum wine combined with glutinous rice saccharification fermentation and preparation method thereof

InactiveCN110029034AIncrease the juice yieldIncrease profitAlcoholic beverage preparationMicroorganism based processesYeastRhizopus

The present invention discloses a preparation method of green plum wine combined with glutinous rice saccharification fermentation. The preparation method comprises the following steps: 1, high-quality green plums are selected, the selected green plums are washed, and the washed green plums are drained; 2, the drained green plums are frozen; 3, the frozen green plums are thawed and the thawed green plums are squeezed into juice to obtain green plum juice; 4, glutinous rice is soaked, the soaked glutinous rice is steamed, the steamed glutinous rice is sprayed to be cooled to 30-32 DEG C, the cooled glutinous rice is put into a cylinder, rhizopus is added, hole-digging saccharification fermentation is conducted for 44-48 hours, the green plum juice and water for wine-brewing are added, initial sugar content of fermentation liquid is controlled at 20-23%, and pH is 3.2-3.5; 5, acid-lowering yeasts are added; 6, main fermentation is conducted; 7, wine body and wine residues are quickly separated; 8, the wine body is clarified with a clarifying agent and the clarified wine body is put still at room temperature for 3 days; and 9, filtering and wine heating for sterilization are conductedto obtain clarified golden wine liquid. The green plum freezing and juice squeezing, glutinous rice saccharification and green plum wine acid-lowering fermentation are combined to obtain the green plum wine which is golden in wine liquid, has a mellow green plum flavor, and is full in the wine body, pure in mouthfeel and high in total antioxidant capacity.

