Patents

Literature

86results about "Mass flow control device" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Emulsified liquid flow dynamic and comprehensive optimization setting method suitable for cold continuous rolling unit

ActiveCN106311754AFull cooling effectUniform cooling effectMass flow control deviceMetal rolling arrangementsEngineeringCooling capacity

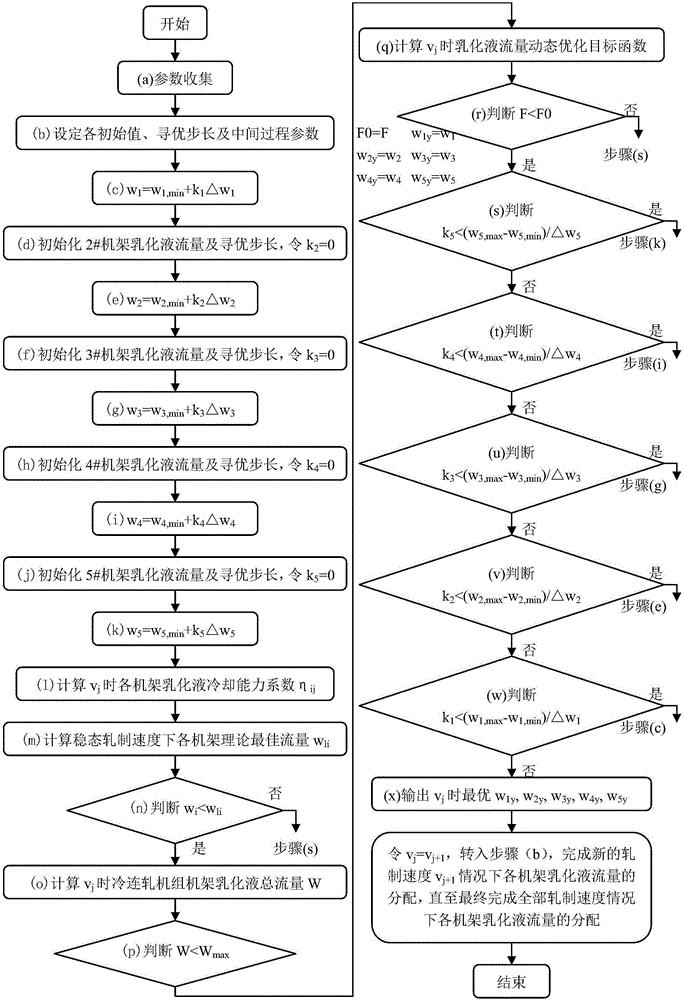

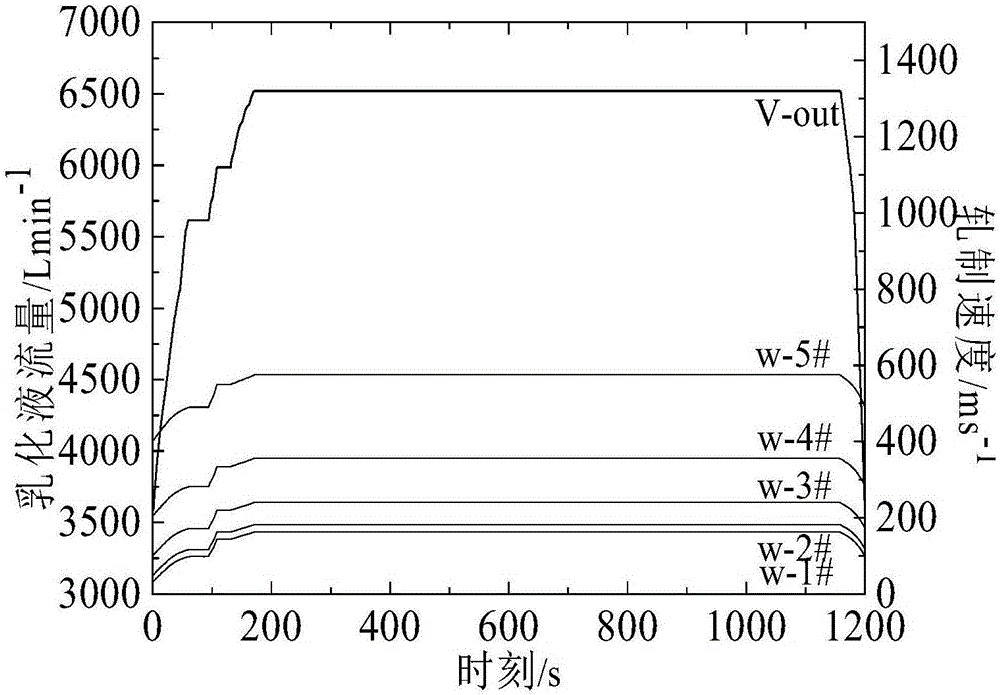

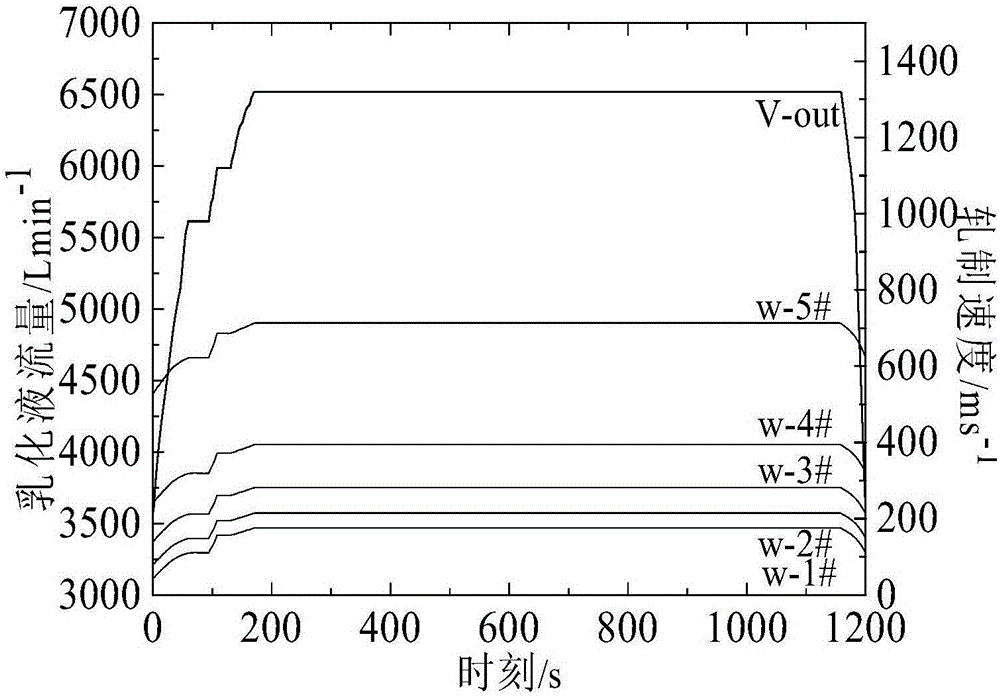

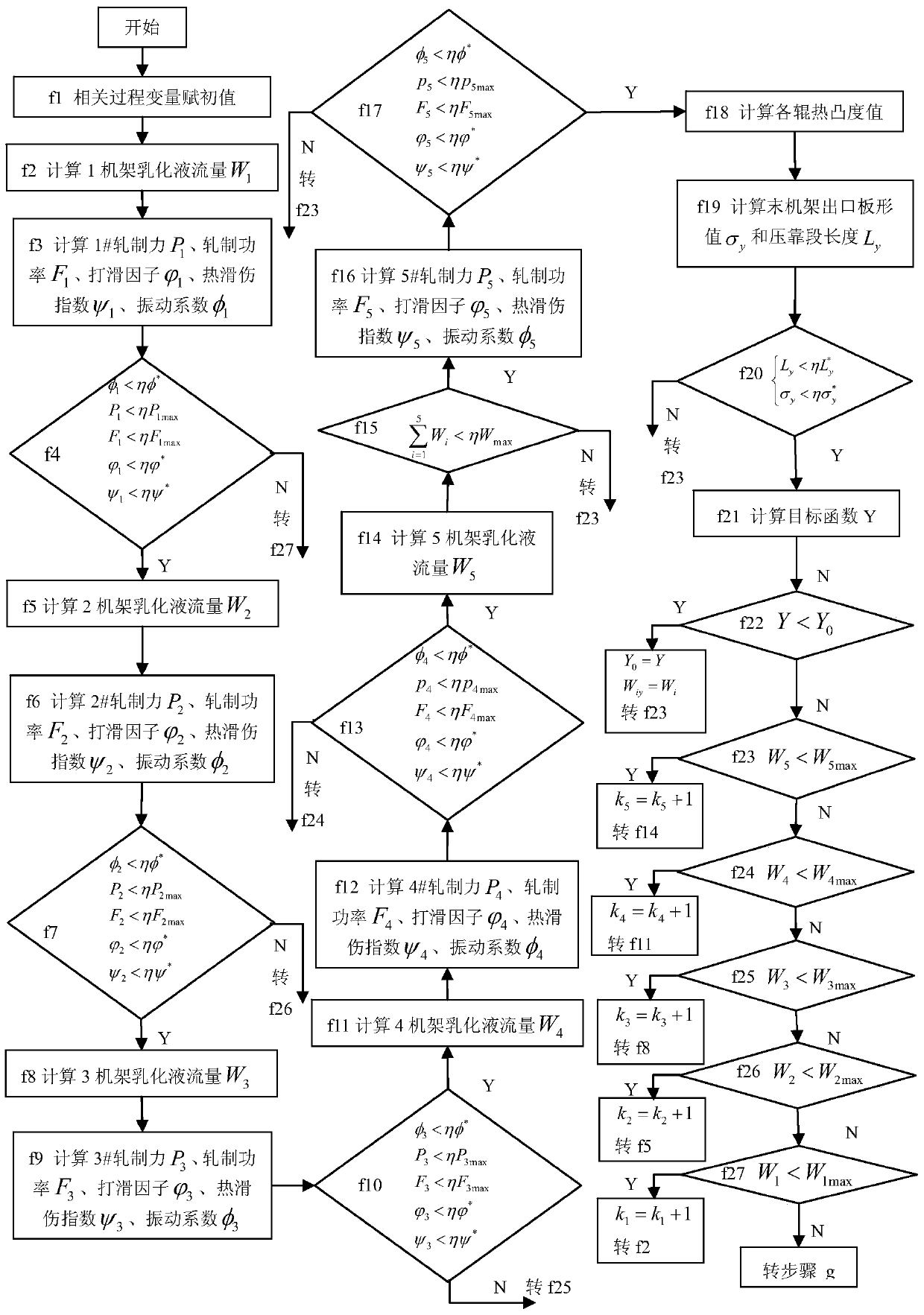

The invention relates to an emulsified liquid flow dynamic and comprehensive optimization setting method suitable for a cold continuous rolling unit. The method mainly comprises the following steps that (1) parameters are collected; (2) initial values, optimizing step sizes and middle process parameters are set; (3) the flow and the optimizing step sizes of emulsified liquid of a No.2 rack, a No.3 rack, a No.4 rack and a No.5 rack are defined; (4) cooling capacity coefficients of the emulsified liquid of the racks are calculated; (5) the theoretical optimal flow of the racks at the steady rolling speed is calculated; (6) the total flow of the emulsified liquid of the racks is calculated; (7) an emulsified liquid flow dynamic and comprehensive optimization objective function is calculated; (8) the optimal flow of the emulsified liquid of the racks is output; and (9) distribution of the flow of the emulsified liquid of the racks at the new rolling speed is completed till distribution of all the flow is completed. According to the method, the problems that due to fixed distribution of the flow of the emulsified liquid between the racks, the rolling pressure is increased abnormally, and the rolling pressure is inverted are avoided; the cooling capacity of the emulsified liquid is given full play, and the cooling capacity of the emulsified liquid of the racks is more uniform; and the production stability is improved.

Owner:唐山市榕泽钢铁加工有限公司

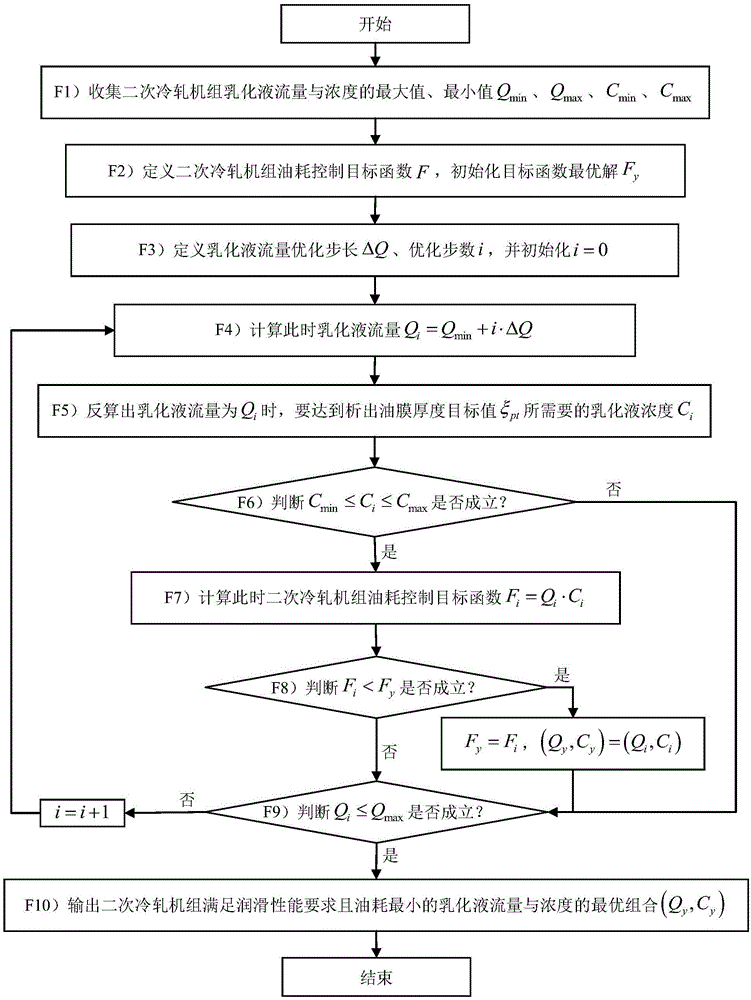

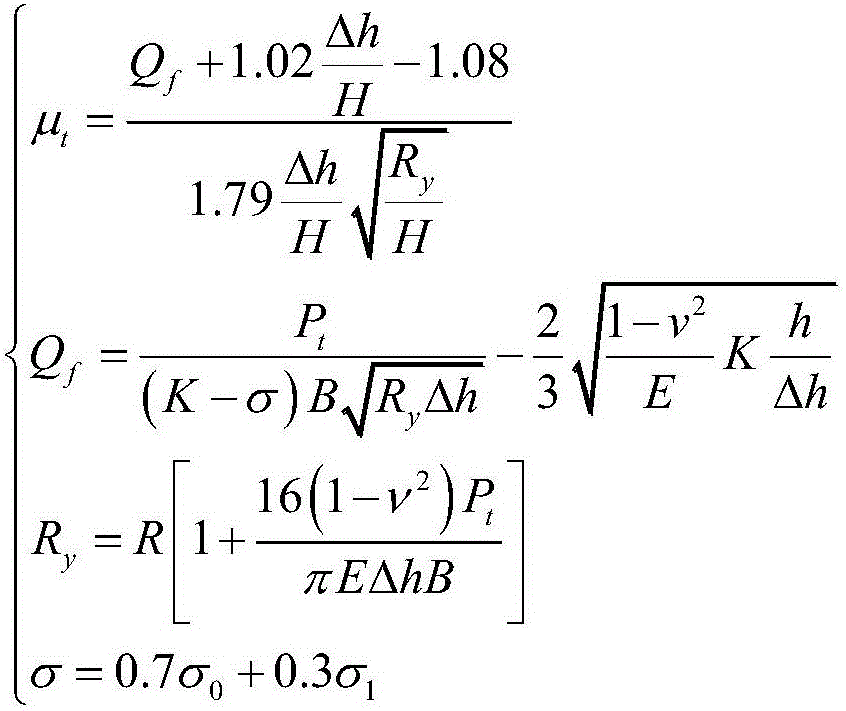

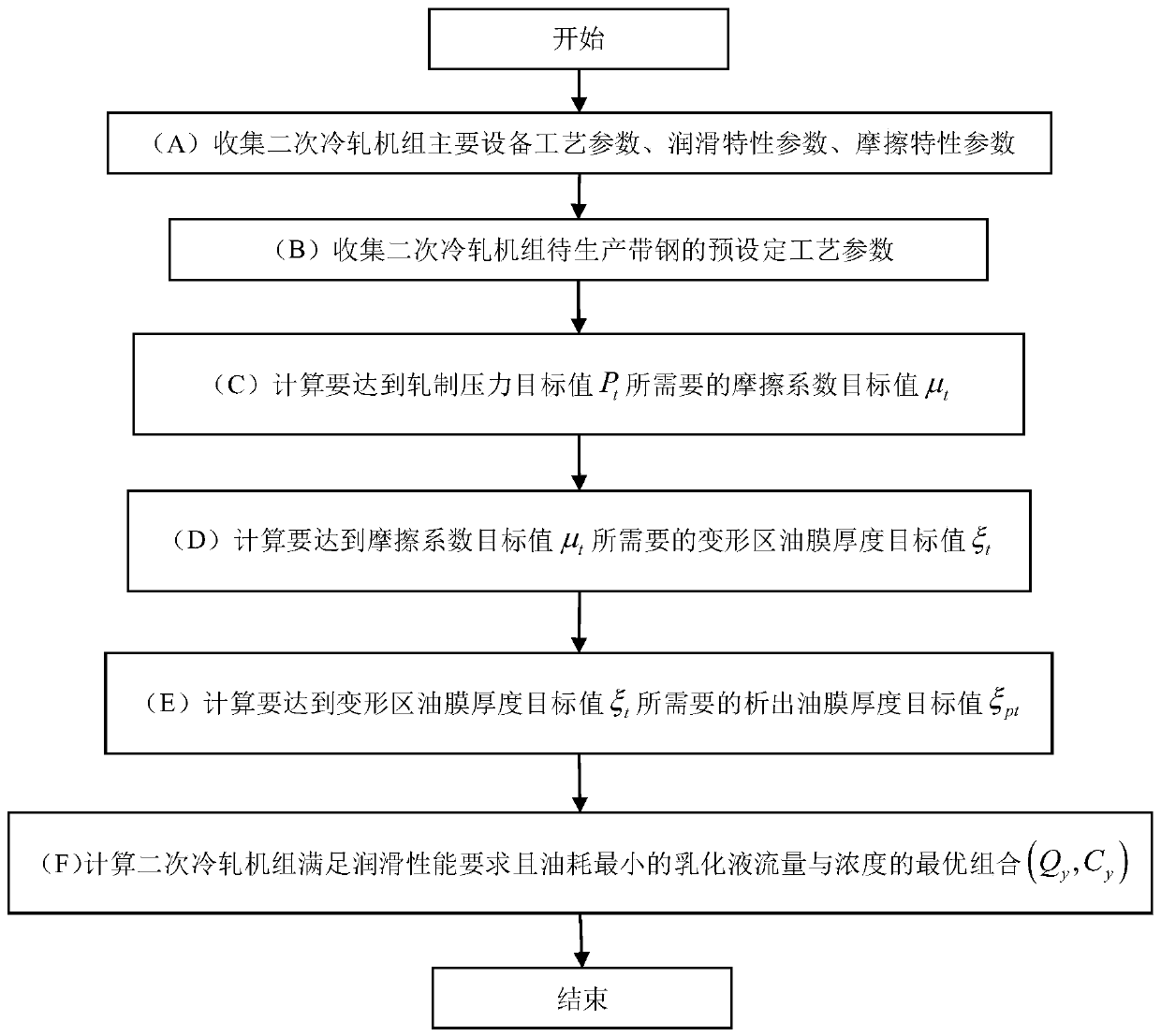

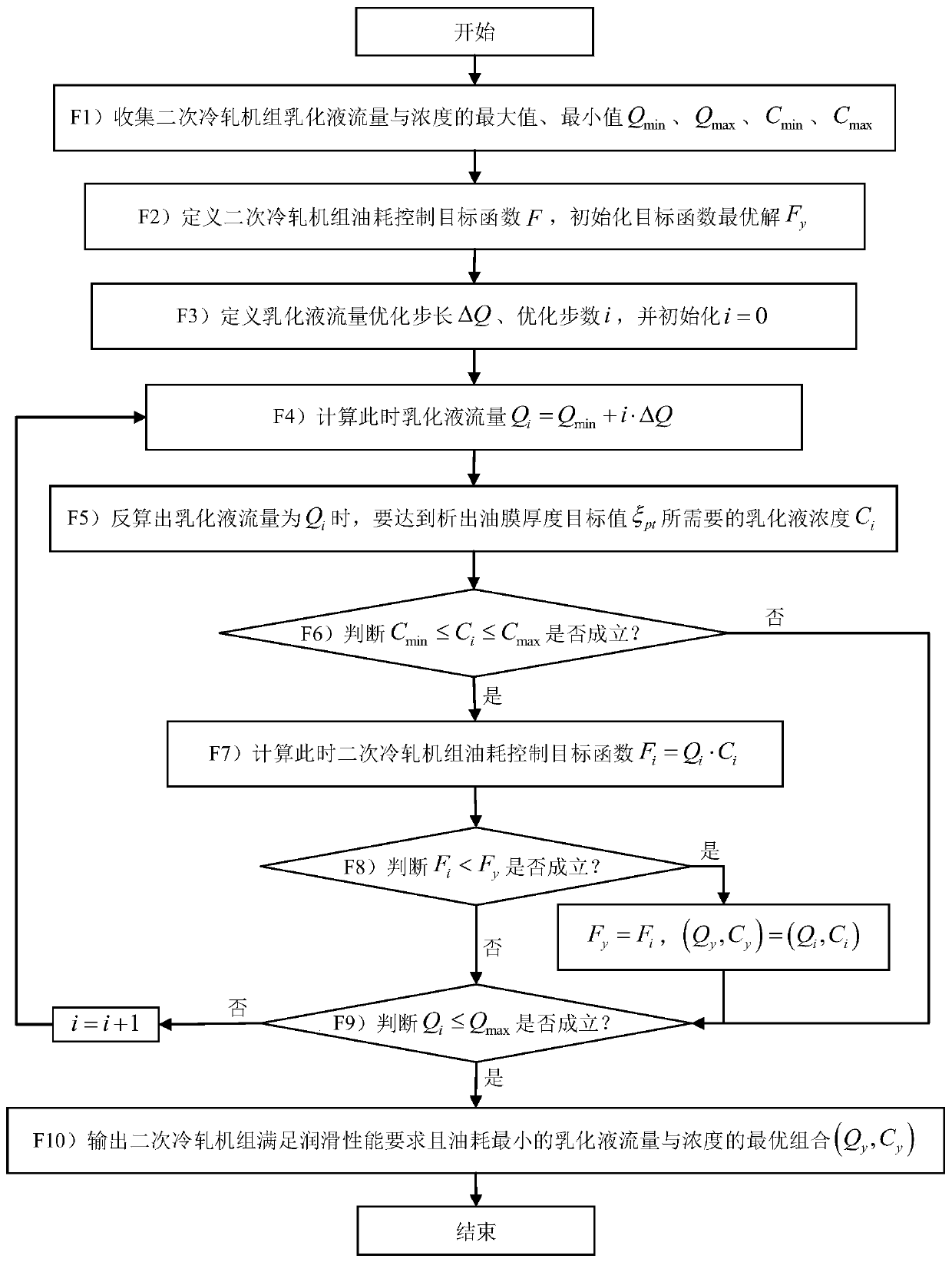

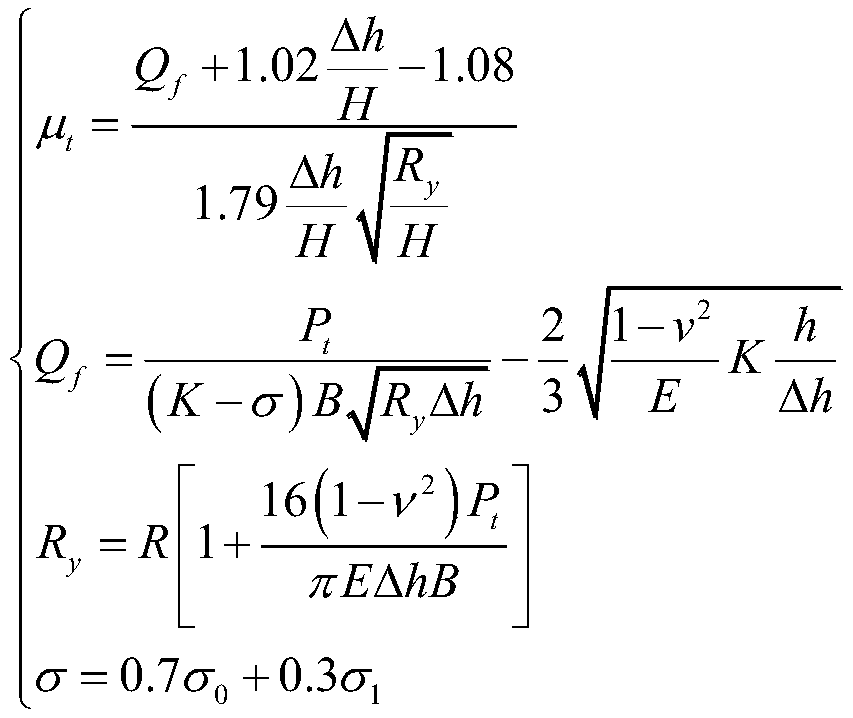

Emulsified liquid process optimization method taking oil consumption control as target by secondary cold rolling unit

