Test method for improving response speed of hot-rolled laminar cooling water valve

A technology of response speed and test method, applied in workpiece cooling devices, metal rolling, length measuring devices, etc., can solve the problems of low strip coiling temperature compliance rate, uneven response time, and uneven strip cooling. Achieve the effect of improving statistical efficiency and valve maintenance cycle, reducing accident rate and reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

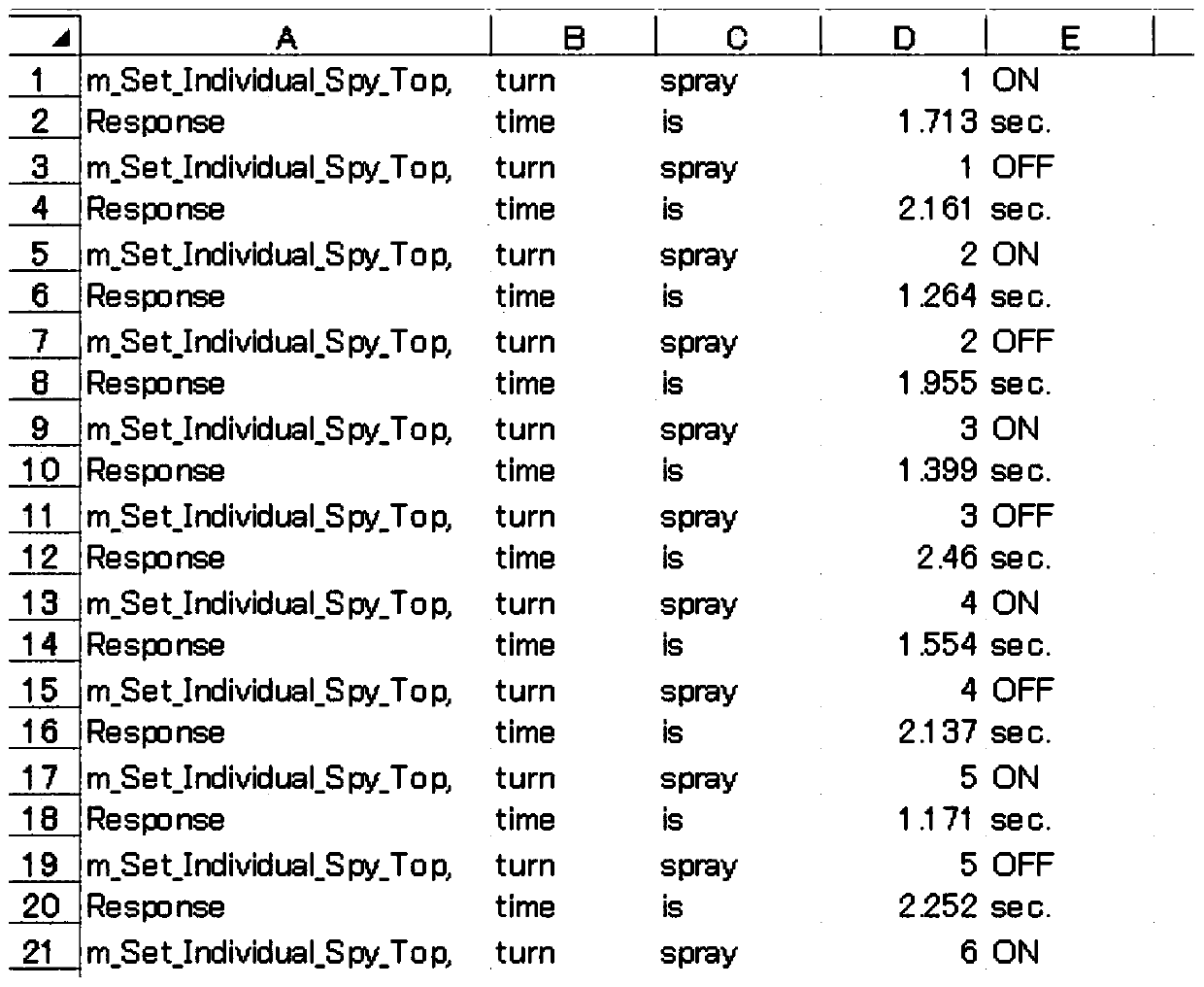

