30CrMnSiNi2A high-strength steel for aviation and production method thereof

A production method and high-strength steel technology, applied in the field of metal materials, can solve the problems of mass production, systematic and energy-saving production, large waste of energy and cost, prone to transverse cracks and longitudinal cracks, etc., and achieve delayed grain Growth tendency, prevent steel cracks, and inhibit the effect of grain growth tendency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

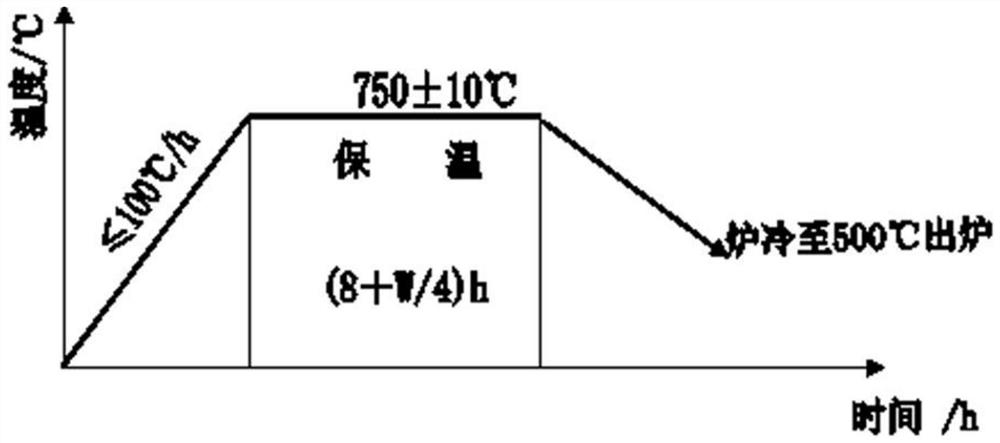

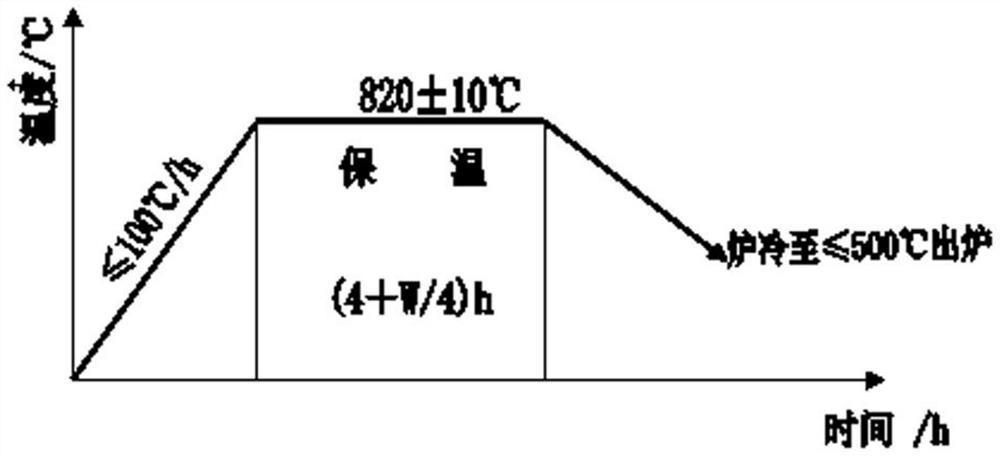

[0054] This embodiment relates to a kind of 30CrMnSiNi2A high-strength steel for aviation and its production method, including Consteel electric furnace primary smelting, LF refining, VD vacuum degassing, weak argon operation, continuous casting pouring, continuous casting slab into pit for heat preservation and stress relief annealing, electric Ten steps of slag remelting and electroslag ingot stress relief annealing, electroslag ingot heating billet opening, process billet heating, continuous rolling and heat preservation, and annealing, specifically:

[0055] (1) Consteel electric furnace primary refining

[0056] Steelmaking raw materials are composed of blast furnace molten iron and low-phosphorus returned scrap steel. After full melting in the initial stage of smelting, smelting and slagging are carried out at a temperature of 1510-1540 ° C. The use of P removal reaction at a lower temperature is conducive to the formation of P in the direction of positive reaction. 2 o ...

