Device and method for simultaneous forming of double nozzles by uniaxial extrusion

An extrusion device and nozzle technology, which is applied in the field of uniaxial extrusion and double nozzle simultaneous forming device, can solve the problem of stress corrosion resistance and low strength at the connection between nozzle and pipe, shortened service life, and not large double pipe Improve the mechanical and structural properties, reduce manufacturing costs, and save materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0041] The invention provides a device and method for simultaneous forming of double nozzles by uniaxial extrusion.

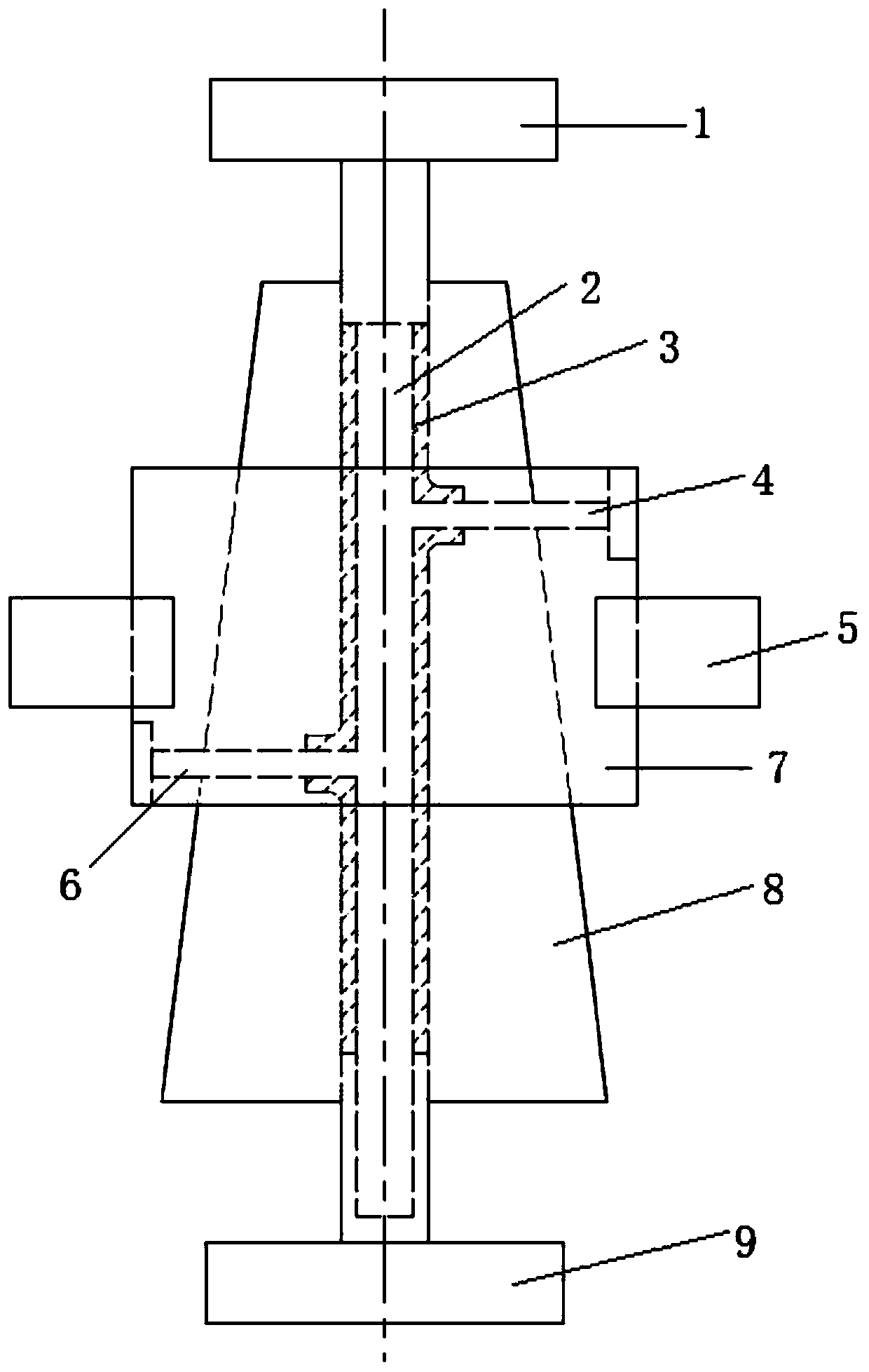

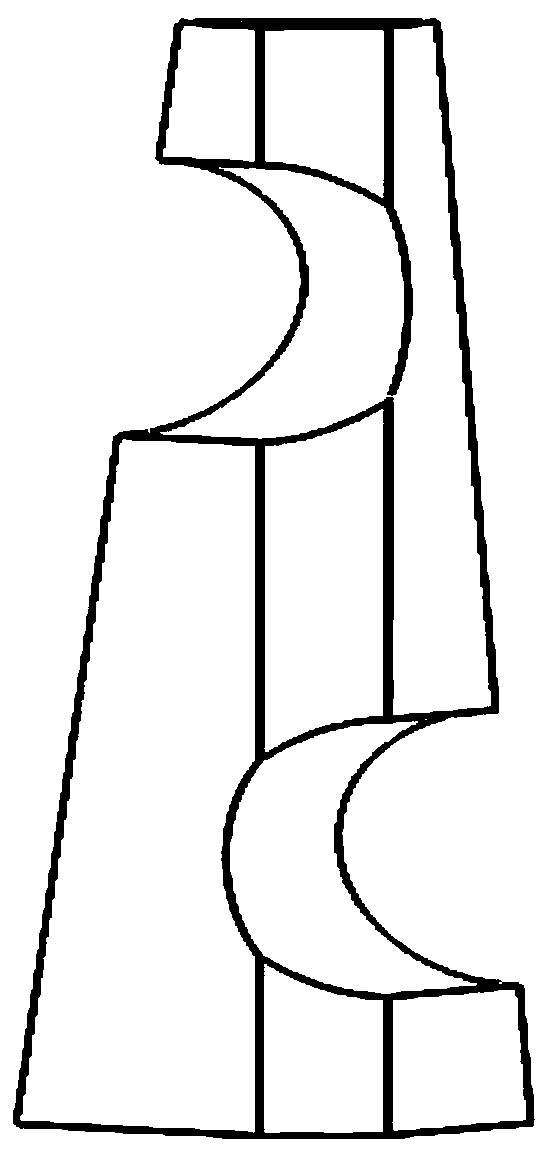

