Patents

Literature

338 results about "Quality performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

System and method for monitoring and measuring quality performance of health care delivery and service

InactiveUS20120303378A1Avoid disadvantagesFinanceOffice automationProcess qualityQuality performance

A software driven health care quality management system is disclosed. This system is user friendly, allowing easy navigation through various screens that enable the user to identify drivers of Star Rating System performance. The present invention offers easy drill-down functionality from a plan level, to a provider group, individual provider, and member level to provide actionable data that can improve the quality of care and ultimately a plan's star ratings. This system addresses each of the drivers that influence overall plan revenue, by providing an enterprise business intelligence system, designed to maximize process quality measures, promote value-based purchasing, and maximize risk-adjusted revenue for such health plans and health provider organizations.

Owner:ESSENTIALSTARS

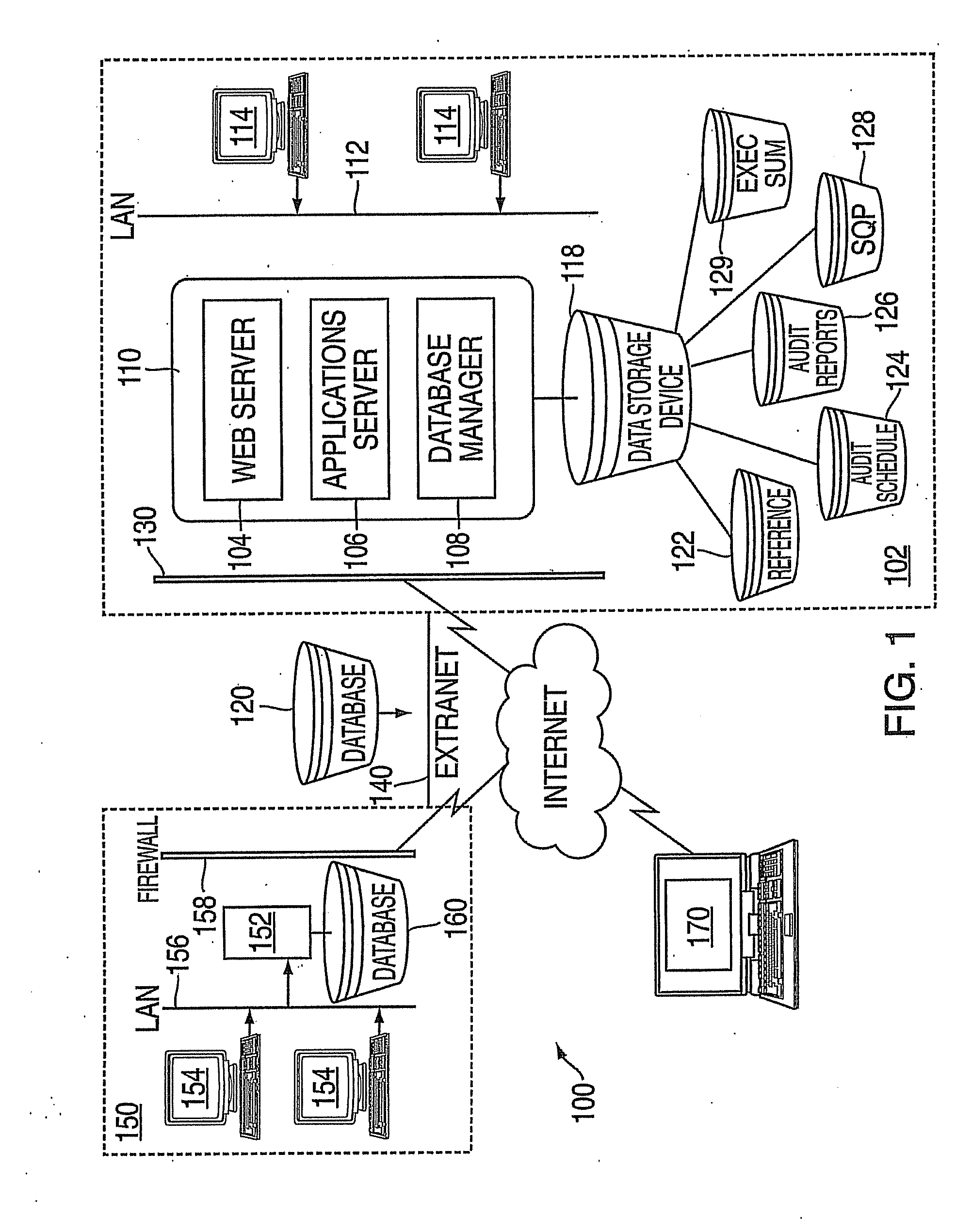

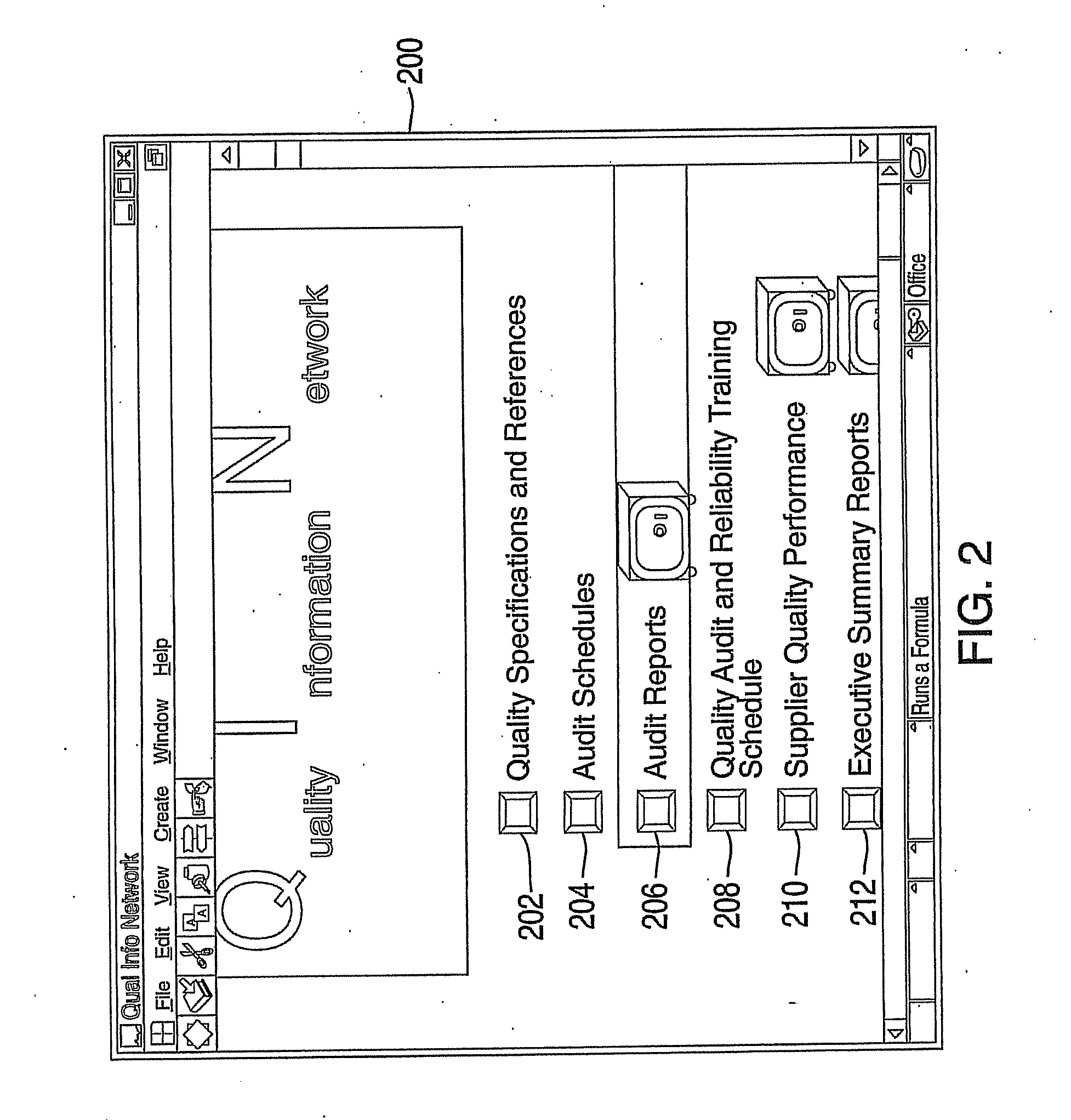

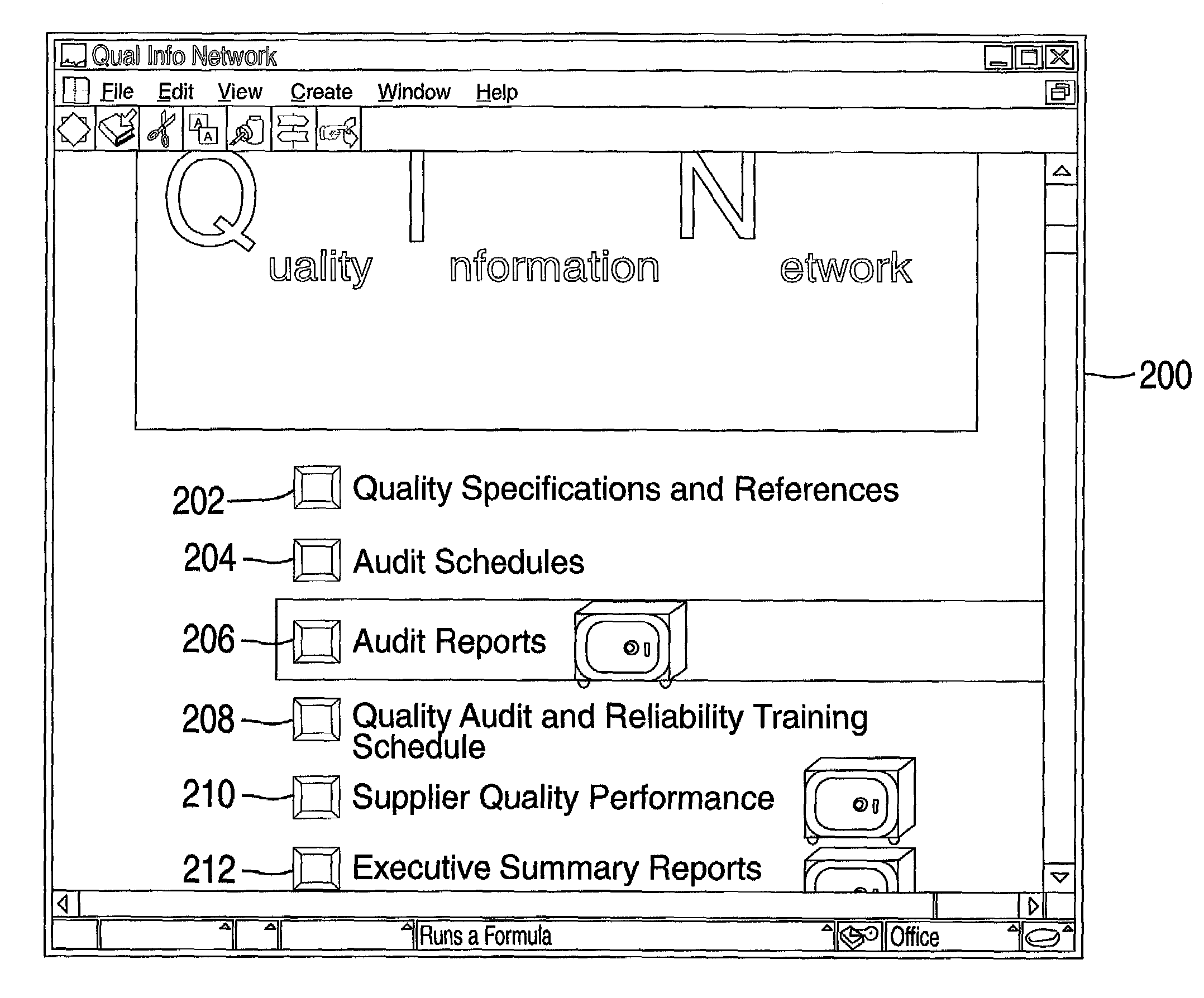

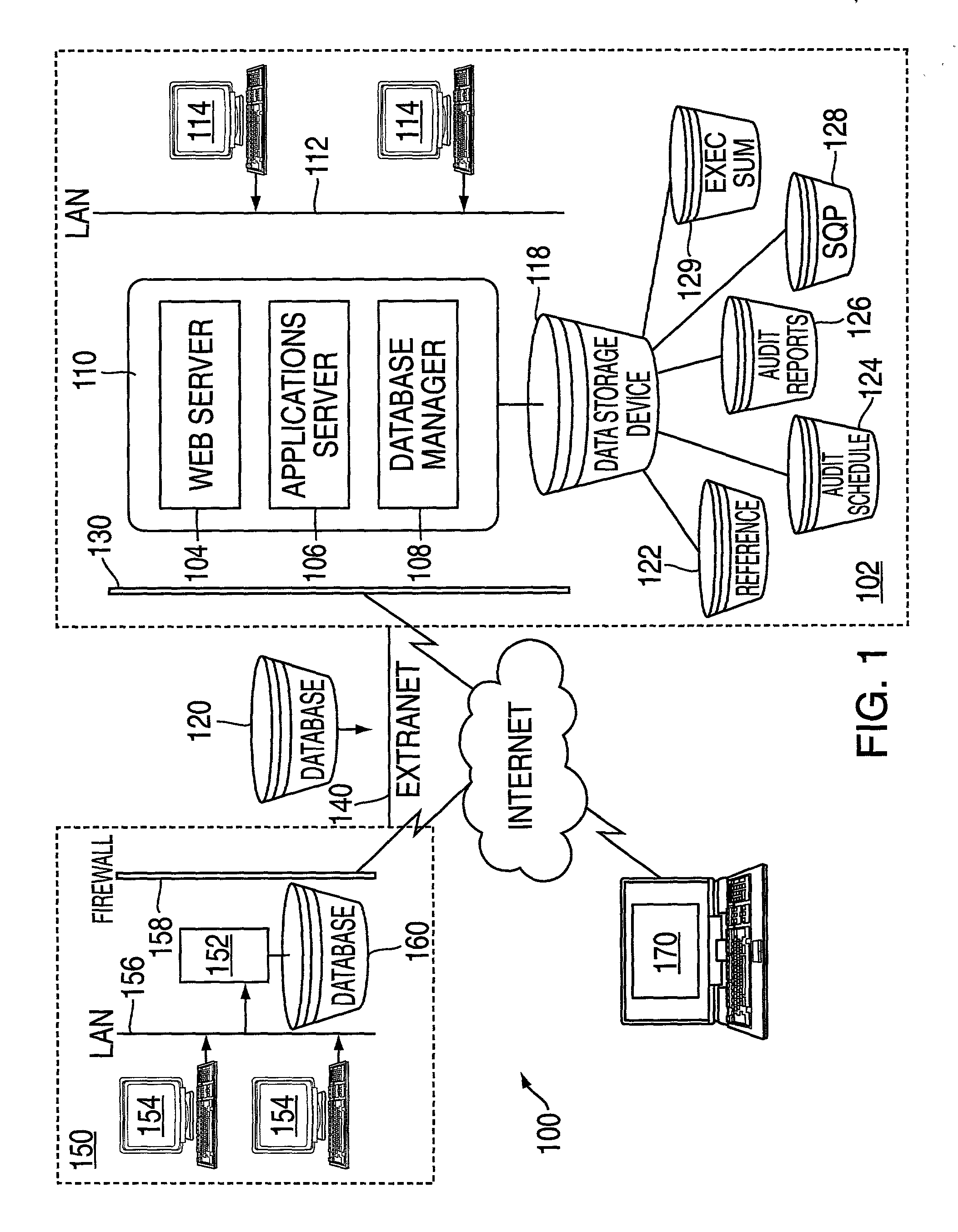

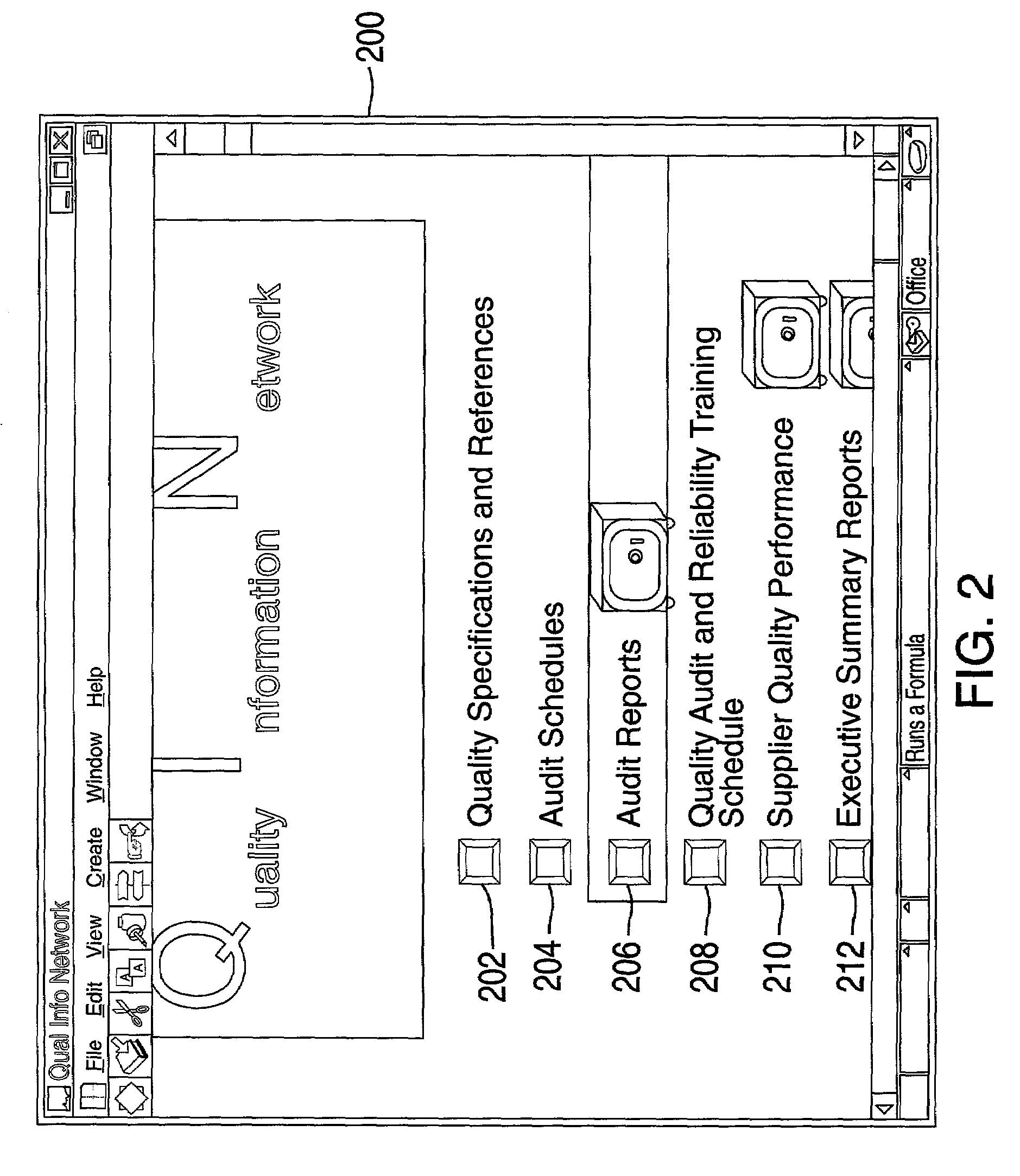

Gathering and disseminating quality performance and audit activity data in an extended enterprise environment

A method for facilitating supplier auditing functions in a communications network environment is disclosed. The method includes receiving a request from a user system of an enterprise system to initiate an activity. The activity includes assessing a supplier record for determining a need to schedule a supplier audit, and scheduling the audit for performing an initial or ongoing qualification of an existing or prospective trading partner of the enterprise system. Assessing the supplier record includes reviewing past audit activity, date of last audit, and results of past audits. The enterprise system retrieves data from at least one database, which corresponds to the request. The enterprise system includes a quality information network application for executing activity options that include the activity requested by the user system.