Owner:SHAOXING UNIVERSITY

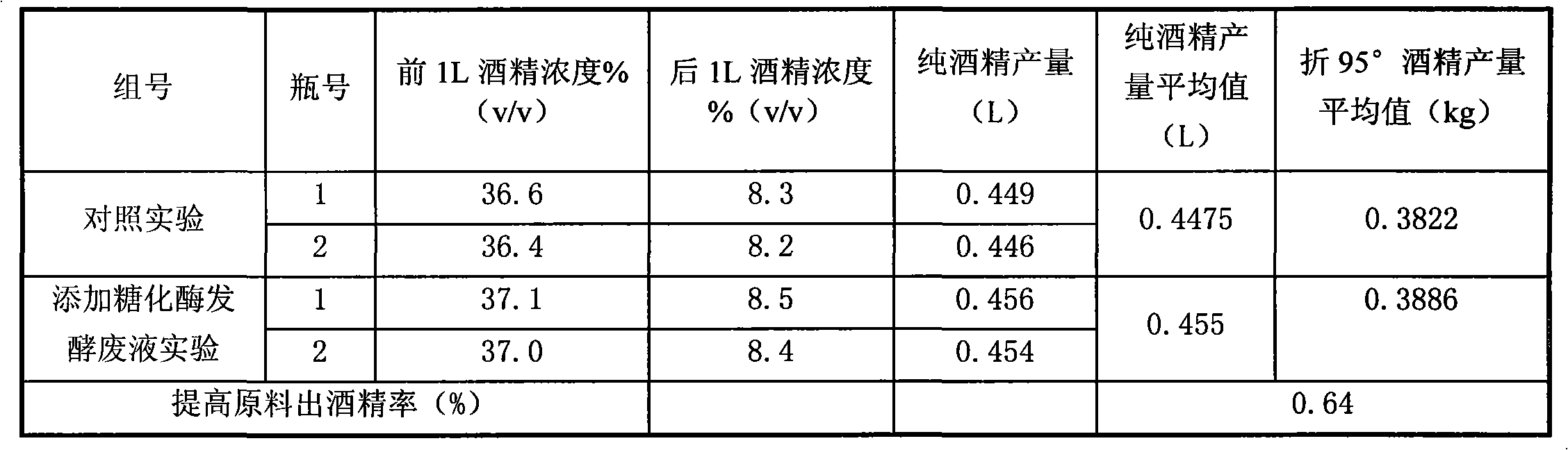

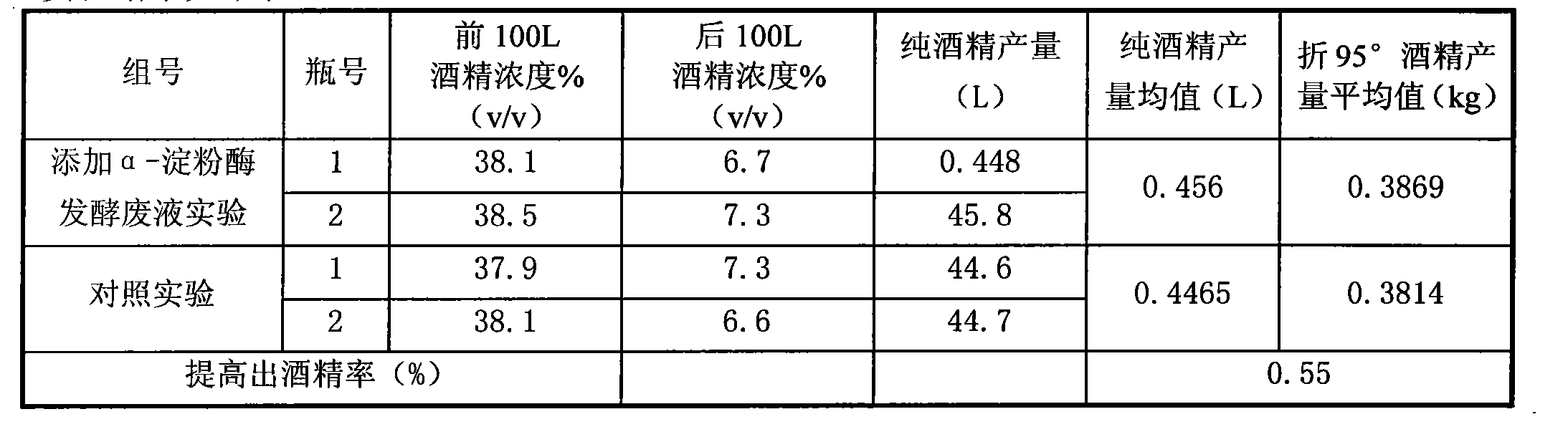

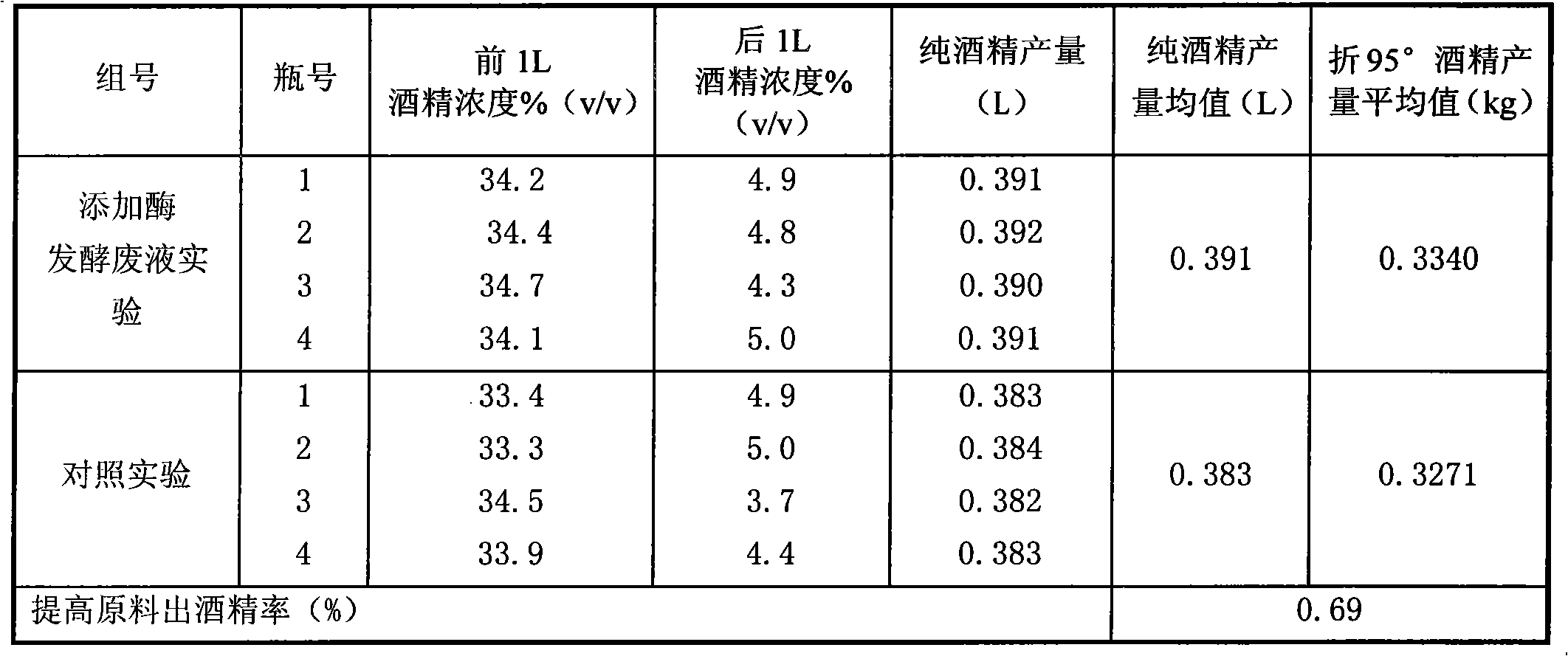

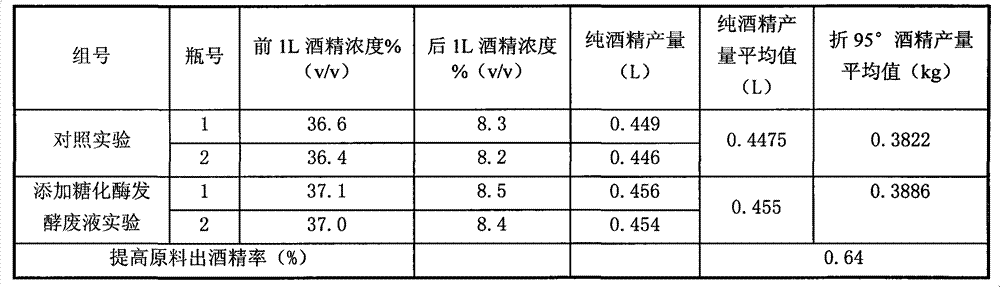

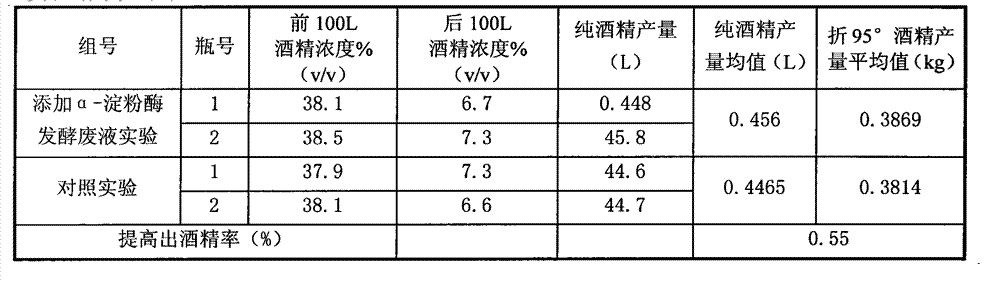

Method for producing alcohol by utilizing cassava as a raw material through applying enzyme preparation production fermenting waste liquid

InactiveCN102146420AReduce dosageTake advantage ofMicroorganism based processesFermentationAlcohol productionEnzyme

The invention relates to a method for producing alcohol by utilizing cassava as a raw material and adding the production fermenting waste liquid of amylase and diastatic enzyme, which belongs to the technical field of fermentation. The method for producing alcohol by utilizing cassava as a raw material through applying enzyme preparation production fermenting waste liquid comprises the steps of cassava powder slurrying, liquefaction, saccharification and fermentation. The method is characterized by singly adding amylase fermenting waste liquid in the liquefying process without adding amylase or simultaneously adding amylase fermenting waste liquid when adding amylase and / or singly adding diastatic enzyme fermenting waste liquid in the saccharifying process without adding diastatic enzyme or simultaneously adding diastatic enzyme fermenting waste liquid when adding diastatic enzyme. Practical production indicates that the method can improve the alcohol yield of cassava raw materials, reduce the amylase consumption, diastatic enzyme consumption, nutritive salt consumption and the waste liquid treatment cost of enzyme preparation production and improves production benefits of alcohol.

