Patents

Literature

50results about How to "Good organizational performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

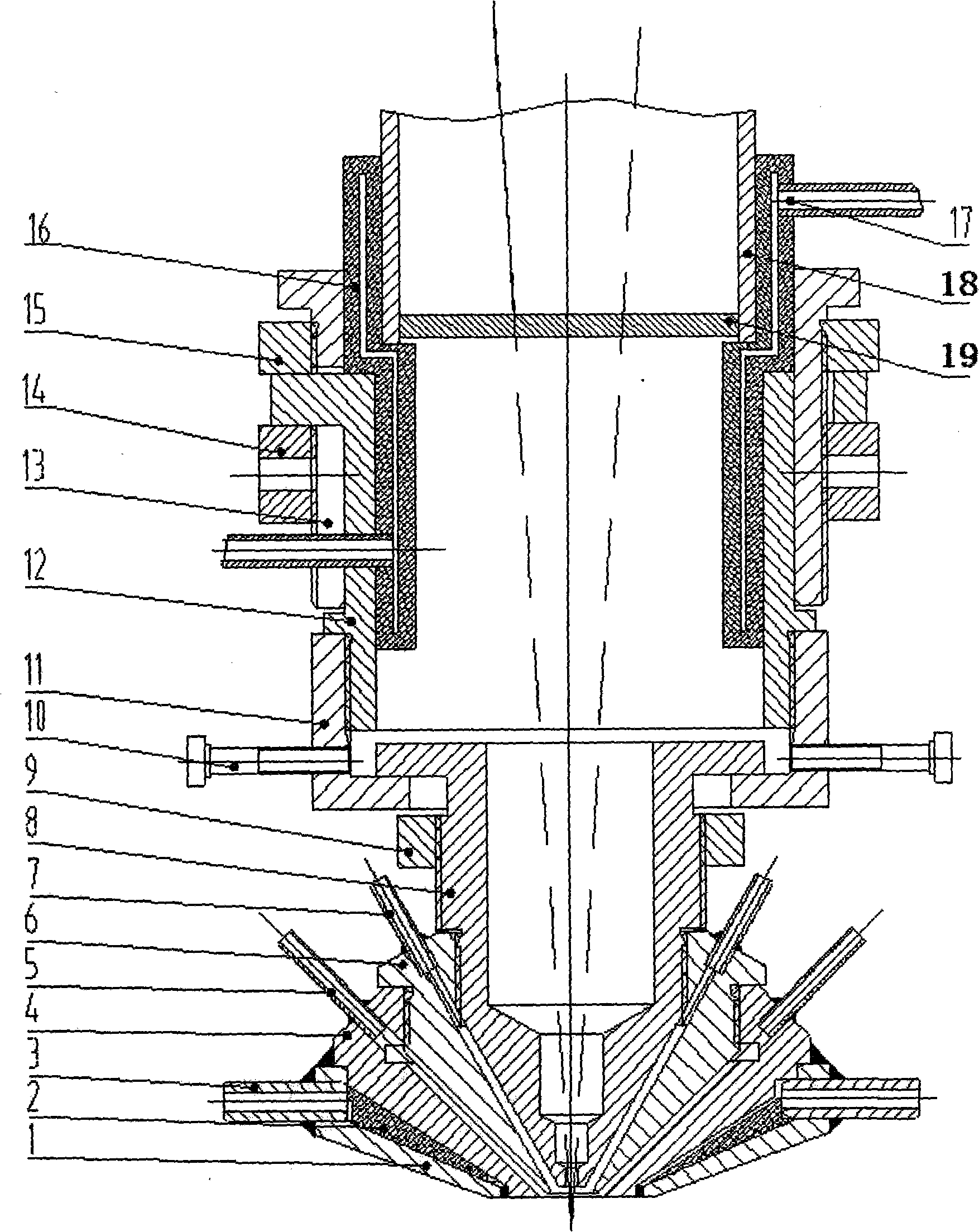

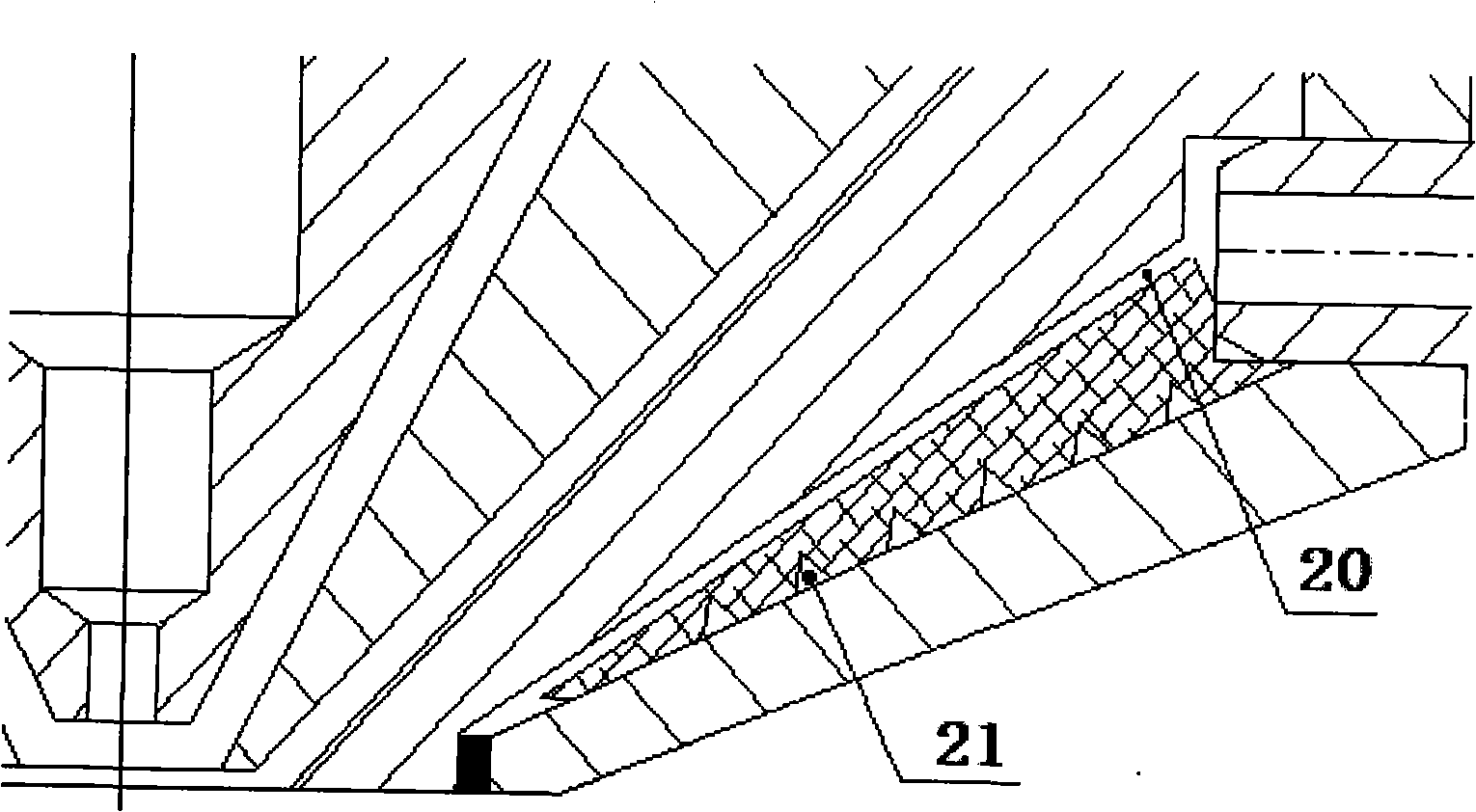

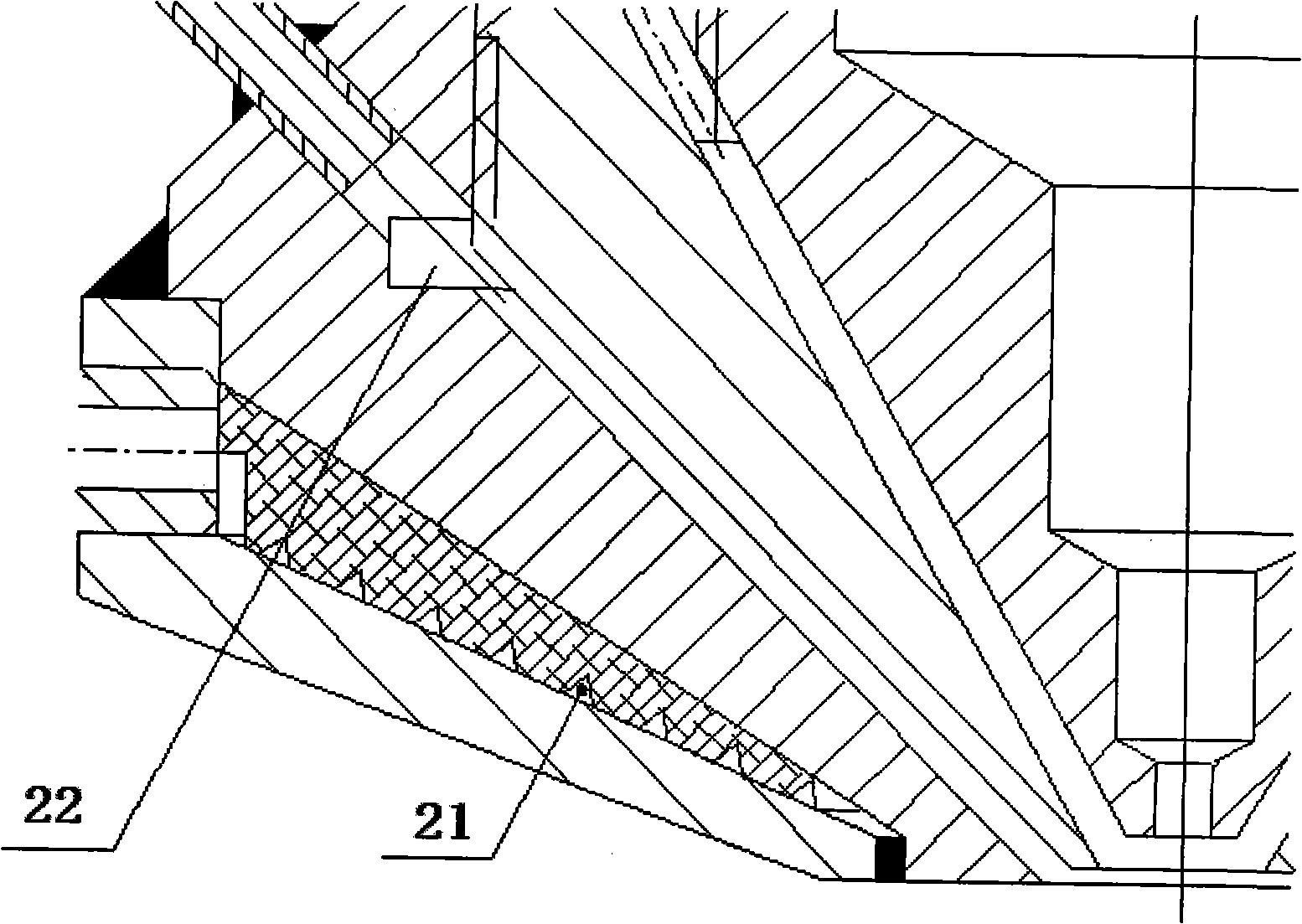

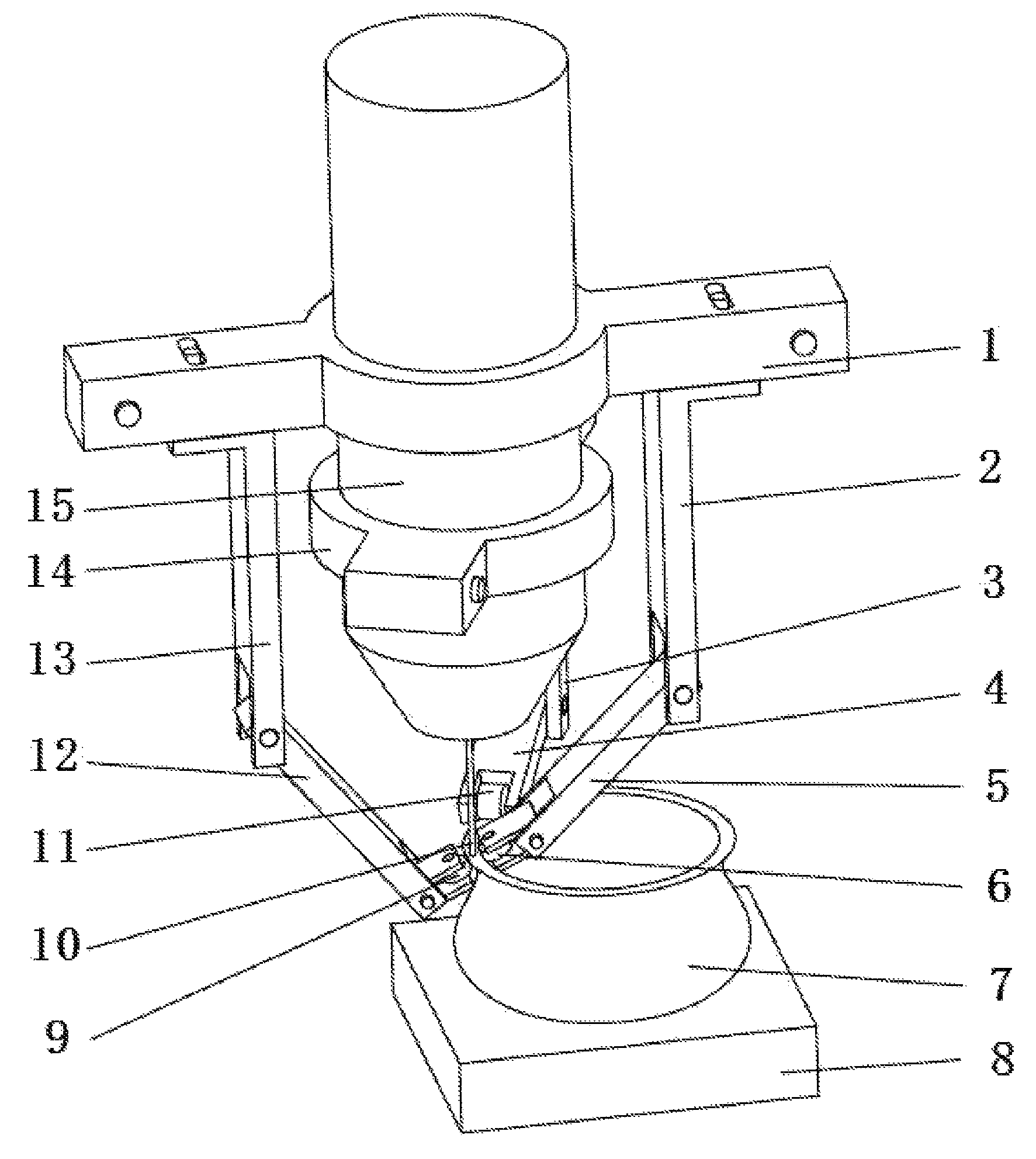

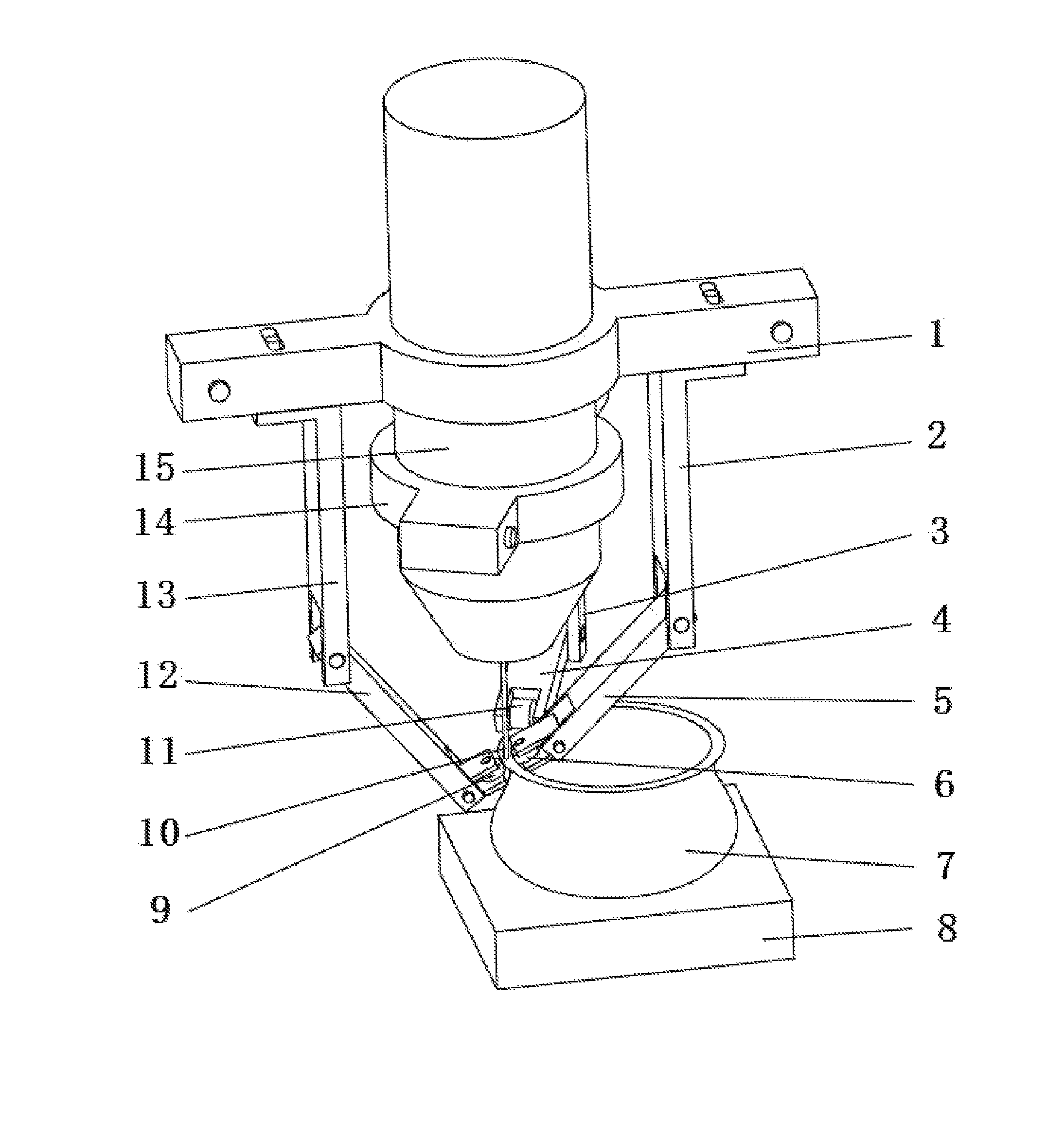

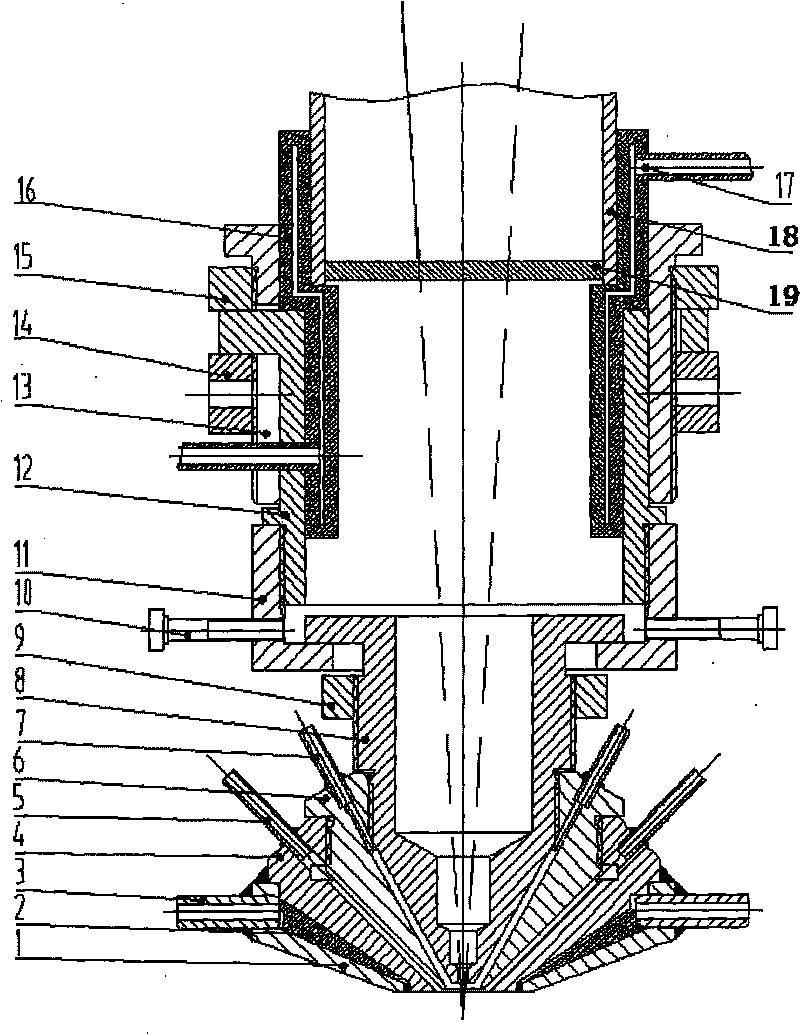

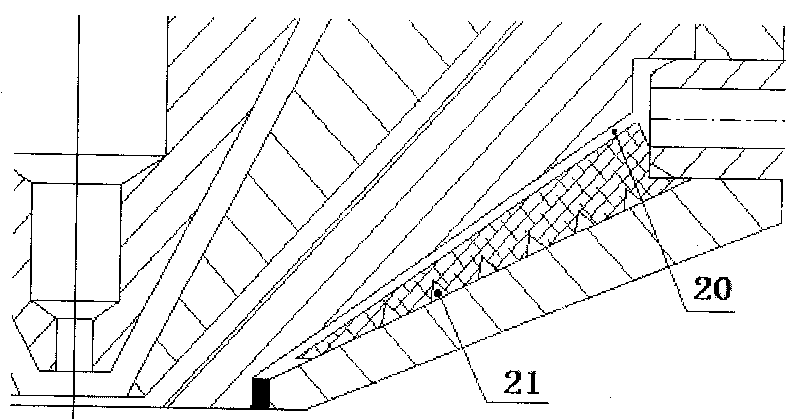

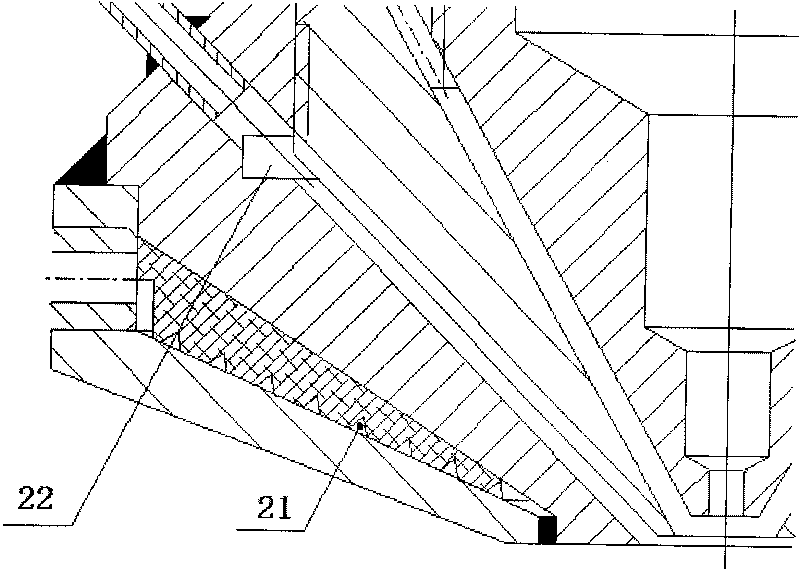

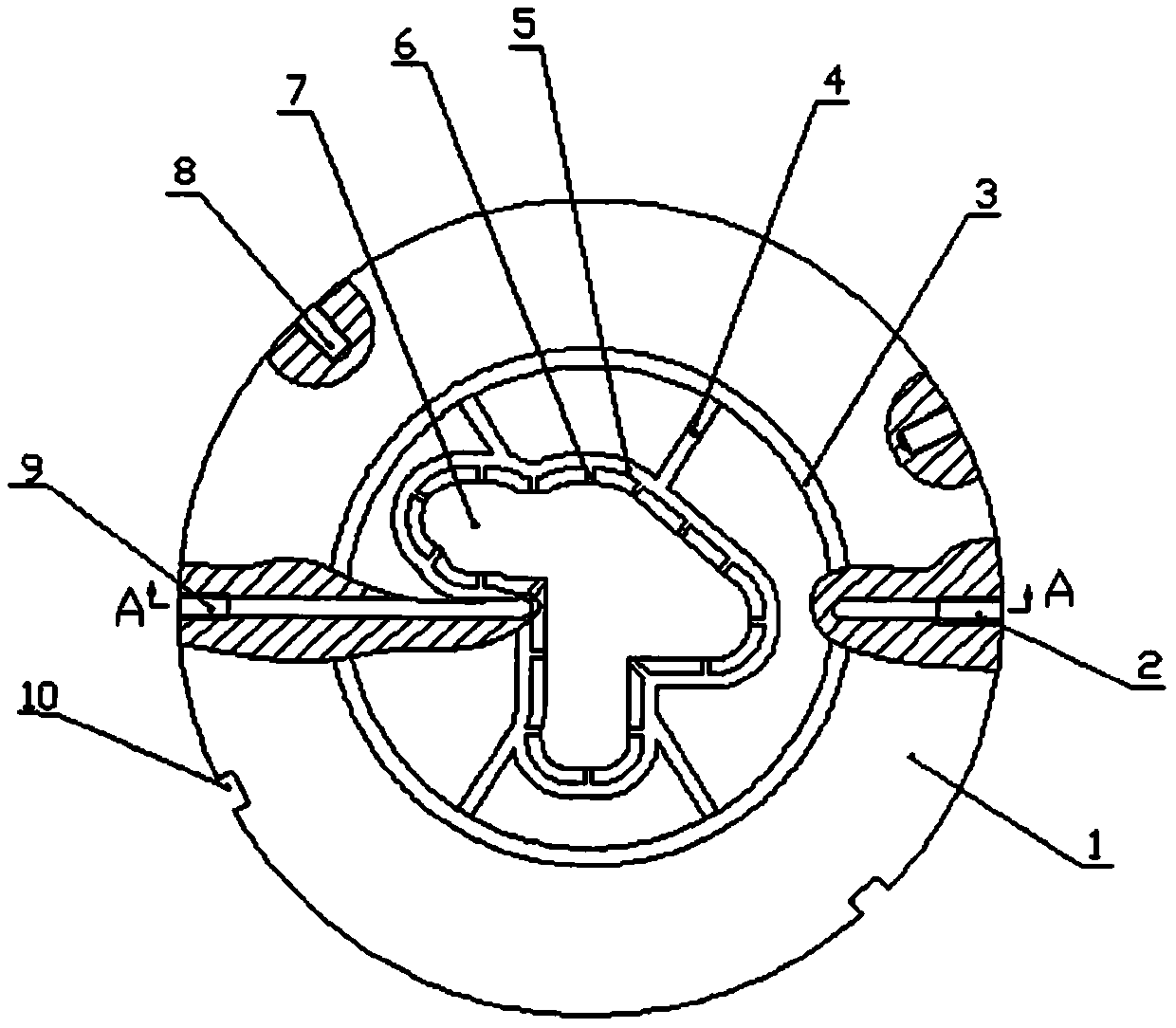

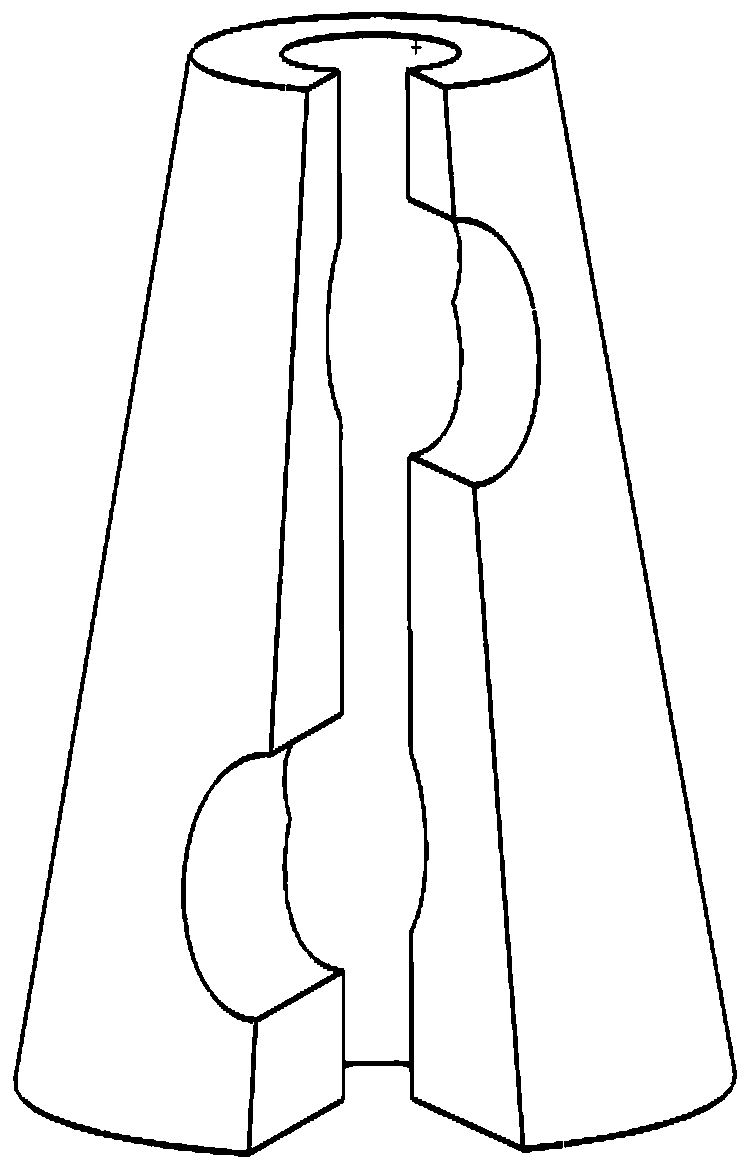

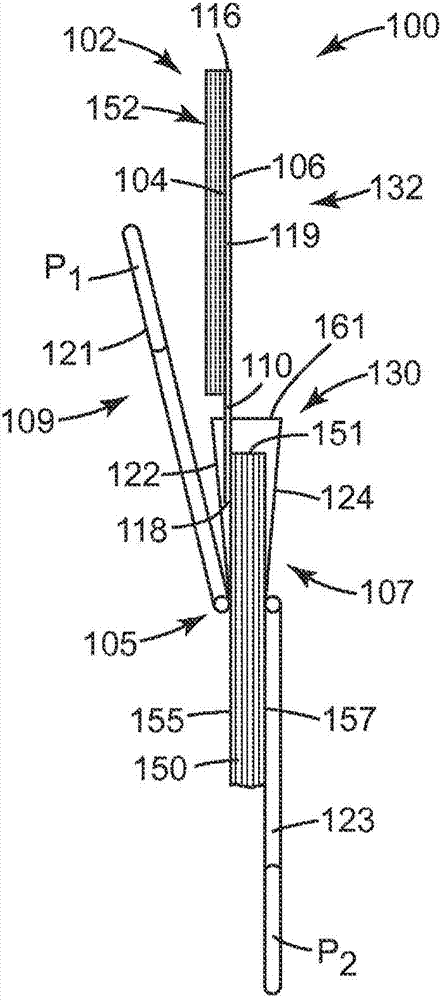

Adjustable laser coaxial powder feeding nozzle

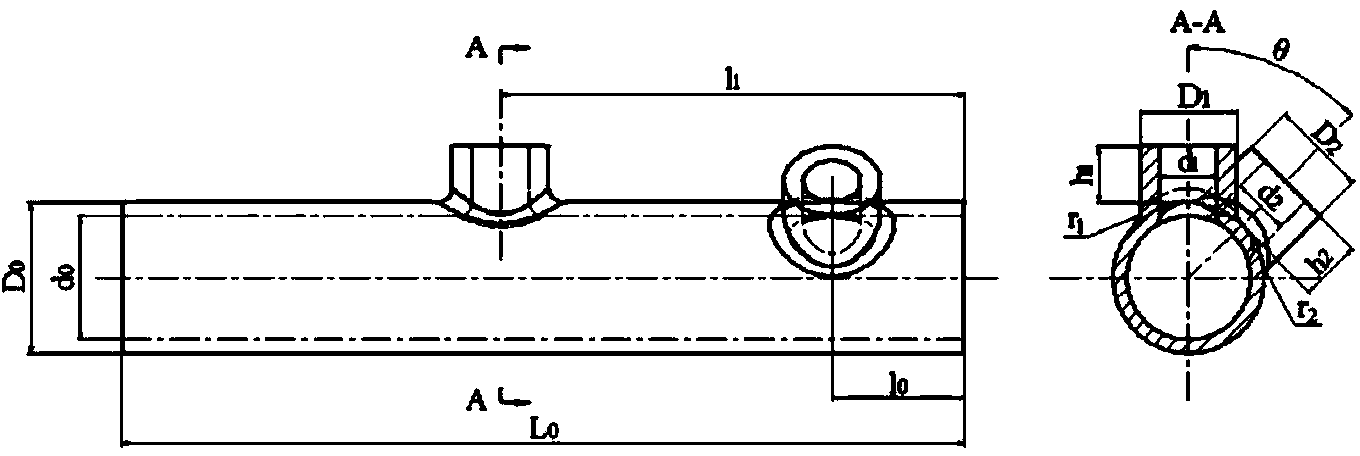

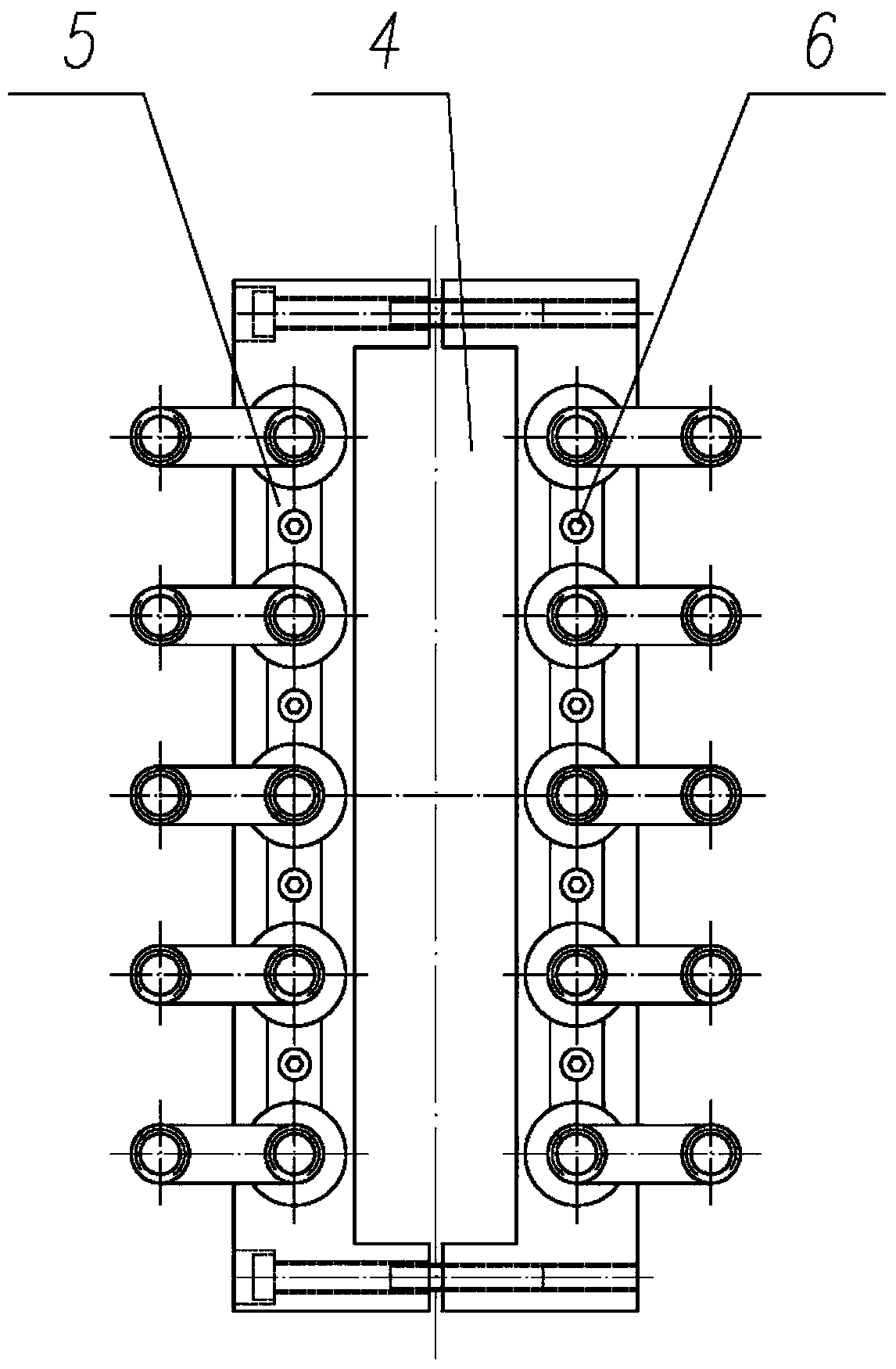

The invention discloses an adjustable coaxial laser nozzle for sending powder, comprising a laser head, a protection lens, a water-cooling sleeve for the protection lens and a column laser cavity arranged on the upper part, a coaxial conical laser cavity which is formed by the inner layer of a laser sleeve and arranged in the middle part, wherein a powder cavity, a secondary external protective cavity and an external water-cooling cavity are arranged on the lower part of the external part of the laser sleeve; the powder cavity is formed between the laser sleeve and a power cavity sleeve screwed together; the secondary external protective cavity is formed between the powder cavity and a protective air casing screwed together; the powder cavity and the protective sir casing are screwed together and adjustable between 1mm to 3mm; 4 to 6 power transmitting pipes and 4 to 6 air tubes are respectively positioned around the top parts of the cones of the powder cavity and the protective air cavity. The adjustable coaxial laser nozzle for sending powder has the advantages that the focus length of the focus lamp fit for the coaxial powder-sending nozzle is between 100mm to 300mm, which ensures convenient assembly and disassembly, even velocity, flexible adjustment of the powder converge diameter, convenient changeable lower coaxial conical parts (the powder cavity, the air casing and the water cavity).