Owner:INT BUSINESS MASCH CORP

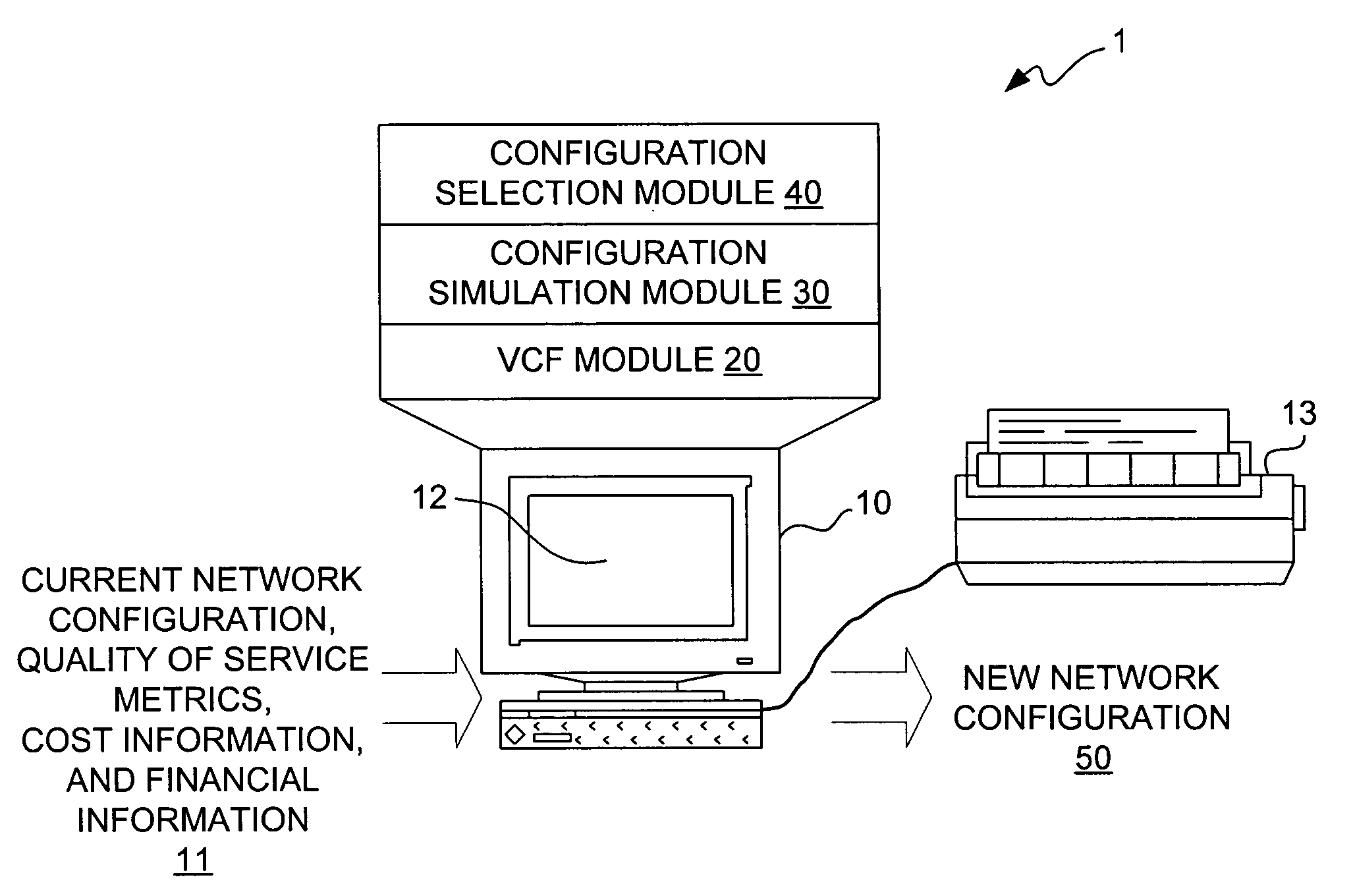

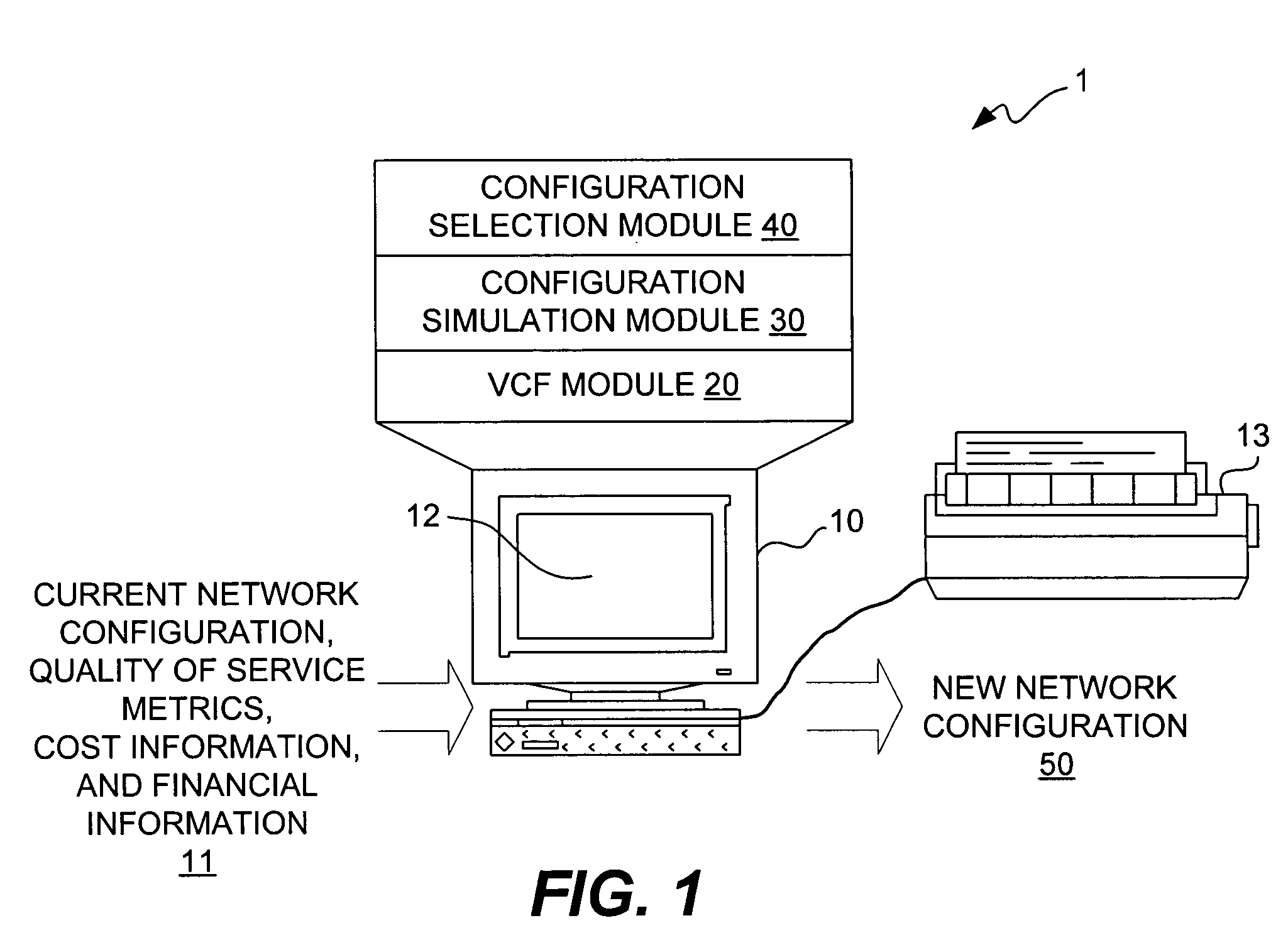

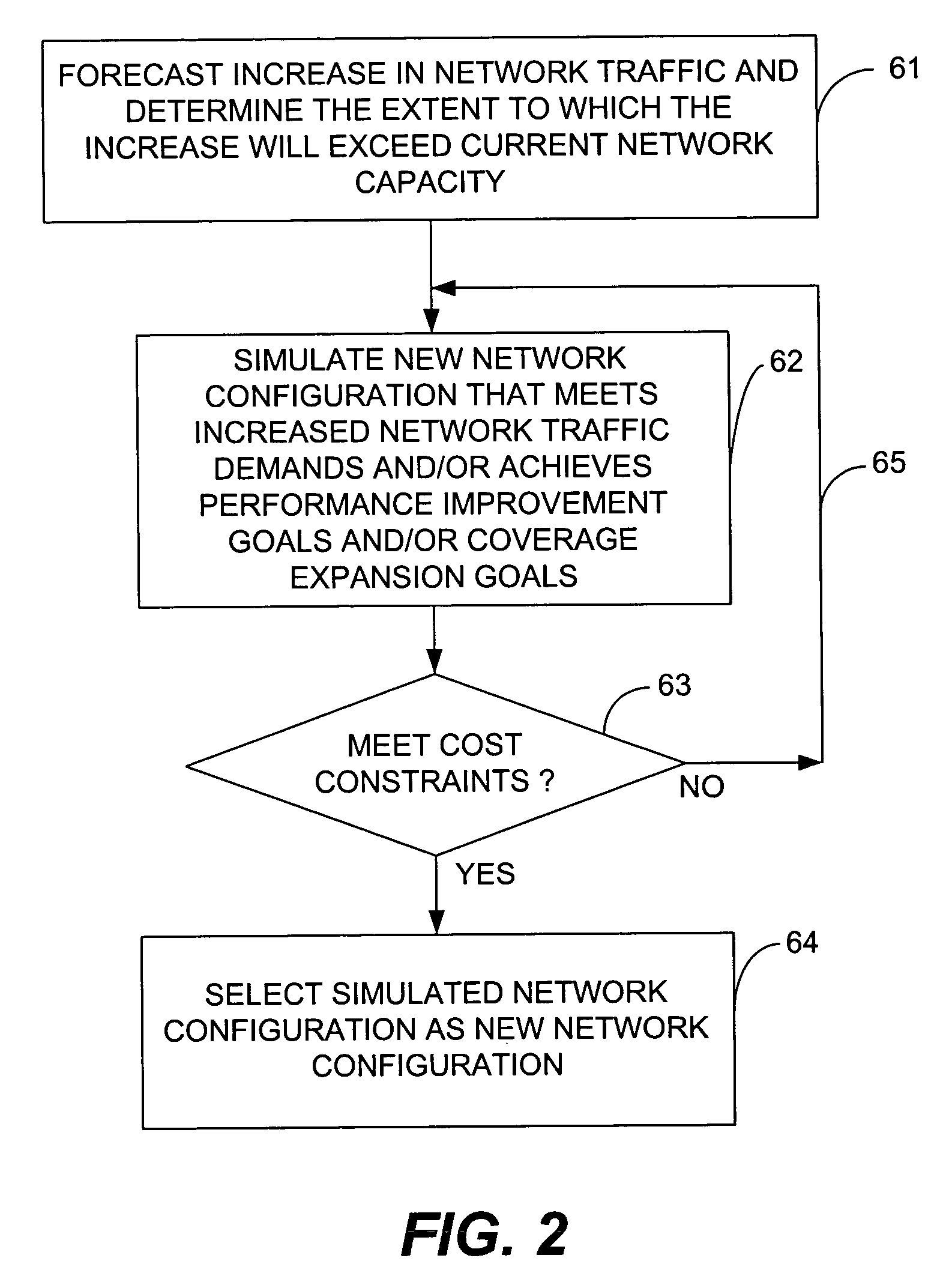

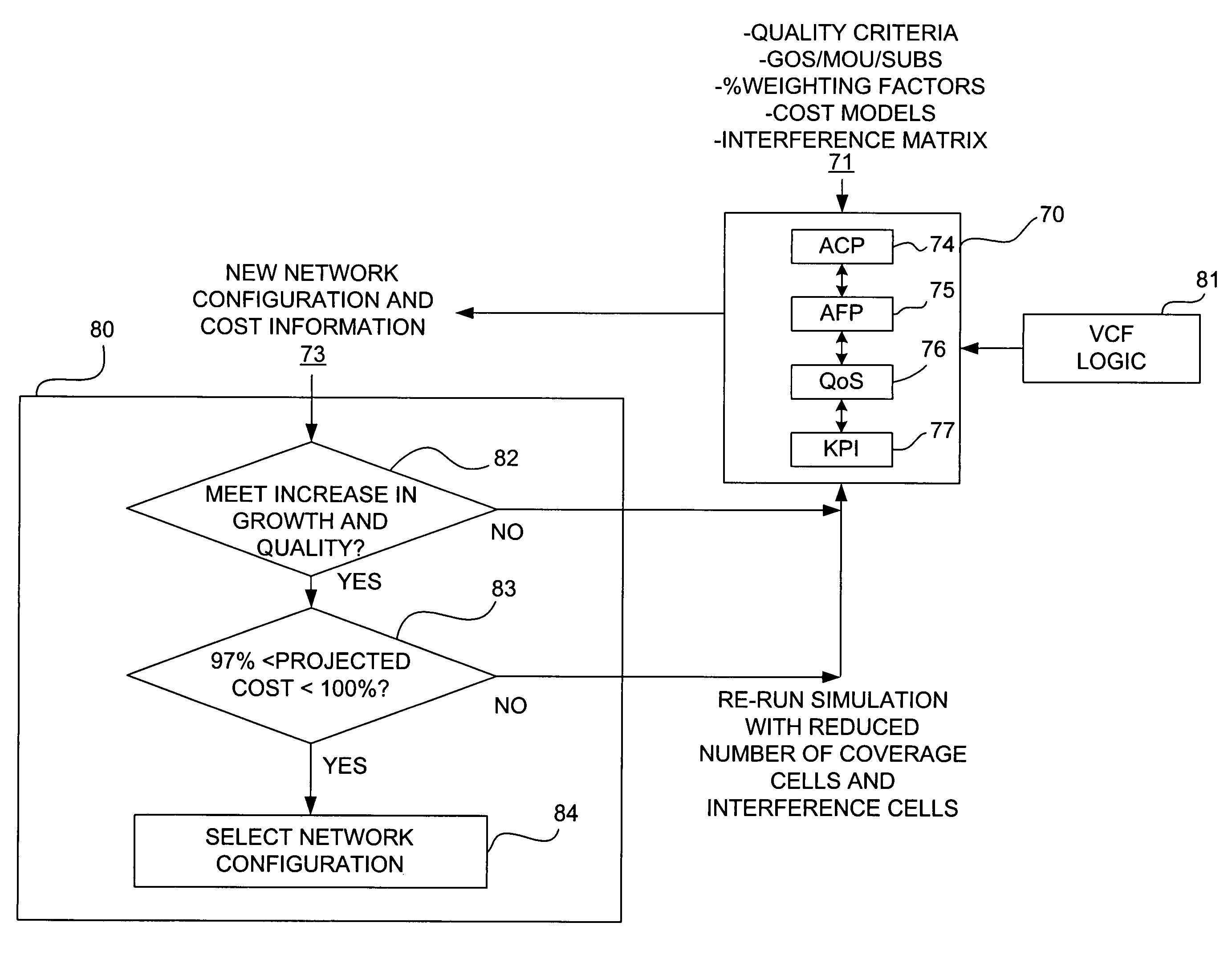

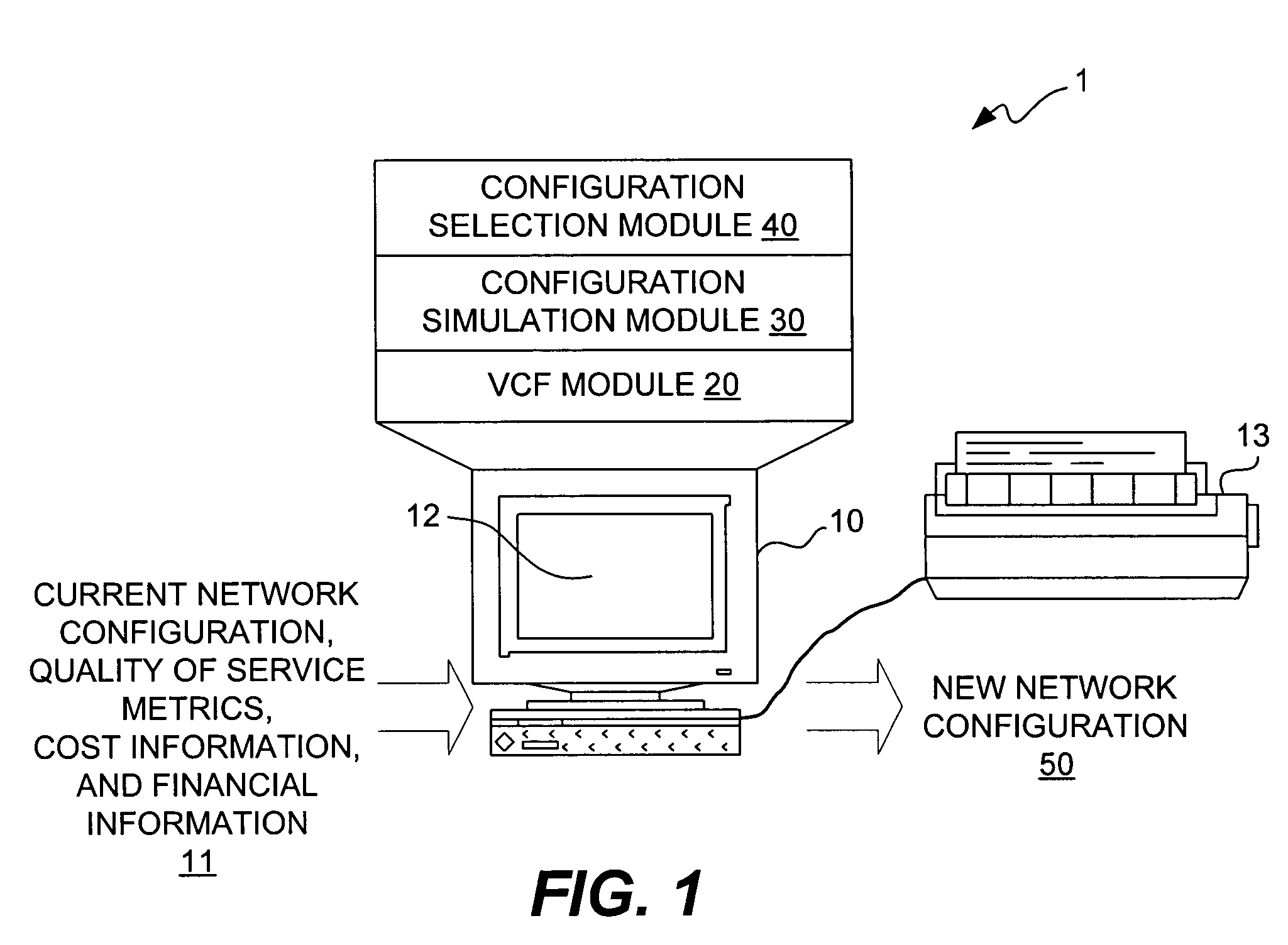

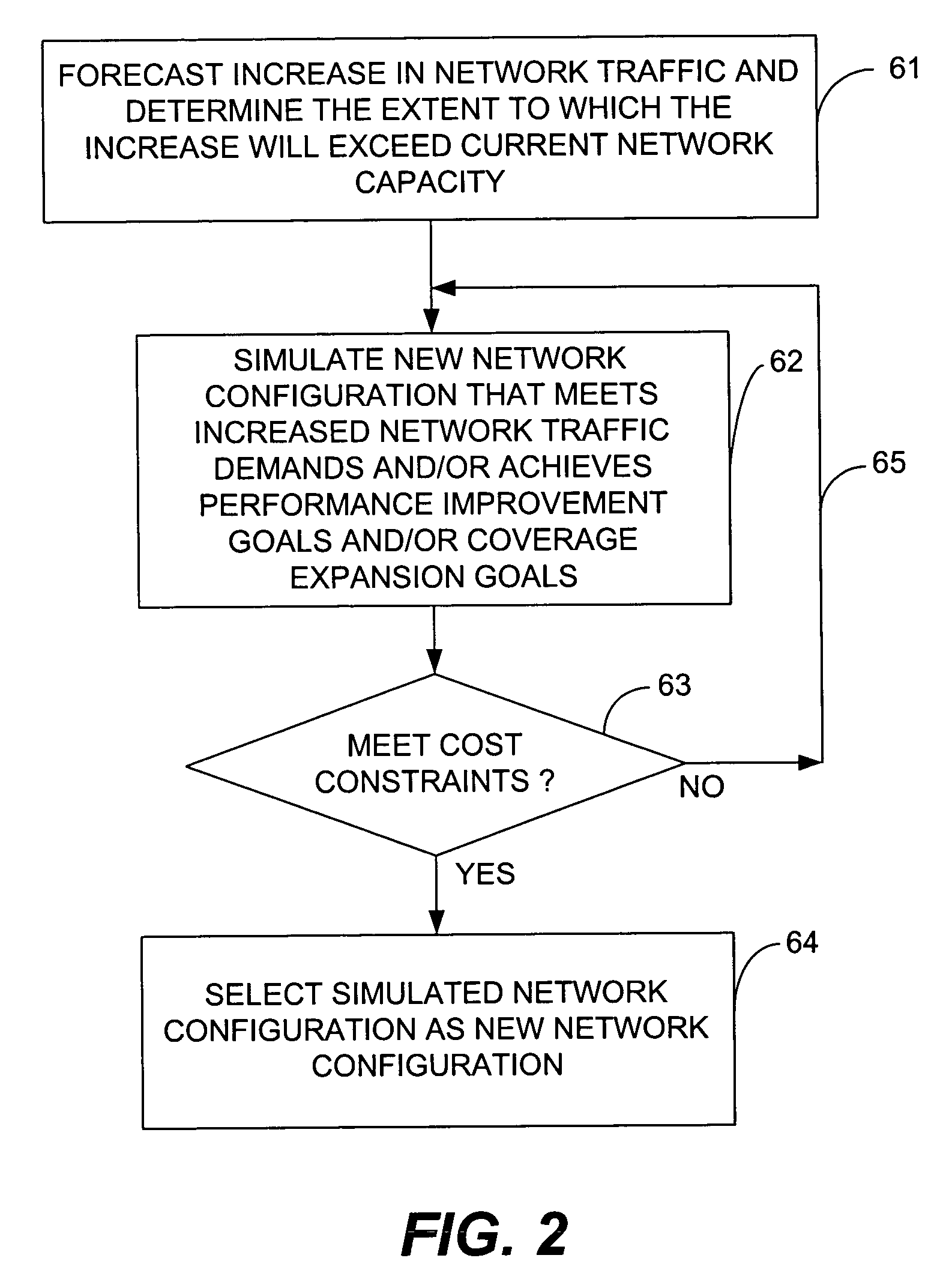

Method and apparatus for automatically determining the manner in which to allocate available capital to achieve a desired level of network quality performance

InactiveUS20060083170A1Multiplex system selection arrangementsError preventionInternet trafficQuality performance

A method and apparatus for simulating a modification to or expansion of a communications network and for determining whether the simulated modified or expanded network meets cost criteria. First logic forecasts an increase in network traffic. Second logic simulates a modification to or expansion of the network based on the forecasted increase in network traffic and / or based on performance improvement criteria and / or based on coverage expansion criteria. Third logic determines whether the simulated modified or expanded network meets cost criteria.