Owner:QILU UNIV OF TECH

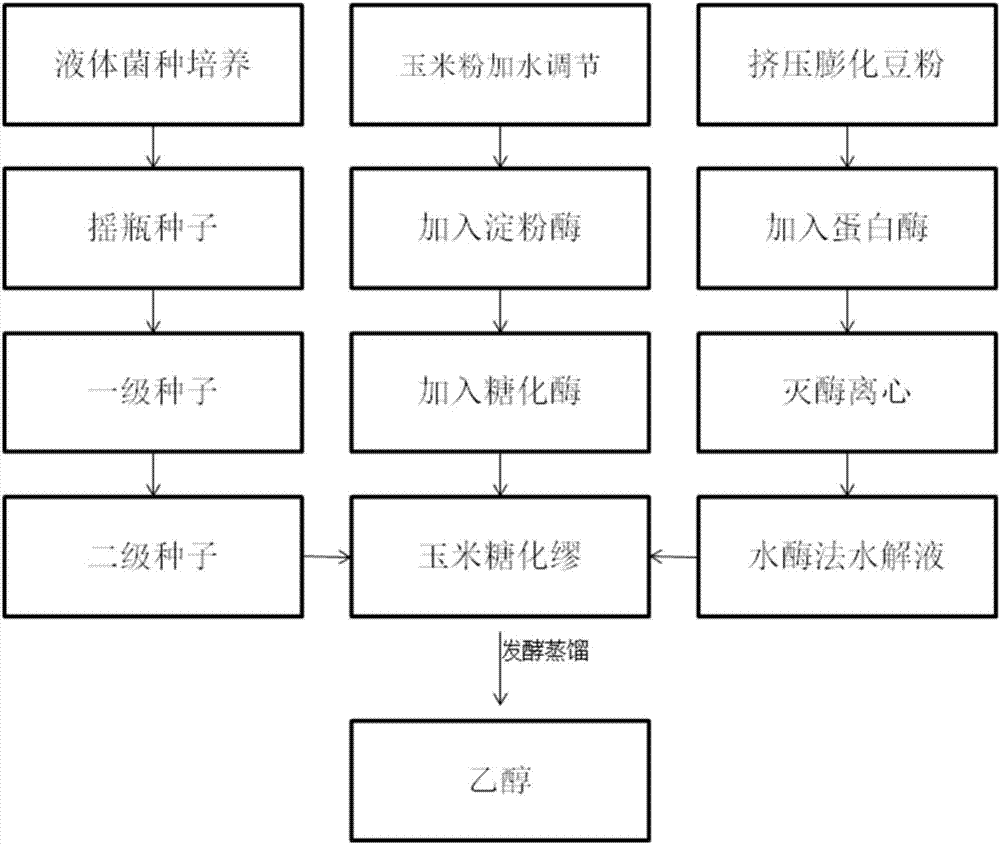

Method for fermenting alcohol by mixing corn mash and soybean aqueous enzymatic hydrolysate

InactiveCN107130004AIncrease alcohol yieldShorten fermentation timeBiofuelsMicroorganism based processesChemistryInsoluble residue

The invention discloses a method for fermenting alcohol by mixing corn mash and soybean aqueous enzymatic hydrolysate. The method includes the steps: (1) blending corn powder and water in proportion to prepare mixed liquid, adding amylase, increasing temperature to 90 DEG C, keeping the temperature for 30 minutes, adding an appropriate amount of saccharifying enzyme when the temperature is reduced to 56 DEG C, performing heat preservation and saccharification for 18 hours and saccharifying supernate to obtain saccharifying mash; (2) mixing puffing soybean powder with deionized water, adding Alcalase alkaline protease, performing enzymolysis at the temperature of 55 DEG C for 3 hours, killing enzyme, performing centrifugation and removing soybean oil, emulsion and lower insoluble residues to obtain the hydrolysate; (3) selecting Trichoderma pseudokoningi as a fermentation strain and performing step-by-step scale-up culture under an aseptic condition; (4) adding 10% liquid fermentation strains into the corn saccharifying mash, adding equivalent aqueous enzymatic hydrolysate, fermenting the corn saccharifying mash and the hydrolysate for 72 hours under the condition of the culture temperature of 30 DEG C, the tank pressure of 0.8kg / cm<2>, the stirring speed of 130r / min and the pH (potential of hydrogen) value of 4.5, and producing the alcohol by distillation. The method has the advantages of short fermentation time, low needed cost, high alcohol purity and the like.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Alcohol output increasing method and device

InactiveCN1986820BImprove filtration efficiencyWide variety of sourcesBioreactor/fermenter combinationsBiological substance pretreatmentsPectinasePtru catalyst

The present invention relates to alcohol producing fermentation process and apparatus with starch as material. After biological enzyme active catalyst on carrier is set inside some container, turbid liquid with starch is made to stay in the container to contact with the catalyst for 30-60 min. The biological enzyme active catalyst includes pectinase in 8-15 wt%, cellulase in 10-20 wt% and trace elements, and the carrier is porous material, with the pectinase and cellulase being obtained through strain fermentation. The present invention has increased alcohol yield.

Owner:黄荣胜

Preparation method of yin-nourishing and health-care yellow wine

InactiveCN105062813AAlcoholic alcoholFull of nutritionDigestive systemAlcoholic beverage preparationPolygonum odoratumAlpha-amylase

The invention discloses a preparation method of yin-nourishing and health-care yellow wine. The yin-nourishing and health-care yellow wine is prepared from the following raw materials in parts by weight: 200-220 parts of glutinous rice, 20-22 parts of wine yeast, 12-15 parts of crab meat, 2-3 parts of sea cucumber, 3-4 parts of lucid ganoderma powder, 0.8-0.9 parts of radix polygonati officinalis, 0.7-0.9 parts of mango seed, 0.6-0.7 parts of prepared rehmannia root as well as proper amounts of egg white powder, alpha-amylase, saccharifying enzyme and pullulanase. The yellow wine disclosed by the invention is sweet and mellow in texture, aromatic and pleasant, rich in nutrition and good in taste; and by adding various Chinese herbal medicines during processing, the yellow wine disclosed by the invention has functions of invigorating stomach and helping digestion, enriching yin and nourishing kidney, reducing phlegm and promoting circulation of qi, relaxing tendons and benefiting qi.

Owner:ANHUI CHENYAOHU RICE WINE

Preparation method of arabian jasmine flower scented yellow rice wine

The invention relates to a preparation method of arabian jasmine flower scented yellow rice wine. The arabian jasmine flower scented yellow rice wine is prepared from the following raw materials in parts by weight: 200-220 parts of sticky rice, 20-22 parts of distiller's yeast, 8-9 parts of jasmine flower petals, 3-4 parts of rice vinegar, 2-3 parts of pineapple peel, 0.5-0.7 part of lalang grass rhizome, 0.7-0.9 part of armstrong, 0.5-0.7 part of burdock root, a suitable amount of egg white powder, a suitable amount of alpha-amylase, a suitable amount of saccharifying enzyme, and a suitable amount of pullulanase. The arabian jasmine flower scented yellow rice wine has fragrance of arabian jasmine flowers, gladdens the heart and refreshes the mind, and is good in mouth taste and high in nutrition; multiple Chinese herbal medicines are added during the preparation process, and the arabian jasmine flower scented yellow rice wine has the efficacies of cooling blood and stopping bleeding, reducing fever and causing diuresis, dispelling wind and heat, detoxifying and relieving swelling, and resisting aging.

Owner:ANHUI CHENYAOHU RICE WINE

Making method of radix salviae miltiorrhizae brandy

InactiveCN105482945AGuaranteed withdrawal rateHigh extraction rateAlcoholic beverage preparationFlavorPectinase

The invention belongs to a technical field of brandy processing, in particular to a making method of radix salviae miltiorrhizae brandy. The brandy is made by freezing and squeezing the radix salviae miltiorrhizae, enzymolysis and dipping, sterilizing, fermenting, distilling, ageing, filtering and bottling procedures, wherein, the enzymolysis and dipping adopts pectinase and amylase-mixed enzyme to dip at low temperature; fermenting comprises: regulating sugar degree of solution to be fermented to 20-23 degrees and acidity to 0.4-0.5g / L, and then inoculating an activated strain at low temperature for fermentation; the enzymolysis and dipping and fermenting are consistent in the low temperature environment temperature. The method has the characteristics of short fermenting period, low cost and high wine yield, the brandy is natural and bright in color and fresh and mellow in mouth feeling, has unique flavor of the radix salviae miltiorrhizae and has blood fat reducing, antibacterial and detoxifying and blood promoting and stasis removing effects.