Owner:XI AN JIAOTONG UNIV

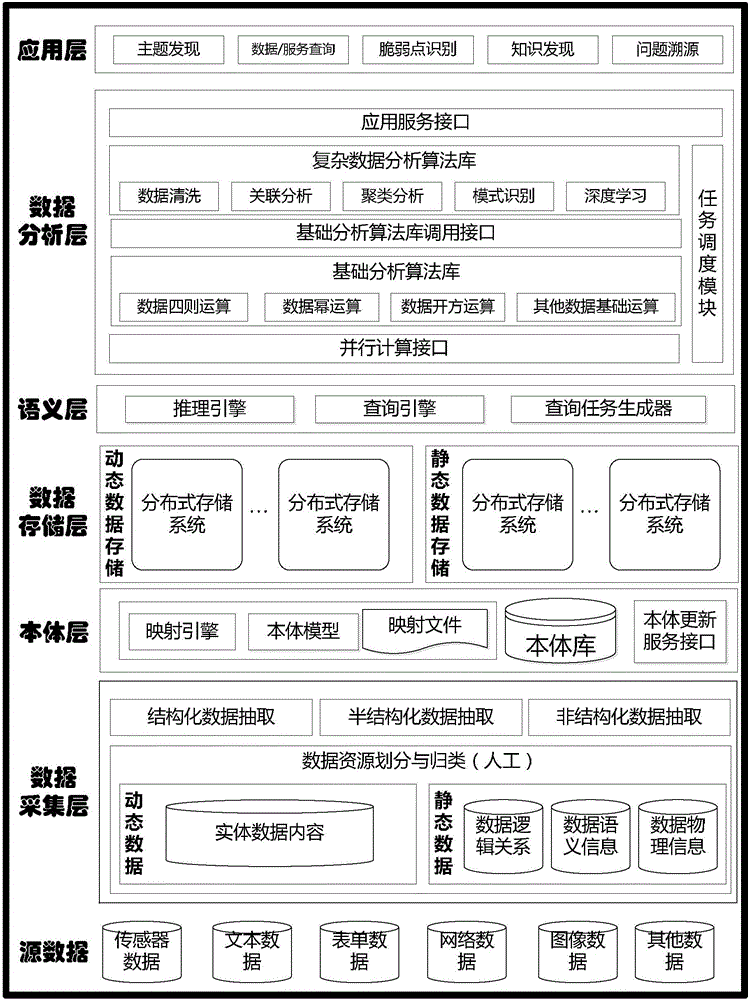

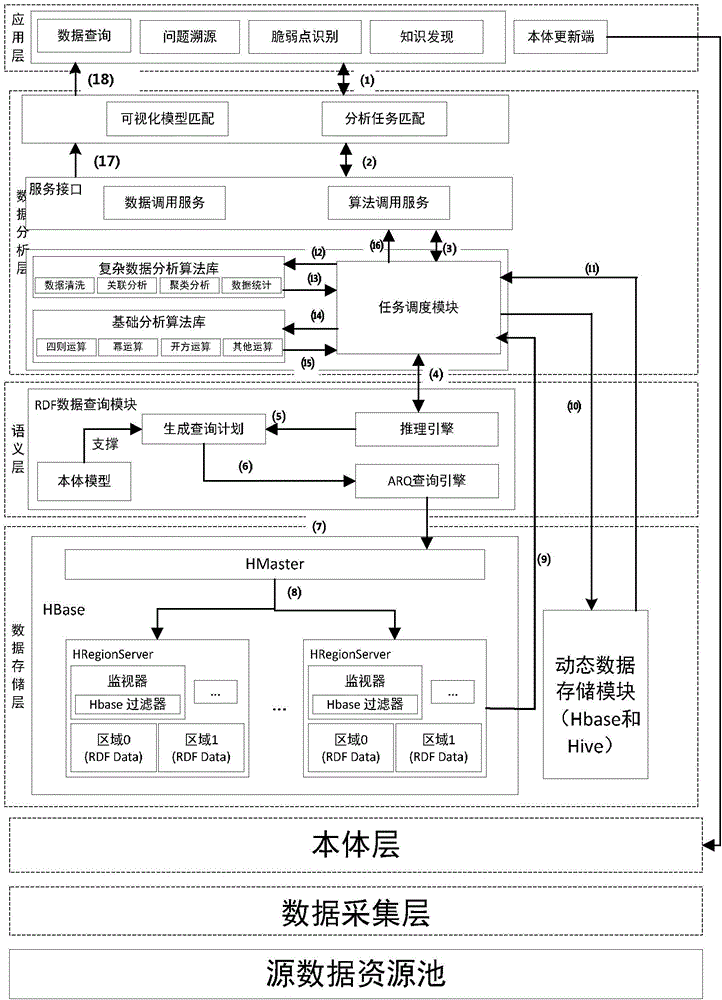

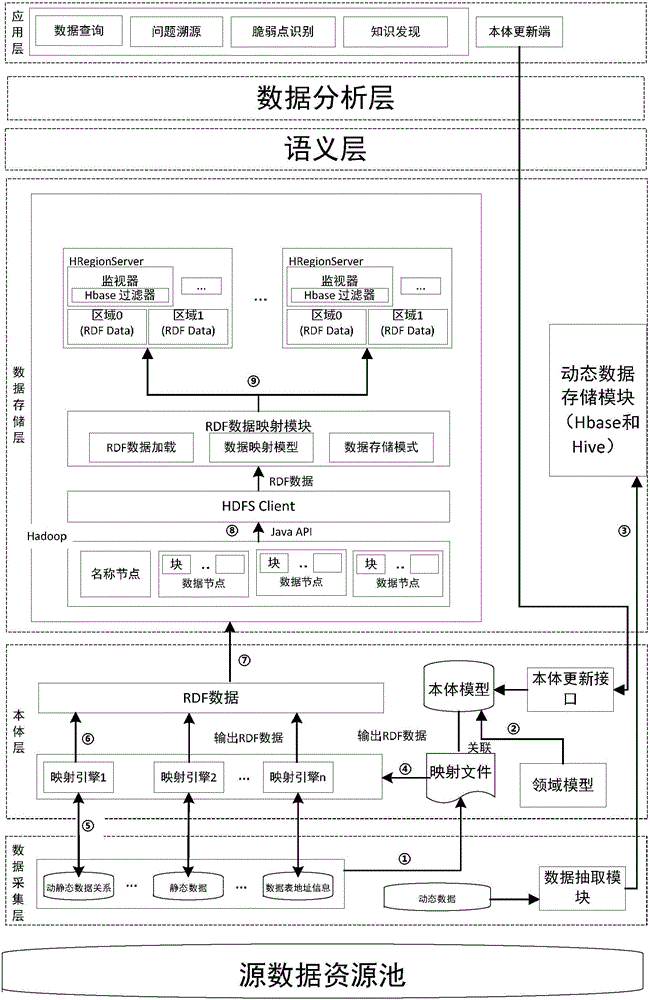

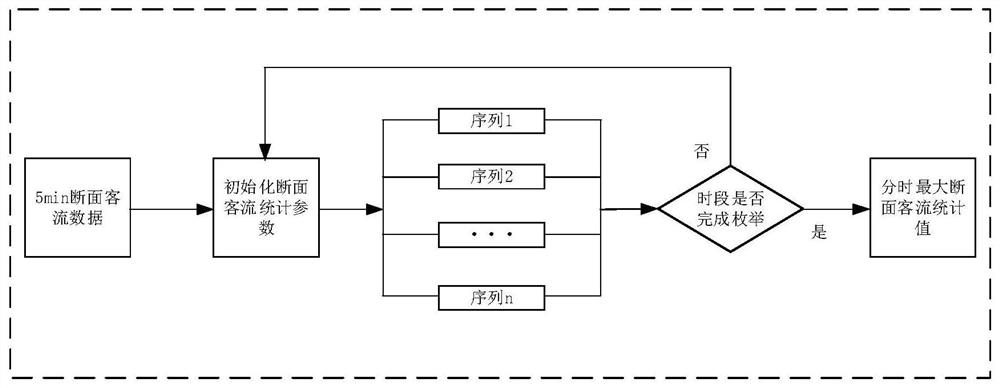

Semantic net based large scale offline data analysis framework

InactiveCN106570081AGood organizational performanceValid updateDatabase updatingSpecial data processing applicationsData informationData acquisition

The invention relates to a semantic net based large scale offline data analysis framework. The large scale offline data analysis framework includes a data acquisition layer, a body layer, a data storage layer, a semantic layer, a data analysis layer and an application layer. A data source includes dynamic data and static data, and the static data includes data and database internal logic semantic and structure type. The static data is established into a body model in the analysis framework; the static data is extracted and modeled, and then the static data orients a user or an upper analysis task in a semantic service manner. The large scale offline data analysis framework can effectively improve the ability to organizing multi-source heterogeneous offline data and has a uniform interface to upper data; and application users or data analysis workers can access a lower data source through a semantic interface without knowing all the information of different data sources, and relevant data information is acquired. The large scale offline data analysis framework can effectively update the whole data source from a global perspective by correction of the body structure having changed content and update and inference service built in an application tool.