InactiveCN107520253AReduce on-site production costsMinimum consumptionMass flow control deviceMetal rolling arrangementsProcess optimizationFrictional coefficient

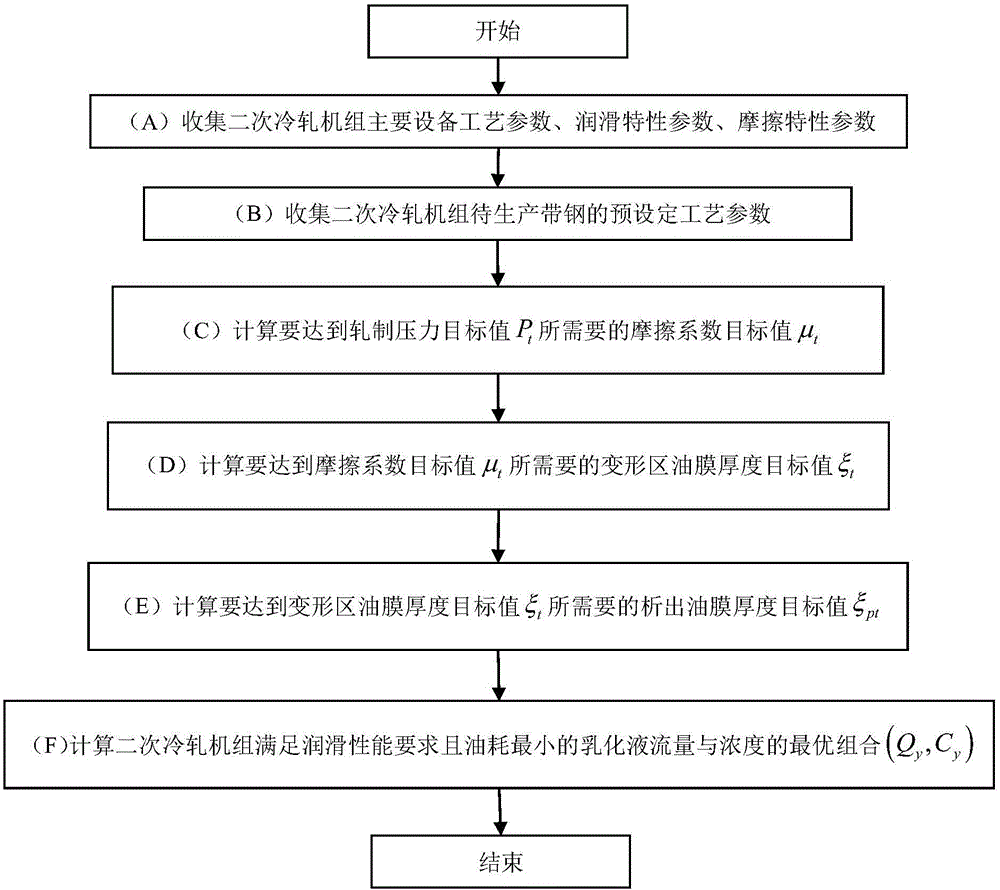

The invention relates to an emulsified liquid process optimization method taking oil consumption control as a target by a secondary cold rolling unit. The method comprises the following steps executed by a computer; (A) collecting a primary equipment process parameter, a lubricating characteristic parameter and a frictional characteristic parameter of the secondary cold rolling unit; (B) collecting a preset process parameter of to-be-produced strip steel of the secondary cold rolling unit; (C) calculating a frictional coefficient target value [mu]t needed to reach a rolling pressure target value Pt; (D) calculating a deformation region oil film thickness target value xit needed to reach the frictional coefficient target value [mu]t; (E) calculating a separated out oil film thickness target value xipt needed to reach the deformation region oil film thickness target value xit; and (F) calculating the optimum combination (Qy and Cy) of flow and concentration f an emulsified liquid, wherein the secondary cold rolling unit meets the demand on the lubricating performance and the oil consumption is the minimum. By comprehensively optimizing concentration and flow of the emulsified liquid, the minimum consumption of rolling oil is achieved, and the field production cost of the secondary cold rolling unit and the sewage treatment cost of the emulsified liquid are lowered.

Owner:唐山格诺金属科技有限公司

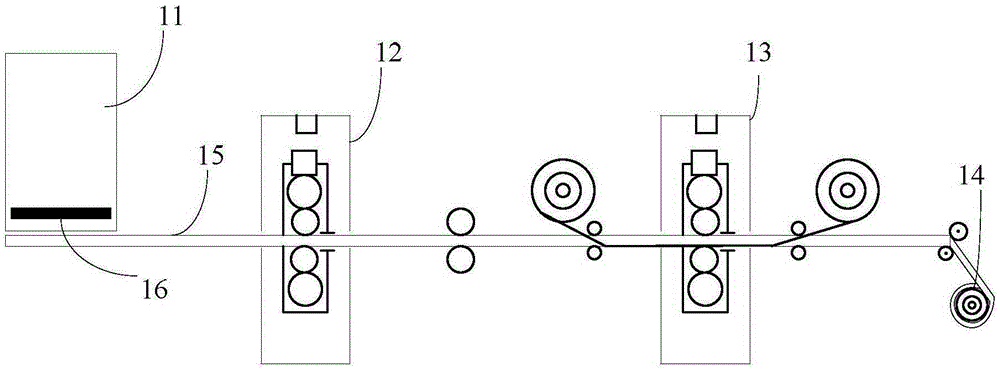

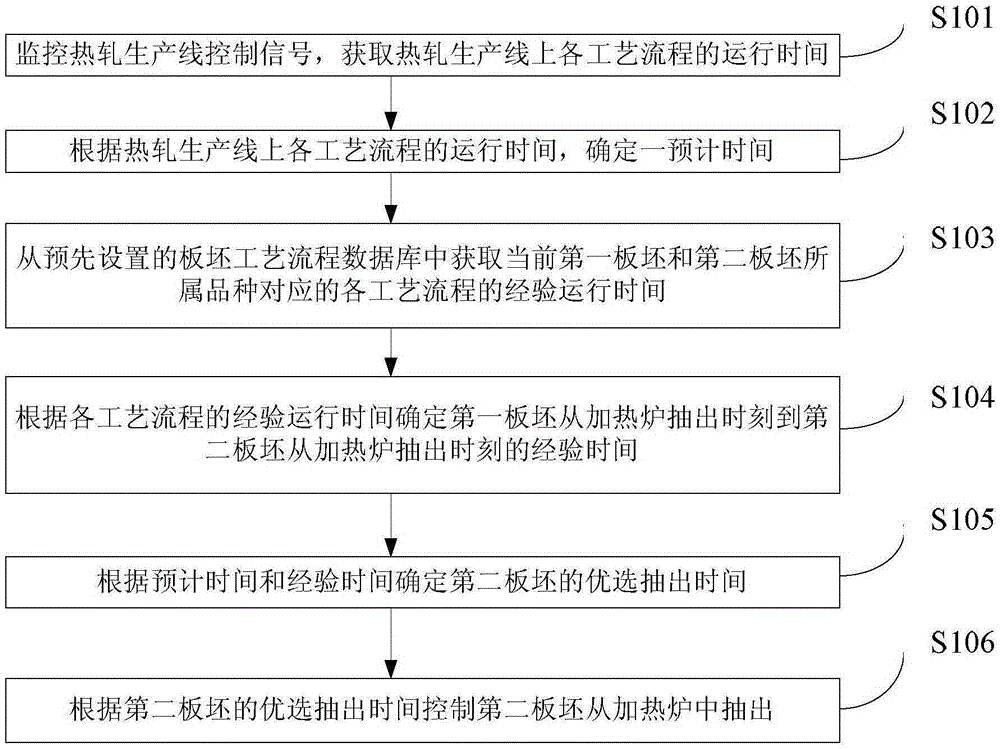

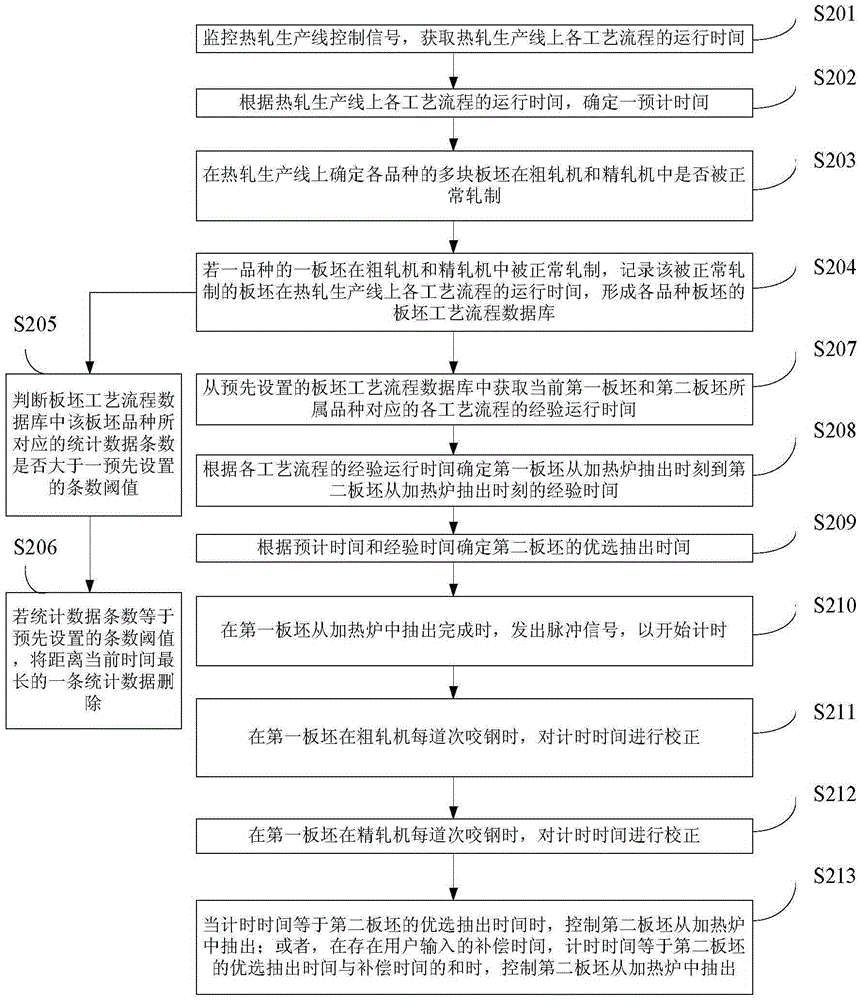

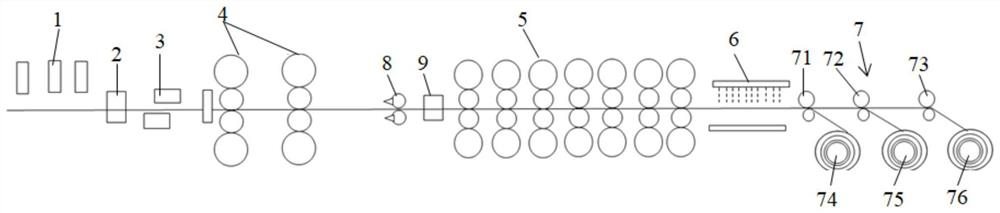

Steel drawing control method and device for hot rolling production line

ActiveCN105396878AAvoid lossSteel pumping rhythm is stableMass flow control deviceMetal rolling arrangementsProduction lineControl signal

The invention provides a steel drawing control method and device for a hot rolling production line, and relates to the technical field of steel hot rolling. The method includes the steps that control signals of the hot rolling production line are monitored, operation time of technological processes on the hot rolling production line is obtained, and scheduled time from the moment when a first plate blank is drawn out of a heating furnace to the moment when a second plate blank is drawn out of the heating furnace is determined; experience operation time of the technological processes corresponding to varieties of the first plate blank and the second plate blank is obtained from a plate blank technological process database; experience time from the moment when the first plate blank is drawn out of the heating furnace to the moment when the second plate blank is drawn out of the heating furnace is determined; preferred drawing time of the second plate blank is determined according to the scheduled time and the experience time; and the second plate blank is drawn out of the heating furnace according to the preferred drawing time of the second plate blank. Through the steel drawing control method and device, the problems that since the steel drawing rhythm of the hot rolling production line is controlled through manual judgment at present, the idle running time of equipment is prone to being long, product quality is affected, and loss of the equipment and loss of power are caused are solved.

Owner:ZHANGJIAGANG POHANG STAINLESS STEEL

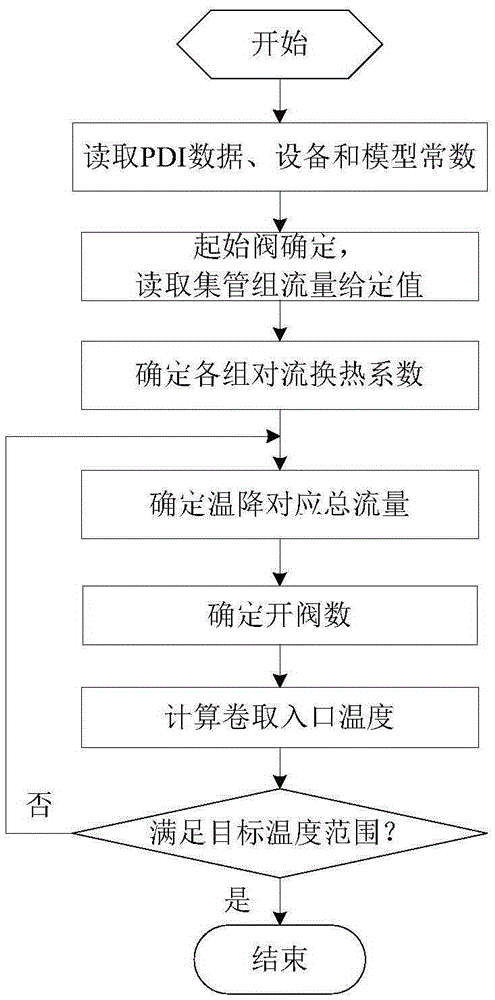

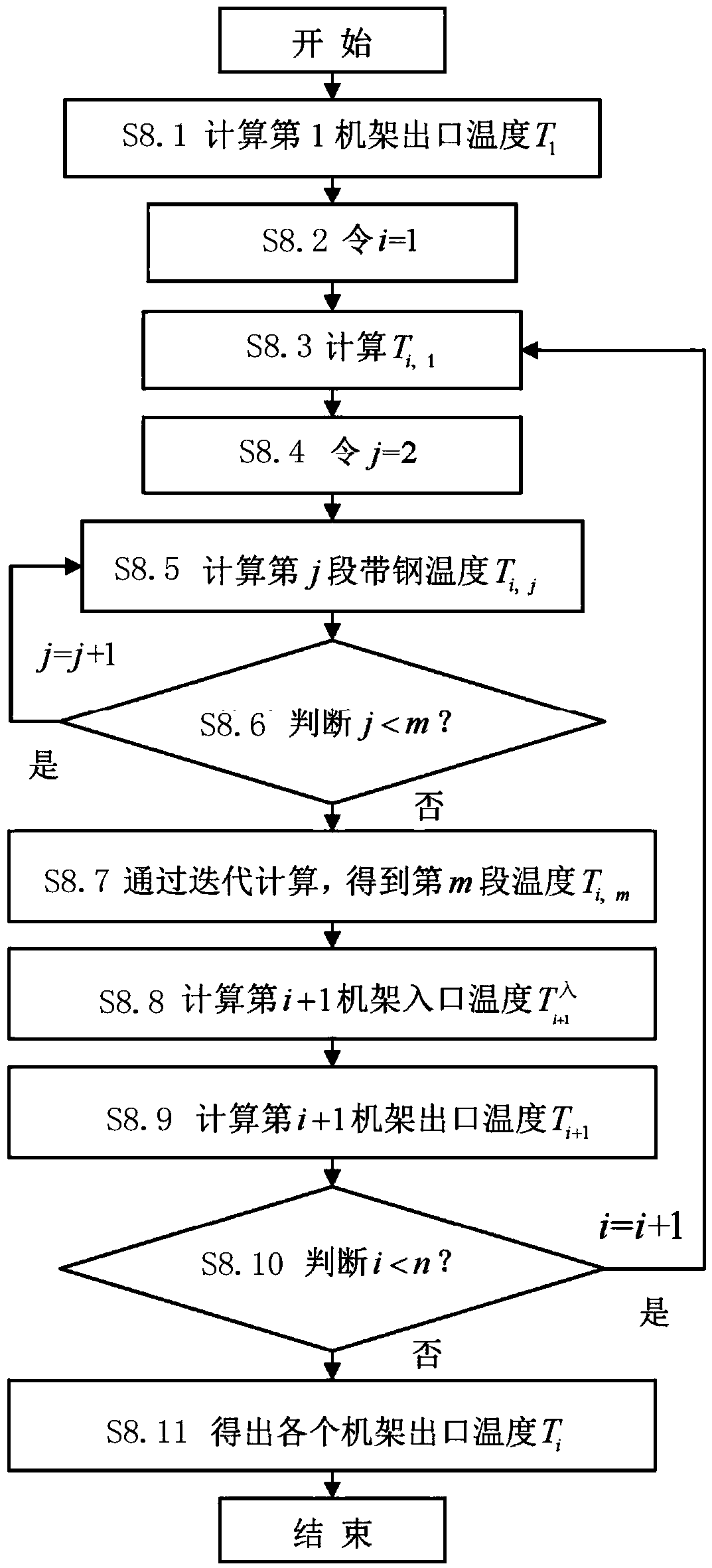

Flow control method for rolling temperature of hot rolled steel strip

ActiveCN105327949AImprove coiling temperature hit rateSmall temperature fluctuationsTemperature control deviceWork cooling devicesAutomatic controlModel parameters

The invention provides a flow control method for the rolling temperature of a hot rolled steel strip and belongs to the technical field of rolled steel automatic control. The method comprises: reading plate blank PDI data, equipment parameters and rolling temperature model parameters, and extracting the actual measurement values of pyrometers when the steel strip reaches a finish rolling inlet and a finish rolling outlet; determining the given configuration and flow of the material specification of beginning valve and headers; according to the given flow and the rolling temperature model of each group of headers, determining the convective heat transfer coefficient of each group of headers; according to the rolling temperature model, calculating total flow required by cooling from the finish rolling outlet to a rolling inlet; determining total valve opening number required by cooling, and sending the set configuration to a level I basic automation executor; and carrying out feedback calculation according to the actual rolling temperature, regulating the opening and closing state of headers in a fine tuning zone, and ensuring a target rolling temperature. The method can stably control the rolling temperature index, ensure that the first block of an another specification of strip steel and a thick specification of strip steel can stably pass, improve the rolling temperature hit rate and improve the quality performance of a product.

