A looper control method for pipeline steel

A control method and pipeline steel technology, applied in the direction of tension/pressure control, etc., can solve problems such as economic losses of enterprises, affecting the normal operation of rolling lines, looper vibration, etc., to reduce abnormal downtime, solve hydraulic looper vibration, and ensure The effect of automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

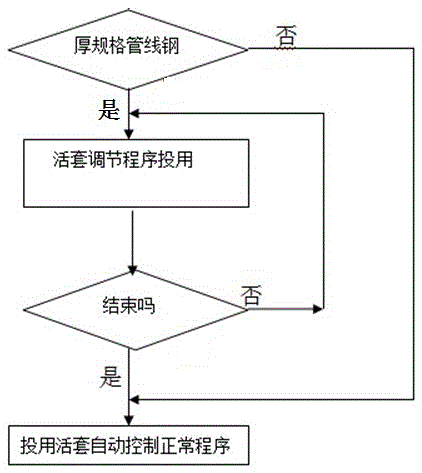

Image

Examples

Embodiment

[0016] When the rolling steel type is L360 and the thickness is 8mm, the secondary computer (HP server) checks the tension coefficients of all loops through the table model and sends them to the primary computer (PLC controller) before the strip enters the finishing mill. The first-level computer is based on the final rolling temperature of the strip steel at 810°C and the thickness of the finished strip steel at 8mm as the selection symbol for the control technology, and at the same time puts into the control of the corresponding rolling mill looper according to the tracking load signal of each rolling mill. The scan time of this program is 5ms, 0# looper: integration time 2500ms, steel tension coefficient 0.6; 1# looper: integration time 2650ms, steel tension coefficient 0.6; 2# looper: integration time 2800ms, steel tension coefficient Coefficient 0.55; 3# looper: integration time 3000ms, steel tension coefficient 0.45; 4# looper: integration time 3200ms, steel tension coeff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com