Owner:TONGJI UNIV

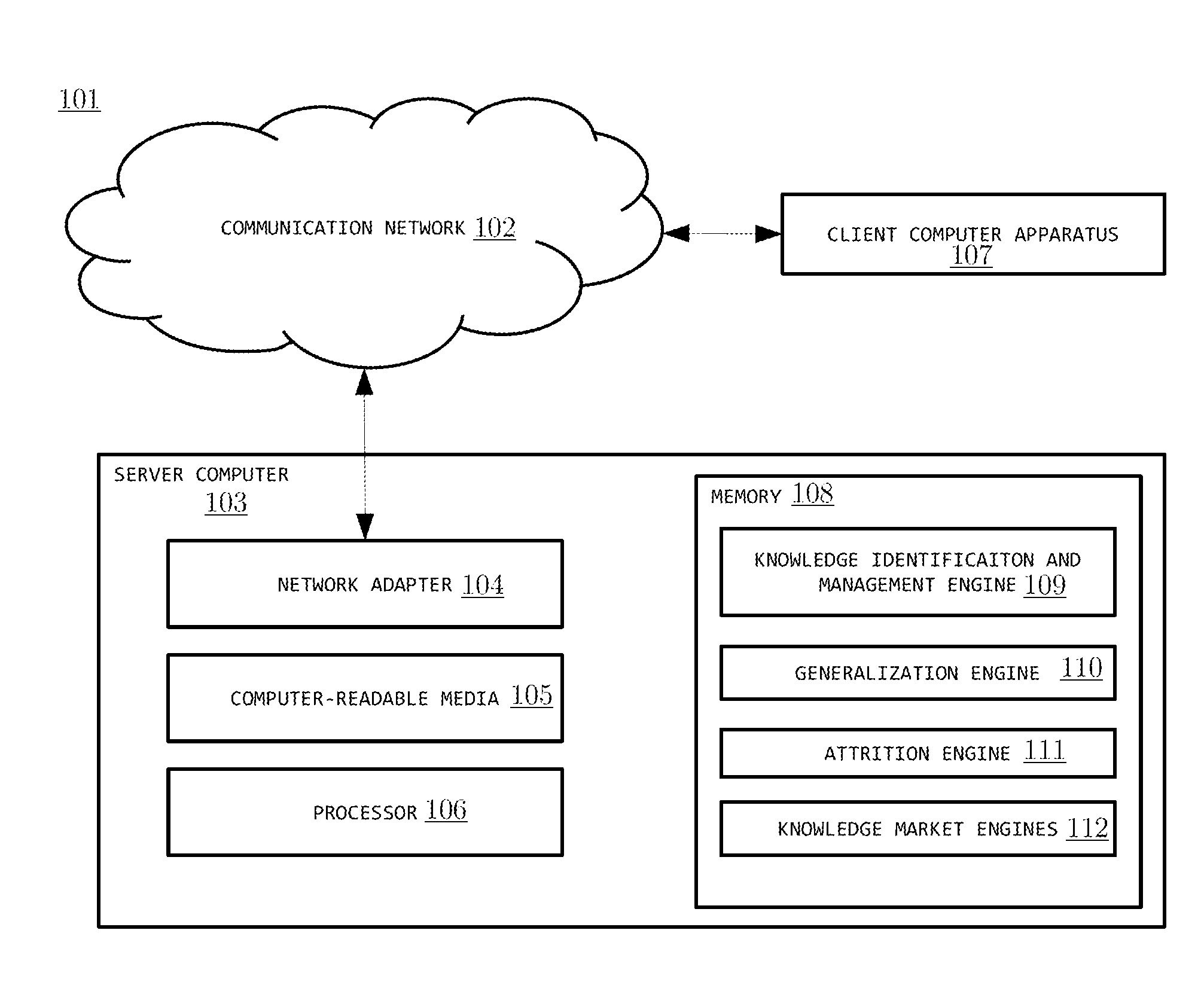

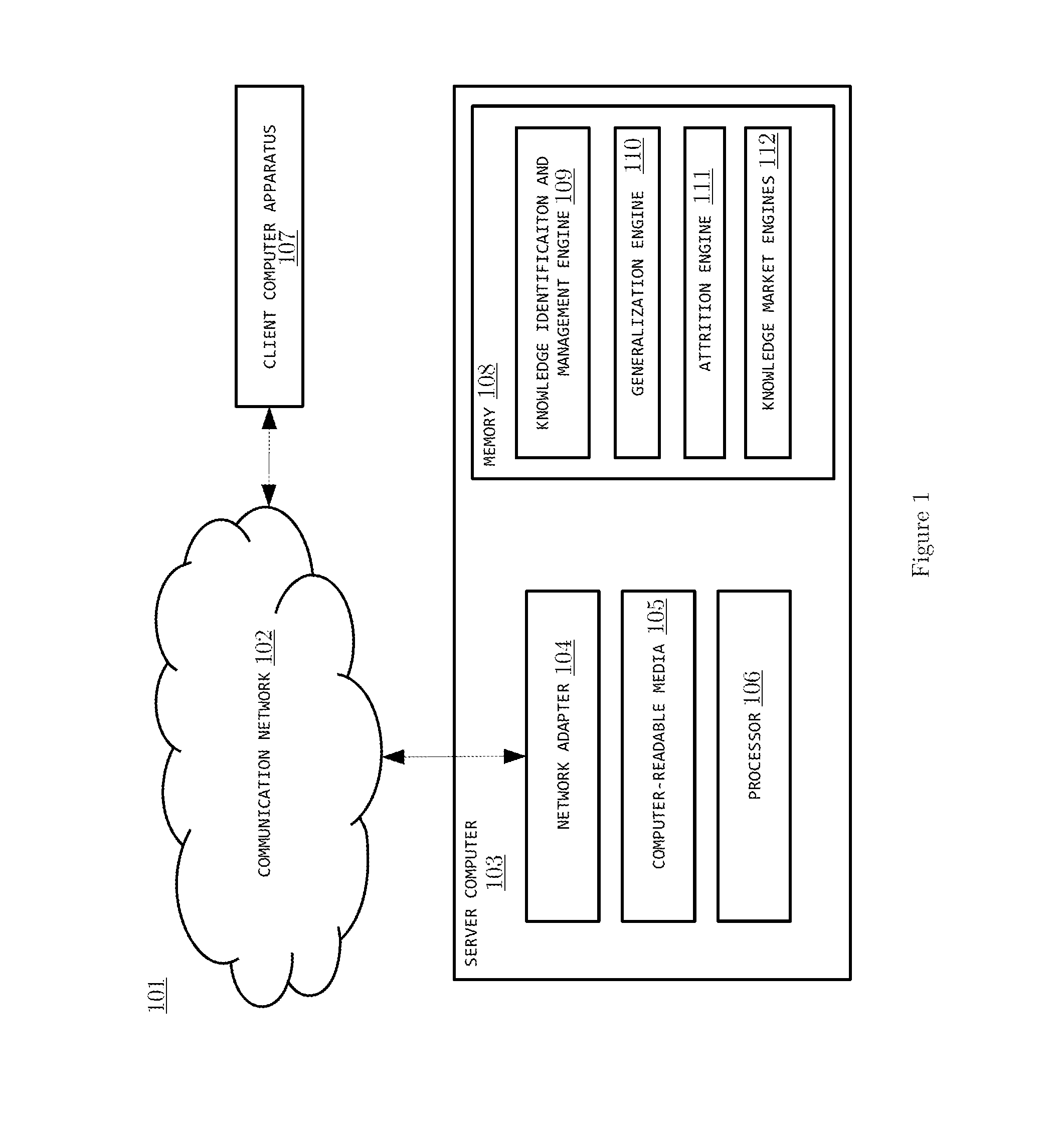

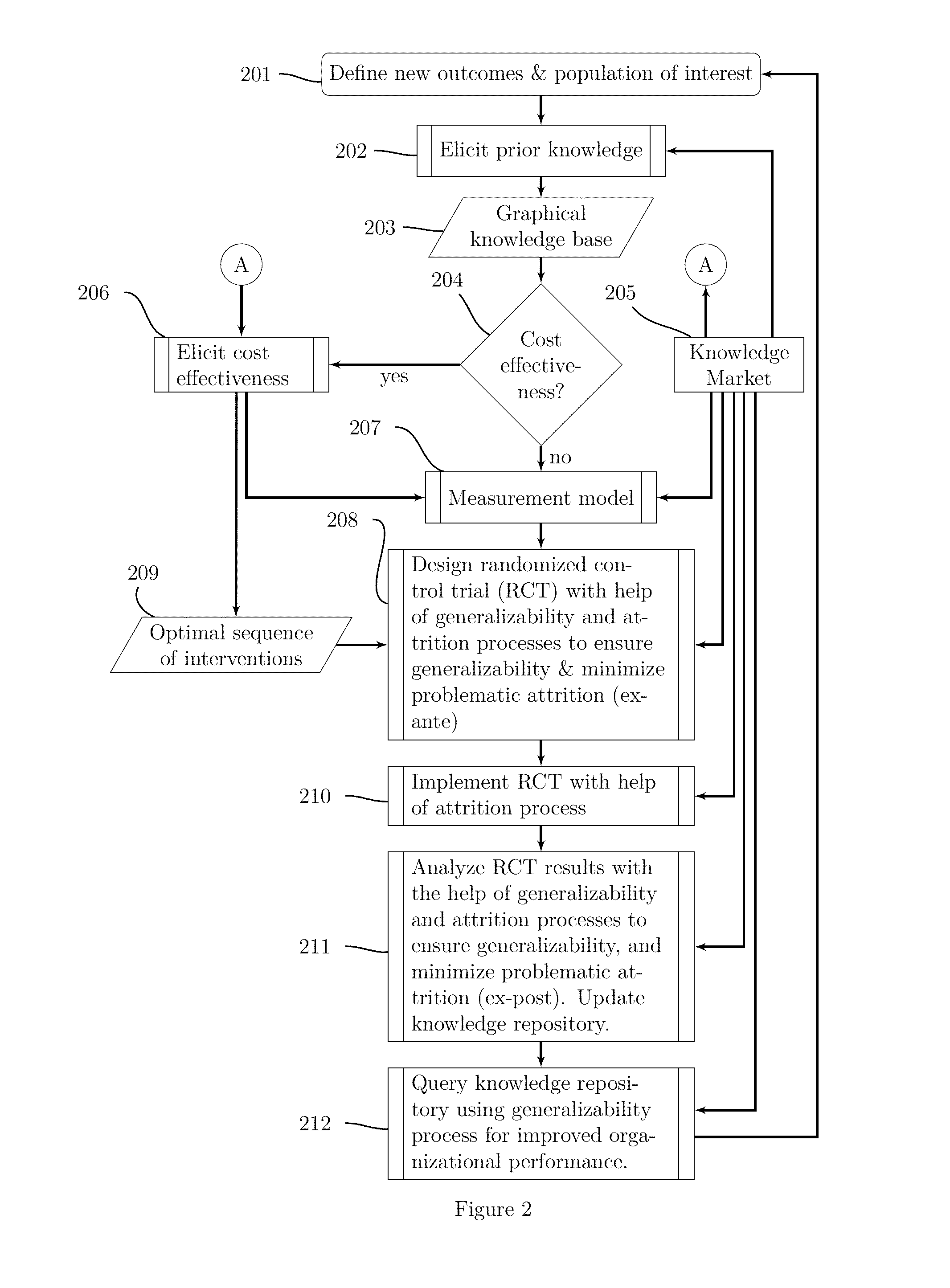

Methods, systems, and articles of manufacture for the management and identification of causal knowledge

InactiveUS20160292248A1Simplify the management processIncreased cost-effectivenessVisual data miningStructured data browsingPopulationData science

Systems, methods, and articles of manufacture are disclosed for the identification and management of causal knowledge. Organizations can use this knowledge to improve performance by, for example, designing cost-effective interventions to change customer or employee behavior. These methods use novel ways to abstract, standardize, and automate the identification and management of causal knowledge, thus making it accessible and affordable to most business users. Moreover, methods are disclosed that—for the first time—solve two critical problems of randomized controlled trials: Missing data on the outcomes of interest, and the inability to generalize findings from the experimental sample to the population using non-probability samples. This includes solving a fundamental problem (present also in probability samples) with the generalization of segmented analysis from a study sample to a population. Use of these embodiments will make the identification and management of causal knowledge much more cost effective, efficient, and reliable.

Owner:CAMBRIDGE SOCIAL SCI DECISION LAB

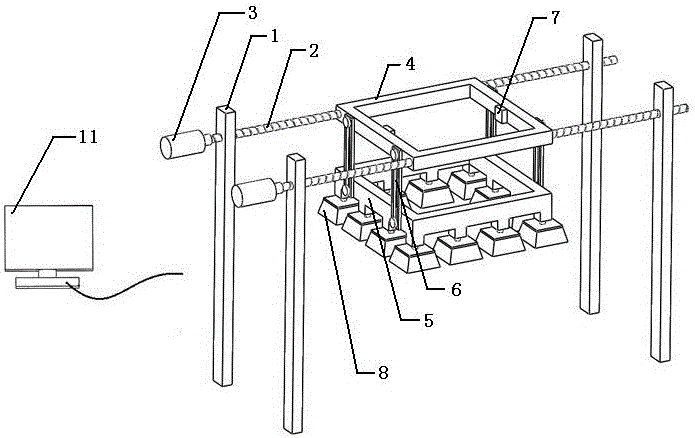

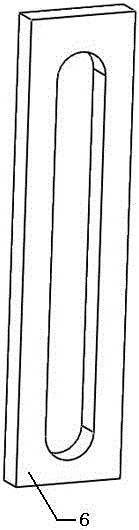

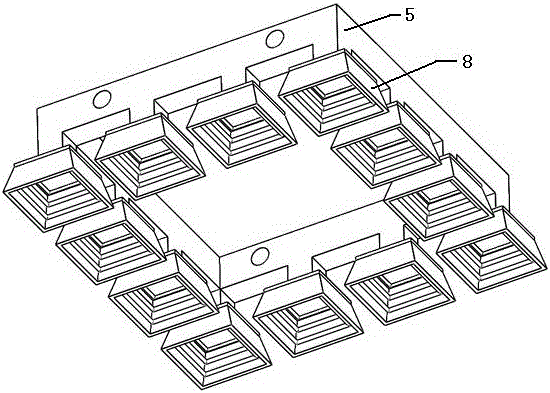

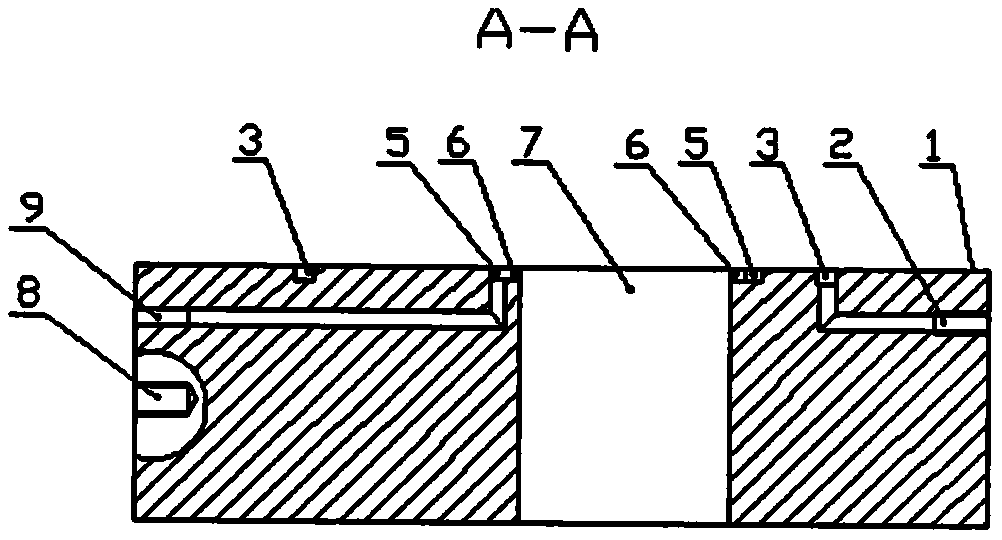

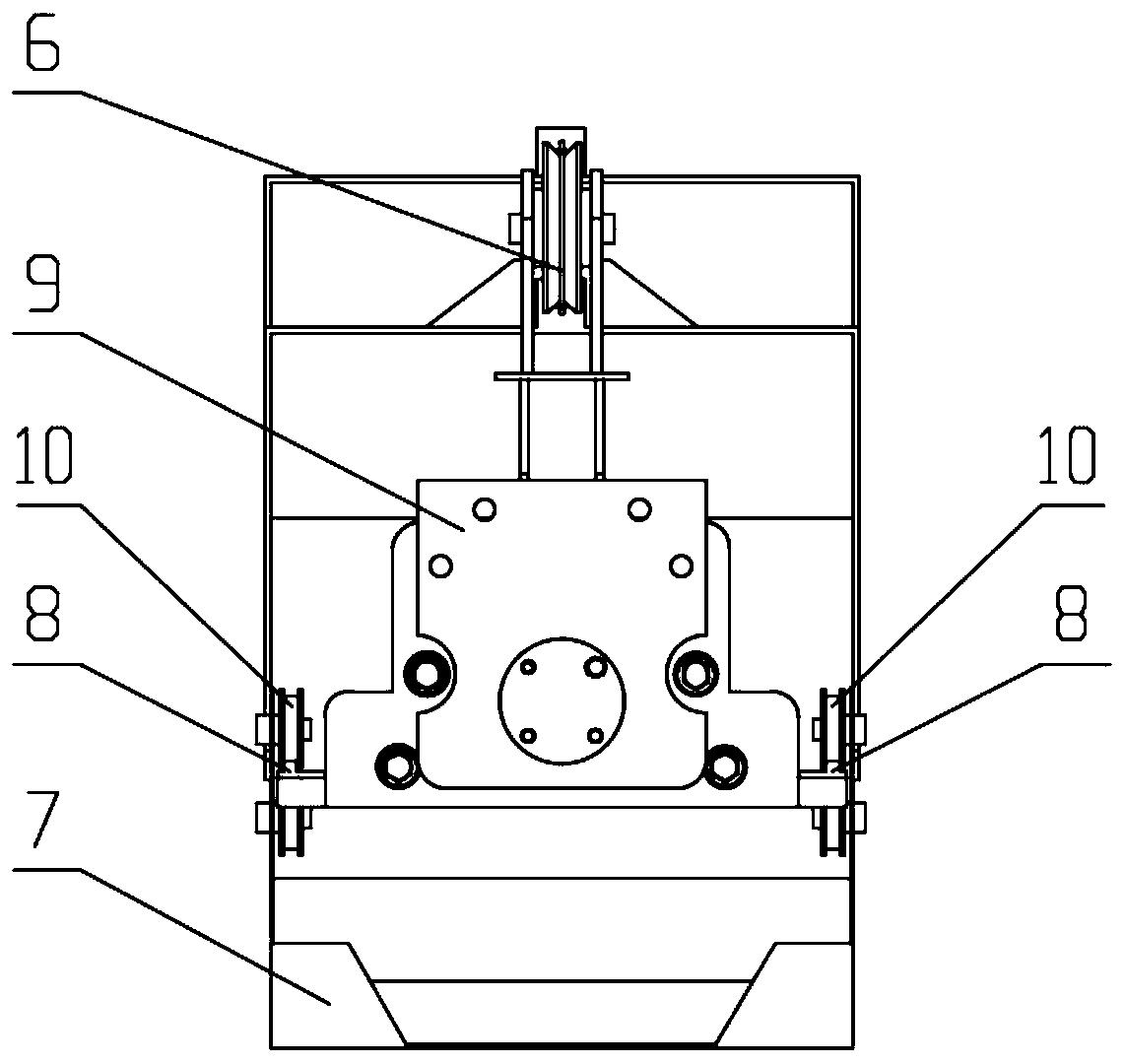

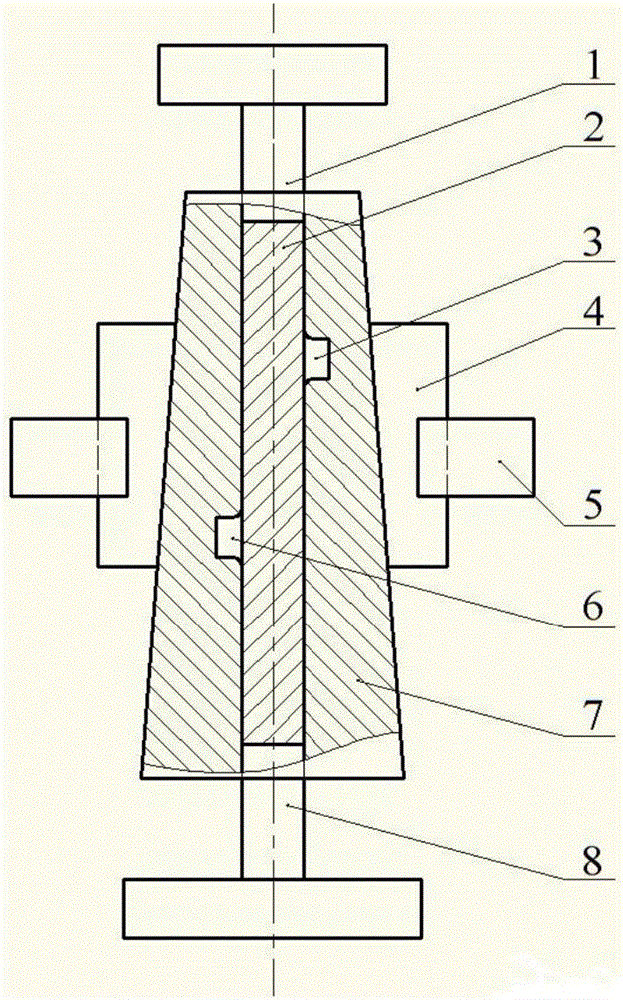

Selective laser sintering SLS laid powder preheating device

InactiveCN106001575AWarm up evenlyHigh precisionAdditive manufacturing apparatusIncreasing energy efficiencyInfraredSelective laser sintering

The invention provides a selective laser sintering SLS laid powder preheating device. The selective laser sintering SLS laid powder preheating device comprises stand columns, lead screws, driving motors, an upper support, a lower support, height adjusting plates, infrared temperature measuring devices, a plurality of rectangular pyramid hollow shells and a control system, wherein each rectangular pyramid hollow shell, a heating rod inside the rectangular pyramid hollow shell and a reflector on the inner wall of the rectangular pyramid hollow shell form a corresponding independent preheating device; and the independent preheating devices divide a forming region into a plurality of small regions capable of preheating independently, are directly controlled by the control system and do not interfere one another. When temperatures of different regions of the laid powder are different, the independent preheating devices can be adjusted to preheat the different regions at different temperatures, so that the laid powder is integrally preheated uniformly; and the direction of each independent preheating device in three-dimensional space is adjustable, the preheating regions can be adjusted according to the size of a formed part, preheating efficiency is improved, and energy is saved. By the selective laser sintering SLS laid powder preheating device, the precision and the structure property of the formed part can be improved effectively; and the selective laser sintering SLS laid powder preheating device has an important significance on development of an SLS forming technology.

Owner:ZHONGBEI UNIV

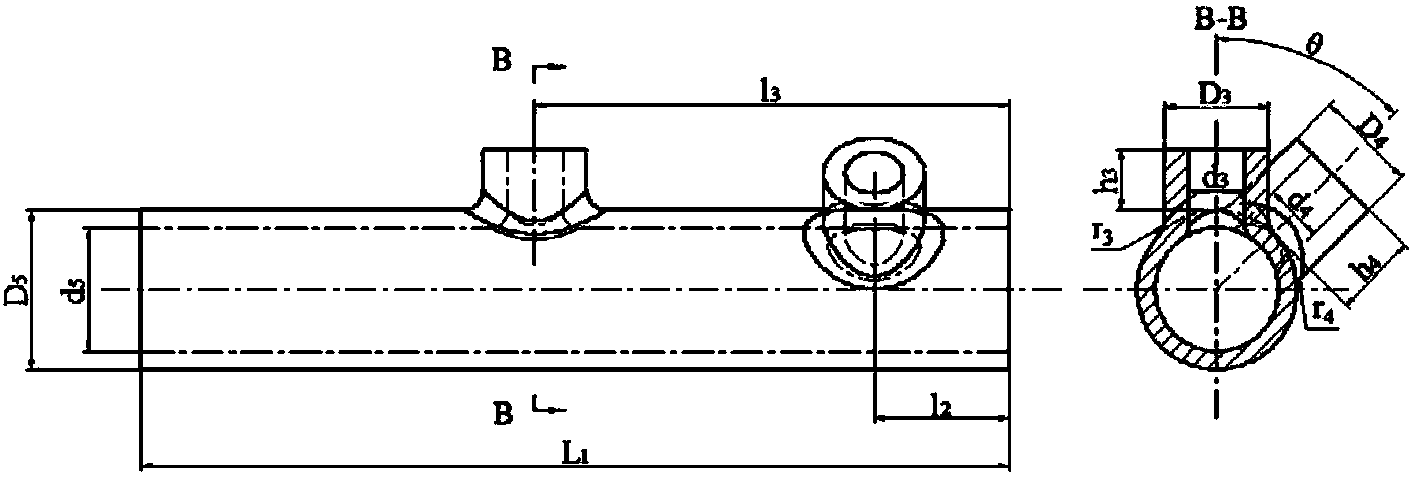

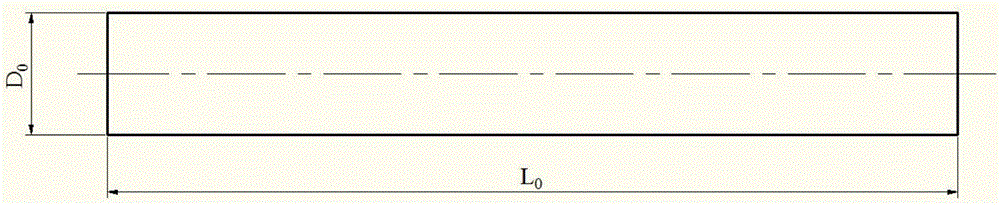

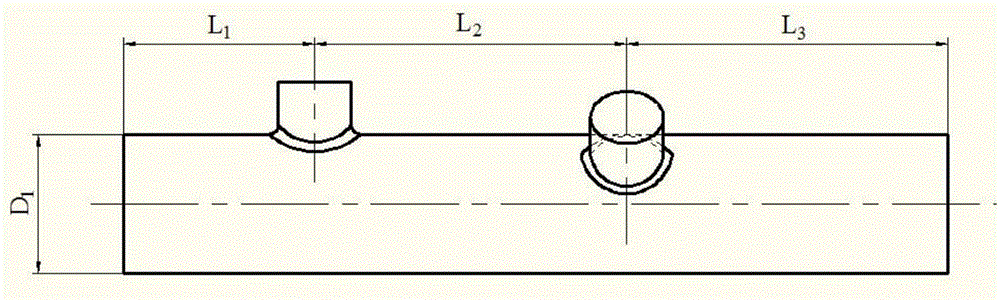

Large-sized multi-nozzle pipe hot extrusion forming process formulation and mold design method

InactiveCN103537509AIncrease productivityShorten the manufacturing cycleExtrusion diesExtrusion containersStructure propertyEngineering

The invention discloses a large-sized multi-nozzle pipe hot extrusion forming process formulation and mold design method. Taking a double-nozzle pipe for example, the method comprises the following steps: determining the size of each part of an unmachined double-nozzle pipe after hot extrusion forming; determining the size of an initial pipe blank; determining the position of the center of a prefabricated hole and the size of the aperture; determining amount of compression in the axial direction of the pipe blank with the prefabricated hole, of which oxide skin is removed, required for finishing hot extrusion forming of a second nozzle; determining amount of compression in the axial direction of the pipe blank required for continuing to finish hot extrusion forming of a first nozzle; determining the dimensional parameter of a key part of the hot extrusion mold; selecting the structural form of the hot extrusion mold; determining the extrusion capacity parameter and selecting forming equipment; determining a technological flow of the double-nozzle pipe hot extrusion forming process. According to the method, a pipe inner hole and a nozzle inner hole can be directly formed, the structural strength at the nozzle is improved, the metal mechanic property and the structure property are improved, the manufacturing period is shortened, and the material utilization rate is improved.

Owner:UNIV OF SCI & TECH BEIJING

Manufacture method of irregular pipe

ActiveCN102756011AImprove mechanical propertiesGood organizational performanceQuality performanceEngineering

The invention discloses a manufacture method of an irregular pipe. The manufacture method comprises the steps of: S1, carrying out upsetting extrusion on a straight pipe so as to form a first pressure inlet on the surface of the straight pipe; S2, carrying out upsetting extrusion on the straight pipe with the first pressure inlet so as to form a second pressure inlet on the surface of the straight pipe, wherein the second pressure inlet and the first pressure inlet form a first angle along the peripheral direction; and S3, bending the straight pipe with the first pressure inlet and the second pressure inlet, thus forming a preset curvature between the first pressure inlet and the second pressure inlet. According to the manufacture method of the irregular pipe, the internal hole of the pipe can be directly formed, and therefore the problems that in the prior art, the manufacture period is long and the material utilization is relatively low caused by manually cutting the internal hole by mechanically processing can be solved; and moreover, the heating is less frequently carried out during the operation, and the cutting allowance is low, and the percent of pass is high, and the quality performance is stable.