Owner:BEIJING ARITIME INTELLIGENT CONTROL

Method for automatically improving per-second flow balance of strip steel in hot continuous rolling strip threading process

ActiveCN104801548AIntelligent adjustment of speed ratioAdapt to changes in external working conditionsFlexible work arrangmentsMass flow control deviceLoop lengthEngineering

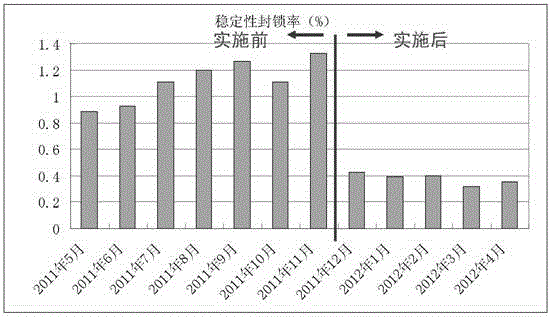

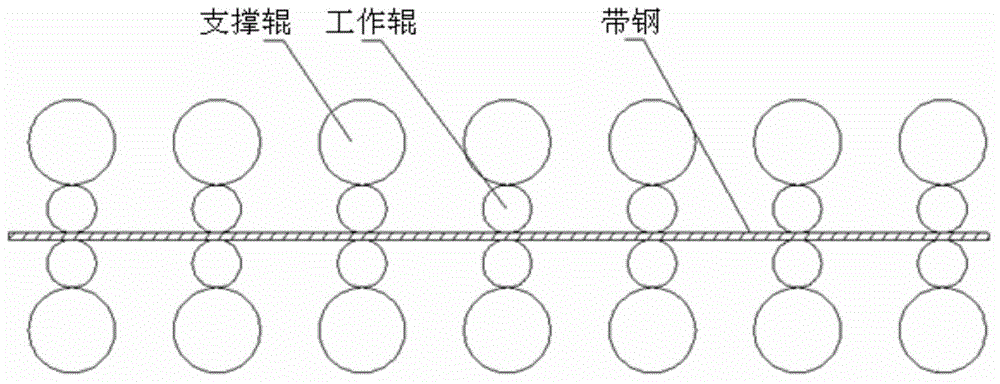

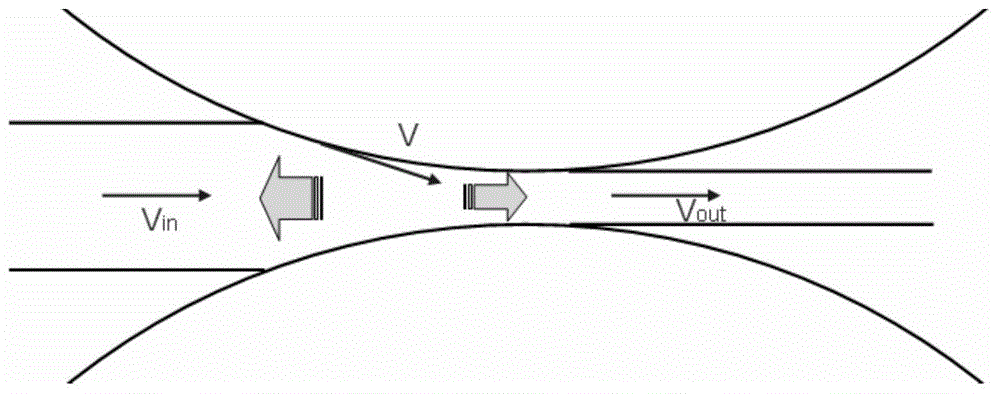

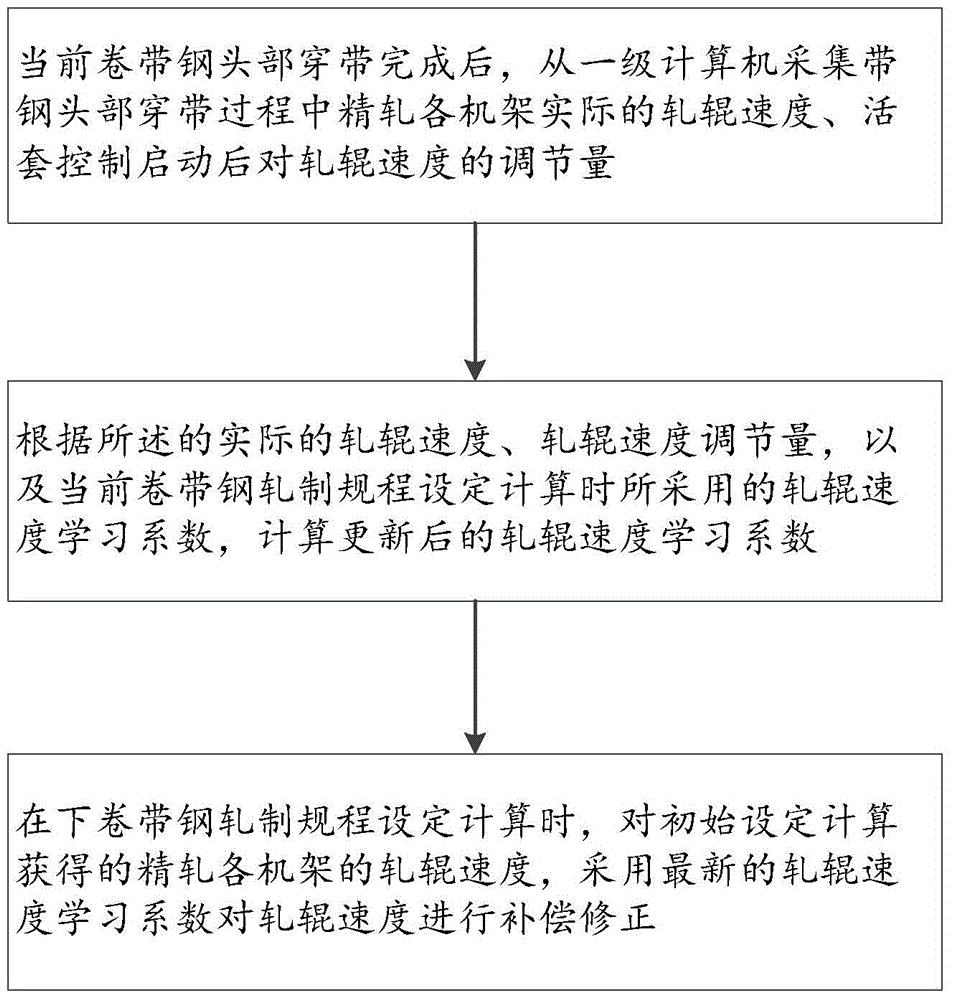

The invention provides a method for automatically improving per-second flow balance of strip steel in the hot continuous rolling strip threading process. Due to the fact that 'later' intervention of an operator is basically correct, the per-second flow balance can be changed more reasonable, an ideal rack speed matching value of a piece of steel is calculated by analysis the loop length and manual invention amount of the operator in the strip threading process and used for correcting setting of a next piece of same-specification steel. Compared with routine techniques, the method is characterized in that 'later intervention' is converted into accurate 'advanced correction', accordingly a complicated and tedious forward slip formula is omitted, and racks can have an 'intelligent learning' function on the speed aspect. According to the method, the complicated and tedious forward slip formula is omitted, and a method for automatically adjusting per-second flow matching between racks is found. The method is used for improving the per-second flow balance in the hot continuous rolling strip threading process and improving rolling stability so as to decrease strip steel head rolling breakage times and width decrease times. In addition, automation degree of strip threading is improved, and the working load of the operator is decreased.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for realizing flow per second balance among hot rolling continuous mill stands through rolling mill speed compensation

ActiveCN104874613AReduce the sizeCan't afford to reduceMass flow control deviceMetal rolling arrangementsAdaptive learningLoop control

The invention discloses a method for realizing flow per second balance among hot rolling continuous mill stands through rolling mill speed compensation, relates to the field of hot-rolling production process control, and aims to solve the problem of flow per second imbalance in the head wearing process of a hot rolling strip steel. The practical roll speed for finish rolling of each frame and the roll speed regulating quantity required by loop control is acquired from a level 1 computer according to the regulating process of the roll speed for finish rolling of each frame required by loop control in a threading process, specification-classifying self-adaptive learning is performed on the change rate of the roll speed required by the loop control according to steel type*thickness*frame, and the roll speed is corrected by adopting a latest learning coefficient during setting calculation of a next roll of strip steel in order that the flow per second among the finish-rolled frames tends to be balanced. By adopting the method, the phenomena of large loop rise or no loop rise, finish rolling steel scrap, width reduction and the like can be reduced, and the rolling stability of a finish rolling process is improved remarkably.

Owner:科大集智数据科技(武汉)有限公司

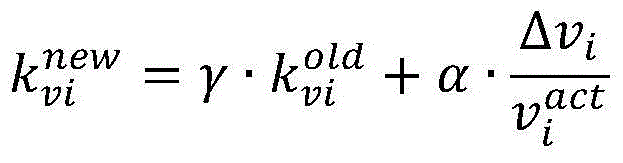

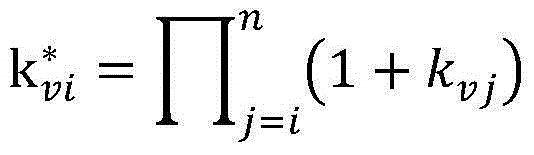

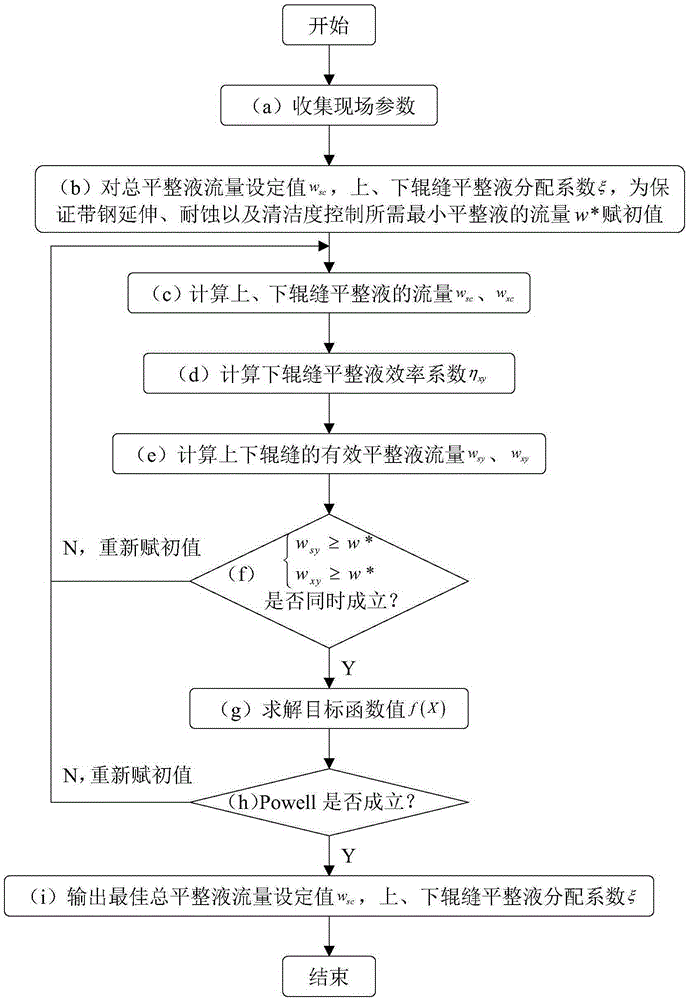

Difference optimization setting method for leveling liquid flow in wet leveling rolling process

InactiveCN105234185AReduce consumptionReduce processing costsMass flow control deviceMetal rolling arrangementsEngineeringStrip steel

The invention discloses a difference optimization setting method for leveling liquid flow in the wet leveling rolling process. The difference optimization setting method mainly comprises the following steps that firstly, field parameters are collected; secondly, the total leveling liquid flow set value, the upper roll gap leveling liquid distributing coefficient and the lower roll gap leveling liquid distributing coefficient are initialized; thirdly, the flow of the upper roll gap leveling liquid and the flow of the lower roll gap leveling liquid are calculated; fourthly, the low roll gap leveling liquid efficiency coefficient is calculated; fifthly, the effective leveling liquid flow of an upper roll gap and a lower roll gap is calculated; and sixthly, the optimal total leveling liquid flow set value, the optimal upper roll gap leveling liquid distribution coefficient and the optimal lower roll gap leveling liquid distribution coefficient are output. According to the difference optimization setting method, the differences of extension, roughness, corrosion resistance and cleanliness of the upper surface and the lower surface of strip steel are reduced, meanwhile, waste of the upper roll gap leveling liquid is reduced, and the total consumption of the leveling liquid and the waste liquid treatment cost are reduced to the maximum degree.

Owner:唐山扬邦钢铁技术研究院有限公司

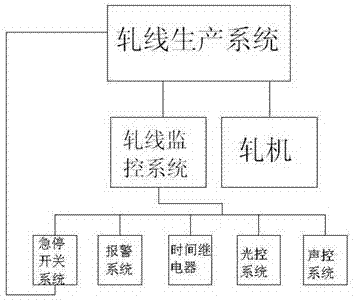

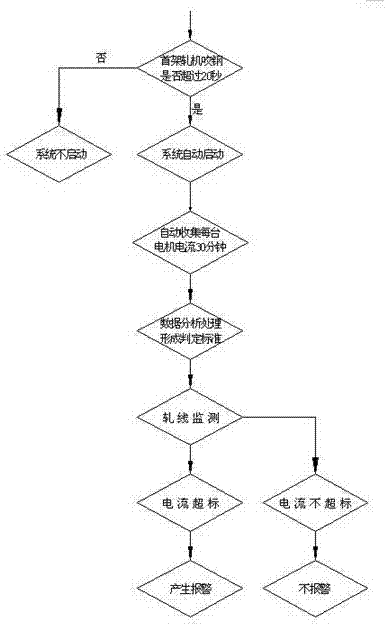

Current tracking method for rolling line production abnormity

InactiveCN107377636AAccurate monitoringStop in timeMeasuring devicesMass flow control deviceStable statePower flow

The invention discloses a current tracking method for rolling line production abnormity. The current tracking method mainly comprises the steps that at the time when the production state is just established, a rolling line monitoring system automatically collects and analyzes current values of motors of all rolling mills, a control interval target value of the current is automatically set according to the maximum limit value and the minimum limit value of the current values and serves as the judgment standard, the current under the subsequent stable-state production condition is checked, if the value of the current of a certain motor frequently exceeds the interval target value, then it means the corresponding rolling mill on a rolling line has production abnormity, an alarm system is started at the same time to remind site operation personnel to deal with the production abnormity in time, and otherwise, production is normal.

Owner:张家港联峰钢铁研究所有限公司

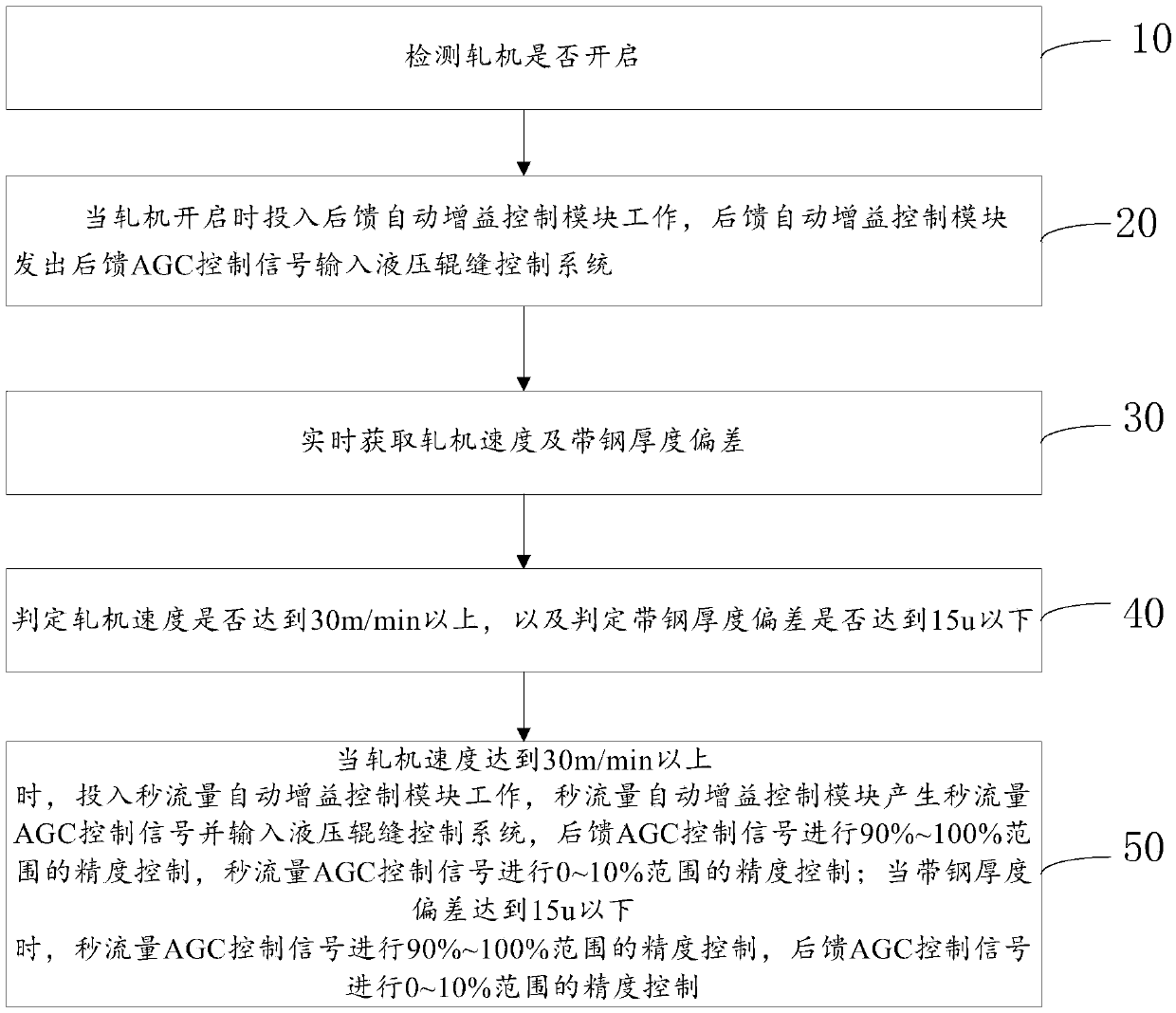

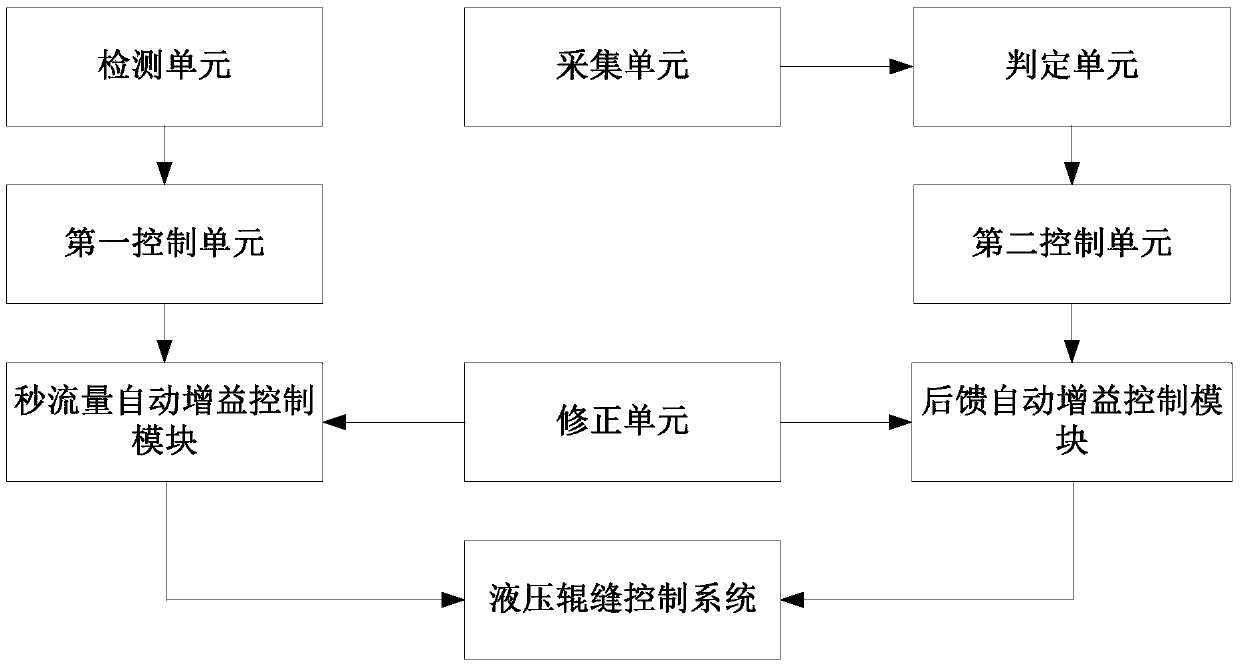

Automatic gain control method and device for mass flow of rolling mill

ActiveCN105499277AMeet control requirementsImprove pass rateMass flow control deviceMetal rolling arrangementsControl systemComputer module

The invention relates to the technical field of steel rolling, in particular to an automatic gain control method and device for mass flow of a rolling mill. The method comprises the following steps: detecting whether the rolling mill is started or not; enabling a feedback automatic gain control module to work when the rolling mill is started; acquiring the speed of the rolling mill and strip steel thickness deviation in real time; and judging whether the speed of the rolling mill is above 30 m / min or not and judging whether the strip steel thickness deviation is below 15 mu or not. A mass flow automatic gain control module and the feedback automatic gain control module are controlled flexibly. The device comprises a detecting unit, a first control unit, an acquiring unit, a judging unit, a second control unit and a correcting unit. By the automatic gain control method and device for the mass flow of the rolling mill, the control precision of a hydraulic roll gap control system is improved, standard deviation of thicknesses of finished rolled silicon steels is controlled within 0.4 mu m, thickness deviation is controlled within 5 mu m, and yield is above 98%.

Owner:武汉钢铁有限公司

Hot-rolled H-shaped steel and production method thereof

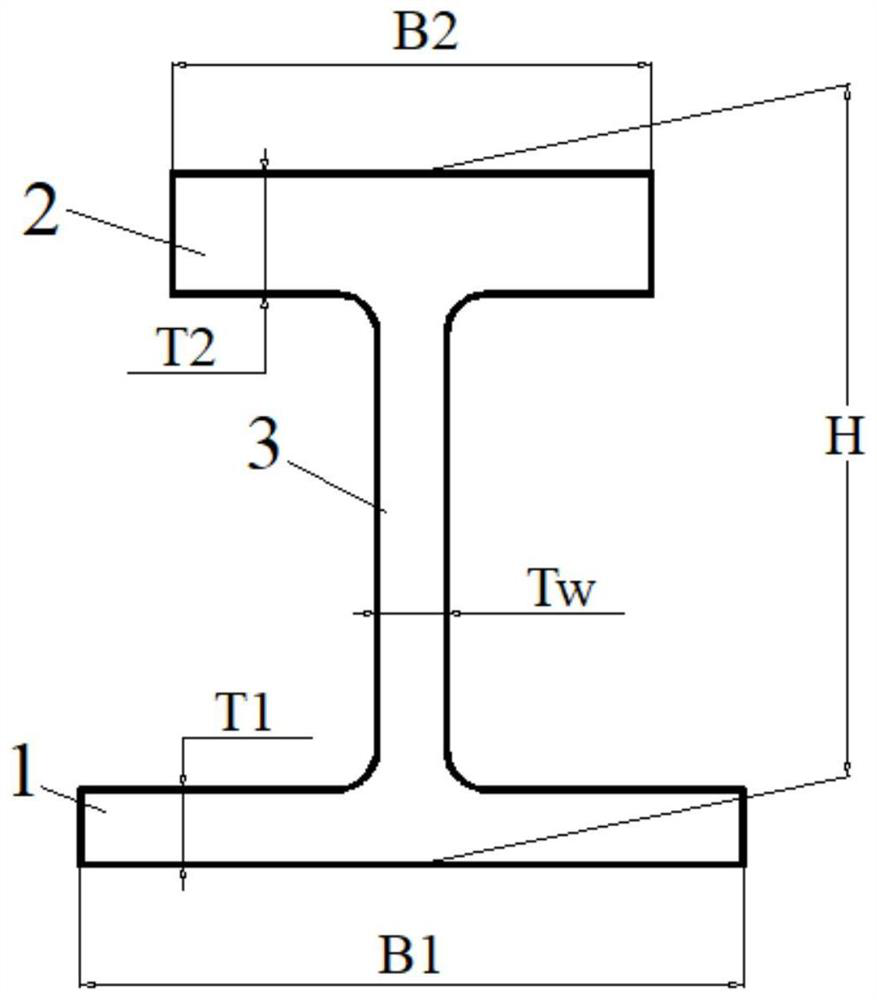

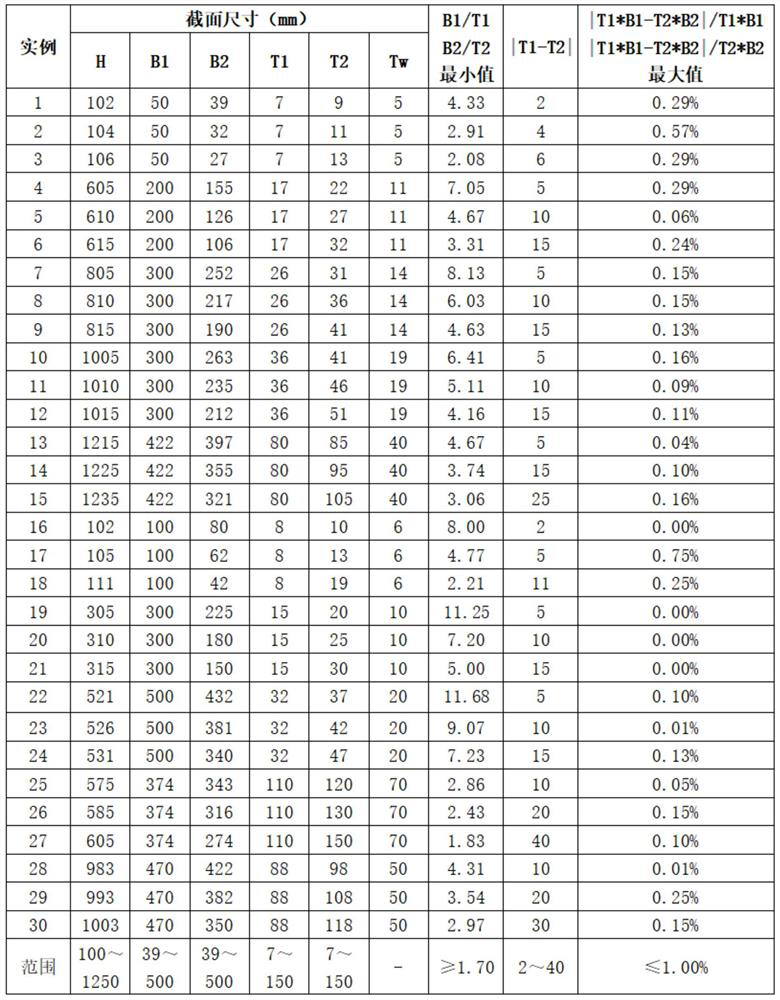

ActiveCN113399453AMeet production requirementsStable Production RequirementsElongated constructional elementsMass flow control deviceMetallurgyEngineering

The invention discloses hot-rolled H-shaped steel, which comprises a web plate, a first flange plate and a second flange plate; the difference value T1-T2 between the thickness value of the first flange plate and the thickness value of the second flange plate is larger than 0; the ratio of the area difference S1-S2 of the first flange plate and the second flange plate to the area S1 of the first flange plate is not larger than 1, or the ratio of the area difference S1-S2 of the first flange plate and the second flange plate to the area S2 of the second flange plate is not larger than 1. According to the hot-rolled H-shaped steel provided by the invention, the production requirement that the flanges on the two sides of various specifications are different in thickness can be met, meanwhile, lateral bending in the rolling process can be avoided, the metal second flow difference of the flanges on the two sides in the rolling process is controlled within a certain range, and therefore the hot-rolled H-shaped steel with the flanges on the two sides being different in thickness is stably produced. The invention further discloses a production method of the hot-rolled H-shaped steel.

