Wine brewing yeast strain and method for producing ethanol by efficient sugarcane juice fermentation

A technology of Saccharomyces cerevisiae and sugarcane juice, which is applied in the field of Saccharomyces cerevisiae biological fermentation, can solve the problems of slow fermentation speed of ethanol strains, high residual sugar, cumbersome production process, etc., and achieve easy process control, improved alcohol yield and simplified process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment one: 20L triple fermentation tank sugarcane juice fermentation ethanol small test

[0036] 1. Small amount of yeast culture in liquid medium

[0037] Put the CCTCC NO: M208110 single colony preserved on the YPD plate into the liquid YPD medium, culture at 28°C, and culture overnight.

[0038] 2. Liquid medium to expand yeast strain culture

[0039] Take the YPD culture solution in step 1 as the seed solution, insert the processed sugarcane juice (adding concentrated sulfuric acid to adjust the pH to 3.5~4.0, adding mass ratio is 0.1% urea, mass ratio is 0.02% by 1% inoculum size) Phosphoric acid) to prepare 500ml of sugarcane juice culture fluid.

[0040] 3. Sugarcane juice fermentation in 20L triple fermenter

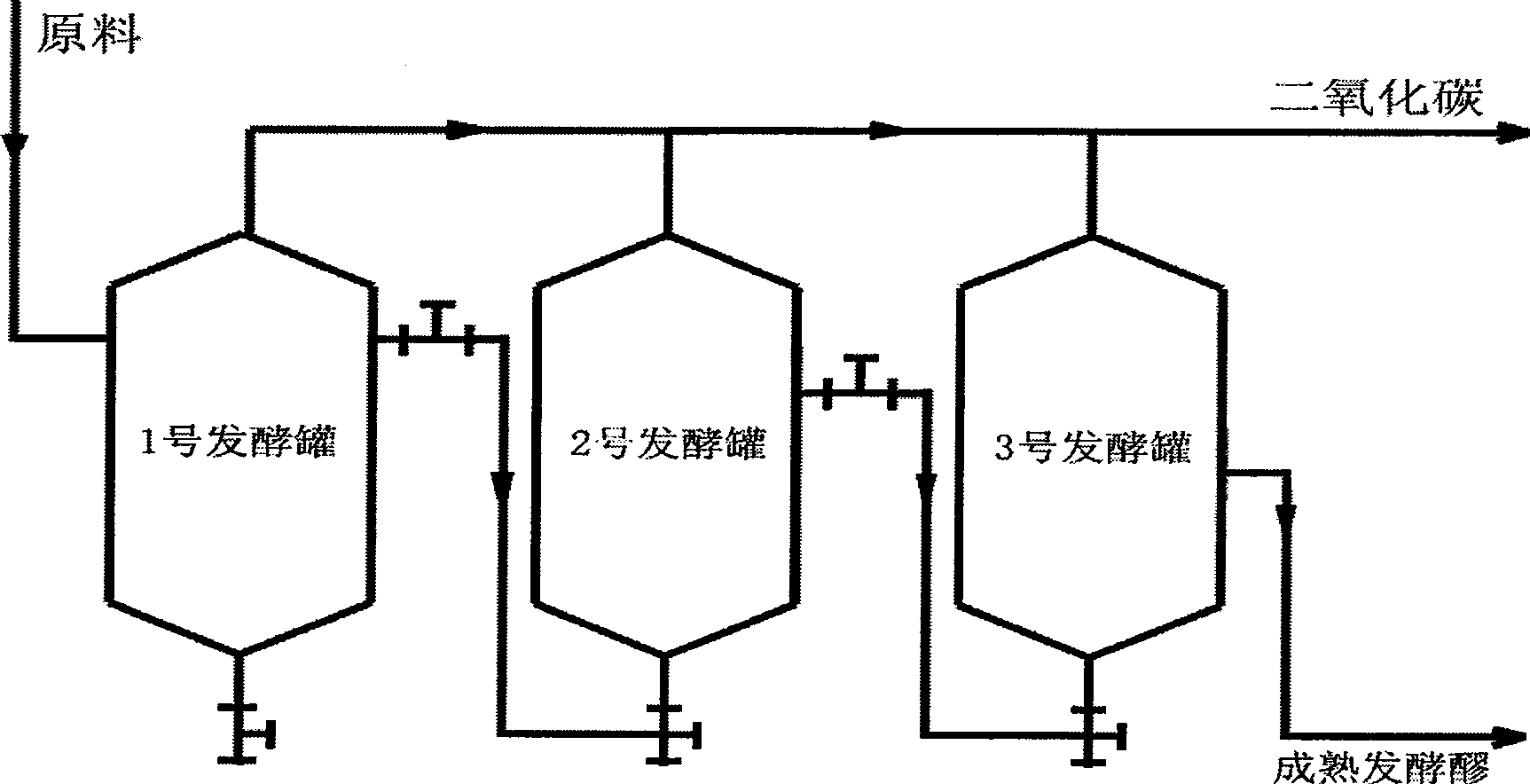

[0041] With the sugarcane juice nutrient solution in the step 2 as seed liquid, insert in No. 1 fermenter (volume is 20L) containing 10L to process sugarcane juice, carry out fermentation, in No. 1 fermenter, control ventilation is 100L / h, The fer...

Embodiment 2

[0042] Embodiment two: sugarcane juice fermentation daily production 10 tons of ethanol pilot test

[0043] 1. The cultivation of a small amount of yeast strains in liquid medium and the cultivation of expanded yeast strains in liquid medium are the same as in Example 1.

[0044] 2. Using sugarcane juice as raw material to ferment, the daily production of 10 tons of ethanol is pilot-tested.

[0045] Refer to attached figure 2 , after CCTCC NO: M208110 bacterial strain is expanded and cultivated to 50L, the fresh seed liquid of gain is inserted in the fermentor (volume is 120 cubic meters) containing 10 tons of sugarcane juice that has been treated to carry out fermentation. The sugarcane juice treatment method is as follows: adding concentrated sulfuric acid to the sugarcane juice to adjust the pH to 3.0-4.0, adding 0.1% urea in mass ratio, and 0.02% phosphoric acid in mass ratio. Control the ventilation in No. 1 tank, and the fermentation temperature is 26°C. When the numb...

Embodiment 3

[0046] Embodiment three: sugarcane juice fermentation daily production 10 tons of ethanol pilot test

[0047] 1. The cultivation of a small amount of yeast strains in liquid medium and the cultivation of expanded yeast strains in liquid medium are the same as in Example 1.

[0048] 2. Using sugarcane juice as raw material to ferment, the daily production of 10 tons of ethanol is pilot-tested.

[0049] Refer to attached figure 2 , after CCTCC NO: M208110 bacterial strain is expanded and cultivated to 50L, the fresh seed liquid of gain is inserted in the fermentor (volume is 120 cubic meters) containing 10 tons of sugarcane juice that has been treated to carry out fermentation. The sugarcane juice treatment method is as follows: adding concentrated sulfuric acid to the sugarcane juice to adjust the pH to 3.0-4.0, adding 0.1% urea in mass ratio, and 0.02% phosphoric acid in mass ratio. Control the ventilation in No. 1 tank, and the fermentation temperature is 29°C. When the nu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com