Owner:TSINGHUA UNIV +1

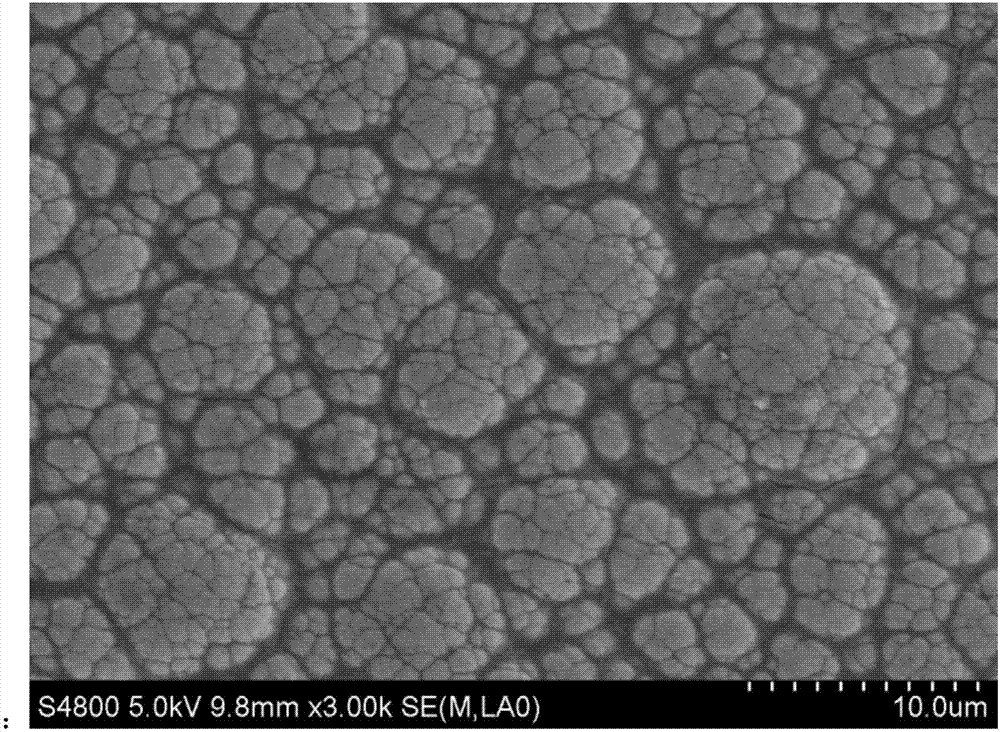

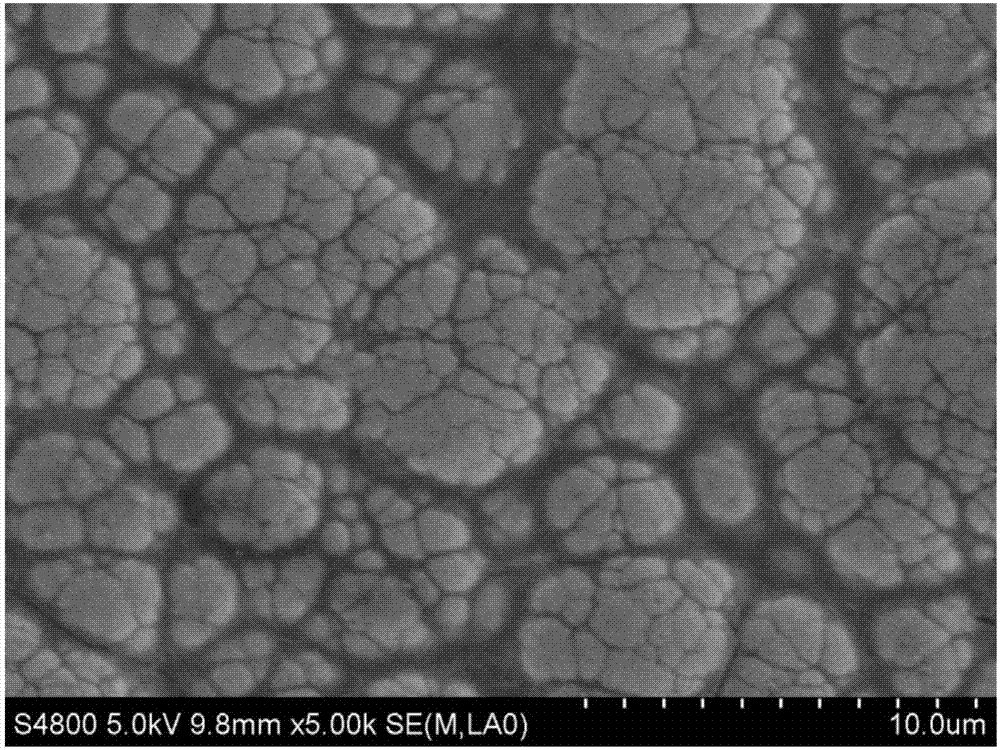

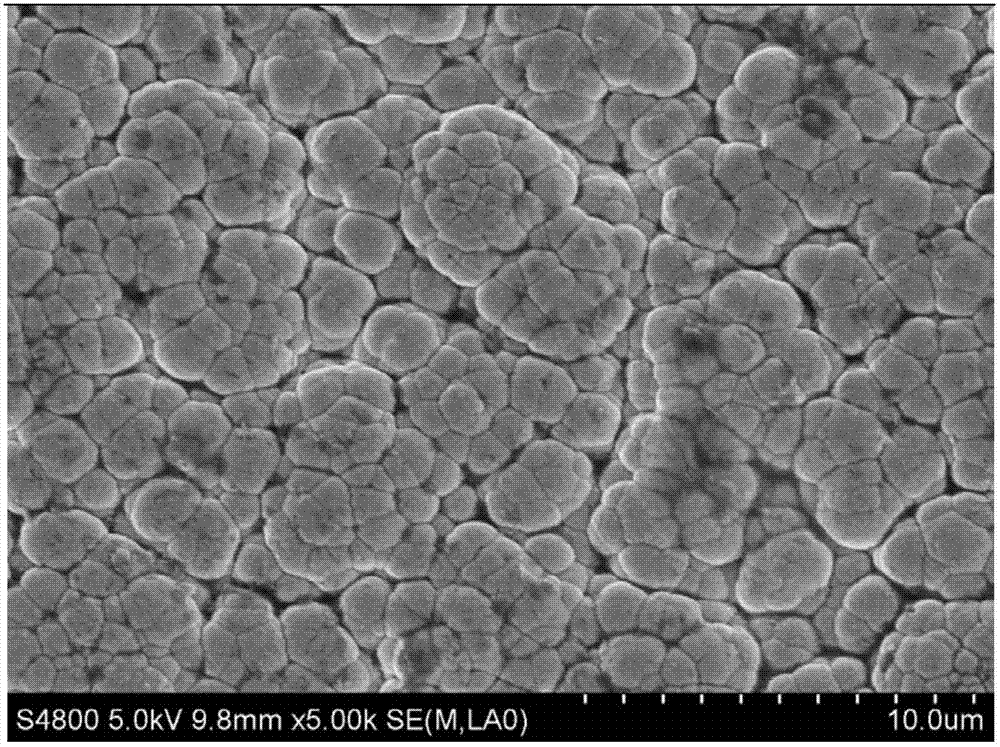

RE-Ni-Mo/GO nano composite deposition liquid as well as preparation method and application thereof

ActiveCN104911642AGood organizational performanceImprove coating crystal orientationRare-earth elementTrisodium citrate

The invention discloses an RE-Ni-Mo / GO nano composite deposition liquid. Each liter of the deposition liquid comprises 0.25-5g of graphene oxide, 45-55g of nickel sulfate, 4-10g of sodium molybdate, 55-65g of trisodium citrate, 0.2g of lauryl sodium sulfate, 0.1-5g of a rare earth element RE and the balance of distilled water. The invention further discloses a method for forming an RE-Ni-Mo / GO multifunctional nano composite deposition layer on the surface of low-carbon steel. By adopting the composite deposition liquid and with the combination of ultrasonic wave and electric deposition techniques, the RE-Ni-Mo / GO multifunctional nano composite deposition layer can be prepared on the surface of low-carbon steel. By adopting the composite deposition layer prepared by using the method disclosed by the invention, the corrosion resistance, the surface hardness, the wearing resistance, the breaking strength and the like of the low-carbon steel are effectively improved, and moreover, the difficulty that powder micro particles can be agglomerated in conventional composite electric deposition.

Owner:CHINA GATEWAY PHARMA DEV CO LTD

Molding method and molding apparatus for pipe structure having nozzle boss

The present invention discloses a molding method and a molding apparatus for a pipe structure having a nozzle boss. The molding method comprises the following steps: S1, constructing a plastic rheology area on a pipe billet, and arranging an outer mold outside the plastic rheology area of the pipe billet, wherein a volume of the material within the plastic rheology area length range is more than or equal to a volume of a nozzle boss requiring molding; and S2, applying axial upsetting-extruding force on the plastic rheology area of the pipe billet from both ends of the pipe billet, such that the material within the plastic rheology area of the pipe billet laterally moves to form the nozzle boss. With the molding method of the embodiments of the present invention, mechanical properties of the nozzle boss structure of the pipe are improved, and characteristics of simple and easily-controllable operation, high material utilization rate, high qualification rate and short manufacturing period are provided during the nozzle boss molding process.

Owner:TSINGHUA UNIV

Research and development project process capacity evaluation system

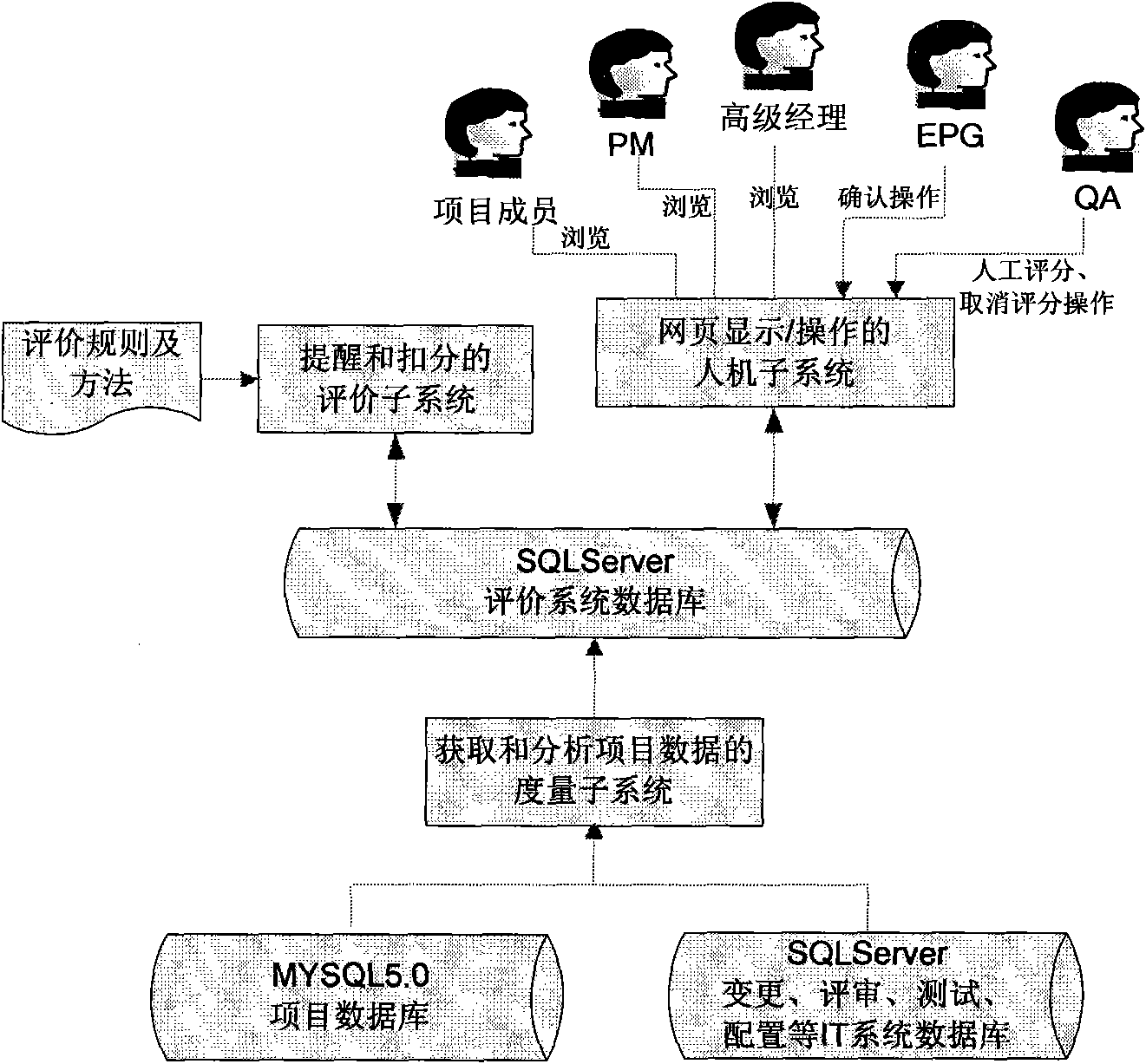

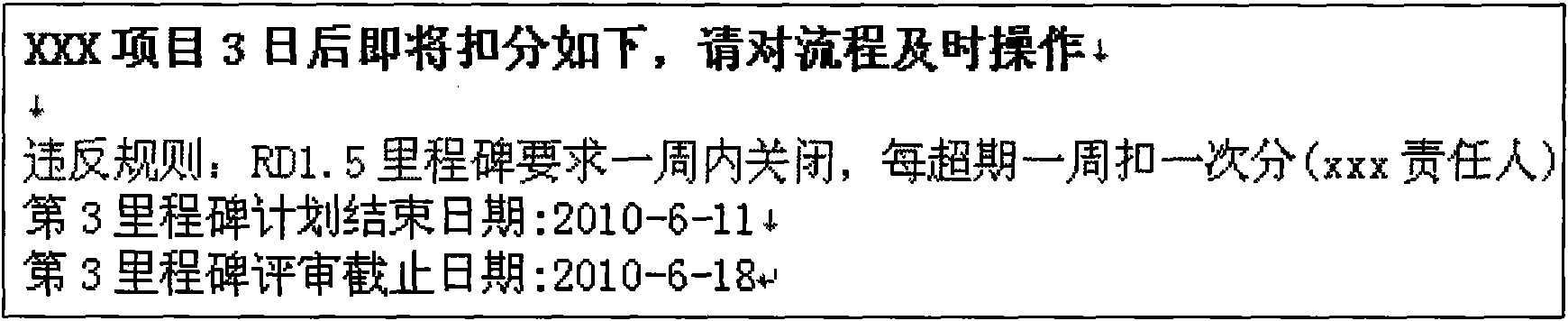

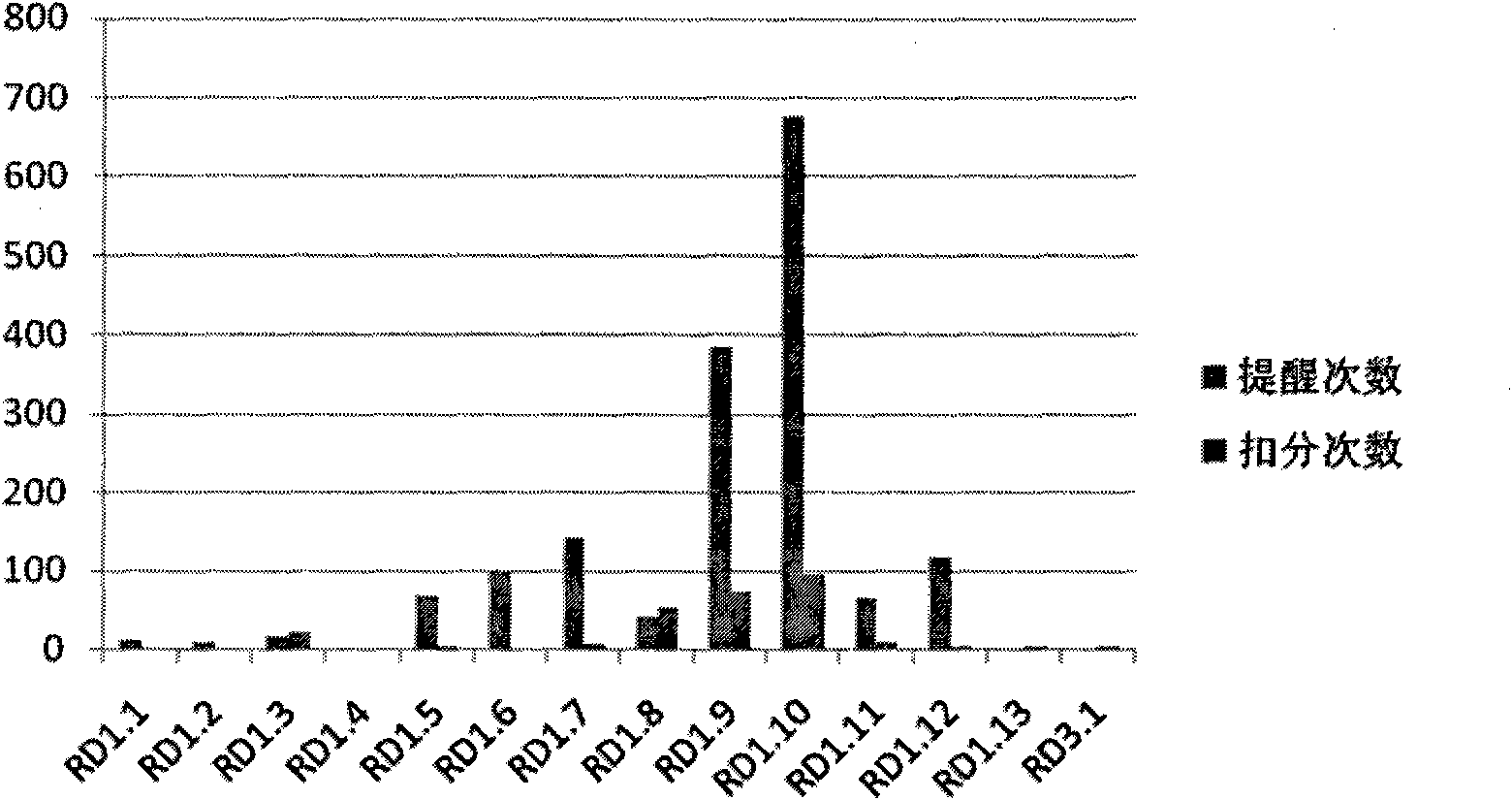

InactiveCN101957948AReduce administrative workloadReduce human involvementResourcesMan machineProject management

The invention discloses a research and development project process capacity evaluation system, which consists of three subsystems, namely the first subsystem is a measurement subsystem for automatically acquiring and analyzing project data; the second subsystem is an evaluation subsystem for prompting and deducting according to the preset evaluation rule; and the third subsystem is a man-machine subsystem. In addition, the system is provided with an evaluation system database to be connected with the evaluation subsystem, the man-machine subsystem and the measurement subsystem respectively; the measurement subsystem and the evaluation subsystem of the evaluation system are deployed at an organization server and performs timed background operation in a mode of a service process; the man-machine subsystem accesses intranet websites through a browser; and the evaluation system adopts a B / S framework to be integrated with a mail system, supports evaluation information viewing and operating function of EPG, QA, PM, project members and other roles, conveniently, normatively and efficiently improves project management efficiency of the PM and examination efficiency of the QA, and pushes process executive force of CMMI.

Owner:NR ELECTRIC CO LTD +1

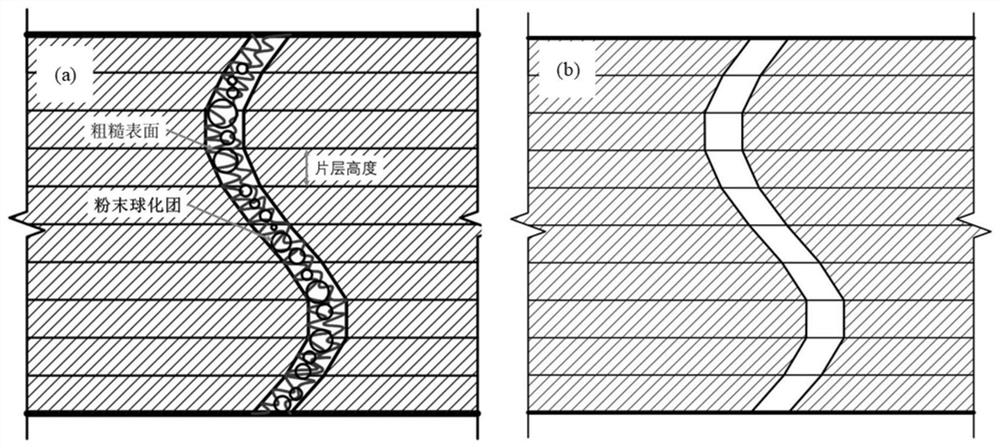

Method for manufacturing metal parts and molds and micro-roller used therefor

ActiveUS9302338B2Formability of complexImprove accuracyArc welding apparatusAdditive manufacturing with liquidsNumerical controlGradient material

A method for manufacturing parts and molds by: 1) slicing a three-dimensional CAD model of a part or mold; 2) planning a modeling path according to slicing data of the three-dimensional CAD model, whereby generating numerical control codes for modeling processing; and 3) performing fused deposition modeling of powders or wire material of metal, intermetallic compounds, ceramic and composite functional gradient materials by layer using a welding gun on a substrate layer via a numerical control gas shielded welding beam or laser beam according to a track specified by the numerical control code for each layer. A micro-roller or a micro-extrusion unit is installed at a contact area between melted and softened areas. The micro-roller or the micro-extrusion unit synchronously moves along with fused deposition area, which results in compressing and processing of the fused deposition area during the fused deposition modeling.