Owner:贵州黔贵天赐大健康集团有限公司

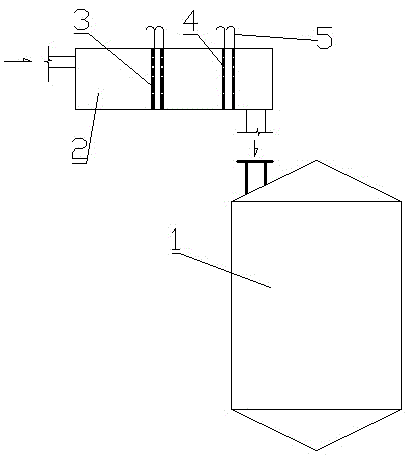

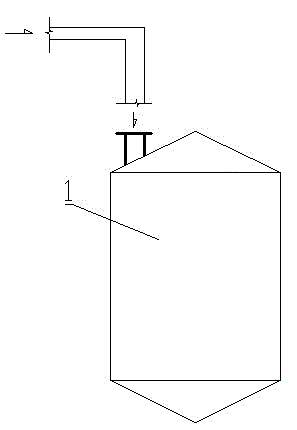

Process and device for recovering gluten from starch slurry

ActiveCN102974146AHigh extraction rateReduce the number of blocked heat exchange equipmentBioreactor/fermenter combinationsBiological substance pretreatmentsAlcohol productionEconomic benefits

The invention belongs to the technical field of flour milling, and particularly relates to a process and device for recovering gluten from starch slurry. A starch slurry filtering tank is additionally arranged in front of a feeding opening of a liquefaction tank in a gluten workshop; and the gluten in the starch slurry can be filtered through a two-stage filtering screen, and can be pumped into the liquefaction tank. The filtered gluten is recovered in time by a manual method according to the content of the gluten in the thick slurry, so that the amount of the gluten entering the liquefaction tank can be controlled, and furthermore, the purposes of stabilizing alcohol production, reducing production cost and improving economical benefits can be realized.

Owner:BINZHOU ZHONGYU FOOD

Preparation method of wind-dispelling and intestine-moistening wheat-flavored yellow wine

InactiveCN105062812AAlcoholic alcoholFull of nutritionAntipyreticAnalgesicsIntestinal structureAlpha-amylase

The invention discloses a preparation method of wind-dispelling and intestine-moistening wheat-flavored yellow wine. The wind-dispelling and intestine-moistening wheat-flavored yellow wine is prepared from the following raw materials in parts by weight: 200-220 parts of glutinous rice, 20-22 parts of wine yeast, 4-6 parts of sesame, 8-12 parts of wheat, 4-5 parts of fruit of Chinese wolfberry, 0.5-0.6 parts of common cnidium fruit, 0.6-0.8 parts of radix tetrastigme, 0.8-0.9 parts of glabrous sarcandra herb, 0.9-1.1 parts of Japanese raisintree fruit as well as proper amounts of egg white powder, alpha-amylase, saccharifying enzyme and pullulanase. The yellow wine disclosed by the invention is sweet and mellow in texture, aromatic and pleasant, rich in nutrition and good in taste; and by adding various Chinese herbal medicines during processing, the yellow wine disclosed by the invention has functions of warming kidney and enhancing yang, dispelling wind and relieving itching, clearing away heat and toxic materials, smoothening secretion, dispelling wind and removing obstruction in meridians.