Embodiment 2

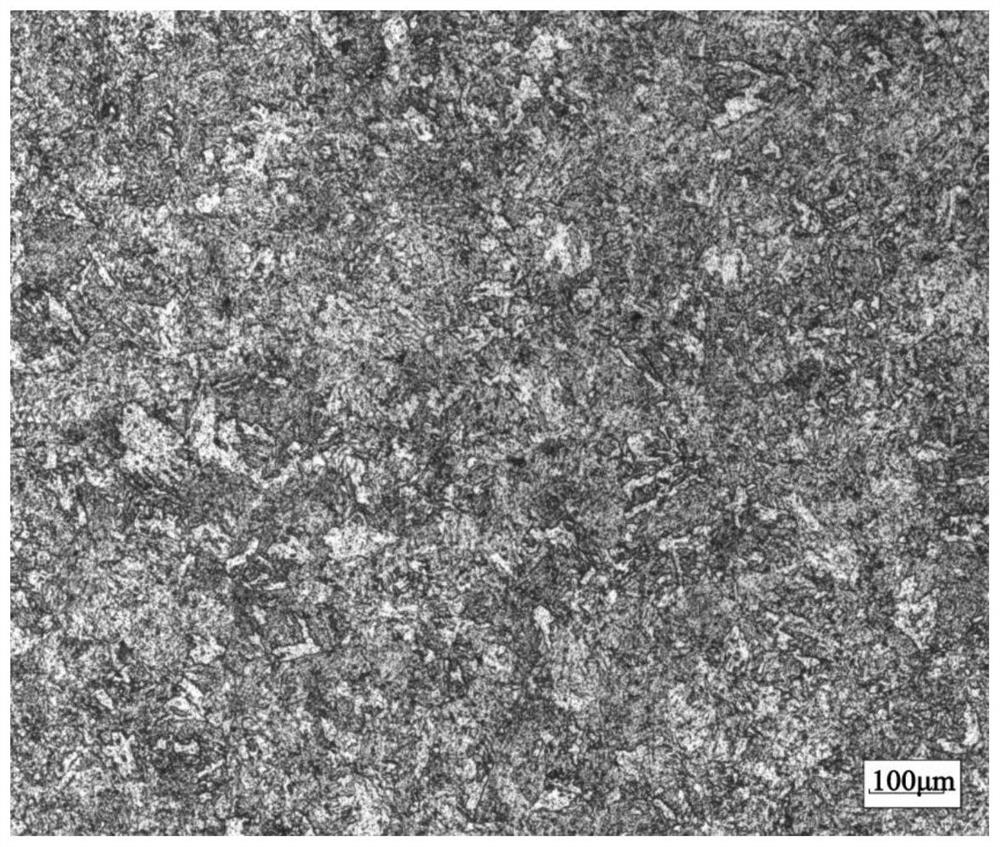

[0093] Two furnaces of 30CrMnSiNi2A high-strength steel for aviation were prepared by using the 30CrMnSiNi2A high-strength steel for aviation in Example 1 and its production method, and the furnace numbers were L19310117 and L19310118 respectively. The 30CrMnSiNi2A steel production method of Comparative Example 1 was used to prepare two furnaces of 30CrMnSiNi2A steel for comparison, and the furnace numbers were L17X16286 and L17X16284 respectively. The two heats of 30CrMnSiNi2A steel prepared by the above-mentioned new method were compared with the two heats of 30CrMnSiNi2A steel prepared by the old method. microstructure.

[0094] (1) Gas content detection

[0095] The gas content test method is as follows: 30CrMnSiNi2A steels smelted in normal smelting furnaces with different furnace numbers are respectively taken to detect the oxygen content in them.

[0096] The specific detection data are shown in Table 4: gas content in 30CrMnSiNi2A molten steel:

[0097] Table 4

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com