A kind of cr54 steel for high-quality coal mine chain link and its production method

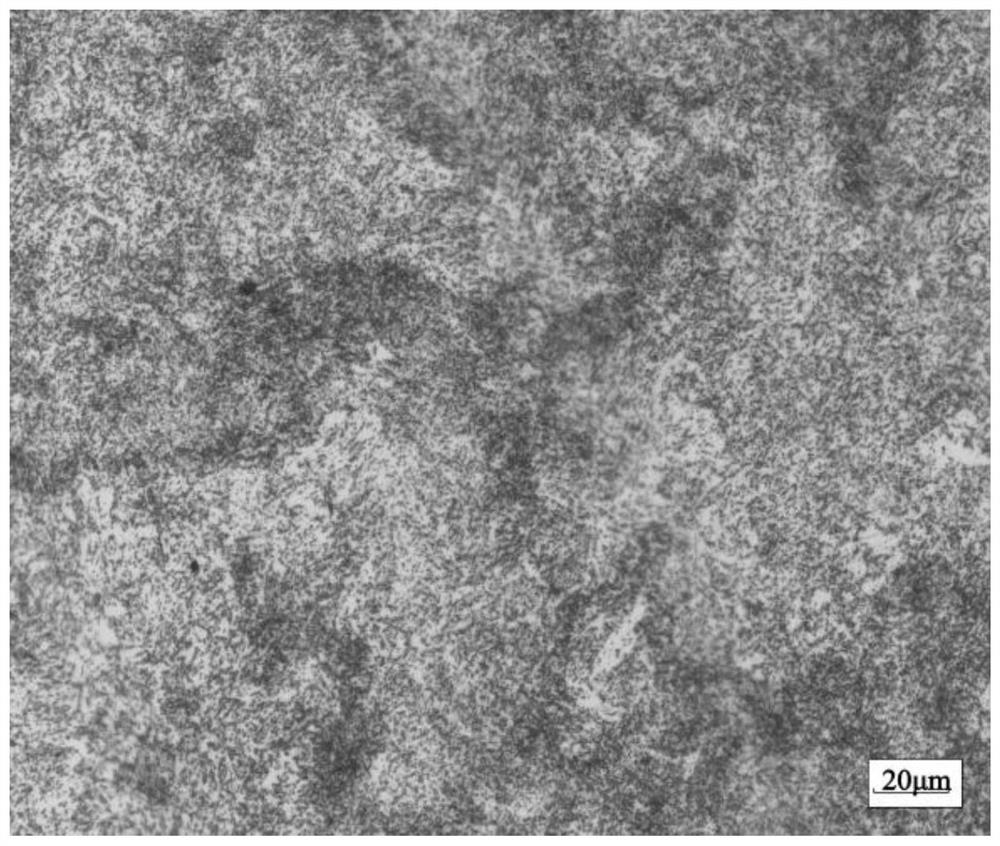

A production method and high-quality technology, applied in the field of high-quality Cr54 steel for coal mine chain links and its production, and high-strength coal mine chain steel materials, can solve the problems of insufficient fatigue life of materials, fluctuations in structure uniformity, etc., and achieve surface quality Improvement, improvement of steel surface quality, improvement of microstructure performance and fatigue performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

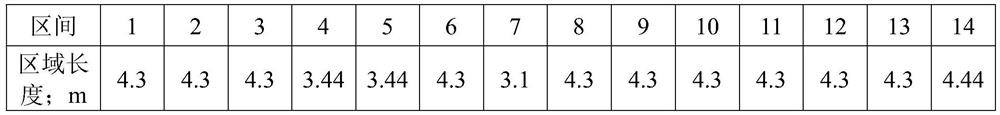

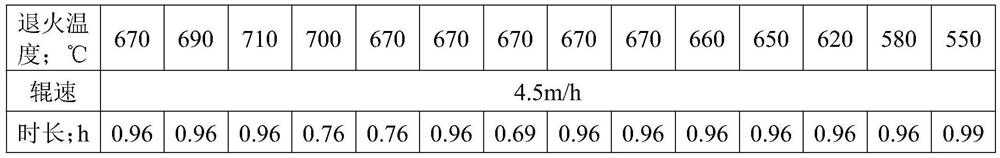

[0048] A production method of Cr54 steel for high-quality coal mine chain links, including seven steps of primary smelting in a Consteel electric furnace, LF refining, VD vacuum degassing, continuous casting, billet rolling and peeling, continuous rolling, and annealing, specifically:

[0049] (1) Consteel electric furnace primary refining

[0050] During the melting period, use 1500-1540°C to make slag, and take advantage of the favorable opportunity for the de-P reaction to proceed to the positive reaction direction at a lower temperature to effectively remove P; after full melting, the temperature is ≥1540°C, and oxidation begins, and the flow of oxygen supply is controlled. At 1000~3000NM 3 / h, decarburization amount 0.6-1.1%, the timing of adding iron ore depends on the temperature in the furnace, and the total amount is controlled at 9-12Kg / t;

[0051] During the tapping period, when the tapping temperature of the electric furnace is ≥1620°C, it is forbidden to drop oxi...

Embodiment 2

[0080] Adopt the production method of a kind of high-quality coal mine chain link Cr54 steel of embodiment 1 to prepare four groups of high-quality coal mine chain links Cr54 steel, obtain test piece, test piece number is respectively: V64, B36, D66, K27; The production method of Cr54 steel in ratio 1 prepared four groups of control Cr54 steel, and obtained control test pieces, the test piece numbers were: V64, B36, D66, K27.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com