Owner:HUAZHONG UNIV OF SCI & TECH

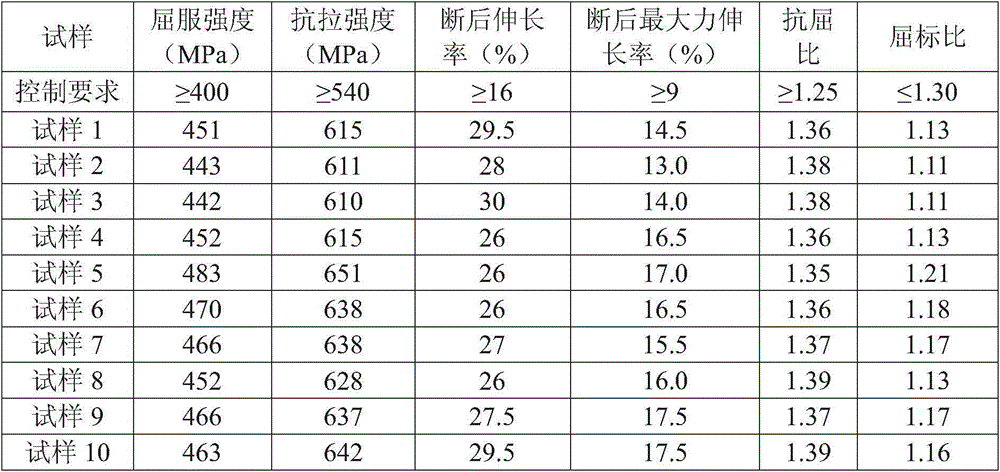

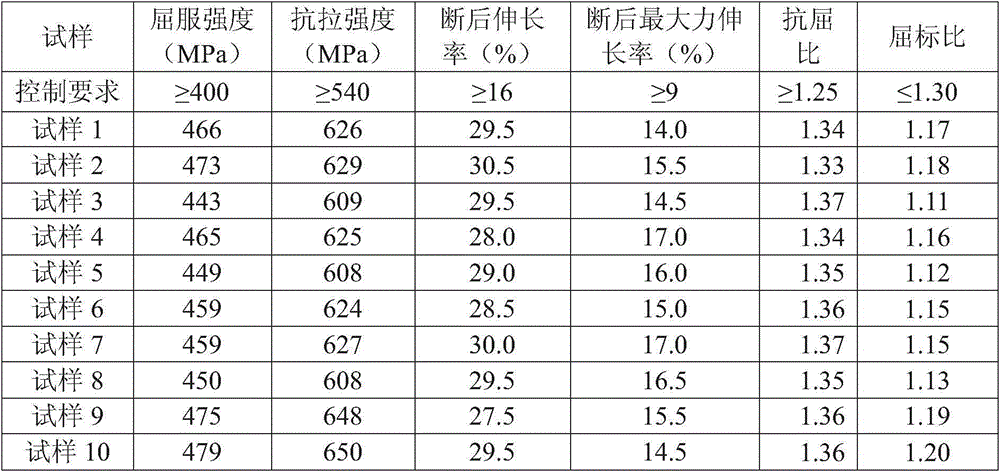

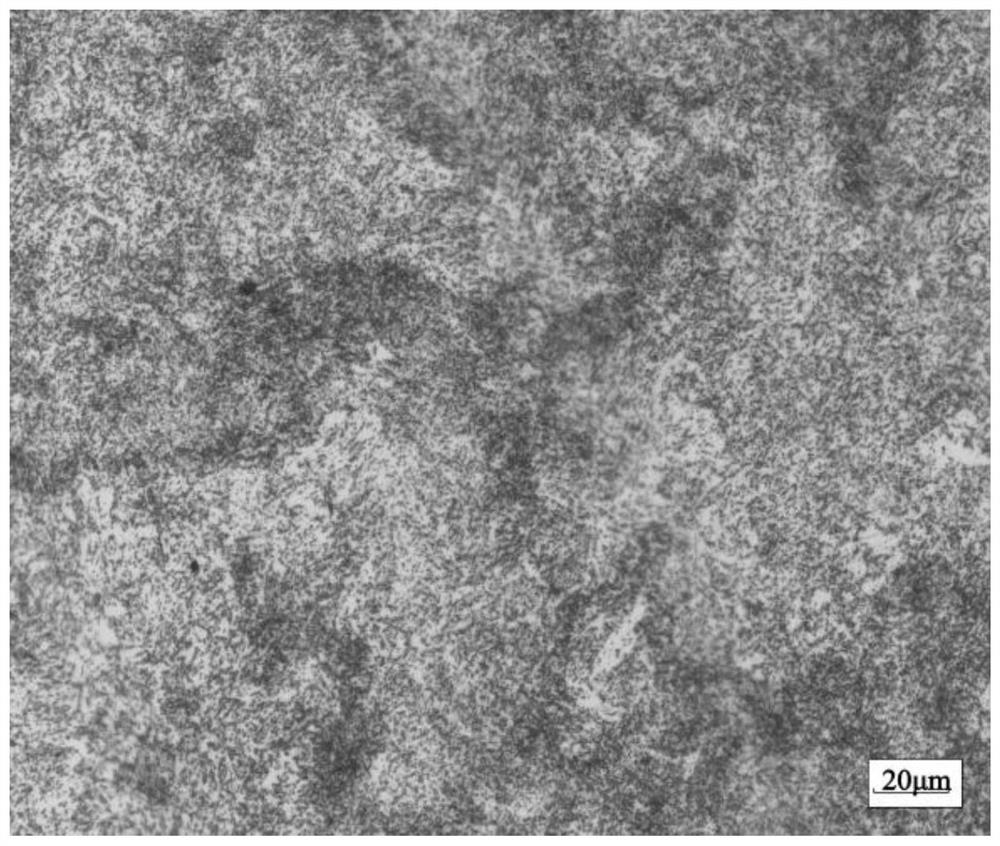

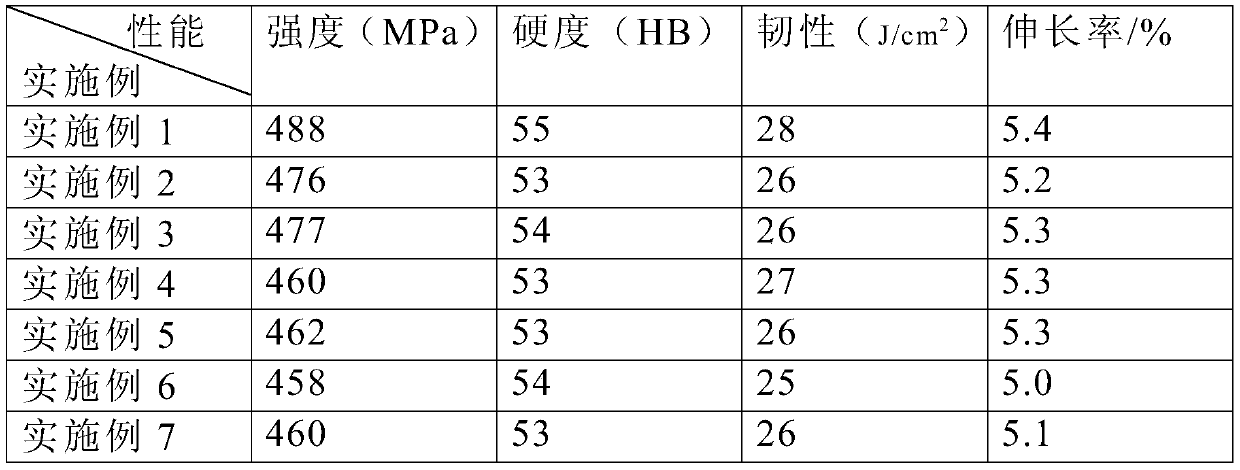

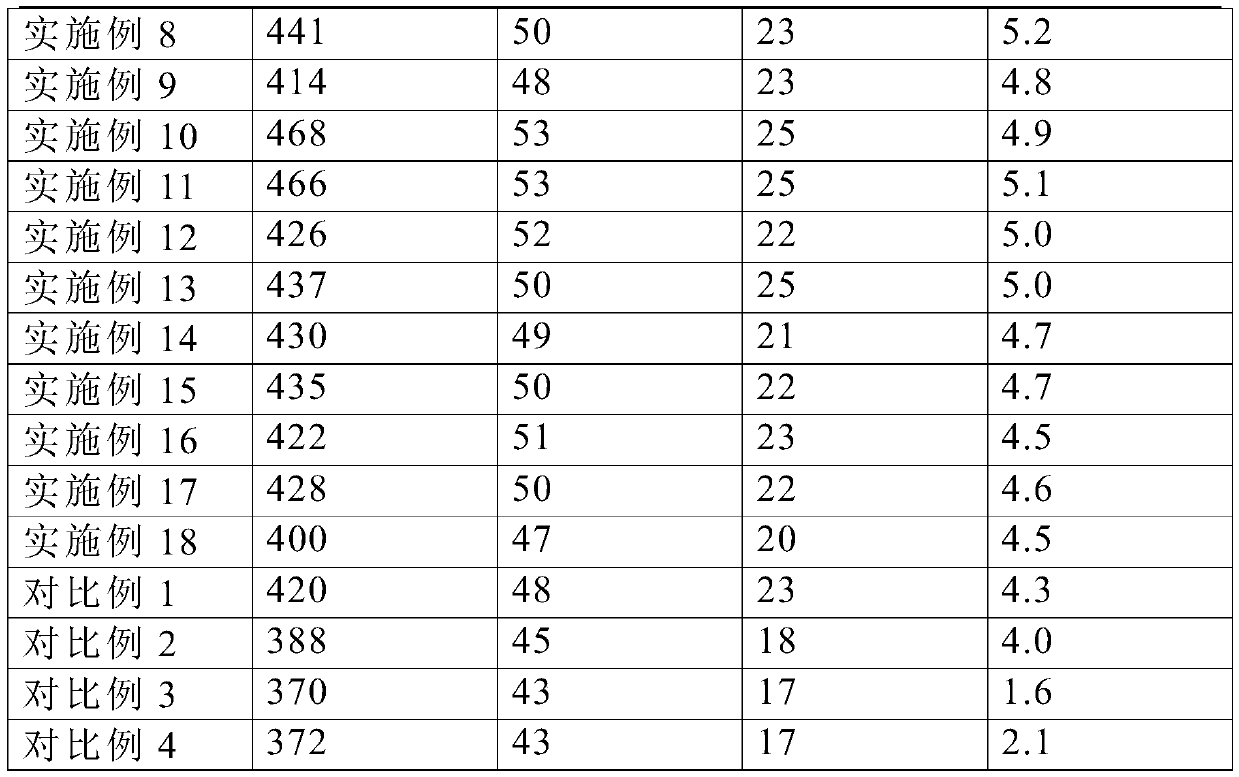

HRB400E high-strength aseismic coiled reinforced bar and production method thereof

The invention discloses an HRB400E high-strength aseismic coiled reinforced bar and a production method thereof. The HRB400E high-strength aseismic coiled reinforced bar is composed of the following components in percentage by weight: 0.20-0.25% of C, 0.30-0.40% of Si, 0.90-1.10% of Mn, 0.010-0.015% of V and the balance of Fe, wherein the content of impurities is controlled so that S is less than or equal to 0.045% and P is less than or equal to 0.045%. The HRB400E coiled reinforced bar produced by use of the production method of the HRB400E high-strength aseismic coiled reinforced bar is excellent in structure properties; besides, the alloy cost is greatly reduced.

Owner:陕西钢铁集团有限公司

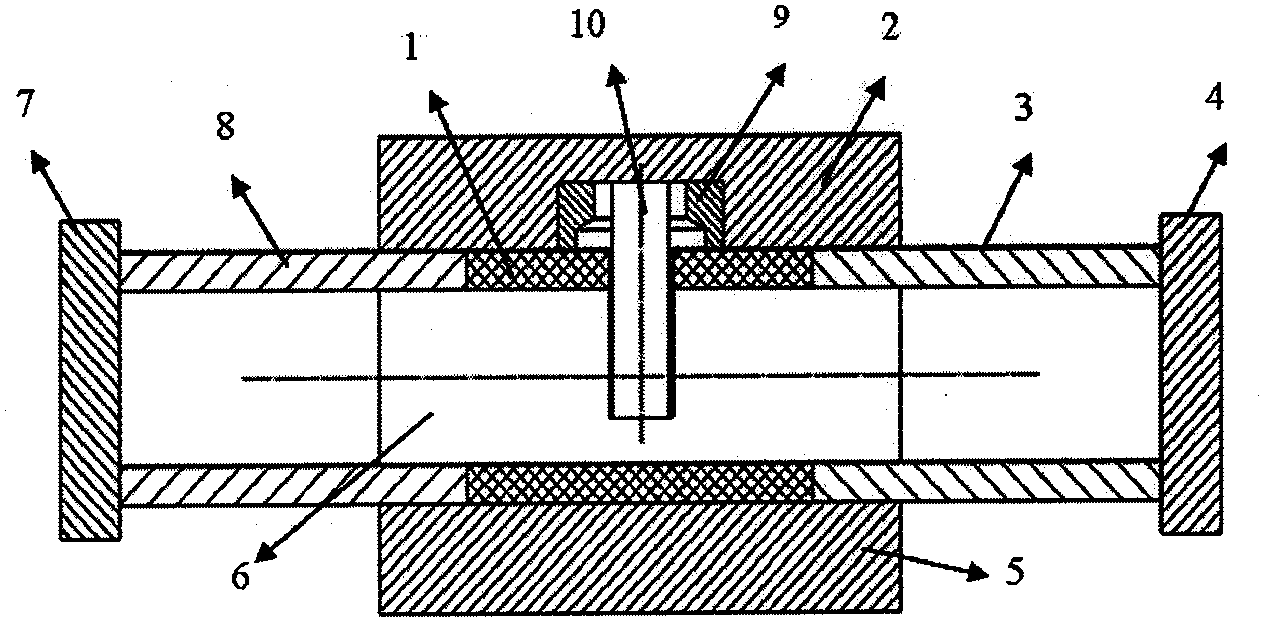

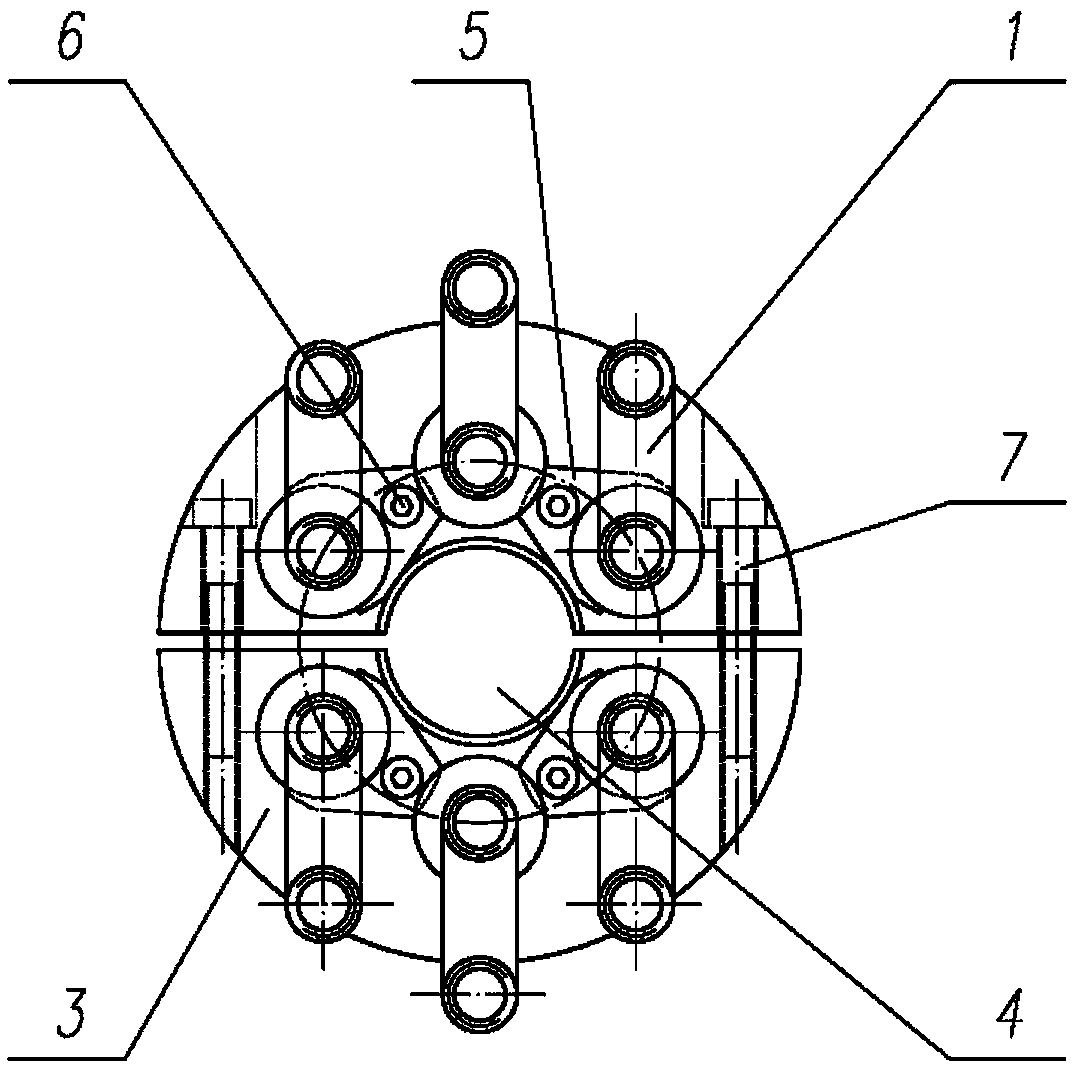

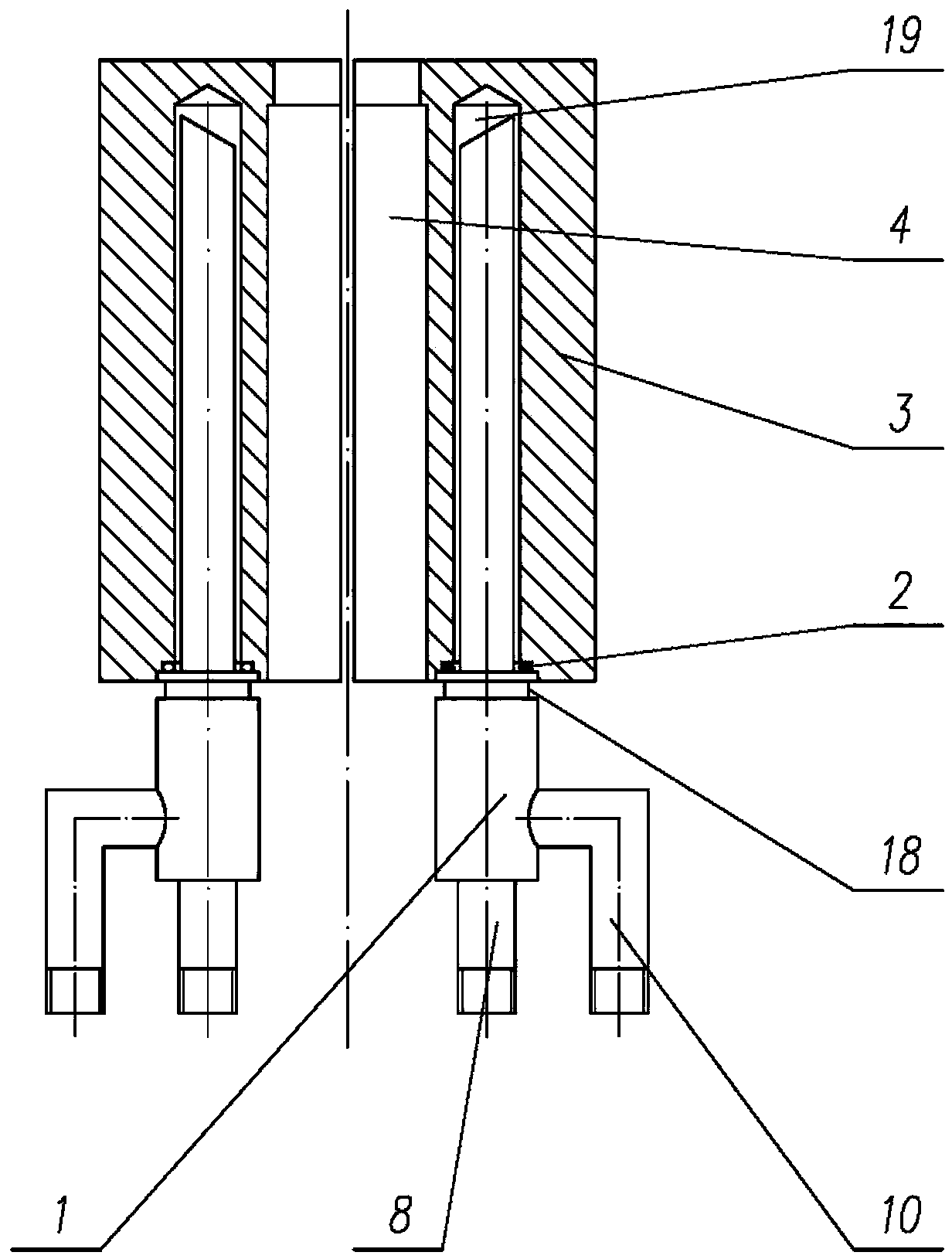

Adjustable laser coaxial powder feeding nozzle

The invention discloses an adjustable coaxial laser nozzle for feeding powder, comprising a laser head, a protection lens, a water-cooling sleeve for the protection lens and a column laser cavity arranged at the upper part, a coaxial conical laser cavity which is formed by the inner layer of a laser sleeve in the middle part; wherein, a powder cavity, a secondary external protective cavity and anexternal water-cooling cavity are arranged on the lower part of the external part of the laser sleeve; the powder cavity is formed between the laser sleeve and a power cavity sleeve screwed together;the secondary external protective cavity is formed between the powder cavity and a protective air casing screwed together; the powder cavity and the protective air casing are screwed together and adjustable between 1mm to 3mm; 4 to 6 power transmitting pipes and 4 to 6 air tubes are respectively positioned around the top parts of the cones of the powder cavity and the protective air cavity. The adjustable coaxial laser nozzle for feeding powder has the advantages that the focus length of the focus lamp fit for the coaxial powder-feeding nozzle is between 100mm to 300mm, which ensures convenient assembly and disassembly, even velocity, flexible adjustment of the powder converge diameter, and convenient changeable lower coaxial conical parts (the powder cavity, the air casing and the water cavity).

Owner:XI AN JIAOTONG UNIV

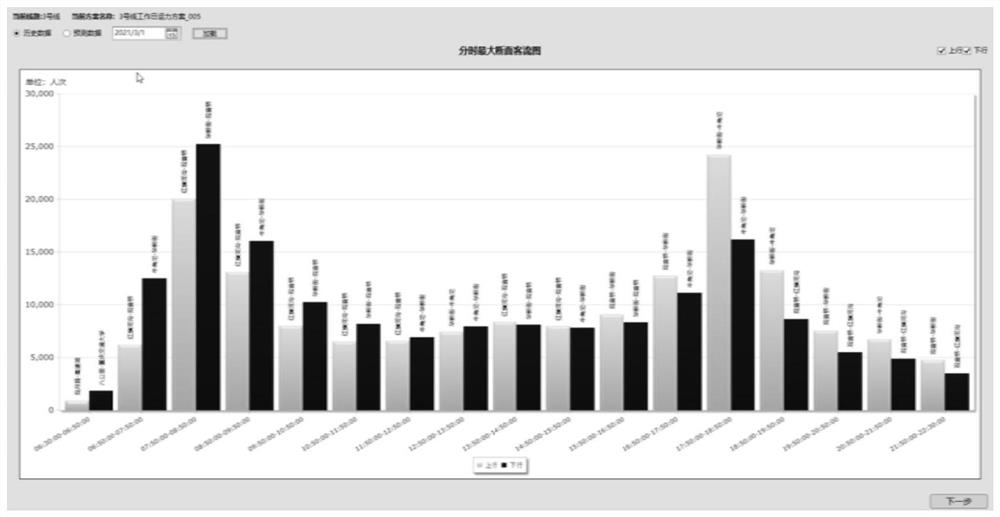

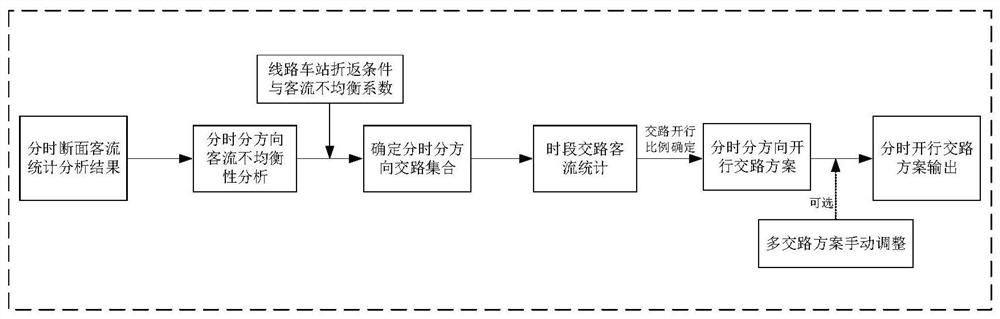

Train operation scheme optimization compilation method and system

PendingCN113919650AFully coupledSupport automatic compilationGeographical information databasesResourcesSimulationRail transit

The invention belongs to the technical field of urban rail transit. The existing train operation scheme is difficult to balance the operation cost and the service level. The invention provides a train operation scheme optimization compilation method. The method comprises the following steps: matching passenger flows of the same type according to the type of a compiled operation scheme to obtain a characteristic day passenger flow so as to perform time period division and time period attribute determination of the operation scheme; according to operation scheme time period division and time period attributes, determining the train operation frequency and the route crossing scheme in each time period by taking the plan-to-which-belongs route operation train ownership as a main constraint; determining turn-back and stop schemes of each time period according to the time-sharing train operation frequency and the traffic scheme and by considering the spatial and temporal distribution characteristics of the passenger flow of entering and exiting the station on the characteristic day; and according to the passenger flow imbalance of each transfer direction of the transfer station, determining a main transfer direction, and carrying out networked connection adjustment on the first and last buses of the operation scheme. Automatic compilation of operation schemes including multi-route, multi-marshalling and special driving organization modes is realized and supported.

Owner:BEIJING JIAOTONG UNIV

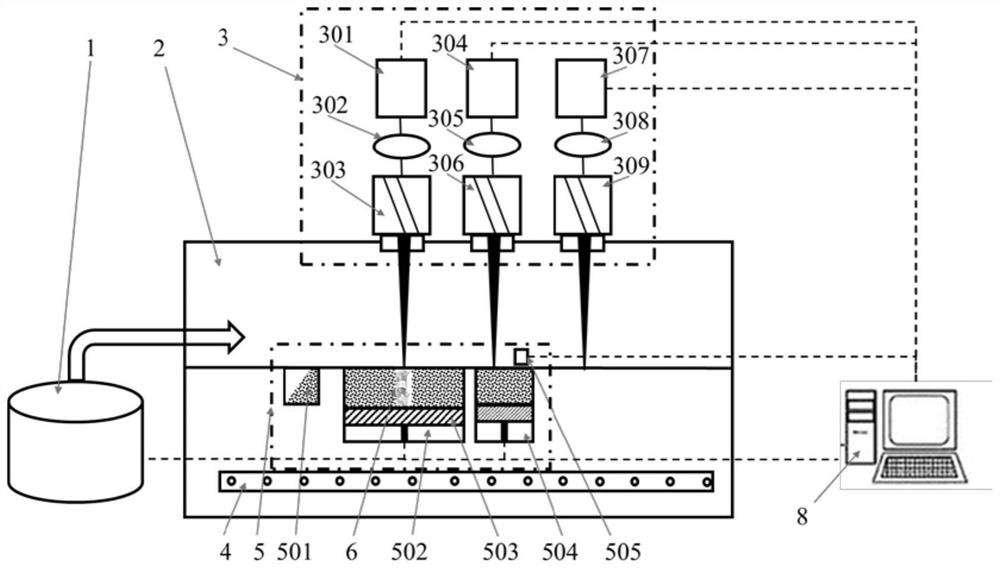

Device conducting composite manufacturing on basis of laser technology

PendingCN111992712AImprove mechanical propertiesImprove the finishAdditive manufacturing apparatusIncreasing energy efficiencyLaser technologyEngineering

The invention discloses a device conducting composite manufacturing on the basis of a laser technology. The device comprises a sealed forming chamber, an inert protective gas source and a machining forming platform. The inert protective gas source is connected with the sealed forming chamber. The machining forming platform is arranged in the sealed forming chamber, and a light path selection system is arranged over the machining forming platform. A machining station is arranged on the machining forming platform, and the machining forming platform is arranged on a guide rail and can slide forwards and backwards through the guide rail. The light path selection system comprises a shock reinforcing independent laser light path, an additive independent laser light path and a subtractive independent laser light path. The light paths are arranged in the direction of the guide rail, and all the independent laser light paths do not share equipment and are arranged over the machining forming platform. According to the device, the laser shock reinforcing technology and the laser additive and subtractive technology are integrated, the forming precision, the surface quality, the organization performance and the residual stress state of a complex fine additive workpiece are improved, and one-stop high-efficiency high-precision and high-performance additive workpiece preparation is achieved.