Owner:ANHUI CHENYAOHU RICE WINE

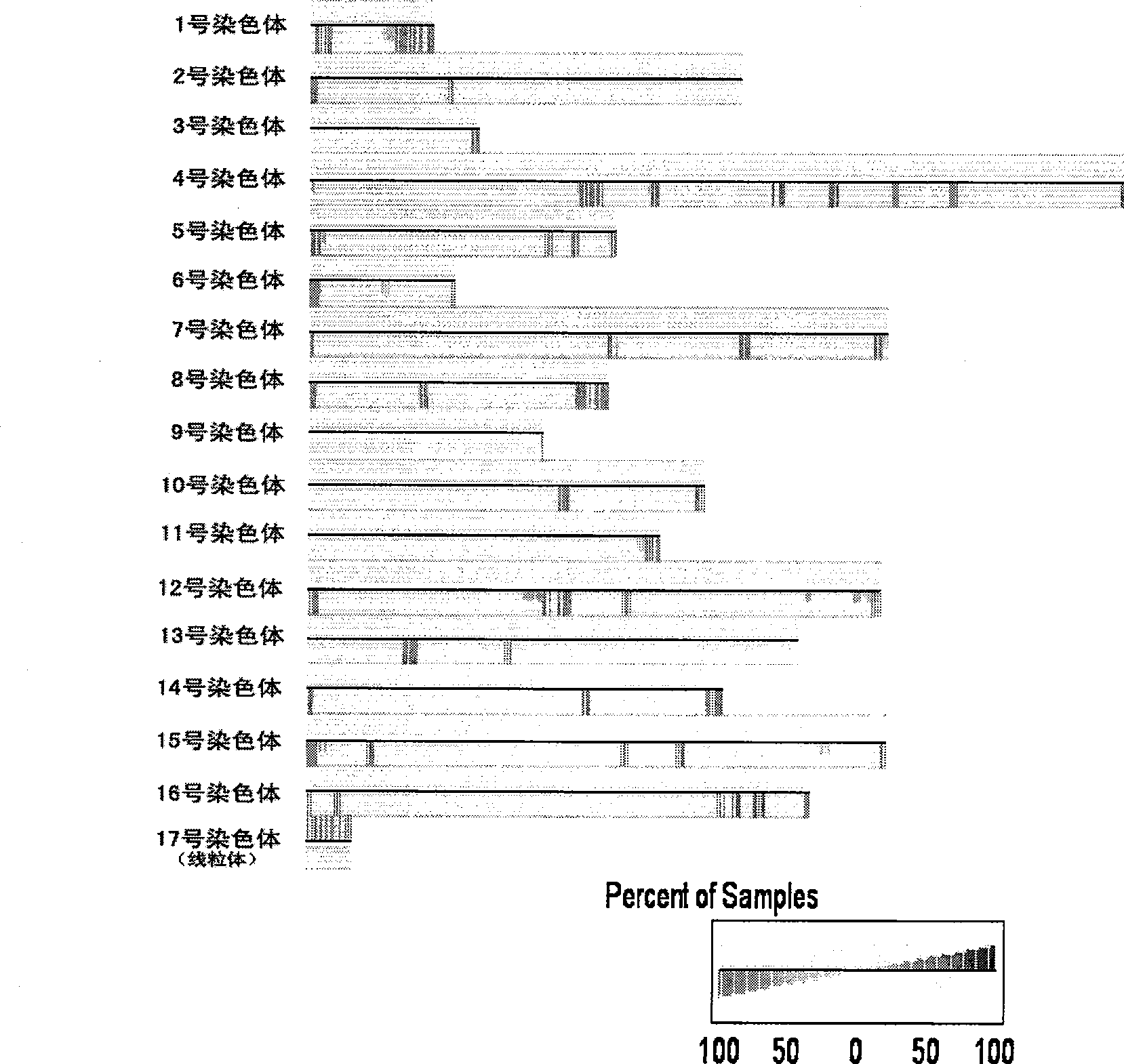

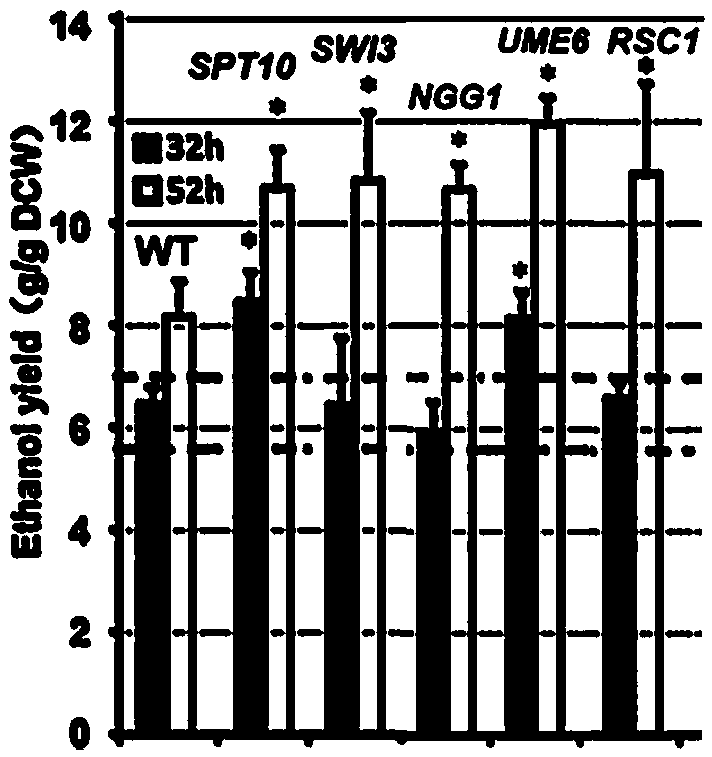

Application of chromatin remodeling factor genes in saccharomyces cerevisiae in increasing yield of fermentation alcohol

PendingCN109666705AIncrease alcohol yieldIncrease productivityBiofuelsMicroorganism based processesBiotechnologyAlcohol

The invention discloses application of chromatin remodeling factor genes in saccharomyces cerevisiae in increasing the yield of fermented alcohol. The chromatin remodeling factor genes comprise SPT10,SWI3, NGG1, UME6 and RSC1 genes, and the nucleotide sequences are shown in SEQ ID NO.1-5. A new method is provided for improving the production efficiency of alcohol fermentation, and important information is provided for constructing an excellent saccharomyces cerevisiae engineering strain of high-yield alcohol.

Owner:SHANDONG UNIV OF TECH

Method for producing alcohol by applying enzyme preparation production fermenting waste liquid to raw material of cassava

InactiveCN102146420BReduce dosageTake advantage ofMicroorganism based processesFermentationAlcohol productionEnzyme

The invention relates to a method for producing alcohol by utilizing cassava as a raw material and adding the production fermenting waste liquid of amylase and diastatic enzyme, which belongs to the technical field of fermentation. The method for producing alcohol by utilizing cassava as a raw material through applying enzyme preparation production fermenting waste liquid comprises the steps of cassava powder slurrying, liquefaction, saccharification and fermentation. The method is characterized by singly adding amylase fermenting waste liquid in the liquefying process without adding amylase or simultaneously adding amylase fermenting waste liquid when adding amylase and / or singly adding diastatic enzyme fermenting waste liquid in the saccharifying process without adding diastatic enzyme or simultaneously adding diastatic enzyme fermenting waste liquid when adding diastatic enzyme. Practical production indicates that the method can improve the alcohol yield of cassava raw materials, reduce the amylase consumption, diastatic enzyme consumption, nutritive salt consumption and the waste liquid treatment cost of enzyme preparation production and improves production benefits of alcohol.

Owner:QILU UNIV OF TECH

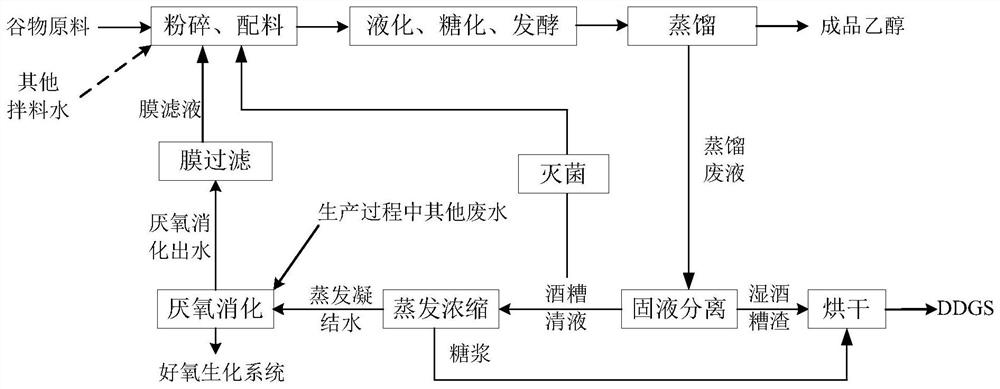

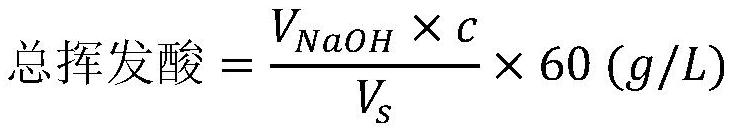

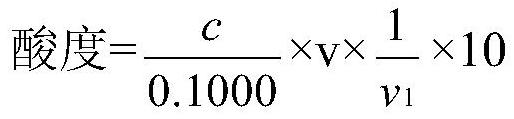

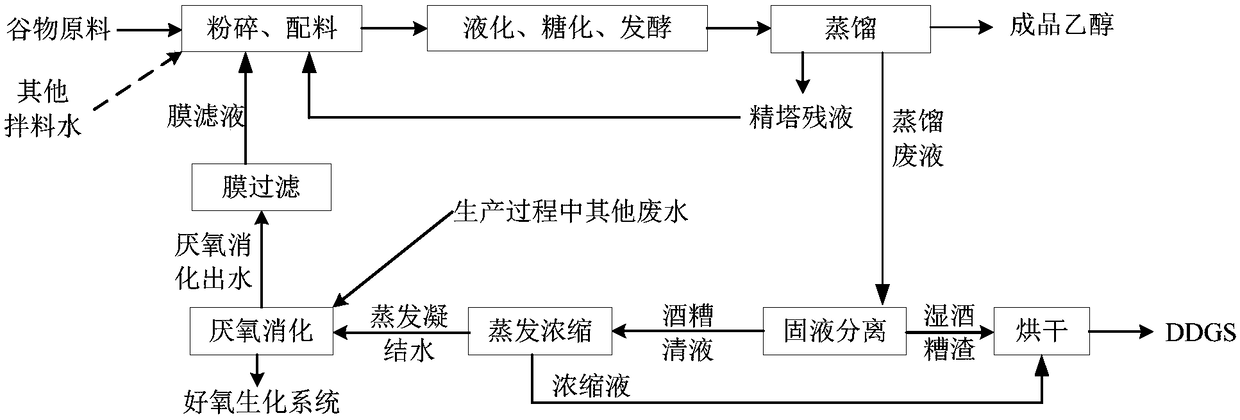

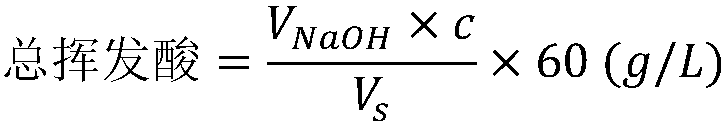

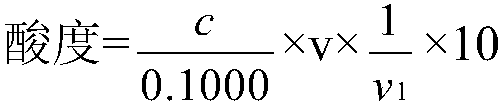

A method of reusing anaerobic digestion effluent and distiller's grains to produce ethanol