Owner:MAANSHAN IRON & STEEL CO LTD

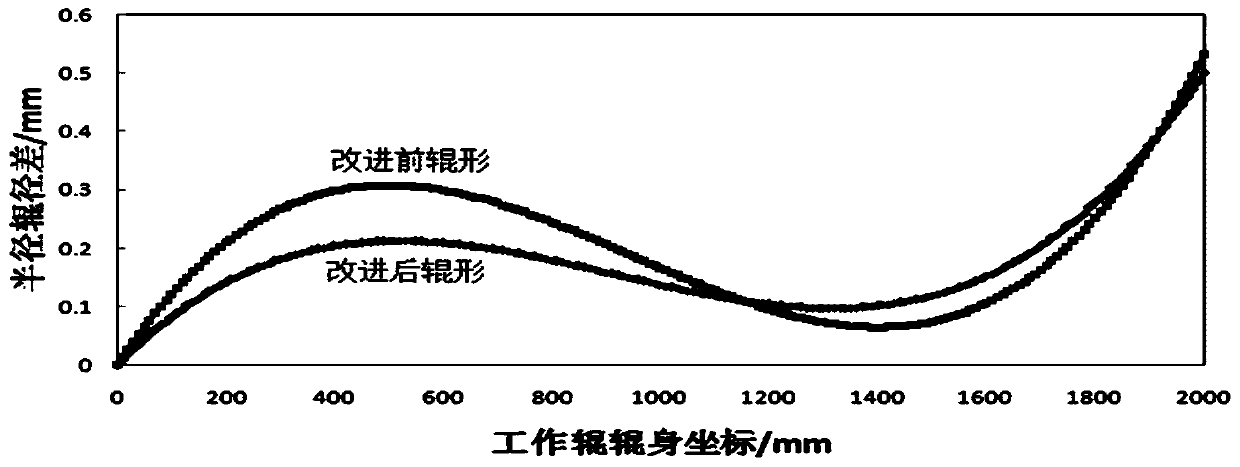

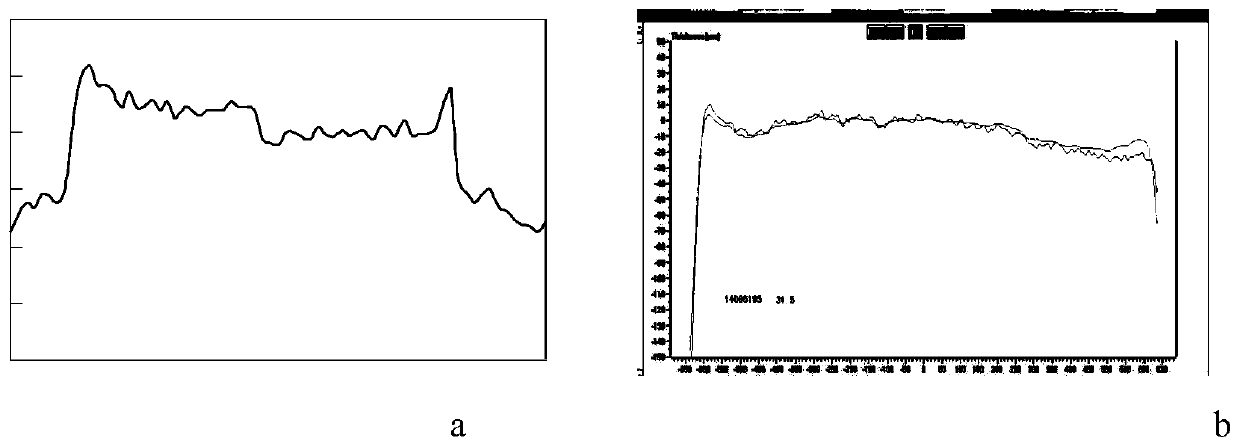

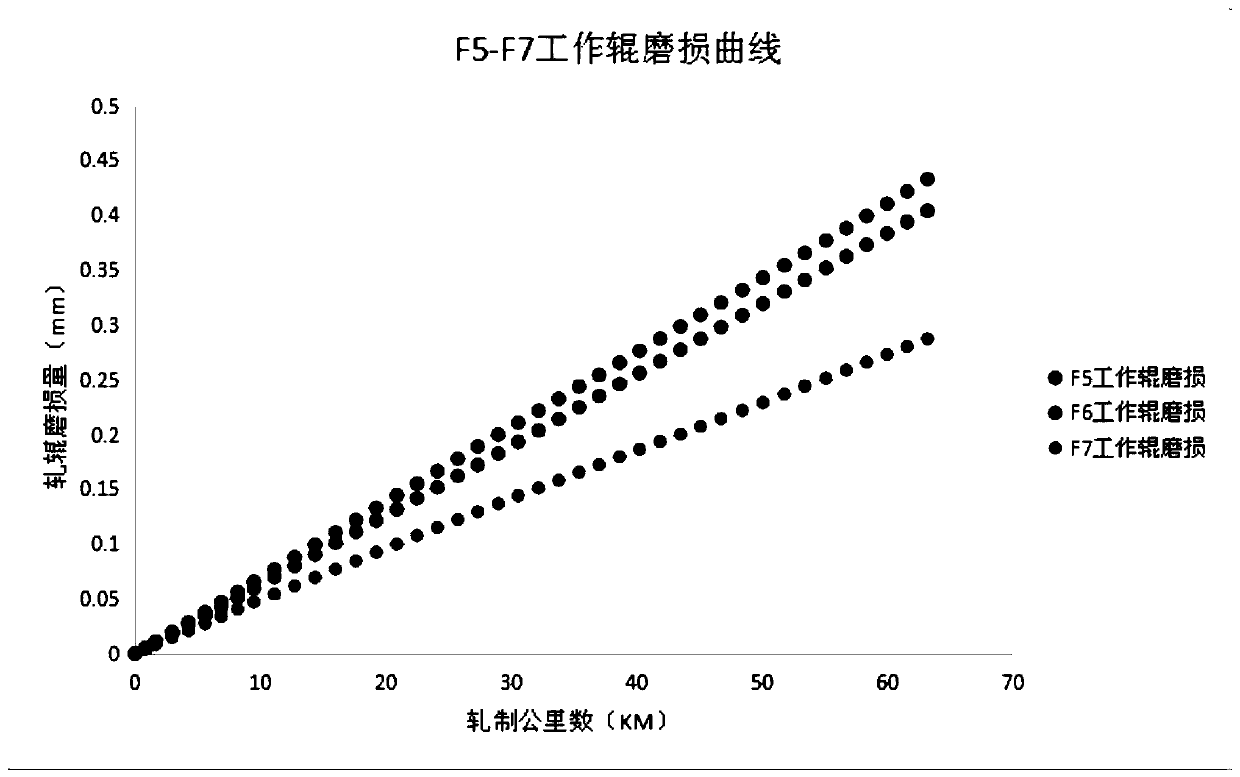

Control method for reducing transverse thickness difference of hot-rolled strip steel

ActiveCN111389925AImprove the transverse thickness plate shape indexReduce roll consumptionRoll force/gap control deviceRollsStructural engineeringStrip steel

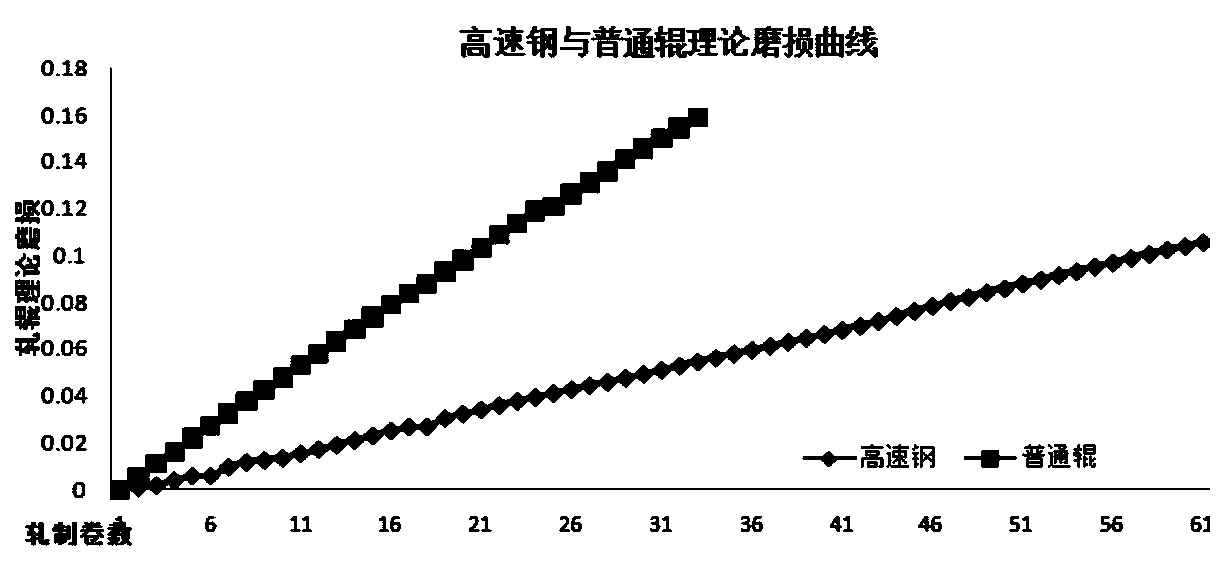

The invention discloses a control method for reducing the transverse thickness difference of hot-rolled strip steel. Rolling control process parameters are designed by control over the thickness of acontinuous casting machine plate blank, configuring of finish rolling high-speed steel, roller cooling, the working roller channeling stroke, the vertical roller side pressure and the oil mass of rolling oil, so that the purpose of reducing the transverse thickness difference of the hot-rolled strip steel is achieved. Transverse thickness plate shape indexes of hot-rolled silicon steel raw materials can be remarkably increased, the silicon steel sheet 7u intra-plate difference precision is improved from 90% to 93%, and the 5u intra-plate difference precision is improved from 40% to 80%. On thepremise of guaranteeing the plate shape indexes, the rolling period is prolonged from 800 tons to 1,800 tons, and the roller consumption during silicon steel rolling is remarkably reduced.

Owner:武汉钢铁有限公司

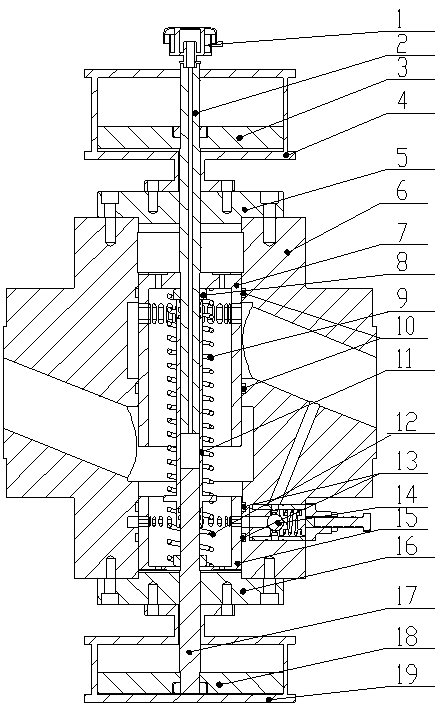

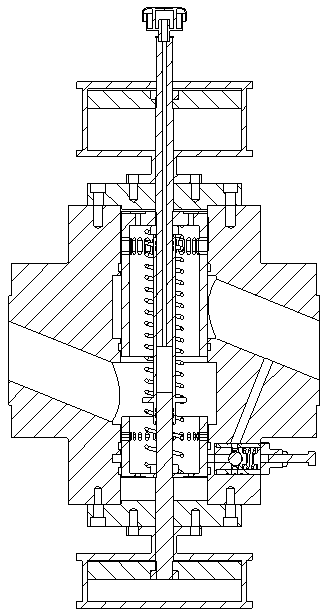

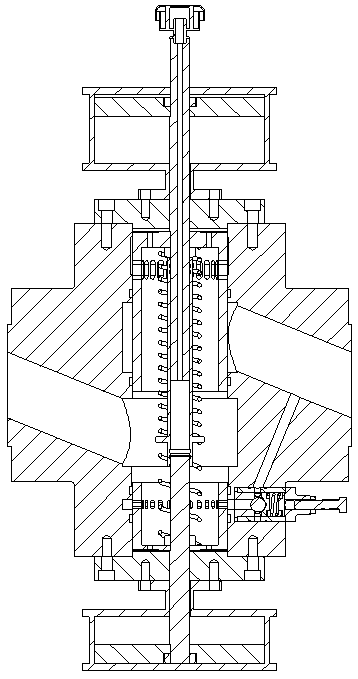

High-pressure descaling injection valve

ActiveCN109282051AExtended service lifeAvoid misuseOperating means/releasing devices for valvesWork treatment devicesAir filterEngineering

The invention relates to a high-pressure descaling injection valve. The injection valve comprises an upper air cylinder assembly, a lower air cylinder assembly, an upper plunger assembly, a lower plunger assembly, an air filter, a valve body and a shaft sleeve, the upper plunger assembly and the lower plunger assembly are arranged on the upper side and the lower side of the valve body correspondingly, the upper air cylinder assembly and the lower air cylinder assembly are symmetrically arranged at the upper end and the lower end of the valve body, and the air filter is arranged above the upperair cylinder assembly. According to the technical scheme, the equipment cost is greatly reduced, original pre-flushing units which are in parallel connection with a main pipeline are all omitted, andmeanwhile, the stability of a descaling system is also greatly improved; and the technical scheme skillfully utilizes a key part, namely the injection valve, of the descaling system to output and control pre-flushing water, and then a pre-flushing effect is achieved.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Grease lubrication system and method of roller for magnesium alloy rolling

PendingCN108160713AEvenly distributedImprove surface qualityRollsMass flow control deviceDistributorLubrication

The invention provides a grease lubrication system and method of a roller for magnesium alloy rolling. The grease lubrication system the roller for the magnesium alloy rolling comprises a grease sprayer, the grease sprayer comprises a first grease box, a second grease box, sprinklers and a gas storage tank; the first grease box is connected with a plurality of sprinklers through a first oil distributor; the second grease box is connected with a plurality of sprinklers through a second oil distributor; the first grease box is connected with the second grease box; the first grease box and the second grease box are separately connected with a control cubicle; the gas storage tank is connected with a plurality of sprinklers; and each sprinkler is connected with the gas storage tank and the first oil distributor, or each sprinkler is connected with the gas storage tank and the second oil distributor. The grease lubrication system and method of the roller for the magnesium alloy rolling creatively uses grease lubrication to lubricate magnesium alloy rolling and overcomes the problems when using lubricating oil and has the advantages that uniform in distribution, stable in performance, low in usage amount, slow in influence on the roller temperature, and convenient to lubricate the lower surface of an magnesium plate without worrying about recycling at the same time.