Owner:CINGULAR WIRELESS II LLC

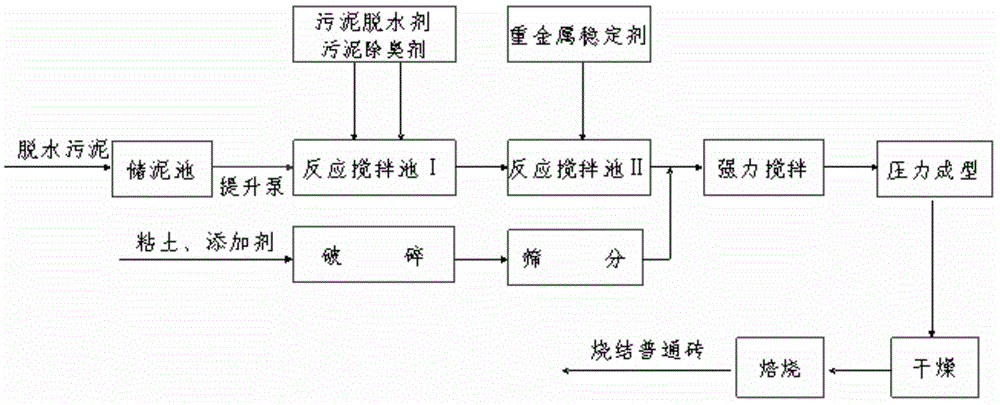

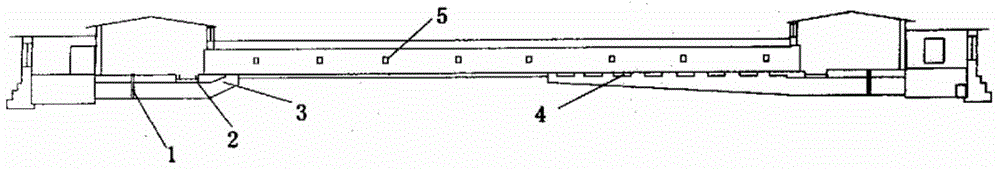

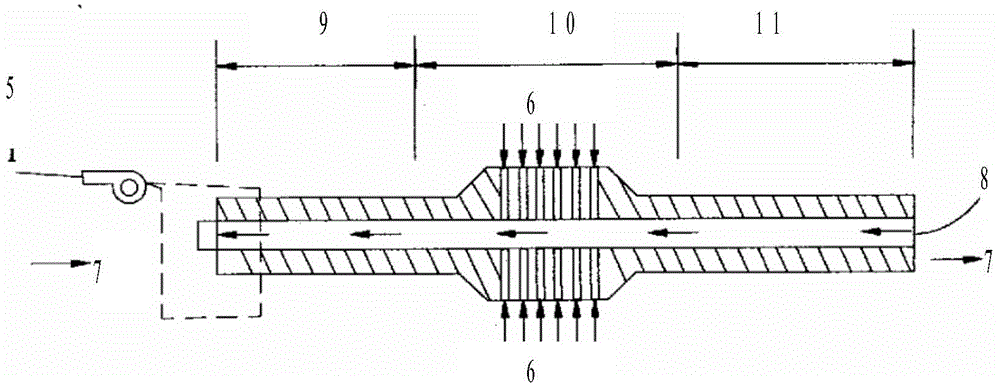

Novel sludge brick making technique

ActiveCN104649650AShorten the preprocessing processImprove utilization rateCeramic materials productionClaywaresTunnel kilnBrick

The invention discloses a novel sludge brick making technique which comprises the following steps that municipal sludge is subjected to dewatering conditioning and desodoration treatment; heavy metal is controlled; treated sludge pug, clay and an additive are blended to form a material; the material is fed into a brute force extrusion mixer to be mixed fully, and is ground and homogenized by brute force roll grinding and aged; the aged brick making pug is fed into an adobe making workshop to be subjected to compression moulding for adobe making; the moulded adobes are fed into a drying room to be dried; and the dried adobes are placed in a back stage of a tunnel kiln to be sintered. According to the technique, the sludge from a sewage plant is mixed with the raw clay directly, so that energy resources consumed due to sludge drying are saved; targeted improvement measures are put forwards to solve the problems of sludge dewatering, odor control, heavy metal stabilization, etc.; the quality performance and the strength grade of sludge bricks are improved by methods of optimizing a sludge blending ratio and feeding the additive, etc.; the reduction, harmlessness, reclamation and industrialization treatment goals on the municipal sludge are realized; and the sludge bricks, serving as a product, have objective economic benefits.

Owner:XIAN LISHENG SLUDGE TREATMENT +1

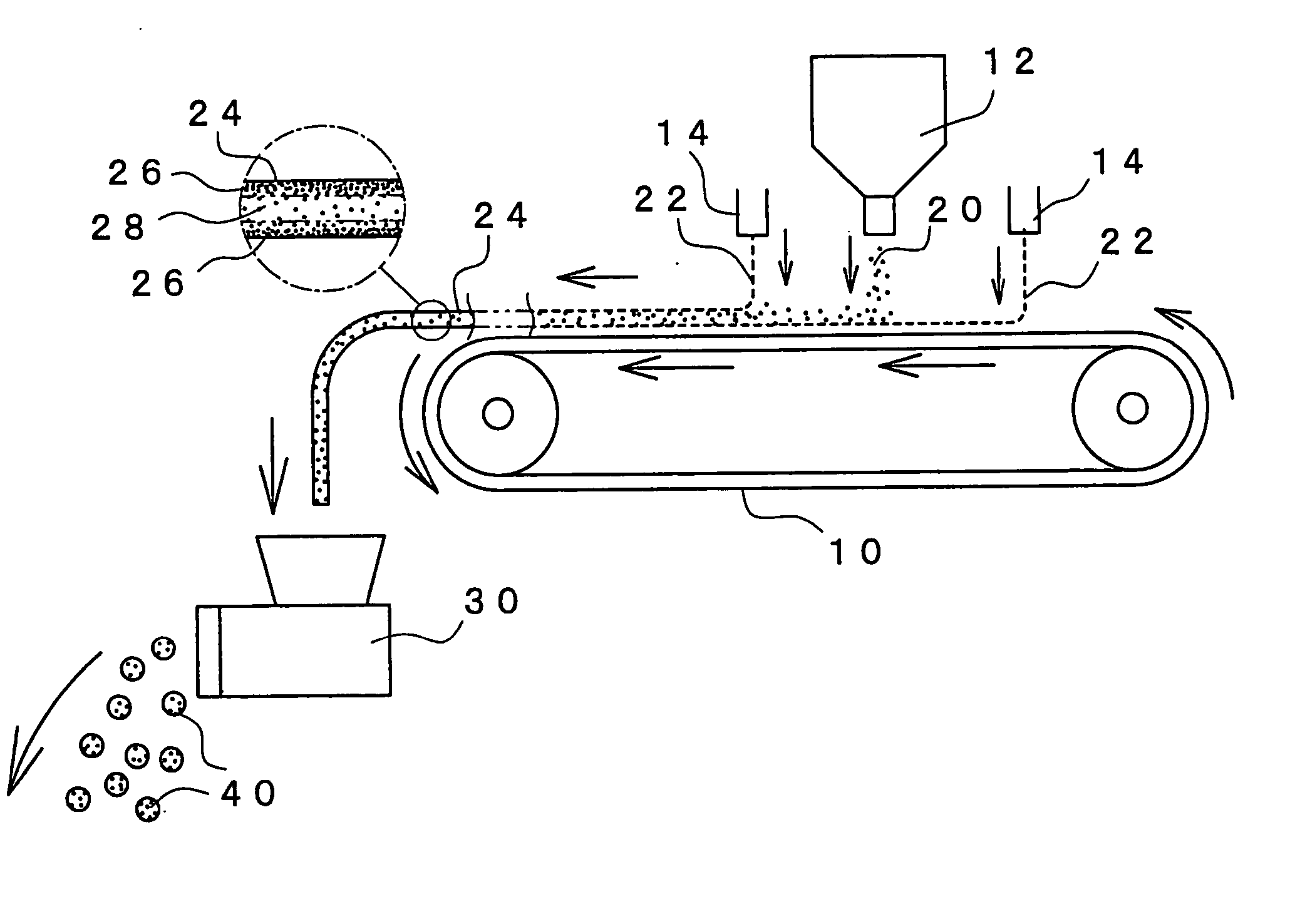

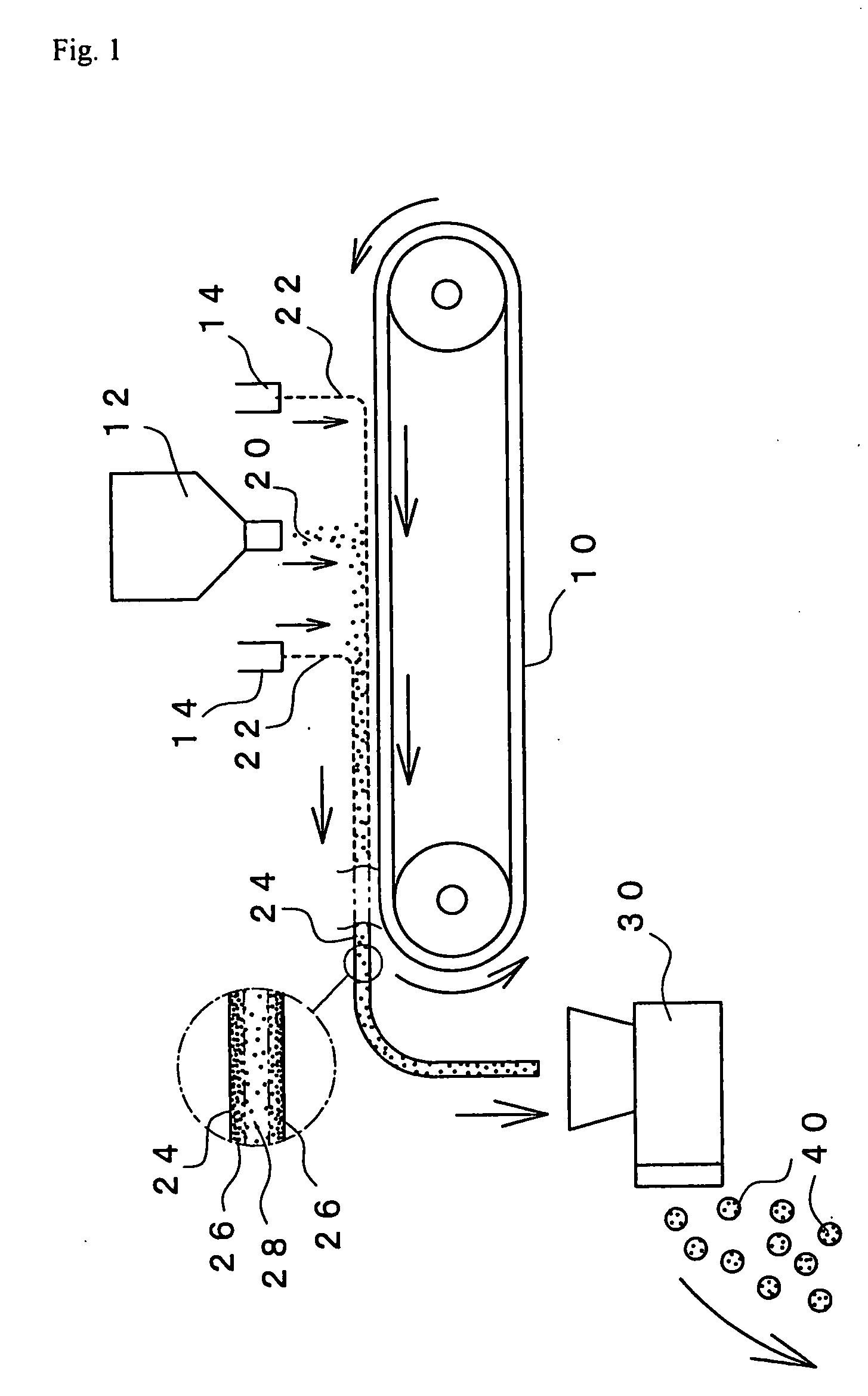

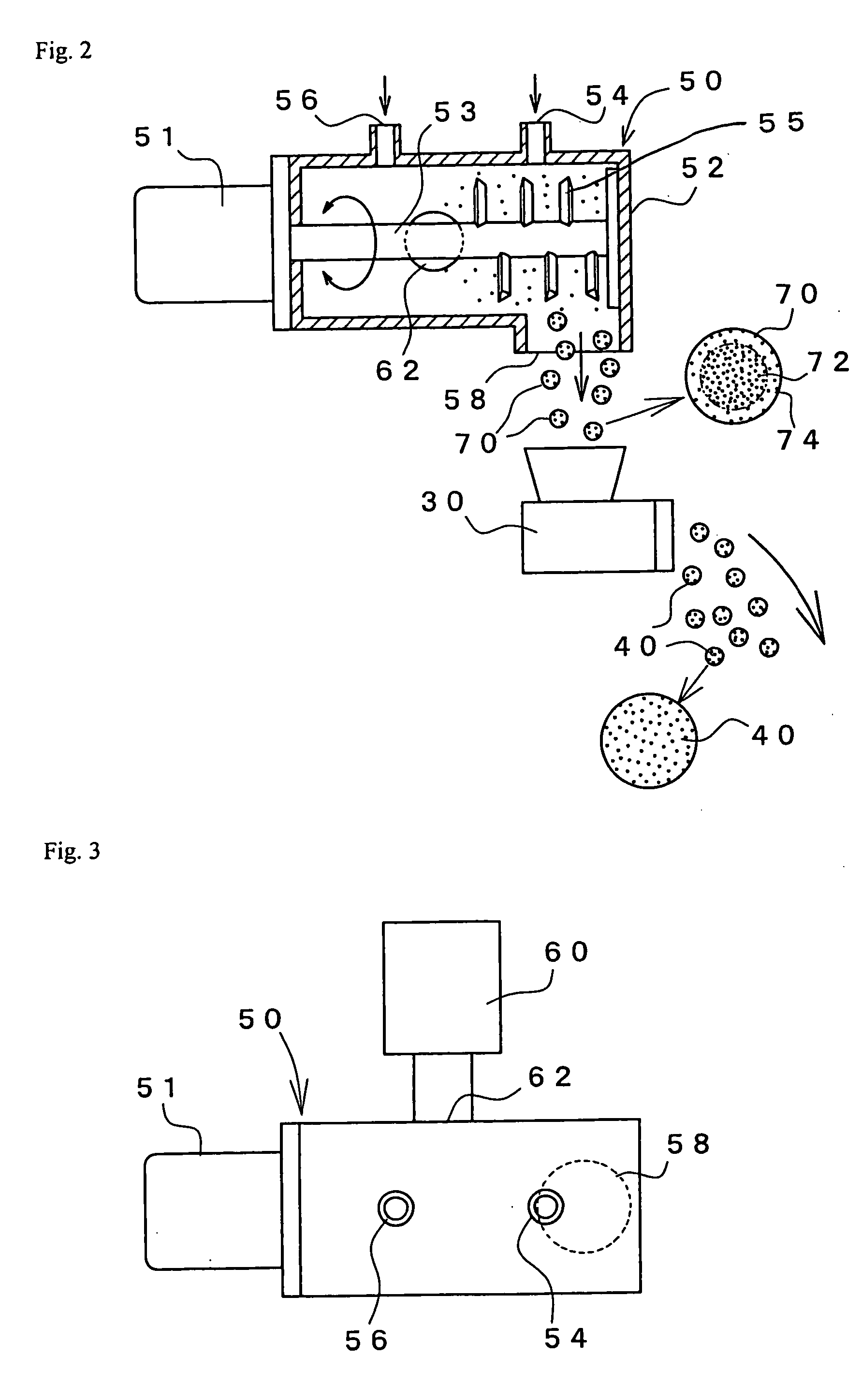

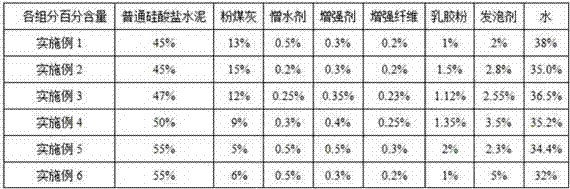

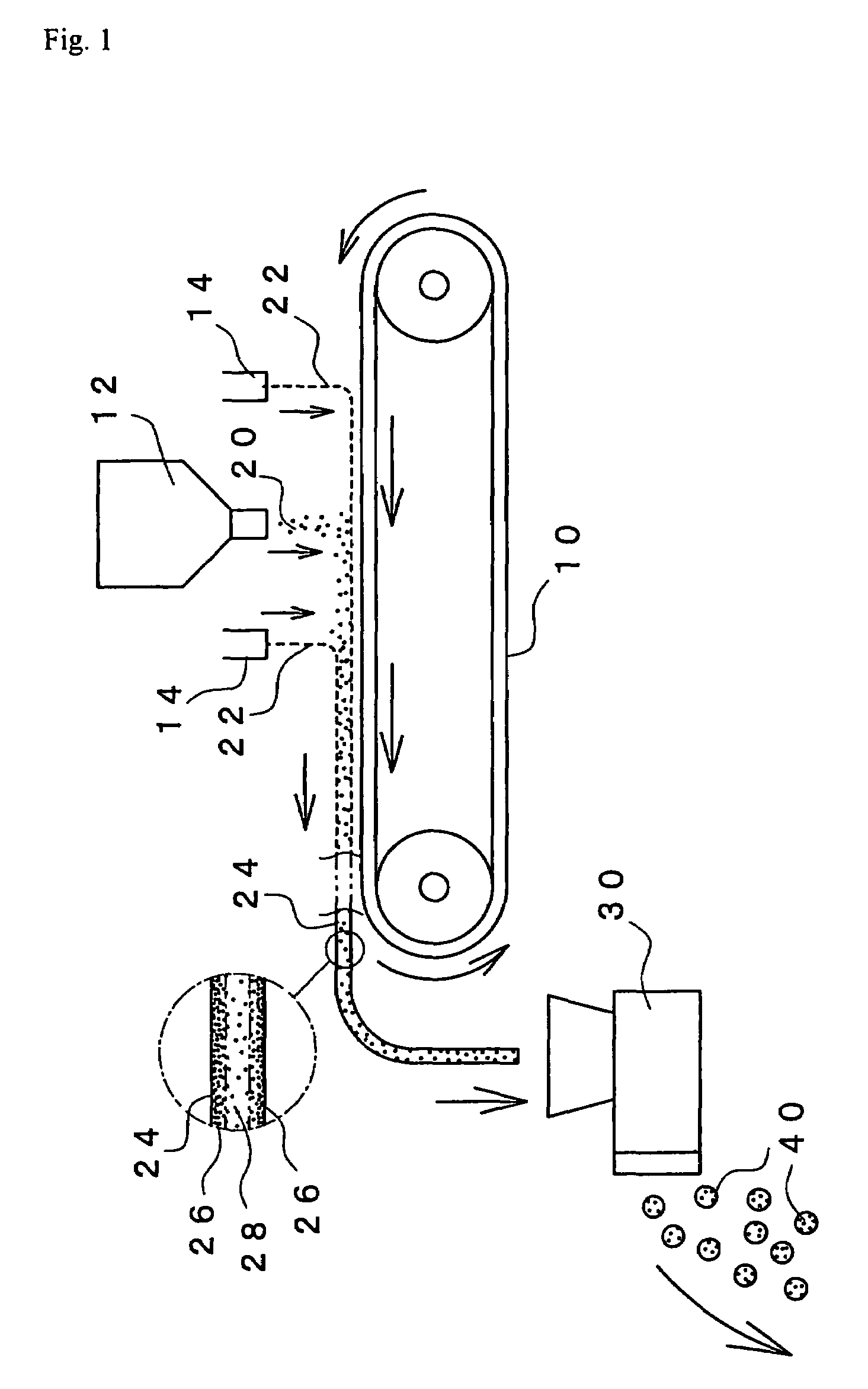

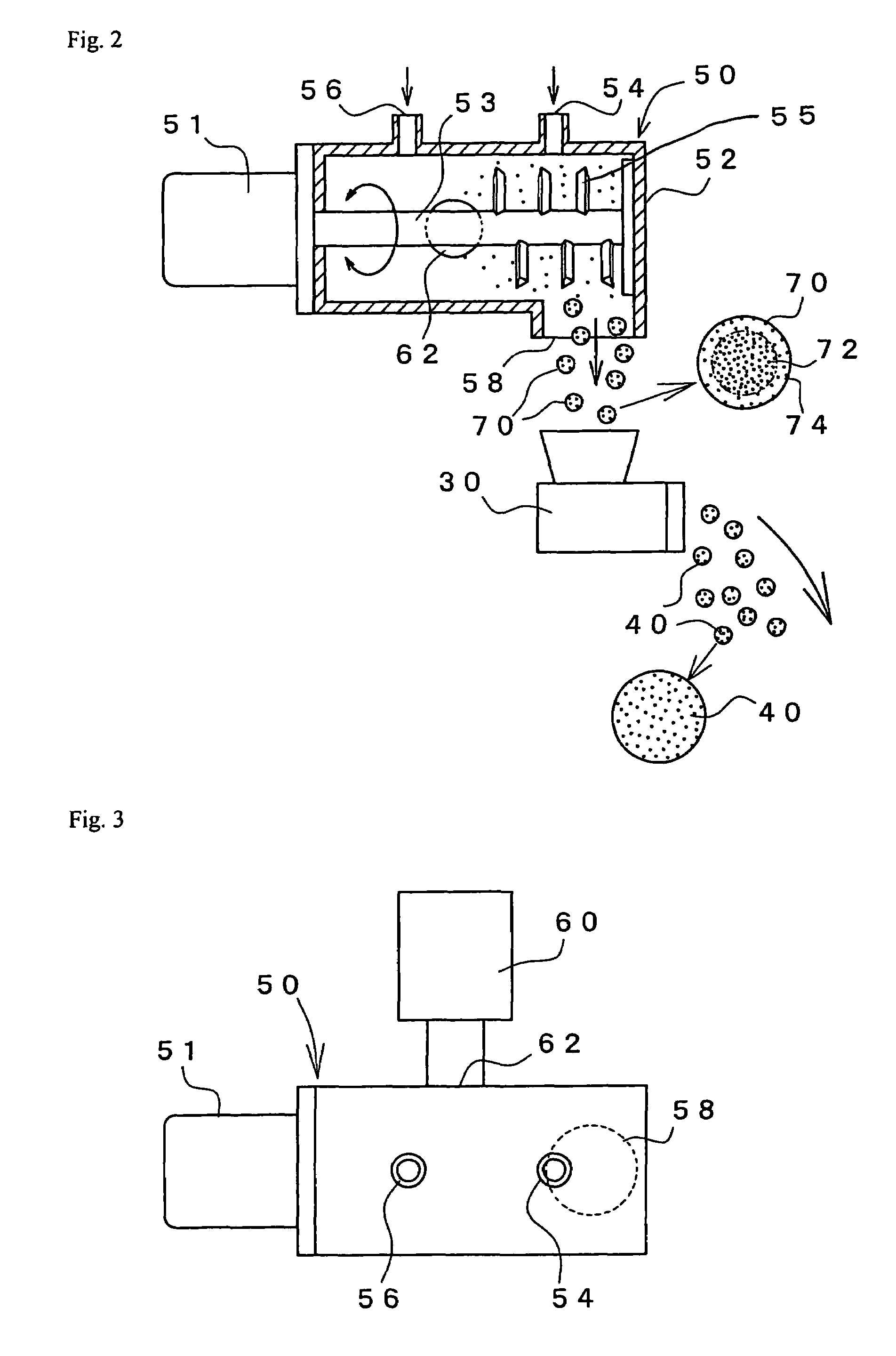

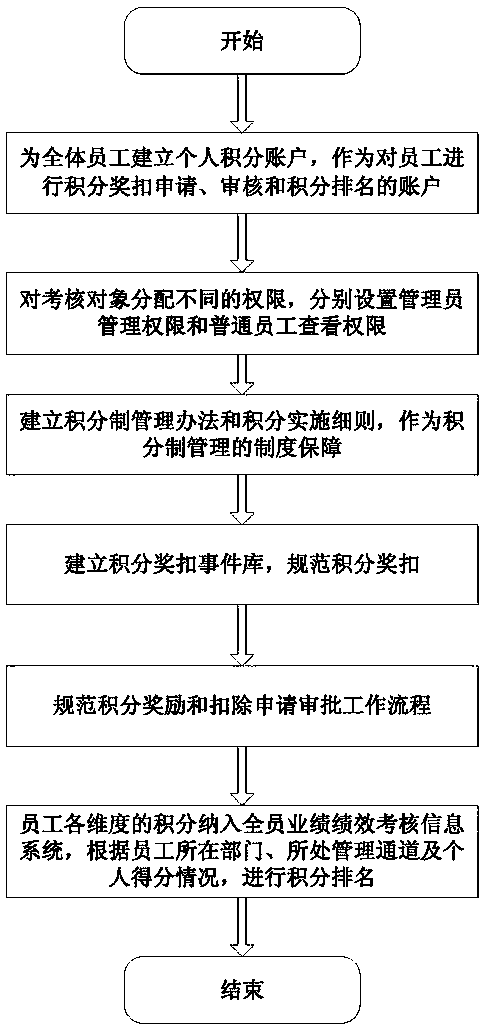

Process for production of water-absorbing material

ActiveUS20040249120A1Strong tackinessStrong adhesionOther chemical processesSolid waste disposalParticulatesMicroparticle