ActiveCN108841873BIncrease the reuse ratioEmission reductionBiofuelsFermentationAlcohol ethylPulp and paper industry

The invention discloses a method for producing ethanol by recycling anaerobic digestion effluent and vinasse clear liquid and belongs to the technical fields of waste water treatment and ethanol fermentation industry. The method comprises the following steps: mixing and blending membrane filtrate obtained after membrane filtration of anaerobic digestion effluent, part of vinasse clear liquid, other material mixing water and crushed cereal raw materials, and performing processes of liquefying, saccharifying, fermenting and distilling to obtain ethanol, wherein the membrane filtrate accounts for30 to 90 percent of the total weight of the blending water, the vinasse clear liquid accounts for 10 to 40 percent of the total weight of the blending water, and the rest is other material mixing water; and the concentration of volatile acid of the blending water is controlled to be 100 to 1200 mg / L (based on acetic acid) by adjusting the proportion of the membrane filtrate, the vinasse clear liquid and other material mixing water or adding the acetic acid. By the method, discharge of ethanol production waste water is greatly reduced and water resources are saved; meanwhile, the problem thatthe ethanol is fermented to generate acid is effectively avoided, the alcohol yield is significantly increased, the utilization rate of the raw materials is increased by 1 to 5 percent, and the production energy consumption and cost of the ethanol are reduced.

Owner:JIANGNAN UNIV

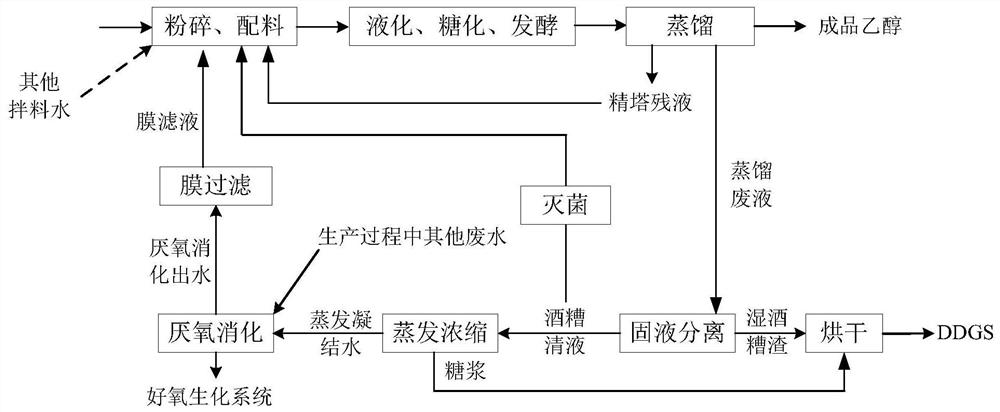

A method for producing ethanol from grain

The invention discloses a method for producing ethanol by using grain as a raw material, and belongs to the technical field of waste water treatment and ethanol fermentation industry. In the present invention, the anaerobic digestion effluent is mixed with the membrane filtrate after membrane filtration, the residual liquid of the refining tower, partly sterilized distiller's grain clear liquid and other mixing water and the pulverized grain raw material, and then undergoes liquefaction, saccharification and fermentation , distillation and other processes to obtain ethanol, among which, the membrane filtrate accounts for 40-90% of the total batching water quality, the fine tower residue accounts for 1-15% of the total batching water quality, and the distiller's grains accounts for 1-30% of the total batching water quality , and the rest is mixing water. By adjusting the ratio of membrane filtrate, refining tower residual liquid, distiller's grains clear liquid and other mixing water, or adding acetic acid, the volatile acid concentration of the mixing water is controlled at 100-1200mg / L. The method of the invention greatly reduces the discharge of ethanol production wastewater, saves water resources, effectively avoids the problem of ethanol fermentation acid generation, significantly improves the alcohol yield, improves the utilization rate of raw materials by 1-5%, and reduces the energy consumption and energy consumption of ethanol production. cost.

Owner:JIANGNAN UNIV

Process and device for recovering gluten from starch slurry

ActiveCN102974146BHigh extraction rateReduce the number of blocked heat exchange equipmentBioreactor/fermenter combinationsBiological substance pretreatmentsAlcohol productionEconomic benefits

The invention belongs to the technical field of flour milling, and particularly relates to a process and device for recovering gluten from starch slurry. A starch slurry filtering tank is additionally arranged in front of a feeding opening of a liquefaction tank in a gluten workshop; and the gluten in the starch slurry can be filtered through a two-stage filtering screen, and can be pumped into the liquefaction tank. The filtered gluten is recovered in time by a manual method according to the content of the gluten in the thick slurry, so that the amount of the gluten entering the liquefaction tank can be controlled, and furthermore, the purposes of stabilizing alcohol production, reducing production cost and improving economical benefits can be realized.

Owner:BINZHOU ZHONGYU FOOD

Method for producing alcohol from straws and distilled grains abandoned during production of white spirit

ActiveCN102250966AIncrease sugar concentrationReduce pollutionBiofuelsMicroorganism based processesAlcoholHydrolysate

