Control method of reverse belt threading in vertical continuous annealing furnace

A technology of continuous annealing furnace and control method, which is applied in the direction of heat treatment process control, furnace, manufacturing tools, etc., can solve the problem of late start time of purging and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

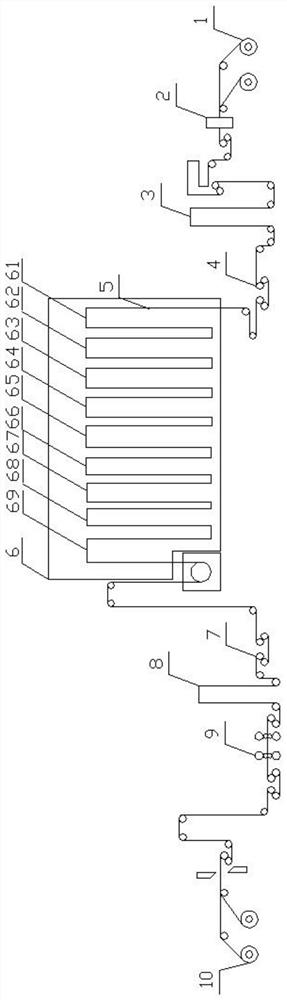

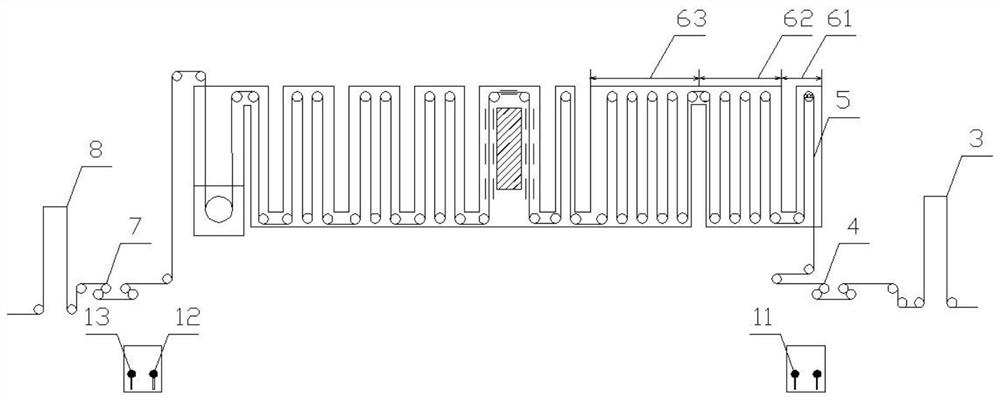

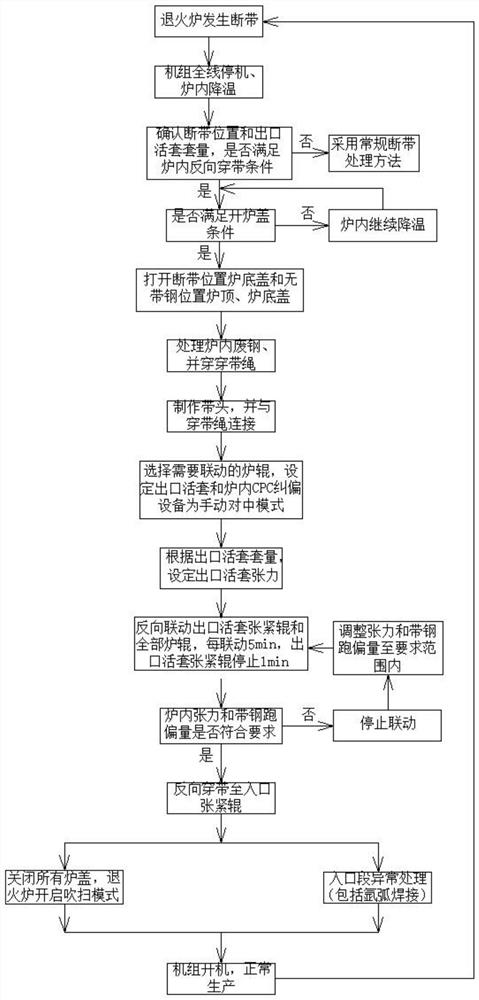

[0024] Embodiment 1: see Figure 1-Figure 3 , a vertical continuous annealing furnace reverse belt threading control method, the control method is as follows:

[0025] S1. The unit is shut down, and the annealing furnace is switched to the cooling mode;

[0026] S2. Confirm whether the position of broken belt in the furnace and the amount of looper at the outlet are sufficient, and decide whether to adopt the reverse belt threading operation method;

[0027] S3. When the furnace temperature drops below the furnace cover opening temperature, open the corresponding furnace cover according to the broken belt in the furnace and carry out scrap steel processing and rope threading operations, make a leader at the end of the broken belt, and connect it with the belt threading rope;

[0028] S4. Select the furnace roll that needs to be linked, and set the exit looper and the annealing furnace CPC deviation correction device to the manual centering state;

[0029] S5. Set the tension...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com