Owner:SHANGHAI LIZHENG SATELLITE APPL TECH CO LTD

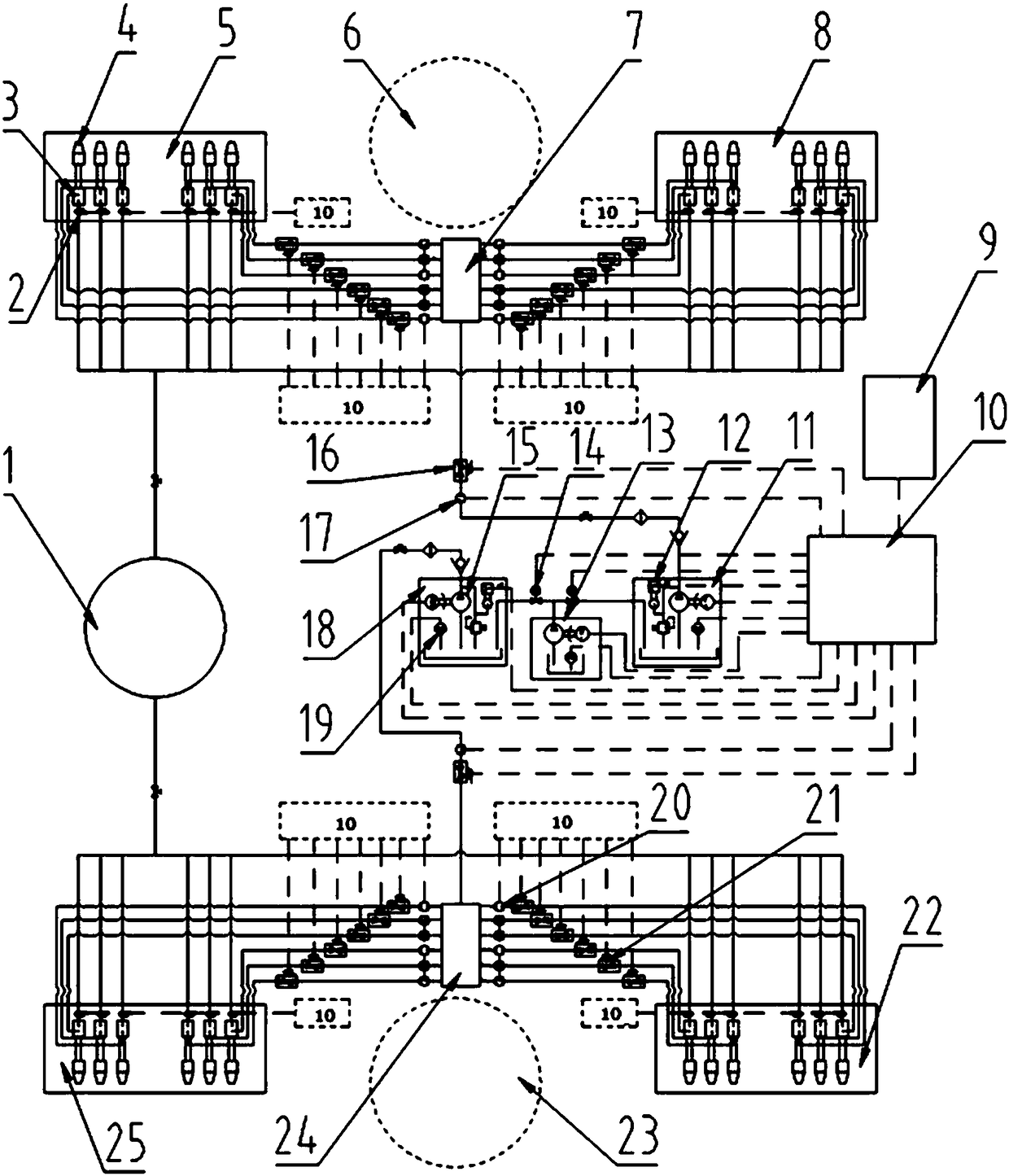

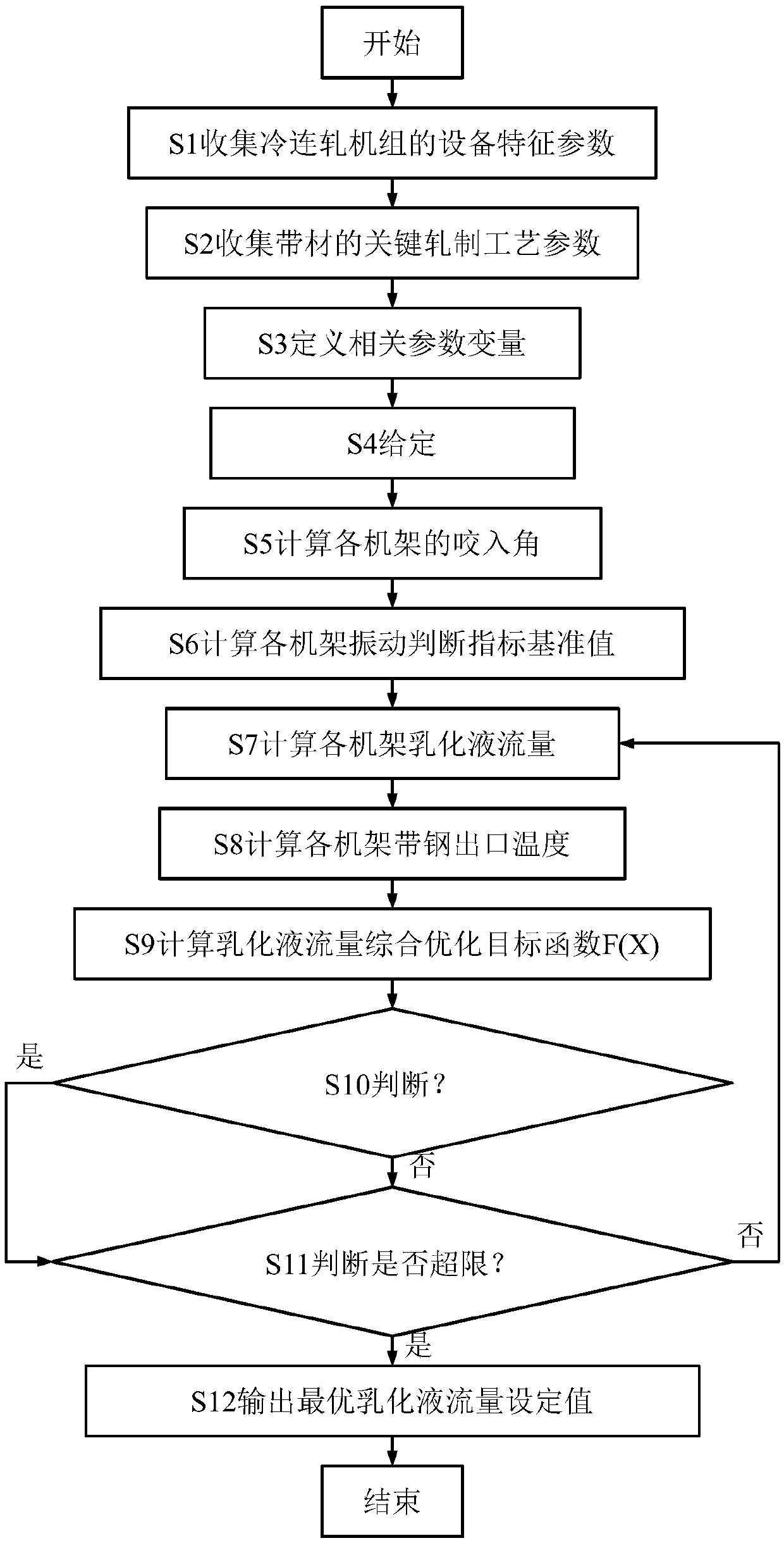

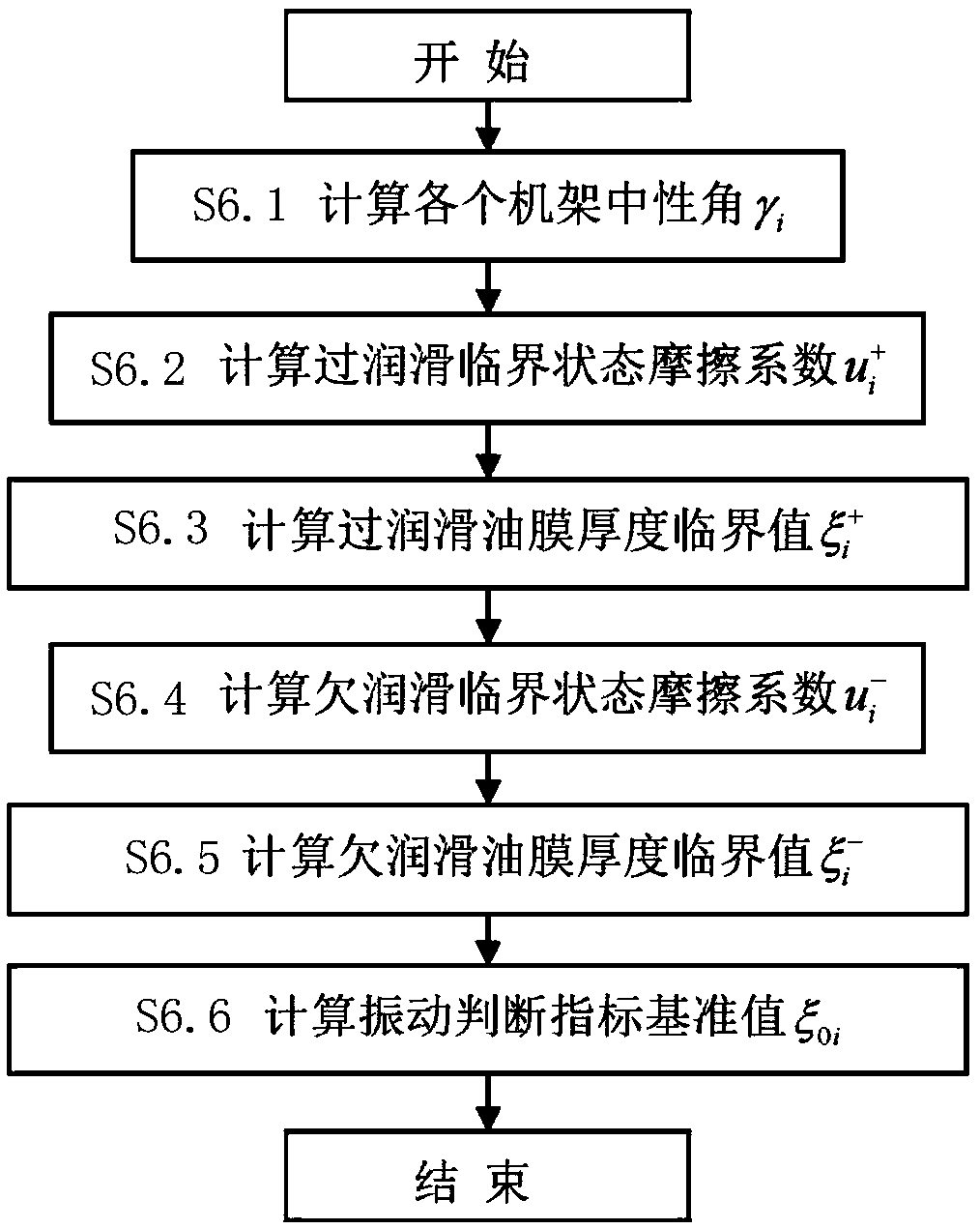

Emulsion flow optimization method for inhibiting vibration of cold continuous rolling unit

ActiveCN110842031AReduce incidenceAchieve governanceDesign optimisation/simulationVibration control deviceThermodynamicsEmulsion

The invention discloses an emulsion flow optimization method for inhibiting the vibration of a cold continuous rolling unit, relates to the technical field of cold continuous rolling, and particularlyrelates to the emulsion flow optimization method suitable for the cold continuous rolling unit and taking vibration inhibition as a target. The method is characterized in that the vibration inhibition is taken as a target, on the basis that the over-lubricating oil film thickness critical value and the under-lubricating oil film thickness critical value are provided, and through an oil film thickness model and a friction coefficient model, the emulsion flow optimal set values, taking the vibration inhibition as the target, of racks are obtained. According to the method, the occurrence rate ofvibration defects of a rolling mill is greatly reduced, the production efficiency and the product quality are improved, and great economic benefits are brought to enterprises; and the vibration defects of the rolling mill are overcome, and the surface quality and the rolling process stability of finished strip steel of the cold continuous rolling unit are improved.

Owner:BAOSHAN IRON & STEEL CO LTD

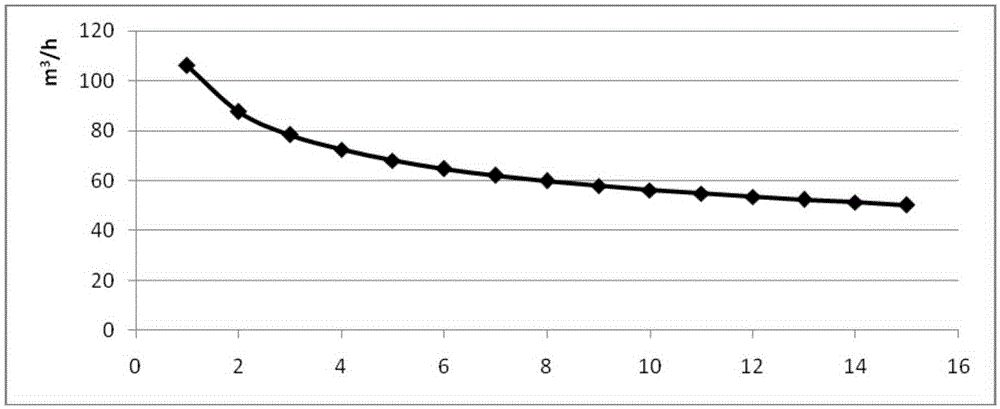

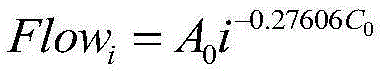

Control method for laminar flow two-section type cooling of thick hot-rolled strip steel

ActiveCN112872059AComparable performanceIncrease cooling rateTemperature control deviceWork cooling devicesLaminar coolingEngineering

The invention discloses a control method for laminar flow two-section type cooling of thick hot-rolled strip steel. The control method mainly solves the technical problems that in the two-section type cooling process of hot-rolled strip steel with the thickness of 6.0-13.0 mm, the control precision of the middle temperature and the air cooling time is low, and the cooling efficiency of a second section is low. According to the control method for laminar flow two-section type cooling of the thick hot-rolled strip steel, cooling equipment on a rolling line is located on the rear side of a finishing mill and the front side of a coiling machine, the cooling equipment comprises 15 sets of headers including first cooling sections, a middle pyrometer, second cooling sections and fine adjustment cooling sections, and the control method comprises the steps that laminar flow two-section type cooling parameter instructions are received; the strip steel threading speed is calculated; a boiled water array of laminar flow two-section type cooling water is pre-calculated; the position of an initial valve of a first-section header of laminar flow two-section type cooling is determined; the laminar flow two-section type cooling water is opened; the cooling water of the first laminar flow cooling sections is dynamically adjusted; the middle air cooling time of laminar cooling is regulated and controlled; and the coiling temperature is regulated and controlled. According to the method, the production cost is reduced.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

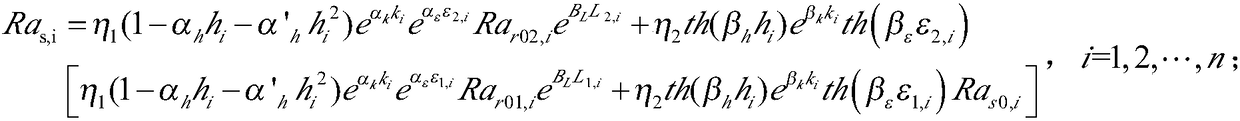

Method for controlling tempering lubricant flow in wet temper rolling process of cold-rolled steel sheet

ActiveCN108213088AGuaranteed surface quality stabilityMass flow control deviceProfile control deviceSheet steelSurface roughness

The invention discloses a method for controlling the tempering lubricant flow in a wet temper rolling process of a cold-rolled steel sheet. The method is mainly used for solving the technical problemthat in the prior art, a method for accurately controlling the surface roughness of a cold-rolled steel sheet through control over the tempering lubricant flow of a wet temper mill is unavailable. Themethod for controlling the tempering lubricant flow in the wet temper rolling process of the cold-rolled steel sheet comprises the steps that parameters are collected; the initial value of an objective function is set; the lubricant quantity WL, j of temper rolling deformation areas of a rack 1# and a rack 2# are calculated; the friction coefficient mui, j, corresponding to the parameters of thei strip steel in the current state, of the temper rolling deformation areas of the rack 1# and the rack 2# are calculated; the ductility epsilon1, i of the i strip steel on the rack 1# and theductility epsilon2, i of the i strip steel on the rack 2# in the current state are inversely calculated; and the total mill ductility epsiloni of the i strip steel in the current state is calculated. By adoption of the method for controlling the tempering lubricant flow in the wet temper rolling process of the cold-rolled steel sheet, accurate control over the surface toughness of the cold-rolled steel sheet is achieved, and the stability of the surface quality of the cold-rolled steel sheet is ensured.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

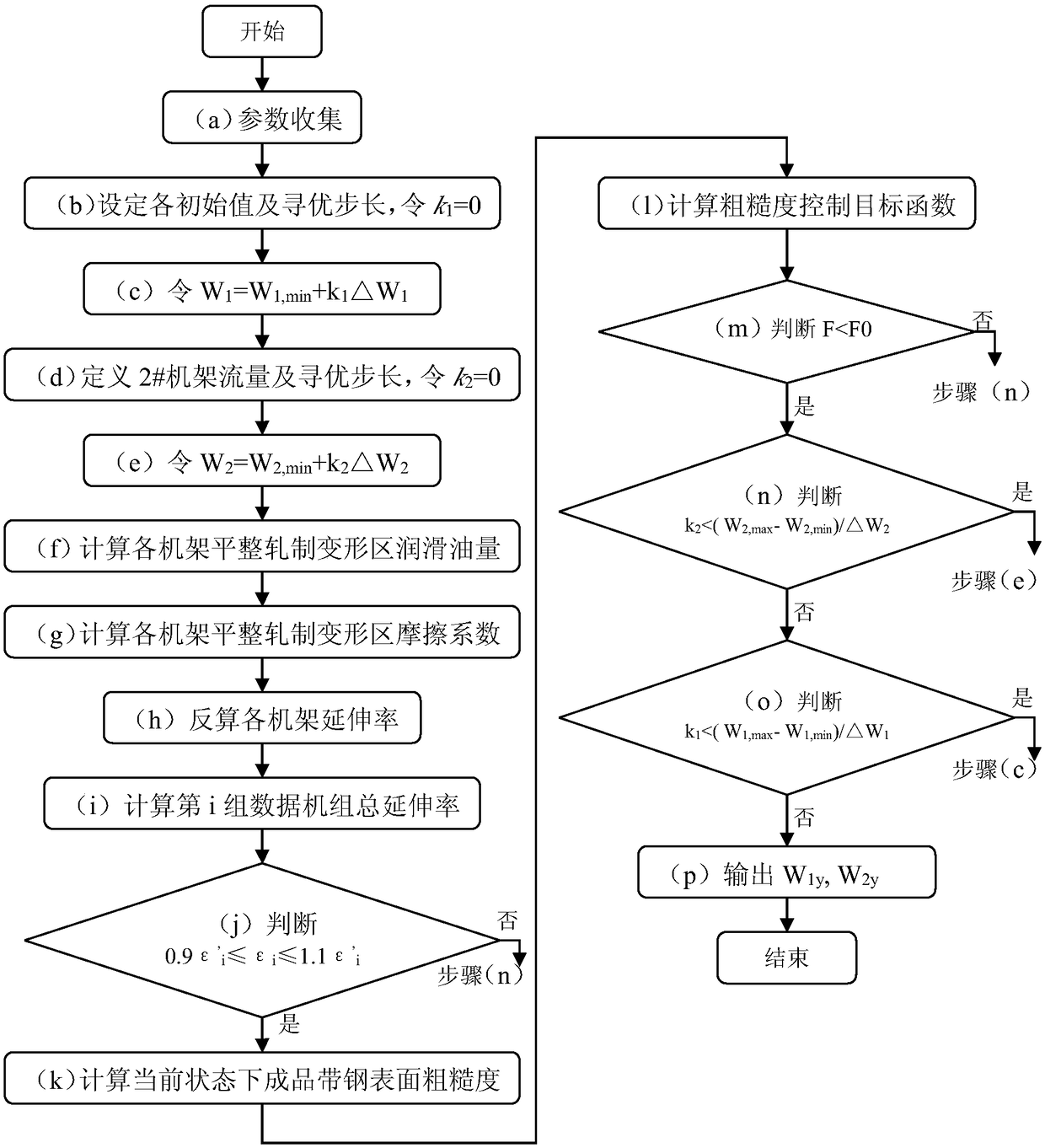

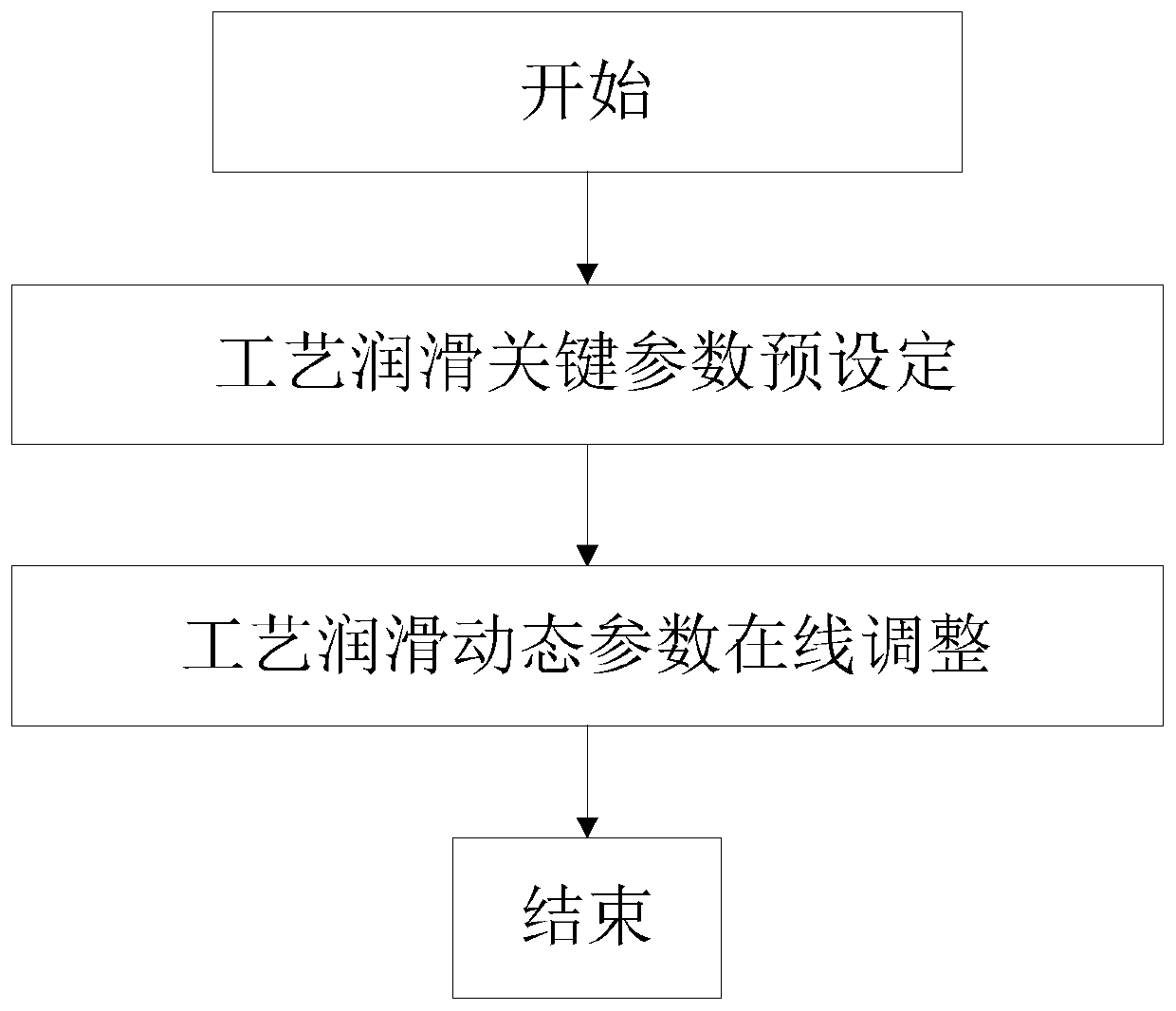

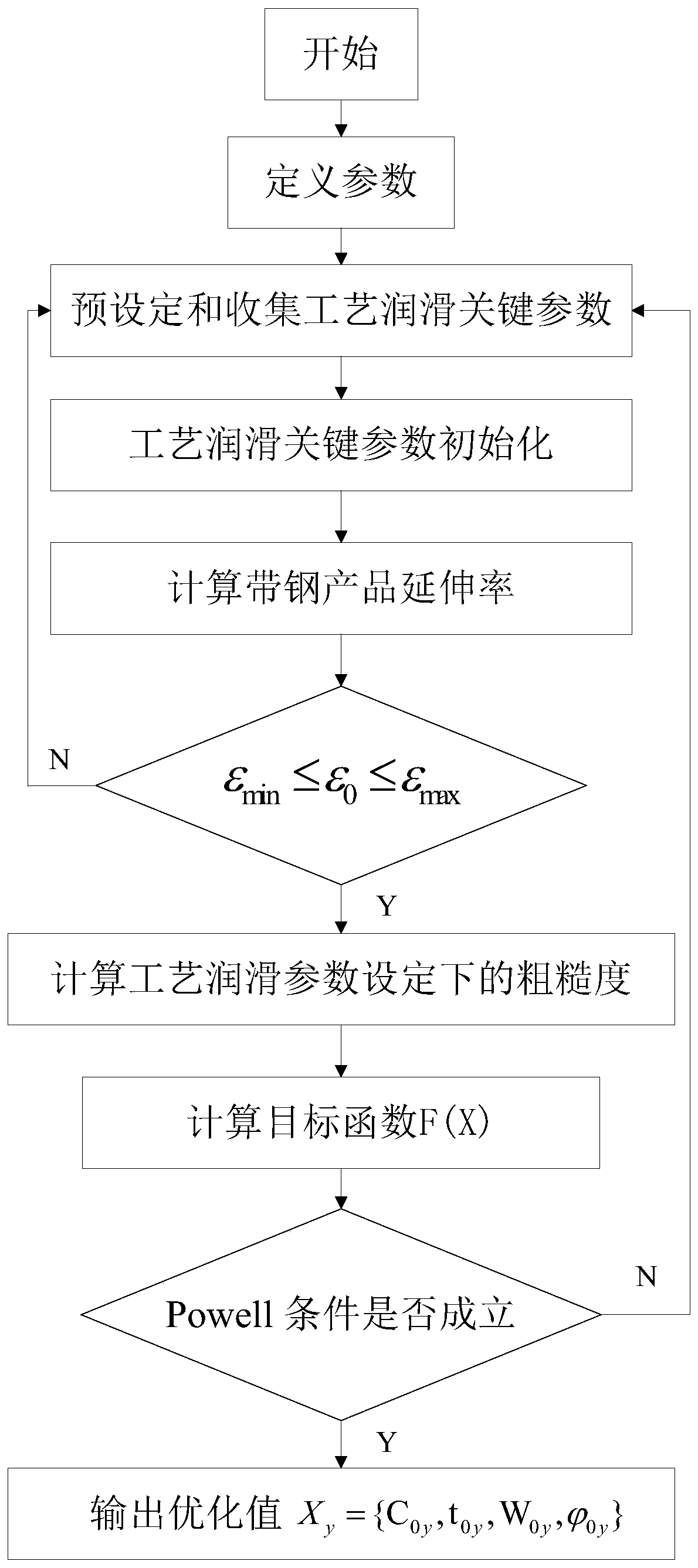

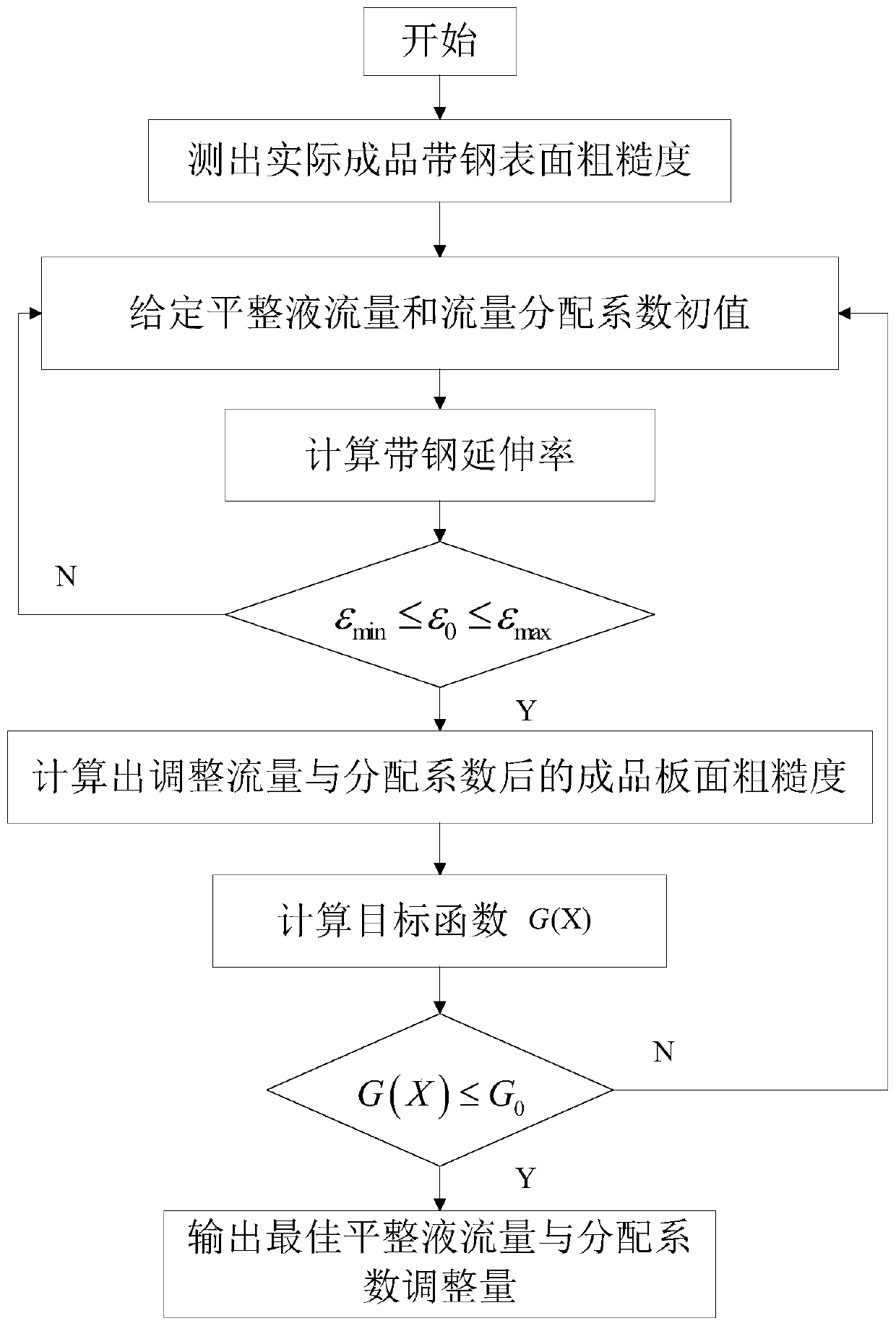

Process lubricating system control method for wet leveling unit aiming at coarseness

ActiveCN110624957AGood control effectMass flow control deviceMetal rolling arrangementsValue setSurface roughness

The invention relates to a process lubricating system control method for a wet leveling unit aiming at coarseness. The process lubricating system control method comprises the following steps executedby a computer: (a) pre-setting of process lubricating key parameters: including pre-setting and collecting process lubricating parameters, initializing the process lubricating parameters, giving target coarseness, calculating ductility of strip steel, calculating a coarseness calculated value set under the process lubricating parameter, and calculating a target function; and (b) online adjustmentof the process lubricating dynamic parameter: including measuring surface coarseness of the strip steel, giving a flow initial value of a leveling fluid, calculating ductility of the strip steel, calculating coarseness of a product panel after flow adjustment and coefficient distribution, calculating a target function, and outputting the most level fluid flow and the coefficient distribution adjustment amount. The process lubricating system control method achieves quantitative analysis an d control of the surface coarseness of the product strip steel in a double rack wet leveling rolling process, and reduces an overproof closing ratio of the surface coarseness of the product strip steel from 3% to within 0.1%, so that a good economical benefit is brought to the unit.

