Sharing maintenance system ensuring normal operation of wind turbines and realization method thereof

A wind turbine, normal operation technology, applied in the direction of electrical program control, sustainable building, comprehensive factory control, etc., can solve the problems of low utilization rate, long procurement cycle, and many monitoring parameters, so as to improve utilization rate and reduce abnormal downtime effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

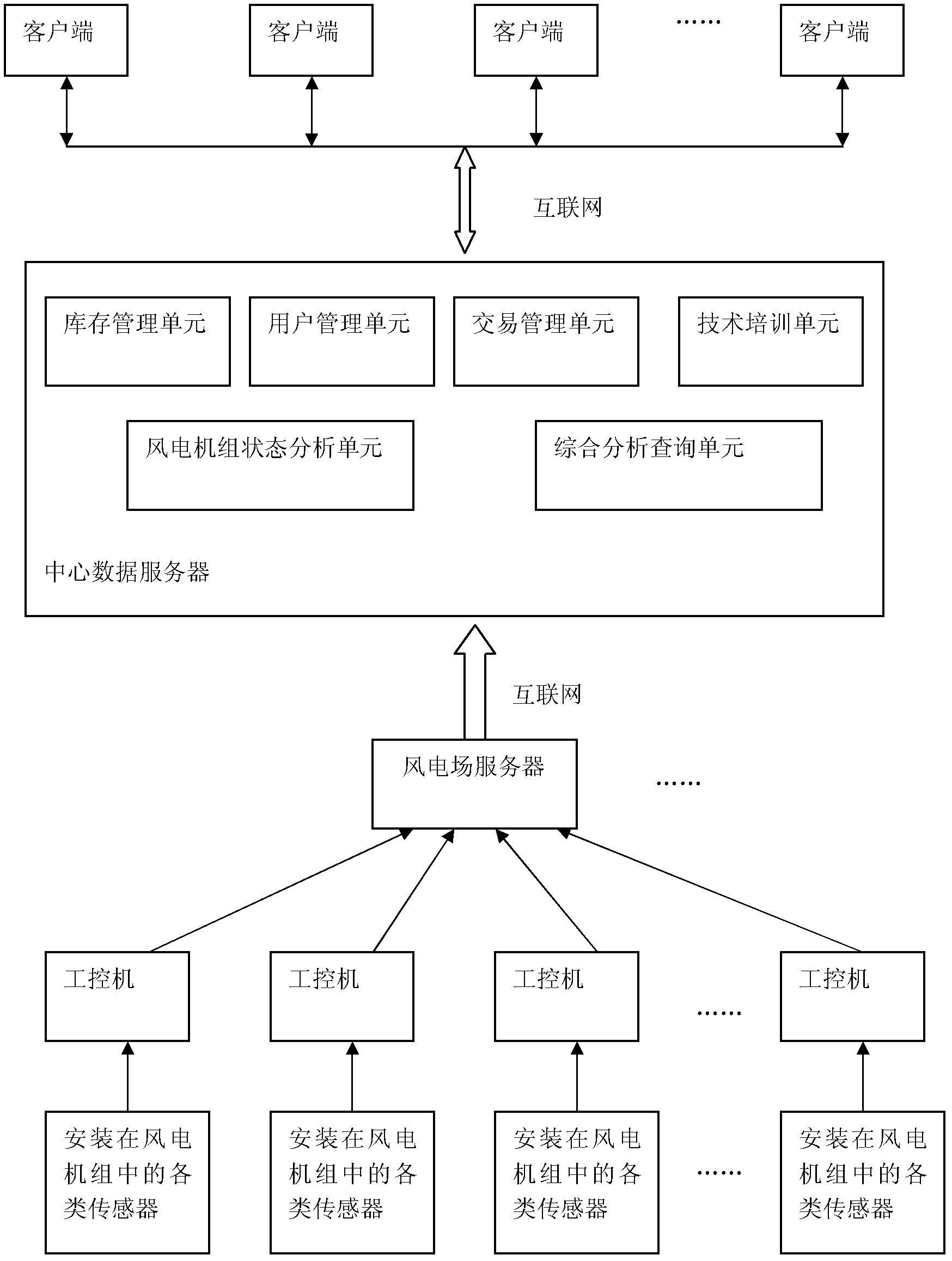

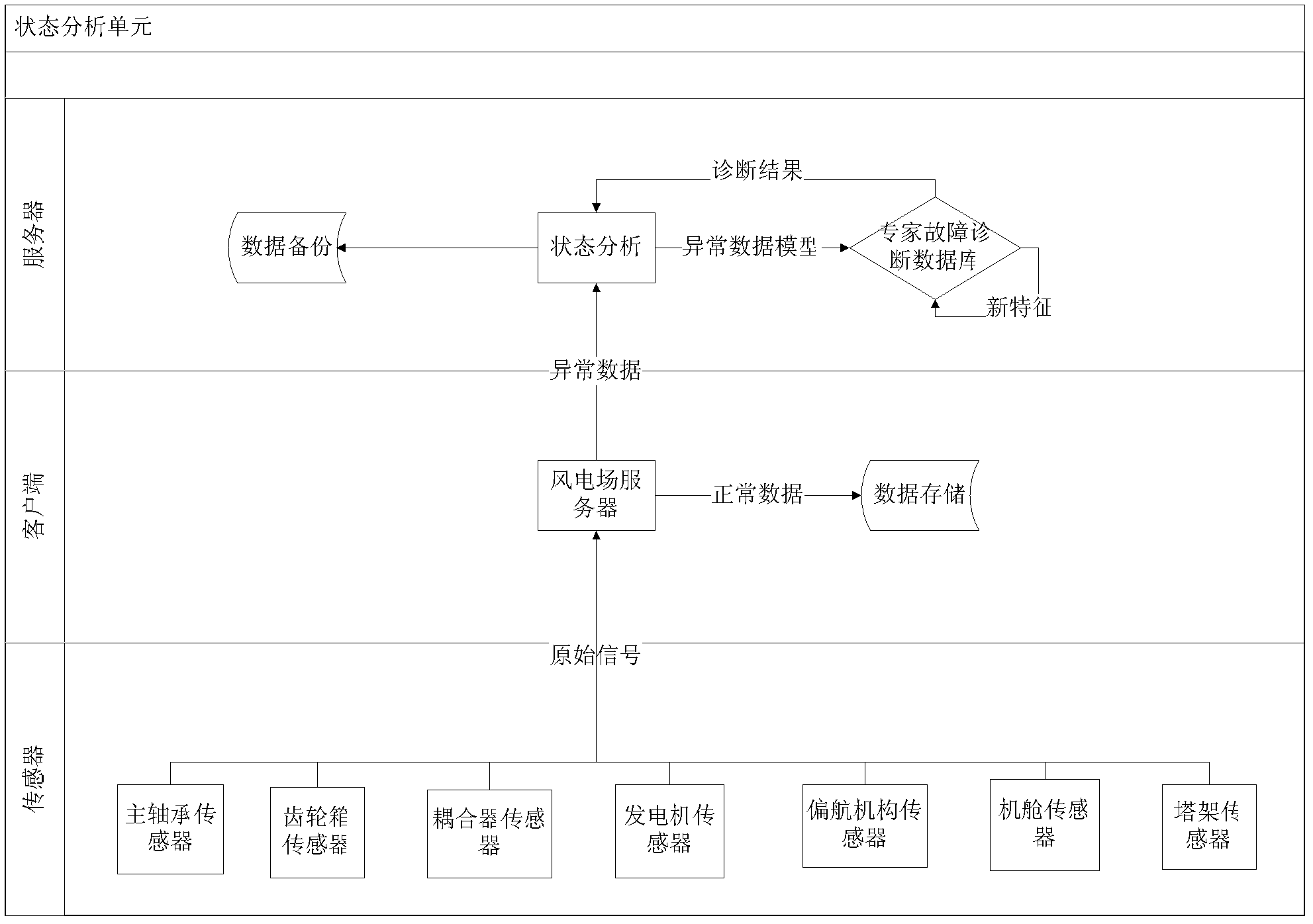

[0034] see figure 1, the wind turbine condition monitoring device is mainly composed of various sensors installed in each wind turbine and the industrial computer. The frame collects the following raw signals: temperature of all bearings; engine room temperature, gearbox oil temperature, generator coil and air gap temperature; main shaft speed and generator speed; main shaft bearings, gearbox front and rear end bearings, and generator front and rear end bearings vertical vibration; vertical vibration of gearbox housing, base, yaw mechanism, nacelle and tower. The industrial computer is installed with wind turbine status detection system software, which is mainly responsible for controlling each sensor to complete the original signal sampling of the main components of the wind turbine, and transmitting the signals obtained by various sensors to the wind farm server after data conversion and preliminary processing. The server uses scanning to receive the data sent by the indust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com