Additional given value control method of hot-continuous-rolling thin-specification running sleeve and idle sleeve

A control method and thin-gauge technology, applied in metal rolling, tension/pressure control, etc., can solve the problems of slow adjustment of strip loops and virtual sets, reduce abnormal downtime, ensure product quality, and reduce product quality problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

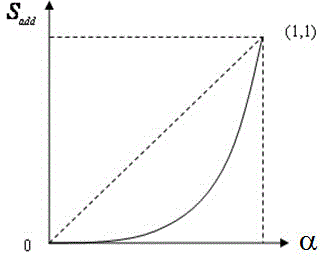

[0030] Example 1: There are five loopers from 0# to 5# in the hot continuous rolling and finishing mill. Take Q235A carbon steel specification 1.48mm*1250mm 5# looper as an example: when the torque deviation ΔM is greater than zero, it indicates that the looper belt In order not to affect the normal looper control of the steel virtual sleeve, the additional setting of the looper servo after the virtual sleeve adopts the torque deviation exponential function curve as follows: figure 1 For adaptive control, additional given value Sadd=α 5 , α=ΔM÷M Tref , the index value is 2, and when the torque deviation value ΔM is 4000, the additional given value is calculated to be 0.64.

[0031] kT is 0.15, T is 18, W is 1250mm, H is 1.48mm,

[0032] Torque deviation ΔM = set torque of strip steel - actual torque of strip steel = 4000;

[0033] The set torque of the strip steel is 12500, when the actual torque of the strip steel is 8500, there is a false cover, then the torque deviation ...

Embodiment 2

[0038] There are five loopers from 0# to 5# in the hot continuous rolling finishing unit. Take the container plate size 1.6mm*1250mm 4# looper as an example: when the torque deviation ΔM is greater than zero, it indicates that the looper strip is false. It does not affect the normal looper control, and the additional setting of the looper servo after virtual looping adopts the torque deviation exponential function curve as follows: figure 1 Carry out adaptive control, the algorithm is as formula 1, the index value is 2, and the corresponding additional given value is obtained according to different torque deviation values, and finally applied to the servo valve of the looper. When the torque deviation value ΔM is 1000, the calculated additional setting is 0.23.

[0039] kT is 0.15, T is 15, W is 1250mm, H is 1.48mm,

[0040] Torque deviation ΔM = set torque of strip steel - actual torque of strip steel = 1000;

[0041] The set torque of the strip steel is 13500, when the act...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com