Owner:JIANGSU JIUTIAN PHOTOELECTRIC TECH CO LTD +1

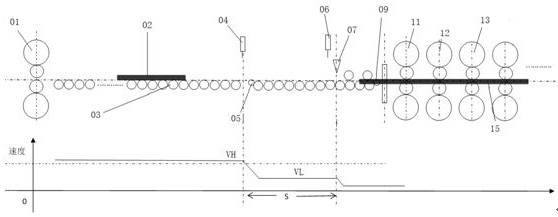

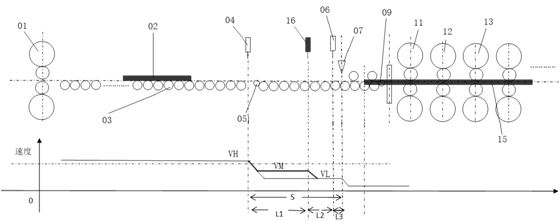

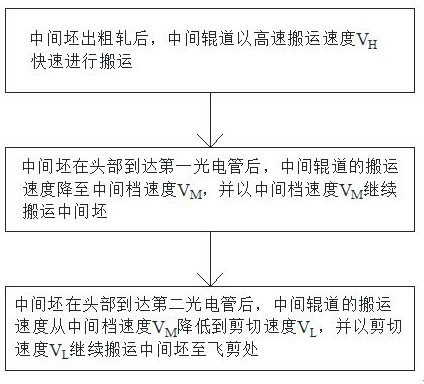

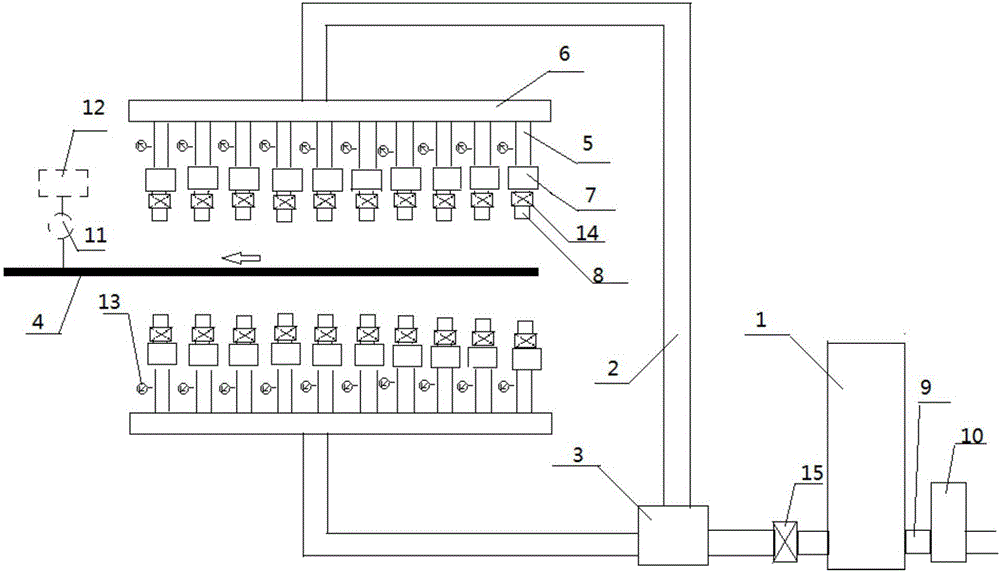

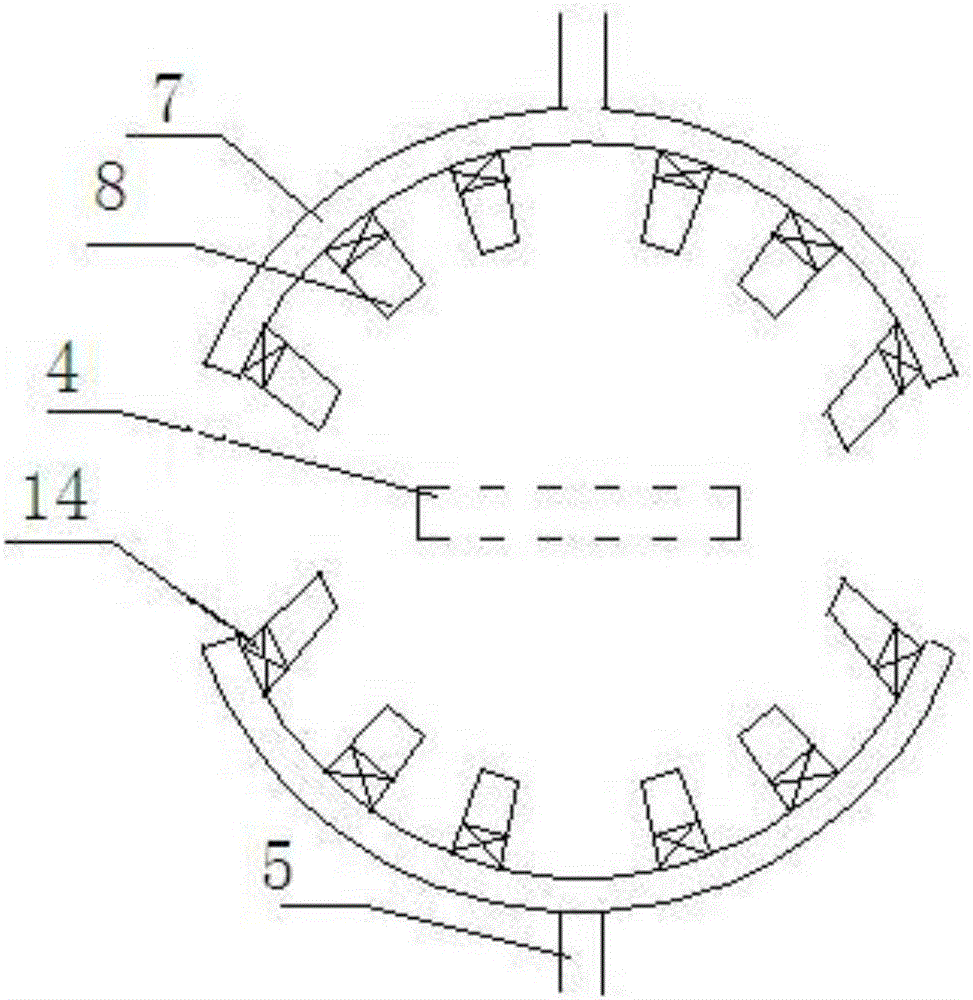

Speed hierarchical control device and method for front roller way of finish rolling flying shear

ActiveCN112139251AFine control of handling speedSave handling timeMass flow control deviceMetal rolling arrangementsGratingEngineering

The invention discloses a speed hierarchical control device and method for a front roller way of a finish rolling flying shear. The device comprises a rough mill (01), an intermediate billet (02), anintermediate roller way (03), a first photoelectric tube (04), a first speed measuring roller (05), an optical grating (06), the flying shear (07), a second speed measuring roller (09), a finish rolling F1 rack (11), a finish rolling F2 rack (12) and a finish rolling F3 rack (13); a second photoelectric detection device is arranged above the intermediate roller way; the second photoelectric detection device is located between the first speed measuring roller and the optical grating; and the speed of the head of the intermediate billet is reduced to the middle gear speed when reaching the firstphotoelectric tube, and the speed of the intermediate billet is reduced to the shearing speed when reaching the second photoelectric detection device, namely a speed level is added between the firstspeed measuring roller and the optical grating. According to the speed hierarchical control device for the front roller way of the finish rolling flying shear provided by the invention, the photoelectric detection device is additionally arranged in the area in front of a finish rolling inlet flying shear, fine hierarchical control is conducted on the roller way speed of the inlet area based on theposition of the tail of front strip steel, the strip steel carrying time of the area in front of the finish rolling flying shear is shortened, and the rolling rhythm is improved.

Owner:BAOSHAN IRON & STEEL CO LTD

Cooling device for rolling mill

InactiveCN106734262AConvenient and controllable cooling processImprove cooling effectWork cooling devicesMass flow control deviceSheet steelCooling effect

The invention discloses a cooling device for a rolling mill. The cooling device comprises a water tank, a water inlet pipe, a driving device, an upper side cooling device and a lower side cooling device; the upper side cooling device is used for cooling the upper surface of a hot-rolled steel plate steel strip in a cooling section; the lower side cooling device is used for cooling the lower surface of the hot-rolled steel plate steel strip in the cooling section; each of the upper side cooling device and the lower side cooling device comprises water inlet branch pipes, a flow dividing device, a plurality of rows of cooling water pipes and nozzles; and the water tank is connected with the water inlet pipe, the water inlet pipe is provided with the driving device, the flow dividing device is arranged between the water inlet pipe and the water inlet branch pipes, the water inlet branch pipes are connected with cooling water pipes, the cooling water pipes are perpendicular to the running direction of the hot-rolled steel plate steel strip, and cooling water pipe bodies are provided with the multiple nozzles. The cooling device guarantees the cooling uniformity of the rolling mill and is good in cooling effect.

Owner:SICHUAN DESHENG GRP VANADIUM & TITANIUM CO LTD

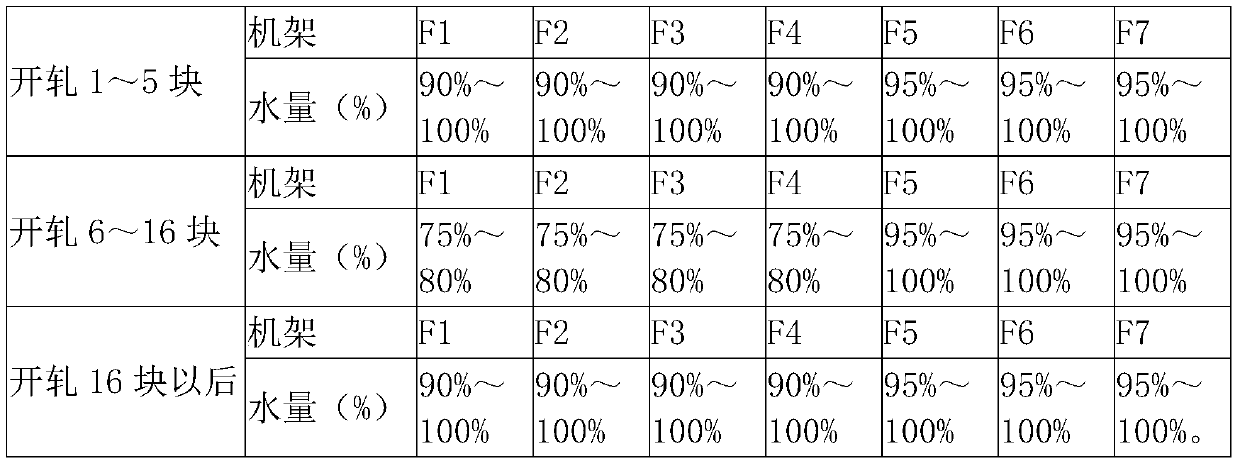

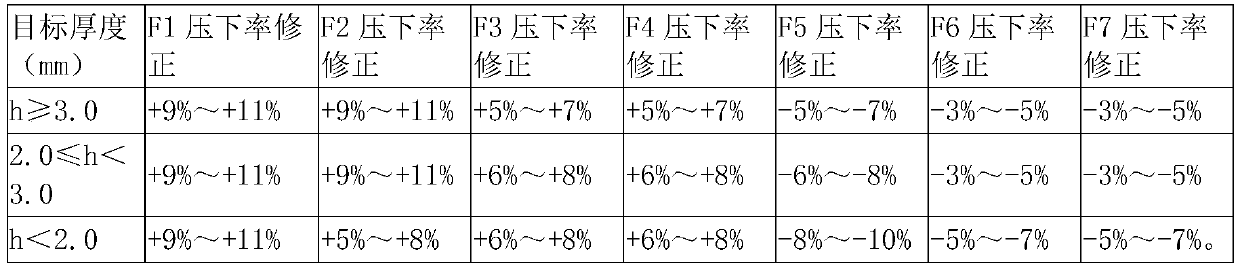

Method for controlling surface pitting defect of medium-carbon low-alloy ultra-thin specification strip steel in short-process rolling

ActiveCN111389912AQuality improvementImprove stabilityRoll force/gap control deviceMass flow control deviceStrip steelAlloy

The invention discloses a method for controlling the surface pitting defect of medium-carbon low-alloy ultra-thin strip steel in short-process rolling. The method comprises the following steps of controlling the cooling water amount of a working roll of a rolling mill, controlling the rolling rhythm, controlling the reduction rate of a rack, controlling roll gap lubrication and controlling the usemode of speed-up rolling. Compared with the prior art, the method has the advantages that the problem of surface pocking marks of the strip steel during rolling of the medium-carbon low-alloy strip steel in the short process is solved, the purpose of high-quality and high-stability large-scale production of the medium-carbon low-alloy strip steel during rolling in the short process is achieved, equipment does not need to be transformed in the implementation process, and existing equipment and control can be used; the method is suitable for solving the problem of surface pocking marks of stripsteel during rolling of medium-carbon low-alloy strip steel of all specifications; and the method is simple, easy to operate and high in practicability.

Owner:武汉钢铁有限公司

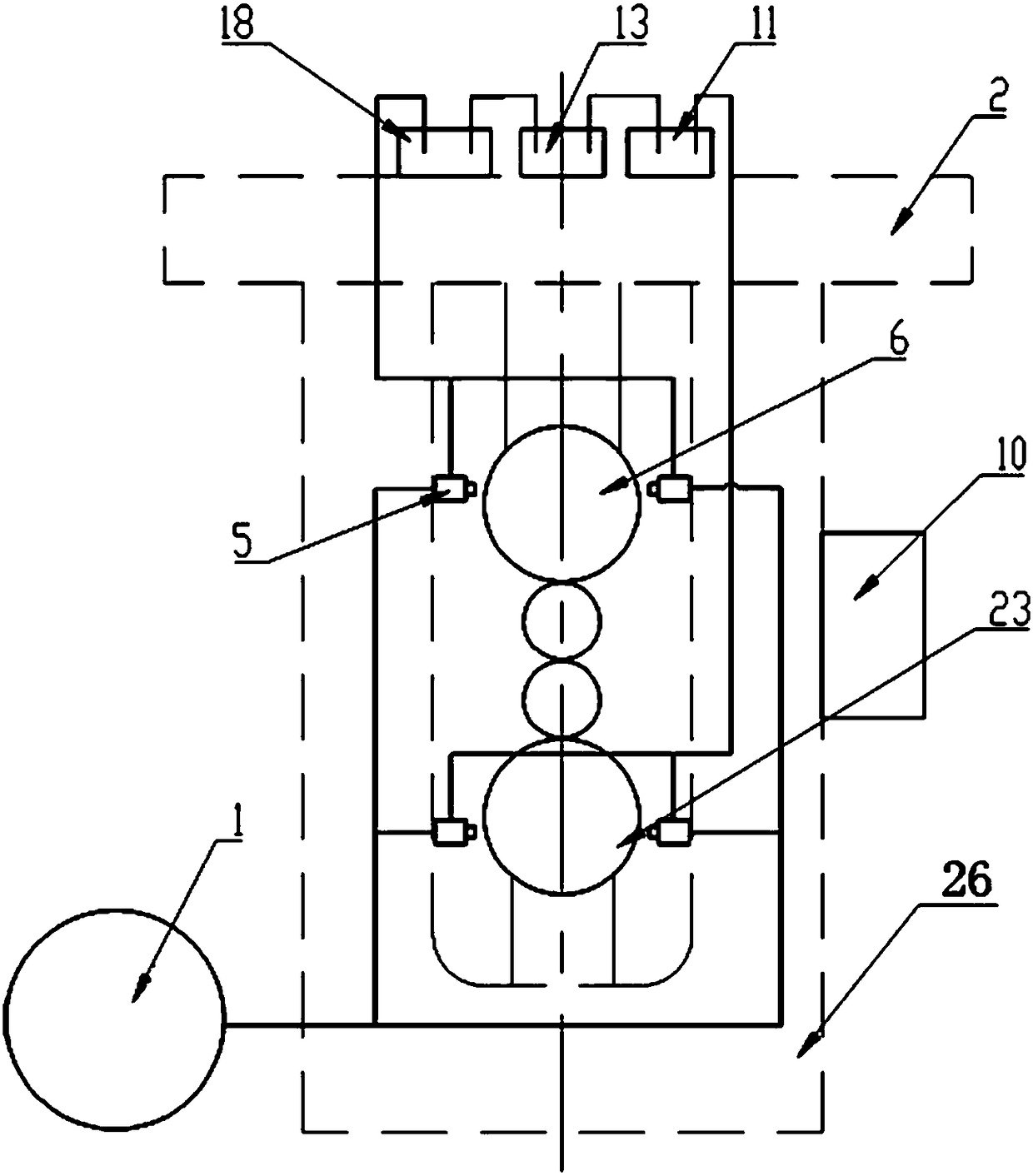

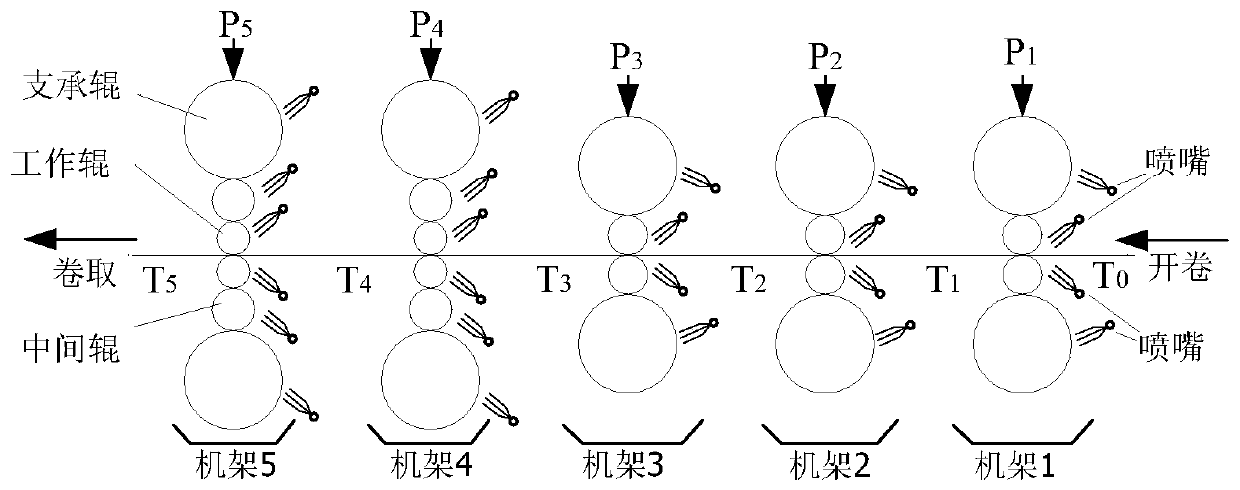

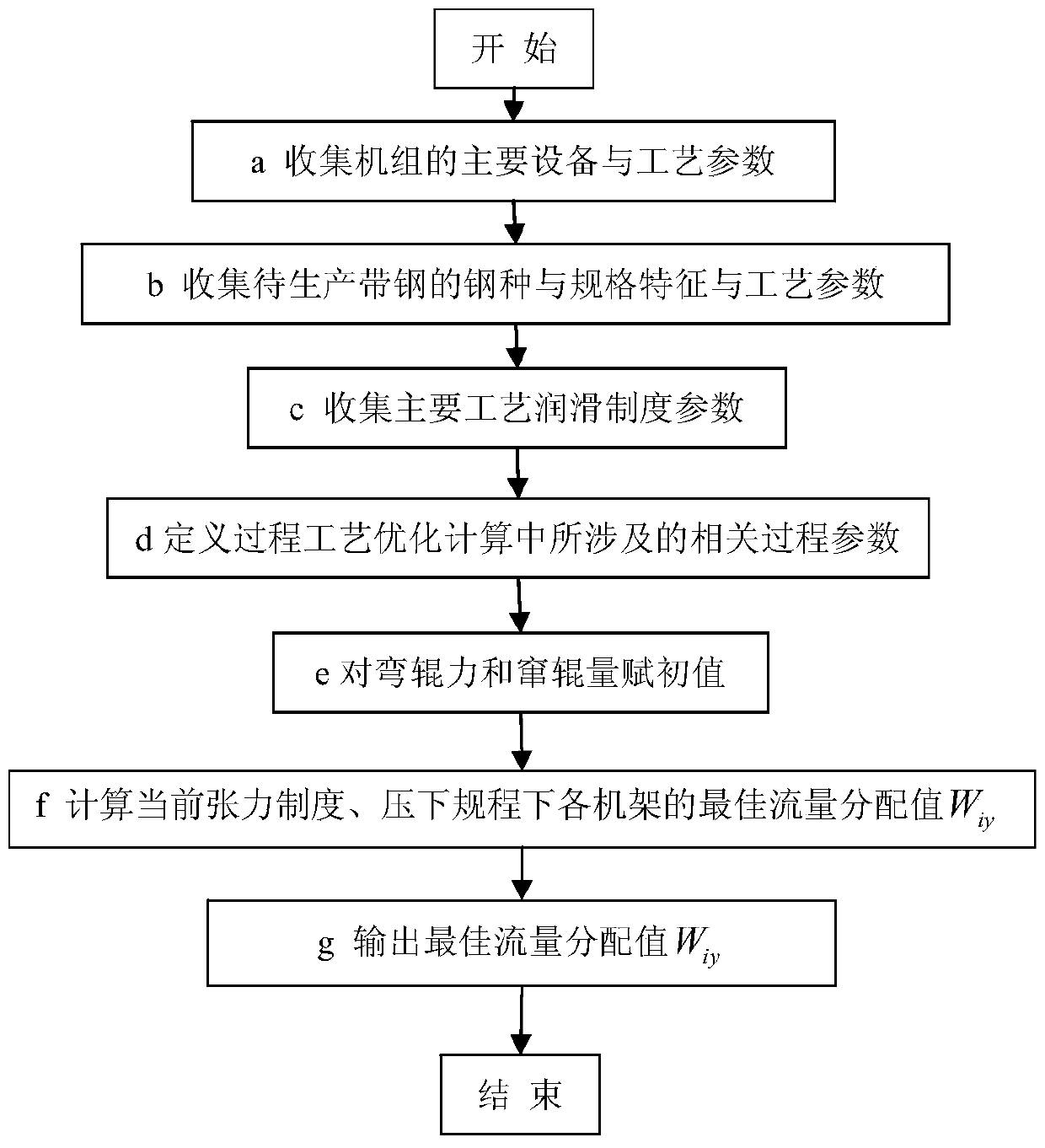

A Comprehensive Optimization Method of Emulsion Flow for Ultra-Thin Strip Rolling in Cold Tandem Mill

ActiveCN104858241BIncrease production capacityReduce vibrationMass flow control deviceMetal rolling arrangementsEmulsionControl system

The invention discloses an emulsion flow comprehensive optimization method in cold continuous rolling set ultrathin strip steel rolling, and relates to special control equipment or a method for a metal rolling mill or processed products thereof, in particular to the emulsion flow comprehensive optimization for comprehensive control in a cold continuous rolling set ultrathin material rolling process; traditional equipment parameter and process parameter data of a cold continuous rolling set control system is used for defining emulsion flow comprehensive optimization process parameters synchronously considering the slip, the vibration and the heat slide damage and giving consideration to the plate shape and the pressing control to determine optimal flow distribution values of all frames under present tension system and reduction schedules; and the emulsion flow comprehensive optimization setting in the ultrathin strip steel rolling is realized through the computer program control. The method adopts different emulsion flow systems for strip steels with different thicknesses, so that the vibration phenomenon of the final frame can be obviously weakened, the stable rolling speed is greatly stabilized, and the capacity of the cold continuous rolling set is improved while enhancing the quality of rolled ultrathin strip steel products.