An object of the present invention is to make it possible, in order to form the fine powder of the water-absorbent resin into a water-absorbing material having particle diameters favorable for practical use, that a water-absorbing material which has high agglomeration strength and is excellent in the quality performances is obtained at a low cost with good efficiency without causing the problems of the adhesion to such as treatment apparatus. As a means of achieving this object, a process according to the present invention for production of a water-absorbing material is a process for production of a water-absorbing material from a fine powder of a water-absorbent resin wherein the water-absorbing material is a particulate water-absorbing material having particle diameters larger than the fine powder, with the process comprising: a step (a) of adding an aqueous liquid to the fine powder of the water-absorbent resin with such as a high-speed stirring type continuous extrusion mixer 50 so that the overall average water content will be in the range of 20 to 60 weight %, whereby particles of the fine powder are agglomerated to thus obtain a particulate hydrous material 70 of the water-absorbent resin; and a step (b) of applying a mechanical compression force to the particulate hydrous material 70 and, at the same time, knead-pulverizing it, with such as a meat chopper apparatus 30, thereby obtaining particulate agglomerates 40 of the water-absorbing material.

Owner:NIPPON SHOKUBAI CO LTD

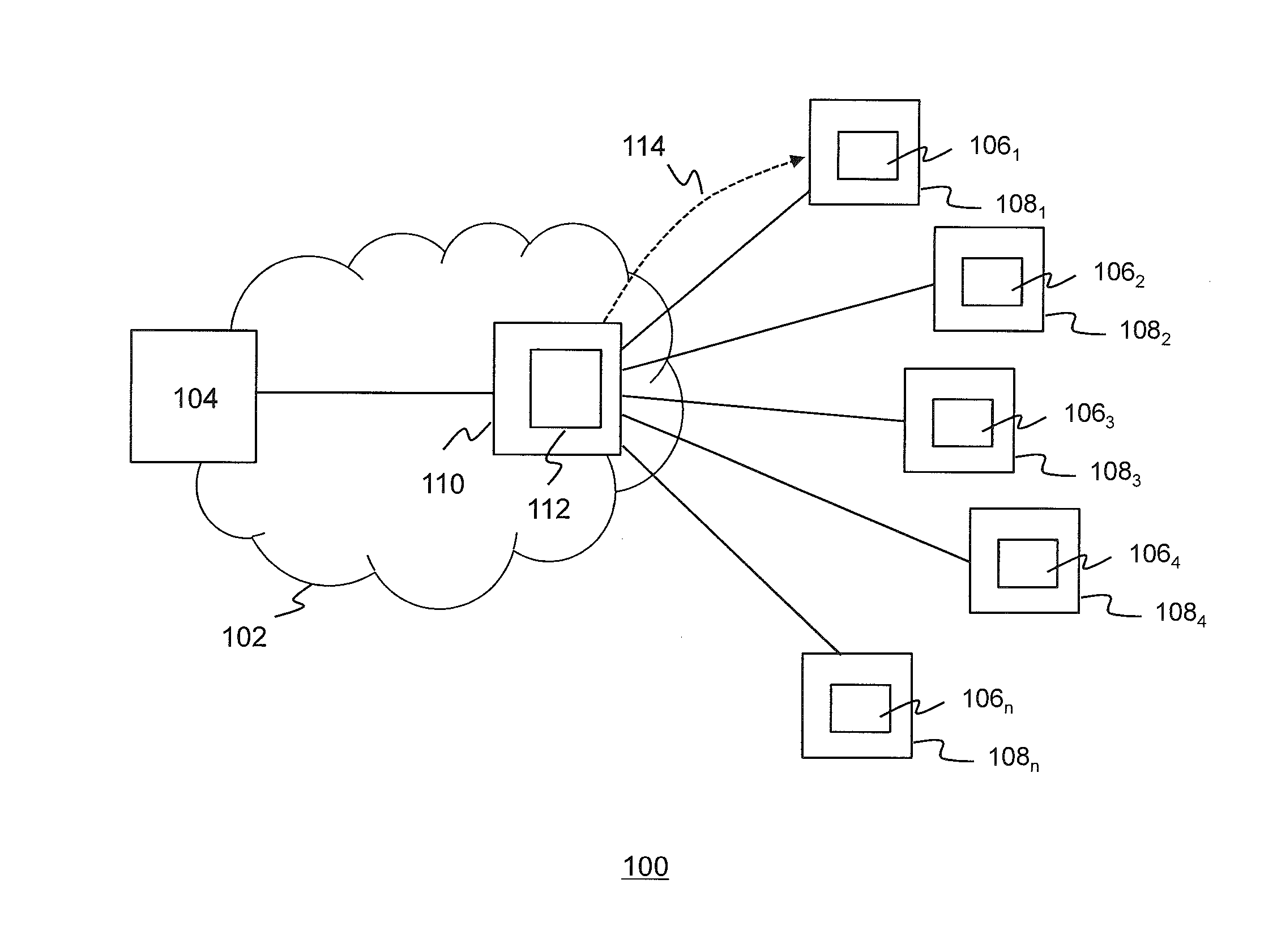

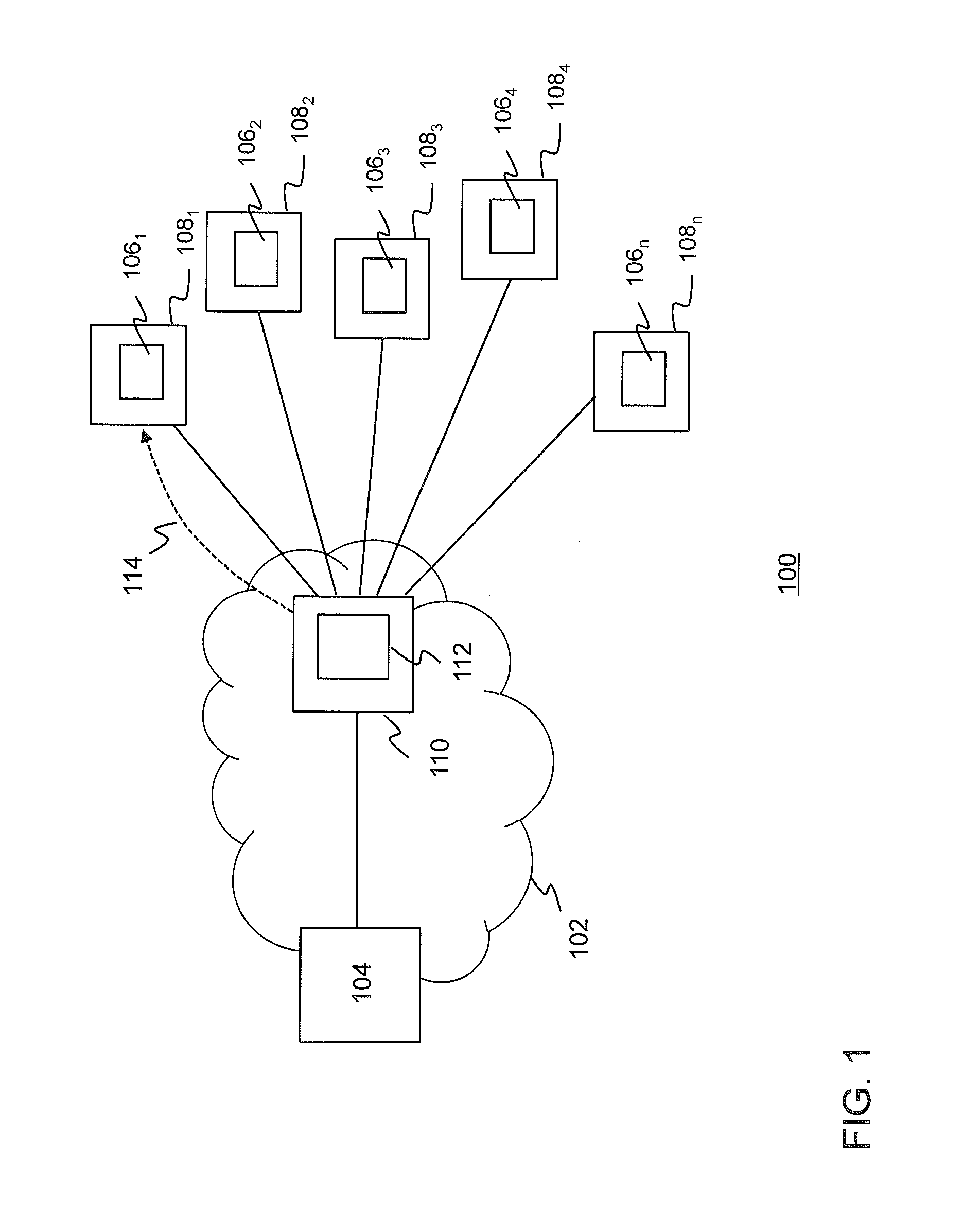

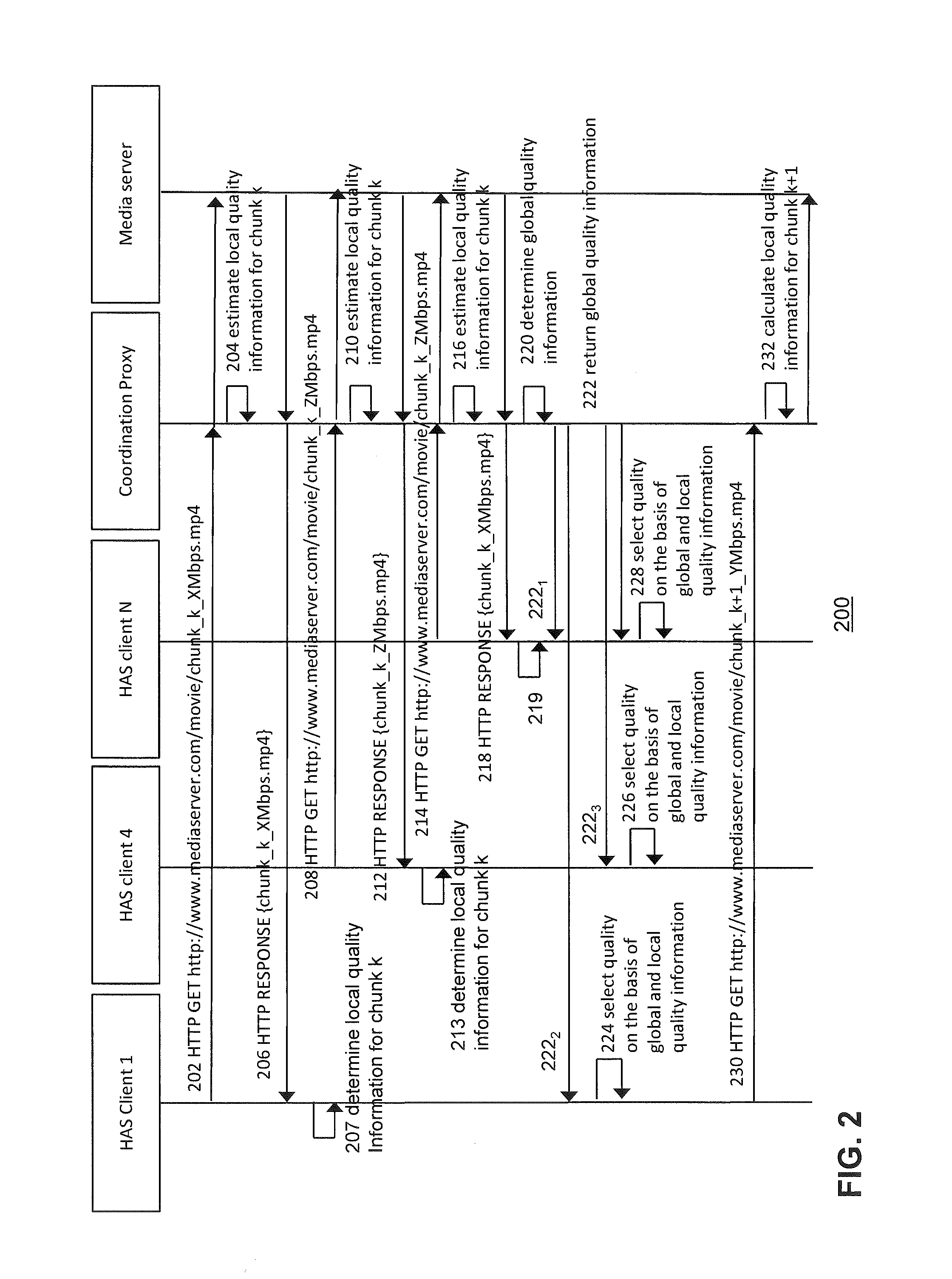

Fair Adaptive Streaming

ActiveUS20160248835A1Minimize the differenceQuality information is simpleTransmissionQuality levelQuality performance

A method and system for enabling a plurality of adaptive streaming client devices to share network resources includes a network node monitoring chunk request messages of client devices configured to select a quality level of a chunk from a plurality of quality levels and to request a media server for transmission of a chunk of the selected quality level. The quality level in a monitored chunk request message of a client device is used to estimate local quality information associated with the quality performance of the client device. Global quality information, determined based on the estimated local quality information associated with the client devices, and being indicative of the global quality performance of the client devices, is sent to the client devices. The client devices are configured for selecting a quality level for a subsequent chunk based on the global quality information and based on local quality information determined by the client during or after rendering media data of a requested chunk such that deviations between the global quality information and the local quality information is minimized.

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW) +2

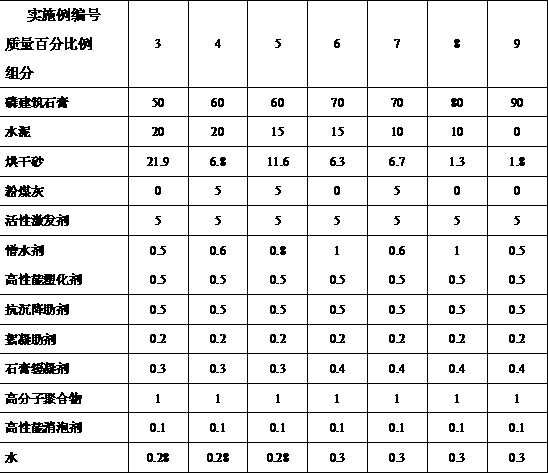

Preparation method of phosphorus building gypsum-based water-resisting and self-leveling mortar

The invention discloses a preparation method of phosphorus building gypsum-based water-resisting and self-leveling mortar. The anti-cracking mortar is prepared from the following components in percentage by mass: 50 to 90 percent of phosphorus building gypsum, 10 to 50 percent of baked sand, 0 to 20 percent of cement, 0 to 5 percent of fly ash, 0 to 15 percent of an active activator, 0 to 3 percent of a water repellent, 0.1 to 1 percent of a high-performance plasticizer, 0 to 0.2 percent of an anti-settling agent, 0 to 0.2 percent of a flocculating agent, 0.01 to 0.4 percent of a calcium sulfate retarder, 0 to 3 percent of a high-molecular polymer and 0.05 to 0.3 percent of a high-performance defoaming agent. According to the preparation method disclosed by the invention, phosphogypsum which is an industrial waste is used as a main raw material, so that the prepared self-leveling mortar is high in quality performance and high in water resistance, can be applied to a leveling project for indoor and outdoor grounds, is particularly applicable to a floor heating project and a wood floor base course leveling project, is high in coagulation and hardening speed, high in volume stability,high in temperature change resistance, and low in cost, and does not crack, and product properties meet relevant standard requirements; a production process is simple and low in energy consumption; compared with other self-leveling mortar products, the phosphorus building gypsum-based water-resisting and self-leveling mortar is higher in market competitiveness and high in practicability.

