Automatic control device and control method for contact force transfer displacement of electrospark deposition surfacing welding

An automatic control device, the technology of electric spark deposition, applied in welding equipment, welding accessories, arc welding equipment and other directions, to achieve the effect of small friction coefficient, improve reliability and improve stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The invention will be described in further detail below with reference to the accompanying drawings and specific examples.

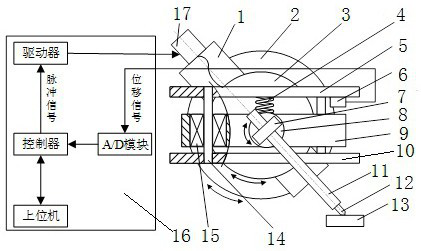

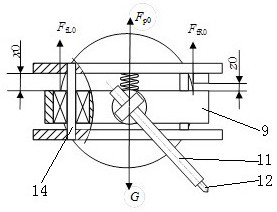

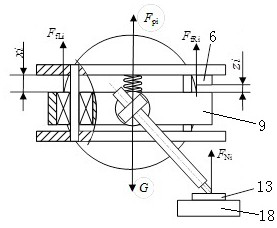

[0030] Such as figure 1 As shown, an automatic control device of an electric spark deposition reducing welding contact force transfer is mainly composed of a mechanical system and an electronically controlled system 16, wherein the mechanical system includes a feed mechanism 1, a floating elastic mechanism, a sander mechanism 7 and a welding gun. 11; the feed mechanism 1 is mainly composed of a feed screw, a feed slide, and a feed base, and the feed screw is disposed on the feed base, and the rotation drive of the screw is driven to the slide; The floating elastic mechanism is mainly composed of the upper base 5, the optical axis 14, the straight bearing 15, the lower base 10, the spring 4, the floating slide 9, the upper base 5 and the lower base 10 are parallel to each other, between the two, and the two The optical axis 14 is connected (the optical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com