Owner:BAOSHAN IRON & STEEL CO LTD

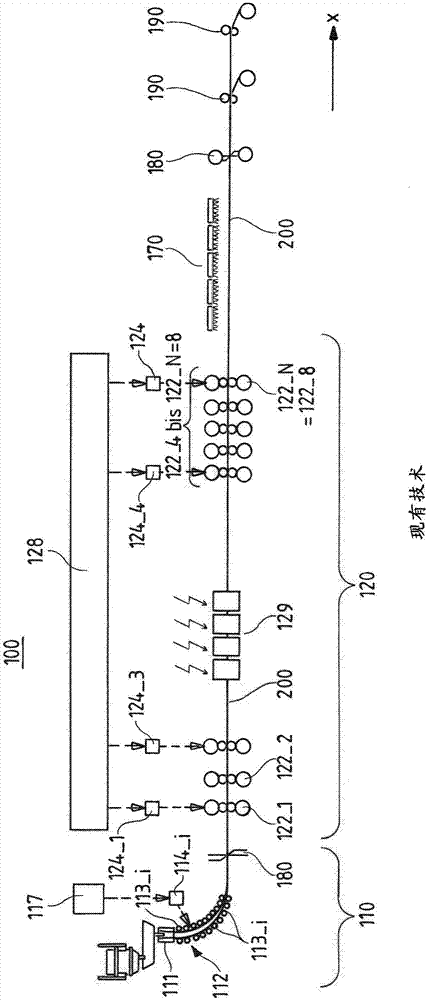

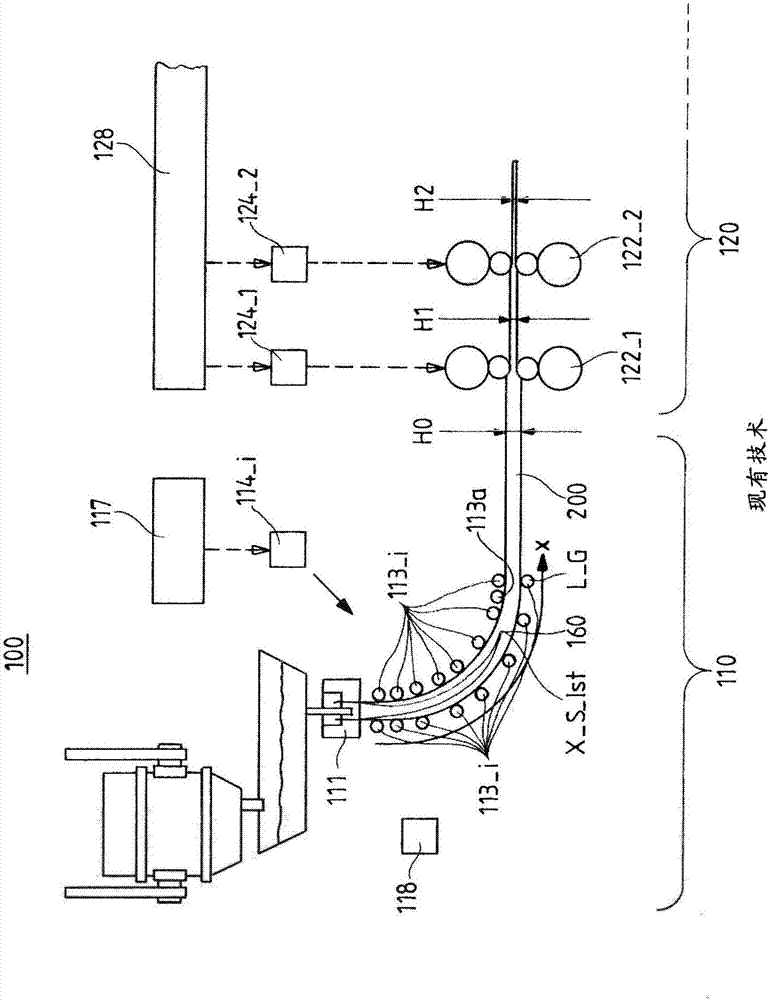

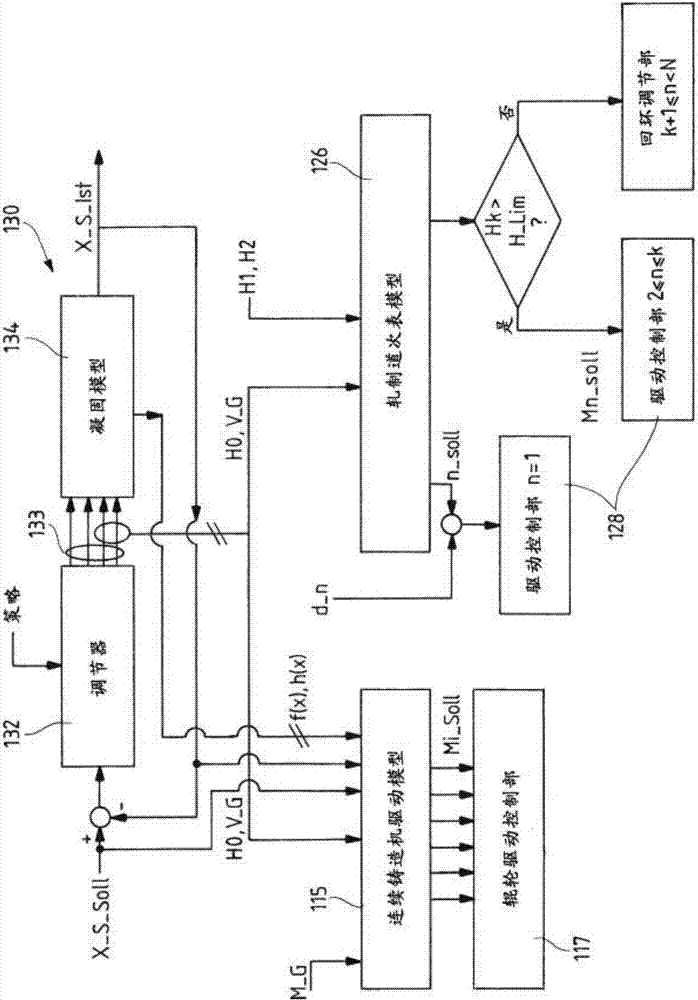

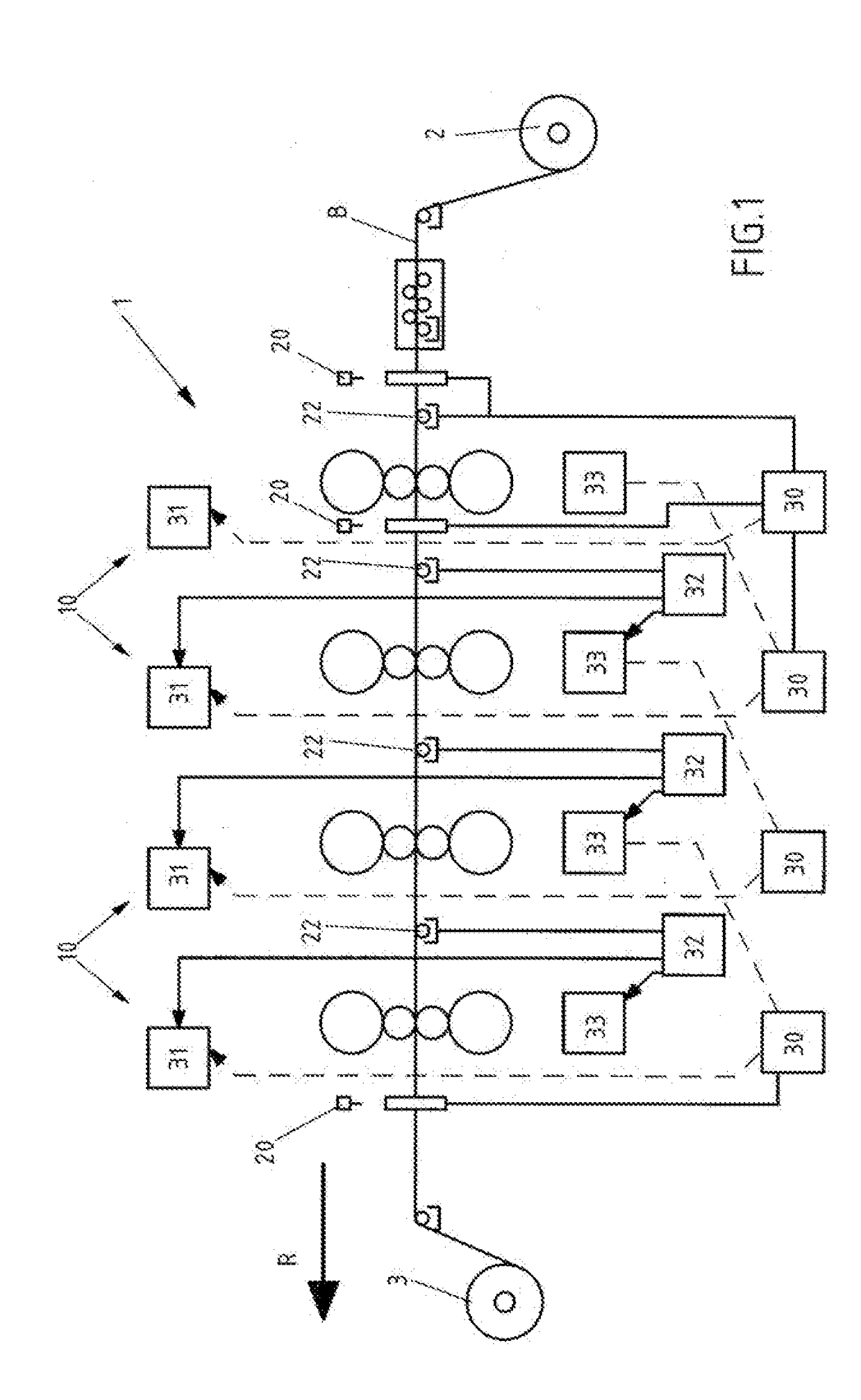

Method and casting/rolling system for casting and rolling a continuous strand material

The invention relates to a method for operating a casting / rolling system 100 and to a corresponding system for casting and rolling an endless strand material 200. The casting / rolling system comprises a strand casting machine 110 and a rolling train arranged downstream of the strand casting machine. The method has the following step: controlling the drive 124 for the rollers of the first roller frame 122_1 of the rolling train by means of a drive control 124 in response to a target value specification of the pass sequence model 126. Furthermore, the drive 114 of the at least one strand guiding roller 113 is controlled by a strand guiding roller drive control 117 in response to a target value specification of the strand casting machine drive model 115. The aim of the invention is to synchronize the drives of both the strand casting machine and of the rolling train in a superordinated manner with respect to a mass flow with an equal and constant value in the two aforementioned system parts. This is achieved in that the pass sequence model 126 specifies a target rotational value for the drive 124_1 of the first roller frame 122_1 as a target value specification, and the strand casting machine drive model 115 specifies a target torque for the drive 114_i of the at least one driven strand guiding roller 113_i as a target value specification.

Owner:SMS GRP GMBH

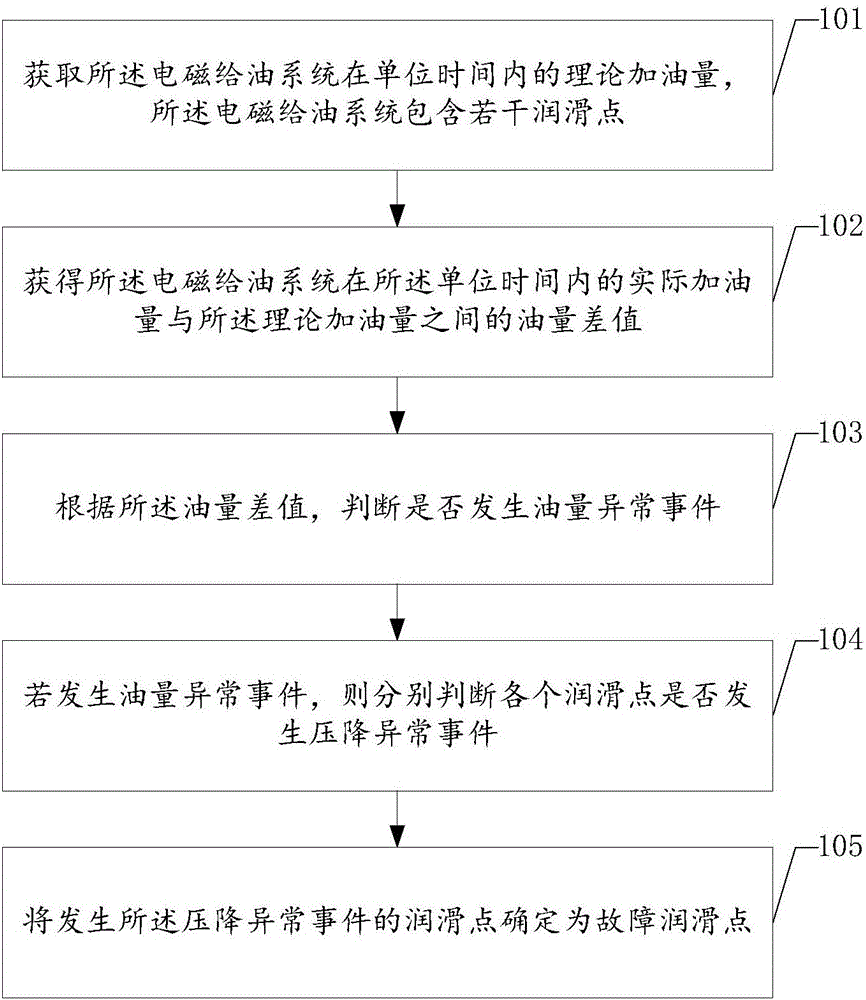

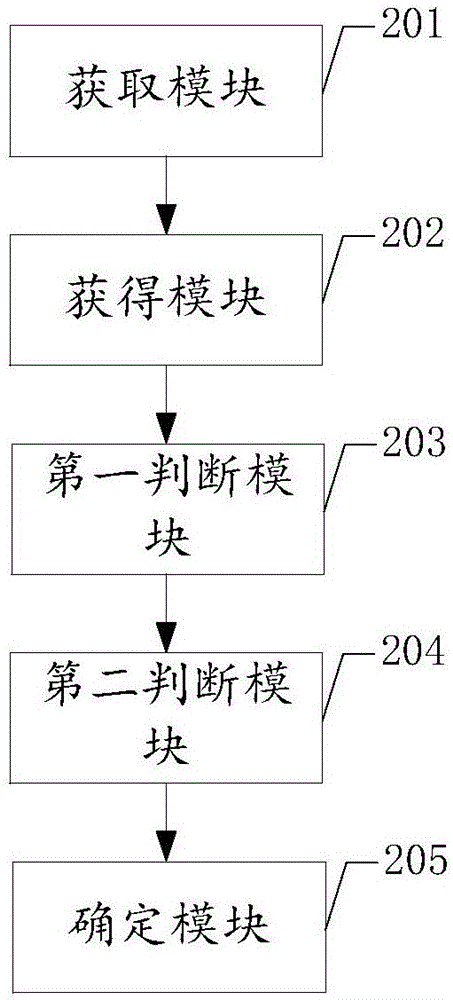

Method and device for monitoring oil feeding amount of electromagnetic oil feeding system

ActiveCN107520252AAvoid wastingMass flow control deviceMetal rolling arrangementsOil and greasePetroleum engineering

The invention relates to the technical field of lubricating systems, in particular to a method and device for monitoring the oil feeding amount of an electromagnetic oil feeding system. The method comprises the steps of acquiring the theoretical oil adding amount of the electromagnetic oil feeding system in unit time, wherein the electromagnetic oil feeding system comprises a plurality of lubricating points; acquiring an oil amount difference value between the actual oil adding amount and the theoretical oil adding amount of the electromagnetic oil feeding system in unit time; according to the oil amount difference value, judging whether an oil amount anomalous event occurs or not; if the oil amount anomalous event occurs, judging whether a pressure drop anomalous event occurs on each lubricating point or not; and determining the lubricating point with the pressure drop anomalous event occurring as a fault lubricating point. According to the method and the device for monitoring the oil feeding amount of the electromagnetic oil feeding system provided by the invention, the fault lubricating point with an oil leaking fault occurring can be accurately determined, the waste of oil grease is avoided, and the oil feeding amount of the electromagnetic oil feeding system is effectively monitored.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

Emulsion Process Optimization Method Aiming at Fuel Consumption Control in Secondary Cold Rolling Mill

InactiveCN107520253BReduce on-site production costsMinimum consumptionMass flow control deviceMetal rolling arrangementsProcess optimizationEmulsion

The invention relates to an emulsified liquid process optimization method taking oil consumption control as a target by a secondary cold rolling unit. The method comprises the following steps executed by a computer; (A) collecting a primary equipment process parameter, a lubricating characteristic parameter and a frictional characteristic parameter of the secondary cold rolling unit; (B) collecting a preset process parameter of to-be-produced strip steel of the secondary cold rolling unit; (C) calculating a frictional coefficient target value [mu]t needed to reach a rolling pressure target value Pt; (D) calculating a deformation region oil film thickness target value xit needed to reach the frictional coefficient target value [mu]t; (E) calculating a separated out oil film thickness target value xipt needed to reach the deformation region oil film thickness target value xit; and (F) calculating the optimum combination (Qy and Cy) of flow and concentration f an emulsified liquid, wherein the secondary cold rolling unit meets the demand on the lubricating performance and the oil consumption is the minimum. By comprehensively optimizing concentration and flow of the emulsified liquid, the minimum consumption of rolling oil is achieved, and the field production cost of the secondary cold rolling unit and the sewage treatment cost of the emulsified liquid are lowered.

Owner:唐山格诺金属科技有限公司

Control method for surface color difference of precision stainless strip steel

ActiveCN112275804AGood removal effectImprove surface color differenceTemperature control deviceFurnace typesStrip steelMachining process

The invention discloses a control method for surface color difference of precision stainless strip steel. The control method comprises the steps: S1, selecting materials; S2, performing rolling of thefirst rolling process; S3, carrying out rolling of the finished product rolling process; and S4, conducting degreasing cleaning on a steel coil obtained after rolling of the finished product rollingprocess is completed. By means of the rolling mode of completely removing a pickling passivation film, a precision surface with the uniform and consistent surface is obtained in the subsequent machining process, and therefore the defects that removing of the pickling passivation film on the surface of a steel coil raw material is poor, the surface color difference is large, and roughness is unevenare overcome.

Owner:SHANXI TAIGANG STAINLESS STEEL PRECISION STRIP CO LTD

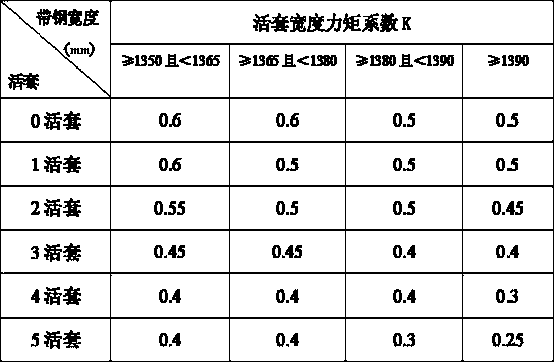

Steel loop control method for low-temperature wide material finishing mill frame of hot continuous rolling mill

InactiveCN105499278AEnsure automatic controlSolve problems such as vibrationMass flow control deviceMetal rolling arrangementsLoop controlAutomatic control

The invention relates to the field of hot continuous rolling low-temperature wide material special steel loop control, in particular to a steel loop control method for a low-temperature wide material finishing mill frame of a hot continuous rolling mill. The steel loop control method for low-temperature wide material finishing mill frame of the hot continuous rolling mill is characterized in that whether low-temperature wide material special band steel is rolled or not is judged; if so, a loop control technology is used until the rolling is completed; otherwise, a normal loop automatic control procedure is used; when the outlet temperature of a finishing mill frame of the band steel is lower than or equal to 850 DEG C, and meanwhile, the width is greater than or equal to 1350mm, the low-temperature wide material special band steel is rolled. The steel loop control method has the advantages that a low-temperature wide material special steel loop control technology is developed; the automatic control of a hydraulic loop during low-temperature wide material band belt rolling is ensured; during the low-temperature wide material band belt rolling, the problems of hydraulic loop oscillation between hot continuous rolling finishing mill frames, and the like are solved.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

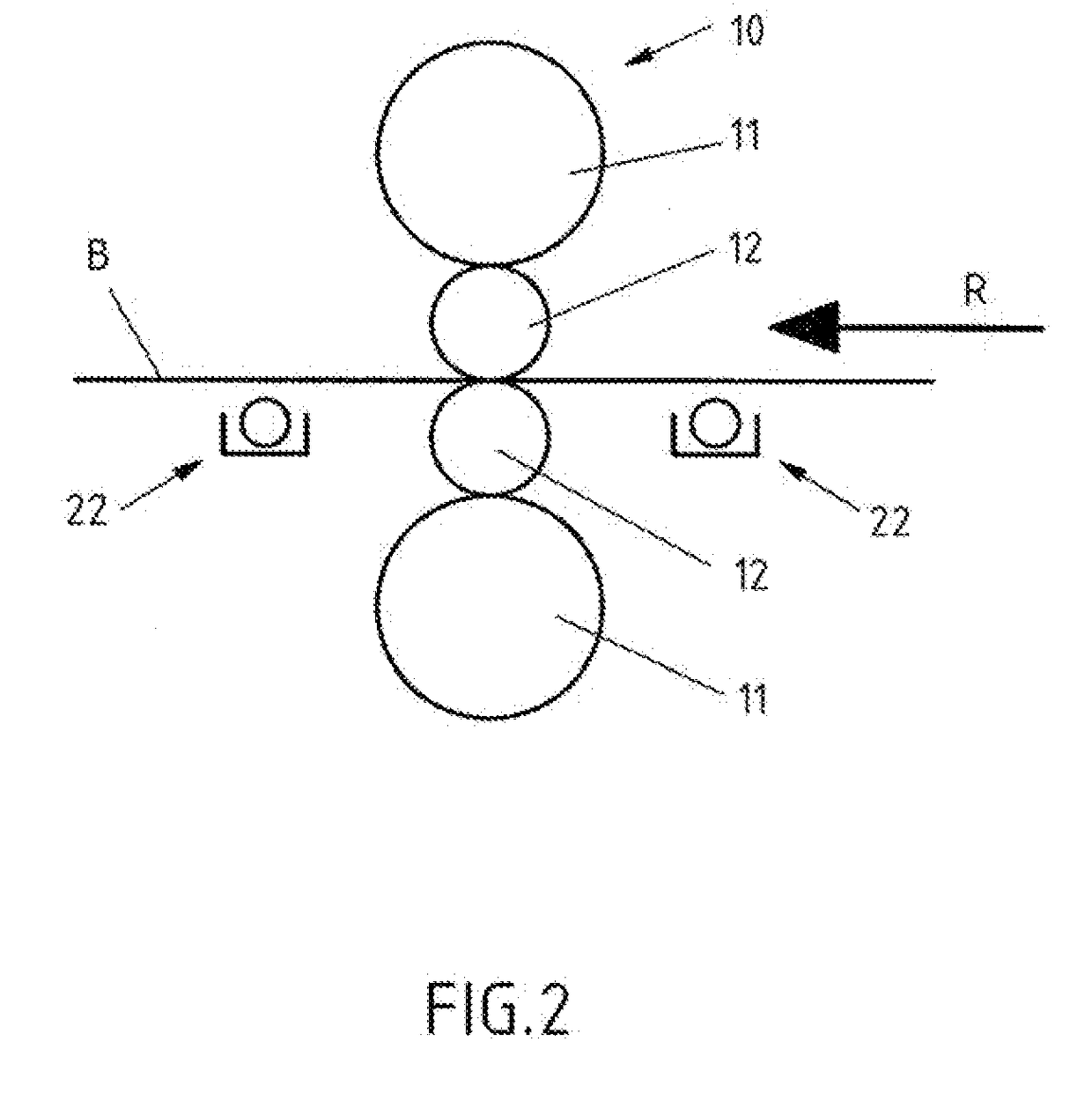

Mass flow regulation in roller devices

ActiveUS20190039107A1High control precisionMetal rolling stand detailsMeasuring devicesEngineeringMechanical engineering