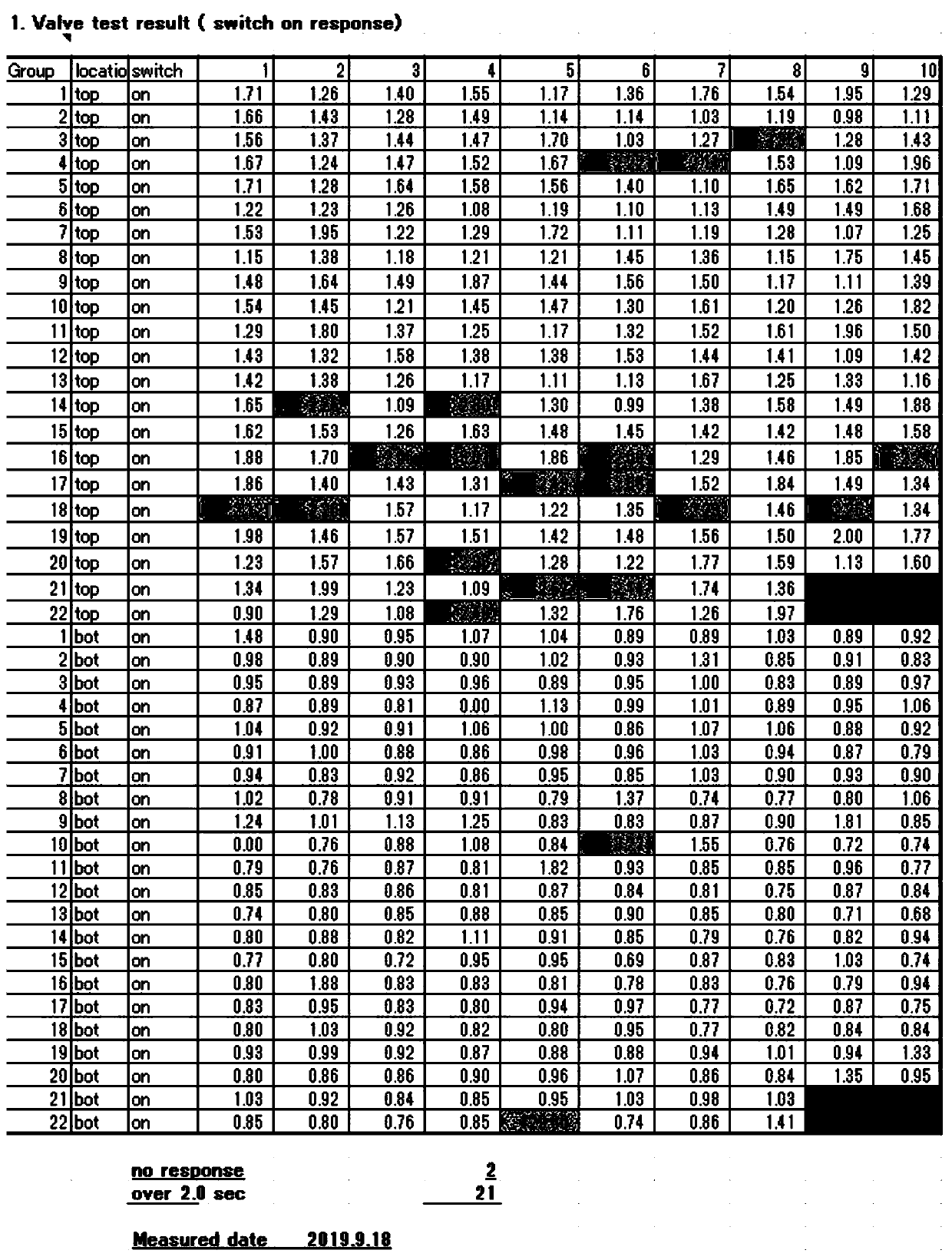

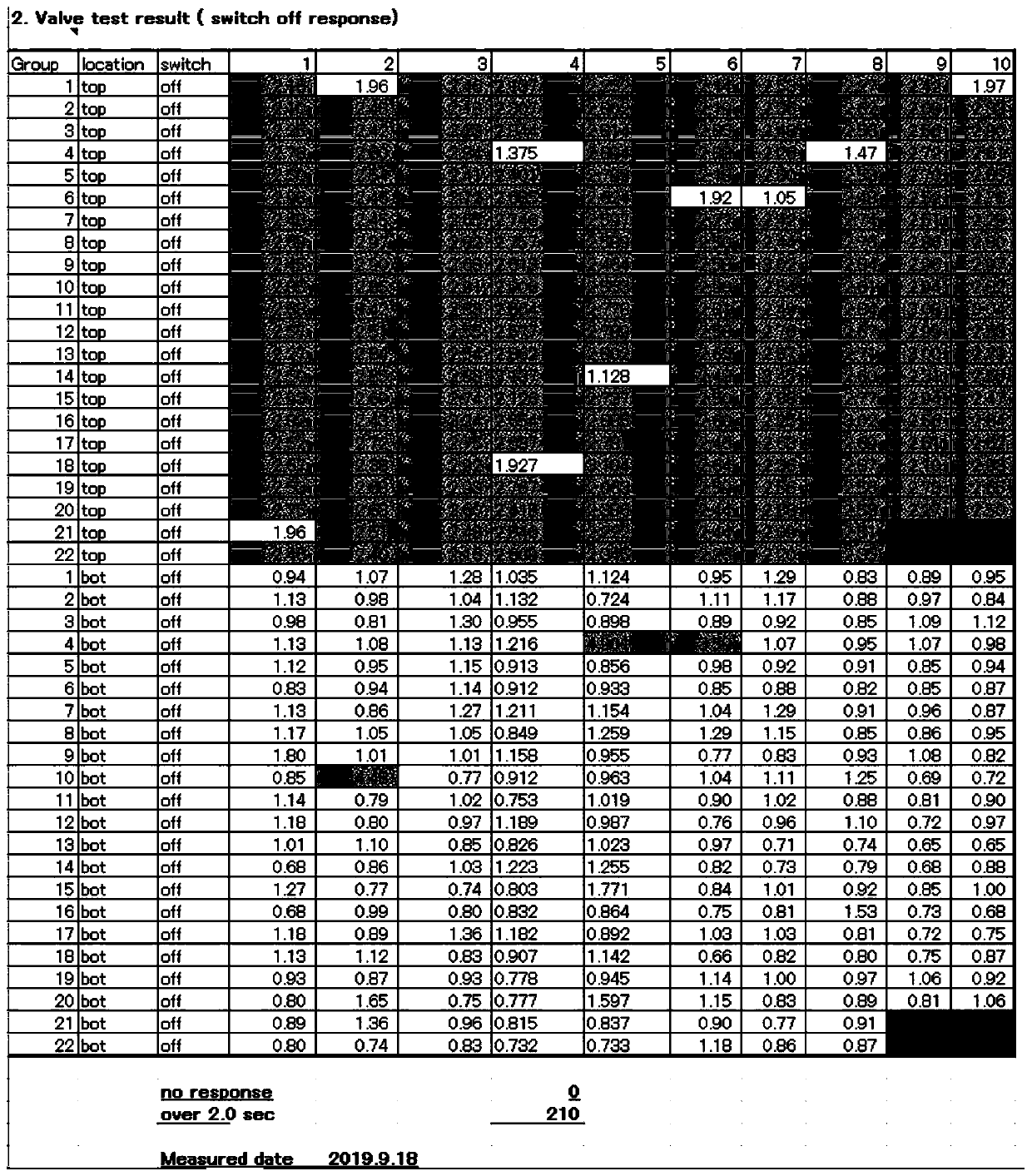

[0021] Further illustrate technical scheme of the present invention below in conjunction with accompanying drawing:

[0022] A test method for improving the response speed of a hot-rolled laminar flow cooling water valve, which mainly includes the following steps:

[0023] a. Line connection, connect the prepared end to the power line of the test handle and the terminal box of the laminar flow cooling water valve to collect the signal of the handle to the inside of the system;

[0024] b. Fix the line to avoid disconnection caused by dragging the handle during the retest process, which will affect the test effect;

[0025] c. Lay the line, lay the line of the connection number to the first group of water valves of the laminar flow cooling water, and reserve a sufficiently long (about 20 meters) line.

[0026] 2. The computer-operated terminal setting of the present invention mainly includes the following steps:

[0027] a. Set the spray mode to Auto in the secondary operatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com