Owner:四川华邦保和涂料有限公司

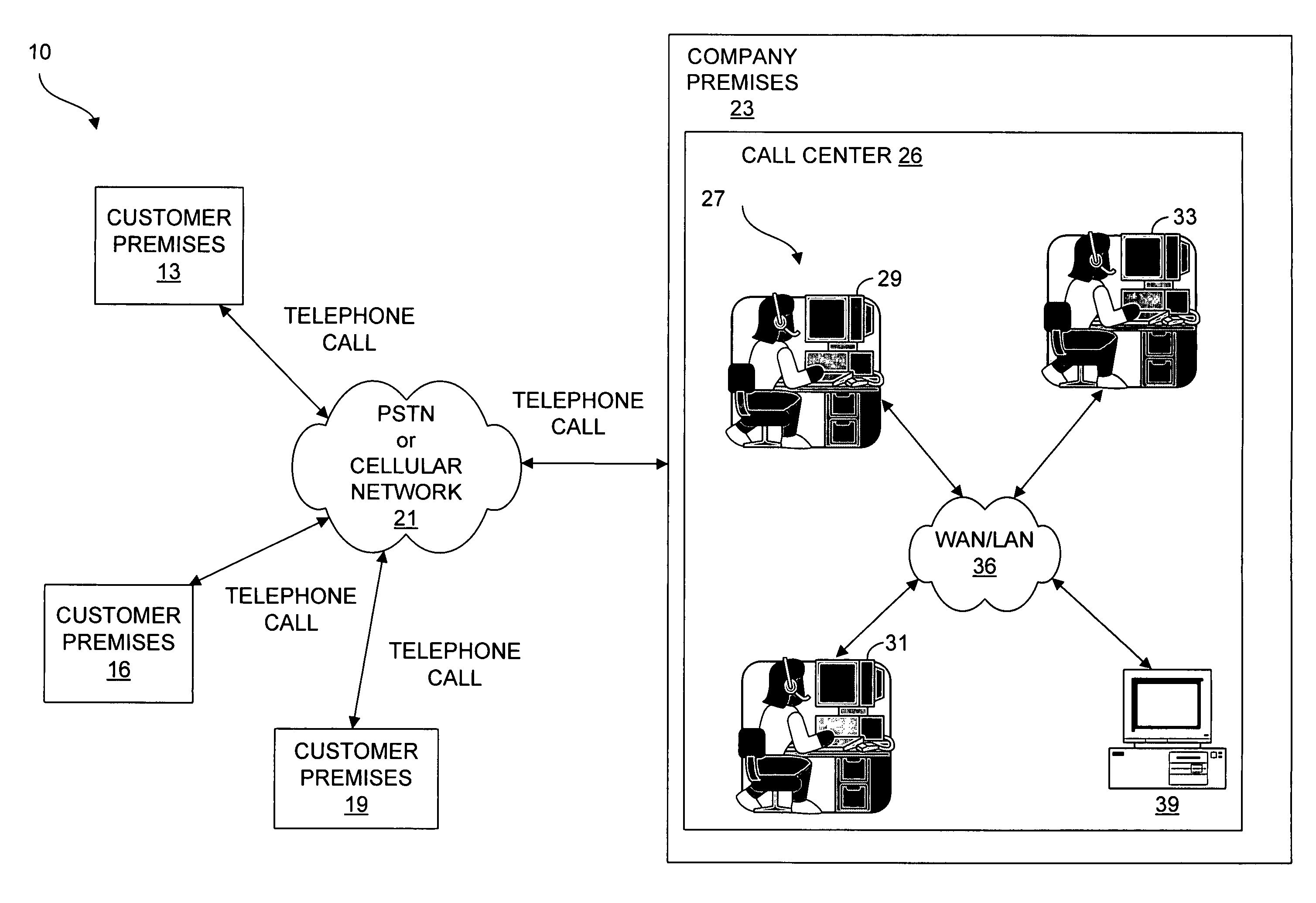

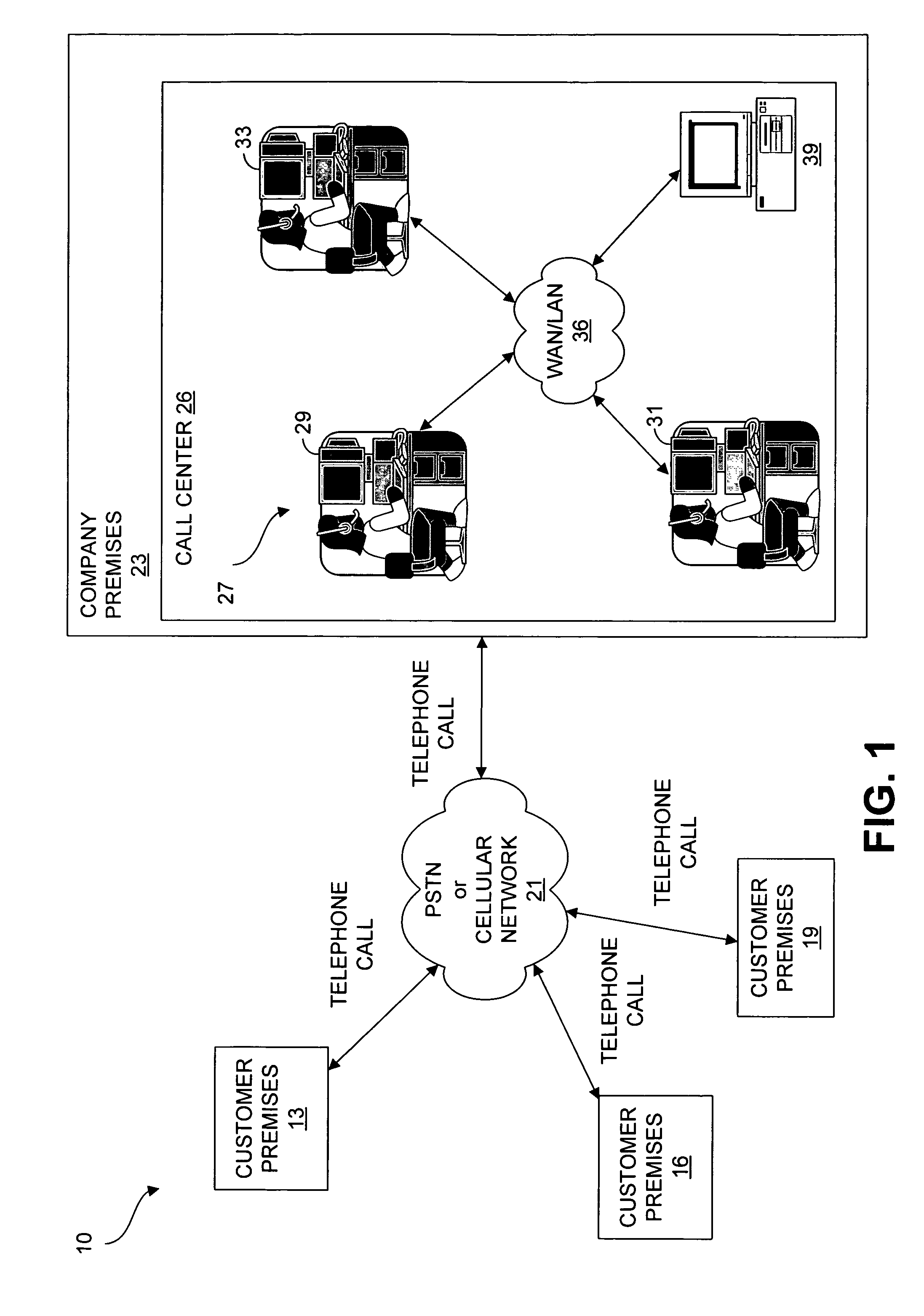

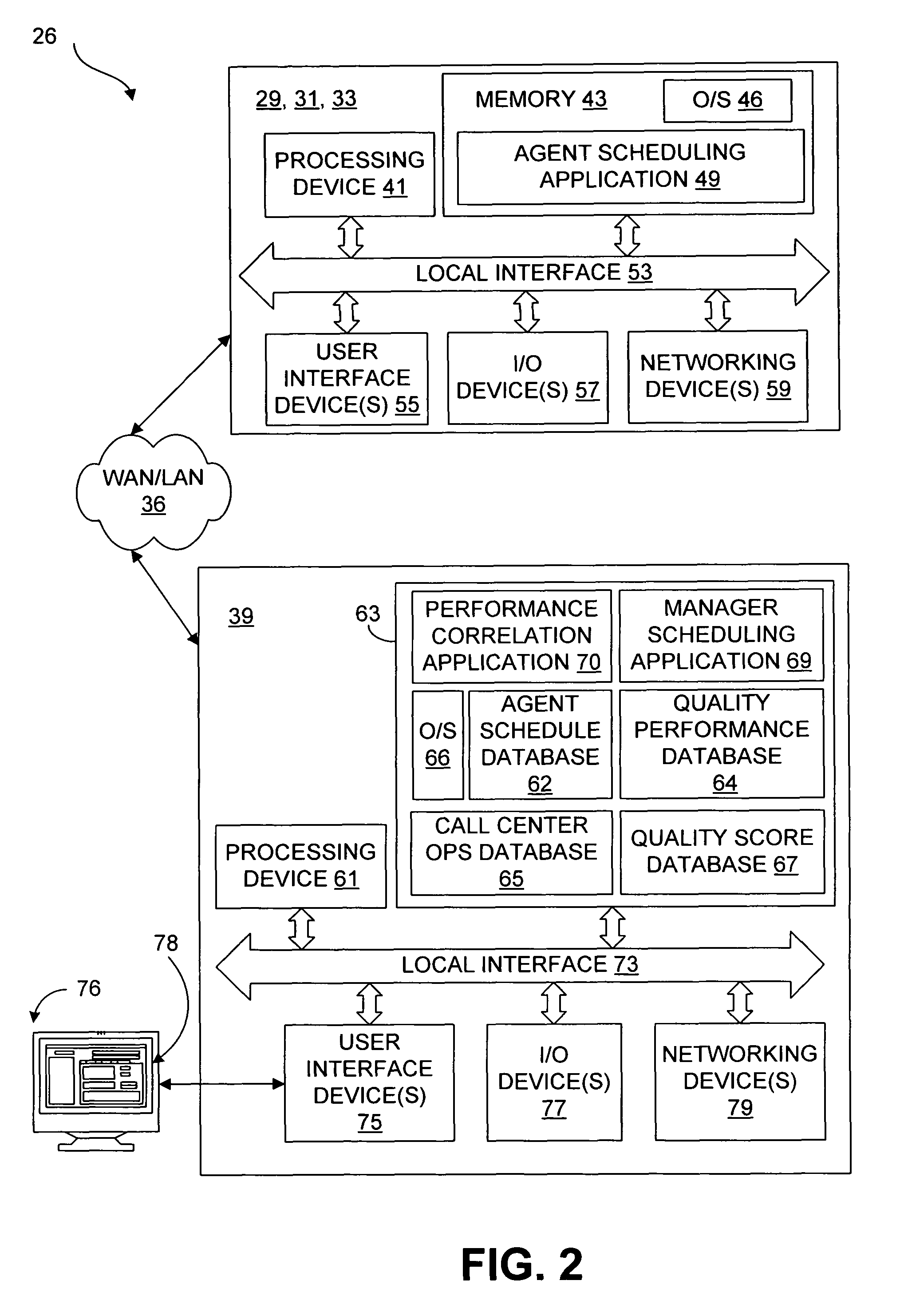

Systems and methods for scheduling call center agents using quality data and correlation-based discovery

Systems and methods for visualization of call center performance are provided. An exemplary method includes the steps of: obtaining quality performance of agents data that includes information on the quality of service and quality characteristics of the agent, obtaining call center operations data that includes information on statistics and details of a call center, correlating the quality performance of agents data and the call center operations data, identifying correlation-based discovery, and optimizing call center performance based on the correlation-based discovery.

Owner:VERINT AMERICAS

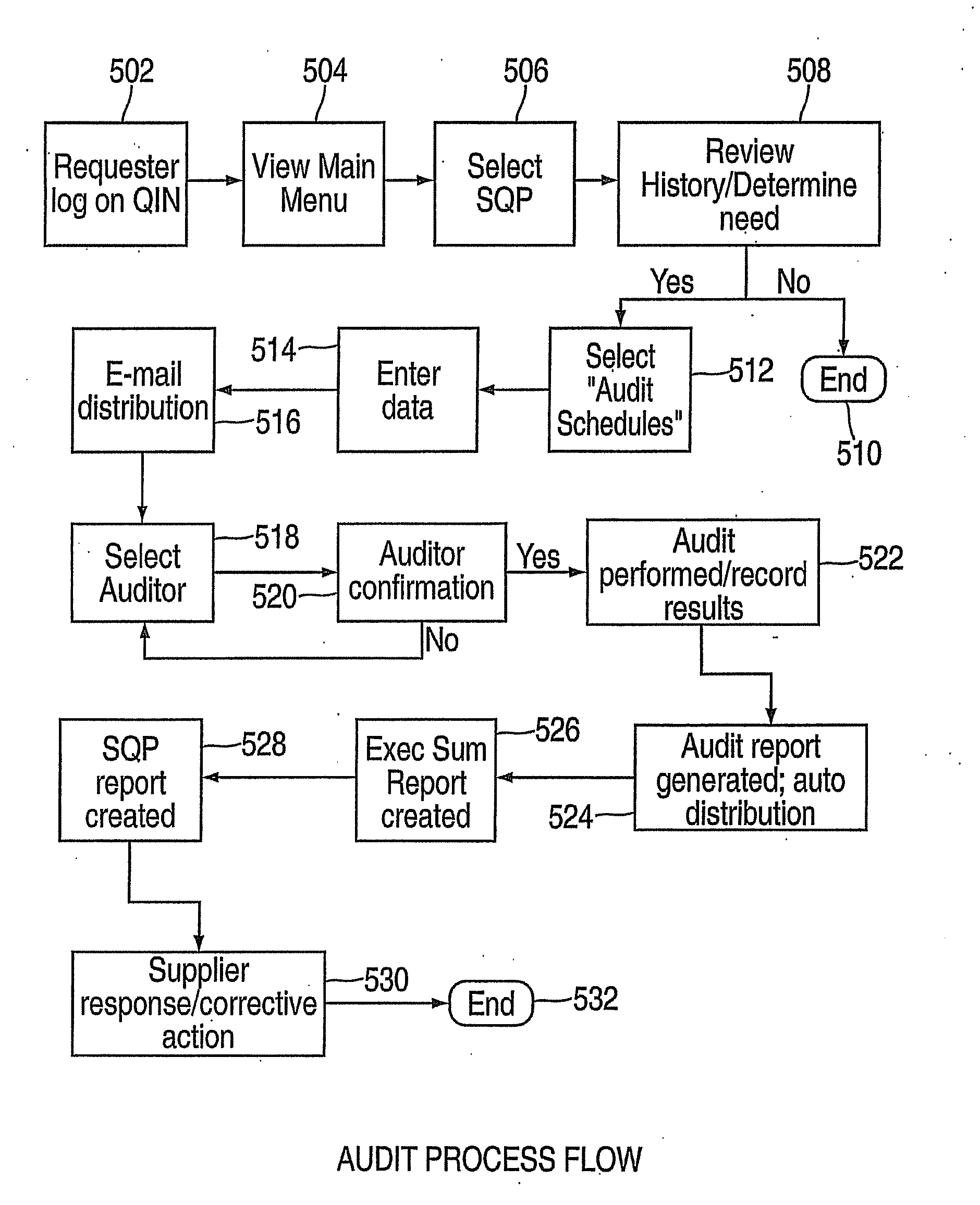

Method and system for gathering and disseminating quality performance and audit activity data in an extended enterprise environment

Method, system, and storage medium for facilitating supplier auditing functions in a communications network environment. The method includes receiving a request from a user system associated with an enterprise system to initiate an activity. The activity includes scheduling an audit for performing an initial or ongoing qualification of a supplier enterprise. The method also includes retrieving data from at least one database by the enterprise system. The data corresponds to the activity selected. The method further includes transmitting the data to the user system. The enterprise system includes a quality information network application for executing activity options.

Owner:INT BUSINESS MASCH CORP

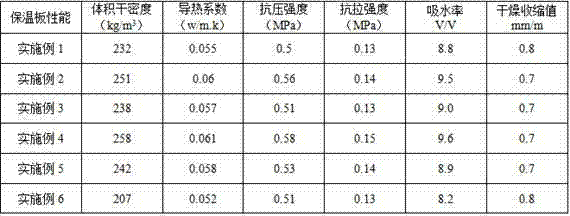

Cement-based composite foam insulation board and preparation method thereof

InactiveCN103755281AWon't happenReduce manufacturing costSolid waste managementCeramicwareFoaming agentQuality performance

The invention discloses a cement-based composite foam insulation board and a preparation method thereof. The cement-based composite foam insulation board is prepared from the following raw materials by weight percent: 45-55% of ordinary portland cement, 5-15% of fly ash, 0.2-0.5% of water repellent, 0.3-0.5% of enhancer, 0.2-0.3% of reinforced fiber, 1-2% of latex powder, 2-5% of foaming agent and 32-38% of water. The method comprises the following steps: firstly, adding water to the ordinary portland cement, the fly ash, the water repellent, the strength agent, the latex powder and the reinforced fiber and stirring for 3-5 minutes according to the weight percent; then adding the foaming agent and stirring for 5-10 seconds; rapidly injecting into a mold to foam; demolding after solidifying for 12 hours; cutting and packaging to form the product after maintaining. The product prepared by the method is low in manufacturing cost, and simple in method, and the quality performance is higher than relevant national standards.

Owner:JIANGSU ANSHENG TECH

Process for production of water-absorbing material

An object of the present invention is to make it possible, in order to form the fine powder of the water-absorbent resin into a water-absorbing material having particle diameters favorable for practical use, that a water-absorbing material which has high agglomeration strength and is excellent in the quality performances is obtained at a low cost with good efficiency without causing the problems of the adhesion to such as treatment apparatus. As a means of achieving this object, a process according to the present invention for production of a water-absorbing material is a process for production of a water-absorbing material from a fine powder of a water-absorbent resin wherein the water-absorbing material is a particulate water-absorbing material having particle diameters larger than the fine powder, with the process comprising: a step (a) of adding an aqueous liquid to the fine powder of the water-absorbent resin with such as a high-speed stirring type continuous extrusion mixer 50 so that the overall average water content will be in the range of 20 to 60 weight %, whereby particles of the fine powder are agglomerated to thus obtain a particulate hydrous material 70 of the water-absorbent resin; and a step (b) of applying a mechanical compression force to the particulate hydrous material 70 and, at the same time, knead-pulverizing it, with such as a meat chopper apparatus 30, thereby obtaining particulate agglomerates 40 of the water-absorbing material.

Owner:NIPPON SHOKUBAI CO LTD

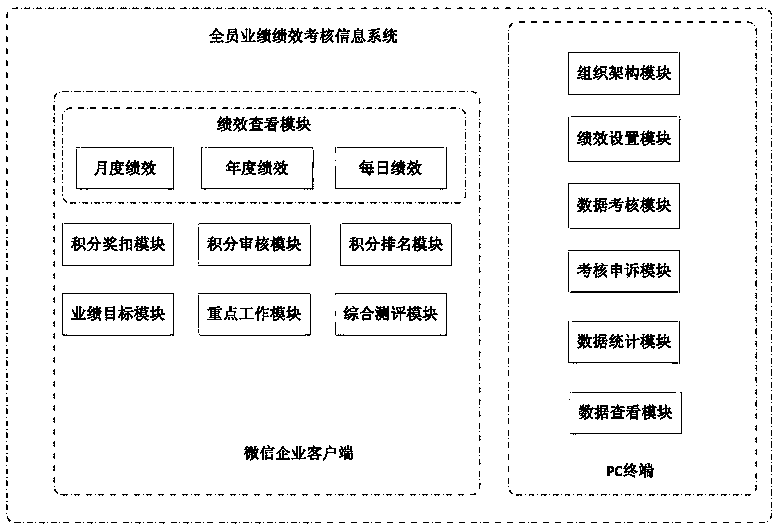

Method for establishing whole-staff performance assessment information system and system

InactiveCN108304987AIncrease motivationImprove targetingOffice automationResourcesSystems managementGoal decomposition

The invention relates to the technical field of staff performance assessment, and relates to a method for establishing a whole-staff performance assessment information system and an assessment information system. The method comprises the steps that first, the whole staff establish personal accumulated point accounts; second, different authorities are distributed to assessment objects; third, an accumulated point system management method and detailed rules for accumulated point implementation are established to serve as a system guarantee for accumulated system management; fourth, an accumulated point rewarding and deducting event base is established so as to standardize accumulated point rewarding and deducting; fifth, the accumulated point rewarding and deducting application and approvalworking process is standardized; and sixth, the accumulated points of the staff in each dimension are taken into the whole-staff performance assessment information system. According to the invention,quantitative assessment is performed on the behavioral and comprehensive quality performance of the staff in the form of point rewarding and deducting through accumulated point system management so asto arouse the enthusiasm of the staff in all directions; the top-down performance assessment system is established, thereby realizing progressive linkage assessment, and achieving in-place goal decomposition, in-place responsibility appointment and in-place assessment and stimulation; and hierarchical and classified management is adopted to enhance the pertinence and effectiveness of the assessment.

Owner:新疆华电喀什热电有限责任公司

Gas nitriding treatment method of 11Cr17 stainless steel slip sheet

ActiveCN102517541ASimple processReduce manufacturing costSolid state diffusion coatingSlip sheetQuality performance

The invention relates to a gas nitriding treatment method of 11Cr17 stainless steel slip sheet, belonging to the technical field of stainless steel treatment. The invention aims at solving the problems of large erosion on the equipment and products and large environmental pollution of the nitriding method of 11Cr17 stainless steel slip sheet in the prior art. The method of the invention comprisesthe steps of: degreasing and cleaning the slip sheet, performing a passive film removal treatment at 300-450 DEG C to remove the passive film on the surface of the slip sheet; continuously filling ammonia, performing a first stage nitriding treatment at 450-530 DEG C, and performing a second stage nitriding treatment at 530-580 DEG C, and cooling to obtain a nitrided 11Cr17 stainless steel slip sheet. The method of the invention has the advantages of simple technique process, low production cost, small environmental pollution, small erosion on the nitriding equipment and capability of prolonging the service life of the equipment; besides, the obtained product has good quality performance and high erosion resistance.

Owner:浙江百达精工股份有限公司

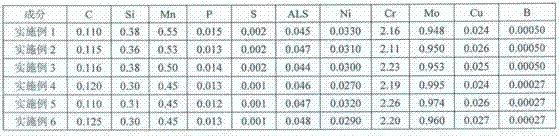

12Cr2Mo1R steel plate for ultra-thick hydrogen-contacting equipment and production method thereof

The invention discloses a 12Cr2Mo1R steel plate for ultra-thick hydrogen-contacting equipment and a production method thereof. The 12Cr2Mo1R steel plate comprises the following chemical components, by mass, 0.08-0.15% of C, 0.20-0.50% of Si, 0.30-0.60% of Mn, equal to or less than 0.018% of P, equal to or less than 0.005% of S, equal to or less than 0.020-0.050% of AlS, 2.0-2.5% of Cr, 0.90-1.10%of Mo, and the balance Fe and residual elements. The production method comprises steps of converter smelting, LF refining, vacuum refining, casting, heating, rolling, controlled cooling, slow cooling, and heat processing. A whole production process from molten iron pretreatment to steel plate heat treatment is executed in strict accordance with above technology, so the object quality performance margin of products is large, wherein the yield margin is 40-80MPa, the tensile margin is 55-70MPa, and the elongation margin is 6-9%, thereby the impact performance is uniform and the margin is large.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

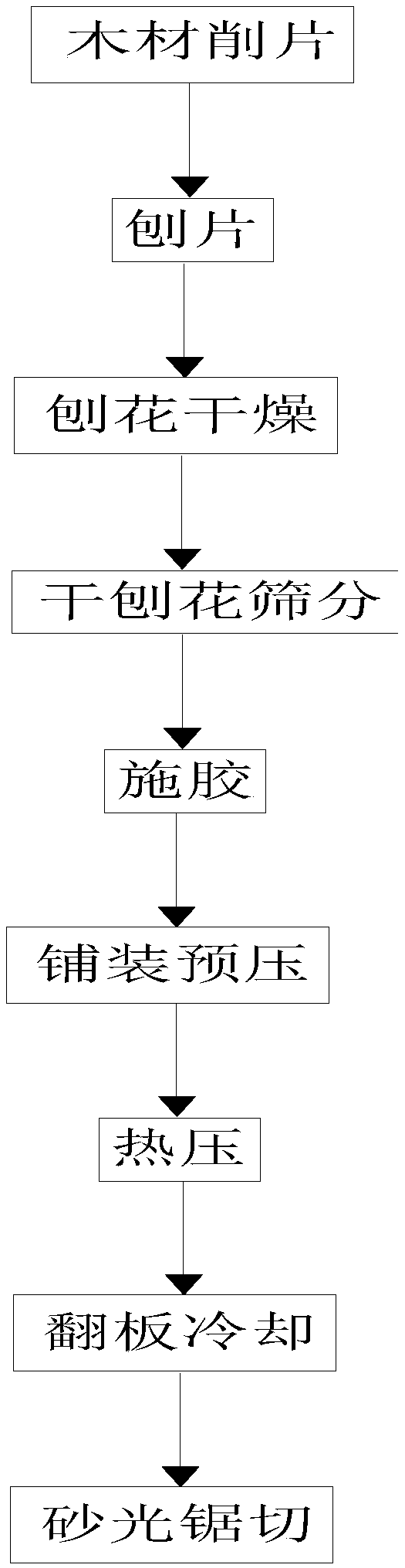

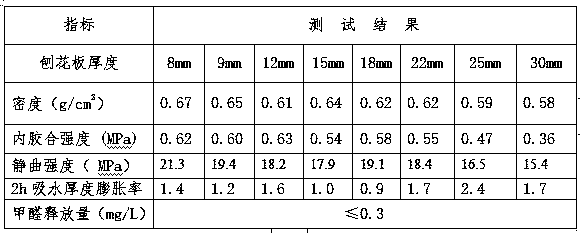

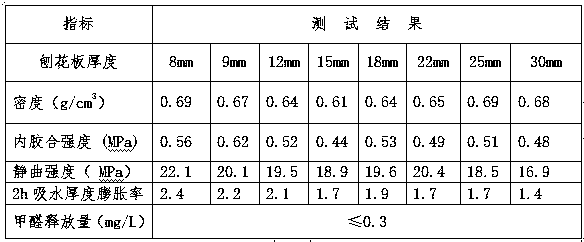

Ultra-strength shaving board manufacturing technology changing morphological structure of wood shavings

InactiveCN109624016ALess squeezeAvoid secondary damageFlat articlesDomestic articlesWood shavingsManufacturing technology

The invention relates to the technical field of artificial plate manufacturing, in particular to an ultra-strength shaving board manufacturing technology changing morphological structure of wood shavings. The ultra-strength shaving board manufacturing technology comprises the processes of wood chipping, flaking, drying, sieving, glue applying, paving and pre-pressing, hot-pressing, board reversingand cooling, sanding and saw cutting, testing and classifying, warehousing and packaging and the like. The quality performance of an ultra-strength shaving board produced and manufactured by the ultra-strength shaving board manufacturing technology is far better than the standards of an European oriented strand board in 'EN300: 2006-OSB' and 'T / CTWPDA03-2017 veneer shaving board', and the strength of the ultra-strength shaving board even reaches the strength level of a hipboard or plywood; the ultra-strength shaving board has the outstanding features of highest mechanical strength compared with a plate with the same density, lowest density compared with a plate with the same strength, and material saving, and the mechanical strength performance of the ultra-strength shaving board is improved greatly due to the fact that the product structure is uniform and compact; and the advantages of a stable size, non-deformation, small thickness tolerance and the like are realized, and the transformation and upgrading of the artificial board industry, especially shaving board industry are facilitated greatly.

