Box-type piling machine for dark green tea

A kind of stacking machine and stacking technology, which is applied in the direction of tea treatment before extraction, etc., can solve the problems of different stacking principles, difficult control of temperature and humidity, changes in tea flavor, etc., to achieve wide application range, scientific and reasonable device design, avoid The effect of tea drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings.

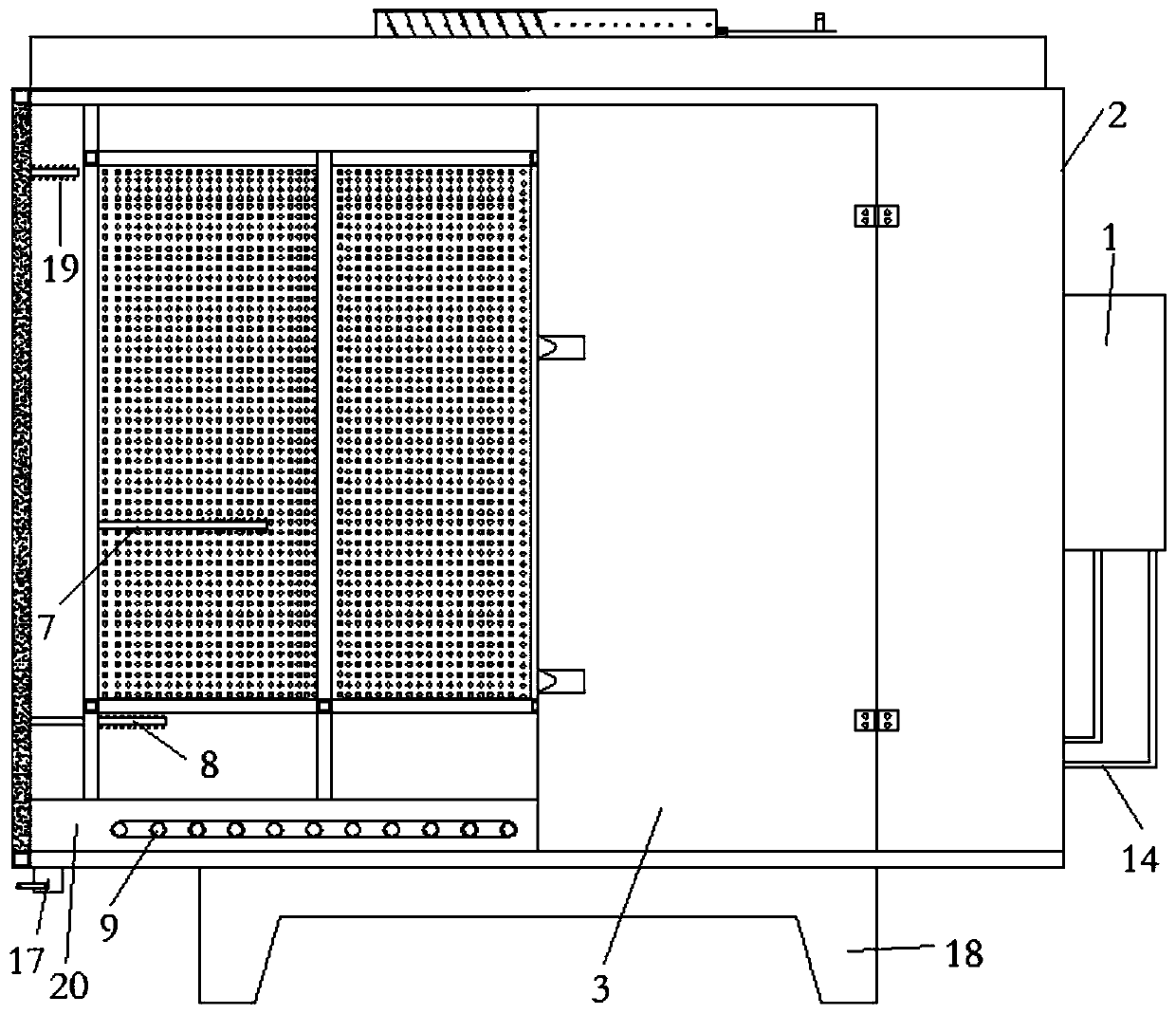

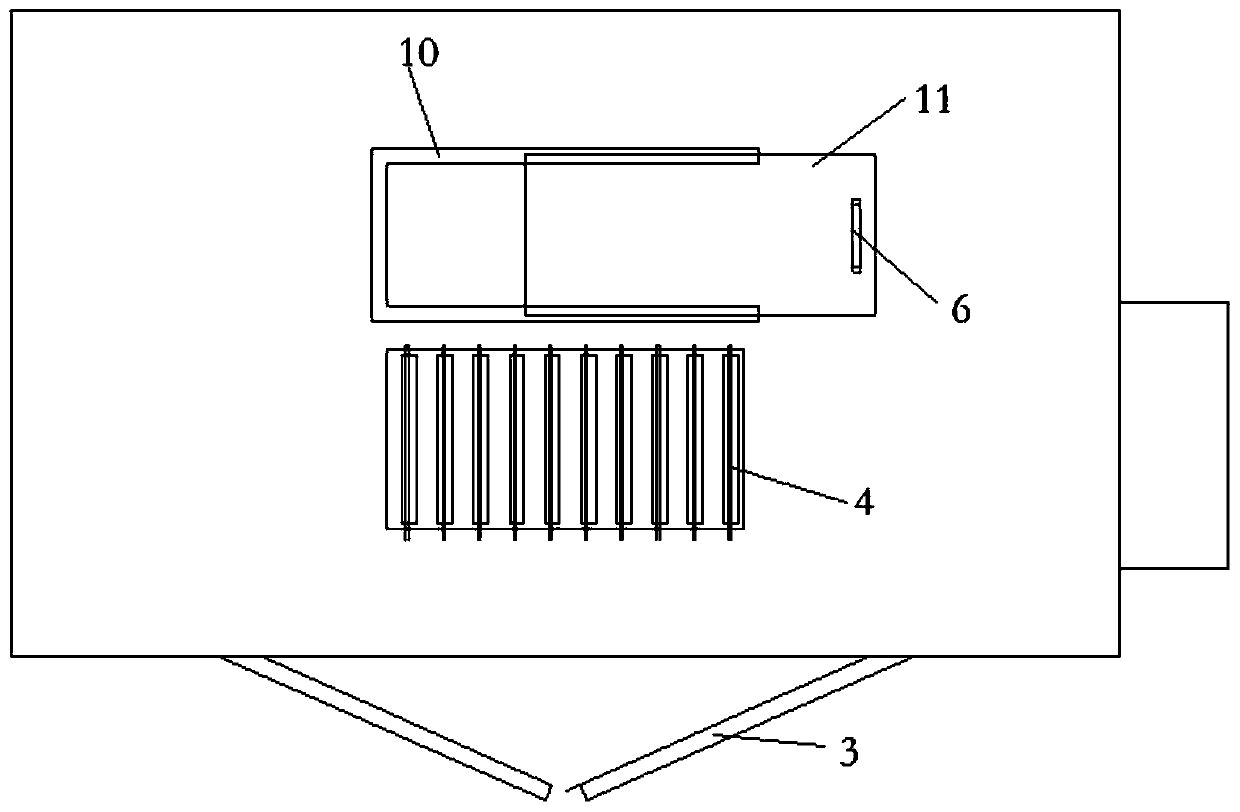

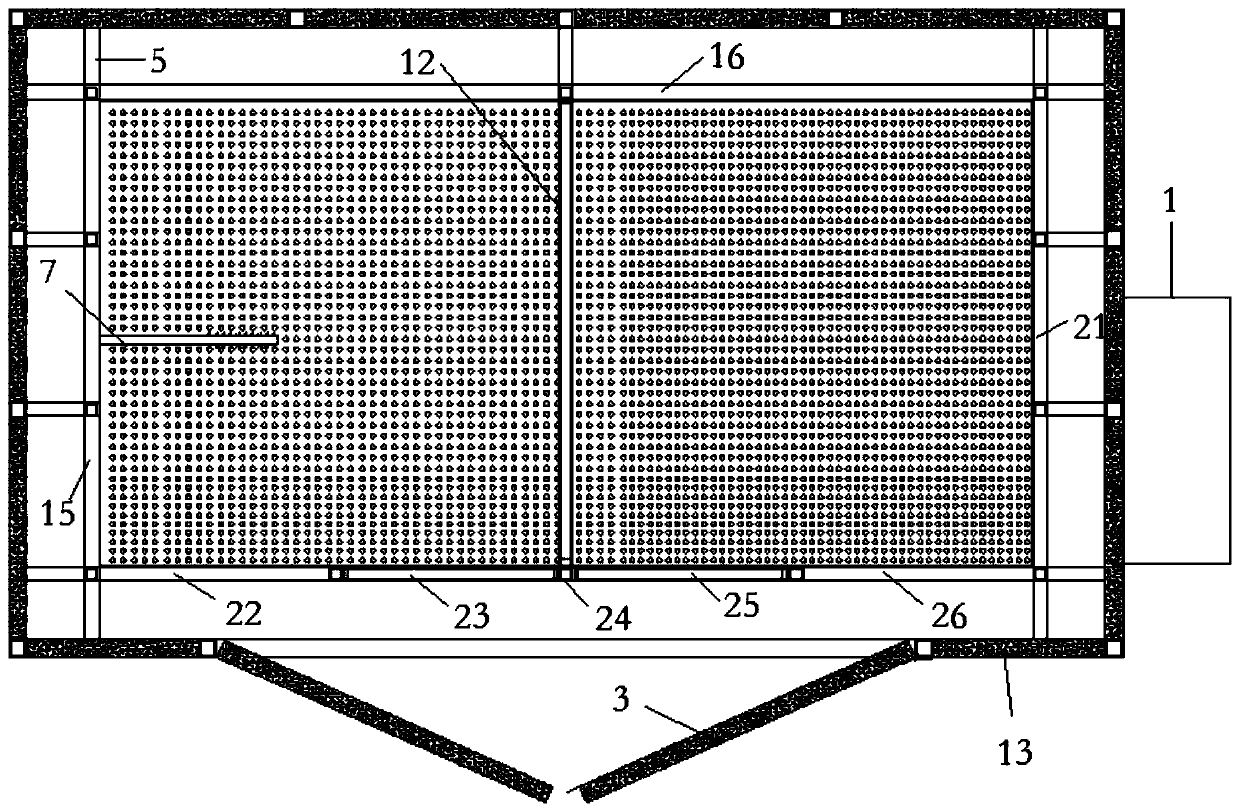

[0021] The structure of the black tea box type stacker provided by the invention is as follows: figure 1 and figure 2 Shown, comprise box body, base 18, feeding mechanism, humidity control mechanism, temperature control mechanism, Wo pile mechanism and controller 17. The casing is fixed on the base 18.

[0022] The box body includes a shell 2 and a box door 3 , the inner side of the shell 2 is provided with an insulating layer 13 , and the box door 3 is installed on the side wall of the shell 2 .

[0023] The feeding mechanism includes a feeding port 10 and a feeding door 11, both of which are square. The feeding port 10 is opened on the top of the shell 2, and the first chute is symmetrically arranged on both edges of the feeding port 10 in the length direction, and the openings of the two first chute slots are facing each other. Two edges in the length directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com