Method for producing alcohol by applying enzyme preparation production fermenting waste liquid to raw material of cassava

A technology for fermentation waste liquid and enzyme preparation, applied in the field of fermentation, can solve the problems of increasing production cost, polluting the surrounding environment, low component content, etc., and achieve the effects of large profits, saving waste liquid treatment costs, and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

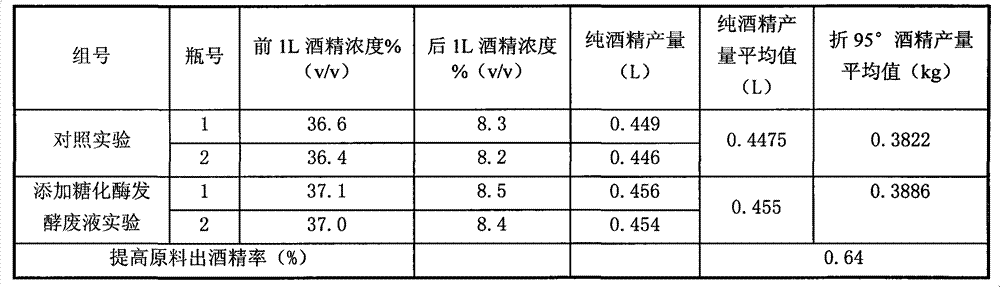

[0023] Embodiment 1 Adding glucoamylase fermentation waste liquid alone to the influence of alcohol production

[0024] Enzyme preparation production fermentation waste liquid is applied to the method for producing alcohol from cassava raw materials, including cassava flour slurry, liquefaction, saccharification and fermentation, and the steps are as follows:

[0025] The cassava is pulverized and passed through a sieve with an aperture of 1.8mm to obtain cassava flour, then take 1kg of cassava flour, mix the cassava flour with 2.6L of water according to the ratio of weight to volume ratio 1: 2.6, and stir evenly to obtain cassava flour slurry; Add 0.04L diluent of amylase (from 20,000 U / mL to 200 U / mL) into the slurry, mix well, and liquefy at 96°C for 80 minutes to obtain liquefied cassava pulp;

[0026] Cool the liquefied cassava pulp to 60°C, add 0.088L glucoamylase diluent (diluted from 100,000 U / mL to 1000U / mL) and 0.15L glucoamylase fermentation waste liquid, mix well, ...

Embodiment 2

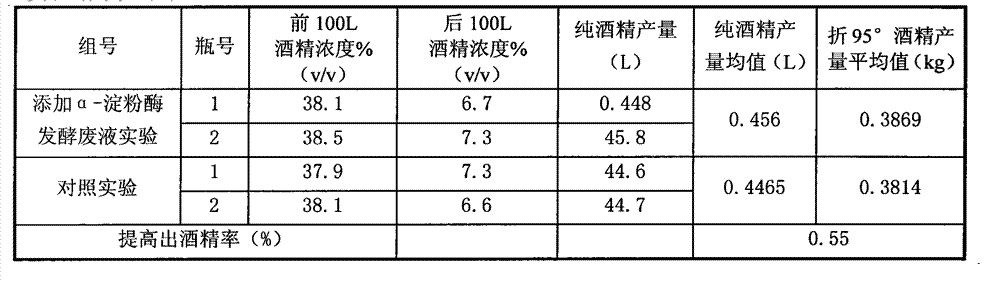

[0036] Embodiment 2 separately adds the impact of amylase fermentation waste liquid on alcohol production

[0037] Enzyme preparation production fermentation waste liquid as described in embodiment 1 is applied to the method for producing ethanol from cassava raw material, and the difference is that only 0.1L amylase fermentation waste liquid is added to cassava pulp in the liquefaction process; Add 0.1L saccharification enzyme diluent to the liquefied cassava pulp at 60°C, without adding saccharification enzyme fermentation waste liquid.

[0038] At the same time, do comparative experiments, as shown in the table below:

[0039]

Group No

Raw material quantity (kg)

+

water (L)

enzyme

to dilute

Liquid (L)

amylase hair

leaven

Waste liquid (L)

Glucoamylase

(L)

Nutrients

(g)

...

Embodiment 3

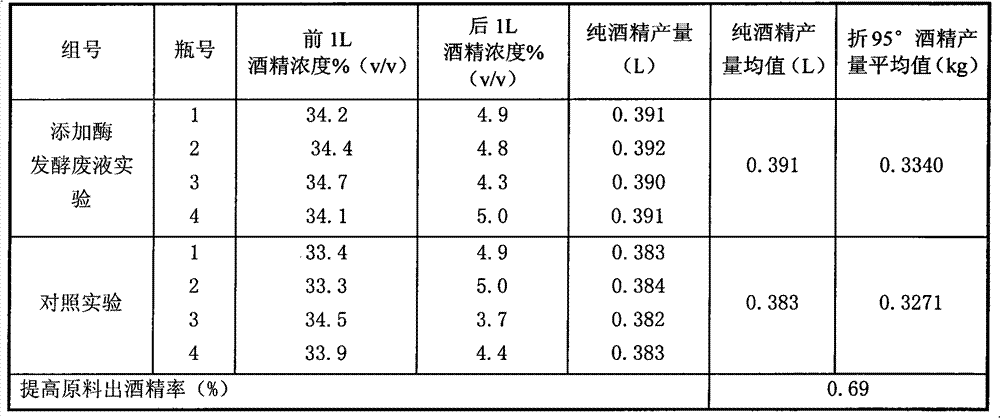

[0045] Example 3 Effects of Simultaneously Adding α-amylase Fermentation Waste Liquid and Glucoamylase Fermentation Waste Liquid on Alcohol Production

[0046]Enzyme preparation production fermentation waste liquid as described in embodiment 1 is applied to the method for cassava raw material production alcohol, and difference is, in cassava slurry, add 0.05L amylase fermentation waste liquid and 0.02L amylase dilution in the liquefaction process, During the saccharification process, add 0.092L glucoamylase dilution and 0.1L glucoamylase fermentation waste liquid to the liquefied cassava pulp cooled to 60°C, add 0.5g nutrient salt, and add 0.02L activated Saccharomyces cerevisiae during the saccharification process.

[0047] At the same time, do a comparative test, as shown in the table below:

[0048]

Group No

Amount of raw material(kg)+

water (L)

dilute amylase

Release solution (L)

amylase hair

leaven

Wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com