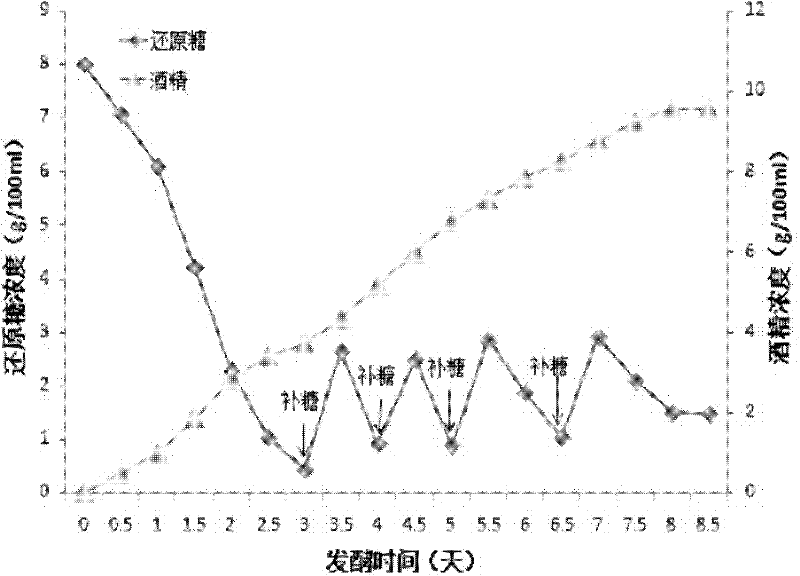

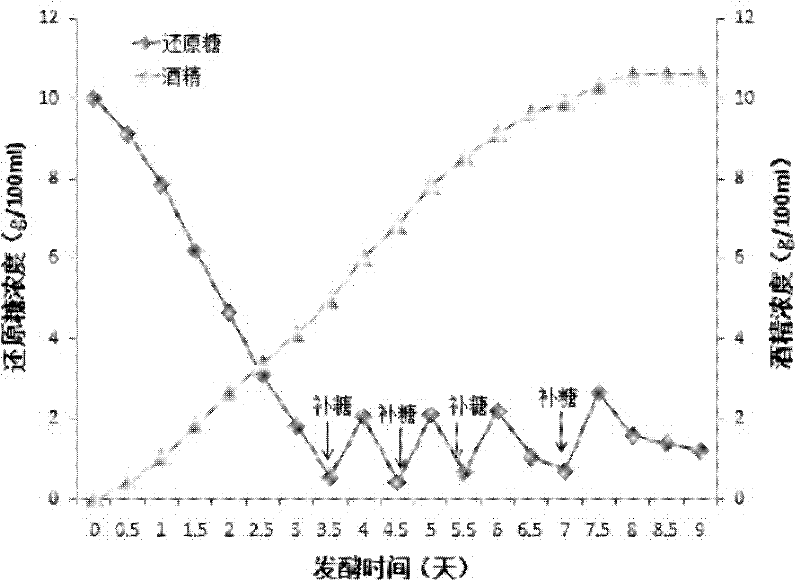

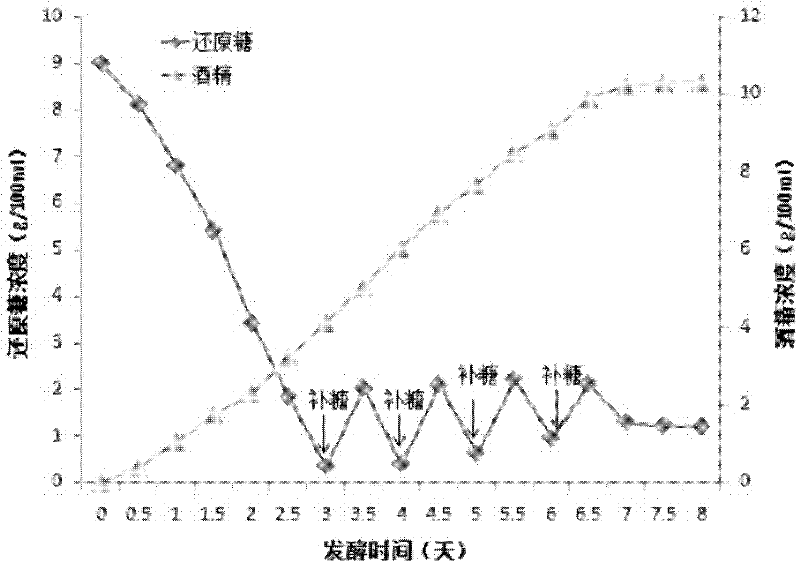

The invention discloses a method for producing alcohol from straws and distilled grains abandoned during the production of white spirit. The method is characterized by comprising the following steps of: mixing fresh distilled grains abandoned during the production of the white spirit and crushed straws at a ratio of 1 to (0.6-1); mixing the mixture with H2SO4 with the concentration of 80wt% at aweight-to-volume ratio of 1 to (1-1.5); mixing to saccharify the mixture for 30-40 minutes; adding water into the solution until the concentration of sulfuric acid is 20-25wt%; hydrolyzing the solution in boiling water for 100-120 minutes; and adding calcium carbonate into filtrate for neutralizing and collecting a sugar solution after filter-pressing the solution, wherein the sugar solution is used for alcoholic fermentation after decompressed and concentrated. The reducing sugar in acid hydrolysate obtained in the invention has the concentration of 3-5g / 100ml and the degradation rate of 0.3-0.5g (glucose) / g (dry raw materials). The concentration of reducing sugar in the neutralized and concentrated sugar solution is 6-8g / 100ml; and the final alcohol concentration can reach 9-11g / 100ml after yeast and sugar are added for fermentation.

Owner:SICHUAN UNIV

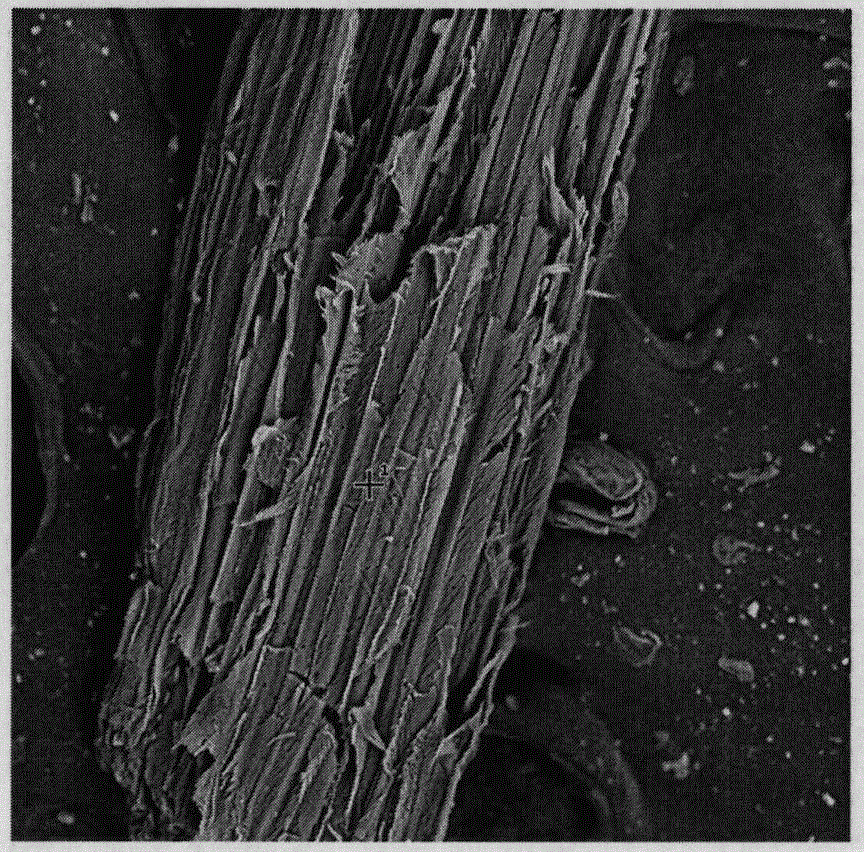

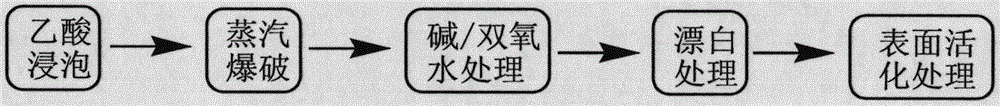

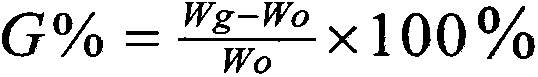

A kind of bagasse pretreatment method of activating surface groups

ActiveCN104213447BImprove accessibilityHigh activityPretreatment with alkaline reacting compoundsPulp bleachingCelluloseFiber

The invention discloses a bagasse pretreatment method for activating surface groups. The bagasse fiber is pretreated by the unique process of acetic acid soaking, steam explosion, alkali and hydrogen peroxide oxidation, bleaching treatment, acetic acid activation, and surface activation, which greatly improves the surface structure of the bagasse fiber and makes the bagasse easy to graft and modify to prepare various Functional Materials. The method can destroy the intertwined structure of each component of the lignocellulose, effectively improve the surface of the bagasse fiber, activate the surface groups of the bagasse, and make the bagasse easier to be functionally modified.