Owner:GUANGXI FENGLIN WOOD IND GRP CO LTD

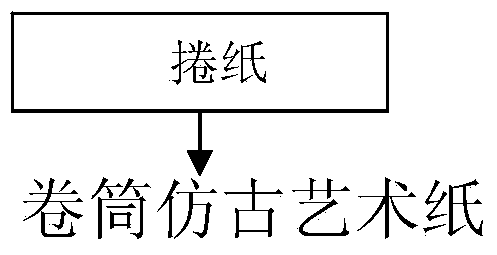

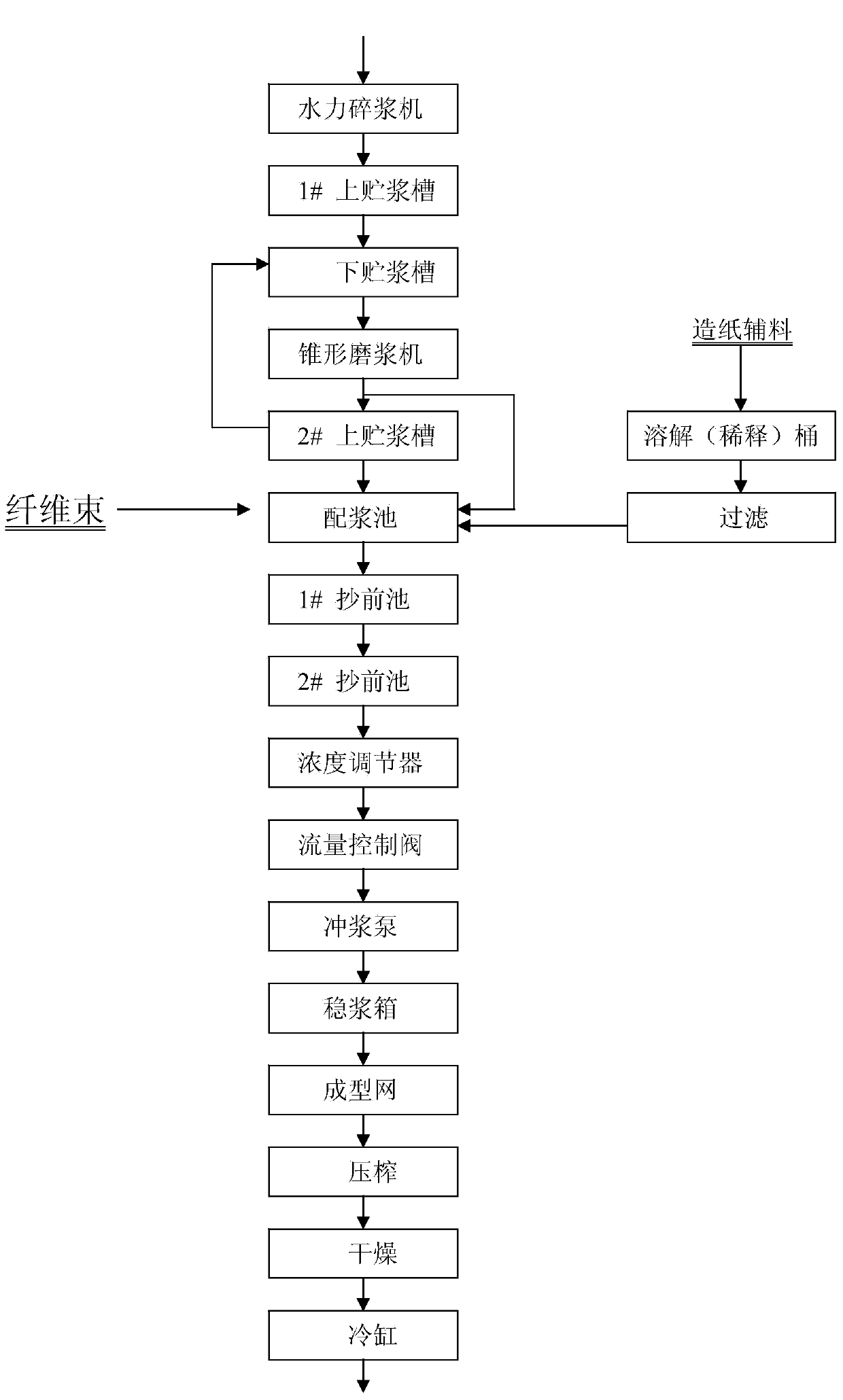

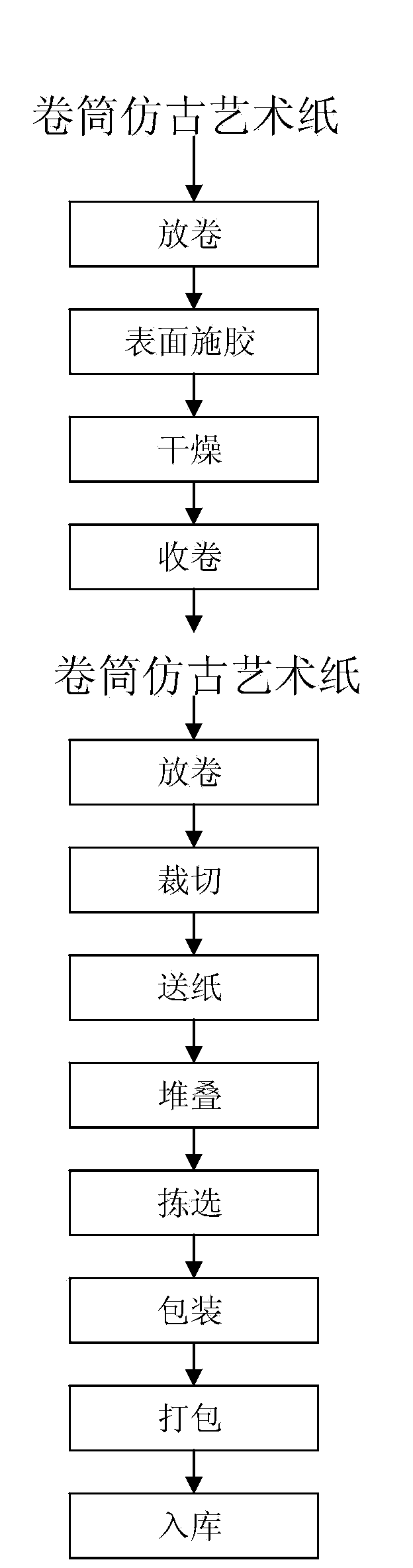

Method for making archaistic art paper

ActiveCN103741558AUniform tissueGood physical propertiesSpecial paperPaper/cardboardFiber bundleBusiness card

The invention provides a method for making archaistic art paper. The method comprises the steps of making paper, carrying out surface sizing and completing. The method has the main characteristics that fiber bundles are added into pulp. Due to the adoption of a fiber bundle adding method, the paper can be more distinctive and eye-catching, the fiber bundles show soft feeling through pulping, and through adding the fiber bundles into excellent pulp, the archaistic art paper can have the high-quality performance of modern art paper and can be endowed with a bit of charm of rough ancient paper; in addition, two forward-flow pulp-overflow circular meshes are selected as paper page formers, so that the method has the characteristic that the forming zone is relatively large, meshing can be achieved at low concentration, the tissue of copied paper is uniform, and the physical properties are good. Therefore, the archaistic art paper made by the method can be used for printing ancient books and periodicals, painting albums, packages of special and local products, business cards and the like.

Owner:上海骏源实业有限公司

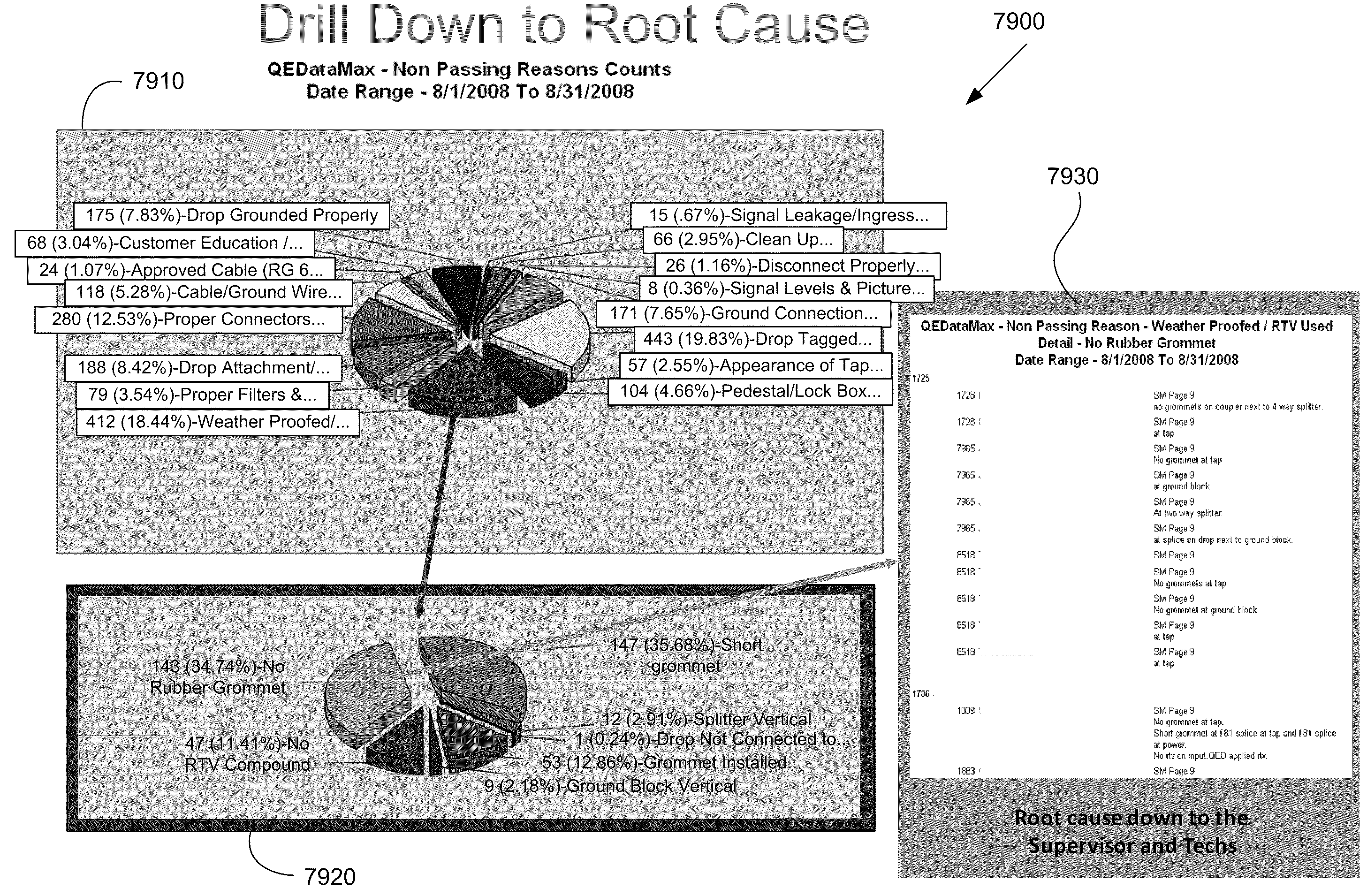

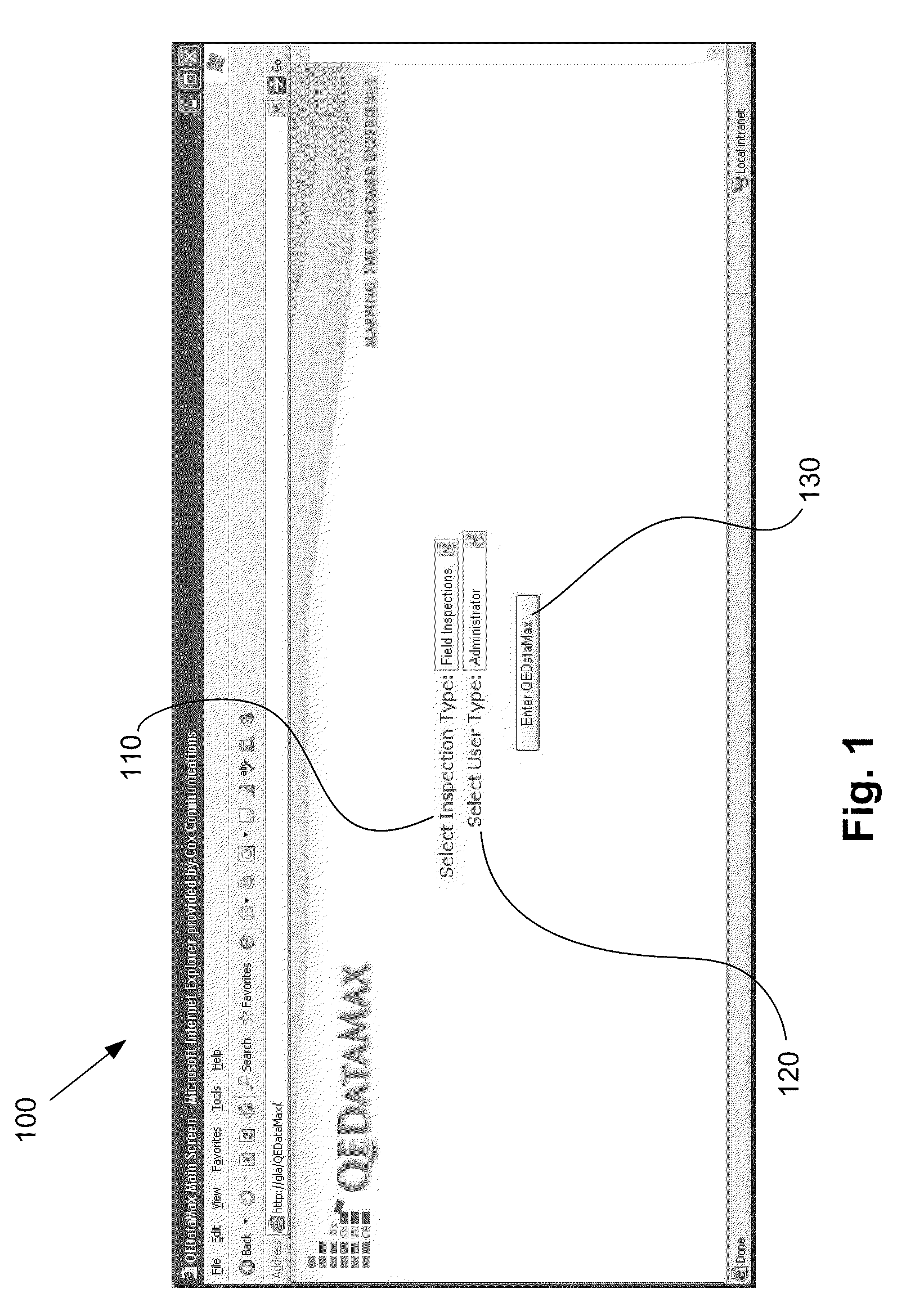

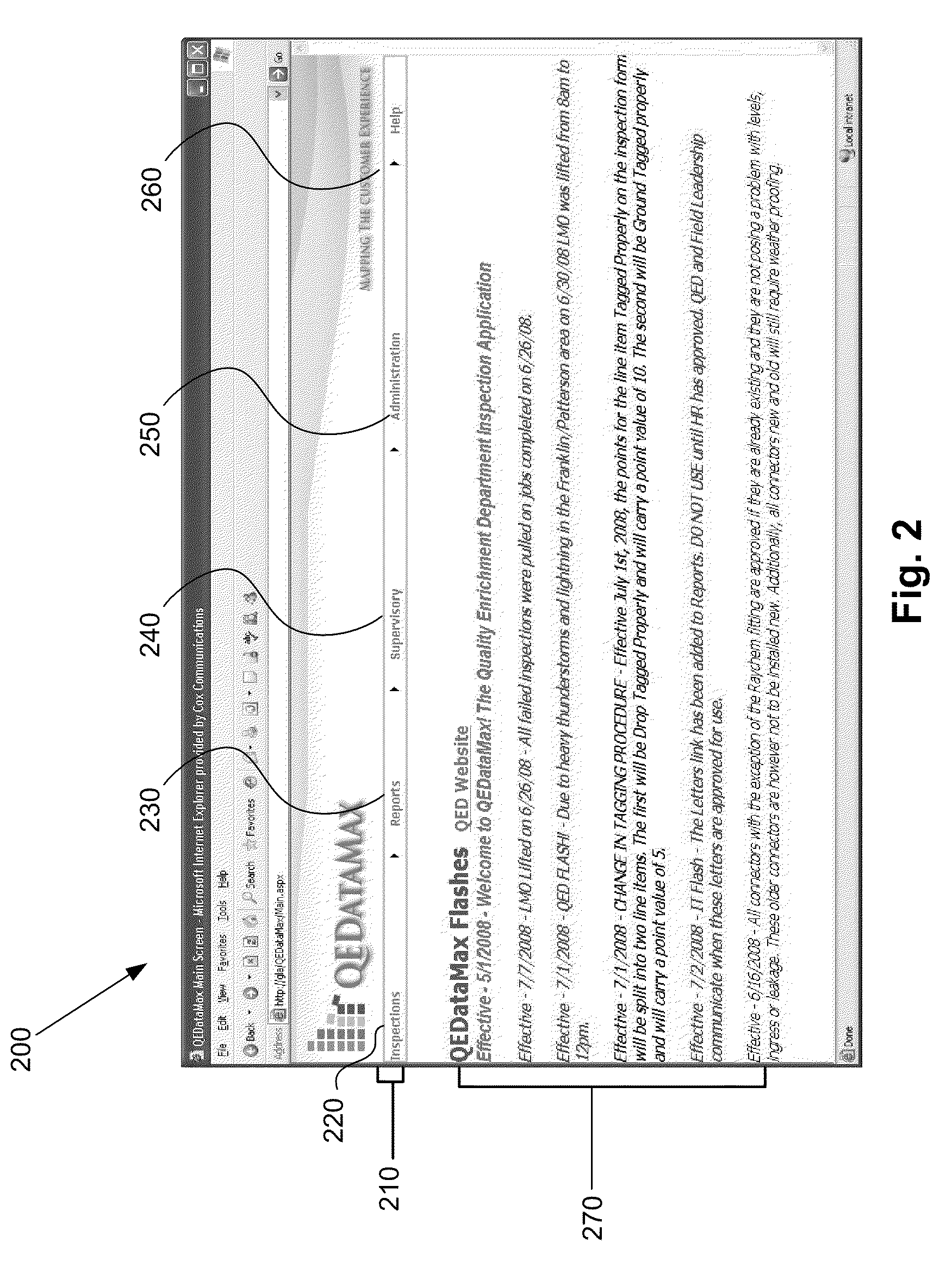

Real-Time Quality Data and Feedback for Field Inspection Systems and Methods

InactiveUS20100161374A1Maintain and control quality performanceRoad vehicles traffic controlDigital data processing detailsQuality dataRoot cause

A system, method and computer-readable medium for providing real-time quality data to a system that may be continuously updated and reviewed to maintain and control quality performance of the business. Quality information is imported into a database. The quality information imported to the database is analyzed and correlated to generate quality performance analytics. System information is provided to the database. Real-time root cause analysis is performed using the generated quality performance analytics and system information to identify root causes of system performance issues. The quality performance analytics is presented to users.

