Flow control method for rolling temperature of hot rolled steel strip

A coiling temperature and flow control technology, applied in temperature control, mass flow control devices, metal rolling, etc., can solve problems such as unstable coiling temperature index control, to ensure coiling temperature and uniformity, and improve product quality. Performance, satisfying the effect of large flow and fast cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

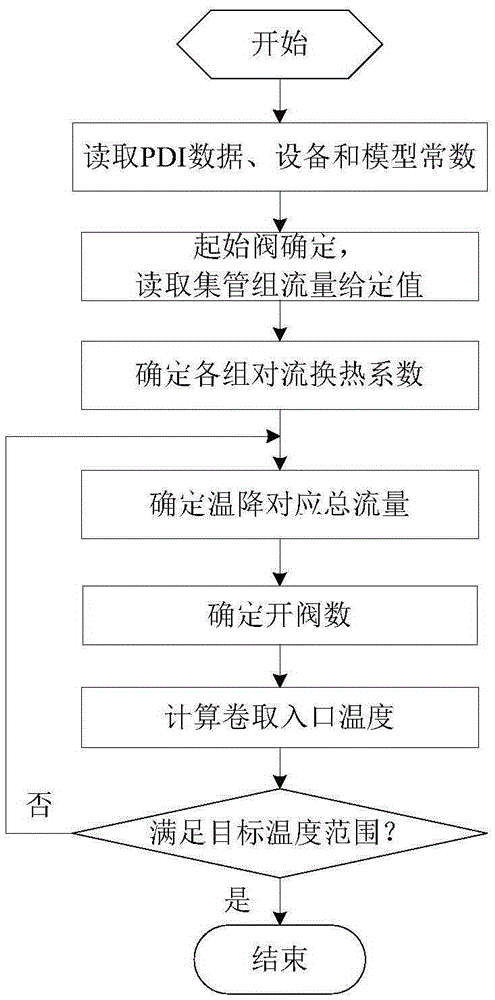

[0041] The present invention takes a medium and wide band 950 hot rolling production line as an example, and combines figure 2 Explain as follows:

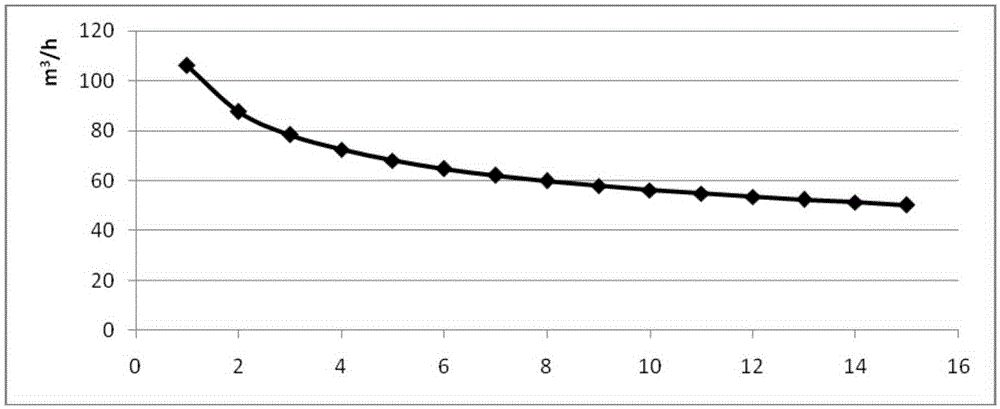

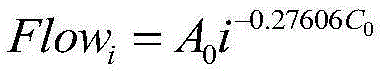

[0042] Step 1. Read the slab PDI data, the slab number is YG151004366, the steel grade is 08AL, the slab specification is 165*770*10000mm, the product target thickness is 3.0mm, the final rolling target temperature is 865℃, and the coiling target temperature is 550 ℃, read the equipment constant and the relevant parameters of the coiling temperature model. The measured value of the pyrometer at the entrance of the slab before the finishing mill is 988℃, and the measured value of the pyrometer at the exit of the finishing mill is 851℃; there are 15 sets of headers in the layer cold zone, The first 13 groups have 4 cooling units in each group, and the last two groups have 8 cooling units in each group, and each group of headers is equipped with a flow meter. The flow meter can better verify the flow control method of the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com