Owner:SHANGHAI UNIV OF ENG SCI

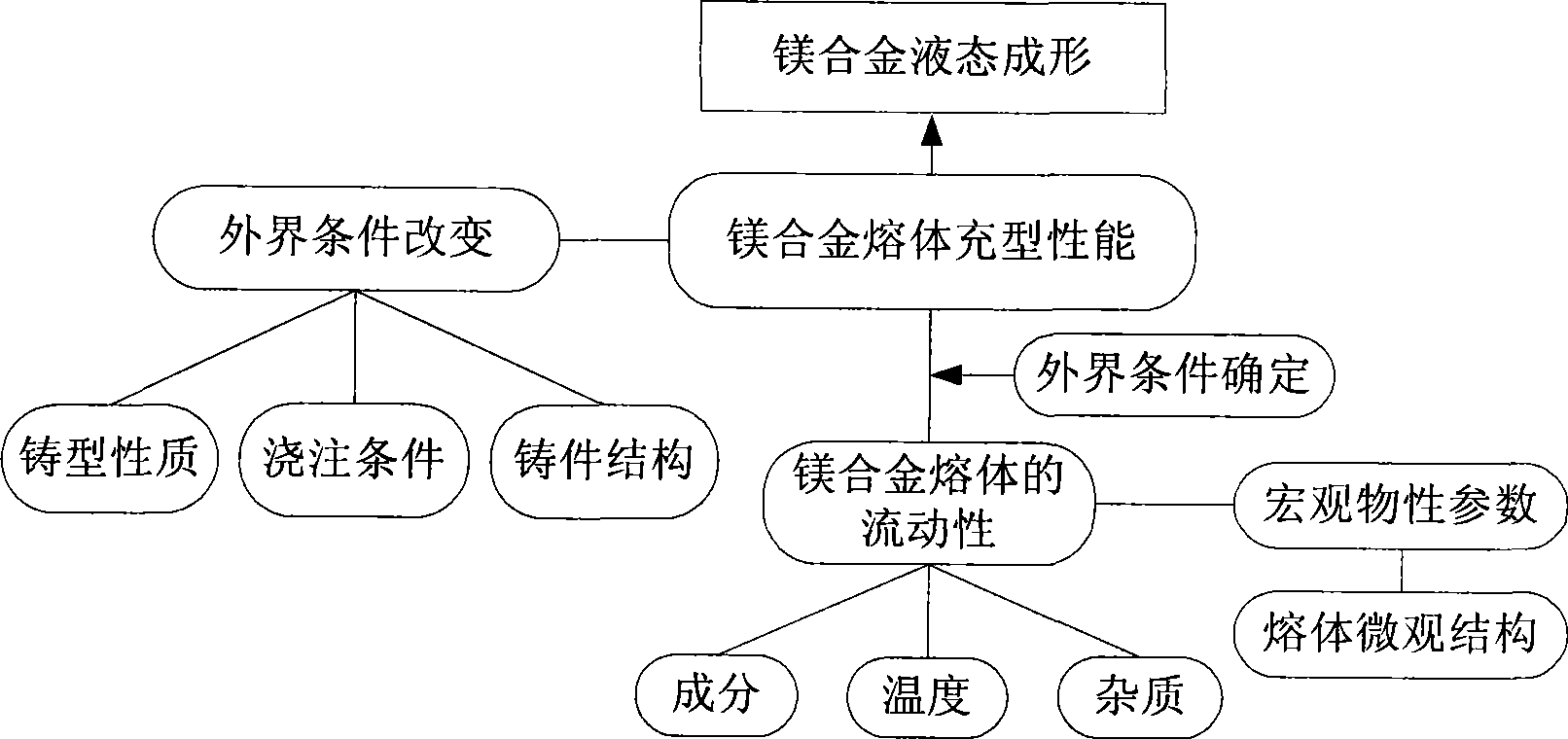

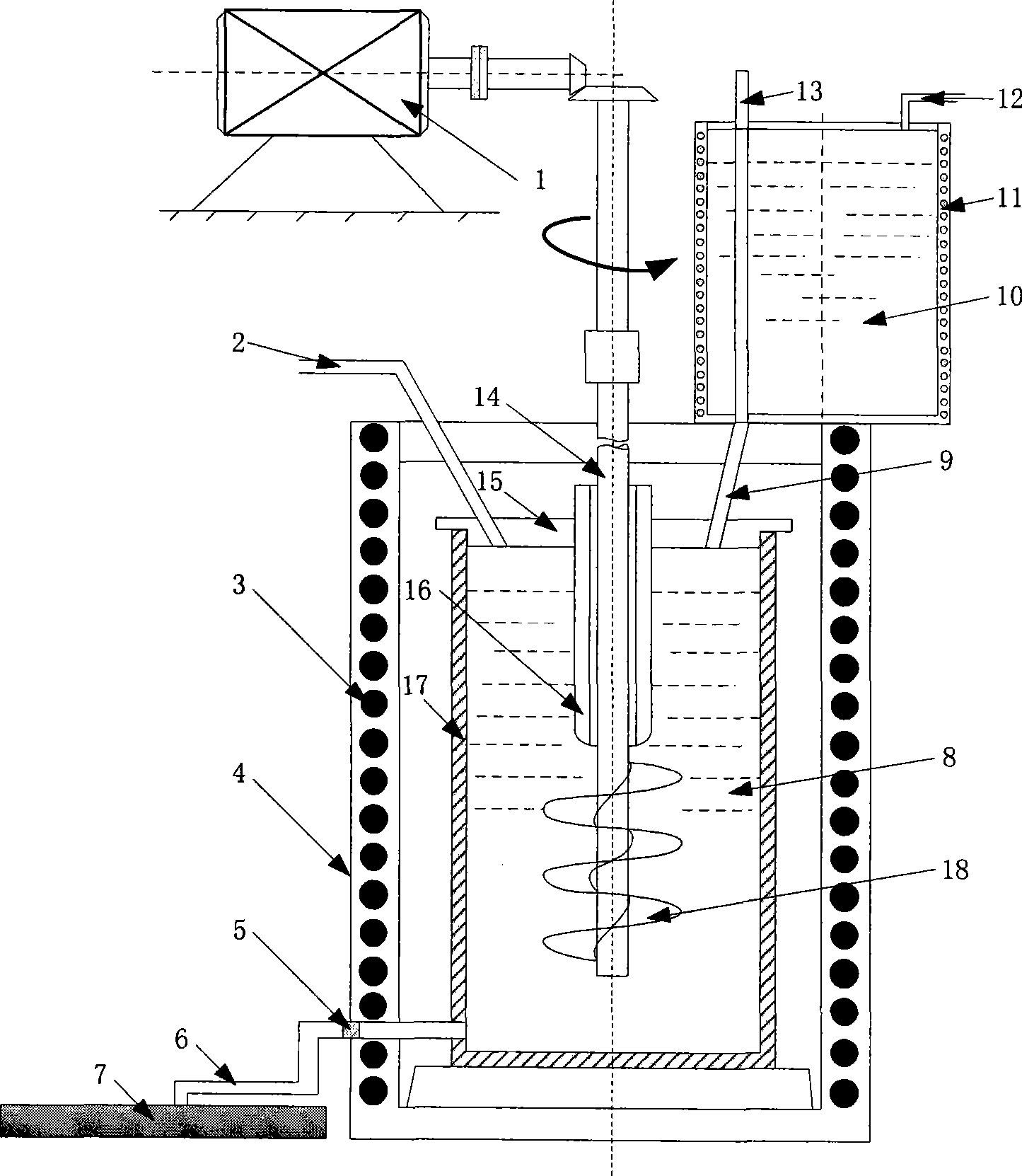

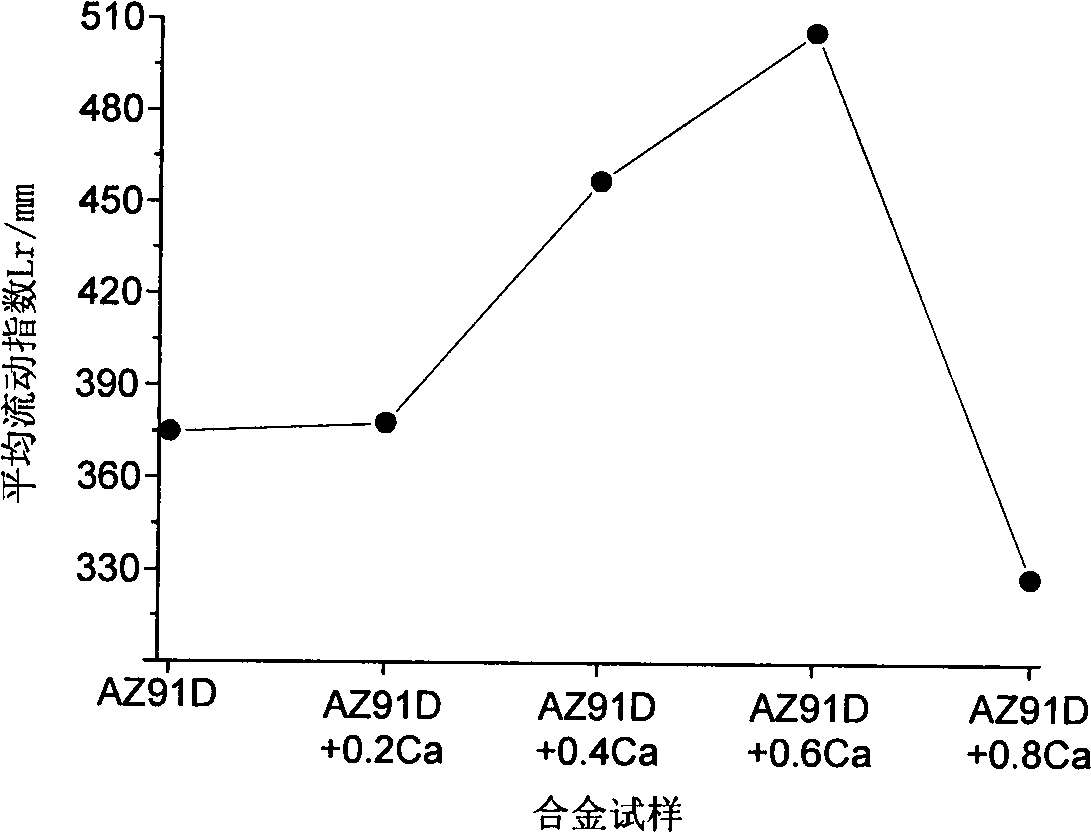

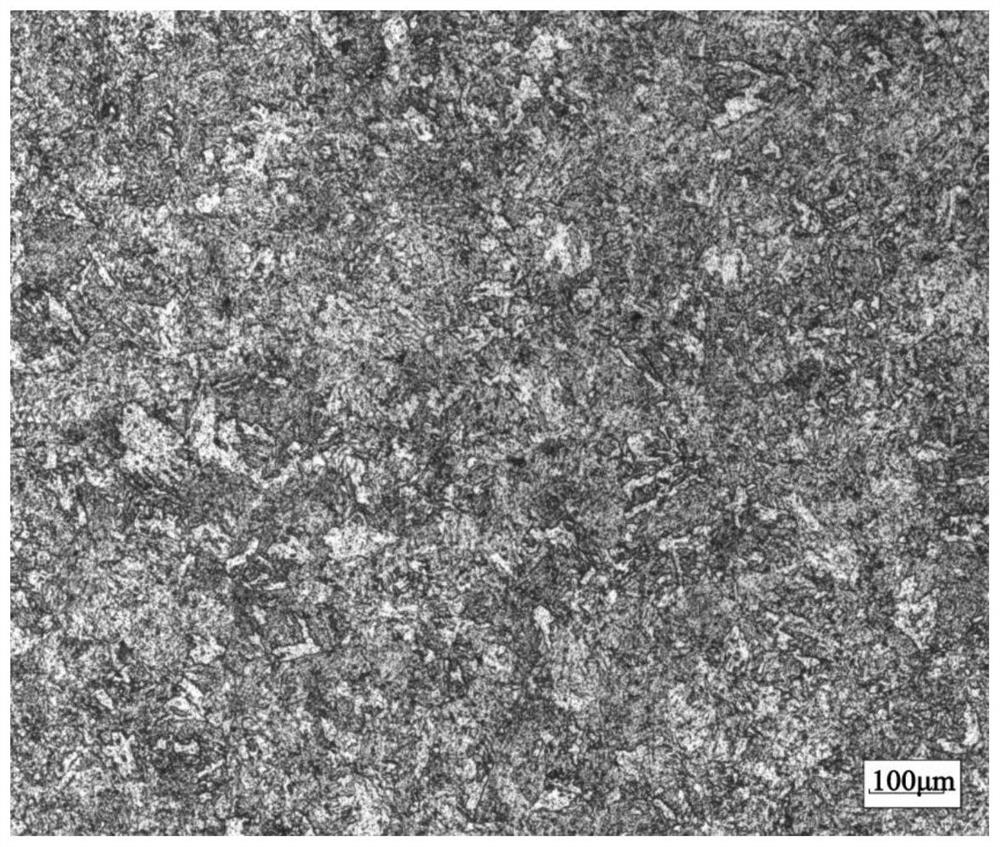

Method for improving fluidness of magnesium alloy melt and special agitating apparatus

The invention discloses a method for improving fluidity of magnesium alloy melts on the basis of revealing the isothermal viscosity changing law of magnesium alloy melts containing calcium and also discloses a special stirring device. The method composes the following steps: (1) the magnesium alloy and Mg-Ca master alloy are heated and melted to obtain overheat magnesium alloy melt containing calcium; and (2) the overheat magnesium alloy melt containing calcium is transferred to a holding furnace for stirring treatment. The 'modification+stirring' composite technology processing treatment is carried out on the overheat magnesium alloy melt and the effect is not a simple cumulative effect but a superimposed compound effect, so the method makes full use of advantages of two melts processing treatment and effectively improves the structure property and fluidity of alloys. The method has the advantages of simple technology, wide application scope, and the like.

Owner:TSINGHUA UNIV

30CrMnSiNi2A high-strength steel for aviation and production method thereof

ActiveCN113502434ADelay and inhibit grain growth tendencyGrain ultrafineProcess efficiency improvementAviationSmelting process

The invention provides 30CrMnSiNi2A high-strength steel for aviation and a production method thereof. The 30CrMnSiNi2A high-strength steel for aviation comprises the following chemical components in percentage by weight: 0.27 to 0.34 percent of C, 0.90 to 1.20 percent of Si, 1.00 to 1.30 percent of Mn, 0.90 to 1.20 percent of Cr, 1.40 to 1.80 percent of Ni, 0.015 to 0.03 percent of Al, 0.02 to 0.03 percent of Mo, 0.02 to 0.03 percent of V, 0.015 to 0.025 percent of Ti, 0.15 to 0.2 percent of W, less than or equal to 0.012 percent of P, less than or equal to 0.01 percent of S and the balance of Fe. According to the 30CrMnSiNi2A high-strength steel for aviation and the production method provided by the invention, a smelting process comprising electric furnace die casting, external refining and electroslag remelting which is always adopted abroad is completely replaced by the method comprising electric furnace continuous casting, external refining and electroslag remelting, so that the effect of improving the material structure property and the fatigue property is obvious. By means of the method, batch, systematic and energy-saving production can be carried out, and energy and cost are obviously saved.

Owner:青海西钢特殊钢科技开发有限公司 +1

Crystallizer cooling device and cooling method thereof

The invention discloses a crystallizer cooling device and a cooling method thereof. The crystallizer cooling device comprises a cooling jacket arranged on a crystallizer in a sleeved manner, and a cooling pipe is assembled on a cooling blind hole through a seal fixing sleeve; the cooling pipe comprises a water inlet pipe, the seal fixing sleeve and a water return pipe, and the seal fixing sleeve is arranged at one end of the water inlet pipe in the sleeved manner, and hermetically connected with the water inlet pipe; the other end of the water inlet pipe extends into the cooling blind hole, and a water return clearance is reserved between the other end of the water inlet pipe and the cooling blind hole; the water return pipe is fixedly connected with the side wall of the seal fixing sleeve, and communicates with the water return clearance through the seal fixing sleeve; the water inlet pipe communicates with a main water inlet pipe through an electric regulating valve, and the water return pipe communicates with a main water return pipe; an outlet pipeline of the water return pipe is further provided with a temperature measuring element, and the temperature measuring element and the electric regulating valve are connected with a PID temperature control regulating unit electrically; and closed-loop control over return water temperature can be achieved by the PID temperature control regulating unit through the electric regulating valve.

Owner:XIAN BRANCH ELECTRIC TECH

Plating solution for electroless Ni-Mo-B/GO multifunctional nano-composite deposition layer and preparation method and application of plating solution

InactiveCN106894006AGood organizational performanceImprove coating crystal orientationLiquid/solution decomposition chemical coatingCarbon steelLead acetate

The invention discloses a plating solution for an electroless Ni-Mo-B / GO multifunctional nano-composite deposition layer and a preparation method and application of the plating solution. The plating solution comprises, by liter, 20-55g of nickel chloride hexahydrate, 0.5-4g of sodium borohydride, 10-25g of sodium molybdate, 20-65g of sodium hydroxide, 15-65g of ethanediamine, 0.1-0.2g of lauryl sodium sulfate, 0.1-10g of graphene oxide, 0.01-1g of lead acetate, and the balance distilled water. The preparation method includes the steps that the nickel chloride hexahydrate, the sodium borohydride, the sodium molybdate, the sodium hydroxide, the ethanediamine, the lauryl sodium sulfate, the graphene oxide and the lead acetate are sequentially added into the distilled water to be dissolved; and then standing is performed, and accordingly the plating solution can be obtained. The plating solution is plated on the surface of a low-carbon steel workpiece, so that a composite coating with good abrasion resistance and high corrosion resistance is formed.

Owner:SHANGHAI APPLIED TECHNOLOGIES COLLEGE

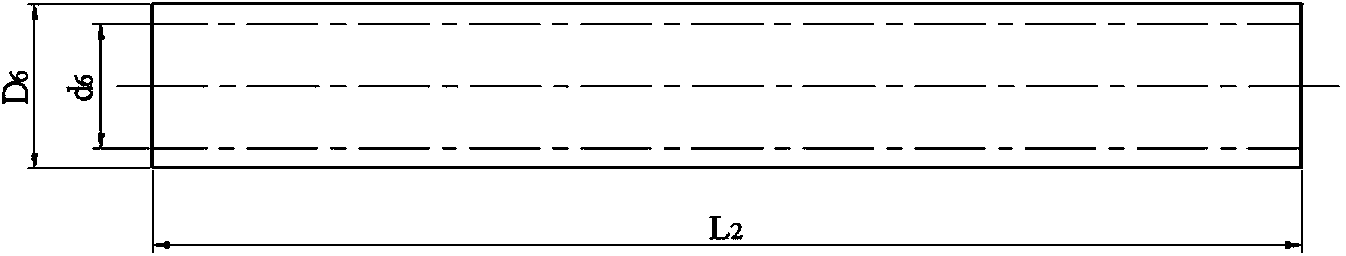

Die cushion special for aluminum alloy profile extrusion

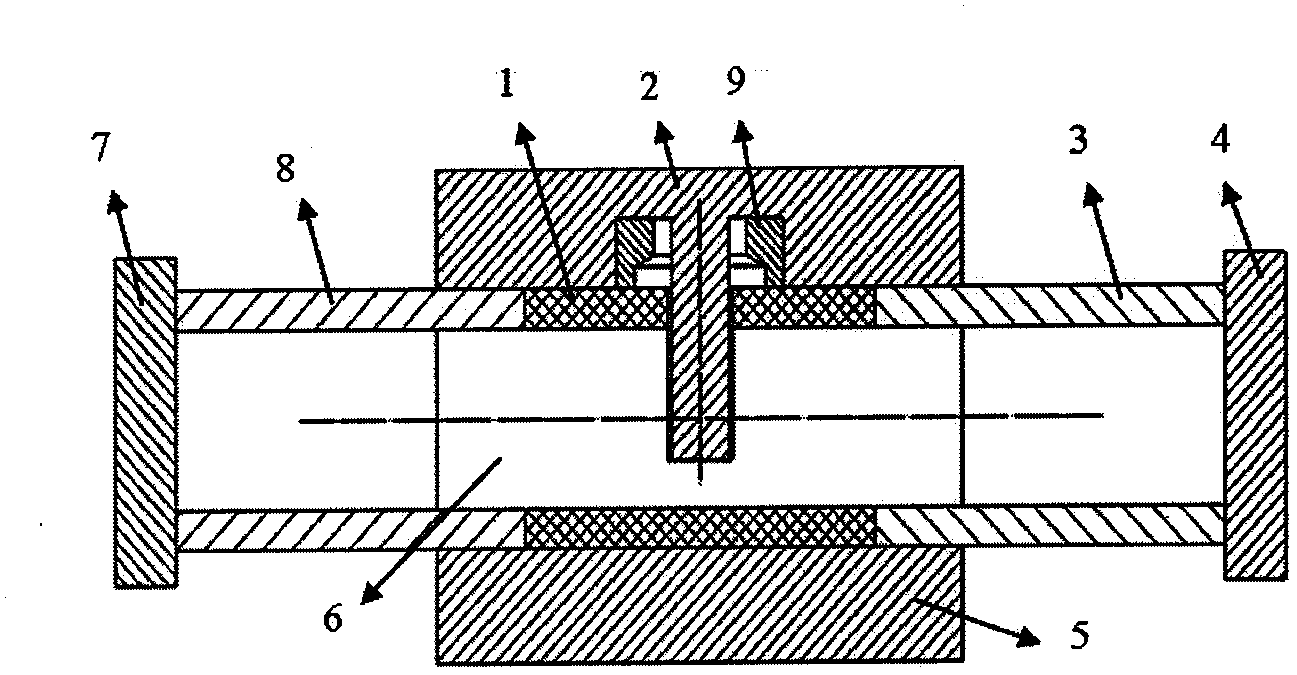

The invention provides a die cushion special for aluminum alloy profile extrusion. The die cushion comprises two cooling channels, namely an outer cooling channel (3) and an inner cooling channel (5),and further comprises two liquid nitrogen channels, namely a first channel (2) and a second channel (9); the inner cooling channel (5) is located on the outer side of a profile extrusion channel (7)and is the same as the profile extrusion channel (7) in section shape, and the outer cooling channel (3) is located on the outer side of the inner cooling channel (5) and is round in the section shape; and the first channel (2) communicates with the outer cooling channel (3), the second channel (9) communicates with the inner cooling channel (5), the outer cooling channel (5) is connected with theinner cooling channel (3) through a first passageway (4), and the inner cooling channel (5) is connected with the profile extrusion channel (7) through a second passageway (6). According to the die cushion special for aluminum alloy profile extrusion, the temperature of a profile extrusion die and the temperature of an extruded profile can be effectively controlled, and contact between the profile and air is reduced, so that surface oxidation of the profile is prevented, the surface quality and the structure performance of the profile are greatly improved, meanwhile, the service life of the die is prolonged by 17%, and the extrusion speed of the profile is increased by 9%.

Owner:安徽生信新材料股份有限公司

Edge shielding device for sheet and strip steel cooling control system

PendingCN110238207AAvoid falling directly onPrevent fallingTemperature control deviceWork cooling devicesEngineeringDevice failure

The invention provides an edge shielding device for a sheet and strip steel cooling control system, and belongs to the technical field of rolling control and cooling control in the metallurgical industry. The device is installed on an upper cooler body in the sheet and strip steel cooling control system, and is composed of a driving device, a driving end frame, a driven end frame, a steel wire rope I, a steel wire rope II, a fixed pulley assembly, a water receiving disc assembly and a sliding rail, wherein two water receiving discs are controlled to be moved in the horizontal direction by adopting a steel wire rope traction mode, the temperature difference between the edge part and the middle part of the sheet steel in the water cooling process can be reduced, and the cooling uniformity and the overall performance of the sheet steel are improved. The device has the advantages of being high in high-temperature and high-humidity working environment adaptability, low in equipment failure rate and low in maintenance workload; the water outlet widths of the edge parts at the two ends of the upper cooler can be accurately adjusted on line, so that sheet steel with different specifications can be adapted; and the occupied space is small, the influence on other equipment is small, installation is convenient, and the popularization and application are easy.

Owner:UNIV OF SCI & TECH BEIJING

A kind of cr54 steel for high-quality coal mine chain link and its production method

Owner:XINING SPECIAL STEEL +1

Method for preparing hydroxytyrosol docosahexenoate from lipase

InactiveCN106755149AGood organizational performanceLower blood fatFermentationHydroxytyrosolIce water

A method for preparing hydroxytyrosol docosahexenoate from lipase comprises the following steps: adding methyl tert-butyl ether to hydroxytyrosol, adding docosahexenoic acid to the obtained hydroxytyrosol solution, adding the lipase to the above obtained alcohol and acid mixed solution, sealing the solution, introducing nitrogen, carrying out an oscillation reaction, carrying out ice water cooling, filtering the obtained solution to remove the lipase, and carrying out rotary evaporation to remove the methyl tert-butyl ether in order to obtain a crude product; and dissolving the crude product in ethanol, adding sodium carbonate and water, carrying out reflux saponification under the protection of nitrogen, extracting the obtained saponification solution with n-hexane, and carrying out rotary evaporation to obtain the hydroxytyrosol docosahexenoate. The hydroxytyrosol reacts with the docosahexenoic acid under the catalysis of enzyme to prepare the hydroxytyrosol ester, so the hydroxytyrosol docosahexenoate can enhance the ability of the hydroxytyrosol entering cells and tissues, so the half life is prolonged; and DHA has inflammation inhibiting, blood fat lowering and memory and thinking ability enhancing functions.