Owner:COX COMMUNICATIONS

Production process for reclaimed rubber

InactiveCN102061006AQuickly pull awayReduce elastic meshPlastic recyclingQuality performanceEngineering

The invention discloses a production process for reclaimed rubber, which is characterized in that the reclaimed rubber is prepared by adopting the following steps of: classifying various waste steel wire tires and processing, and after performing coarse crushing, intermediate crushing and fine crushing by utilizing a crushing machine, and filling crushed and sorted fine rubber powder into a devulcanizer; adding a rubber activating agent and a rubber softener which serve as auxiliary materials into the devulcanizer, and closing a charging opening; heating raw materials in the devulcanizer till the temperature is between 220 and 230 DEG C and the pressure is between 2.0 and 2.7 MPa, keeping the temperature and the pressure for 2 hours, performing desulfurization plasticizing, and opening a pressure relief valve to discharge gas in the devulcanizer; and after taking the desulfurized reclaimed rubber out of the devulcanizer, tableting by a refiner and an open mill in rubber pressing equipment to form reclaimed rubber products. The process can improve the production efficiency, obviously increase the tensile strength and break elongation and meet the high quality performance requirement of users.

Owner:焦作市弘瑞橡胶有限责任公司

Method and apparatus for automatically determining the manner in which to allocate available capital to achieve a desired level of network quality performance

InactiveUS7929459B2Multiplex system selection arrangementsData switching by path configurationInternet trafficQuality performance

A method and apparatus for simulating a modification to or expansion of a communications network and for determining whether the simulated modified or expanded network meets cost criteria. First logic forecasts an increase in network traffic. Second logic simulates a modification to or expansion of the network based on the forecasted increase in network traffic and / or based on performance improvement criteria and / or based on coverage expansion criteria. Third logic determines whether the simulated modified or expanded network meets cost criteria.

Owner:CINGULAR WIRELESS II LLC

Manufacture method of irregular pipe

ActiveCN102756011AImprove mechanical propertiesGood organizational performanceQuality performanceEngineering

The invention discloses a manufacture method of an irregular pipe. The manufacture method comprises the steps of: S1, carrying out upsetting extrusion on a straight pipe so as to form a first pressure inlet on the surface of the straight pipe; S2, carrying out upsetting extrusion on the straight pipe with the first pressure inlet so as to form a second pressure inlet on the surface of the straight pipe, wherein the second pressure inlet and the first pressure inlet form a first angle along the peripheral direction; and S3, bending the straight pipe with the first pressure inlet and the second pressure inlet, thus forming a preset curvature between the first pressure inlet and the second pressure inlet. According to the manufacture method of the irregular pipe, the internal hole of the pipe can be directly formed, and therefore the problems that in the prior art, the manufacture period is long and the material utilization is relatively low caused by manually cutting the internal hole by mechanically processing can be solved; and moreover, the heating is less frequently carried out during the operation, and the cutting allowance is low, and the percent of pass is high, and the quality performance is stable.

Owner:TSINGHUA UNIV +1

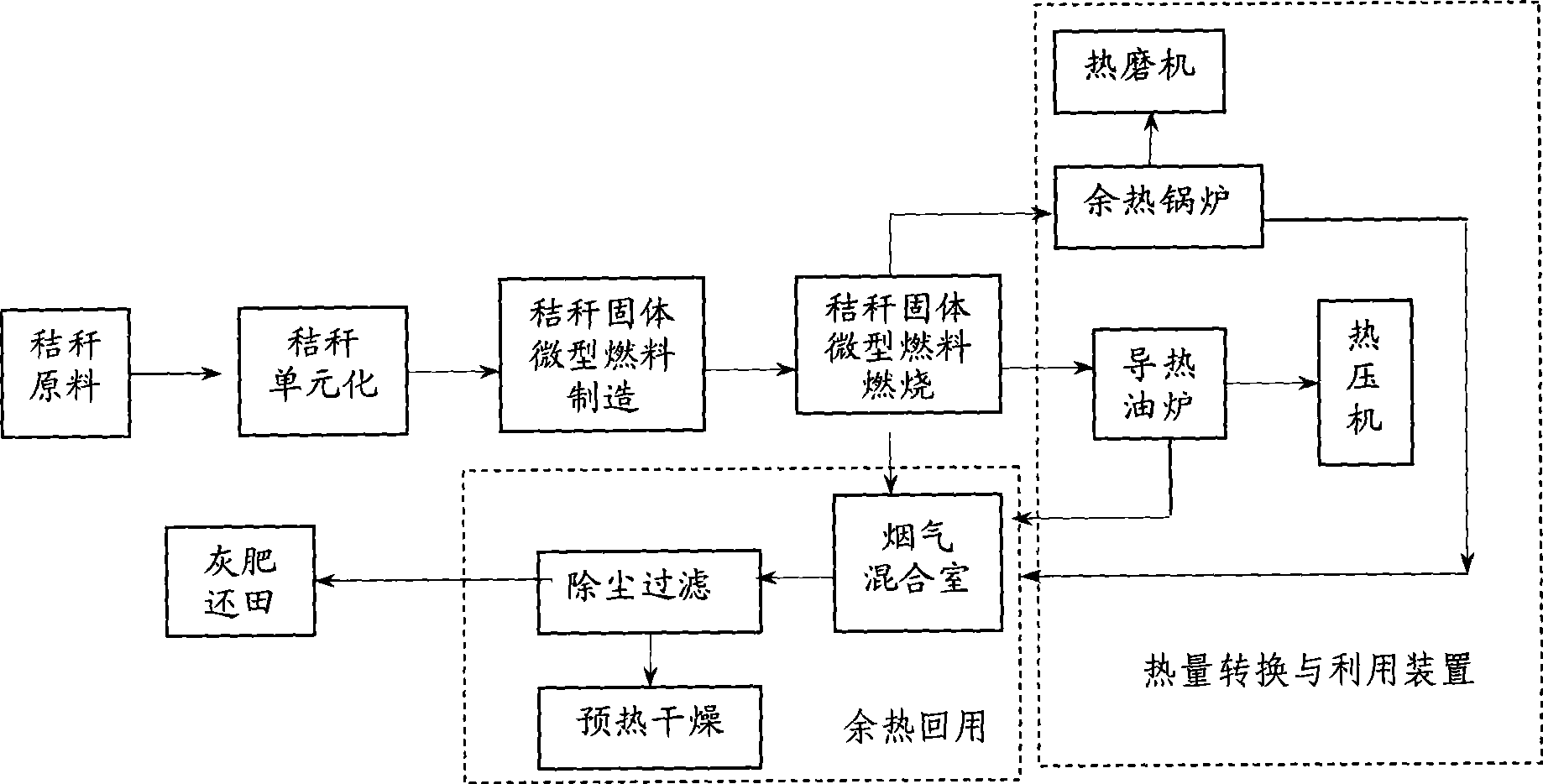

Process flow of artificial board enterprise energy-saving emission reduction with corps stalk as energy resource

InactiveCN101430097AGuarantee normal productionSave raw materialsSteam generation heating methodsClimate change adaptationQuality performanceCoal

The invention relates to a process for saving energy and reducing emission for artificial board enterprises by taking crop stalks as energy, and the process is characterized in that the process steps comprise 1) preparing stalk raw materials; 2) unitizing stalks; 3) manufacturing stalk solid micro-fuel; 4) burning the stalk solid micro-fuel; 5) using a heat conversion and utilization device; 6) reusing waste heat; 7) and returning ash manure to field. The process has the advantages that: the process proposes to manufacture the solid micro-fuel by taking the crop stalks as the raw materials around the energy conservation and the emission reduction of the artificial board enterprises, the appraisal indicators of a stalk fuel combustion device are as follows: the combustion rate is not less than 95 percent and the thermal efficiency is not less than 85 percent, thereby replacing coal and waste wood; the process can realize the purposes of saving energy, saving raw materials, protecting environment and reducing cost under the premise of ensuring the normal production of the enterprises, thereby having an important practical significance for realizing the energy conservation and the emission reduction of the enterprises. Farmers can increase income by selling the crop stalks as the fuel. The product quality performance indexes are in line with the requirements in the China's medium density fiberboard standards.

Owner:NANJING FORESTRY UNIV

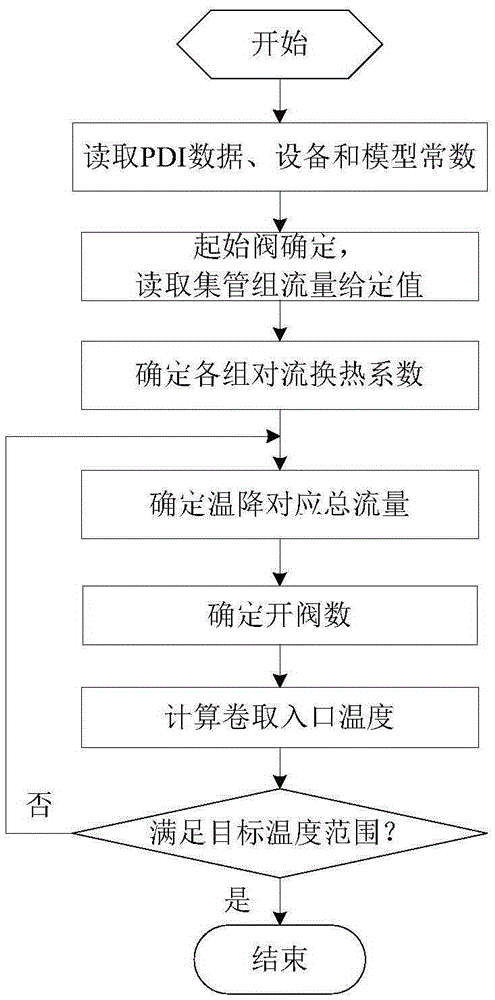

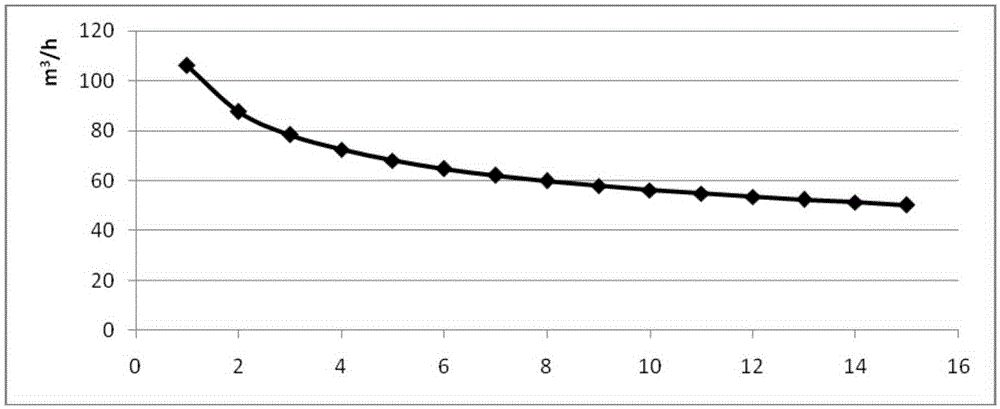

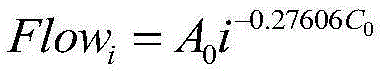

Flow control method for rolling temperature of hot rolled steel strip

ActiveCN105327949AImprove coiling temperature hit rateSmall temperature fluctuationsTemperature control deviceWork cooling devicesAutomatic controlModel parameters

The invention provides a flow control method for the rolling temperature of a hot rolled steel strip and belongs to the technical field of rolled steel automatic control. The method comprises: reading plate blank PDI data, equipment parameters and rolling temperature model parameters, and extracting the actual measurement values of pyrometers when the steel strip reaches a finish rolling inlet and a finish rolling outlet; determining the given configuration and flow of the material specification of beginning valve and headers; according to the given flow and the rolling temperature model of each group of headers, determining the convective heat transfer coefficient of each group of headers; according to the rolling temperature model, calculating total flow required by cooling from the finish rolling outlet to a rolling inlet; determining total valve opening number required by cooling, and sending the set configuration to a level I basic automation executor; and carrying out feedback calculation according to the actual rolling temperature, regulating the opening and closing state of headers in a fine tuning zone, and ensuring a target rolling temperature. The method can stably control the rolling temperature index, ensure that the first block of an another specification of strip steel and a thick specification of strip steel can stably pass, improve the rolling temperature hit rate and improve the quality performance of a product.

Owner:BEIJING ARITIME INTELLIGENT CONTROL

Sterilization by down radiation

InactiveCN101073670AAvoid infectionIncrease temperatureRadiationQuality performanceThrough transmission

The invention is concerned with the method of irradiation serilization for feather, that is, setup the irradiation facility with certain operation parameter, the material pack contents a standard amount of feather is sent through the irradiation facility for irradiation serilization process by the transmission system. The invention concentrates on systemic managing irradiation machin, which serilizes bactirum under the perfect packing prevents infection with no leftover; it is not only destroy bactirum copelely with high speed process, low managing cost with high quality performance, and also operating eaily, saving the power supply.

Owner:上海东隆羽绒制品有限公司

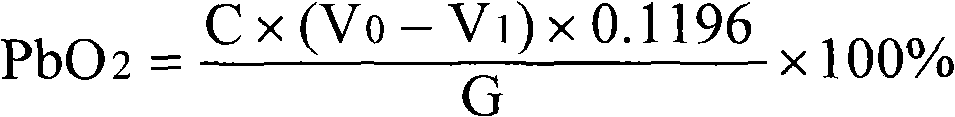

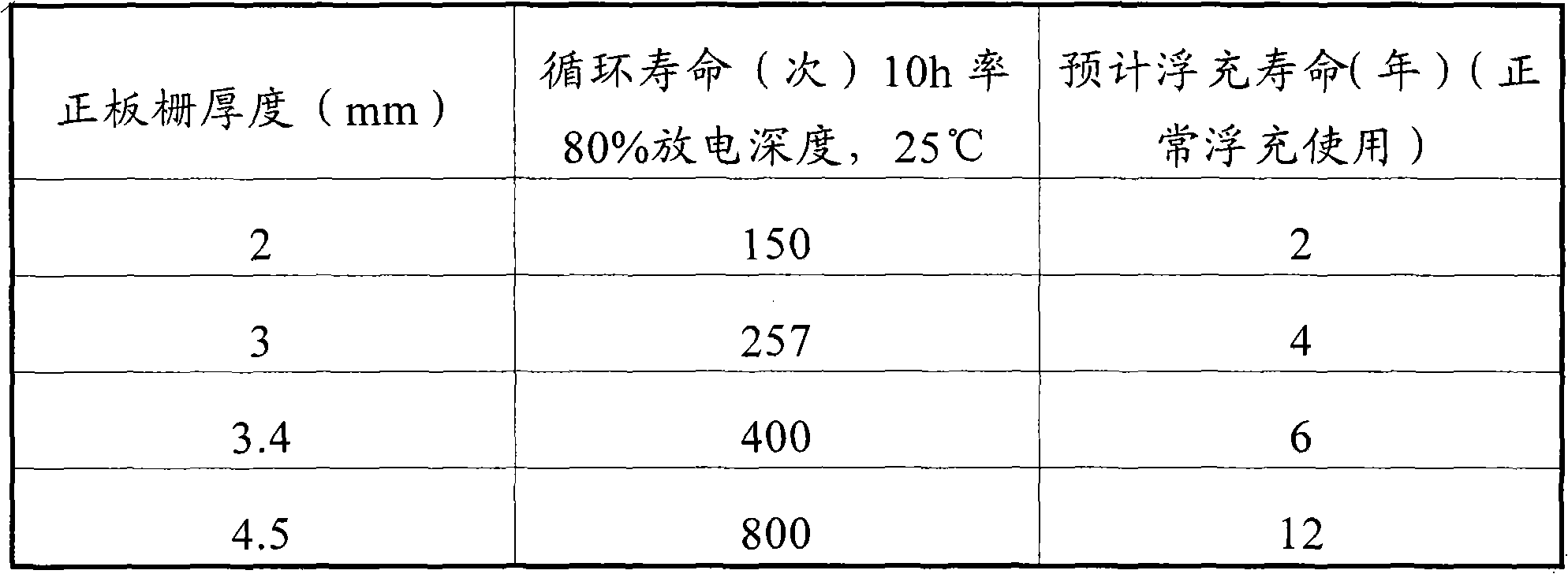

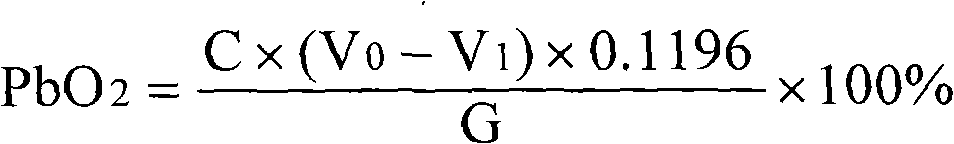

Method for analyzing and testing quality of storage battery

ActiveCN102053084AReduce testing costsReduce energy consumptionMaterial analysis by observing effect on chemical indicatorAnalysis by thermal excitationChemical compositionTest quality

The invention discloses a method for testing and analyzing the quality of a storage battery from a brand new investigation dimensionality. The principle that the quality performance of the storage battery is actually determined by the contents of the internal chemical components of the storage battery is utilized, and the contents of the internal chemical components of the storage battery are measured, and the contents are compared with a preset standard to analyze the quality of the storage battery. The method disclosed by the invention has the advantages of low cost, low energy consumption and the like; and the test result is more reliable.

Owner:CHINA MOBILE COMM GRP CO LTD +1

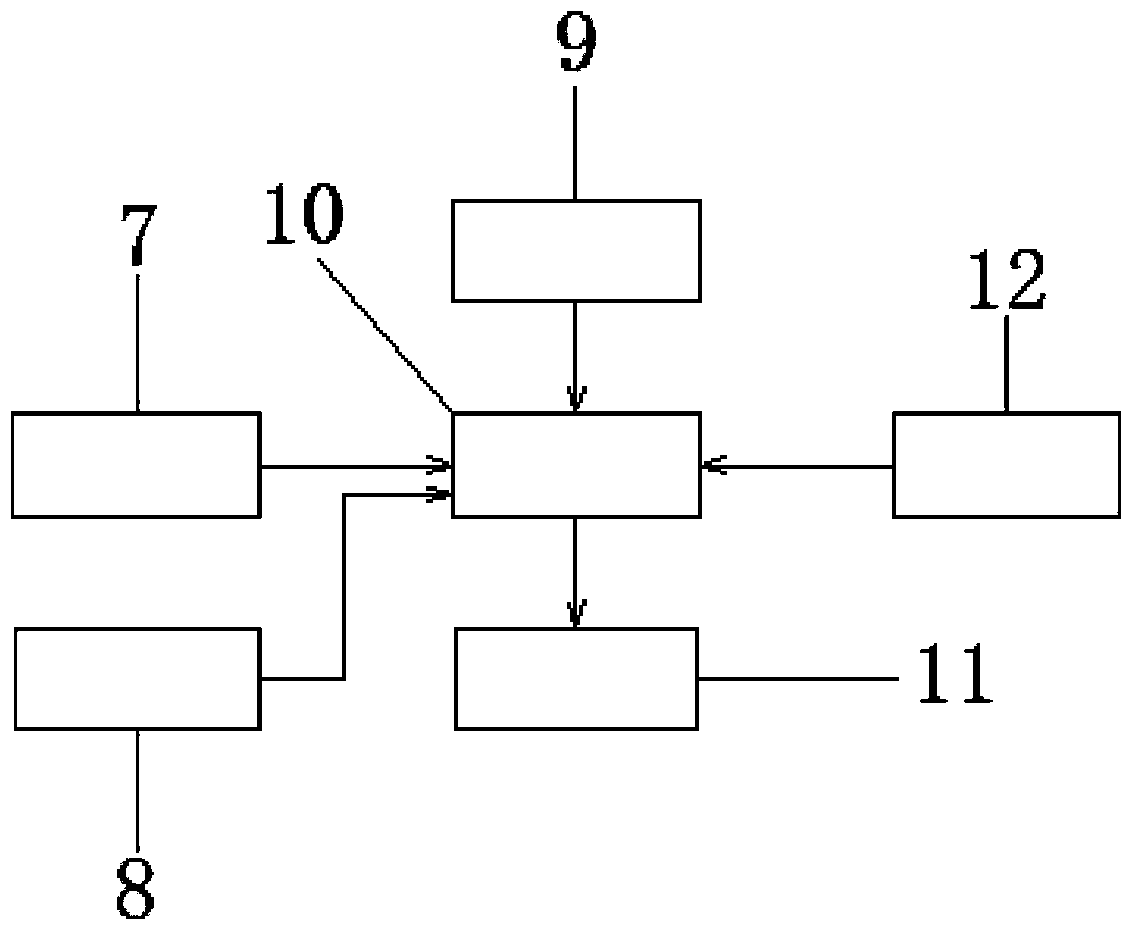

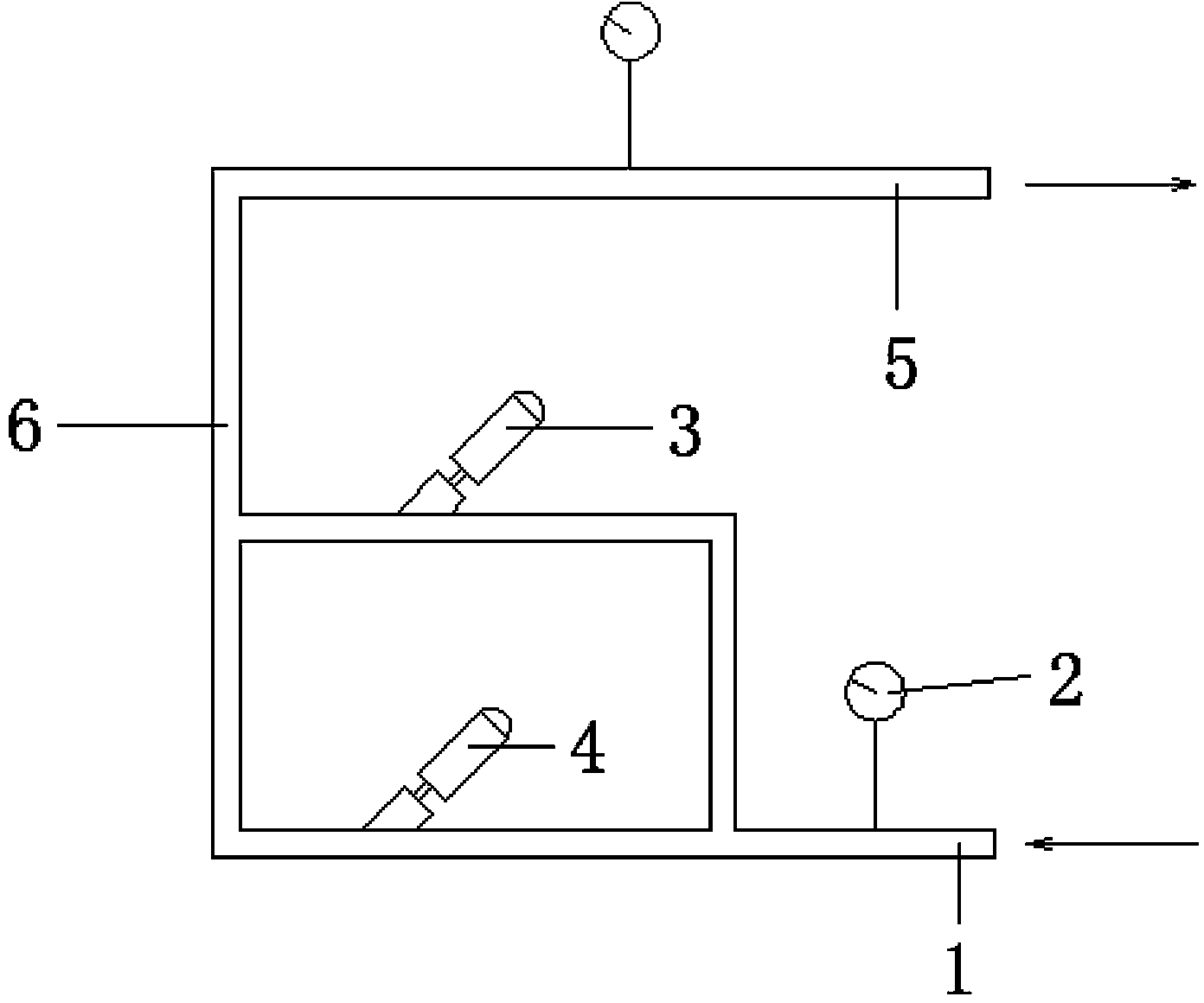

System for moulding sand quality on-line inspection and humidity automatic control

