Alcohol output increasing method and device

A production and alcohol technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, specific-purpose bioreactors/fermenters, etc., can solve the problem of no obvious effect of alcohol fermentation, and achieve the elimination of pectin and miscellaneous bacteria , Improve the alcohol yield, improve the effect of fermentation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

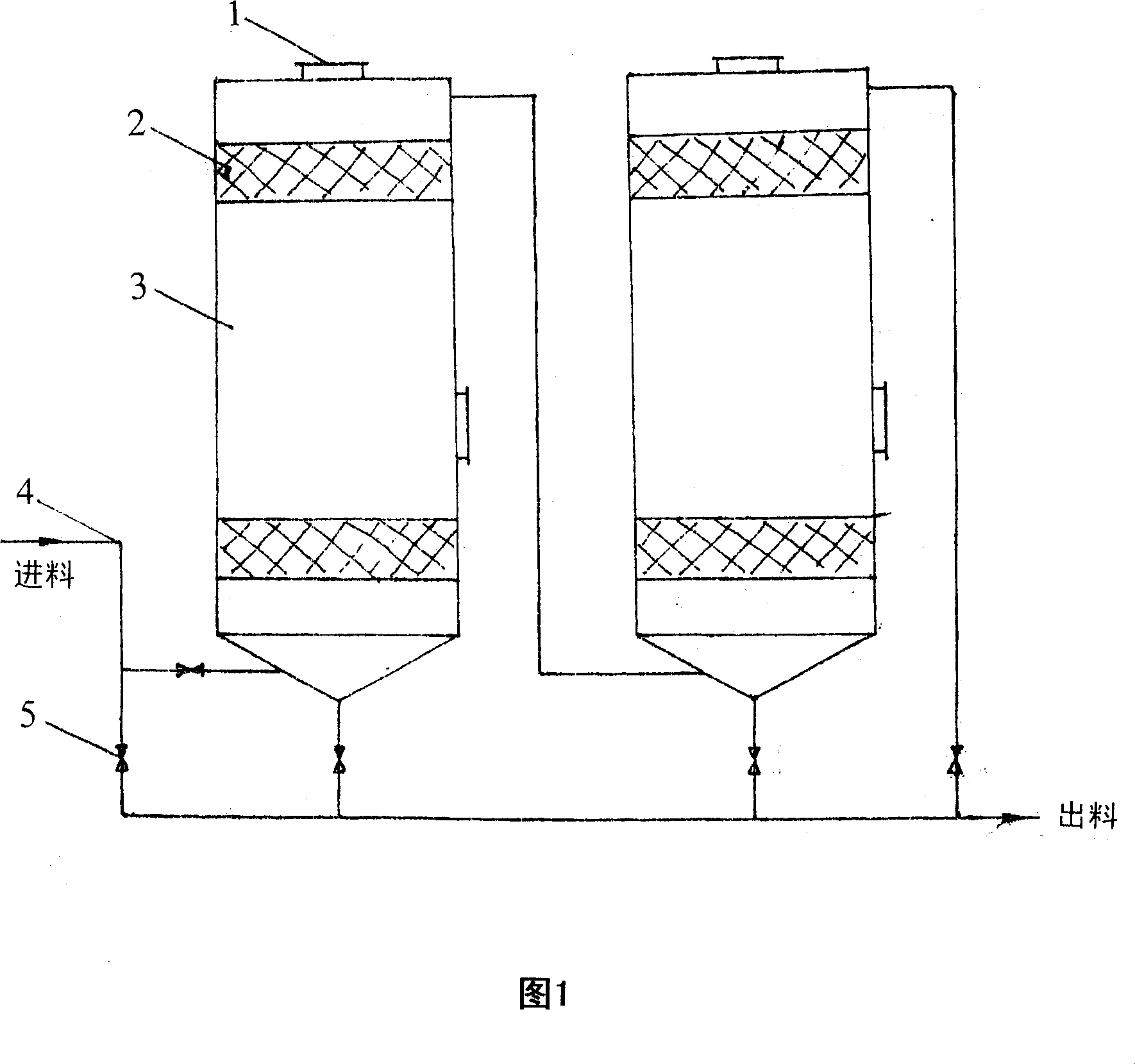

Image

Examples

Embodiment 1

[0030] Aspergillus niger (Aspergilus niger, AN) is added to the culture medium and placed in a greenhouse at 25-35℃ for 1-2 days. Per liter of culture medium starch accounts for 20-30 grams, peptone 20-30 grams, sucrose or glucose 20-30 grams, 5-10 grams of sodium chloride, add distilled water to make it reach 1 liter, and then acclimate to the fermentation concentration of yellow pulp water for another day (the temperature and other conditions remain unchanged) after the culture, and it is best to add manganese during the culture process Water-soluble inorganic salts of iron, zinc, antimony and tin, the added amount of manganese salt accounts for 0.5-2% of the mass percentage of the culture medium; iron salt accounts for 2-5% of the mass percentage of the culture medium; zinc salt accounts for the culture 1-2% of the base mass percentage; antimony salt accounts for 0.2-1% of the medium mass percentage; tin salt accounts for 0.3-1 of the medium mass percentage, 30 kg of fermented ...

Embodiment 2

[0032]Kluyveromyces (Kluyveromyces), Trichoderma Koningii (Trichoderma Koningii) were first added to the culture medium and placed in the greenhouse at 25-35 ℃ for 1-2 days, each liter of culture medium starch accounted for 20-30 grams, peptone 20-30 grams of sucrose or glucose, 20-30 grams of sodium chloride, 5-10 grams of sodium chloride, add distilled water to make it reach 1 liter, after incubation, it will be acclimated for another day according to the fermentation concentration of yellow pulp water, (temperature and other conditions Unchanged) It is better to add water-soluble inorganic salts of manganese, iron, zinc, antimony and tin during the cultivation process. The amount of manganese salt added accounts for 0.5-2% of the mass percentage of the medium; iron salt accounts for the mass percentage of the medium. 2-5%; zinc salt accounts for 1-2% of the medium mass percentage; antimony salt accounts for 0.2-1% of the medium mass percentage; tin salt accounts for 0.3-1 of th...

Embodiment 3

[0034] Erwinia (Erwinia), Trichoderma reesei Rut C-30 (Trichoderma reesei Rut C-30) were added to the culture medium and placed in the greenhouse at 25-35℃ for 1-2 days, and each liter of culture medium starch accounted for 20-30 Grams, 20-30 grams of peptone, 20-30 grams of sucrose or glucose, 5-10 grams of sodium chloride, add distilled water to make it reach 1 liter, after incubation, it will be acclimated for another day according to the fermentation concentration of yellow pulp water, ( Conditions such as temperature remain unchanged) During the cultivation process, it is best to add water-soluble inorganic salts of manganese, iron, zinc, antimony and tin, and the amount of manganese salt added accounts for 0.5-2% of the mass percentage of the medium; iron salt accounts for 100% of the mass 2-5% of the medium content; zinc salt accounts for 1-2% of the medium mass percentage; antimony salt accounts for 0.2-1% of the medium mass percentage; tin salt accounts for 0.3- of the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com