Alcohol vapor waste heat recycling process

A technology of waste heat recovery and juice vapor, applied in evaporation, heat exchanger, distillation and separation, etc., can solve the problems of low energy utilization rate, high energy consumption, and large energy waste, so as to improve utilization rate, reduce pollution, and increase heat energy The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

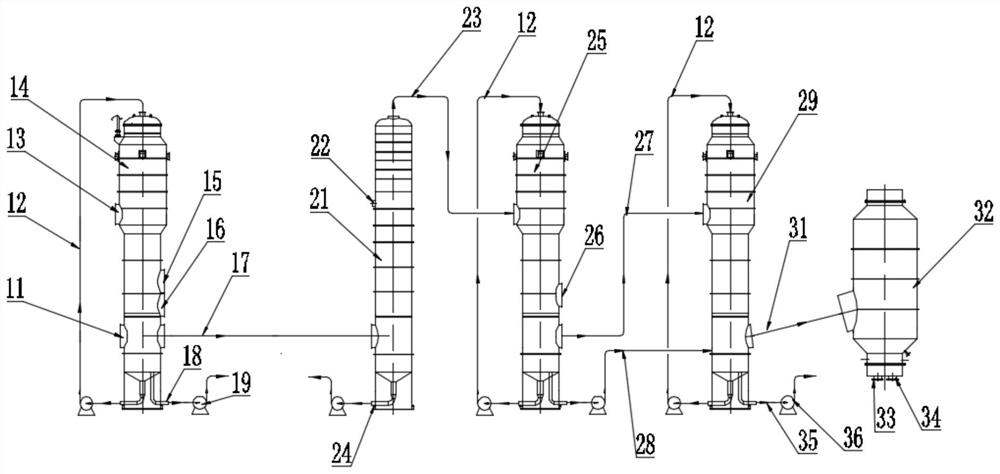

[0043] Such as figure 1 As shown, this embodiment is a process for recovering and utilizing waste heat from alcohol evaporated juice vapor, which specifically includes the following steps:

[0044] Step 1: Pass the 95°C steam from the dryer and the 80°C clear liquid from the decanter centrifuge into the single-effect falling film generator;

[0045] Step 2: The juice vapor produced in the single-effect falling film generator enters the distillation section crude tower 21 through the first juice vapor pipe 17 connected between the single-effect falling film evaporator 14 and the distillation section rough tower 21 to be the distillation section rough tower 21. The mash in the tower 21 supplies heat, carries out heat transfer, produces wine vapor;

[0046]Step 3: The wine vapor generated in the crude tower 21 of the distillation section enters the No. 1 falling film generator through the wine vapor pipe 23 to provide heat for the materials in the No. 1 falling film generator, a...

Embodiment 2

[0055] Such as figure 1 As shown, the difference from Example 1 is that the concentration of the concentrated solution discharged from the single-effect falling film generator in this example is controlled to be 7%.

Embodiment 3

[0057] Such as figure 1 As shown, based on Example 1 and Example 2, the single-effect falling film generator, No. 1 falling film generator, and No. 2 falling film generator of this example are all connected with a material circulation structure.

[0058] Wherein, the material circulation structure comprises the material circulation pipe 12 connected between the bottom and the top of the single-effect falling film evaporator 14, the No. 1 falling film evaporator 25, and the No. 2 falling film evaporator 29, and the material circulation pipe 12 is connected with Evaporation circulation pump.

[0059] The single-effect falling film evaporator 14, the No. 1 falling film evaporator 25, and the No. 2 falling film evaporator 29 are all connected to the circulation structure, and the power provided by the evaporation circulation pump connected to the material circulation pipe 12 makes the materials flow in the single-effect respectively. Efficient falling film evaporator 14, No. 1 fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com