Owner:DALIAN POLYTECHNIC UNIVERSITY

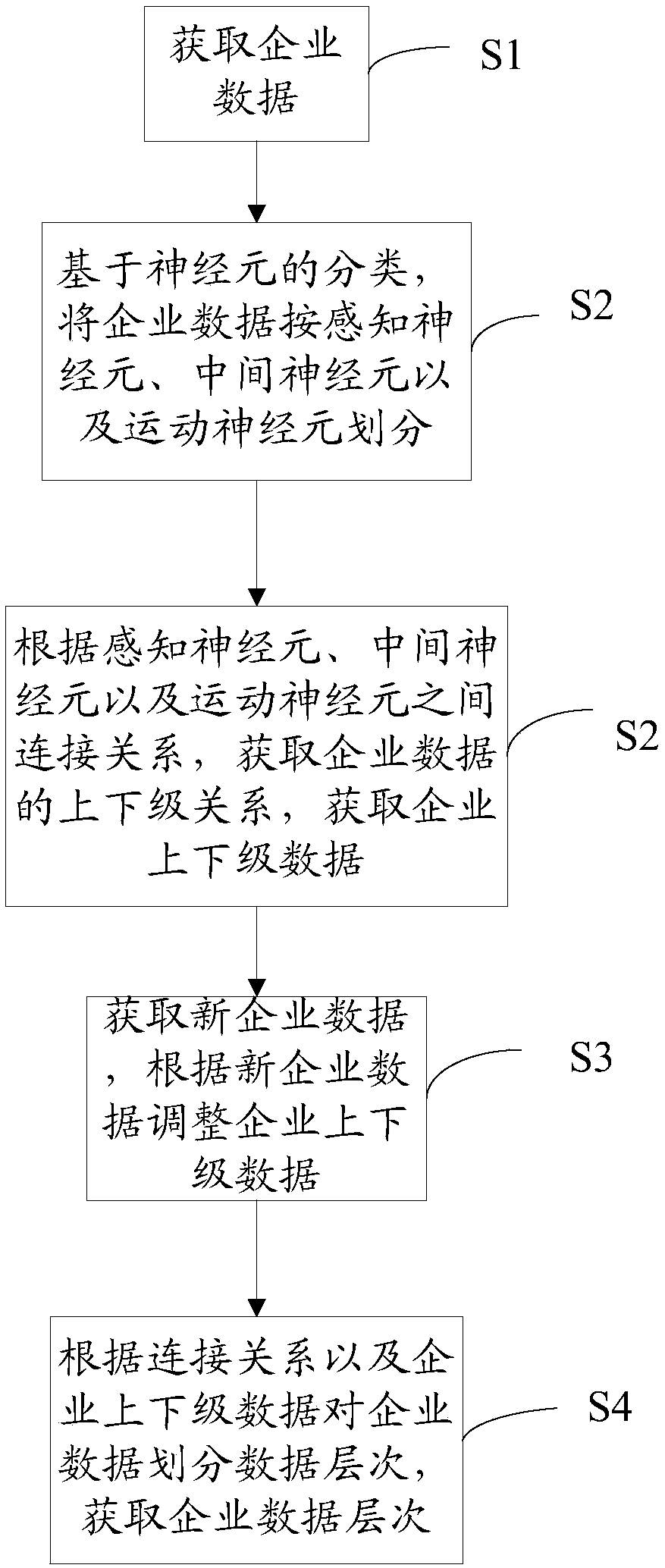

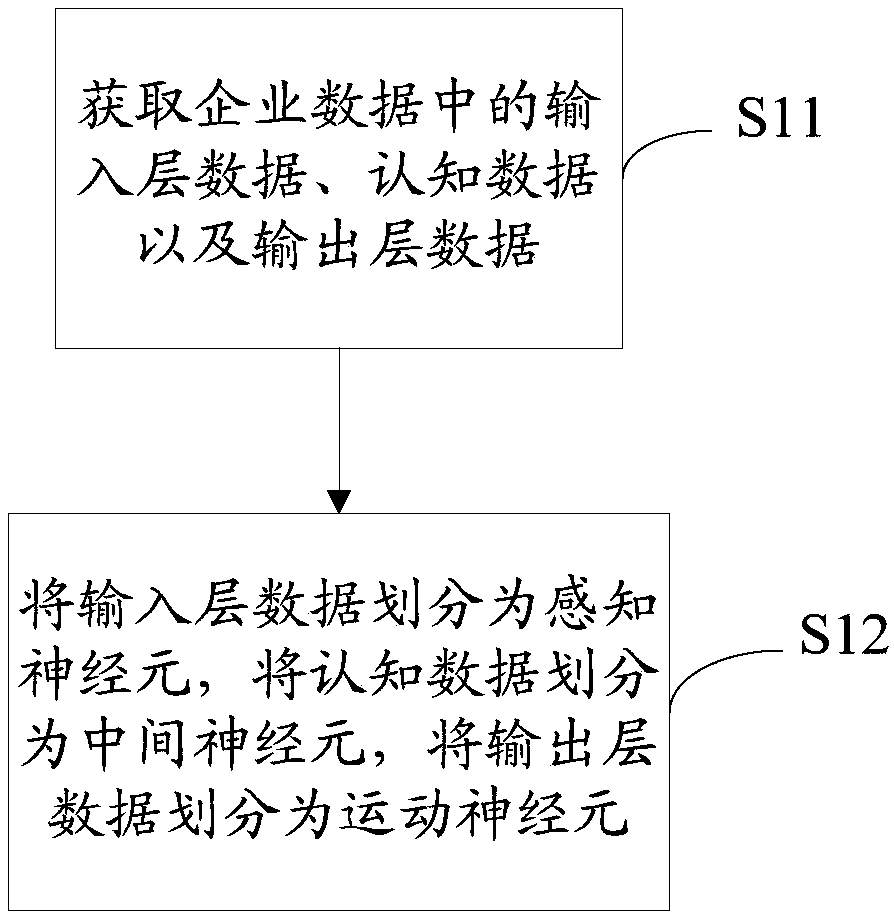

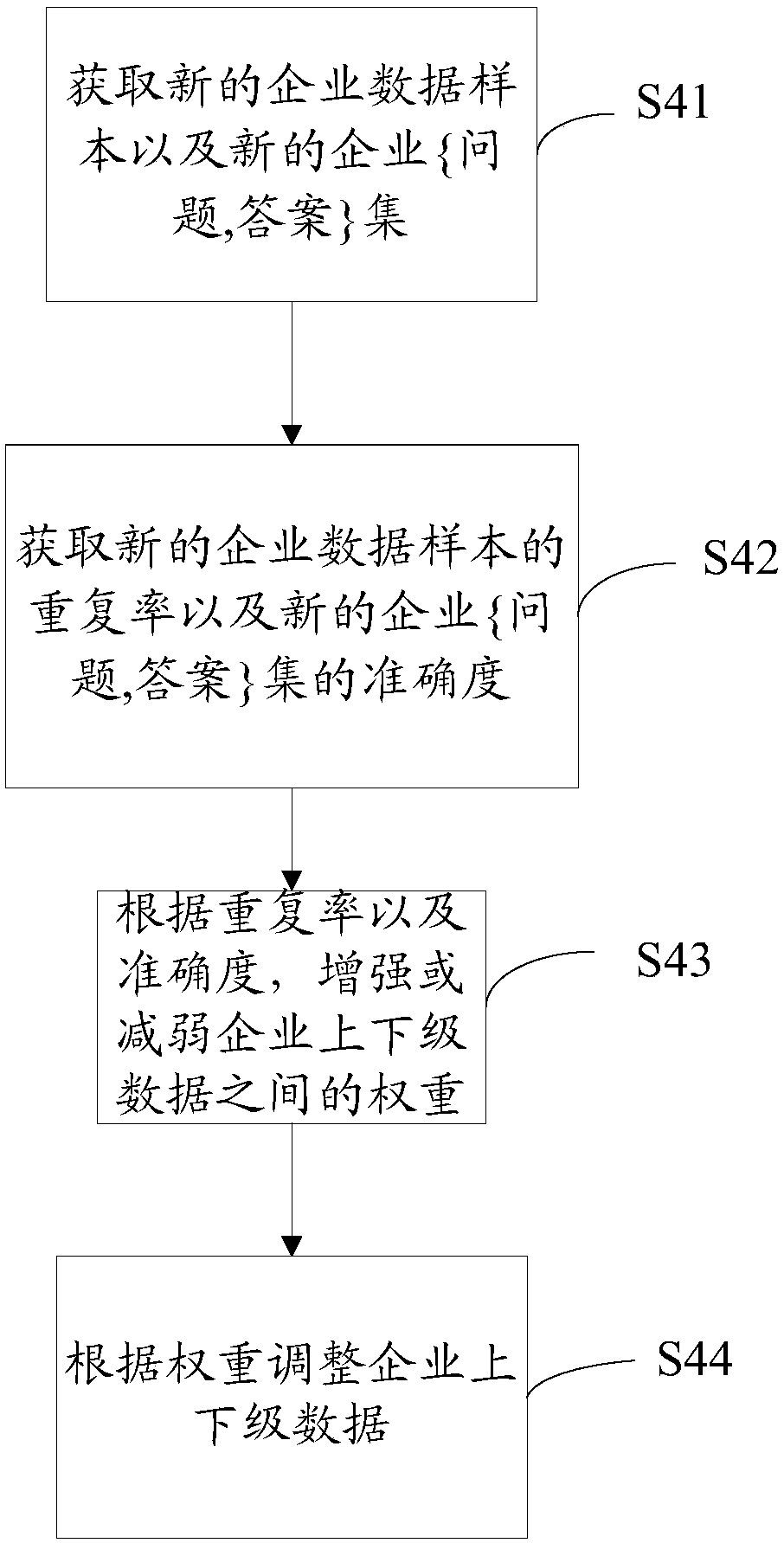

Method of neuron-imitating enterprise data hierarchy representation and system thereof

InactiveCN107609639AGuaranteed atomicityReduce redundancyPhysical realisationOriginal dataInterneuron

The invention relates to a method of neuron-imitating enterprise data hierarchy representation and a system thereof. The method includes: acquiring enterprise data; dividing the enterprise data on thebasis of neuron categories according to perceiving neurons, interneurons and motor neurons; acquiring upper / lower-level relationships of the enterprise data according to connection relationships between the perceiving neurons, the interneurons and the motor neurons, and acquiring enterprise upper / lower-level data; and carrying out data hierarchy dividing on the enterprise data according to the connection relationships and the enterprise upper / lower-level data to acquire an enterprise data hierarchy. According to the method, utilizing a human brain neural-network to build the enterprise data hierarchy is realized, guaranteeing atomicity of the data is facilitated, redundancy of data storage is reduced, comprehensiveness and organization of evaluation of an enterprise service institution ororganization on an enterprise are improved, and correctness, accuracy and high efficiency of the original data hierarchy are more efficiently guaranteed.

Owner:前海梧桐(深圳)数据有限公司

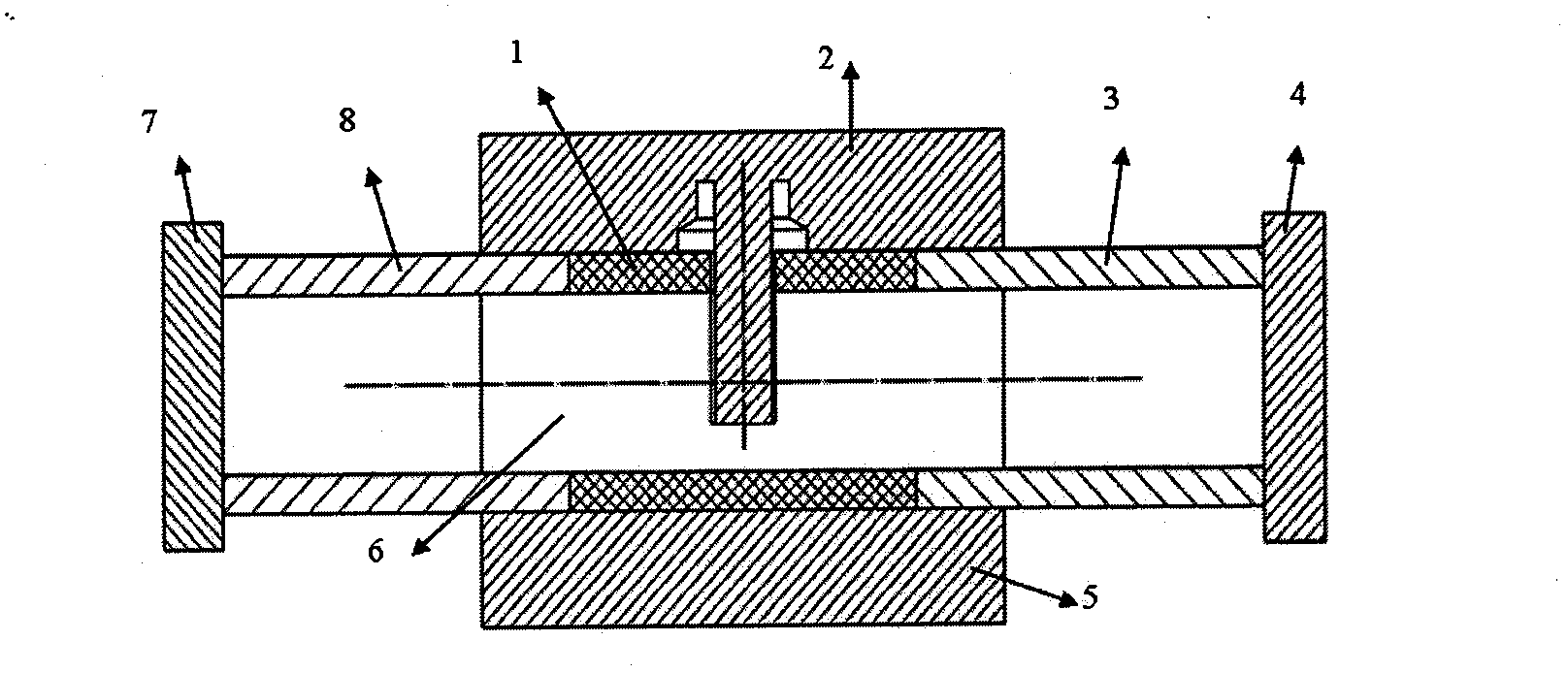

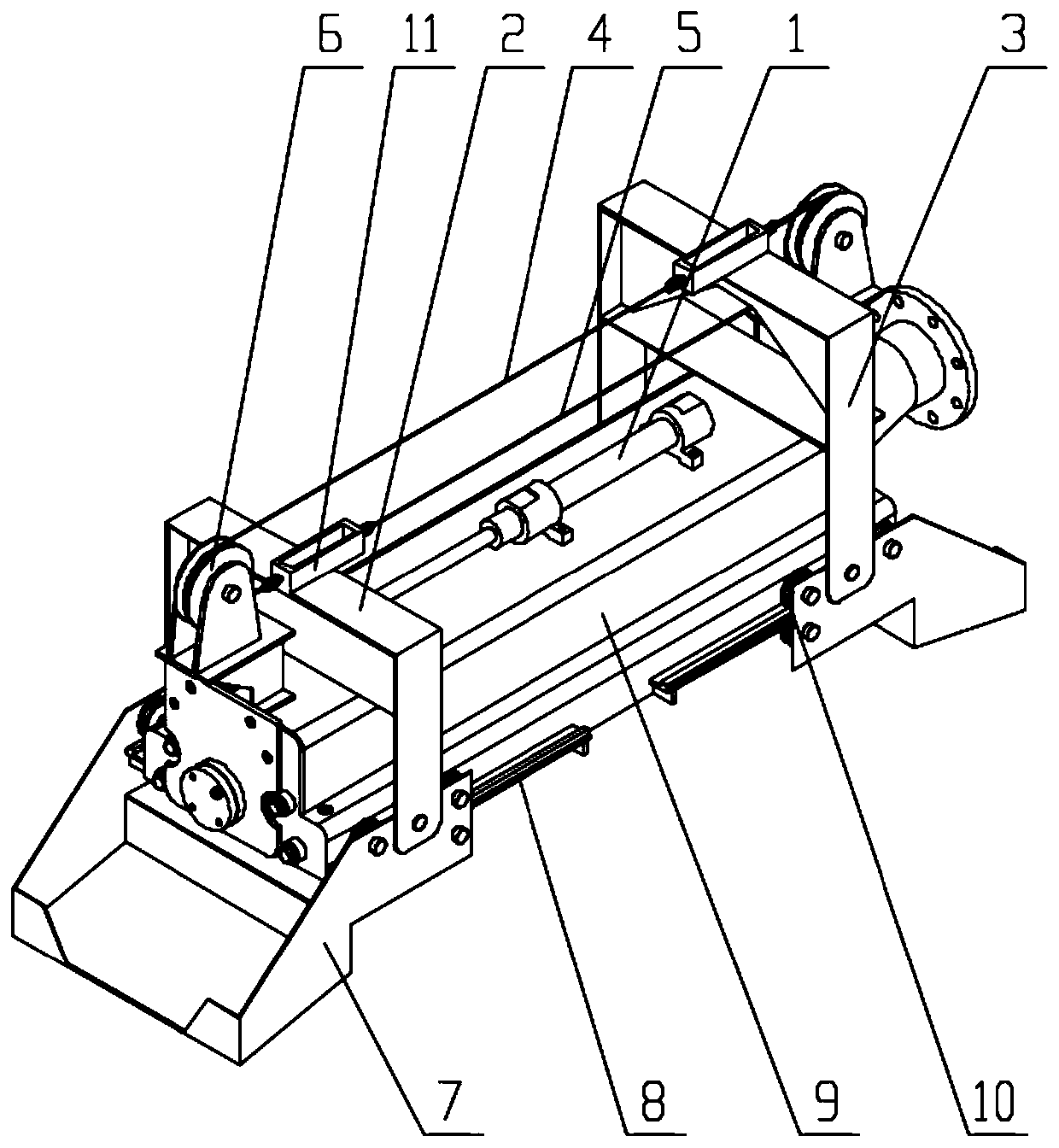

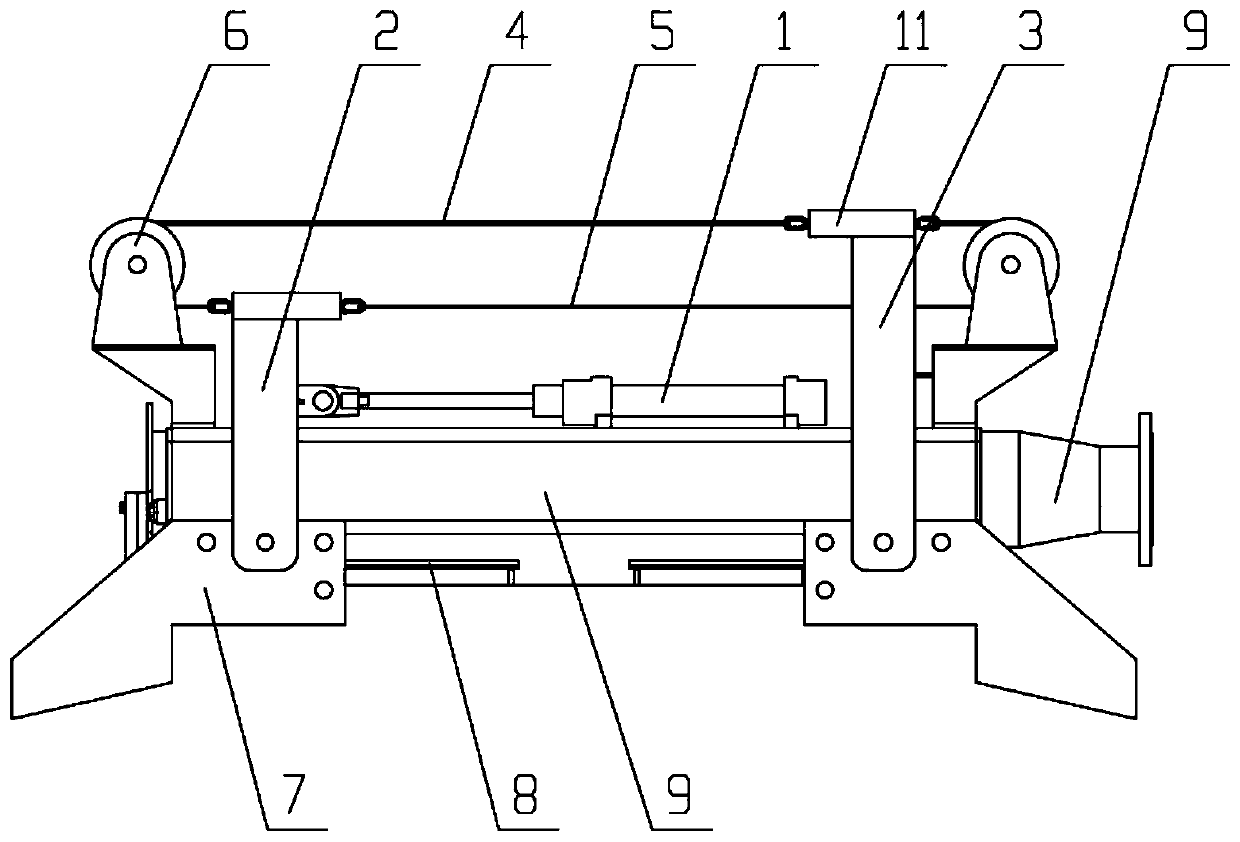

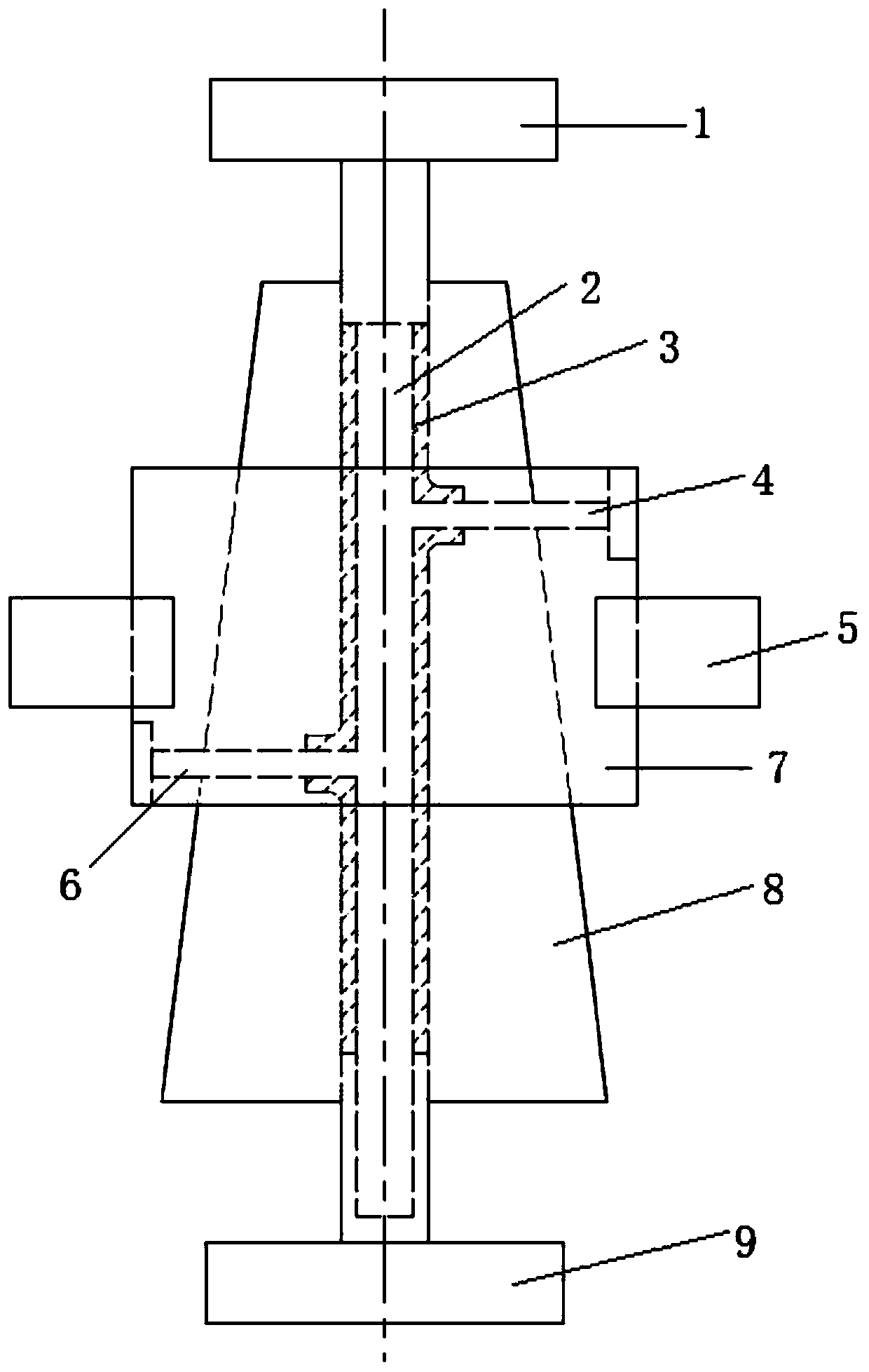

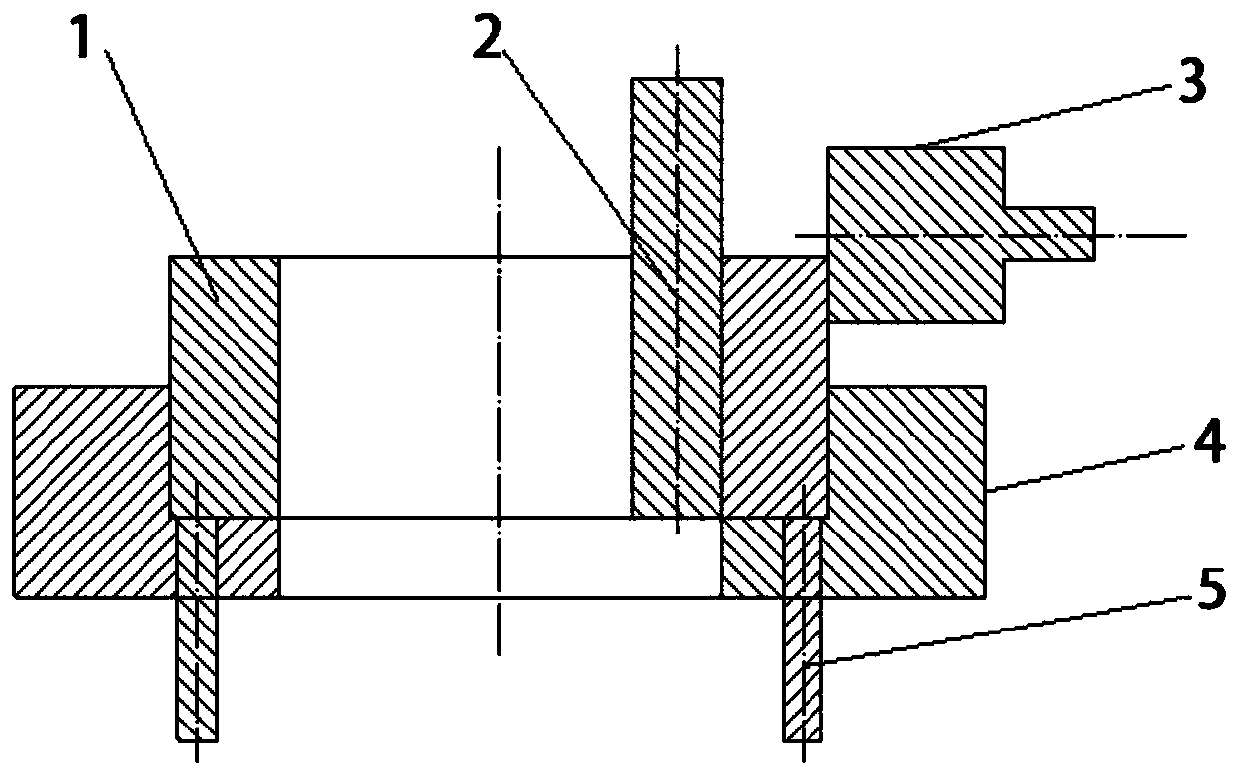

Extruding device and method for double-mouth and thick-wall pipe blank extrusion manufacturing

The invention provides an extruding device and a method for double-mouth and thick-wall pipe blank extrusion manufacturing, and belongs to the technical field of thick-wall pipe extrusion manufacturing. The device comprises an upper ejector rod, a lower ejector rod, an extrusion cylinder and a floating extrusion cylinder cover; the device is mounted on an extruder; the outer surface of the extrusion cylinder is tightened and fixed by the floating extrusion cylinder cover; the floating extrusion cylinder cover is connected with an extrusion cylinder oil cylinder; the upper end of the upper ejector rod is connected with an extrusion shaft of the extruder through a fixed plate; and the lower end of the lower ejector rod is connected with an extruder lower platform through a fixed plate. In the use process of the device, the upper ejector rod downwards moves for extrusion at a certain speed; meanwhile, the oil cylinder drives the floating extrusion cylinder cover to downwards move at a certain speed to realize synchronous formation of upper and lower pipe mouths. Compared with a traditional forging process, the method has such characteristics as short manufacturing flow, high efficiency, excellent performance and low cost, and can be applied to high-performance forming production of high-performance thick-wall pipes and pipe fittings with pipe mouths for nuclear power and thermal power.