Owner:SMS GRP GMBH

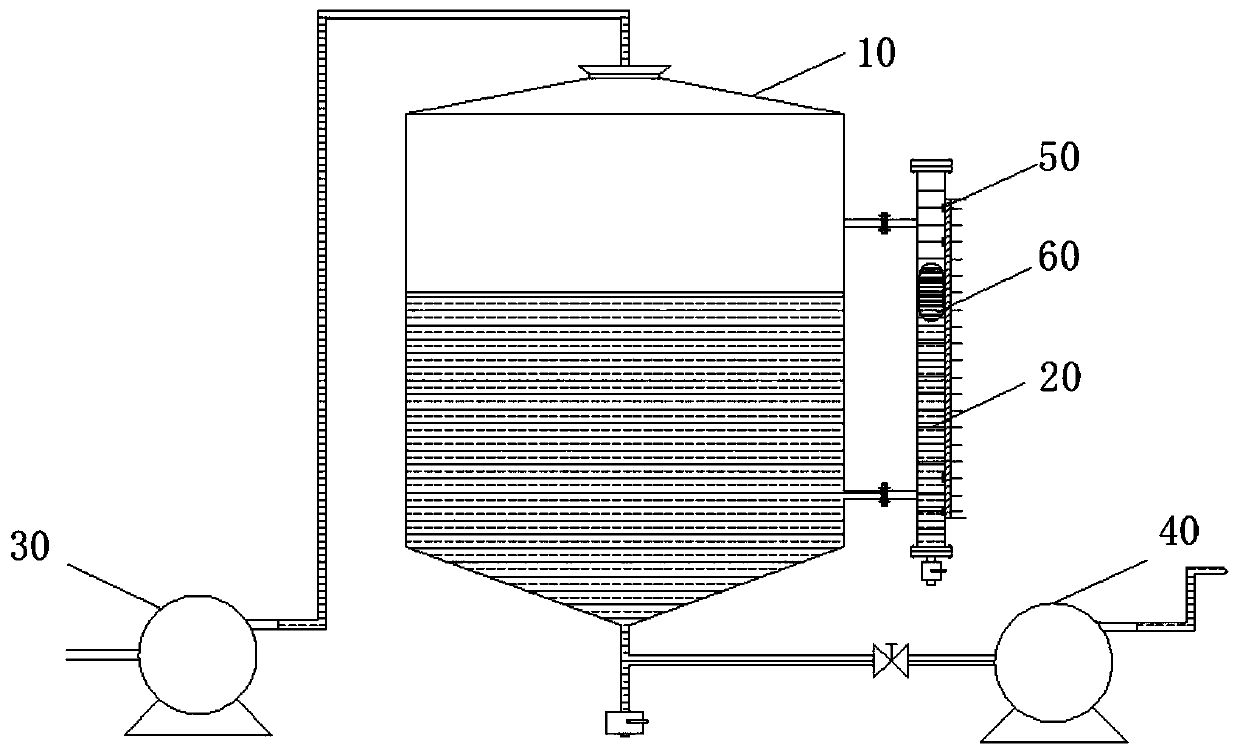

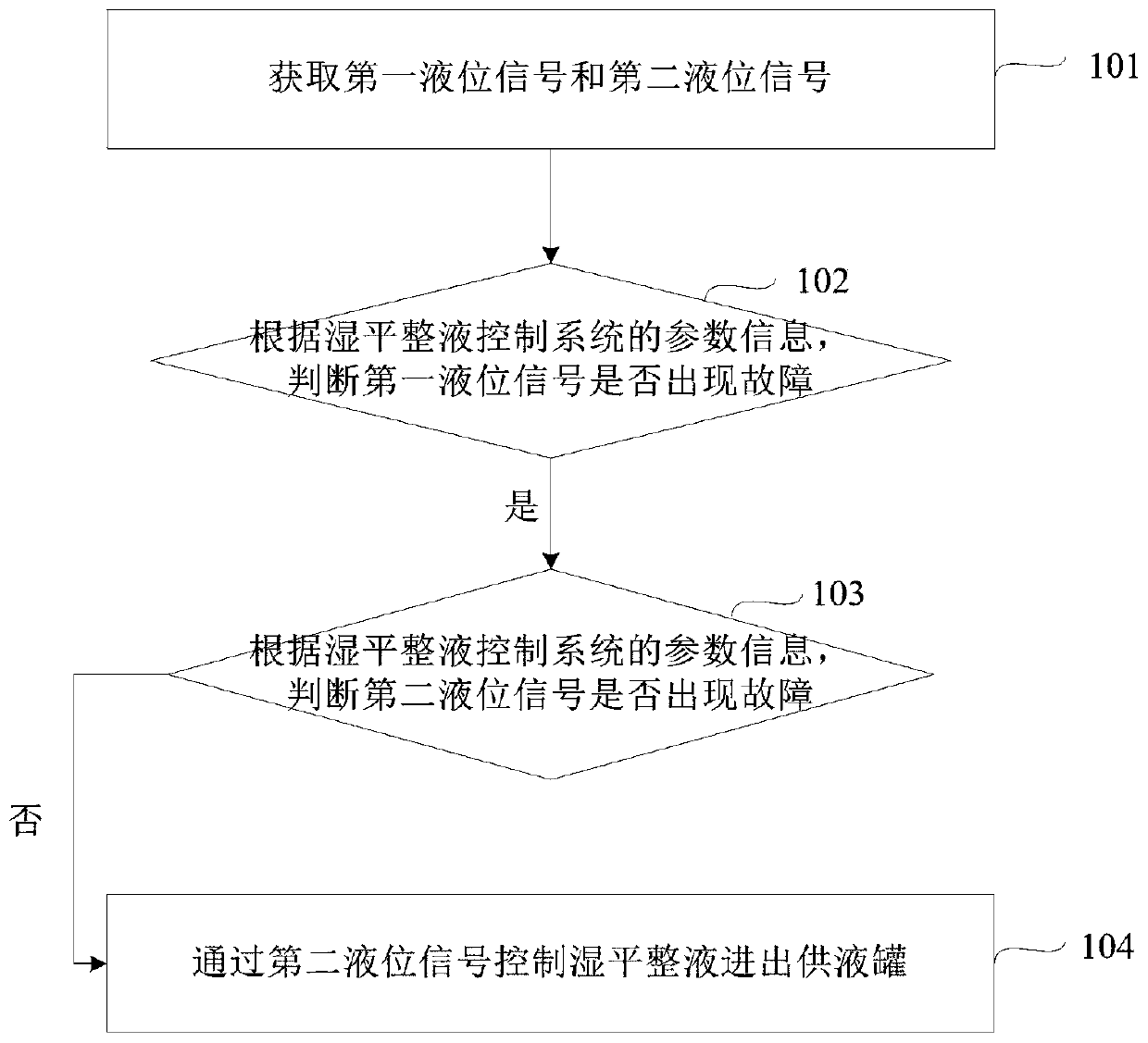

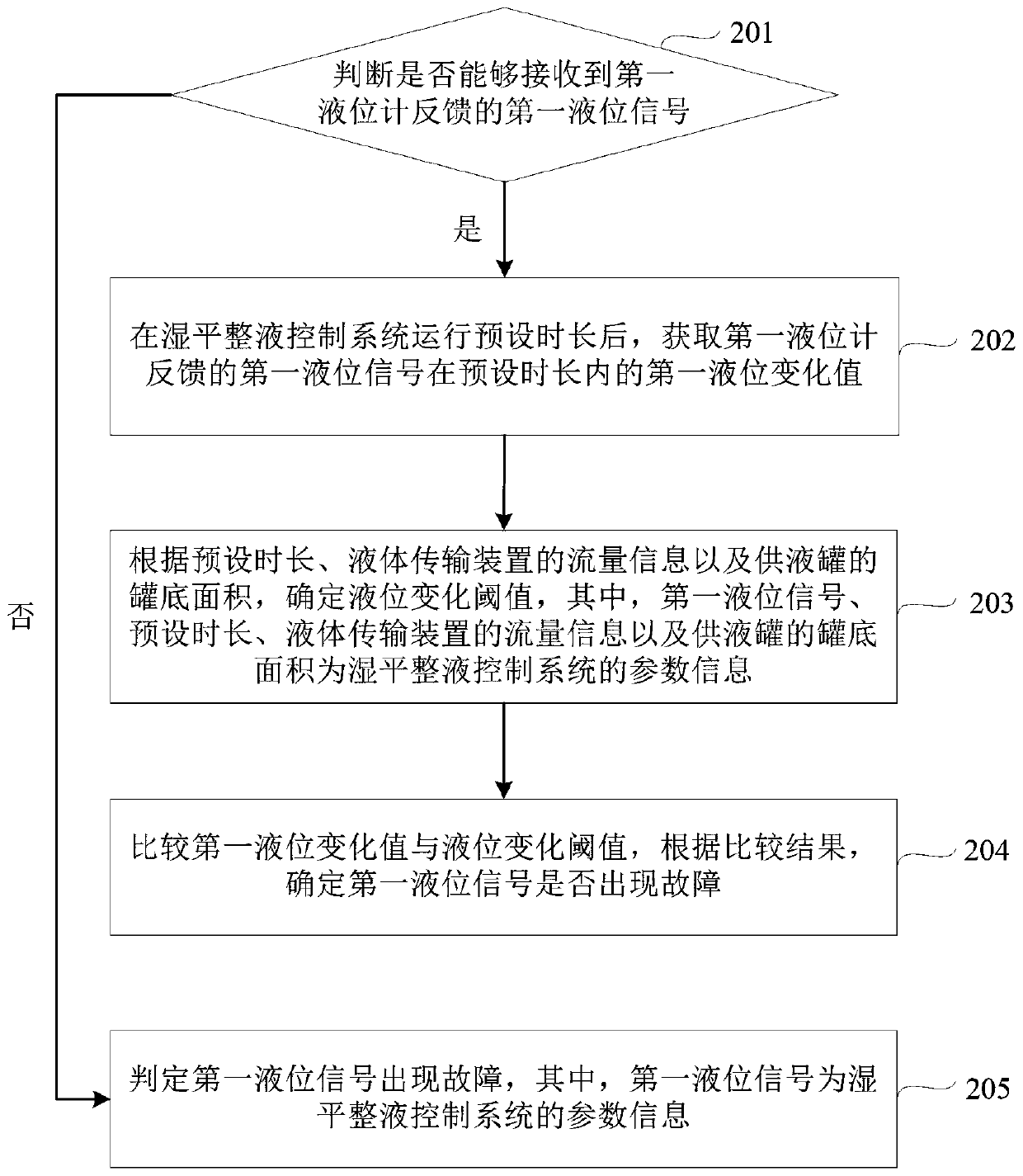

A control method, device and system for wet leveling liquid entering and exiting a liquid supply tank

ActiveCN108817099BImprove stabilityImprove reliabilityWork cooling devicesMass flow control deviceControl system

The embodiment of the invention discloses a method, device and system for controlling a wet leveling liquid to enter or exit from a liquid supply tank. The method comprises the following steps that after a first liquid level signal and a second liquid level signal are acquired, and if the wet leveling liquid is controlled through the first liquid level signal to enter or exit from the liquid supply tank, according to parameter information of the control system of the wet leveling liquid, whether the first liquid level signal has a fault or not is judged; if the first liquid level signal has the fault, whether the second liquid level signal has a fault or not is judged according to the parameter information of the control system of the wet leveling liquid; and if the second liquid level signal does not have a fault, the wet leveling liquid is controlled to enter and exit from the liquid supply tank through the second liquid level signal. By the adoption of the method, device and systemfor controlling the wet leveling liquid to enter or exit from the liquid supply tank, when a fault occurs in the first liquid level signal, the wet leveling liquid is controlled to enter and exit fromthe liquid supply tank through the second liquid level signal, so that the reliability of controlling the wet leveling liquid to enter and exit from the liquid supply tank is improved.

Owner:ELECTRON CO LTD

Process and control method for eliminating winding of thin hot-rolled strip steel on pinch roll of coiling machine

ActiveCN114101334AReduce chance of pastingEliminate accidentsTemperature control deviceMeasuring devicesLaminar coolingStrip steel

The invention discloses a process for eliminating winding of thin hot-rolled strip steel on a pinch roll of a coiling machine. The process comprises the following steps: a, heating a steel billet in a heating furnace; b, primary descaling is conducted, specifically, the heated steel billet enters a descaling procedure I to remove oxide scale formed on the surface of the steel billet; c, the descaled steel billets enter a side press, and the width of the steel belt is preliminarily controlled; d, the steel billets enter a rough rolling unit to be roughly rolled, secondary descaling is conducted, and then the steel billets enter a finishing rolling unit to be rolled; and e, the rolled strip steel is guided by a pinch roll of the coiling machine to enter a mandrel of the coiling machine to be coiled after being subjected to laminar cooling. The invention further provides a control method for eliminating winding of the thin hot-rolled strip steel on the pinch roll of the coiling machine, the temperature of the head of the strip steel passing through the pinch roll is controlled according to different coiling temperatures of the strip steel, and the sticking probability of the strip steel and the pinch roll is reduced by compensating the temperature of the head.

Owner:MAANSHAN IRON & STEEL CO LTD

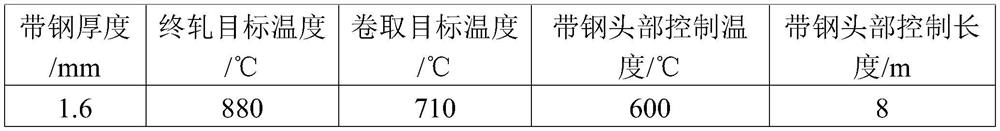

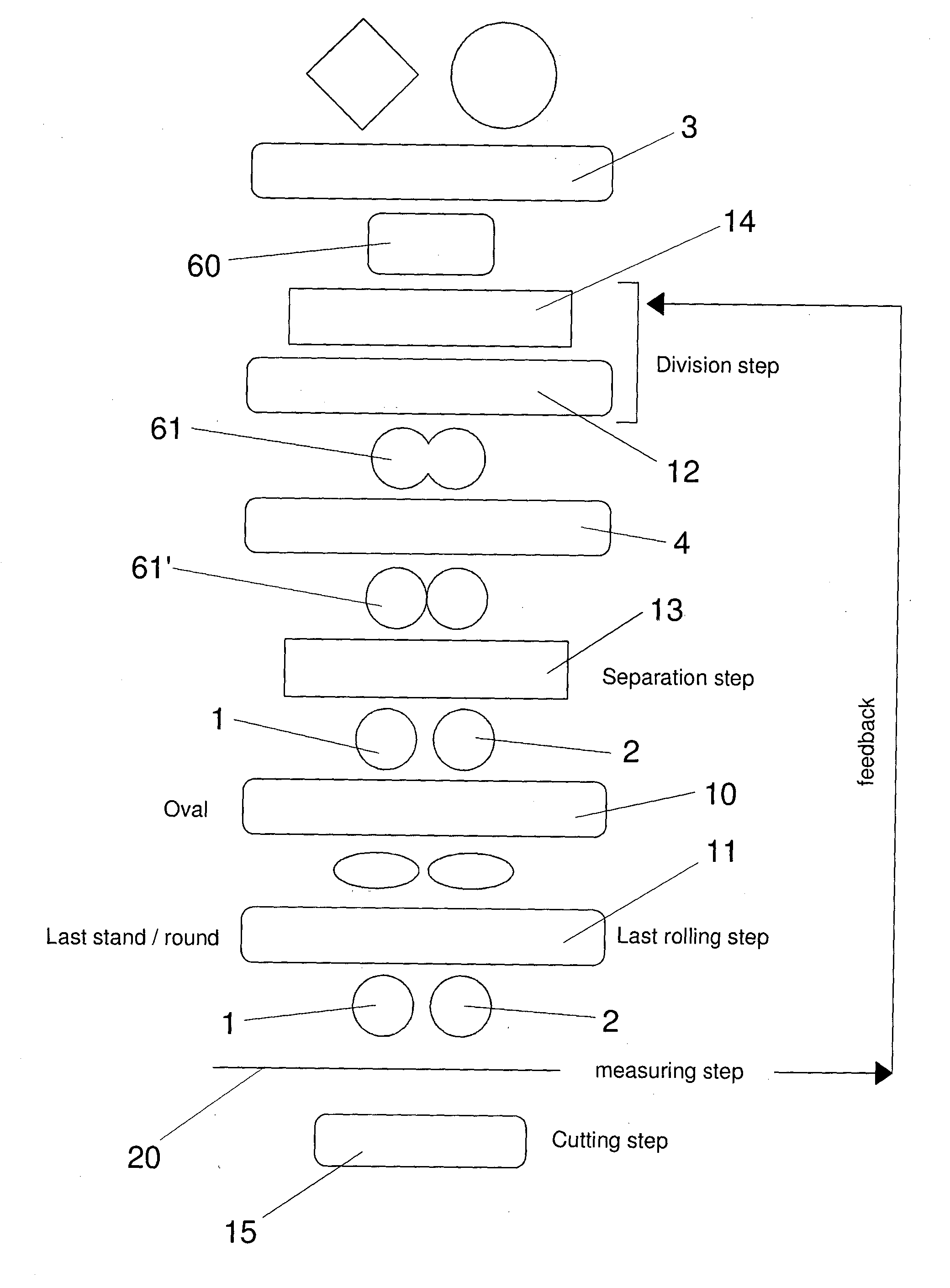

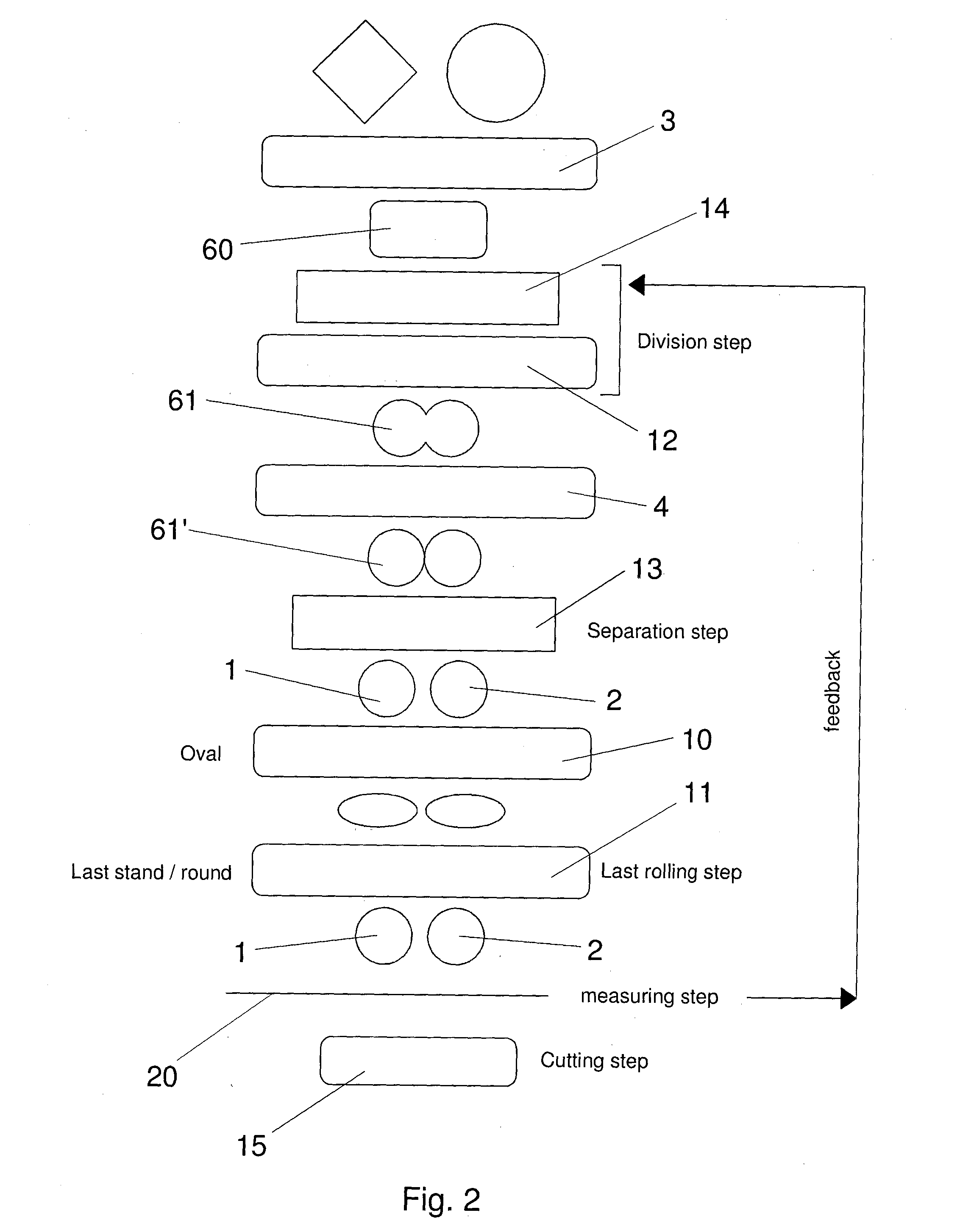

Method for controlling a two continuous strands rolling plant

ActiveUS20150000360A1Minimize difference in lengthReduce discardingMultiple strand roll mill standMass flow control deviceEngineeringControl equipment

A slit plant comprises a rest bar (14), for regulating the transversal position of an inlet guide to the moulder unit (12), a rolling unit for reducing the billet to a rolled section having two sections, a cutting box (13) for separating the two sections into two separate strands, one or more rolling units for rolling the two strands (1, 2), pairs of speed and / or section measurers (20, 21) downstream of the cutting box (13), a shear (15). The method for controlling the plant provides measuring the rolling speeds V1 and V2 of each of the two strands (1, 2) and / or of the division step respective sections A1 and A2 of the two strands (1, 2) downstream of the cutting box (13) by means of pairs of measurers; detecting the lengths of the two strands (1, 2) and calculating the difference in length thereof, based on which the plant, in a successive feedback step, is activated to decrease the difference in length between the two strands (1, 2).

Owner:DANIELI & C OFF MEC SPA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com