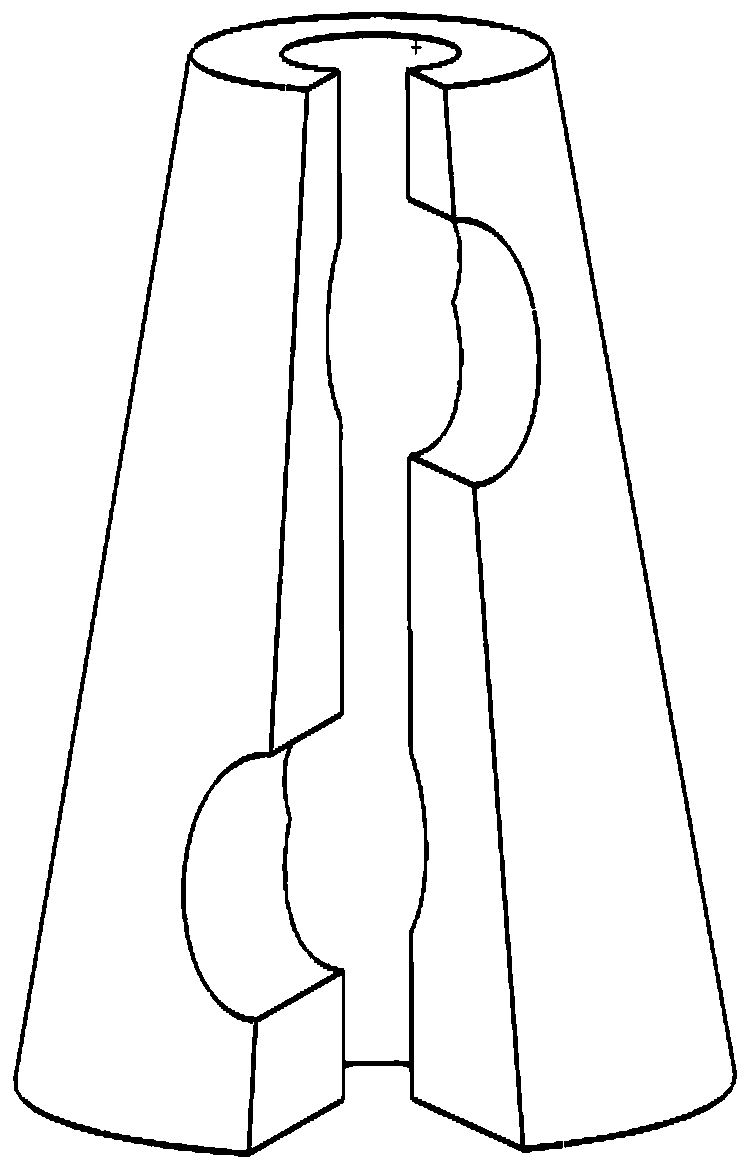

[0042] Such as figure 1 and Figure 2 ( Figure 2a and Figure 2b ) shown in the device, the extrusion machine is equipped with an oil cylinder 5, and the extrusion device includes an upper ejector rod 1, an extrusion cylinder 8, an extrusion cylinder jacket 7 and a lower ejector rod 9, and the extrusion cylinder 8 is externally covered by an extrusion cylinder jacket 7 The hoop is fixed, the upper end of the upper ejector rod 1 is connected with the upper beam of the extruder through the fixed plate, the lower end of the lower ejector rod 9 is connected with the lower platform of the extruder through the fixed plate, the lower part of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com