Owner:UNIV OF SCI & TECH BEIJING

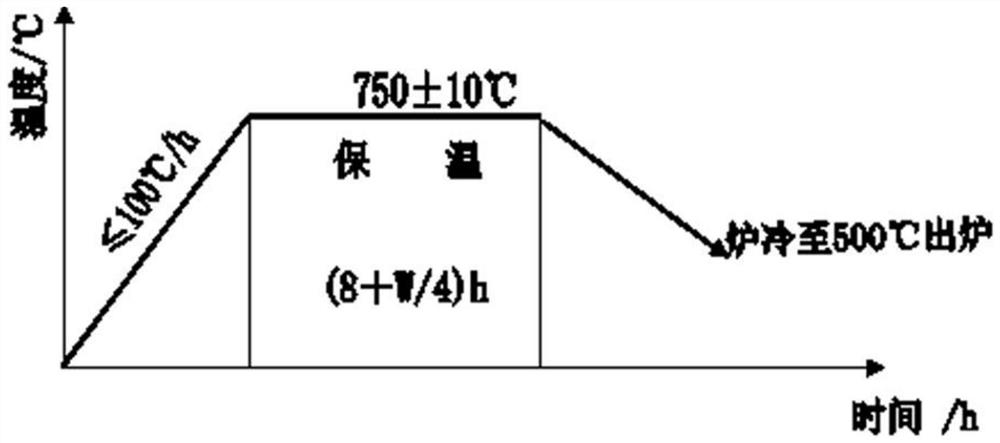

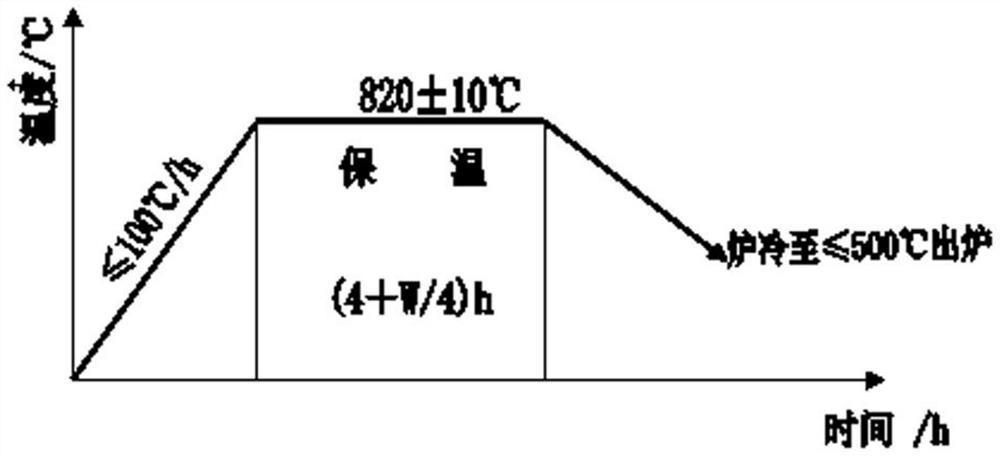

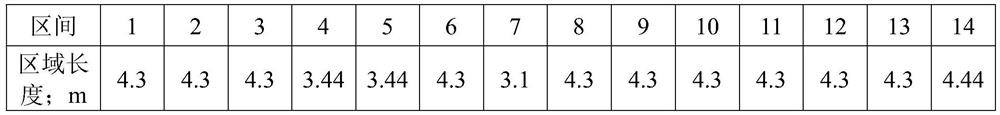

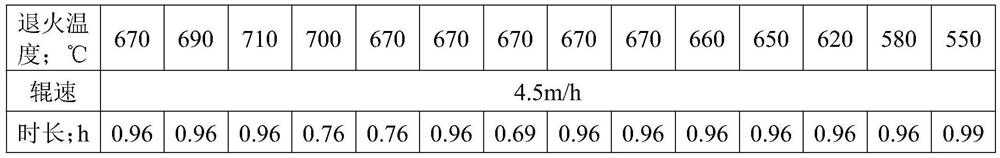

Manufacturing method of brake tube of air brake system

InactiveCN109402526AGuaranteed full austenitizationImprove solubilityFurnace typesPiping arrangementsWater brakeAdditive ingredient

The invention belongs to the technical field of mechanical parts manufacturing, and particularly relates to a manufacturing method of a brake tube of an air brake system. The manufacturing method of the brake tube of the air brake system comprises the following steps of smelting molten steel, casting into die casting billet, electroslag remelting, cogging hot rolling into square billet, forging into round ingots, hot extrusion, lubrication cold rolling, annealing treatment, surface treatment, inspection and entering a storage; in the process of smelting molten steel, the molten steel is produced when the composition of the molten steel meets the following requirements, wherein the molten steel is prepared from the following components in percentage by weight: 0.02%-0.03% of C, 0.018%-0.028% of P, 17.2%-17.4% of Cr, 9.2%-9.5% of Ni, 0.001%-0.002% of S, 0.21%-0.28% of Ti, 0.05%-0.06% of N, 0.01%-0.15% of Cu, the balance of Fe and unavoidable impurities. According to the manufacturing method of the brake tube of the air brake system, through the special design of material ingredients and optimization of partial parameters and methods of hot extrusion, lubrication cold rolling, annealing treatment, surface treatment and the other processes, so that the brake tube of the air brake system has better corrosion resistance and surface quality.

Owner:HEFEI KANGZHIHENG MACHINERY TECH CO LTD

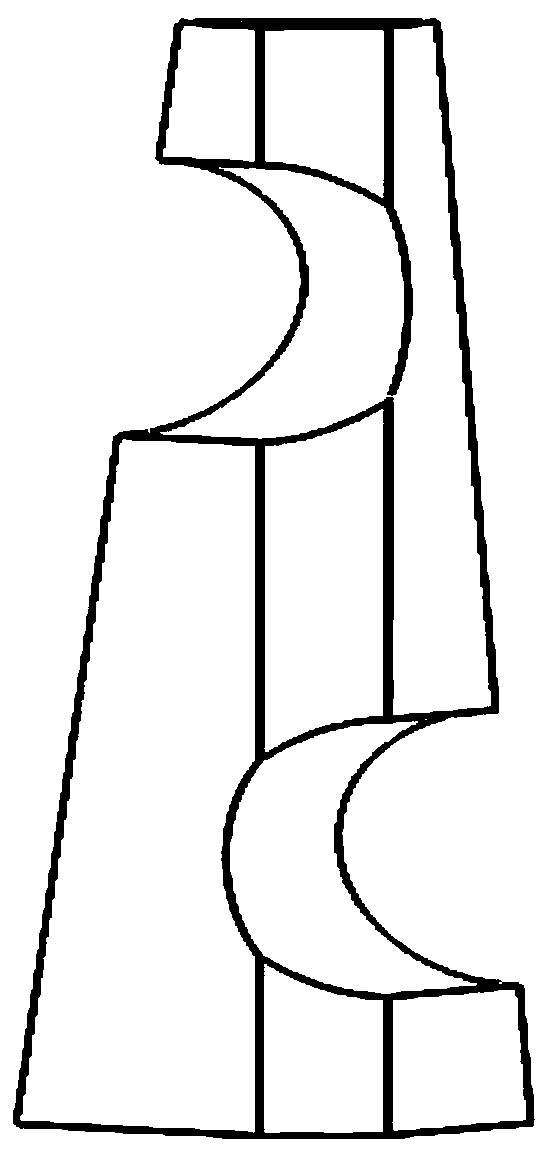

Device and method for simultaneous forming of double nozzles by uniaxial extrusion

Owner:UNIV OF SCI & TECH BEIJING

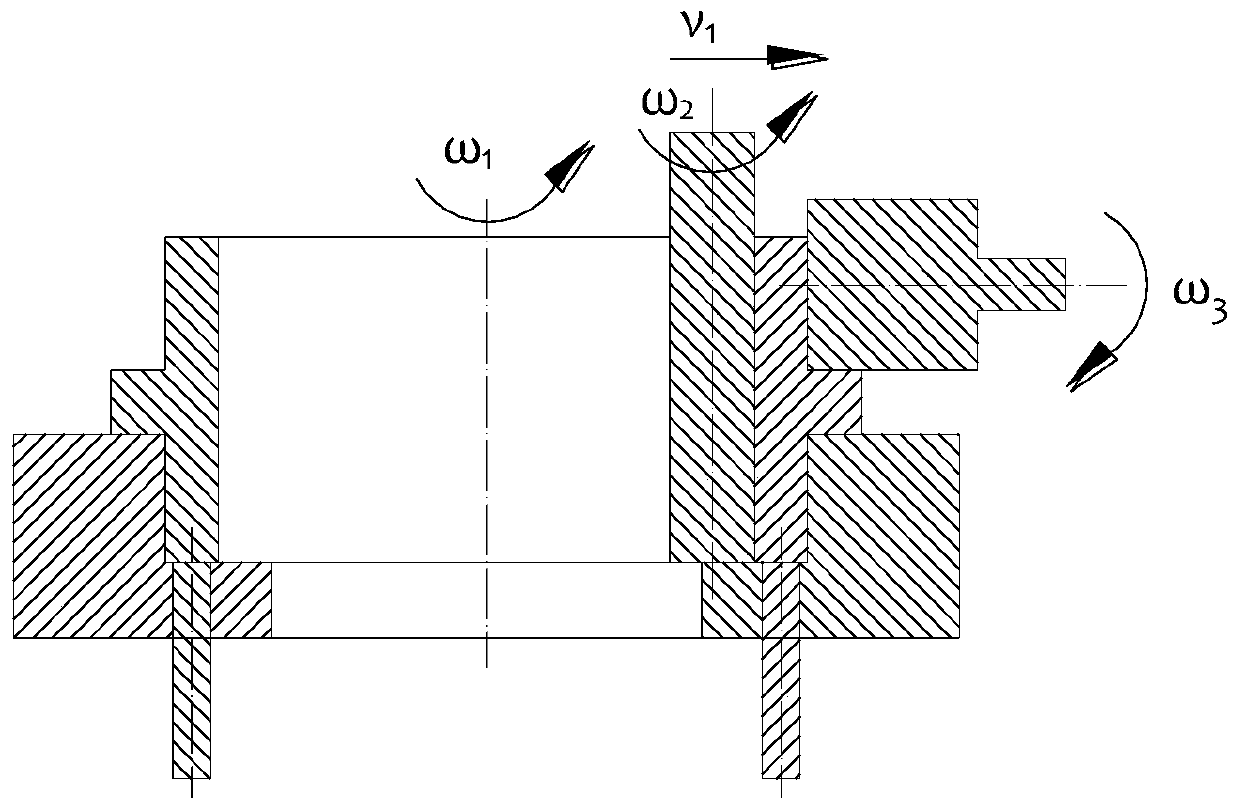

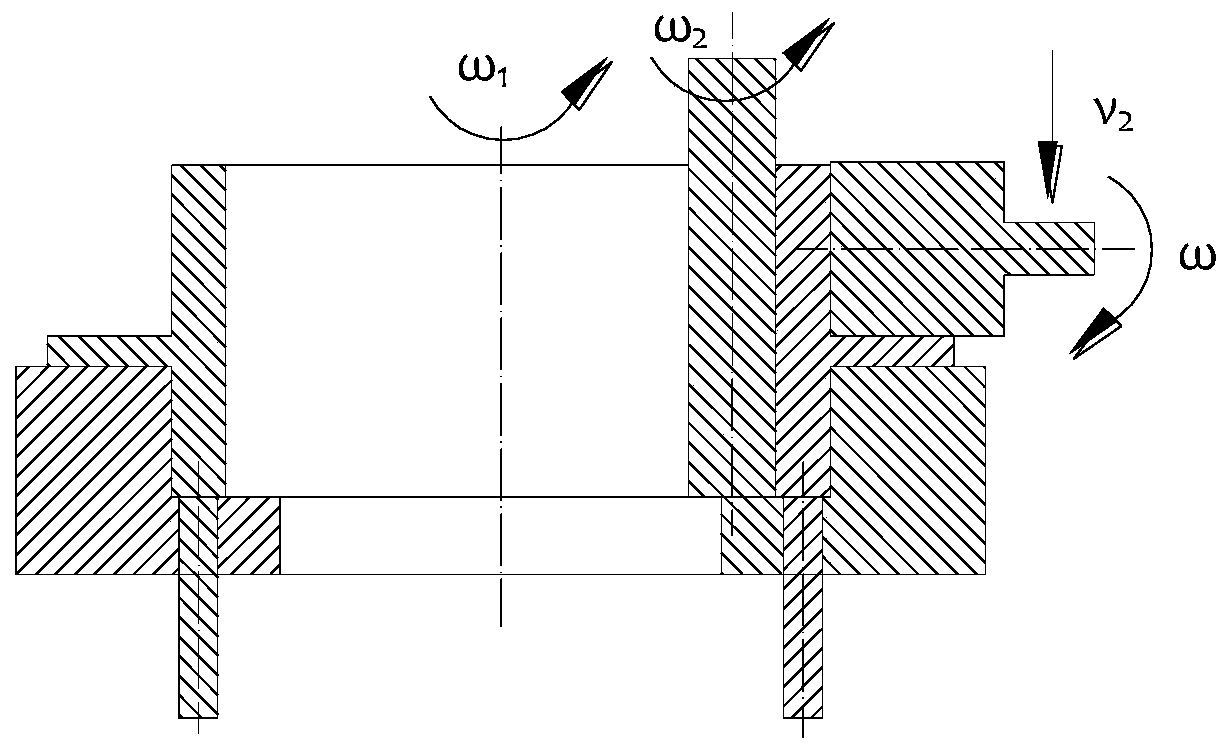

Constrained Radial-Axial Roll Forming Method for Large Thin-walled External T-shaped Ring Members

The invention relates to a constraining radial-axial roll-forming method for a large thin-wall outer T-shaped annular component. The constraining radial-axial roll-forming method comprises the following steps that S1, an annular prefabricated blank is placed in a constraint mold, the bottom face of the annular prefabricated blank is in contact with the lower end face in the constraint mold, and aradial feeding roll is arranged in the annular prefabricated blank; S2, at a radial rolling stage, after rolling is started, the constraint mold drives the annular prefabricated blank to uniformly rotate around the axis of the constraint mold at the rotating speed omega1, the radial feeding roll rotates around the axis of itself at the rotating speed omega2 and meanwhile does feeding motion at thespeed v1 in the radial direction, and an axial feeding roll uniformly rotates around the axis of itself at the rotating speed omega3 and does not do translational motion; S3, at an axial rolling stage, the constraint mold continues to uniformly rotate around the axis of itself at the rotating speed omega1, the position of the radial feeding roll is kept fixed, and the axial feeding roll starts tocarry out downward feeding at the speed v2 in the axial direction while uniformly rotating around the axis of itself; and S4, operation at a demolding stage is carried out. According to the constraining radial-axial roll-forming method, high-performance, high-efficiency, low-cost and near-net forming manufacturing of the large thin-wall complex annular component is achieved.

Owner:WUHAN UNIV OF TECH

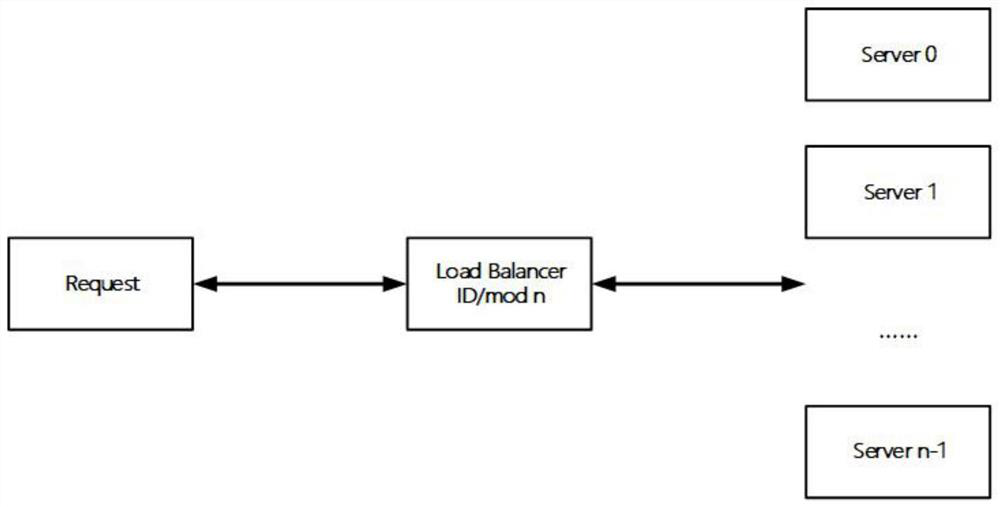

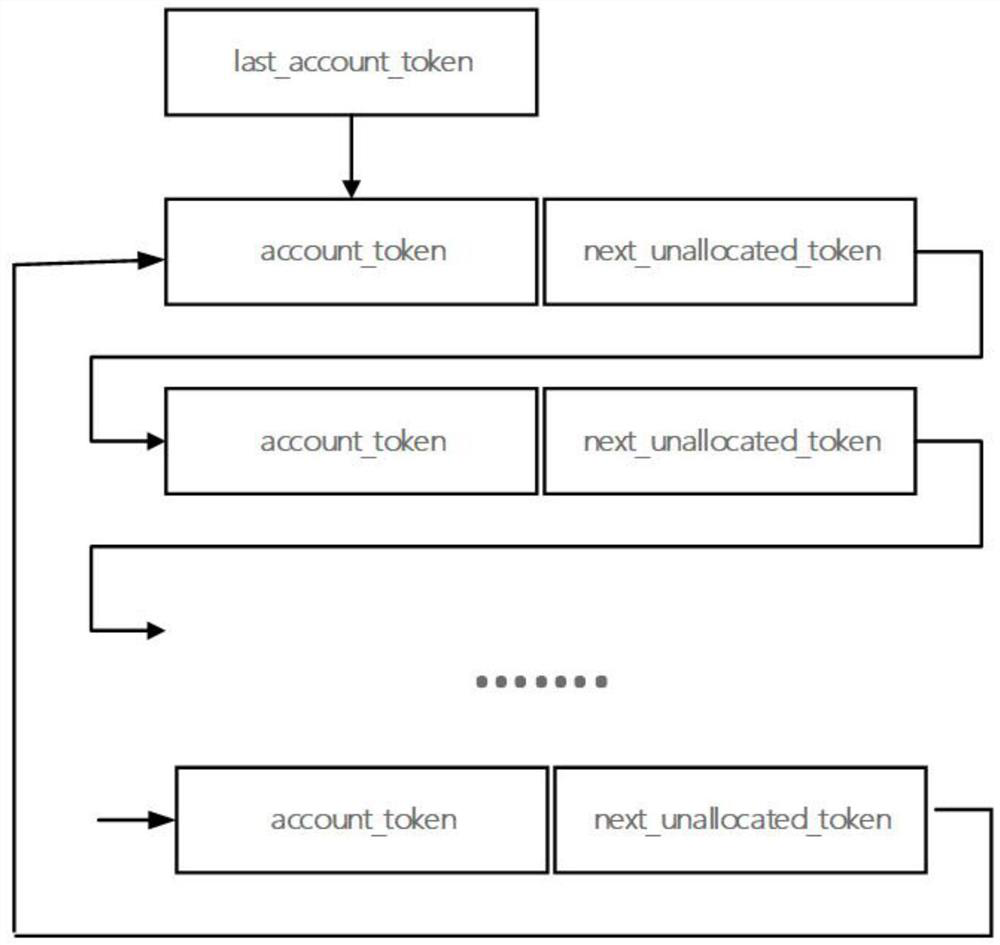

Off-line bar code payment method based on dynamic token

PendingCN112365257AImprove securityCompliance with regulatory requirementsPayment protocolsPlaintextPayment

The invention discloses an off-line bar code payment method based on a dynamic token, and provides a strong-security off-line bar code method which has a strong random number and fits an actual commercial scene through a dynamic token-based payment marking mode, so as to deal with the faced risk fraud problem, and the convenient bar code payment experience can still be provided under the conditionthat the network is unstable. The security is high, and the security is greatly improved as compared with the previous method of automatically extracting and trading after the issued valid string code is cracked, the scheme needs to have algorithm protection and an encrypted random seed value, and the safety is greatly improved; the offline time is long; theoretically infinite seeds are generatedon the basis of the seeds; no sensitive information leakage risk exists, a payment marking scheme is adopted, sensitive information plaintexts such as accounts do not exist in bar codes, and the sensitive information leakage problem does not exist; and parallel processing and rapid expansion are supported.

Owner:TIANYI ELECTRONICS COMMERCE

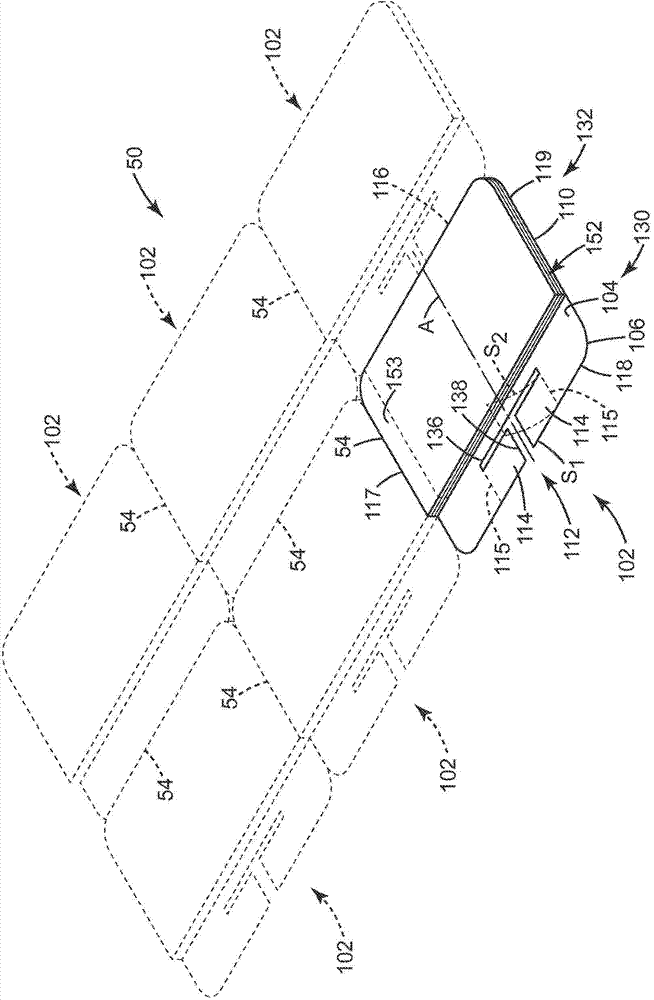

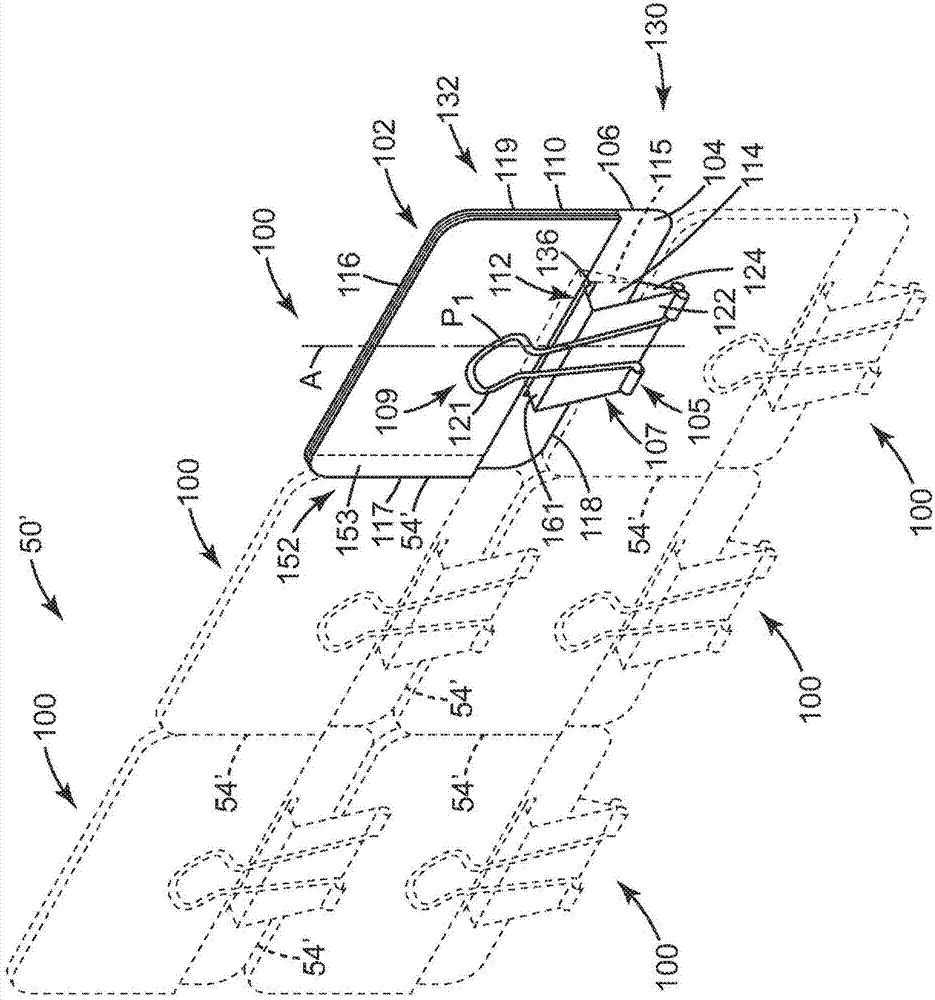

Tabs and binder clip tab assemblies comprising same

InactiveCN103781634AEnhanced archivingGood organizational performanceFiling appliancesHaberdasheryEngineeringMechanical engineering

Owner:3M INNOVATIVE PROPERTIES CO

Machining Technology of Mechanical Spindle

The invention discloses a processing technology of a mechanical main shaft, belonging to the technical field of shaft processing. The mechanical main shaft organically combines with a refining processwith a purification process through the steps of alloy smelting, refining, purification, molding and the like, which greatly improves the comprehensive performance of the main shaft. The refining process is different from a traditional refining process, the specific refining process can be accompanied by the change of the object state of a refining agent, the bonding degree of the refining agentand the alloy is improved, the refining effect is improved, and a composite purification process combined with the air jet and the purifying agent is adopted, and can spread to a whole alloy system inall-round way and avoid the uneven purification of the alloy.

Owner:宁波市鄞州兴韩机械实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com