Owner:GUANGDONG PROVINCIAL BIOENGINEERING INST (GUANGZHOU SUGARCANE IND RES INST)

Preparation method of stomach nourishing peanut yellow wine

InactiveCN105087312AReduce higher alcohol contentShorten fermentation timeDigestive systemAlcoholic beverage preparationTremellaAlpha-amylase

The invention discloses a preparation method of stomach nourishing peanut yellow wine. The yellow wine is prepared from the following raw materials in parts by weight: 200-220 parts of glutinous rice, 20-22 parts of wine yeast, 4-5 parts of white fungus, 3-4 parts of black jujube, 8-9 parts of peanut, 0.6-0.8 parts of pericarpium arecae, 0.5-0.7 parts of lemongrass, 0.5-0.7 parts of bay leaf, 0.5-0.7 parts of sunflower leaf as well as proper amounts of egg white powder, alpha-amylase, glucoamylase and pullulanase. The yellow wine disclosed by the invention is sweet and mellow in texture, and is aromatic and pleasant; and the yellow wine, which is added with various Chinese herbal medicines during processing, has functions of tonifying spleen and stomach, promoting diuresis and expelling toxin, moistening skin, lowering qi downwards and removing stagnation of qi.

Owner:ANHUI CHENYAOHU RICE WINE

A Saccharopolyspora strain reducing biogenic amine and its application

ActiveCN111961615BDoes not affect normal fermentationHigh in amino acidsBacteriaMicroorganism based processesBiotechnologySaccharopolyspora

The invention discloses a saccharopolyspora strain for reducing biogenic amines and an application thereof, belonging to the technical field of food fermentation. The present invention obtains a strain of Saccharopolyspora hirsuta (Saccharopolysporahirsuta) J2 with the effect of reducing the content of biogenic amine from barley koji. While reducing the content of biogenic amines, it increases the content of amino acids and the nutritional value of fermented products, thereby achieving the effects of enhancing the quality of fermented foods and improving the safety of fermented foods, and has broad application prospects.

Owner:JIANGNAN UNIV

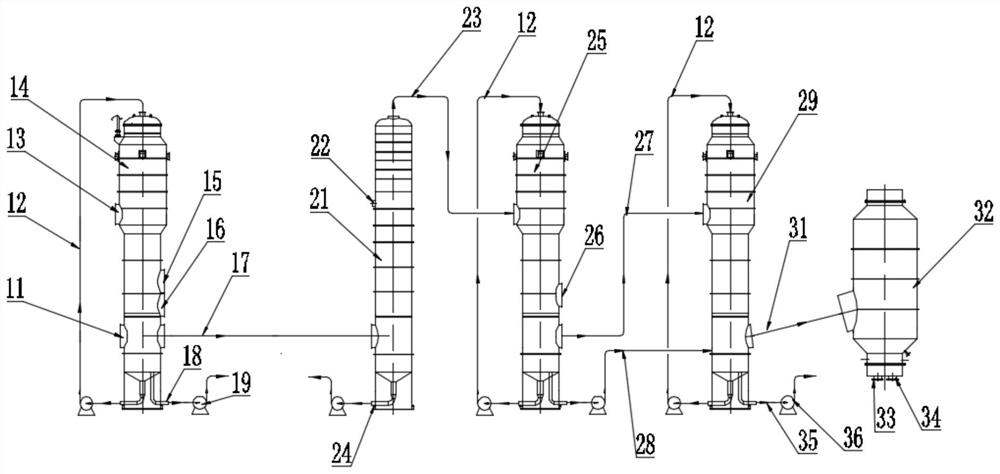

Alcohol vapor waste heat recycling process

PendingCN113730935AReduce manufacturing costIncrease alcohol yieldFermented solutions distillation/rectificationRecuperative heat exchangersAlcohol production facilityProcess engineering

The invention discloses an alcohol vapor waste heat recycling process, relates to the technical field of waste heat recycling treatment equipment, and solves the problems of low energy utilization rate, high energy consumption and large energy waste of alcohol production equipment in the prior art. The process specifically comprises the following steps: vapor of 95 DEG C and clear liquid of 80 DEG C are introduced into a single-effect falling film generator, and generated vapor is introduced into a distillation section crude tower to supply heat to mash in the distillation section crude tower so as to generate alcohol vapor; the generated alcohol vapor enters a first falling film generator; vapor generated in the first falling film generator enters a second falling film generator; meanwhile, concentrated liquid generated in the first falling film generator enters the second falling film generator together to supply heat to materials in the second falling film generator; and vapor generated in the second falling film generator enters a condenser for cooling treatment. According to the process, heat contained in vapor is fully utilized, the utilization rate of heat energy in a feed workshop is increased, and energy waste is reduced.

Owner:成都鸿展慧智科技有限公司

Saccharopolyspora and its application in food

ActiveCN111979146BDoes not affect normal fermentationHigh in amino acidsTobacco treatmentBacteriaBiotechnologyMicrobiology

Owner:JIANGNAN UNIV

Method for producing ethanol by reusing anaerobic digestion effluent and refining tower residue

ActiveCN109182393AIncrease the reuse ratioEmission reductionFermentationWastewater disposalRaw material

The invention discloses a method for producing ethanol by reusing anaerobic digestion effluent and refining tower residue, belonging to the technical field of wastewater treatment and ethanol fermentation industry, including the steps: mixing membrane filtrate of anaerobic digestion effluent filtered through films, the residual liquid of the refining tower and the other ingredient water with the crushed grain raw materials, according to the ratio of ingredient water to the crushed grain raw materials is 1 : (2-3.5), saccharifying, fermenting and distilling to obtain ethanol, wherein that membrane filtrate accounts for 10-90% of the water mass of the total ingredient, and the residual liquid in the refining tower accounts for 1-30% of the total ingredient water, and the other ingredient water accounts for 0-60%, and that volatile acid concentration of the ingredient water is controlled at 100-1200 mg / L by adjust the proportion of the membrane filtrate, the residual liquor of the refining tower and other ingredient water or adding acetic acid (based on acetic acid), and at the same time, the alcohol yield is remarkably improve, and the utilization rate of raw materials is improve by1. 5%, reduce that energy consumption and cost of ethanol production.

Owner:JIANGNAN UNIV

Radix scrophulariae wine brewing method and product thereof

InactiveCN107513481AIncrease alcohol yieldSpecial Scrophulariaceae FlavorAlcoholic beverage preparationMicroorganism based processesMarket potentialScalding

The invention relates to a radix scrophulariae wine brewing method and a product thereof. The method comprises the following steps: cleaning fresh radix scrophulariae, performing scalding cleaning with boiled water, and slicing so as to obtain radix scrophulariae pieces; putting the prepared radix scrophulariae pieces into a fermentation tank, and fermenting with activated or domesticated yeast so as to obtain fermentation broth; and finally distilling the fermentation broth, thereby obtaining the radix scrophulariae wine. By adopting the method, the radix scrophulariae wine is high in conversion rate of harpagide and harpagoside, high in content of radix scrophulariae polysaccharide and high in alcohol yield, so that the prepared radix scrophulariae wine has special radix scrophulariae smell, is good in taste, is well accepted by customers and is large in market potential.

Owner:重庆市药物种植研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com