InactiveCN103713665AGuaranteed quality effectConstant humidity valueHumidity controlMould handling/dressing devicesFoundryAutomatic control

The invention relates to the technical field of processing systems for foundry sand, in particular to a system for moulding sand quality on-line inspection and humidity automatic control. An on-line detection system is arranged on a sand mixer and comprises a controller, and the controller is connected with a humidity sensor, a temperature sensor, a compact rate pressure transmitter and a strength and pressure transmitter. A humidity automatic control system is arranged on a sand supplying belt conveyor in front of a moulding machine, and the humidity automatic control system comprises an automatic water adding device connected with the controller. The system for moulding sand quality on-line inspection and humidity automatic control has the advantages that the on-line detection system arranged on a sand mixer ensures the constant compact rate and wet strength by detecting temperature and humidity, and the humidity automatic detecting system on the sand supplying belt conveyor in front of the moulding machine ensures a constant humidity value by analyzing the humidity and temperature of moulding sand. Combined control of the on-line detection system and the humidity automatic control system ensures quality performance of the moulding sand.

Owner:常州市卓信机电设备制造有限公司

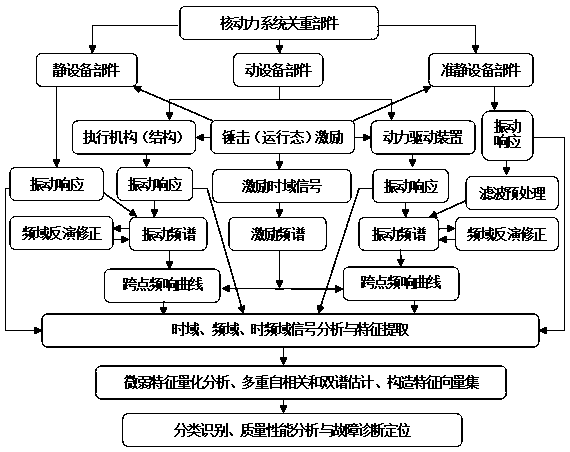

Monitoring and fault diagnosis method for quality performance of key parts of nuclear power unit

ActiveCN107767975APrevent severe wear and tearPrevent looseningNuclear energy generationNuclear monitoringNuclear powerQuality performance

The invention discloses a method for determining quality performance problems and faults of key parts of a nuclear power unit by analyzing a structure vibration response signal under determined excitation. The method comprises the following steps: primarily determining positions of excitation and response points according to analysis on common faults or possible potential quality performance problems of the key parts with different types of the nuclear power unit; requiring that a formed running state point-spanning frequency response function can cover possible quality problems and faults; drawing a multi-running-state point-spanning frequency response function curve of the key parts of the nuclear power unit according to real-time acquired excitation signals and vibration response signals of running states of the key part of the nuclear power unit; analyzing a peak value-frequency, a loss factor and a change rule thereof in each running state point-spanning frequency response function of the key parts with the different types; extracting a characteristic parameter of each running state frequency response property curve; quantitatively describing corrosion, crack, abrasion, loosening, leakage and jamming fault properties; testing and determining influences, caused by each fault and a degree thereof, on the characteristic parameter of each stage.

Owner:ZHONGBEI UNIV

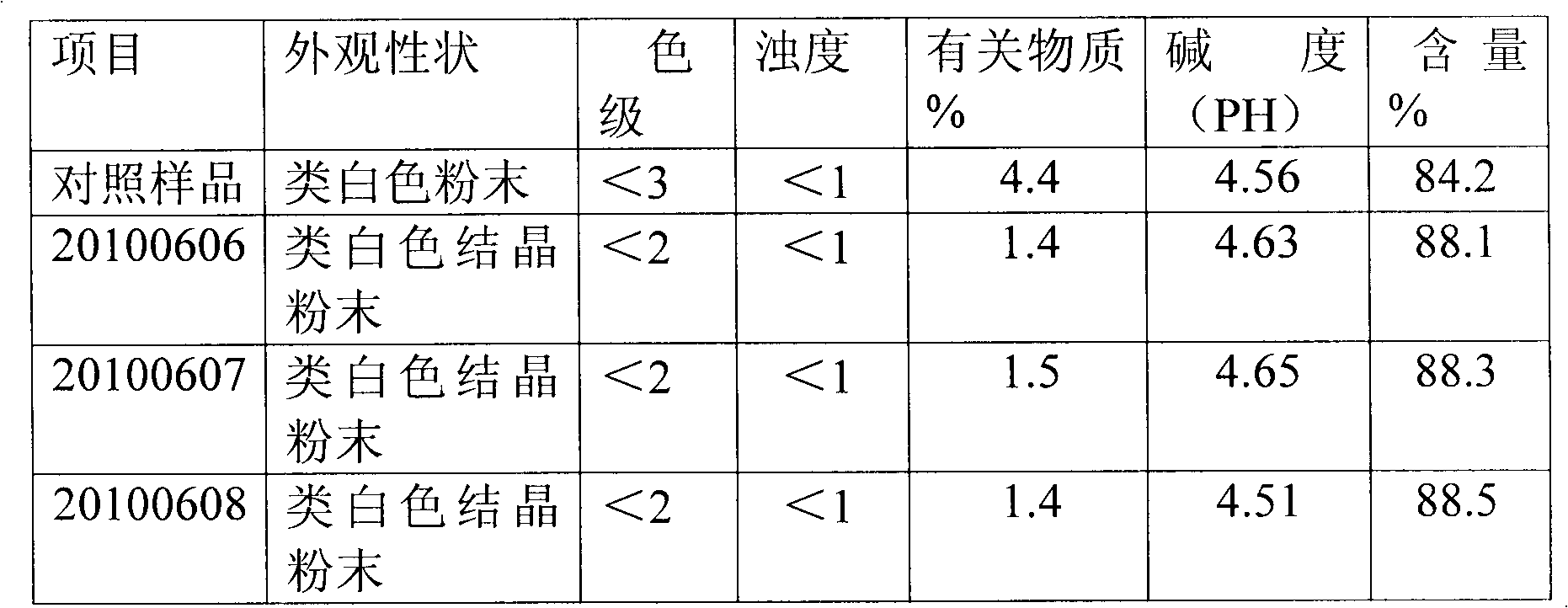

Method for preparing cefmetazole sodium

InactiveCN102127095AThe preparation method is scientific and reasonableHigh product contentOrganic chemistryQuality performanceCEFMETAZOLE SODIUM

The invention relates to a method for preparing cefmetazole sodium, comprising the following steps of: undergoing a reaction of cefmetazole acid and sodium isocaprylate, then purifying, crystallizing, filtering, washing and drying to obtain a finished product. The method for preparing the cefmetazole sodium, provided by the invention, is scientific and reasonable, simple and practicable; and the obtained product has the advantages of stable quality performance, high content, low impurity content, allergy avoidance, and the like.

Owner:SHANDONG LUKANG PHARMA

Method for evaluating metallurgical coke

The invention discloses a method for evaluating metallurgical coke, which comprises several steps of determining and characterizing the relevant basic technical parameters coking single coal and matched coal in different areas to establish a data information base, analyzing the influence weight of the main technical parameters of the metallurgical coke on the behavior of the blast furnace, determining the core parameters for evaluating the quality performance of the metallurgical coke to establish a mathematical equation of the thermal state of the tuyere coke, obtaining the coke thermal reaction property and the post reaction strength of the coke property of the tuyere through putting the core parameter data of the furnace coke into the thermal state performance mathematical equation of the tuyere coke and characterizing the quality of the metallurgical coke in the blast furnace smelting process. The method for evaluating metallurgical coke provides a new scientific basis for reasonably utilizing the low-deterioration degree coking coal with abundant reserves and low cost, and has great economic and social benefits.

Owner:BAOTOU IRON & STEEL GRP

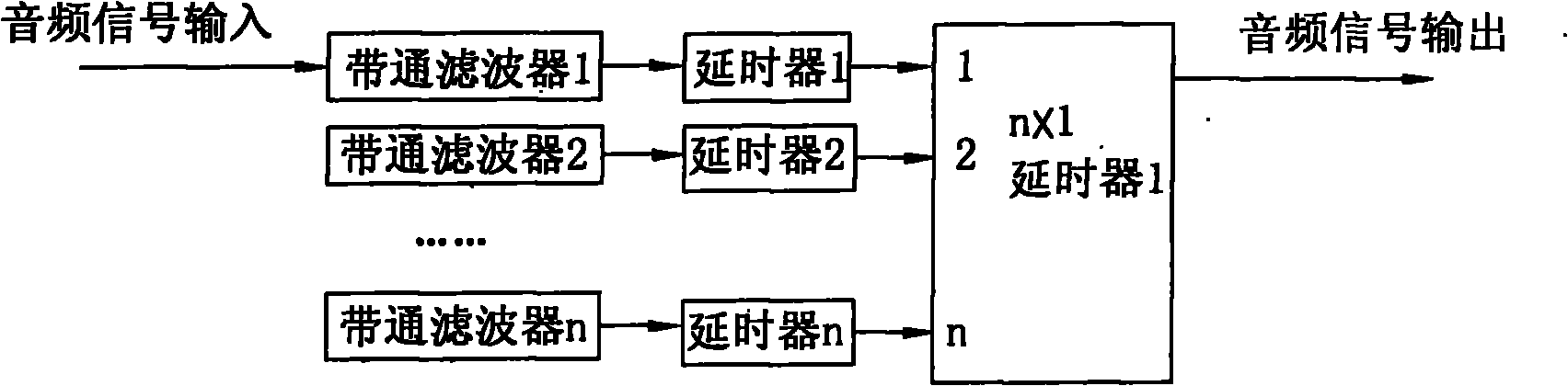

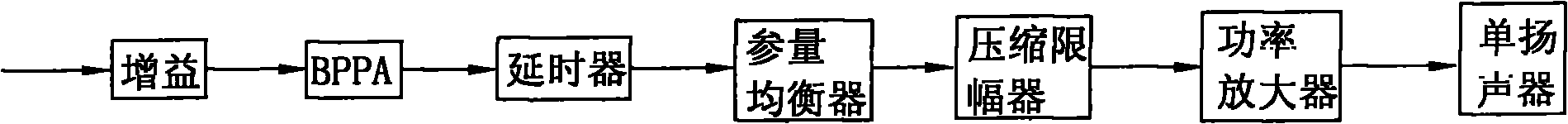

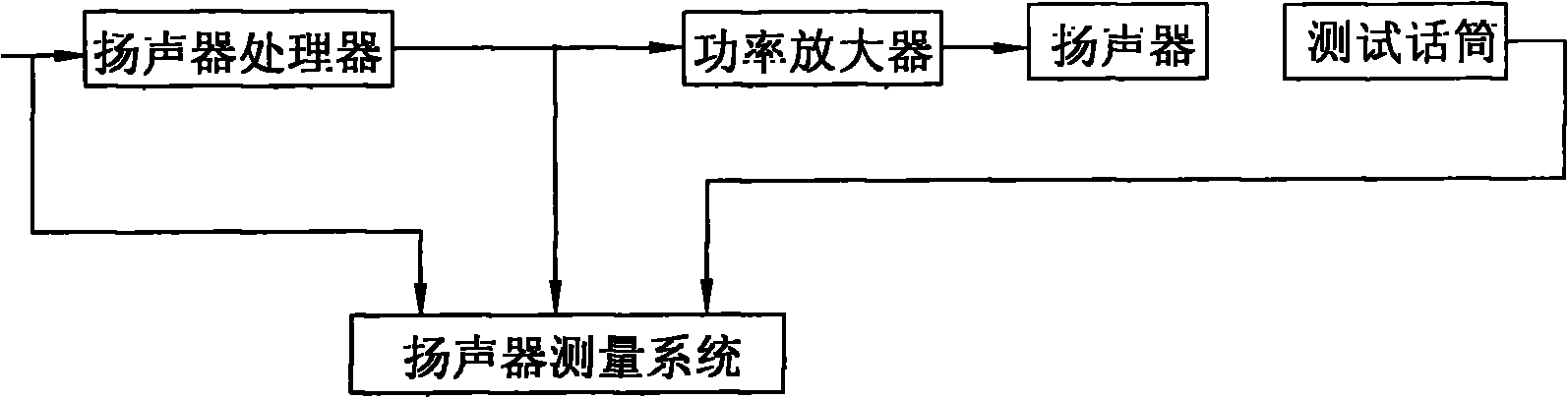

BPPA (Band-Pass Phase Adjustment) digital audio processor and sound box processor using same

ActiveCN101883303AImprove sound performanceImprove transient responseFrequency/directions obtaining arrangementsBand-pass filterQuality performance

The invention discloses a BPPA (Band-Pass Phase Adjustment) digital audio processor and a sound box processor using the same. The digital audio processor comprises n band-pass filters, n time delayers and an n*1 mixer. In the invention, input audio signals are separated into n paths of audio signals according to different frequency bands through the n band-pass filters; the n paths of audio signals are respectively input into the n paths of time delayers; and signals output by the n paths of time delayers are simultaneously input into the n*1 audio mixer to carry out mixing output. The digital audio processor is suitable for sound box processors with a single loudspeaker, two fractional frequencies, three fractional frequencies or multiple fractional frequencies. Based on the chip design of a DSP (Digital Signal Processor), the processors can be adjusted in a large range and large amplitude, have simple operation and obviously and greatly improve the tone quality performance. In addition, the invention can correct the phase deviation of the loudspeaker and improve the frequency response and the transient response of the loudspeaker, thereby reducing the distortion and greatly improving the tone quality performance of the loudspeaker.

Owner:GUANGZHOU LEAFUN CULTURE SCI & TECH

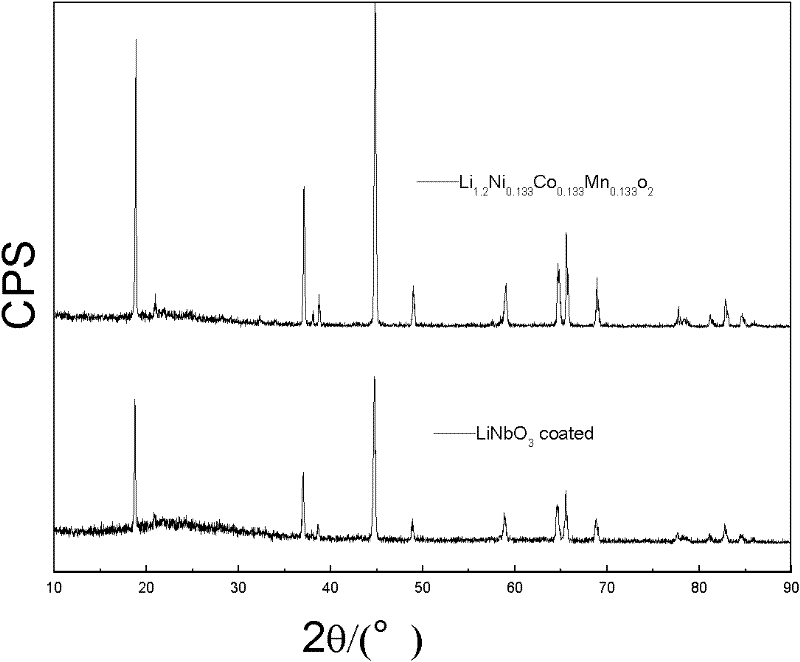

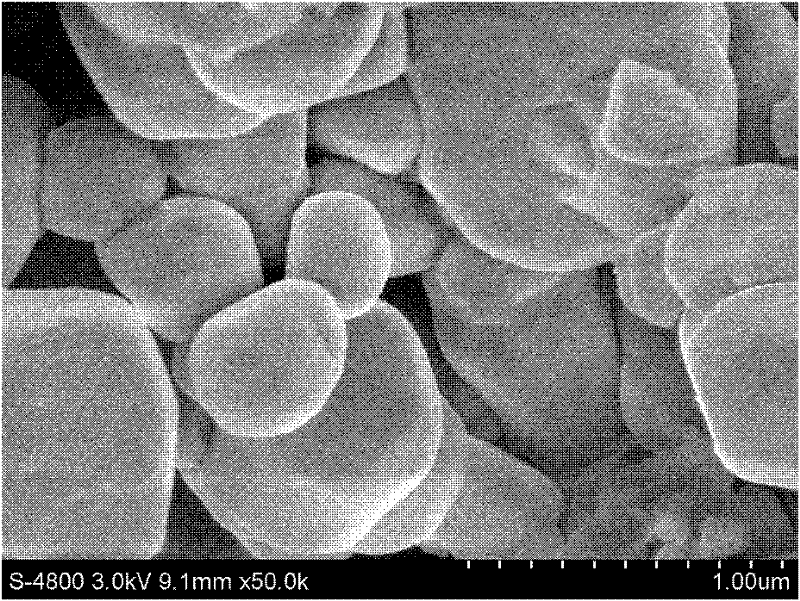

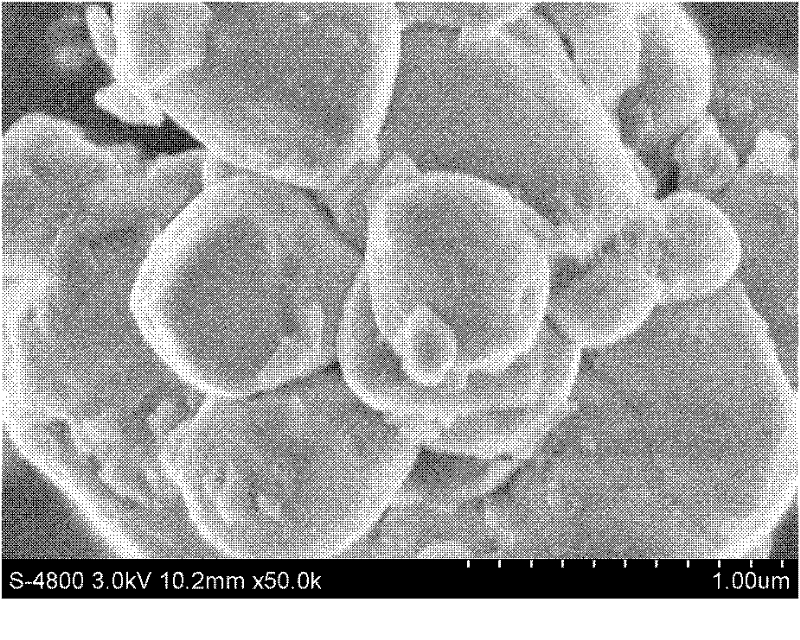

Method for cladding LiNi0.133Co0.133Mn0.544O2 material

The invention relates to a method for cladding a LiNi0.133Co0.133Mn0.544O2 material, which comprises the following steps: 1) weighing Li source, Nb source, organic acid, LiNi0.133Co0.133Mn0.544O2 and an organic solvent according to proportion; 2) dissolving the weighted lithium salt in the organic solvent, adding organic acid, Nb source and LiNi0.133Co0.133Mn0.544O2 and then stirring to obtain sol; volatilizing the solution to form a gel precursor; 3) grinding the precursor and calcining, cooling to obtain the LiNbO3-cladded LiNi0.133Co0.133Mn0.544O2 positive material. According to the invention, niobium source and lithium-rich LiNi0.133Co0.133Mn0.544O2 positive material are added in the organic solution containing lithium source and organic acid, LiNiO3 is cladded on the surface of the positive material, under the premise that the high-quality performance of the LiNi0.133Co0.133Mn0.544O2 material is not changed, the stability and circularity during the charge and discharge process can be enhanced and the electrochemical performance of the material can be increased.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com